Patents

Literature

45 results about "Black sand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Black sand is sand that is black in color. One type of black sand is a heavy, glossy, partly magnetic mixture of usually fine sands, found as part of a placer deposit. Another type of black sand, found on beaches near a volcano, consists of tiny fragments of basalt.

Sewing-free hot melt adhesive TPU-PU leather and preparation method thereof

ActiveCN103437195AExcellent physical and chemical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolymer science

The invention provides a piece of novel sewing-free hot melt adhesive TPU-PU leather, and a preparation method thereof. The TPU-PU leather comprises release paper, a hot melt adhesive film, a TPU film and a dry-type PU film, wherein the release paper comprises a paper bottom layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material is composed of polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; a TPU raw material is composed of polymer polybasic alcohol, 1,4-cyclohexane-diisocyanate, a chain extender and a plurality of functional additives; a PU raw material is composed of polyester dibasic alcohol, straight chain diol, isocyanate, TDI trimer, dimethyl formamide, butanone, black sand, and a plurality of functional addictives. Through the adoption of the preparation method, innovations are conducted on the raw material components of the release paper, the hot melt adhesive, the TPU film and the PU film; the manufactured sewing-free TPU-PU leather has the technical advantages of firmness in adhesion, durability, environment-friendly materials, no invisible harm to a human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

