Patents

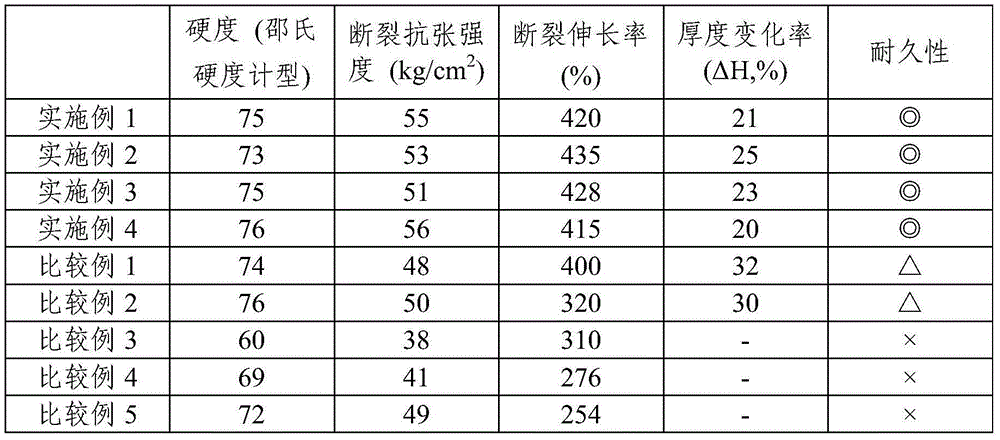

Literature

52 results about "Cyclohexane diisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isocyanates and thioisocyanates, such as 1,4-CYCLOHEXANE DIISOCYANATE, are incompatible with many classes of compounds, reacting exothermically to release toxic gases. Reactions with amines, aldehydes, alcohols, alkali metals, ketones, mercaptans, strong oxidizers, hydrides, phenols, and peroxides can cause vigorous releases of heat.

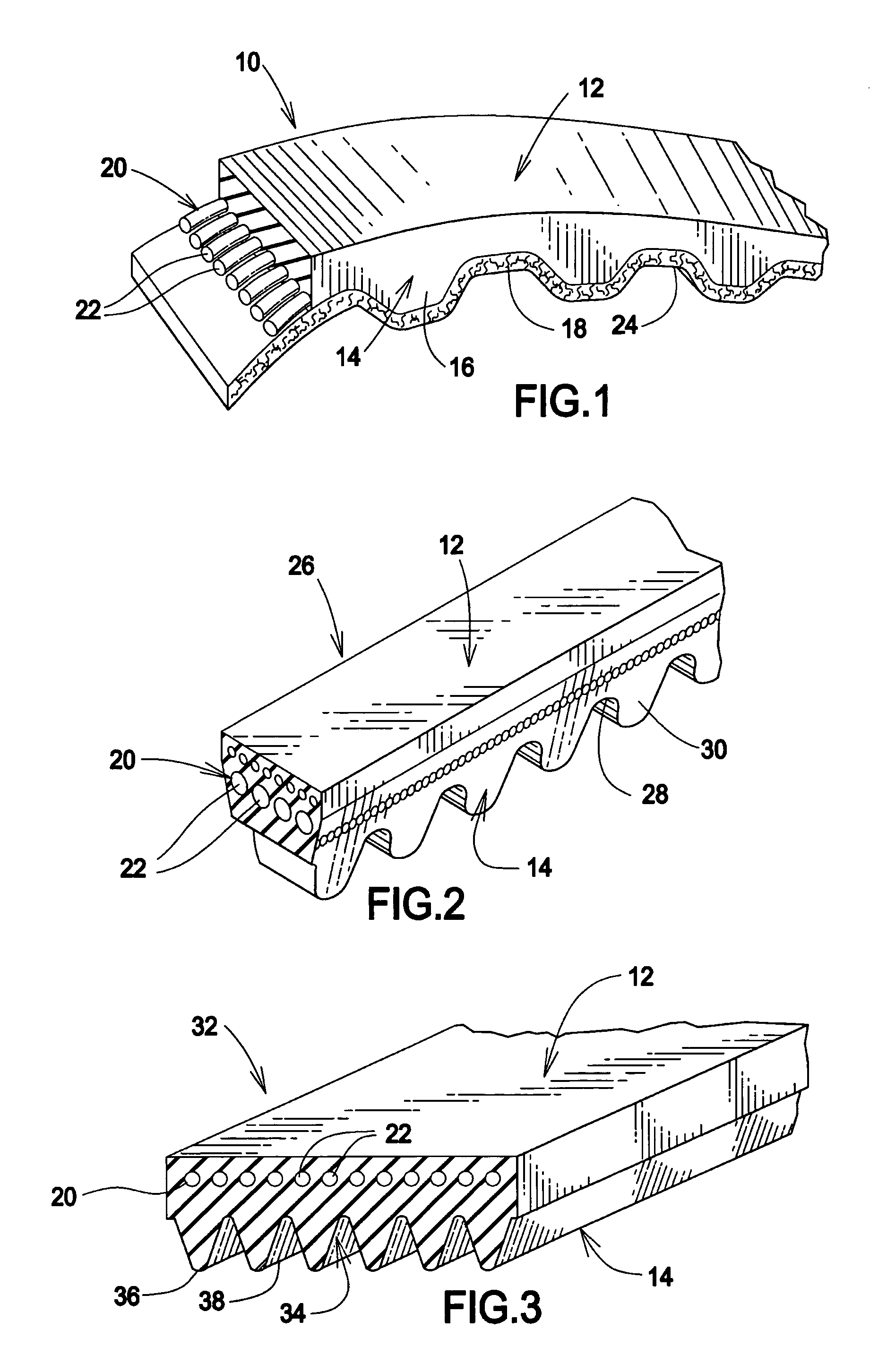

High temperature polyurethane/urea elastomers

InactiveUS6964626B1High and low temperature resistance propertiesHigh and low temperature resistance propertyV-beltsRopes and cables for vehicles/pulleyElastomerPolyester

The present invention relates to molded polyurethane / urea elastomers, and specifically to improved polyurethane / urea elastomers having high temperature stability to about 140–150° C. and low temperature flexibility at about −35–(−40)° C., for use in dynamic applications. These elastomers are particularly useful for application in belts, specifically in automotive timing or synchronous belts, V-belts, multi V-ribbed or micro-ribbed belts, flat belting and the like. The polyurethane / urea elastomers of the present invention are prepared by reacting polyisocyanate prepolymers with symmetric primary diamine chain extenders, mixtures of symmetric primary diamine chain extenders and secondary diamine chain extenders, or mixtures of symmetric primary diamine chain extenders and non-oxidative polyols, which are all chosen to eliminate the need for catalysts via standard molding processes, and to improve phase separation. The polyisocyanate prepolymers are reaction products of polyols which are nonoxidative at high temperatures, such as polycarbonate polyols, polyester polyols, or mixtures thereof, with organic polyisocyanates which are either compact, symmetric and aromatic, such as para-phenylene diisocyanate, 1,5-naphthalene diisocyanate, and 2,6-toluene diisocyanate, or are aliphatic and possess trans or trans,trans geometric structure, such as trans-1,4-cyclohexane diisocyanate and trans,trans-4,4′-dicyclohexylmethyl diisocyanate.

Owner:THE GATES CORP

Preparation method of thermoplastic polyurethane elastomer

InactiveCN103059554AImprove mechanical propertiesImprove heat resistancePolyethylene glycolHydrolysis

