Modifying method of cellulose acetate filtration membrane

A cellulose acetate and filter membrane technology, applied in the field of membrane separation, can solve problems such as difficulty in popularization, and achieve the effects of improving mechanical strength, avoiding reduction of retention rate and reducing reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Performance parameters of cellulose acetate membrane:

[0024] The thickness of the cellulose acetate filter membrane is 100 μm, the average pore size is 1.0 μm, the porosity is 80%, and the water flux is 200ml·cm under the condition of ΔP=100KPa -2 min -1 .

[0025] 2. Modification of cellulose acetate filter membrane:

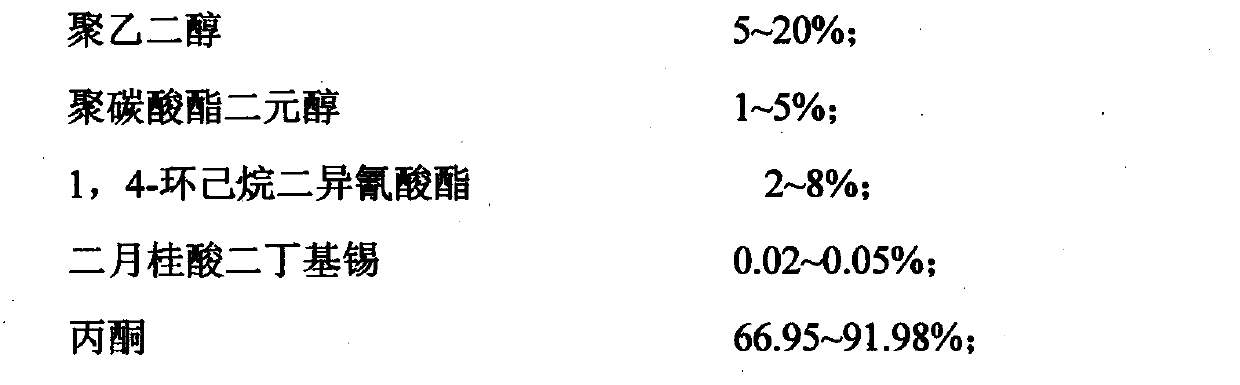

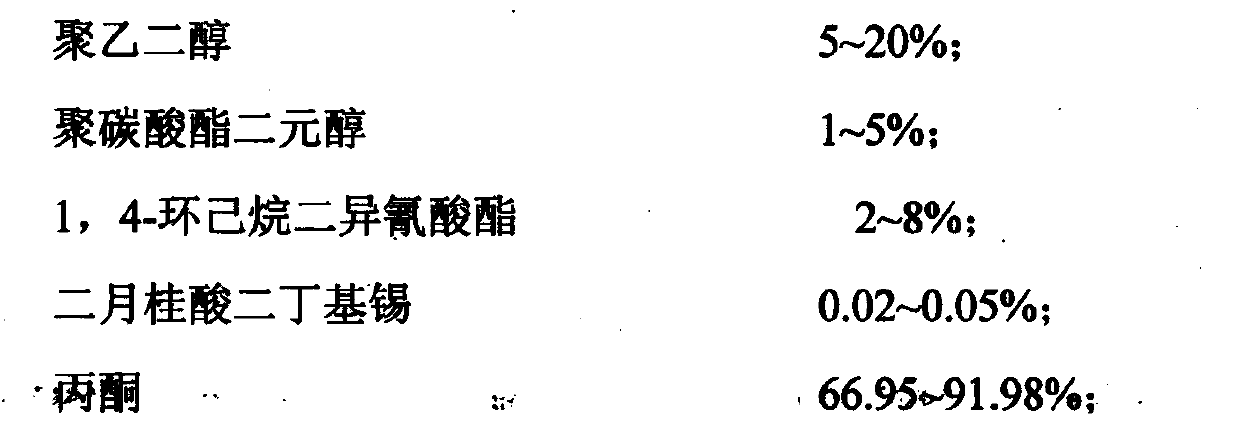

[0026] The first step: dissolving polyethylene glycol PEG-200 and polycarbonate diol in acetone solvent to prepare a hydrophilic modification solution.

[0027] The second step: soak the cellulose acetate filter membrane in the hydrophilic modification solution to fully wet it, add the crosslinking agent 1,4-cyclohexane diisocyanate and the catalyst dilauric acid diisocyanate to the hydrophilic modification solution successively. The grafting reaction of butyltin was carried out, the grafting reaction temperature was 80° C., and the reaction time was 30 minutes.

[0028] Step 3: Take out the reacted cellulose acetate filter membrane and drain it...

Embodiment 2

[0036] 1. Performance parameters of cellulose acetate membrane

[0037] The thickness of the cellulose acetate filter membrane is 110 μm, the average pore size is 0.8 μm, the porosity is 78%, and the water flux is 162ml·cm under the condition of ΔP=100KPa -2 min -1 .

[0038] 2. Modification of cellulose acetate filter membrane:

[0039] The first step: dissolving polyethylene glycol PEG-400 and polycarbonate diol in acetone solvent to prepare a hydrophilic modification solution.

[0040] The second step: soak the cellulose acetate filter membrane in the hydrophilic modification solution to fully wet it, add the crosslinking agent 1,4-cyclohexane diisocyanate and the catalyst dilauric acid diisocyanate to the hydrophilic modification solution successively. Butyl tin is used for grafting reaction, the grafting reaction temperature is 80° C., and the reaction time is 30 minutes.

[0041] Step 3: Take out the reacted cellulose acetate filter membrane and drain it naturally un...

Embodiment 3

[0048] 1. Performance parameters of cellulose acetate membrane:

[0049] The thickness of the cellulose acetate filter membrane is 125 μm, the average pore size is 0.6 μm, the porosity is 76%, and the water flux is 127ml cm under the condition of ΔP=100KPa -2 min -1.

[0050] 2. Modification of cellulose acetate filter membrane:

[0051] The first step: dissolving polyethylene glycol PEG-600 and polycarbonate diol in acetone solvent to prepare a hydrophilic modification solution.

[0052] The second step: soak the cellulose acetate filter membrane in the hydrophilic modification solution to fully wet it, add the crosslinking agent 1,4-cyclohexane diisocyanate and the catalyst dilauric acid diisocyanate to the hydrophilic modification solution successively. Butyl tin is used for grafting reaction, the grafting reaction temperature is 80° C., and the reaction time is 30 minutes.

[0053] Step 3: Take out the reacted cellulose acetate filter membrane and drain it naturally un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com