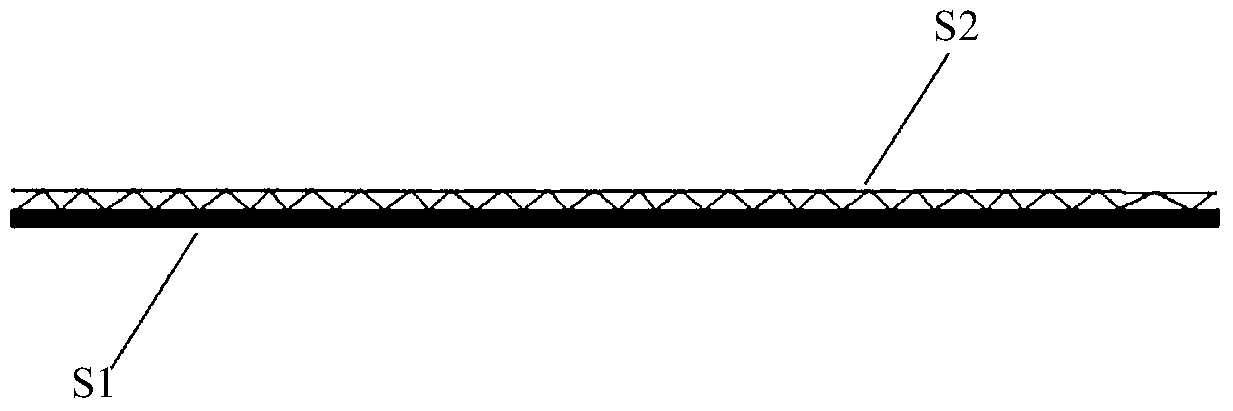

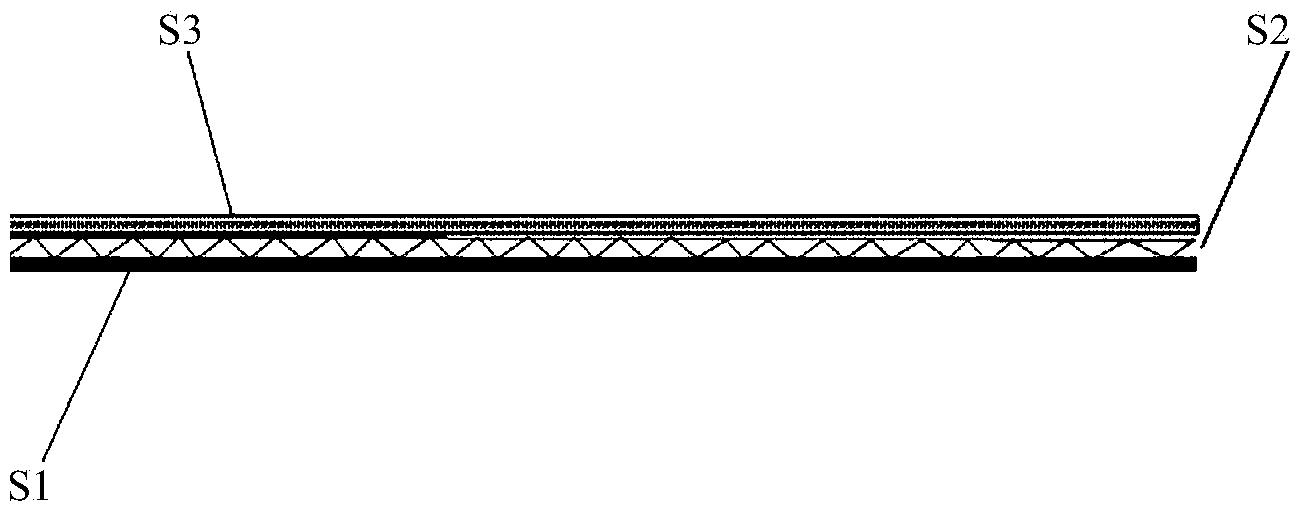

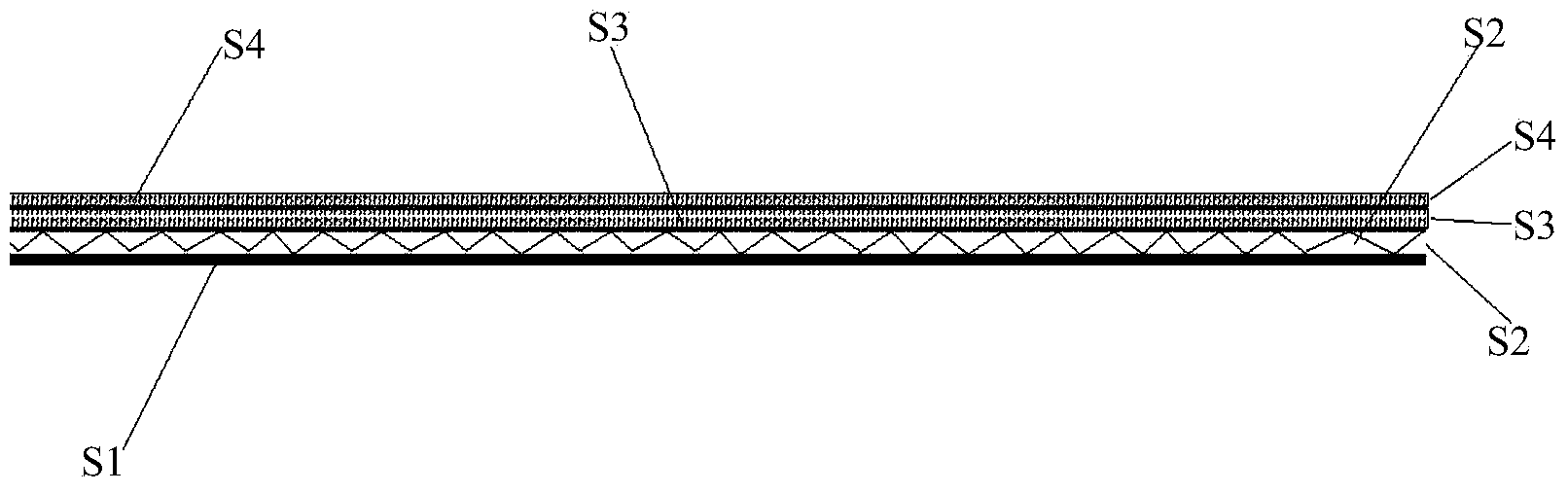

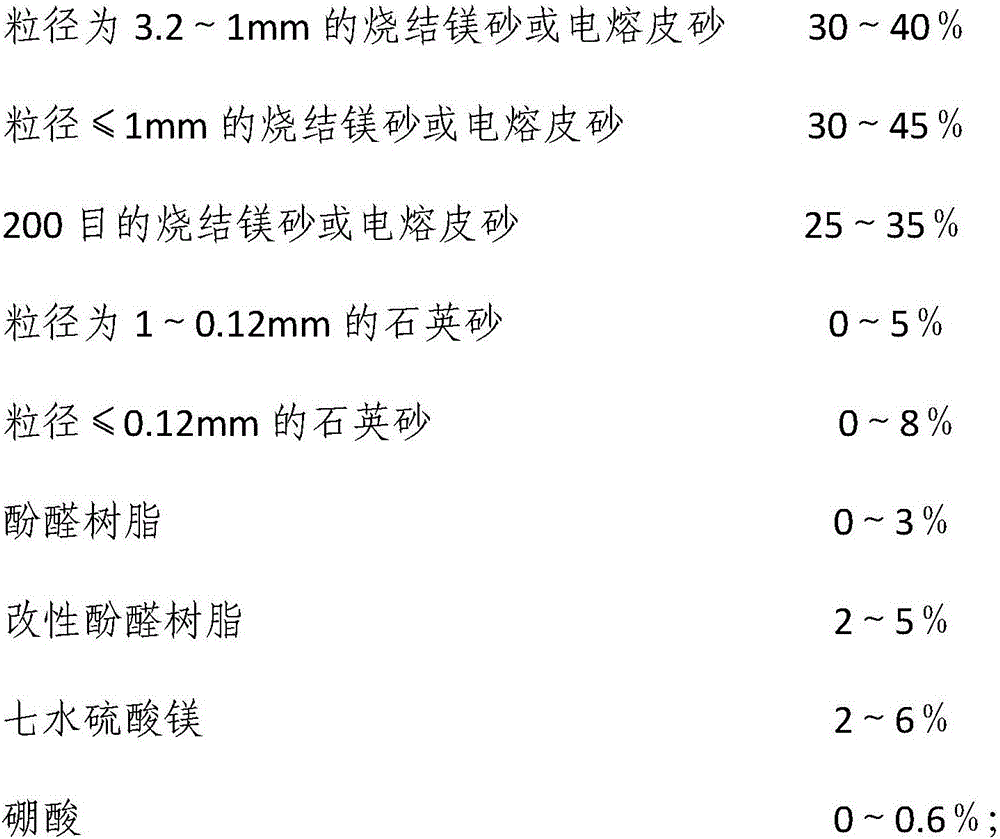

Low-cost tundish dry material with better steel slag penetration resistance and preparation method of low-cost tundish dry material

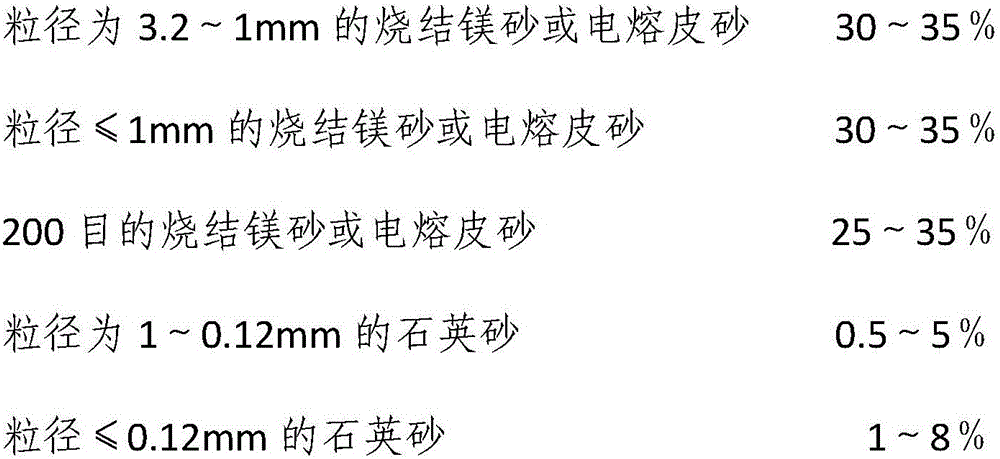

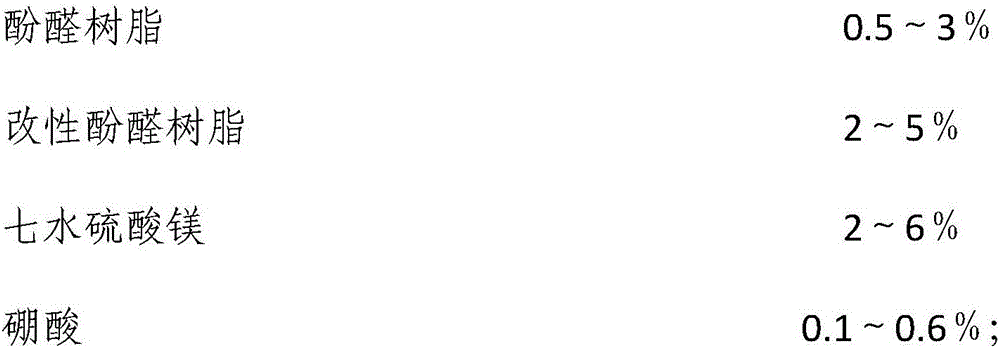

The invention discloses a low-cost tundish dry material with better steel slag penetration resistance and a preparation method of the low-cost tundish dry material and belongs to the technical field of unshaped refractory. The low-cost tundish dry material is characterized by being prepared by mixing the following raw materials in percentage by weight: 30 to 40 percent of magnesite clinker or electrofusion black sand with the particle size of 3.2 to 1mm, 30 to 45 percent of magnesite clinker or electrofusion black sand with the particle size of smaller than or equal to 1mm, 25 to 35 percent of magnesite clinker or electrofusion black sand of 200 meshes, 0 to 5 percent of quartz sand with the particle size of 1 to 0.12mm, 0 to 8 percent of quartz sand with the particle size of smaller than or equal to 0.12mm, 0 to 3 percent of phenolic resin, 2 to 5 percent of modified phenolic resin, 2 to 6 percent of magnesium sulfate heptahydrate, and 0 to 0.6 percent of boric acid, wherein the raw materials jointly constitute 100 percent. Compared with the prior art, a magnesium dry material for a continuous casting tundish working lining layer, disclosed by the invention, has the advantages of low production cost and good steel slag penetration resistance.