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

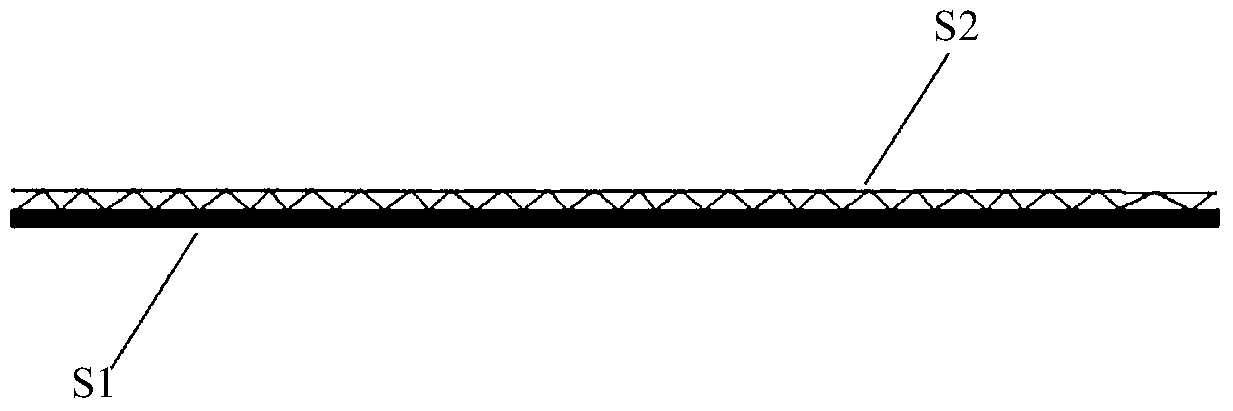

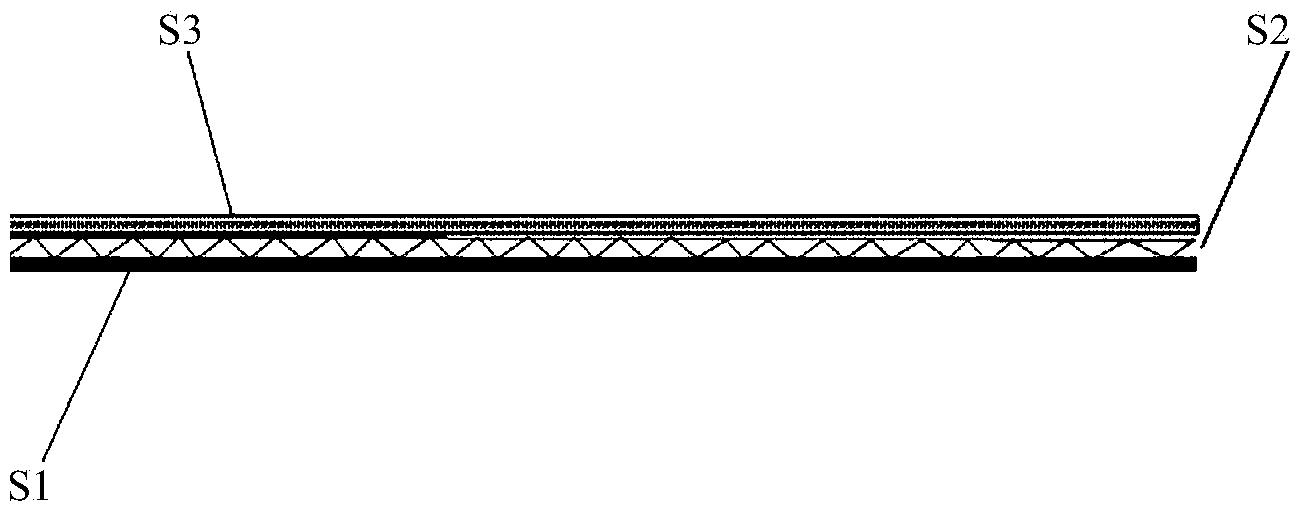

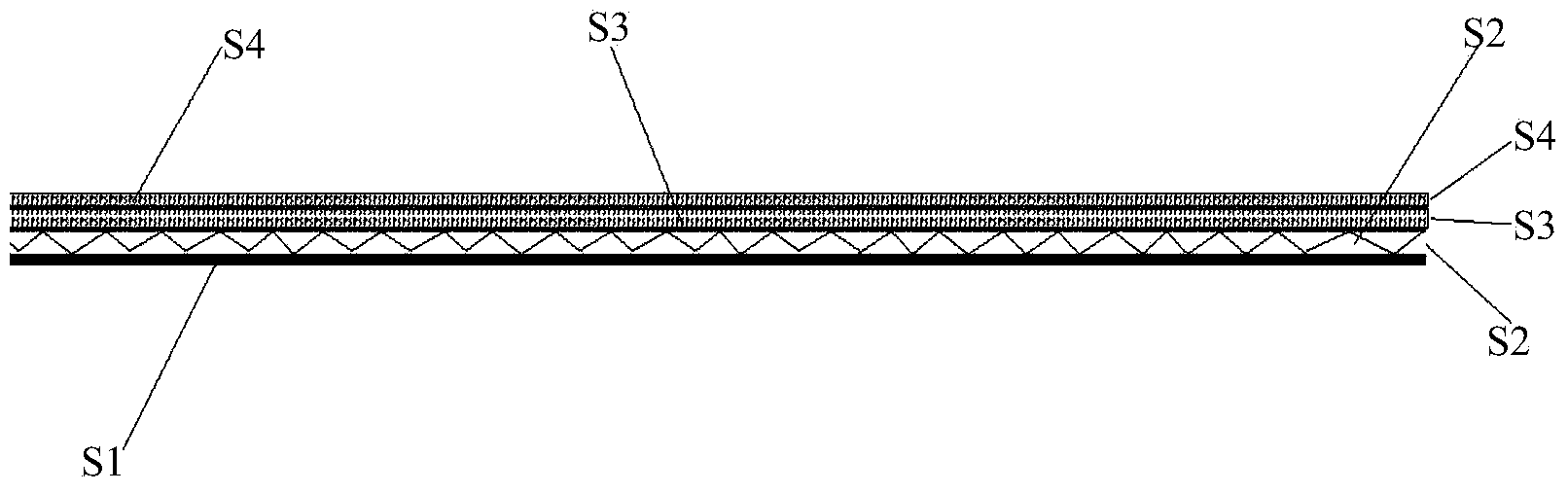

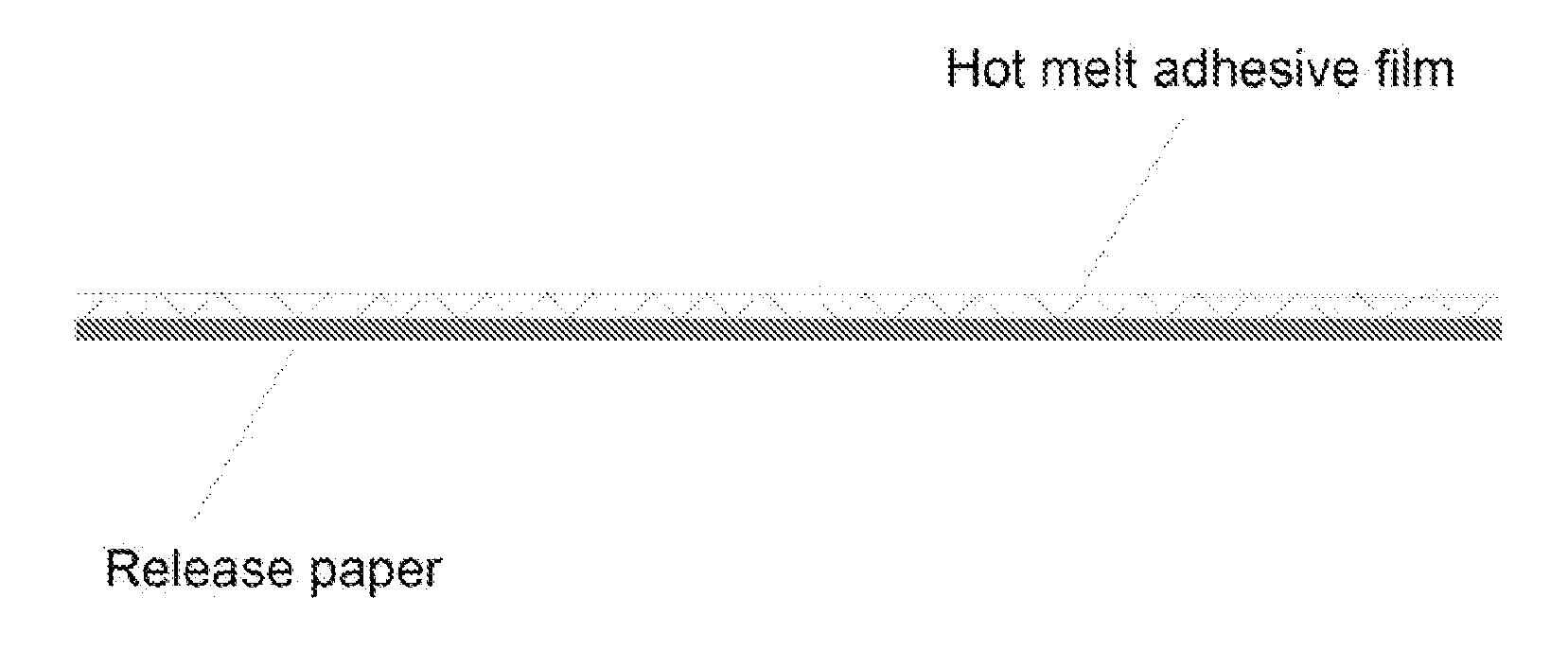

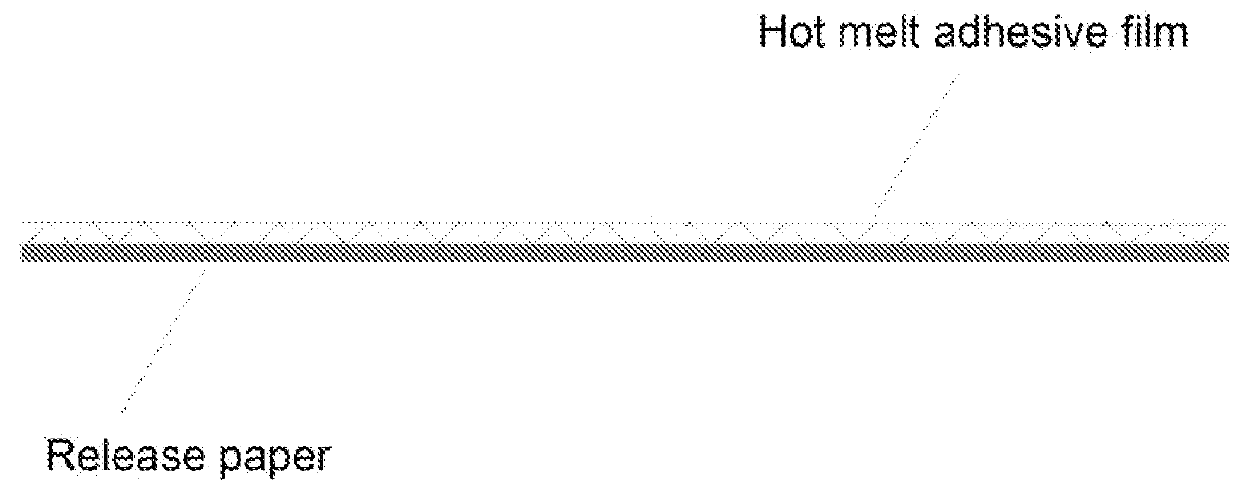

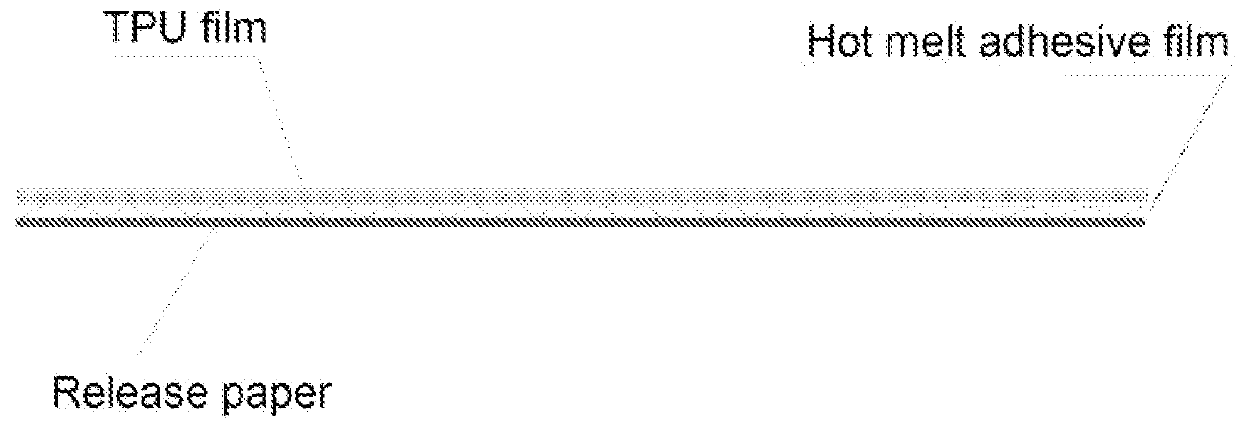

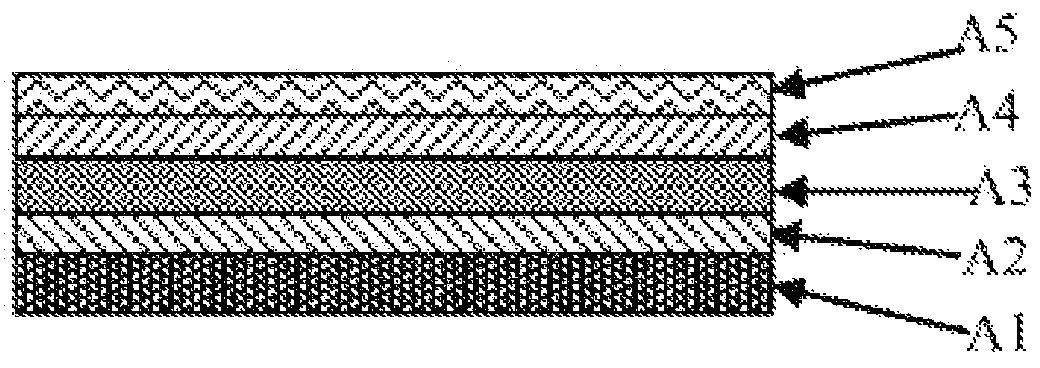

Sewing-free hot melt adhesive TPU-PU leather and preparation method thereof

ActiveCN103437195AExcellent physical and chemical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolymer science

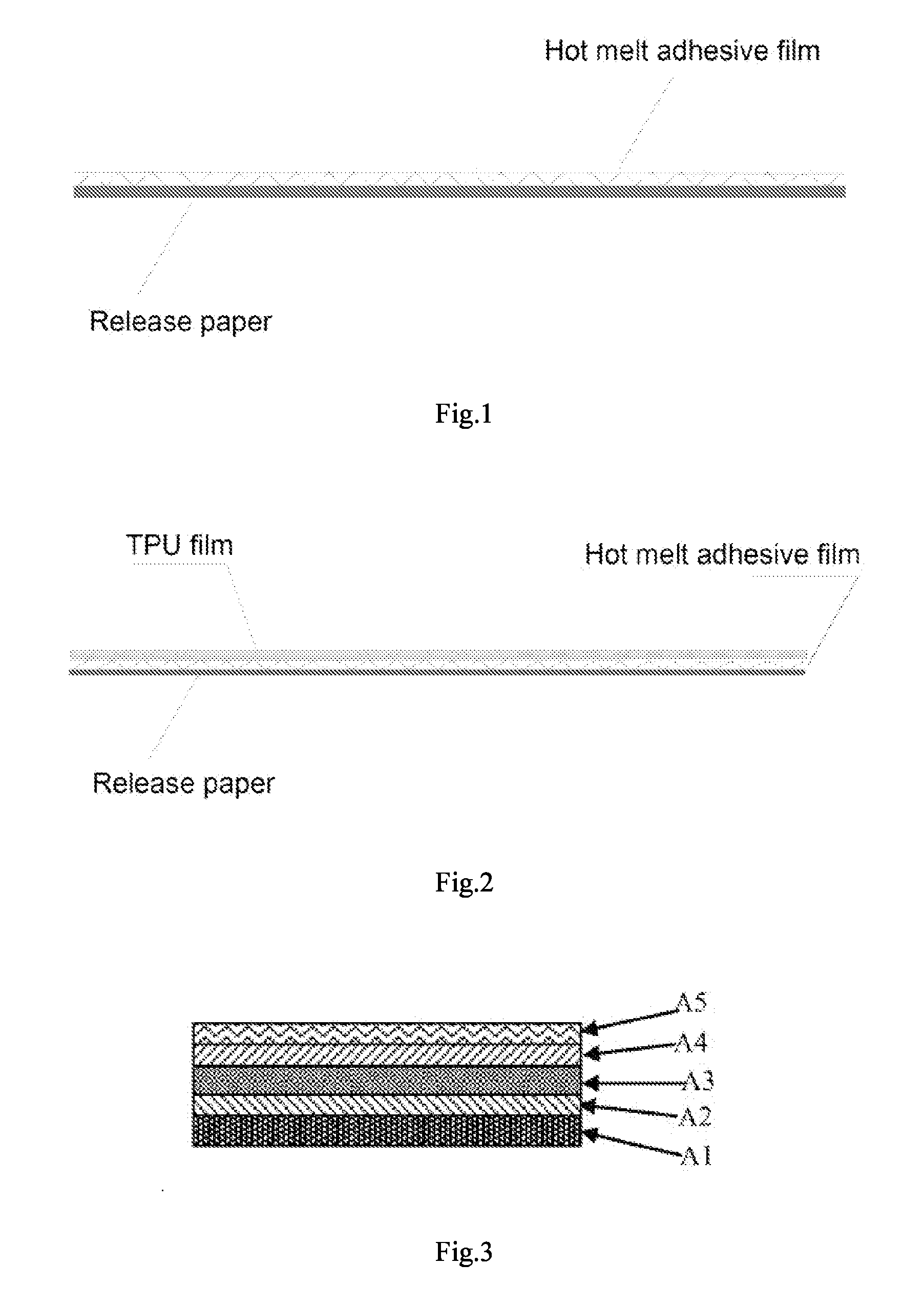

The invention provides a piece of novel sewing-free hot melt adhesive TPU-PU leather, and a preparation method thereof. The TPU-PU leather comprises release paper, a hot melt adhesive film, a TPU film and a dry-type PU film, wherein the release paper comprises a paper bottom layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material is composed of polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; a TPU raw material is composed of polymer polybasic alcohol, 1,4-cyclohexane-diisocyanate, a chain extender and a plurality of functional additives; a PU raw material is composed of polyester dibasic alcohol, straight chain diol, isocyanate, TDI trimer, dimethyl formamide, butanone, black sand, and a plurality of functional addictives. Through the adoption of the preparation method, innovations are conducted on the raw material components of the release paper, the hot melt adhesive, the TPU film and the PU film; the manufactured sewing-free TPU-PU leather has the technical advantages of firmness in adhesion, durability, environment-friendly materials, no invisible harm to a human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

