Waterborne polyurethane adhesive used for shoes and preparation method thereof

A water-based polyurethane and adhesive technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of poor water resistance of polyester polyols, affecting the service life of water-based polyurethane, and poor low temperature flexibility and other problems, to achieve the effect of improving initial viscosity and bonding strength, strong crystallinity, and outstanding water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

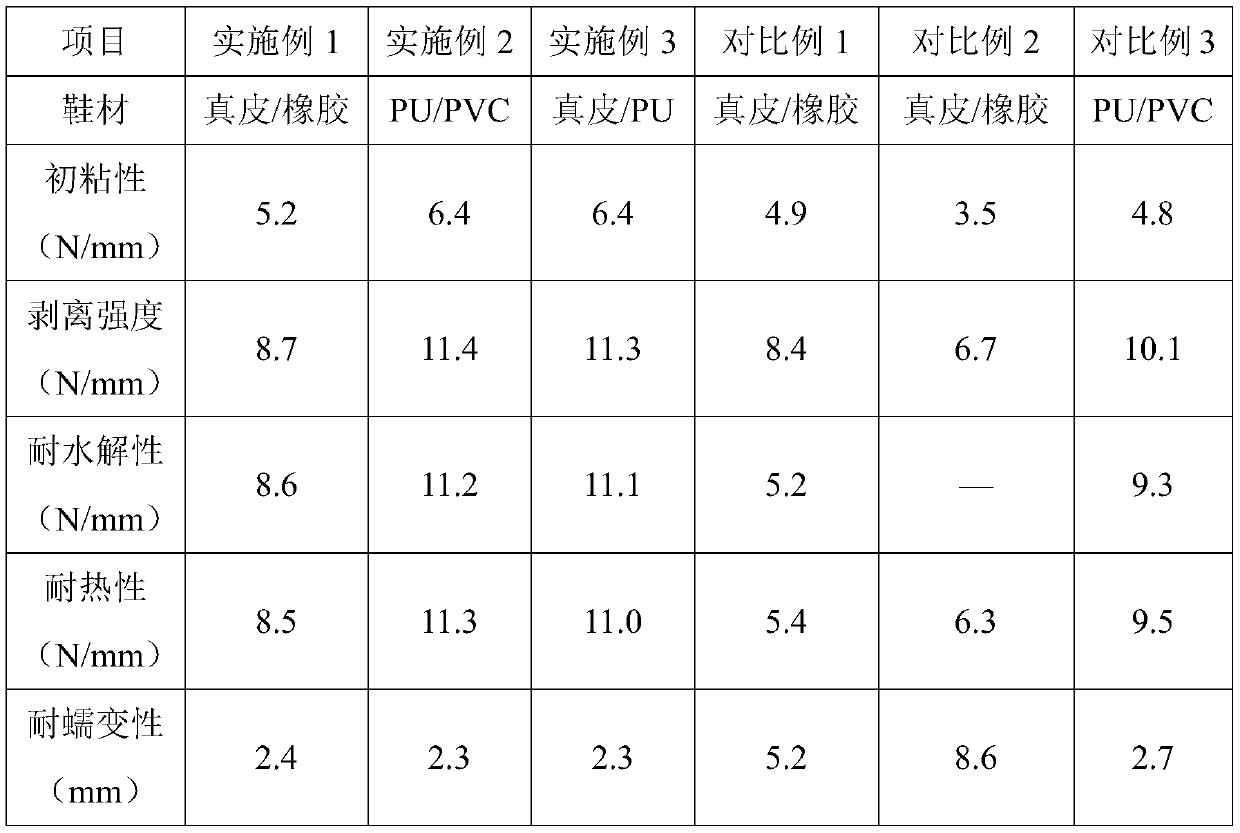

Embodiment 1

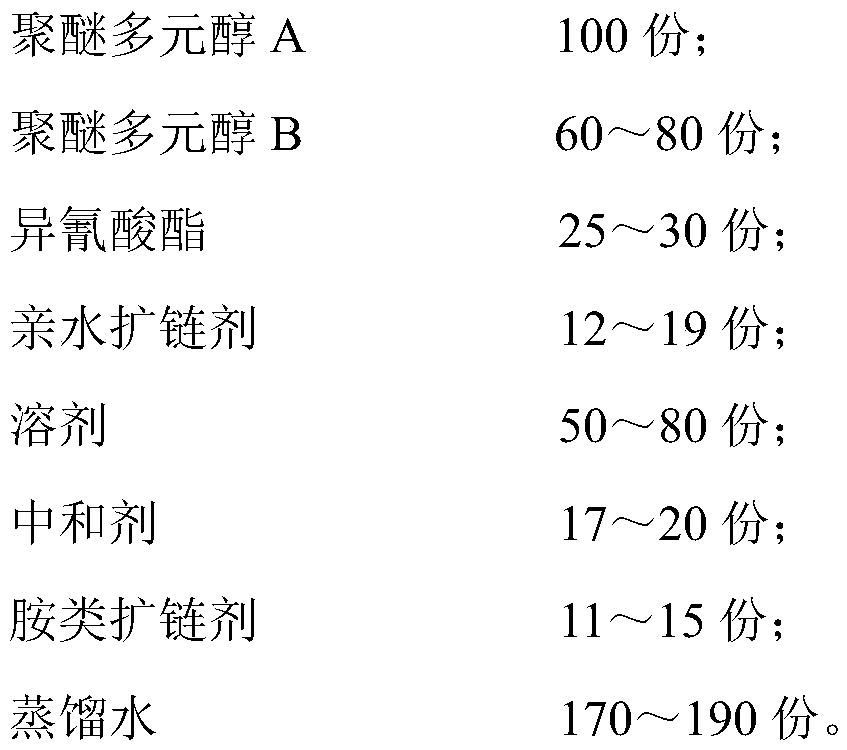

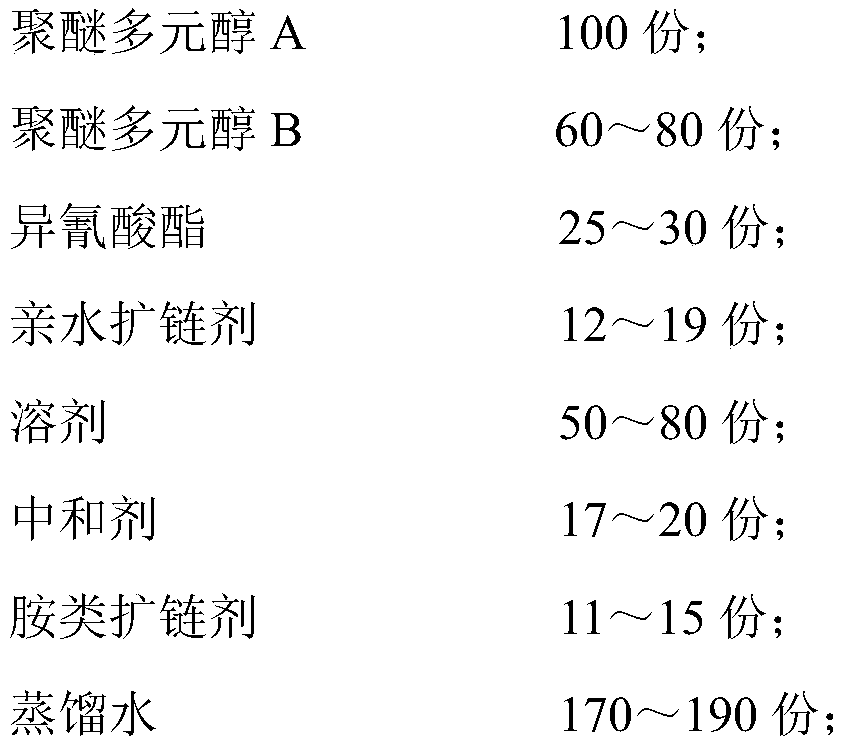

[0024] (1) Mix 100 parts of DMD-5000 and 60 parts of polytetrahydrofuran diol, vacuum dehydrate at 90°C for 1.5h, cool down to 50°C, protect with nitrogen, add 25 parts of CHDI and 12 parts of DMPA, and react at 80°C 1.5h, lower the temperature to 50°C, add acetone to adjust the viscosity of the system, and obtain a polyurethane prepolymer;

[0025] (2) add 17 parts of triethylamine and 170 parts of water in the polyurethane prepolymer that step (1) makes, disperse at high speed under the effect of high-speed shearing force, add 11 parts of ethylenediamines and carry out rear chain extension again, finally The acetone is evaporated under reduced pressure to obtain the water-based polyurethane adhesive for shoes.

Embodiment 2