Owner:山东国茂冶金材料有限公司

High-temperature-resistant black sand grain powder paint

ActiveCN103320008APlay the role of secondary film formationPowdery paintsEpoxy resin coatingsEpoxyPolyester resin

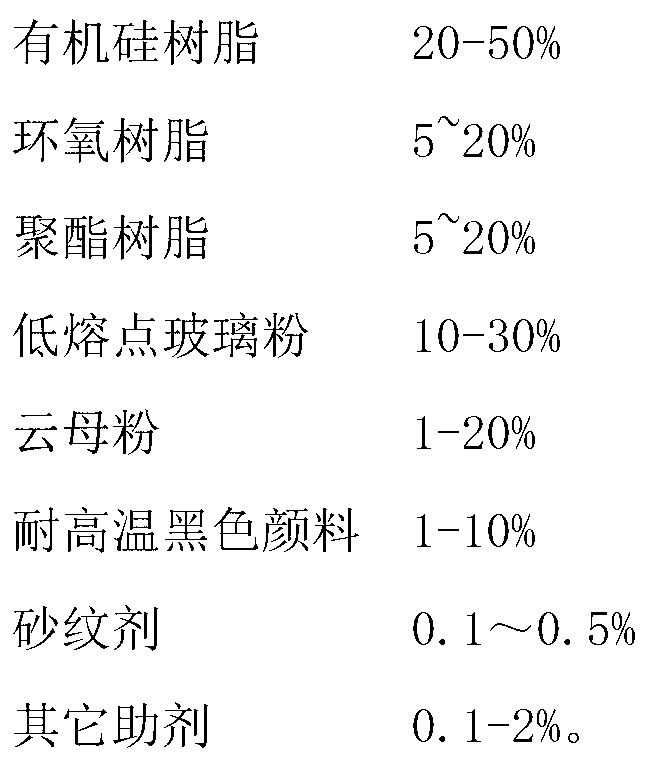

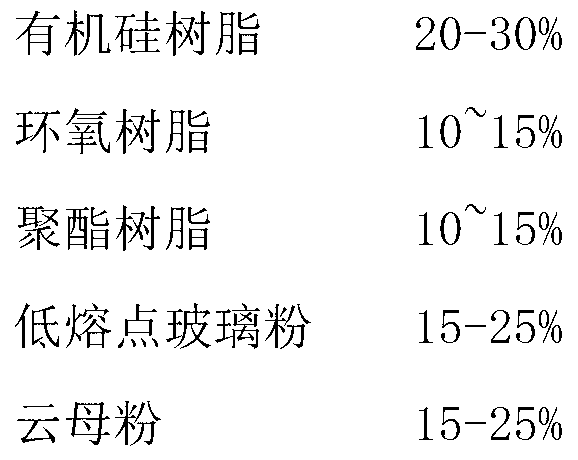

The invention relates to powder paint, and especially relates to high-temperature-resistant black sand grain powder paint. The paint is prepared from the materials of, by weight, 20-50% of silicone resin, 5-20% of epoxy resin, 5-20% of polyester resin , 10-30% of low-melting-point glass powder, 1-20% of mica powder, 1-10% of high-temperature-resistant black pigment, 0.1-0.5% of a sand grain agent, and 0.1-2% of other additives. According to the technical scheme provided by the invention, silicone resin and normal-temperature-cured conventional resin are blended, such that the entire system can be cured and crosslinked into a film under normal temperature, and has excellent physical performances. The silicone resin can resist temperature of at least 500 DEG C. Before the low-melting-point glass powder is formed into a film, a coating is prevented from cracking and falling.

Owner:ZHEJIANG HUACAI NEW MATERIAL CO LTD

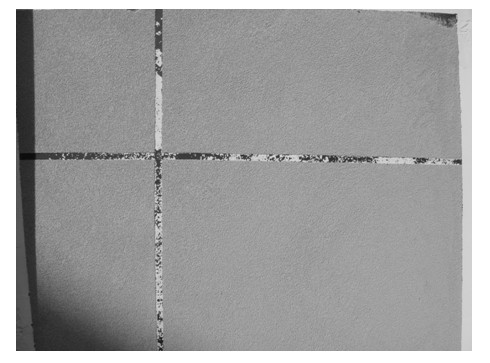

Preparation method of black sand primer paint assorted with ceramic tile simulated outer-wall coating

A preparation method of black sand primer paint assorted with ceramic tile simulated outer-wall coating relates to a preparation method of construction coating primer paint. The technical scheme includes that the black sand primer paint is formed by mixing following materials including, by weight, 100-125 parts of emulsion, 3-5 parts of dispersing agent, 3-4 parts of cellulose ether, 5-15 parts of glycol, 6-10 parts of filming auxiliaries, 1-2 parts of defoamer, 1-5 parts of titanium powder, 50-100 parts of heavy calcium carbonate, 600-700 parts of 200-mesh quartz sand, 1-2 parts of sterilizer and 5-10 parts of mill base. The black sand primer paint can substitute for black primer paint used in the prior art, solves the problem that the black primer paint can release along with branching paper due to poor bonding force thereof during ceramic tile simulated painting, and can be thickened easily by the aid of a rough base material during scraping the ceramic tile paint so that the surface of the painted film is uniform and compact and not easy to expose the bottom. Besides, construction of texture paint is improved, time and labor are saved, and fullness of the painted layer is improved.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