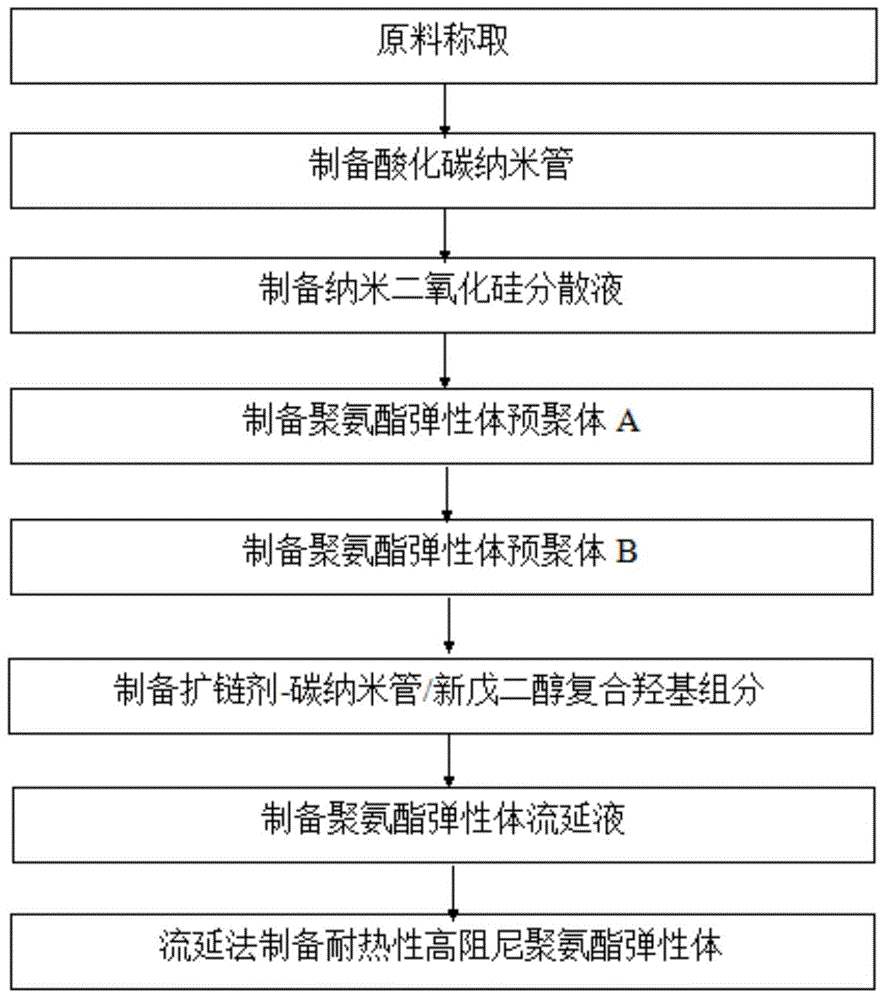

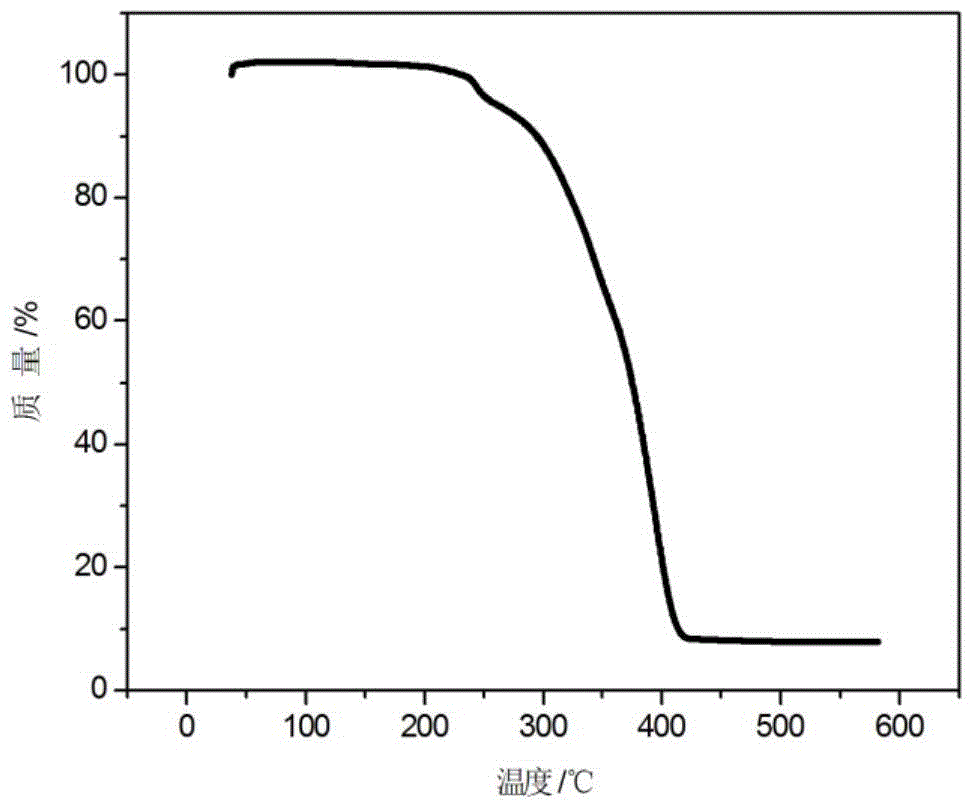

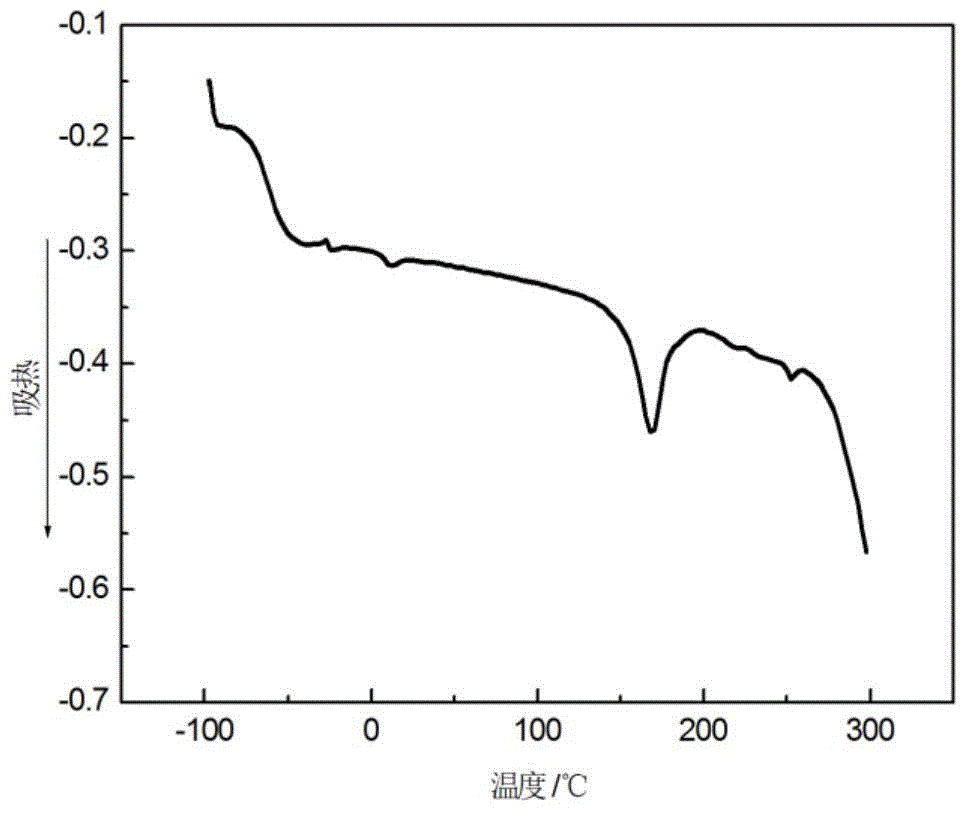

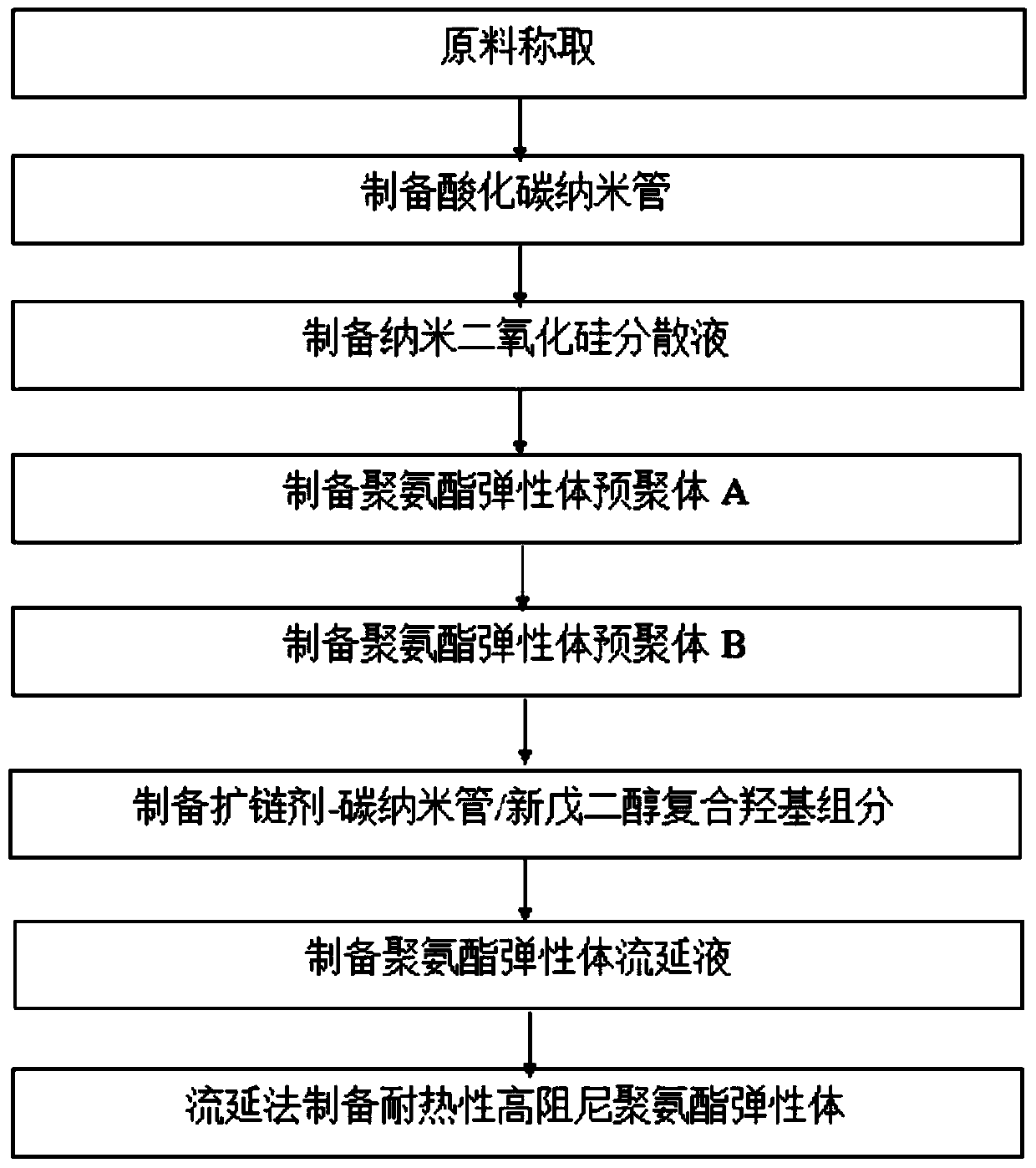

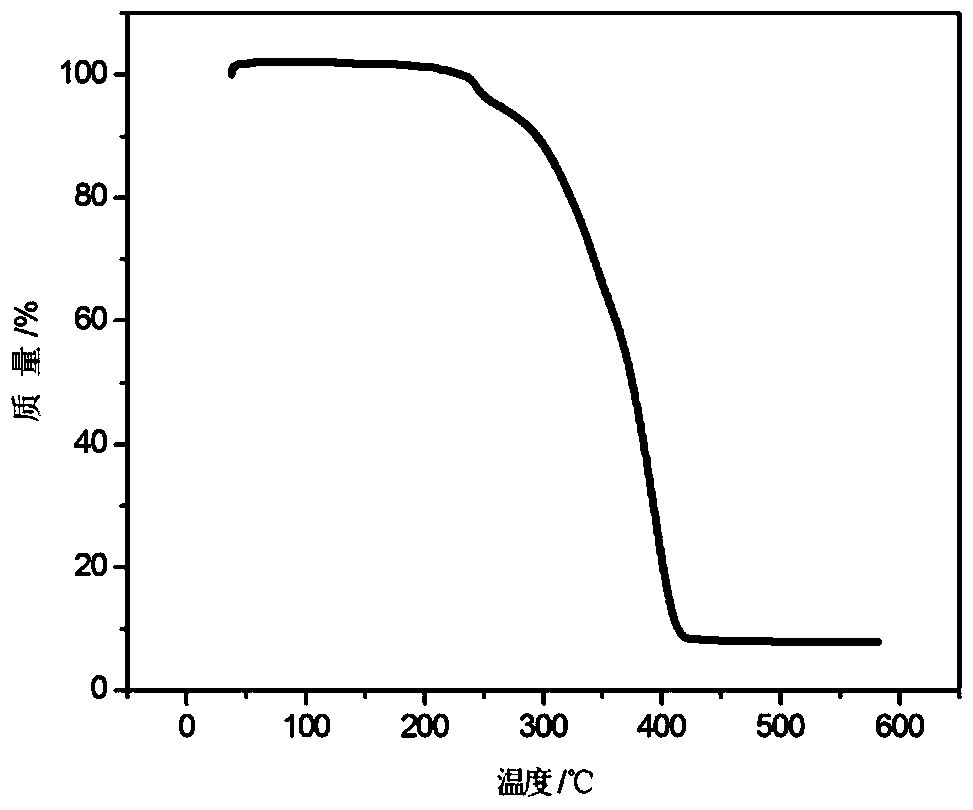

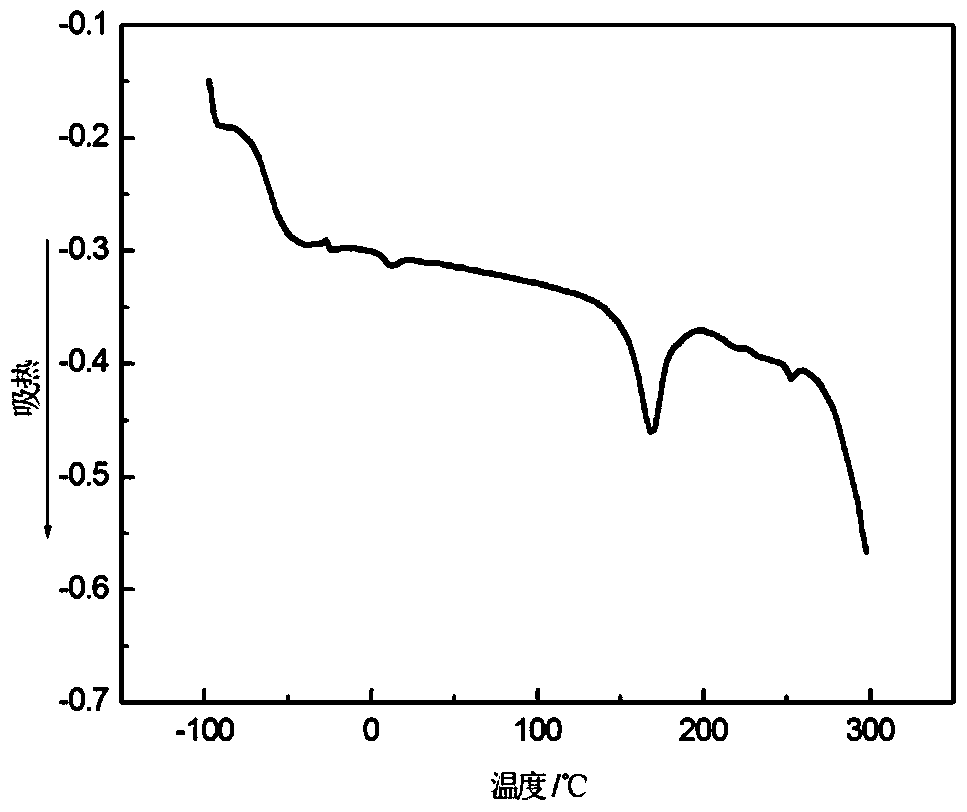

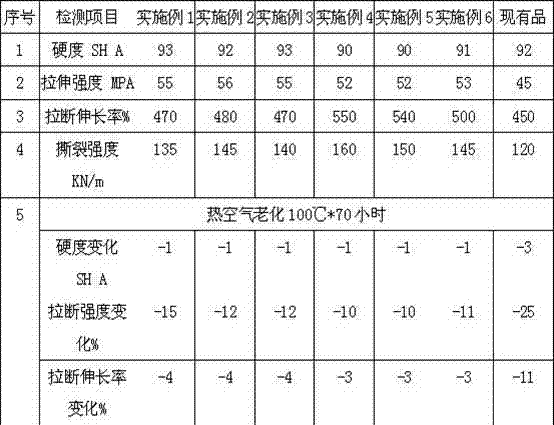

Heat-resistant and high-damping polyurethane elastomer and preparation method thereof

The invention relates to a heat-resistant and high-damping polyurethane elastomer, which is prepared from the following raw materials by weight: 27.92%-33.56% of polytetramethylene glycol, 8.52%-9.03% of diphenyl-methane-diisocyanate, 26.02%-31.66% of polycaprolactone diol, 9.02%-9.70% of 1, 4-cyclohexane diisocyanate, 0.10%-0.30% of N, N'- dicyclohexylcarbodiimide, 4.91%-5.62% of neopentyl glycol, 0.06%-0.10% of dibutyltin dilaurate, 0.60%-0.90% of carbon nanotube, and 15.02%-15.45% of nano-silica, with the sum of the weight percentage of the components being 100%. The preparation method includes: weighing raw materials, preparing an acidified carbon nanotube, preparing a nano-silica dispersion solution, preparing a polyurethane elastomer prepolymer A, preparing a polyurethane elastomer prepolymer B, preparing a chain extender-carbon nanotube / neopentyl glycol composite hydroxyl component, preparing a polyurethane elastomer casting liquid, and preparing the heat-resistant and high-damping polyurethane elastomer by means of tape-casting. The method provided by the invention can solve the problem of poor heat resistance of polyurethane elastomers in the prior art, and the prepared polyurethane elastomer has high heat resistance and high damping property.

Owner:XIAN UNIV OF TECH

Process for the production of polyurethane di(METH)acrylates

A process for the production of polyurethane di(meth)acrylates in which a diisocyanate component, a diol component and hydroxy-C2-C4-alkyl(meth)acrylate in the molar ratio x:(x-1):2 are reacted without solvent and without subsequent purification operations, wherein x means any desired value from 2 to 5, wherein 50 to 80 mol % of the diisocyanate component is formed by 1,6-hexane diisocyanate, and 20 to 50 mol % by one or two diisocyanates, each forming at least 10 mol % of the diisocyanate component and being selected from the group consisting of toluylene diisocyanate, diphenylmethane diisocyanate, dicyclohexylmethane diisocyanate, isophorone diisocyanate, trimethylhexane diisocyanate, cyclohexane diisocyanate, cyclohexanedimethylene diisocyanate and tetramethylenexylylene diisocyanate, wherein the mol % of the respective diisocyanates add up to 100 mol %, wherein the diol component comprises no more than four different diols, and 20 to 100 mol % of the diol component is formed by at least one linear aliphatic alpha,omega-C2-C12-diol, and 0 to 80 mol % by at least one (cyclo)aliphatic diol that is different from linear aliphatic alpha,omega-C2-C12-diols, wherein each diol of the diol component forms at least 10 mol % within the diol component, and wherein the mol % of the respective diols add up to 100 mol %.

