Method for the preparation of microcellular polyurethane elastomers

A technology of polyurethane elastomer and microporous, which is applied in the direction of elastic suspension, spring, transportation and packaging, etc. It can solve the problems of deterioration of polyurethane elastomer performance, short shelf life and high viscosity, and difficulty in handling feeding materials, and achieves the inhibition phase Effects of separation, improved processability, optimized viscosity and shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

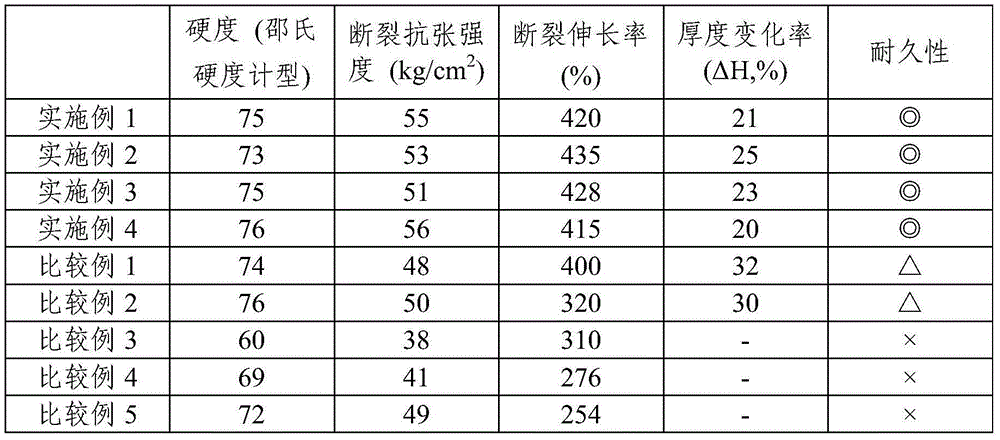

Examples

Embodiment 1

[0046] Using naphthalene diisocyanate (NDI) and polycaprolactone diol (PCL2000) having a number average molecular weight (Mn) of 2000 as a polyol in a molar ratio of 0.3:1, a prepolymer with 5 wt% NCO was obtained. 5 parts by weight of diisobutyl phthalate as a plasticizer and 20 parts by weight of NDI were added to 100 parts by weight of a prepolymer with 5wt% NCO to prepare 20% urea with respect to the prepolymer The prepolymer containing the terminal NCO group of the carbamate structure, and then mix it with 85 parts by weight of water, 2 parts by weight of 2,6-dimethylmorpholine ether as a catalyst, and 1 part by weight of Active agent silicone surfactant, 0.2 parts by weight of butylated hydroxytoluene as an antioxidant and 15 parts by weight of a mixture comprising toluene diisocyanate and 1,4-butanediol in a weight ratio of 1:13 as an emulsifier Mix to obtain a prepolymer blend.

[0047] An additional amount of naphthalene diisocyanate may be used in an amount of 1-40 ...

Embodiment 2

[0051] A microcellular polyurethane elastomer was prepared in the same manner as in Example 1, except that 15 parts by weight of a mixture containing toluene diisocyanate and 1,3-propanediol in a weight ratio of 1:13 was used as an emulsifier.

Embodiment 3

[0053] A microcellular polyurethane elastomer was prepared in the same manner as in Example 1 except that the amount of the emulsifier was changed to 10 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of change | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com