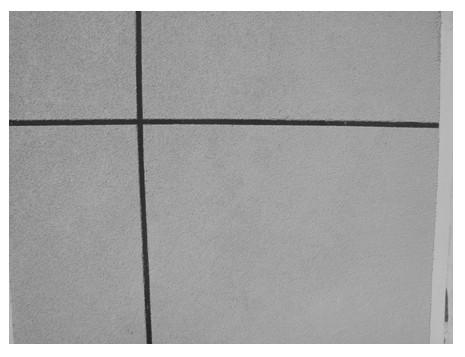

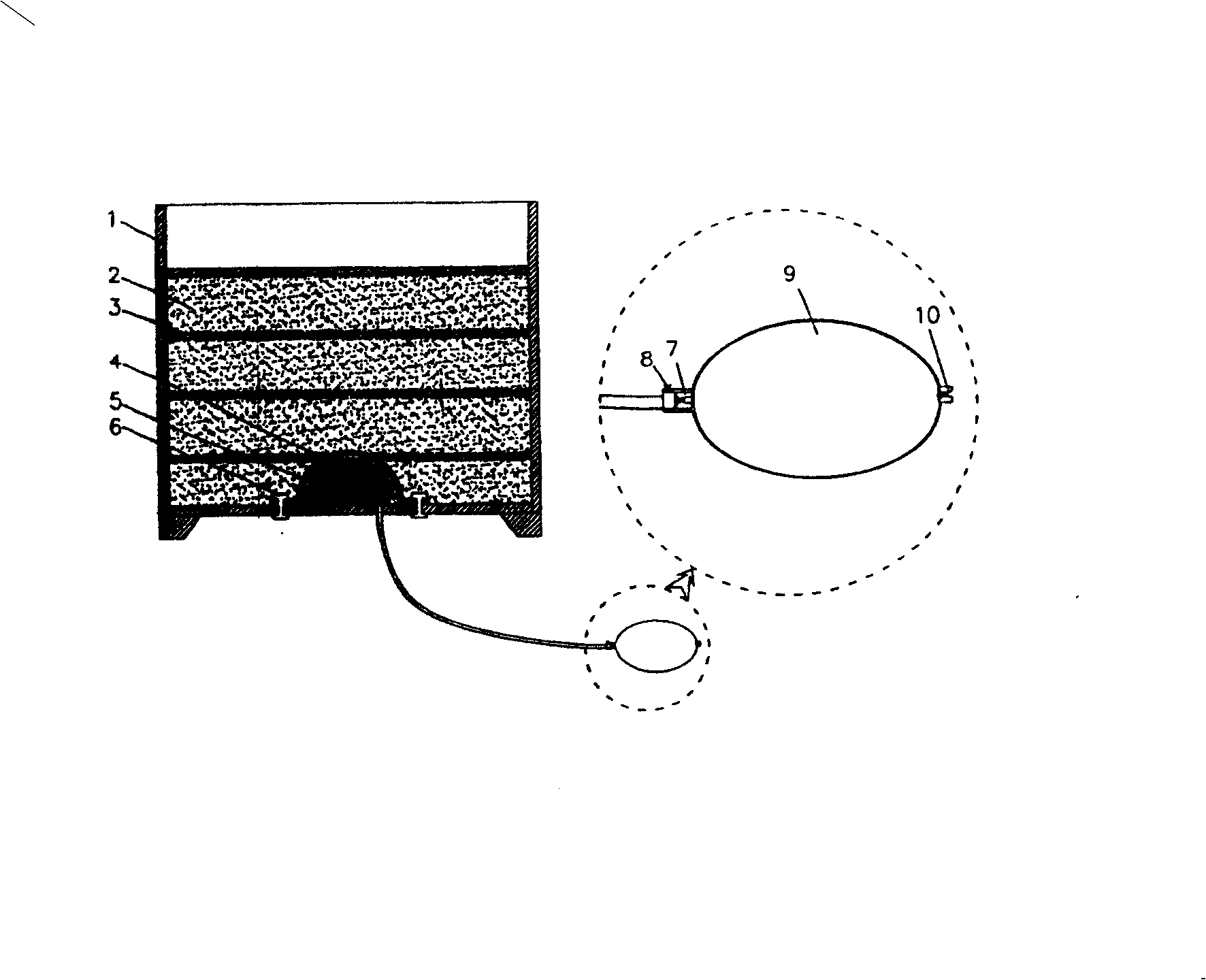

Upper arch effect demonstrating instrument

InactiveCN1975807AObserve the soil arching phenomenonUnderstand the interactionEducational modelsRubber membraneSoil arching

The invention discloses a soil arching effect demonstrator. There is a half cylindrical rubber airbag in the center of the bottom of Perspex box. Outside the airbag there is flexible rubber membrane. They are fixed at the bottom of Perspex box. From bottom to top, the Perspex box is filled with yellow sand and black sand; tube of the airbag is connected with inflatable bag outside the Perspex box; in the tube of inflatable bag, there is release valve and forward one-way valve; there is one backward one-way valve in the inflatable bag. By giving air and releasing air, the soil arching can be directly observed.

Owner:ZHEJIANG UNIV

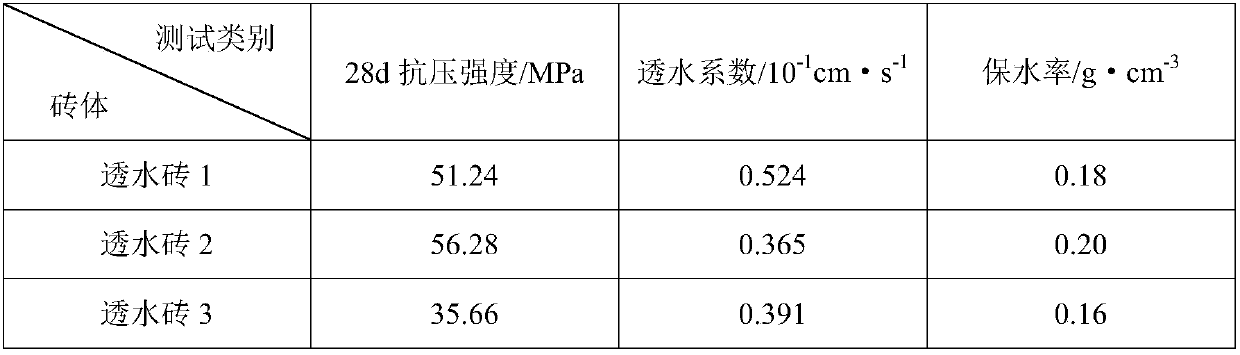

High-strength and high-water-permeation water permeable bricks and preparation technology thereof

InactiveCN108675719AHigh strengthGood water permeabilitySingle unit pavingsPaving gutters/kerbsBrickPermeation

The invention provides high-strength and high-water-permeation water permeable bricks. Being different from common varieties in the prior art, the water permeable bricks provided by the invention arewater permeable bricks which are prepared by taking large-grain-diameter stones as a base material and matching cement and an enhancing agent according to a specific ratio, have high water permeationperformance and keep high strength. Specifically, the invention provides the water permeable bricks; the water permeable bricks are prepared from a bottom-layer material and a surface-layer material according to the ratio. The water permeable bricks provided by the invention are concrete-based materials; the bottom-layer material is formed by selecting the stones and the cement and adding the enhancing agent; the surface-layer material is formed by selecting white cement, black sand and white sand and adding the enhancing agent. According to the water permeable bricks provided by the invention, the stones, the white and the black sand are put into a material storage yard; the materials with the proper ratio are selected and are blended; then a mixture is conveyed into a molding machine anda surface material machine and then is prepared and molded; then the bricks are conveyed into a subequipment porter through a brick conveying machine and a plate hoisting plate; the molded bricks areconveyed to a nursing kiln by the subequipment porter; after curing is finished, the molded bricks are conveyed to a stacking machine, are conveyed and are packaged into finished products; the finished products enter a finished product storage yard and then are delivered from the factory. Immersed oil is recycled through pallets and then is conveyed to the molding machine to convey the bottom-layer material molded bricks.

Owner:浙江寰龙环境科技有限公司

Modified black-sand rubber material

The invention discloses a modified black-sand rubber material composed of the raw materials of, by weight, 0.6-1 part of parachlorometaxylenol, 2-3 parts of ammonium trimolybdate, 47-50 parts of attapulgite, 0.3-0.6 parts of hexamethyl cyclotrisiloxane, 0.2-0.6 parts of 8-10% sulfuric acid, 26-30 parts of melamine, 5-8 parts of a 37% formaldehyde solution, 7-10 parts of urea, 0.7-2 parts of ascorbic acid, 6-10 parts of microcrystalline cellulose, 1-1.2 parts of isopropanol, 3-4 parts of maleic anhydride, 210-230 parts of neoprene S40V, 4-7 parts of vinyl carboxylate, 3-4 parts of an anti-aging agent NBC, and 2-4 parts of sulfur. According to the invention, with the crosslinking effect of maleic anhydride, microcrystalline cellulose forms a closer network structure in melamine resin formed by melamine, urea and formaldehyde, such that resin viscosity and tensile deformation resistance are well improved, and certain reinforcement and tackifying effects are provided in rubber. Therefore, rubber flexural cracking resistance, hot air aging resistance and stability are improved. With added modified black sand, production cost can be effectively reduced, an effect of resource recycling is provided, and rubber toughness and surface strength are effectively improved.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