Owner:EI DU PONT DE NEMOURS & CO

Sewing-free hot melt adhesive TPU leather and preparation method thereof

ActiveUS20160215174A1Excellent physicochemical performanceHigh bonding strengthFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The present invention provides a novel sewing-free hot melt adhesive TPU leather and a preparation method thereof. The hot melt adhesive TPU leather comprises a release paper, a hot melt adhesive film, and a TPU film. The release paper comprises a bottom paper layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material comprises polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; and a TPU raw material comprises polymer polyol, 1,4-cyclohexane-diisocyanate, a chain extender, and a plurality of functional additives. According to the present invention, innovations are conducted on raw material components of the release paper, the hot melt adhesive, and the TPU film, and extrusion shaping is conducted by utilizing the hot melt adhesive with strong plasticity and the TPU thin film; and the prepared sewing-free TPU leather has the technical advantages of firm adhesion, durability, environmentally-friendly materials, no invisible harm to human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

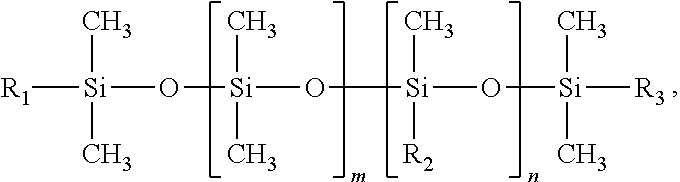

Waterproof anti-bacterial polyurethane composite material

The invention discloses a waterproof anti-bacterial polyurethane composite material. Raw materials of the waterproof anti-bacterial polyurethane composite material include polypropylene oxide glycol, hydroxyl-terminated liquid silicone rubber, 1,4-cyclohexane diisocyanate, 1,5-naphthalene diisocyanate, 1,4-butynediol, 1,4-bis(2-hydroxethoxy)benzene, 4,4'-diaminodiphenyl sulphone, 1H,1H,10H,10H-perfluoro-1,10-decanediol, hydroxypropyl trimethoxysilane, dibutyltin dilaurate, methyl methacrylate, benzoyl peroxide, methyl-tri-butanone-oxime silane, polystyrene, polyvinyl chloride, an acrylonitrile-butadiene-styrene copolymer, a rare earth coordination compound and a composite filling, wherein the composite filling comprises oxidized graphene, a carbon nanotube, nanometer titanium dioxide, nanometer zinc oxide, nanometer copper oxide, nanometer carbon fibers and didodecyldimethylammonium bromide. The waterproof anti-bacterial polyurethane compound material provided by the invention is high in intensity, water resistance and bacterium resistance.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