[0027] (1) Mix 100 parts of DMD-5000 and 80 parts of polytetrahydrofuran diol, vacuum dehydrate at 100°C for 2 hours, cool down to 60°C, protect with nitrogen, add 30 parts of CHDI and 19 parts of DMBA, and react at 90°C for 2 hours , lower the temperature to 50°C, add butanone to adjust the viscosity of the system, and obtain a polyurethane prepolymer;

[0028] (2) add 20 parts of triethylamine and 190 parts of water in the polyurethane prepolymer that step (1) makes, disperse at a high speed under the effect of high-speed shearing force, add 15 parts of ethylenediamines and carry out rear chain extension again, finally Evaporate butanone under reduced pressure to obtain water-based polyurethane adhesive for shoes.

Embodiment 3

[0030] (1) Mix 100 parts of DMD-5000 and 70 parts of polytetrahydrofuran diol, vacuum dehydrate at 100°C for 2 hours, cool down to 60°C, protect with nitrogen, add 28 parts of CHDI and 15 parts of DMBA, and react at 90°C for 2 hours , lower the temperature to 50°C, add ethyl acetate to adjust the viscosity of the system, and obtain a polyurethane prepolymer;

[0031] (2) add 18 parts of triethylamine and 180 parts of water in the polyurethane prepolymer that step (1) makes, disperse at a high speed under the effect of high-speed shearing force, add 13 parts of ethylenediamines and carry out rear chain extension again, finally Ethyl acetate is evaporated under reduced pressure to obtain a water-based polyurethane adhesive for shoes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com