Cold region used antifreezing concrete

Owner:芜湖鑫曜建材实业有限公司

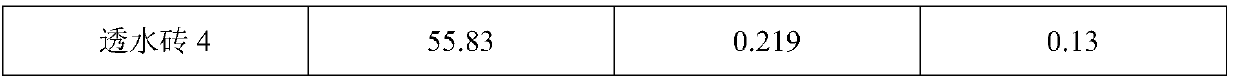

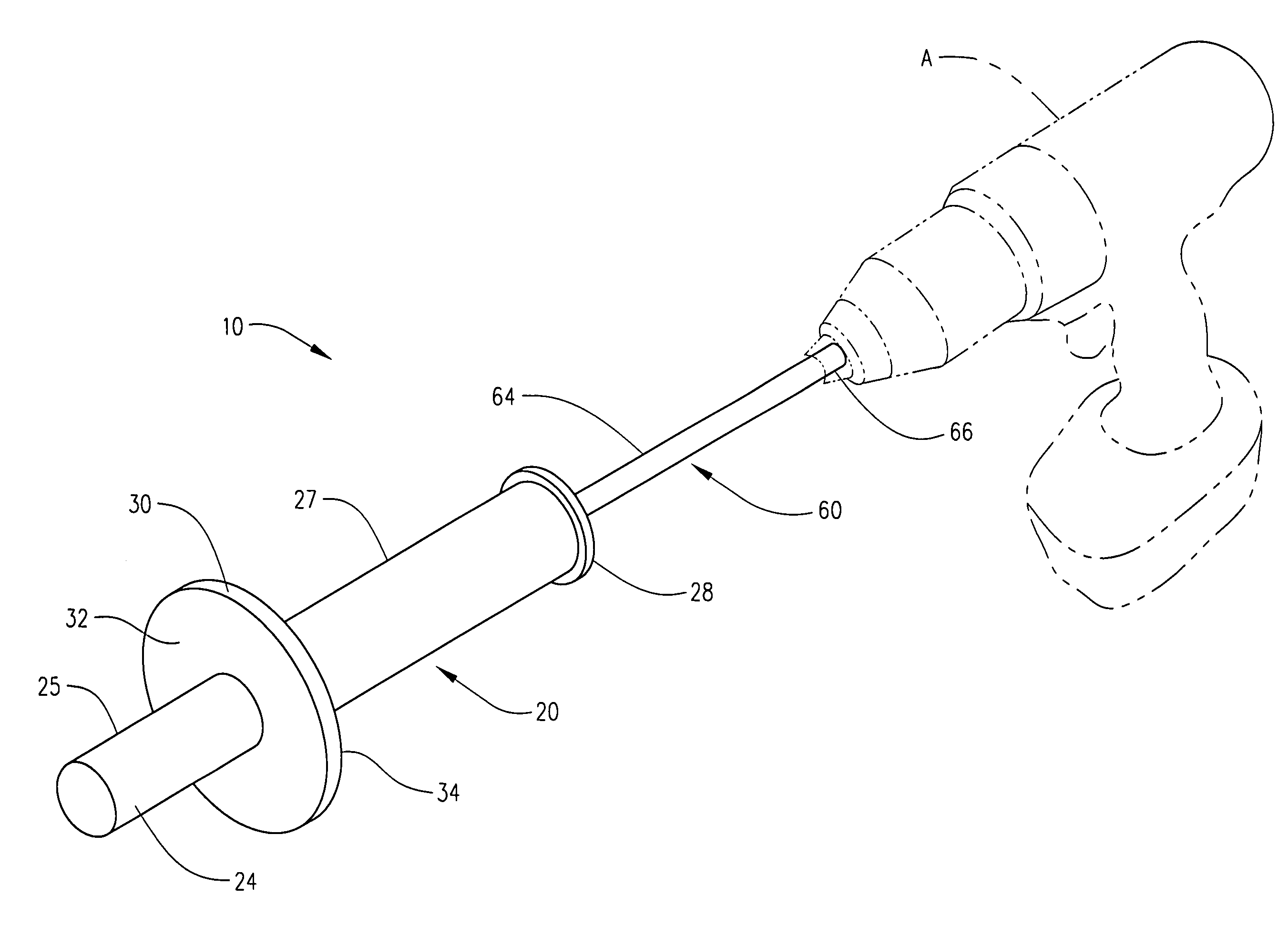

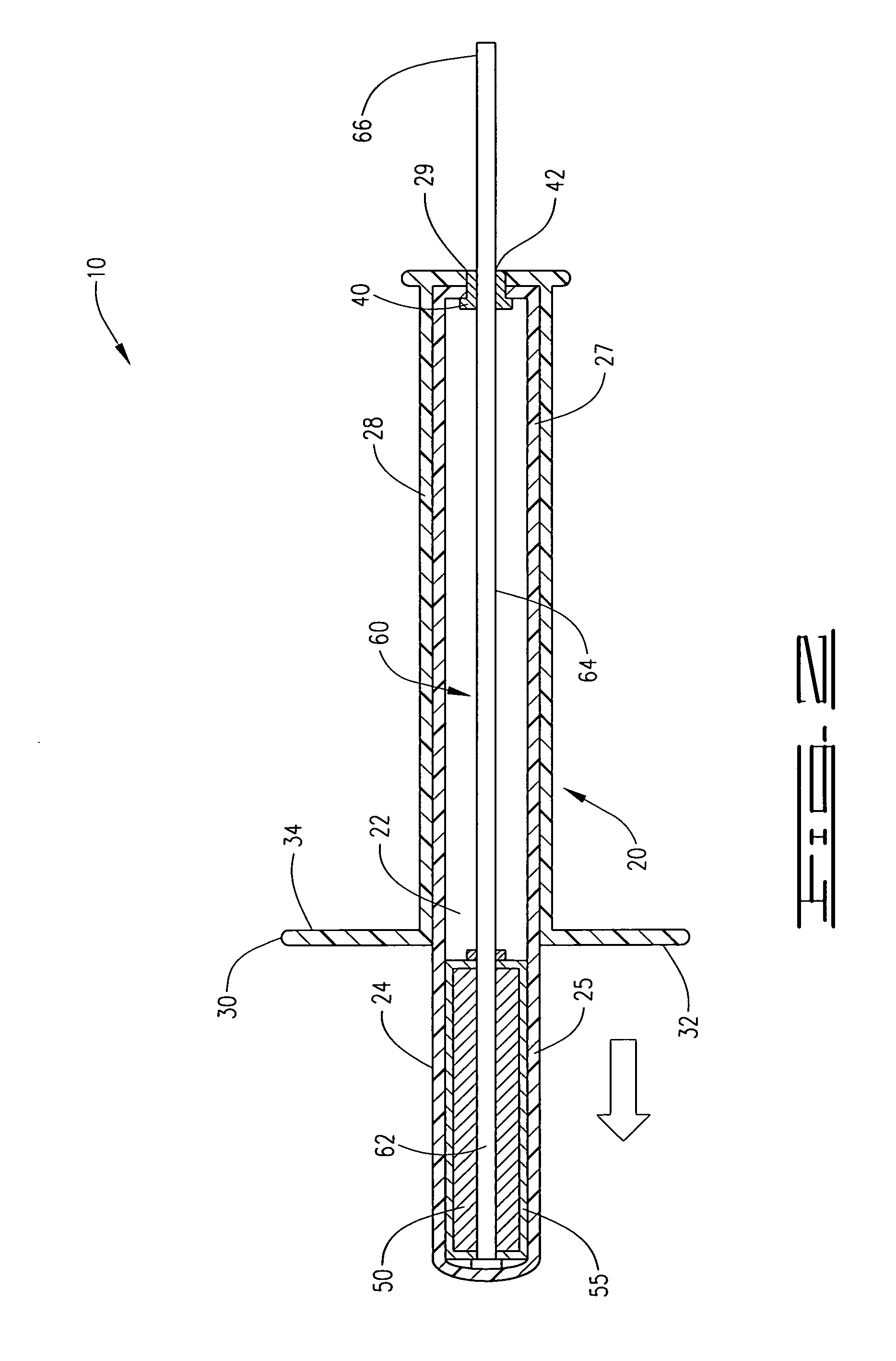

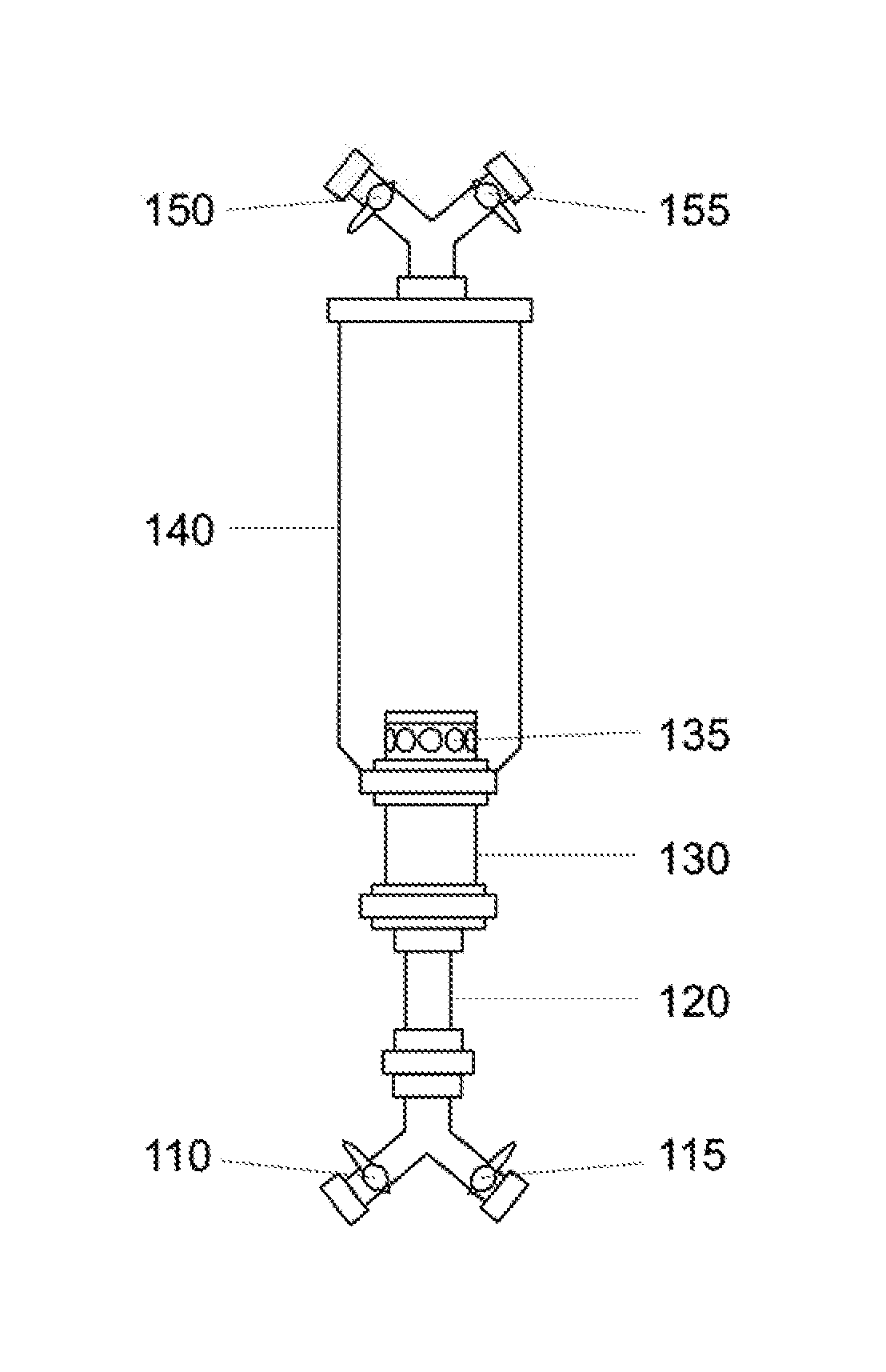

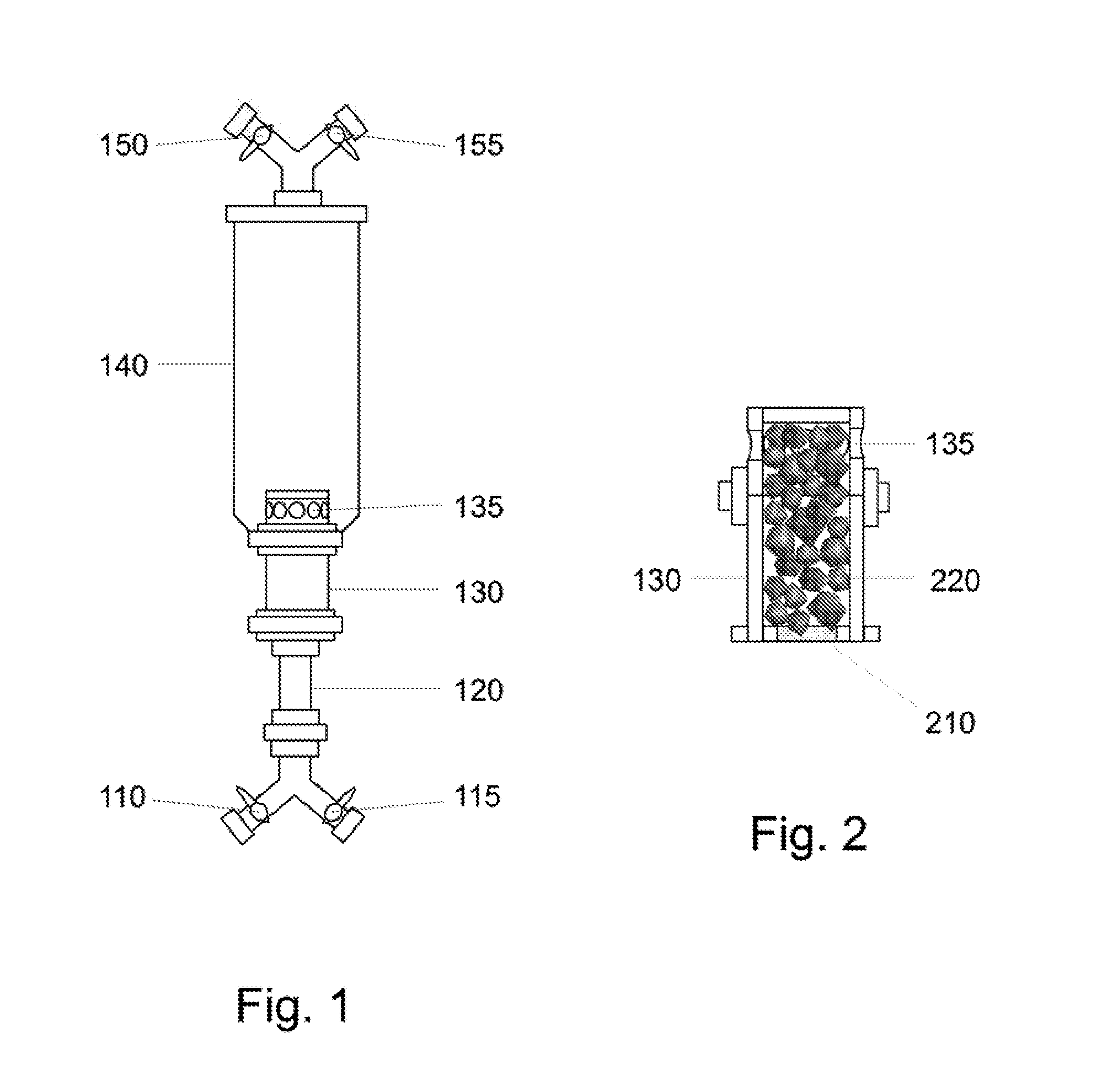

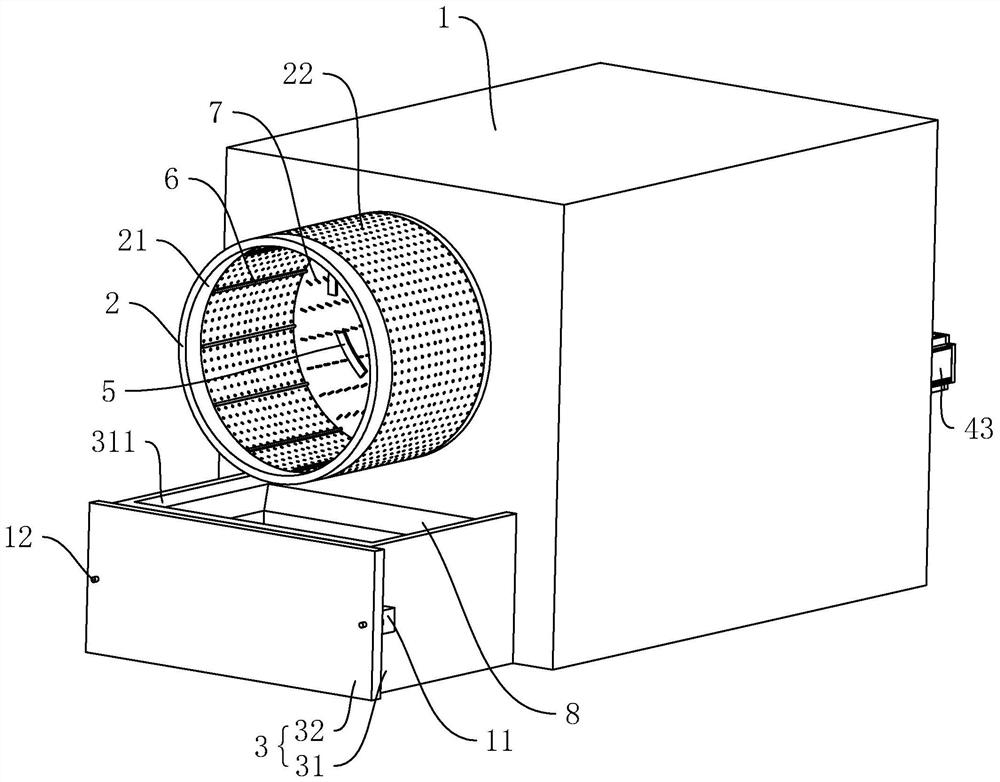

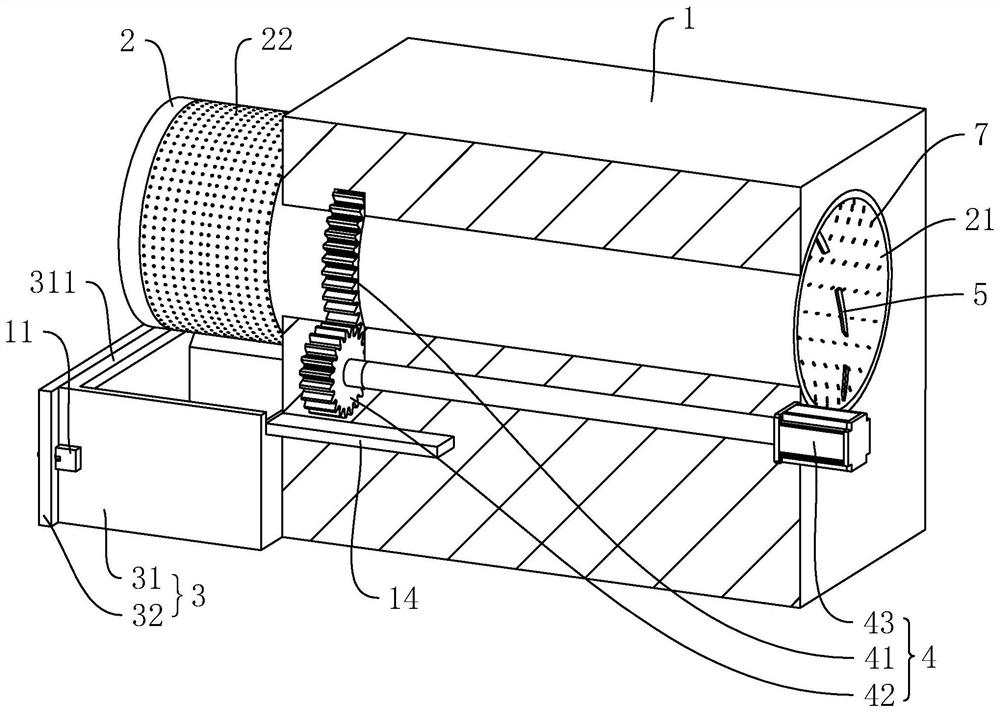