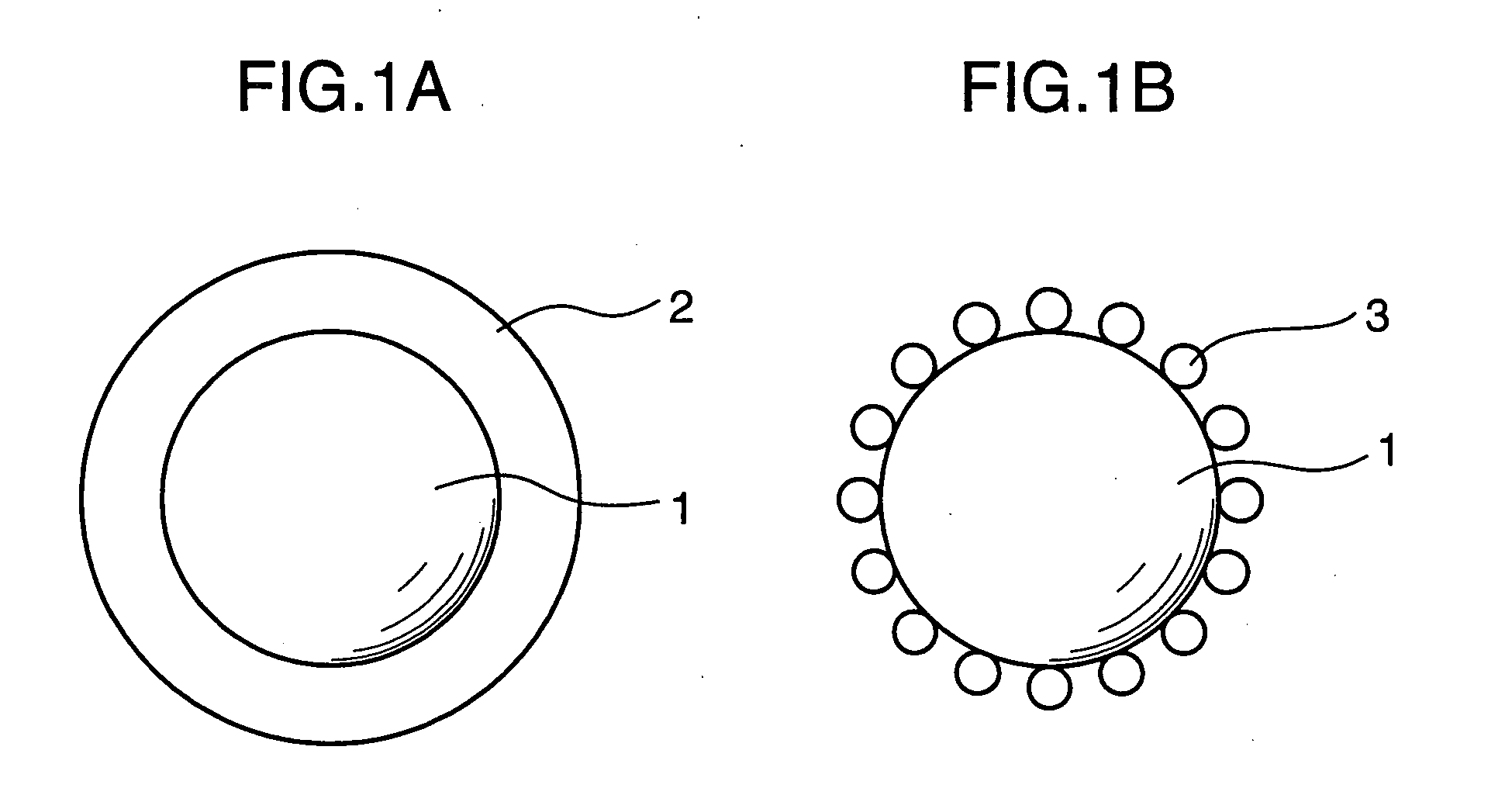

Cover composition for golf ball

ActiveUS20050187336A1Increase resistanceConvenient timeGolf ballsSolid ballsCarbamateCyclohexane diisocyanate

A cover composition for a golf ball includes: an isocyanate group-terminated urethane prepolymer containing an isocyanate component derived from at least one diisocyanate selected from the group consisting of 4,4′-dicyclohexylmethane diisocyanate, isophorone diisocyanate, and cyclohexane diisocyanate; an aromatic polyamine; a light stabilizer; and a titanium oxide applied with a surface treatment capable of suppressing photocatalytic action of the titanium oxide, wherein the cover composition contains 3 to 8 parts by mass of the surface-treated titanium oxide relative to 100 parts by mass of the urethane prepolymer. The golf ball having the cover composition has superior resistance against discoloration or degradation with time, namely, superior weatherability.

Owner:SUMITOMO RUBBER IND LTD

Method for the preparation of microcellular polyurethane elastomers

ActiveCN104024298AImprove machinabilitySpringsResilient suspensionsPolyurethane elastomerToluene diisocyanate

This invention relates to a method of preparing a microcellular polyurethane elastomer by reacting naphthalene diisocyanate with a polyol to prepare a prepolymer containing an isocyanate (NCO) group, followed by mixing the prepared polyurethane prepolymer with a plasticizer, water, an emulsifier and the like, and then foaming the prepolymer blend to prepare a polyurethane elastomer, wherein the emulsifier is a mixture of (a) a compound selected from the group consisting of 2,4-toluene diisocyanate, 2,6-toluene diisocyanate, 2,4-diphenylmethane diisocyanate, 4,4'-diphenylmethane diisocyanate, hexamethylene diisocyanate, 1,4'-cyclohexane diisocyanate and mixtures thereof, and (b) a C2-10 hydrocarbon having a molecular weight of 500 or less with two to four hydroxyl groups, or mixtures thereof. The method of the invention can optimize the viscosity and properties of the prepolymer resulting from the reaction of naphthalene diisocyanate with a polyol, thus improving processability.

Owner:SKC CO LTD

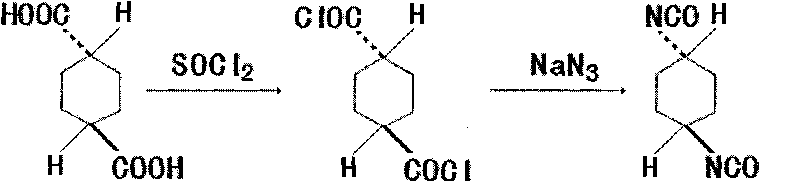

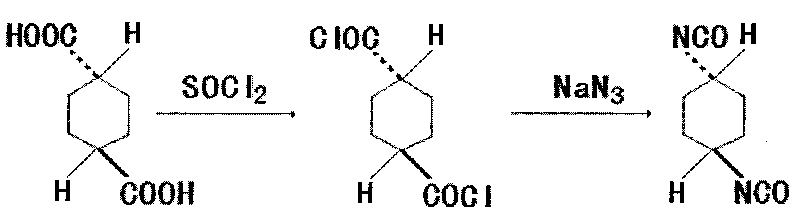

Method for synthesizing trans-1,4-cyclohexane diisocyanate

ActiveCN101735111ASimple process routeRaw materials are easy to getPreparation from carboxylic acid nitrogen analoguesCyclohexane diisocyanateSodium azide

The invention discloses a method for synthesizing trans-1,4-cyclohexane diisocyanate, which comprises the following steps: (1) mixing trans-1,4-cyclohexanedicarboxylic acid with thionyl chloride, heating under reflux, decompressing and recovering the extra thionyl chloride for obtaining trans-1,4-cyclohexanedicarbonyl chloride; (2) adding toluene, benzene or xylene into the trans-1,4-cyclohexanedicarbonyl chloride, heating to 45-75 DEG C, and further adding sodium azide for obtaining mixture; and (3) keeping the temperature of the mixture for 0.5-1.5 hours at the temperature of 45-75 DEG C, filtering for removing insoluble matters, decompressing, recovering the toluene and distilling for obtaining the trans-1,4-cyclohexane diisocyanate. The synthesis method has the advantages of simple process route, easy obtainment of raw materials and short reaction period, thereby being applicable to industrial mass production.

Owner:江苏恒祥化学股份有限公司

Method for the Preparation of Microcellular Polyurethane Elastomers

ActiveUS20140374976A1Easy to processOptimize lifeResilient suspensionsRubber-like material springsToluene diisocyanatePolymer chemistry

This invention relates to a method of preparing a microcellular polyurethane elastomer by reacting naphthalene diisocyanate with a polyol to prepare a prepolymer containing an isocyanate (NCO) group, followed by mixing the prepared polyurethane prepolymer with a plasticizer, water, an emulsifier and the like, and then foaming the prepolymer blend to prepare a polyurethane elastomer, wherein the emulsifier is a mixture of (a) a compound selected from the group consisting of 2,4-toluene diisocyanate, 2,6-toluene diisocyanate, 2,4-diphenylmethane diisocyanate, 4,4′-diphenylmethane diisocyanate, hexamethylene diisocyanate, 1,4′-cyclohexane diisocyanate and mixtures thereof, and (b) a C2-10 hydrocarbon having a molecular weight of 500 or less with two to four hydroxyl groups, or mixtures thereof. The method of the invention can optimize the viscosity and properties of the prepolymer resulting from the reaction of naphthalene diisocyanate with a polyol, thus improving processability.

