Heat-resistant high-damping polyurethane elastomer and preparation method thereof

A technology of polyurethane elastomer and high damping, applied in the field of heat-resistant high-damping polyurethane elastomer and its preparation, can solve the problems of inability to meet the use, poor heat resistance of polyurethane elastomer, etc., and achieve excellent comprehensive performance and excellent oil resistance. , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

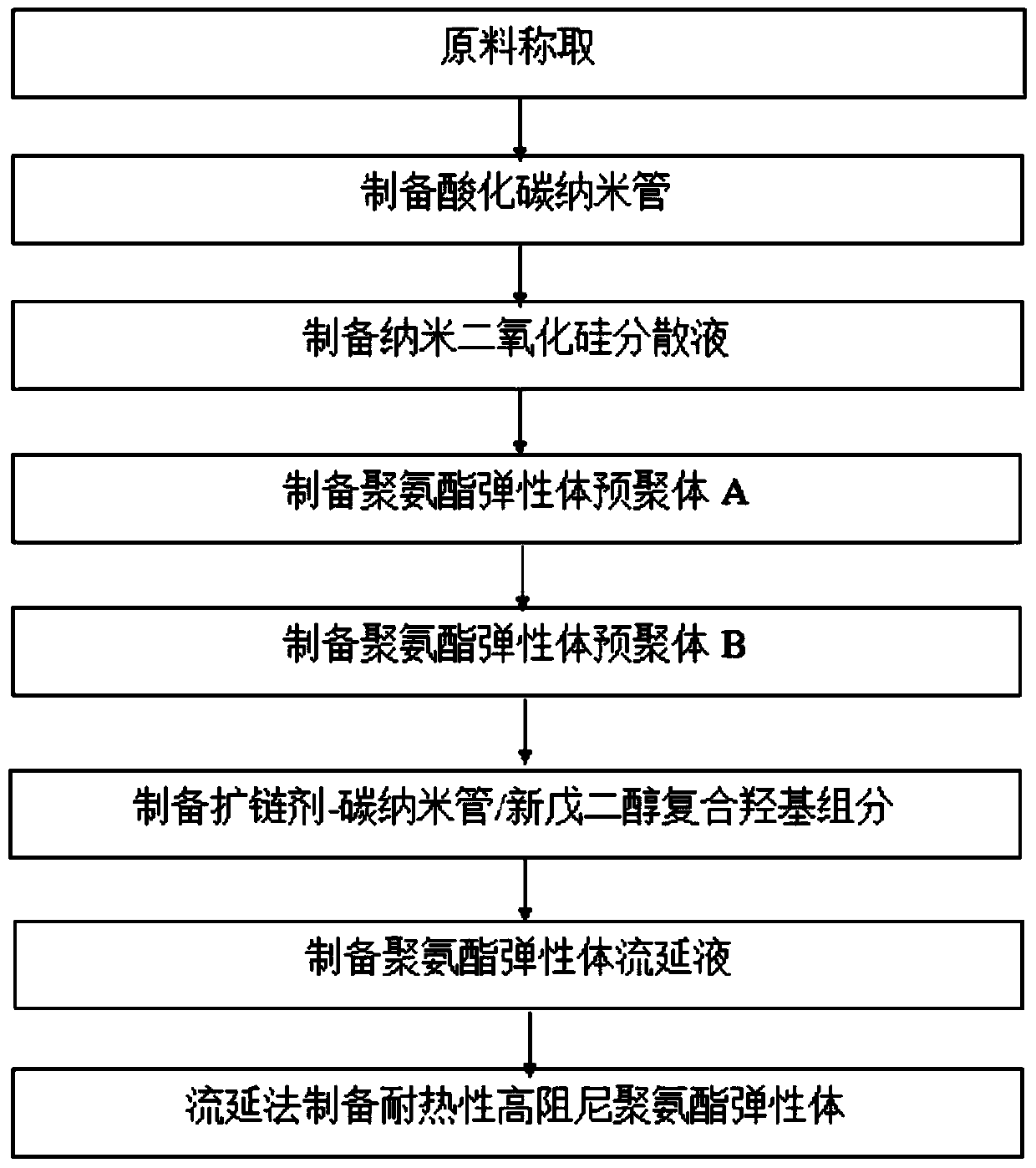

[0030] figure 1It shows the realization flowchart of preparing heat-resistant high-damping polyurethane elastomer according to the embodiment of the present invention. The preparation method of the heat-resistant high-damping polyurethane elastomer of the embodiment of the present invention, the specific steps are as follows:

[0031] Step 1, raw material weighing: according to the following raw material weight percentages, weigh the raw materials respectively;

[0032] Polytetrahydrofuran diol 27.92%~33.56%, diphenylmethane diisocyanate 8.52%~9.03%, polycaprolactone diol 26.02%~31.66%, 1,4-cyclohexane diisocyanate 9.02%~9.70%, N,N'-Dicyclohexylcarbodiimide 0.10%~0.30%, Neopentyl Glycol 4.91%~5.62%, Dibutyltin Dilaurate 0.06%~0.10%, Carbon Nanotube 0.60%~0.90%, The nano silicon dioxide is 15.02%-15.45%, and the sum of the weight percentages of each component is 100%.

[0033] Step 2, preparing acidified carbon nanotubes: adding the weighed carbon nanotubes to concentrated a...

Embodiment 1

[0055] In this embodiment, the heat-resistant high damping polyurethane elastomer is prepared according to the following steps:

[0056] Step 1, according to the following raw material weight percentages, weigh raw materials respectively;

[0057] Polytetrahydrofuran diol 33.56%, diphenylmethane diisocyanate 9.03%, polycaprolactone diol 27.07%, 1,4-cyclohexane diisocyanate 9.02%, N,N'-dicyclohexylcarbodiimide 0.30%, neopentyl glycol 4.91%, dibutyl tin dilaurate 0.06%, carbon nanotube 0.60%, nano silicon dioxide 15.45%, the sum of the weight percentages of each component is 100%.

[0058] Step 2, adding the weighed carbon nanotubes to concentrated H 2 SO 4 and concentrated HNO 3In the mixed acid composed, ultrasonically disperse for 30min at room temperature, and stir and acidify at 60°C for 3h, dilute with distilled water after cooling to room temperature, and vacuum filter with a filter funnel, then dilute with distilled water and vacuum filter, and wash repeatedly To neu...

Embodiment 2

[0066] Example 2 The method for preparing heat-resistant high-damping polyurethane elasticity is the same as Example 1, except that the weight percentages of raw materials used are different. The weight percentages of raw materials used in Example 2 are: polytetrahydrofuran diol 27.92%, diphenylmethane diisocyanate 8.88%, polycaprolactone diol 31.66%, 1,4-cyclohexane diisocyanate 9.7%, N,N'-dicyclohexylcarbodiimide 0.20%, neopentyl glycol 5.62%, dibutyl 0.1% of tin dilaurate, 0.9% of carbon nanotubes, 15.02% of nano silicon dioxide, and the sum of the weight percentages of each component is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com