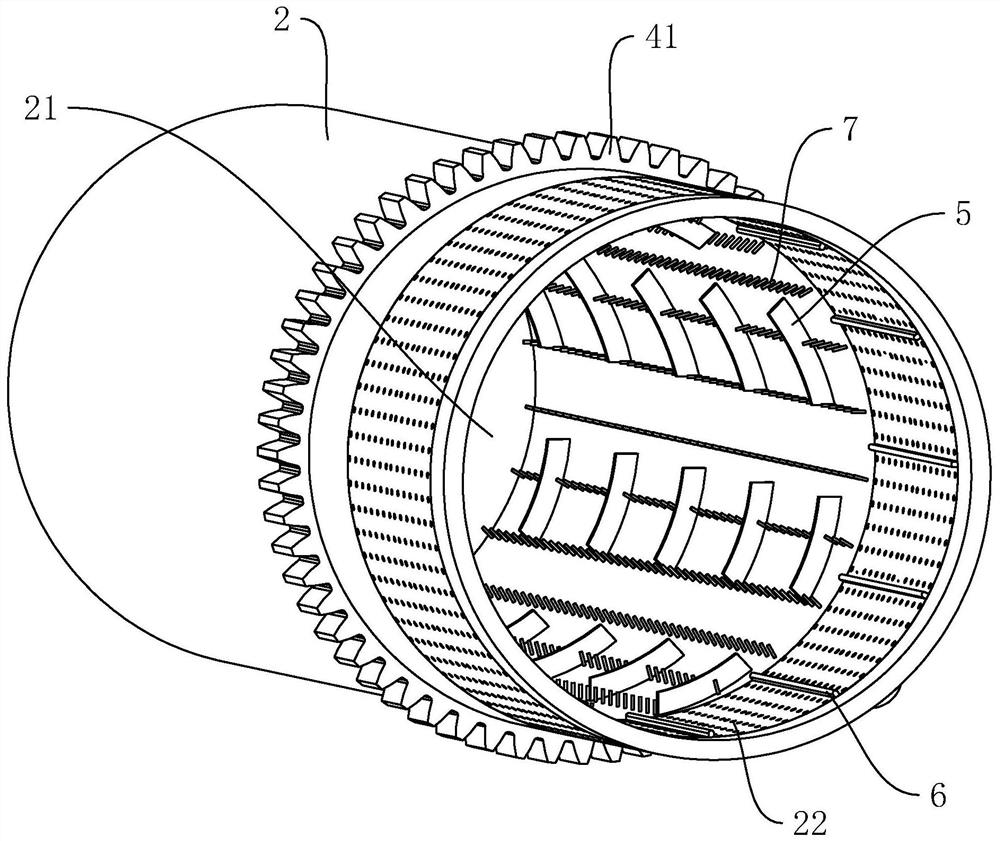

Black sand magnetic separator

ActiveUS20160121341A1High priceLess-expensive technologyElectrostatic separationMagnetic separationMagnetic separatorEngineering

A primary ore separation device used to remove magnetic particles from non-magnetic particles in a mixture utilizes a spinning magnet within a non-conductive cylindrical tube attaching the magnetic particles to the tube while the magnet is spinning and, by using centrifugal force, or the force caused by inertia, separates and spins away the non-magnetic particles, the device generally used upon mixed ore materials containing gold and other precious metals contained within the non-magnetic particles.