Owner:SKC CO LTD

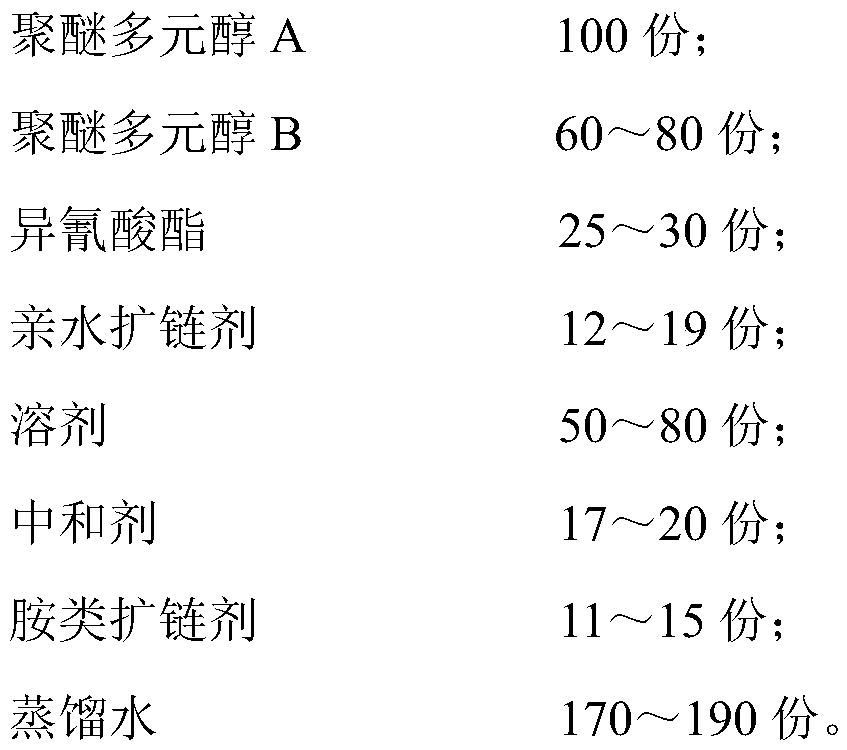

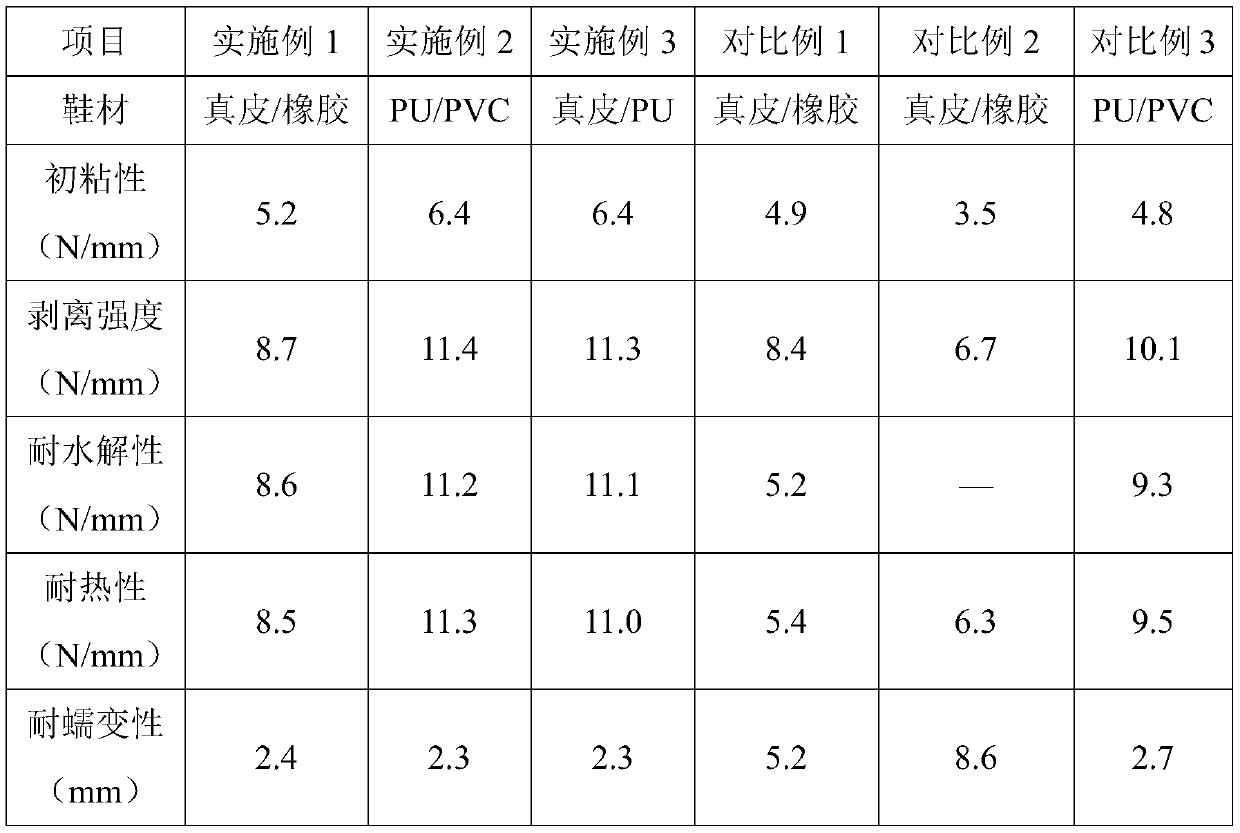

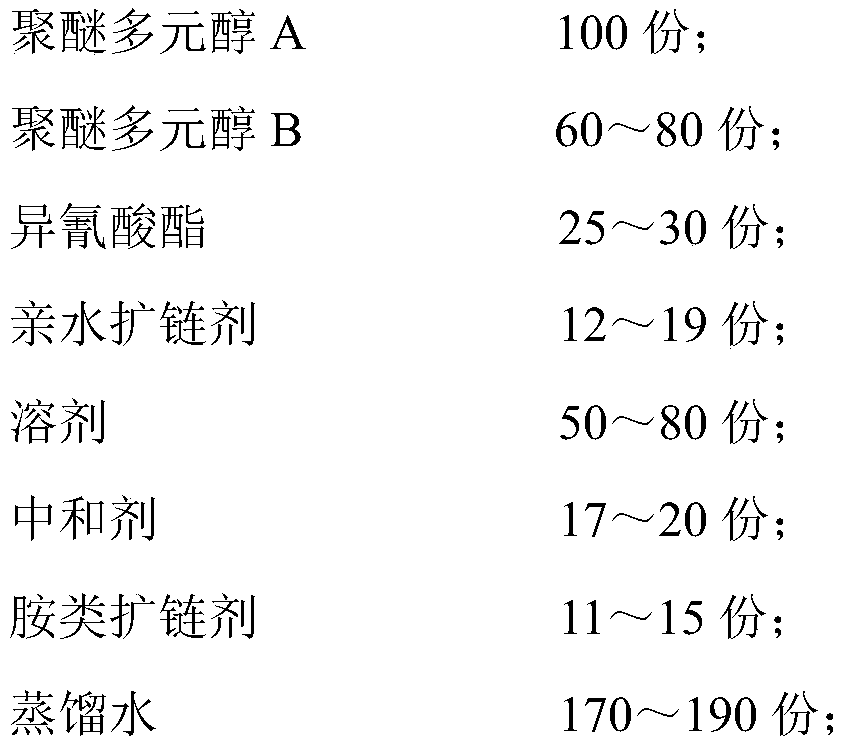

Waterborne polyurethane adhesive used for shoes and preparation method thereof

InactiveCN109705792AImprove water resistanceGood flexibility at low temperaturePolyureas/polyurethane adhesivesPolyurethane adhesiveGlycerol

The invention relates to the technical field of polyurethane adhesives, specifically to a waterborne polyurethane adhesive used for shoes and a preparation method thereof. The waterborne polyurethaneadhesive comprises the following raw materials by mass: 100 parts of polyether polyol A, 60 to 80 parts of polytetrahydrofuran diol, 25 to 30 parts of isocyanate, 12 to 19 parts of a hydrophilic chainextender, 50 to 80 parts of a solvent, 17 to 20 parts of a neutralizing agent, 11 to 15 parts of an amine chain extender and 170 to 190 parts of distilled water, wherein the polyether polyol A is polyether polyol which uses glycerin as a starting agent, uses epoxypropane for ring opening and oxirane for end termination, and has a functionality degree of 2.5 to 3.5 and a number average molecular weight of 4500 to 5500; and the isocyanate is 1,4-cyclohexane diisocyanate. The waterborne polyurethane adhesive provided by the invention has good initial strength and initial adhesion, high bonding strength and good heat resistance and water resistance in the process of use. The invention also provides a preparation method for the waterborne polyurethane adhesive.

Owner:耿佃勇

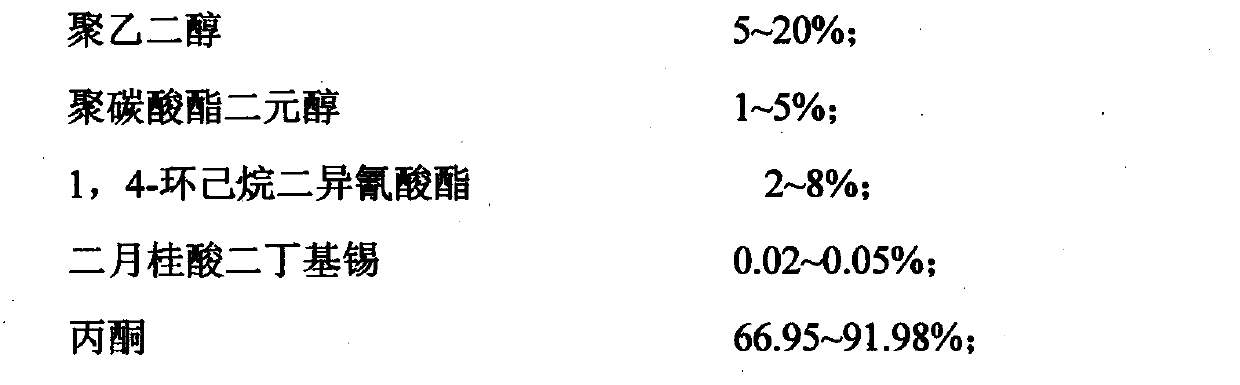

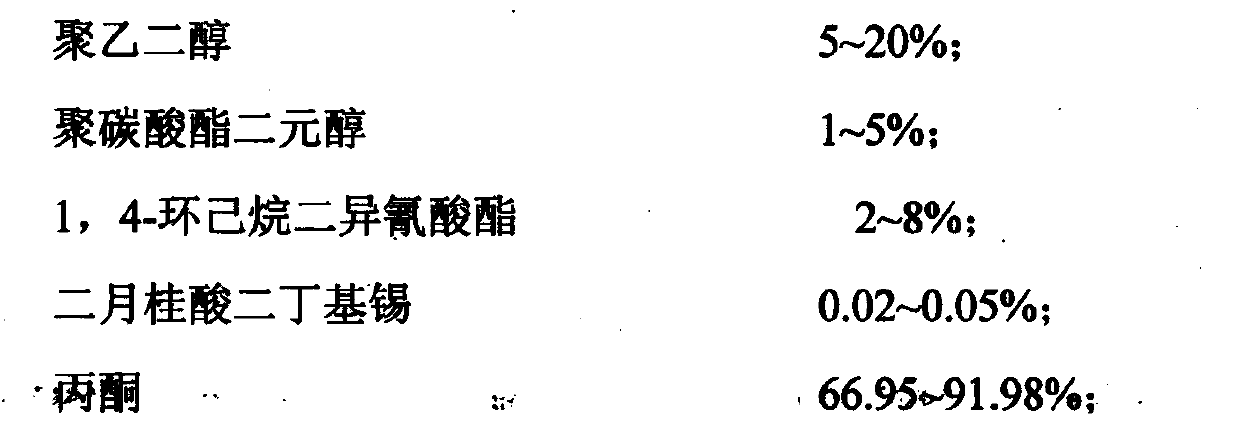

Modifying method of cellulose acetate filtration membrane

ActiveCN103551055AImprove hydrophilicityImprove pollutionSemi-permeable membranesCross-linkFiltration membrane

The invention provides a modifying method of a cellulose acetate filtration membrane. The modifying method of the cellulose acetate filtration membrane is characterized by comprising the following specific steps: step 1, dissolving polyethylene glycol and polycarbonate dihydric alcohol into an acetone solvent so as to prepare a hydrophilic modified solution; step 2, immersing the cellulose acetate filtration membrane completely in the hydrophilic modified solution to moisten fully, sequentially adding a cross-linking agent 1, 4-cyclohexyl diisocyanate and a catalyst dibutyltin dilaurate to the hydrophilic modified solution, and carrying out grafting reaction directly; step 3, taking out the reacted cellulose acetate filtration membrane, draining off naturally until a dissociated solution in the filtration membrane is removed, heating, curing again, and drying completely, thereby preparing the modified cellulose acetate filtration membrane. The modified cellulose acetate filtration membrane prepared by the invention is higher in hydrophilia and pollution-prevention performance.

Owner:CHINA HAISUM ENG

1, 4-cyclohexyl diisocyanate synthesis method

InactiveCN102827035AReduce usageThe synthetic process route is simplePreparation by nitro-carbon monoxide reactionCyclohexane diisocyanateSynthesis methods

The invention discloses a 1, 4-cyclohexyl diisocyanate synthesis method. The 1, 4-cyclohexyl diisocyanate synthesis method comprises the following steps that 1, solid triphosgene is dissolved in chloroform; the solution is cooled to a temperature of -5 to 0 DEG C; and 1,4-cyclohexanediamine is slowly and dropwisely added into the cooled solution; and 2, the mixed solution is heated to a temperature of 40 to 70 DEG C and undergoes a reaction for 6 hours; reaction products are cooled to a temperature of 10 to 20 DEG C and then are washed by an alkali until the reaction products are alkalescent; after the reaction products has a pH value of 7, chloroform is recovered; and 1, 4-cyclohexyl diisocyanate which is a faint yellow waxy solid is obtained by reduced pressure rectification. The 1, 4-cyclohexyl diisocyanate synthesis method has a simple synthesis route, avoids use of hypertoxic gas, and has a high product yield above 80% and high purity above 98.5%.

Owner:江苏恒祥化学股份有限公司

Transparent highly flexible gel-like polyurethane elastomer

InactiveCN101643536AIncrease elasticityExcellent properties of elastomerPolyurethane elastomerPolyester

The invention relates to the technical field of elastomer technology, in particular to a transparent highly flexible gel-like polyurethane elastomer (EPU). The elastomer is prepared by a component A,a component B and a component C, wherein the component A is polyester or a polyether glycol mixture, the polyether glycol mixture contains at least polyether glycol, polyol and functional polyol, thecomponent B is isocyanate prepolymer containing at least diphenylmethane diisocyanate, polyester polyol, 1,6-cyclohexane diisocyanate, the component C is filler containing plasticizer, the weight ratio of the component A to the sum of the component B and the component C is 1.15-1.2:1 and the weight ratio of the component B to the component C is 1:0.8-0.85. The beneficial effect of the invention isthat all the performance parameters of the obtained polyurethane elastomer can meet the demand simultaneously, the performance is excellent, the elasticity is good, and the product is environmentallyfriendly and corresponds to the demand of industrial production.

Owner:冯建龙

Preparation method of heat-resisting modified polyurethane composite

The invention discloses a preparation method of heat-resisting modified polyurethane composite, comprising: adding hexafluobisphenol A and 3-aminopropyl-methyldimethoxysilane into a reaction container, and reacting to obtain silicon-bearing chain extender; mixing well polycarbonate diols, hydroxyl-terminated liquid silicon rubber, nano calcium carbonate, montmorillonite and epoxy resin, adding 1,4-cyclohexane diisocyanate, dibutyltin dioctanoate and butanone, and stirring and reacting to obtain polyurethane prepolymer; mixing well the polyurethane prepolymer with 1,4-bis(2-hydroxyethoxy)benzene, 4,4'-diaminodiphenyl and the silicon-bearing chain extender, and stirring and reacting and then curing to obtain the heat-resisting modified polyurethane composite. The preparation method of the heat-resisting modified polyurethane composite provided herein has a simple process and mild conditions, and the obtained composite has high strength, good heat resistance and excellent ageing resistance and can meet the requirement of use in various fields.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

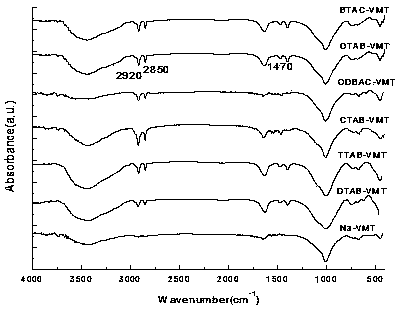

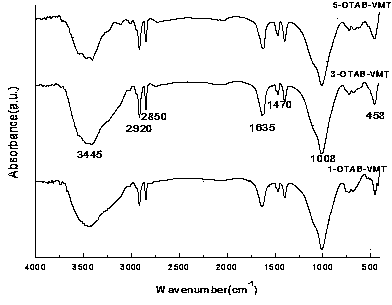

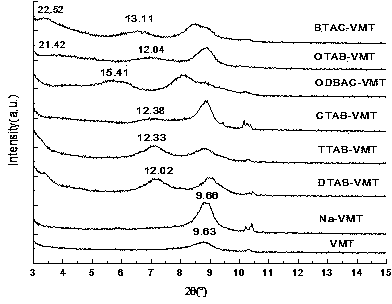

High-temperature-resistant polyurethane/modified vermiculite composite material and preparation method thereof

InactiveCN104194314AImprove mechanical propertiesImprove temperature resistanceWater bathsFiltration

The invention relates to a high-temperature-resistant polyurethane / modified vermiculite composite material and a preparation method thereof. The invention adopts the technical scheme as follows: the preparation method comprises the following steps: (1) performing sodium-based modification on primary mineral of vermiculite as a raw material to obtain sodium-based vermiculite, pulping the sodium-based vermiculite, adding quaternary ammonium salt surfactants with different long chains, stirring in a water bath with the temperature of 70-75 DEG C for about 2 hours, cooling, performing suction filtration, washing, and activating at 110 DEG C for 2 hours to prepare organic modified vermiculite; (2) adding the 3% organic modified vermiculite into polycarbonate polyol, performing high-speed stirring and ultrasonic dispersion for 2 hours, adding 1,4-cyclohexyl diisocyanate, reacting at 75 DEG C for 30 minutes to obtain a prepolymer, cooling the prepolymer to be 70 DEG C, controlling the value of R (-NCO / -OH), and adding a curing agent to obtain the high-temperature-resistant polyurethane / modified vermiculite composite material. The preparation methods of the organic modified vermiculite and the composite material are simple, the reaction conditions are mild, the mechanical property of the prepared composite material is remarkably improved, the temperature-resistant range can reach about 300 DEG C, and the composite material can be used for blocking a thick oil steam breakthrough channel.

