High-performance polyurethane sealing material for large-scale equipment and preparation method of sealing material

A technology of large-scale equipment and sealing materials, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as harsh hydraulic impact force in operating environment, achieve good hydrolysis stability, improve high temperature resistance, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

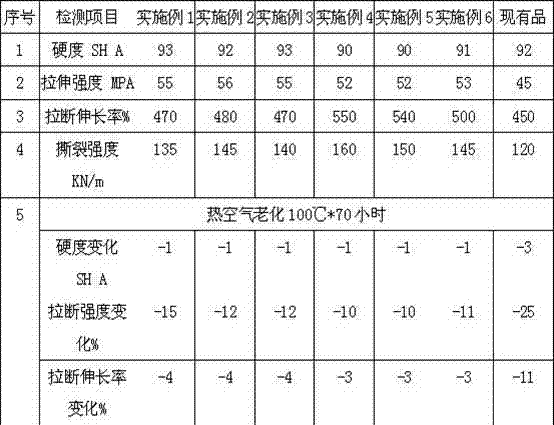

Examples

Embodiment 1

[0025] Taking the total weight of 100g as an example, first add 50g of polyε-caprolactone polyol into the reactor, and dehydrate for 1 hour at a temperature of 100°C, a pressure of -0.05MPa, and a stirring rate of 20 rpm. ; After cooling down to 45°C, add 30g of aromatic isocyanate (diphenylmethane diisocyanate), react at 65°C for 0.2 hours, then add 10g of cycloaliphatic isocyanate (1.4-cyclohexane diisocyanate), at 80°C React for 0.2 hours; then add 5g of 1,4-butanediol and 5g of polyoxyethylene polyoxypropylene polyether at 80°C, stir evenly, pour into the mold, put it into a flat vulcanizing machine, and vulcanize at 130°C for 0.2 hours , Put it in an oven at 80°C for 5 hours to vulcanize.

Embodiment 2

[0027] Taking the total weight of 100g as an example, first add 45g of polyε-caprolactone polyol into the reactor, and dehydrate for 1 hour at a temperature of 100°C, a pressure of -0.05MPa, and a stirring rate of 20 rpm; After cooling down to 45°C, add 30g of aromatic isocyanate (as naphthalene diisocyanate), react at 65°C for 0.2 hours, then add 10g of cycloaliphatic isocyanate (as cyclohexane dimethylene diisocyanate), react at 80°C for 0.2 hours; then add 10g of 1,4-butanediol and 5g of polyoxyethylene polyoxypropylene polyether at 80°C, stir evenly, pour into the mold, put it into a flat vulcanizer, vulcanize at 130°C for 0.2 hours, put Vulcanize in an oven at 80°C for 5 hours.

Embodiment 3

[0029] Taking the total weight of 100g as an example, first add 45g of polyε-caprolactone polyol into the reactor, and dehydrate for 1 hour at a temperature of 100°C, a pressure of -0.05MPa, and a stirring rate of 20 rpm; After cooling down to 45°C, add 30g of aromatic isocyanate (p-phenylene diisocyanate), react at 65°C for 0.2 hours, then add 10g of cycloaliphatic isocyanate (norbornane diisocyanate), react at 80°C for 0.2 hours; then Add 10g of 1,4-butanediol and 5g of polyoxyethylene polyoxypropylene polyether at 80°C, stir evenly, pour into the mold, put it into a flat vulcanizing machine and vulcanize at 130°C for 0.2 hours, put it in a 80°C Oven vulcanization for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com