Heat-resistant and high-damping polyurethane elastomer and preparation method thereof

A polyurethane elastomer and high damping technology, which is applied in the field of heat-resistant high-damping polyurethane elastomer and its preparation, can solve the problems of unsatisfactory use and poor heat resistance of polyurethane elastomer, and achieve excellent comprehensive performance and excellent oil resistance , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

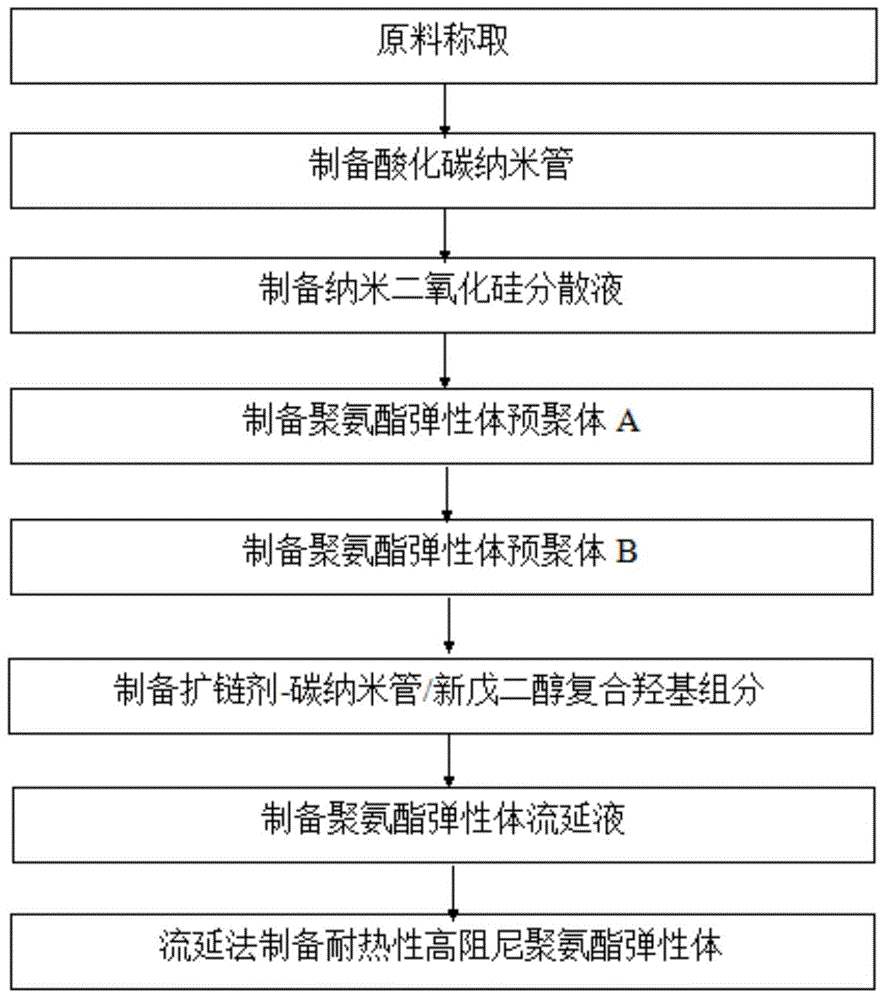

[0030] figure 1It shows the realization flowchart of preparing heat-resistant high-damping polyurethane elastomer according to the embodiment of the present invention. The preparation method of the heat-resistant high-damping polyurethane elastomer of the embodiment of the present invention, the specific steps are as follows:

[0031] Step 1, raw material weighing: according to the following raw material weight percentages, weigh the raw materials respectively;

[0032] Polytetrahydrofuran diol 27.92%~33.56%, diphenylmethane diisocyanate 8.52%~9.03%, polycaprolactone diol 26.02%~31.66%, 1,4-cyclohexane diisocyanate 9.02%~9.70%, N,N'-Dicyclohexylcarbodiimide 0.10%~0.30%, Neopentyl Glycol 4.91%~5.62%, Dibutyltin Dilaurate 0.06%~0.10%, Carbon Nanotube 0.60%~0.90%, The nano silicon dioxide is 15.02%-15.45%, and the sum of the weight percentages of each component is 100%.

[0033] Step 2, preparing acidified carbon nanotubes: adding the weighed carbon nanotubes to concentrated a...

Embodiment 1

[0055] In this embodiment, the heat-resistant high damping polyurethane elastomer is prepared according to the following steps:

[0056] Step 1, according to the following raw material weight percentages, weigh raw materials respectively;

[0057] Polytetrahydrofuran diol 33.56%, diphenylmethane diisocyanate 9.03%, polycaprolactone diol 27.07%, 1,4-cyclohexane diisocyanate 9.02%, N,N'-dicyclohexylcarbodiimide 0.30%, neopentyl glycol 4.91%, dibutyltin dilaurate 0.06%, carbon nanotubes 0.60%, nano silicon dioxide 15.45%, the sum of the weight percentages of each component is 100%.

[0058] Step 2, adding the weighed carbon nanotubes to concentrated H 2 SO 4 and concentrated HNO 3In the mixed acid composed, ultrasonically disperse for 30min at room temperature, and stir and acidify at 60°C for 3h, dilute with distilled water after cooling to room temperature, and vacuum filter with a filter funnel, then dilute with distilled water and vacuum filter, and wash repeatedly To neu...

Embodiment 2

[0066] Example 2 The method for preparing heat-resistant high-damping polyurethane elasticity is the same as Example 1, except that the weight percentages of raw materials used are different. The weight percentages of raw materials used in Example 2 are: polytetrahydrofuran diol 27.92%, diphenylmethane diisocyanate 8.88%, polycaprolactone diol 31.66%, 1,4-cyclohexane diisocyanate 9.7%, N,N'-dicyclohexylcarbodiimide 0.20%, neopentyl glycol 5.62%, dibutyl 0.1% of tin dilaurate, 0.9% of carbon nanotubes, 15.02% of nano silicon dioxide, and the sum of the weight percentages of each component is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com