Owner:SOUTHWEST PETROLEUM UNIV

Process for the production of polyurethane di(meth)acrylates

InactiveUS7071242B2Carbamic acid derivatives preparationOrganic compound preparationMeth-Cyclohexane diisocyanate

A process for the production of polyurethane di(meth)acrylates in which a diisocyanate component, a diol component and hydroxy-C2–C4-alkyl (meth)acrylate in the molar ratio x:(x−1):2 are reacted without solvent and without subsequent purification operations, wherein x means any desired value from 2 to 5, wherein 50 to 80 mol % of the diisocyanate component is formed by 1,6-hexane diisocyanate, and 20 to 50 mol % by one or two diisocyanates, each forming at least 10 mol % of the diisocyanate component and being selected from the group consisting of toluylene diisocyanate, diphenylmethane diisocyanate, dicyclohexylmethane diisocyanate, isophorone diisocyanate, trimethylhexane diisocyanate, cyclohexane diisocyanate, cyclohexanedimethylene diisocyanate and tetramethylenexylylene diisocyanate, wherein the mol % of the respective diisocyanates add up to 100 mol %, wherein the diol component comprises no more than four different diols, and 20 to 100 mol % of the diol component is formed by at least one linear aliphatic alpha,omega-C2–C12-diol, and 0 to 80 mol % by at least one (cyclo)aliphatic diol that is different from linear aliphatic alpha,omega-C2–C12-diols, wherein each diol of the diol component forms at least 10 mol % within the diol component, and wherein the mol % of the respective diols add up to 100 mol %.

Owner:EI DU PONT DE NEMOURS & CO

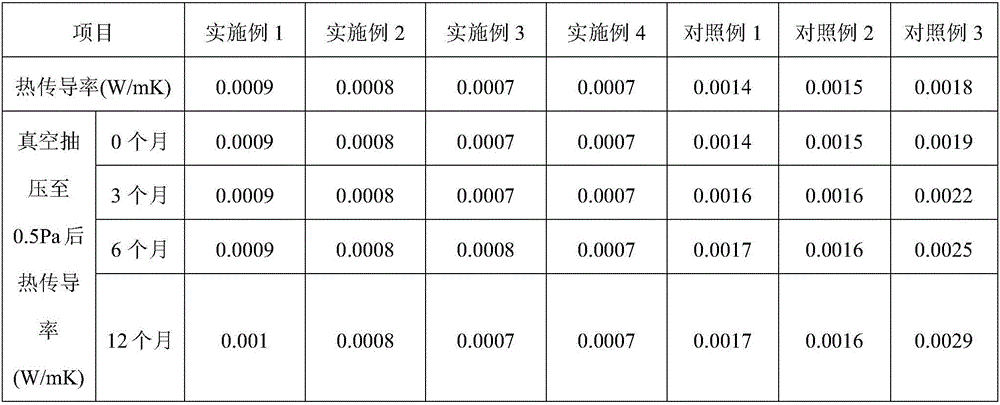

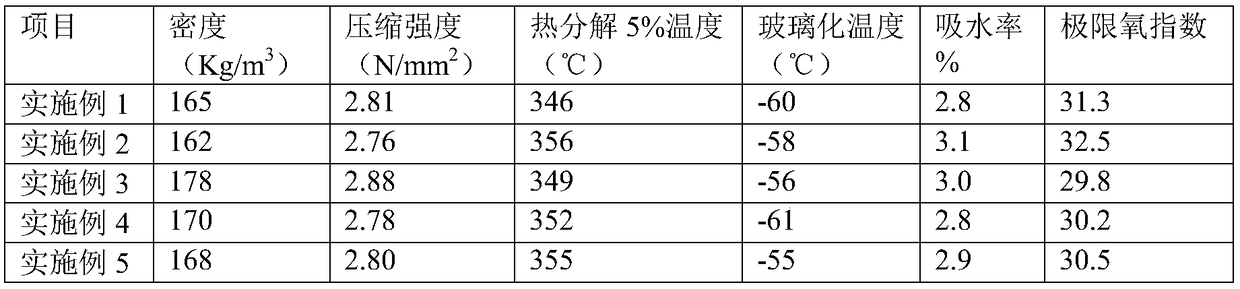

Core material for vacuum heat-insulating board and preparation method thereof

The invention discloses a core material for a vacuum heat-insulating board and a preparation method thereof. The core material comprises the following raw material components: acrylic acid, calcium oxide, polyvinyl alcohol, methacryloylpropyltrimethyl ammonium chloride, stearic acid, potassium bisulfite, glass fiber, silicon dioxide, polyester fiber, 1,4-cyclohexane diisocyanate, polyethylene adipate glycol, a silane coupling agent, pentamethyldiethylene triamine, bentonite, a chain extender and Tween 20. The preparation method comprises the following steps: successively subjecting acrylic acid, calcium oxide, polyvinyl alcohol, methacryloylpropyltrimethyl ammonium chloride, stearic acid and potassium bisulfite to reacting so as to obtain a reactant; then carrying out shearing granulation, and carrying out drying so as to obtain a material 1; and subjecting glass fiber, silicon dioxide, polyester fiber, 1,4-cyclohexane diisocyanate, polyethylene adipate glycol, the material 1 and the remained components to a certain reaction so as to obtain the core material for the vacuum heat-insulating board. The core material obtained by using the method provided by the invention has good heat-insulating performance and vacuum compression use stability.

Owner:JIANGSU JINGWEI INTELLECTUAL PROPERTY OPERATION CO LTD

Polyurethane foam with organosilicon modified expanded graphite as flame retardant

The invention relates to a polyurethane foam, especially to a polyurethane foam with organosilicon modified expanded graphite as a flame retardant. The polyurethane foam must contains organosilicon modified expanded graphite. The polyurethane foam further comprises polyester polyol, 1,4-cyclohexane diisocyanate, hydroxyl-terminated fluorosilicone resin, stannous octoate, triethylenediamine, a surfactant, an antioxidant and a drier. The polyurethane foam of the invention has the following beneficial effects: (1) good flame retardant effect; (2) low addition amount of the flame retardant; (3) good heat preservation effect; (4) no residual raw material inside the foam and no harm to the human body.

Owner:德清顾舒家华高分子材料有限公司

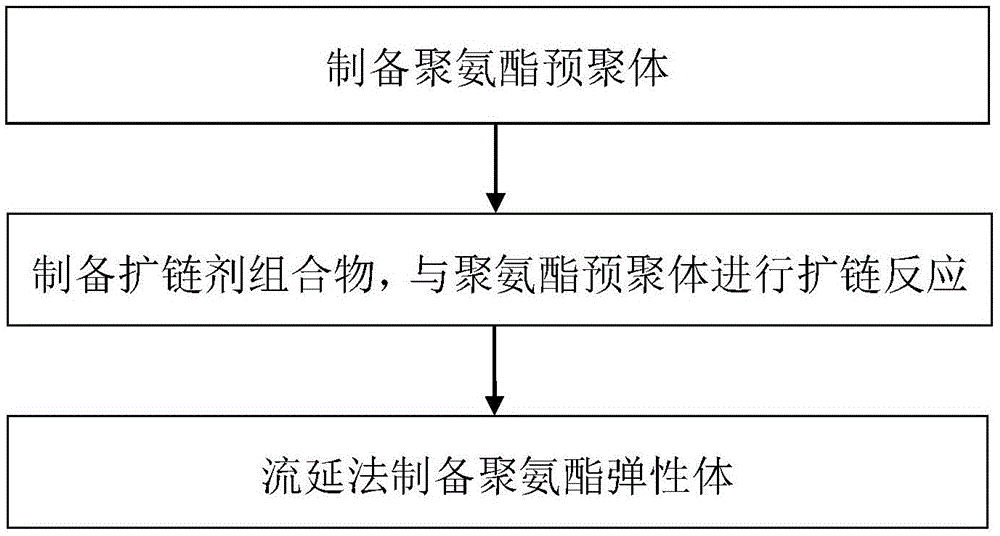

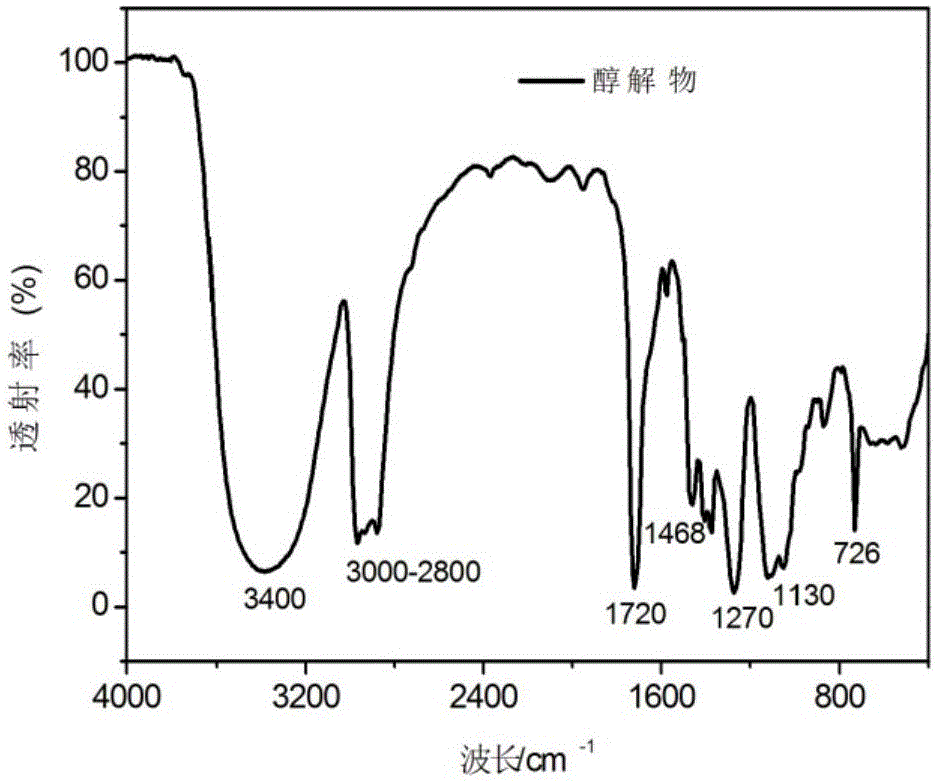

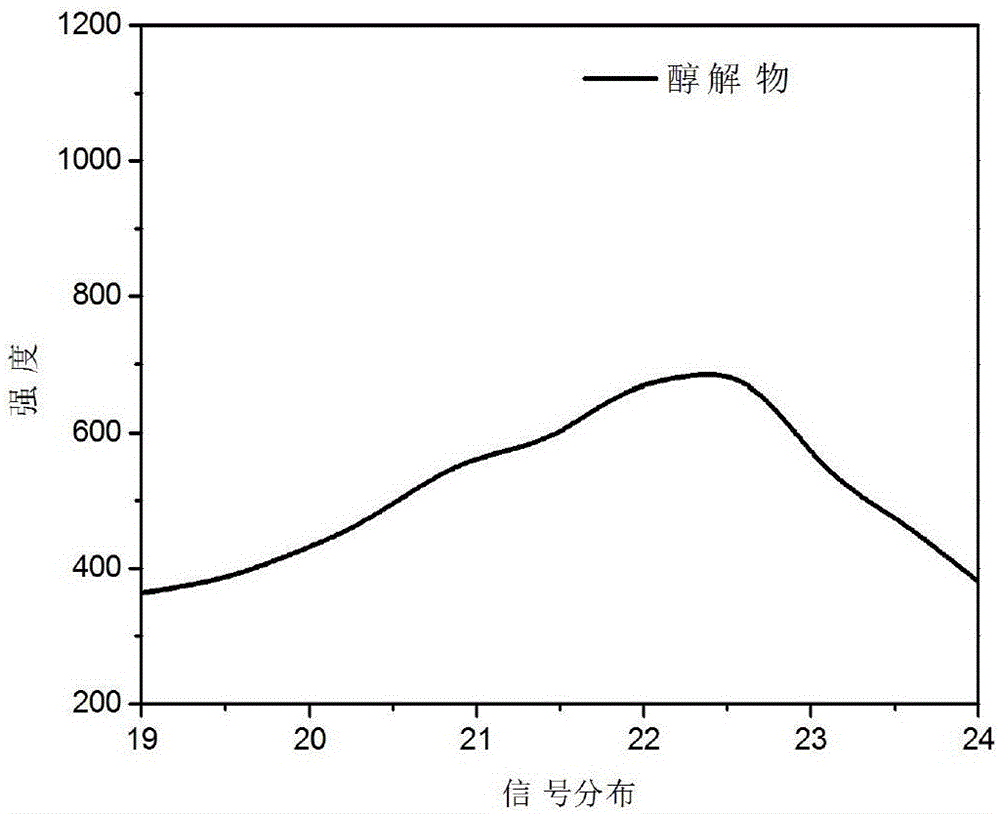

Waste PET-based polyurethane elastomer and preparation method thereof

The invention discloses a waste PET-based polyurethane elastomer which is prepared from the following raw materials, by weight, 20.8-27.7% of polytetramethylene oxide, 10.5-12.4% of methyl diphenylene diisocyanate, 12.6-15.7% of poly (epsilon-caprolactone) di-OH, 10.8-13.4% of 1,4-cyclohexane diisocyanate, 0.2-0.5% of N,N'-dicyclohexylcarbodiimide, 6.5-8.9% of neopentylene glycol, 0.04-0.08% of dibutyltin dilaurate and 27-35.6% of PET alcoholysate. A preparation method of the waste PET-based polyurethane elastomer comprises the following steps: (1) preparation of a polyurethane prepolymer; (2) preparation of a chain extender composition and reaction between the chain extender composition and the polyurethane prepolymer; and (3) preparation of the polyurethane elastomer by a tape casting method. According to the invention, a waste PET bottle is reutilized, and the prepared polyurethane elastomer has high heat resistance and can be applicable to a high-temperature environment. Meanwhile, production cost can be reduced remarkably, and the polyurethane elastomer is suitable for popularization and application.

Owner:XIAN UNIV OF TECH

Preparation method of polygeline injection

ActiveCN101934067AImprove stabilityGood dispersionPeptide/protein ingredientsPharmaceutical delivery mechanismDistillationPotassium

The invention discloses a prescription of polygeline injection and a preparation method thereof. The preparation method comprises the following steps: a. dissolving gelatin with water for injection, regulating the pH value of the gelatin solution to be 4.5-6.0, heating to 116-131 DEG C, keeping the temperature constant for 2-3 hours, stopping heating, and cooling to 25-40 DEG C; b. regulating thepH value of degradation liquid to be 8.0-9.0, adding cyclohexyl diisocyanate acetone solution, and stirring and crosslinking for 1.5-2.5 hours; c. carrying out reduced pressure distillation to obtainacetone; d. adding water for injection, potassium chloride, sodium chloride and calcium chloride in the remaining solution after distillation, and regulating the pH value to be 6.5-7.5; d. adsorbing and filtering; and e. sterilizing, carrying out visual check and packaging. The degradation condition controllability of the method is good; the weight-average molecular weight of polypeptide obtainedby hydrolysis is 5000-18500, which can satisfy the optimum conditional requirements of the crosslinking reaction; the crosslinking degree is high; the crosslinking product polypeptide is globular molecule; and the prepared polygeline injection conforms to the National Drug Standards. The clinical use result proves that the product is safe and effective.

Owner:WUHAN DONGFANGHONG PHARMA TECH

Functional TPU (thermoplastic polyurethane) foaming thin film

The invention belongs to the technical field of a foaming thin film, and particularly relates to a functional TPU (thermoplastic polyurethane) foaming thin film. The functional TPU foaming thin film is prepared from the following raw materials in percentage by mass: 40-80% of water, 10-20% of 1, 4-cyclohexane diisocyanate, 5-35% of polyethyleneglycol adipate glycol, 2-5% of chain extender 1, 4-butanediol, 1-5% of a halogen-free flame retardant, 0.001-0.1% of a catalyst, 0.1-1% of a foam stabilizer and 0.2-0.8% of an antioxidant. Compared with the prior art, the functional TPU foaming thin film has the advantages that as water is used as a foaming agent, the environment damage caused by using fluorine-containing foaming agents such as HCFC-141b is effectively avoided; the flame retardant property of TPU foamed plastics is improved by adding the halogen-free flame retardant, and as the flame retardant in use does not contain halogens and heavy metal elements such as lead, cadmium, mercury and chromium, the functional TPU foaming thin film is in line with European Union VDE (Verband Deutscher Elektrotechniker) requirements and is an environment-friendly material.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Notebook shell coating as well as preparation method and application thereof

InactiveCN104449230AImprove high temperature resistanceImprove wear resistanceRadiation-absorbing paintsEpoxy resin coatingsEpoxyCyclohexane diisocyanate

The invention relates to a notebook shell coating as well as a preparation method and application thereof. The notebook shell coating comprises the following components in parts by mass: 60-65 parts of trans-1,4-cyclohexane didsocyanate, 25-35 parts of n-butyl alcohol, 15-20 parts of an aminosilane coupling agent, 5-10 parts of tributyltin methacrylate, 8-15 parts of dimethylbenzene, 20-30 parts of modified spherical carbonyl iron powder, 4.5-9 parts of epoxy resin, 10-20 parts of aluminum oxide particles, 10-12 parts of borax and 50-100 parts of deionized water.

Owner:TAIXING HEQING MACHINERY FITTINGS FACTORY

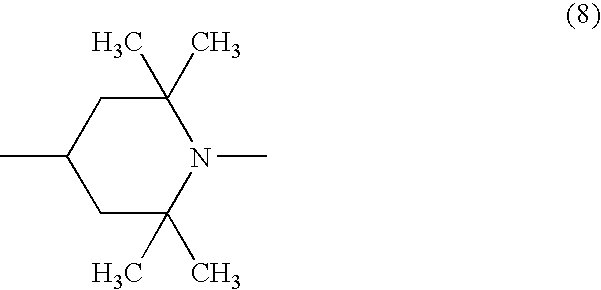

Antiaging polyurethane composite material

The invention discloses an antiaging polyurethane composite material which is prepared from polyoxypropylene diol, hydroxyl-terminated liquid silicone rubber, hydroxyl-terminated liquid nitrile-butadiene rubber, 1,4-cyclohexane diisocyanate, 1,5-naphthalene diisocyanate, 1,4-butynediol, 1,4-di(2-hydroxyethoxy)benzene, 4,4'-diaminodiphenyl sulfone, dibutyltin dilaurate, bis dodecyldimethyl ammonium bromide, graphene oxide, carbon nanotubes, hydroxy polydimethylsiloxane, a heat stabilizer, polystyrene and a rare-earth complex. The heat stabilizer is prepared from nano titanium dioxide, molybdenum trioxide, bismuth trioxide, triglycol bis-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate], pentaerythritol diisodecyl diphosphite, monophenyldiisodecyl phosphite and ethyl 2,2'-thiobis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate].

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Heat-resistant high-damping polyurethane elastomer and preparation method thereof

The invention relates to a heat-resistant and high-damping polyurethane elastomer, which is prepared from the following raw materials by weight: 27.92%-33.56% of polytetramethylene glycol, 8.52%-9.03% of diphenyl-methane-diisocyanate, 26.02%-31.66% of polycaprolactone diol, 9.02%-9.70% of 1, 4-cyclohexane diisocyanate, 0.10%-0.30% of N, N'- dicyclohexylcarbodiimide, 4.91%-5.62% of neopentyl glycol, 0.06%-0.10% of dibutyltin dilaurate, 0.60%-0.90% of carbon nanotube, and 15.02%-15.45% of nano-silica, with the sum of the weight percentage of the components being 100%. The preparation method includes: weighing raw materials, preparing an acidified carbon nanotube, preparing a nano-silica dispersion solution, preparing a polyurethane elastomer prepolymer A, preparing a polyurethane elastomer prepolymer B, preparing a chain extender-carbon nanotube / neopentyl glycol composite hydroxyl component, preparing a polyurethane elastomer casting liquid, and preparing the heat-resistant and high-damping polyurethane elastomer by means of tape-casting. The method provided by the invention can solve the problem of poor heat resistance of polyurethane elastomers in the prior art, and the prepared polyurethane elastomer has high heat resistance and high damping property.

Owner:XIAN UNIV OF TECH

High-performance polyurethane sealing material for large-scale equipment and preparation method of sealing material

InactiveCN102391463AImprove high temperature resistanceImprove impact resistanceOther chemical processesSolventTemperature resistance

The invention discloses a high-performance polyurethane sealing material for large-scale equipment. The high-performance polyurethane sealing material for the large-scale equipment comprises the following components in percentage by weight: 10 to 40 percent of aromatic isocyanate, 10 to 40 percent of cyclic aliphatic isocyanate, 20 to 50 percent of poly-epsilon-caprolactone polyol, 5 to 10 percent of 1,4-butanediol and 5 to 10 percent of polyoxyethylene polyoxypropylene polyether, wherein the aromatic isocyanate is one or more of diphenyl methane diisocyanate, naphthalene diisocyanate and paraphenyl diisocyanate; and the cyclic aliphatic isocyanate is one or more of 1,4-cyclohexane diisocyanate, cyclohexane dimethylene diisocyanate and norbornane diisocyanate. The high temperature resistance, impact resistance, yellowing resistance, solvent resistance and optical stability of the polyurethane sealing material can be improved. The high-performance sealing material for the large-scale equipment can be obtained. The invention also discloses a preparation method for the high-performance polyurethane sealing material for the large-scale equipment.

Owner:ZHEJIANG XIPULI SEALING TECH

Thermoplastic polyurethane elastomer and polyurethane prepolymer material and preparation method thereof

The invention relates to the fields of high polymer materials and production thereof and in particular relates to a thermoplastic polyurethane elastomer and polyurethane prepolymer material and a preparation method thereof. The thermoplastic polyurethane prepolymer material comprises the following components in parts by mass: 15-25 parts of 1,4-cyclohexane diisocyanate, 10-15 parts of nitrile rubber buna, 5-8 parts of a catalyst, 2-7 parts of zinc stearate, 12-22 parts of polyester polyol and 20-35 parts of polycarbonate. The thermoplastic polyurethane elastomer is prepared by performing extrusion pelletizing on the thermoplastic polyurethane prepolymer material and a mixture of polytetrahydrofuran and polystyrene. The prepared thermoplastic polyurethane prepolymer material has excellent mechanical property and ageing resistance, the prepared polyurethane elastomer is good in heat-resistant quality and high in mechanical property, the operating temperature can be more than or equal to 95 DEG C, and the method for preparing the thermoplastic polyurethane elastomer and thermoplastic polyurethane prepolymer material is simple and high in operability.

Owner:CHENGDU DUOLIDUO NEW MATERIAL

Sewing-free hot melt adhesive TPU leather and preparation method thereof

ActiveUS10005926B2Excellent physicochemical performanceHigh bonding strengthPaper/cardboardFurniture partsPolyesterPolymer science

The present invention provides a novel sewing-free hot melt adhesive TPU leather and a preparation method thereof. The hot melt adhesive TPU leather comprises a release paper, a hot melt adhesive film, and a TPU film. The release paper comprises a bottom paper layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material comprises polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; and a TPU raw material comprises polymer polyol, 1,4-cyclohexane-diisocyanate, a chain extender, and a plurality of functional additives. According to the present invention, innovations are conducted on raw material components of the release paper, the hot melt adhesive, and the TPU film, and extrusion shaping is conducted by utilizing the hot melt adhesive with strong plasticity and the TPU thin film; and the prepared sewing-free TPU leather has the technical advantages of firm adhesion, durability, environmentally-friendly materials, no invisible harm to human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Long-storage-life triethylamine method cold core box curing agent and production method thereof

ActiveCN104923713AExtended shelf lifeInhibitory activityFoundry mouldsFoundry coresPhosphatePhosphoric acid

The invention relates to a long-storage-life triethylamine method cold core box curing agent and a production method thereof. The long-storage-life cold core box curing agent comprises the following components in percentage by weight: 70-91% of isocyanate, 8-29% of environment-friendly plant oil, 0.2-1.0% of efficient phosphate fire retardant, and 0.01-0.1% of mixed polyols binary ester, wherein the isocyanate is one of toluene diisocynate, methylene diphenyl diisocyanate, 1, 6-hexamethylene diisocyanate, polymethylene polyphenyl isocyanate, trimethyl 1, 6 hexylidene diisocyanate and transcyclohexane diisocyanate or a combination thereof. The curing agent has the following beneficial effects: compared with such traditional materials as high-boiling-point aromatic solvent oil, the added plant oil is little in poison, is free of black smoke and poisonous gas in the resin sand pouring process, and is excellent in environmental protecting performance; and the efficient phosphate fire retardant and the mixed polyols binary ester effectively inhibit the activity of isocyanate radicals, prolong the storage life of the curing agent in air, and improve the use and storage performance in the production field.

Owner:共享新材料(山东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com