Owner:COLUMBIA RIVER MINING SUPPLIES LLC

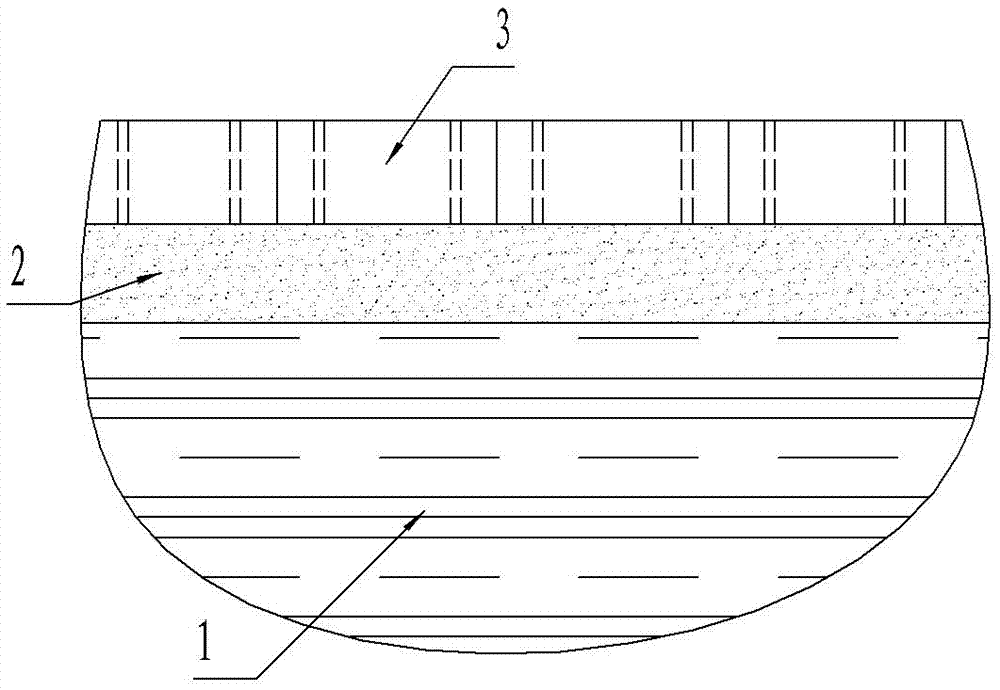

Waterproof anti-cracking footpath

InactiveCN107151964AAvoid crackingEasy to walkSingle unit pavingsSidewalk pavingsBrickRight triangle

The invention discloses a waterproof anti-cracking footpath which comprises a brick layer on a soil layer, wherein the brick layer is embedded by a connection layer; the connection layer is made of black sand; the brick layer is laid on the connection layer; the brick layer is formed by splicing a plurality of bricks prepared from clay; after each brick is mounted, the upper surface of the brick is of a right triangle shape; three edges of each brick are all provided with flanges and grooves, which are embedded with other bricks; the flanges and the grooves of each brick are adjacent; adjacent positions of the flanges and the grooves of each brick are positioned at the middle parts of the corresponding edges; after each brick is mounted, lengths of three edges of the upper surface are between 74mm and 83mm. The waterproof anti-cracking footpath can solve the problem that an existing footpath is easy to accumulate water and easy to be fractured by a vehicle.

Owner:陆运珍

Preparation technique of black sand pottery

InactiveCN102040370ARaise the sintering temperatureCrisp soundClaywaresRoom temperatureMaterials science

The invention discloses a preparation technique of black sand pottery, which comprises the following steps: respectively pulverizing clay, black sand mud, black iron ore and clean coal according to parts by weight, mixing the pulverized materials, and evenly stirring to obtain a mixture A; carrying out throwing or mold pressing on the mixture A to obtain a green body B; carrying out drawing or carving on the green body B to obtain a green body C; putting the green body C at room temperature for more than 2 days to obtain a green body D; sintering the green body D to obtain crude pottery E; and coloring the green body of the crude pottery E, and carrying out heat treatment to obtain fine pottery. By adjusting the formula of the black sand pottery, the invention raises the sintering temperature, so that a semi-porcelanous structure is respectively formed on the surface and inside of the black sand pottery, and the texture of the black sand pottery is between pottery and porcelain. Therefore, the discharged product has the advantages of crisp sound, light structure, beautiful appearance, favorable corrosion resistance and long service life, and is thin, delicate and hard.

Owner:胡正德

Automatic cleaning batch seam sand burning technology for casting part main runner

The invention belongs to the field of casting part sand removing processes, and discloses an automatic cleaning batch seam sand burning technology for a casting part main runner. According to the automatic cleaning batch seam sand burning technology for the casting part main runner, a runner cleaning tool is utilized, and the sand blasting and vibrating processes are combined. The technology comprises the following steps of conducting surface sand removing treatment, using the sand vibrating technology for shot blasting, cleaning arbors, punching a hole with an electric drill with the drill bit, chopping off the arbors with an iron chopper, clamping out the arbors with a clipper, removing main runner burrs, cleaning the bent runner arbors, blowing off one bent runner arbor with oxygen, removing black sand inside the runner, beating a casting part with an iron hammer, enabling the sand inside the runner to flow out through vibration, then conducting secondary sand vibration and shot blasting, and conducting endoscopy. The automatic cleaning batch seam sand burning technology has the advantages of being reasonable, convenient to operate, applicable to the casting part with the complex runner, good in sand removing effect and the like.

Owner:南通华东液压铸业有限公司

Simulated granite external wall panel and preparation method for same

The invention discloses a simulated granite external wall panel and a preparation method for the same. The simulated granite external wall panel comprises a base material layer, a middle material layer and a surface material layer, wherein middle material layer is arranged between the base material layer and the surface material layer; the base material layer is mainly composed of the following raw material: cement, silica fume, coal ash, silica sand, polypropylene fiber and additives; the middle material layer is mainly made of the following raw material of cement, silica fume, coal ash, construction waste powder, polypropylene fibers, magnesium oxide, gangue, steel slag, gypsum and additives; and the surface material layer is made of the following raw material of cement, silica fume, coal ash, black sand, white sand, iron oxide red, iron oxide black, master slices, silver slices and additives. The simulated granite external wall panel has excellent product performance and beautiful and elegant appearance; the material used requires low cost, so production cost can be reduced; and the preparation method is simple and can be easily applied; and production period can be shortened and production efficiency can be improved.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Indoor black sand grain powder coating

InactiveCN106398462AReasonable formulaUniform texturePowdery paintsEpoxy resin coatingsEpoxyPolyester

The invention provides an indoor black sand grain powder coating which comprises the following raw materials in parts by weight: 10-20 parts of epoxy resin; 10-20 parts of polyester; 0.1-0.5 part of a wax powder; 1-5 parts of titanium dioxide; 15-30 parts of barium sulfate; 0.25-1 part of bentonite; 0.05-0.2 part of a sand grain agent; and 0.06-0.25 part of a pigment. The white sand grain powder coating provided by the invention has the advantages of reasonable formula, uniform texture during use, excellent appearance visual sense, outstanding concave-convex touch sense, good weather resistance, good water resistance, good acid-base corrosion resistance, and good mechanical strength, can effectively improve the aesthetics and functions of the coating, also is environmentally friendly, and cannot cause pollution to the environment.

Owner:苏州翰晨商贸有限公司

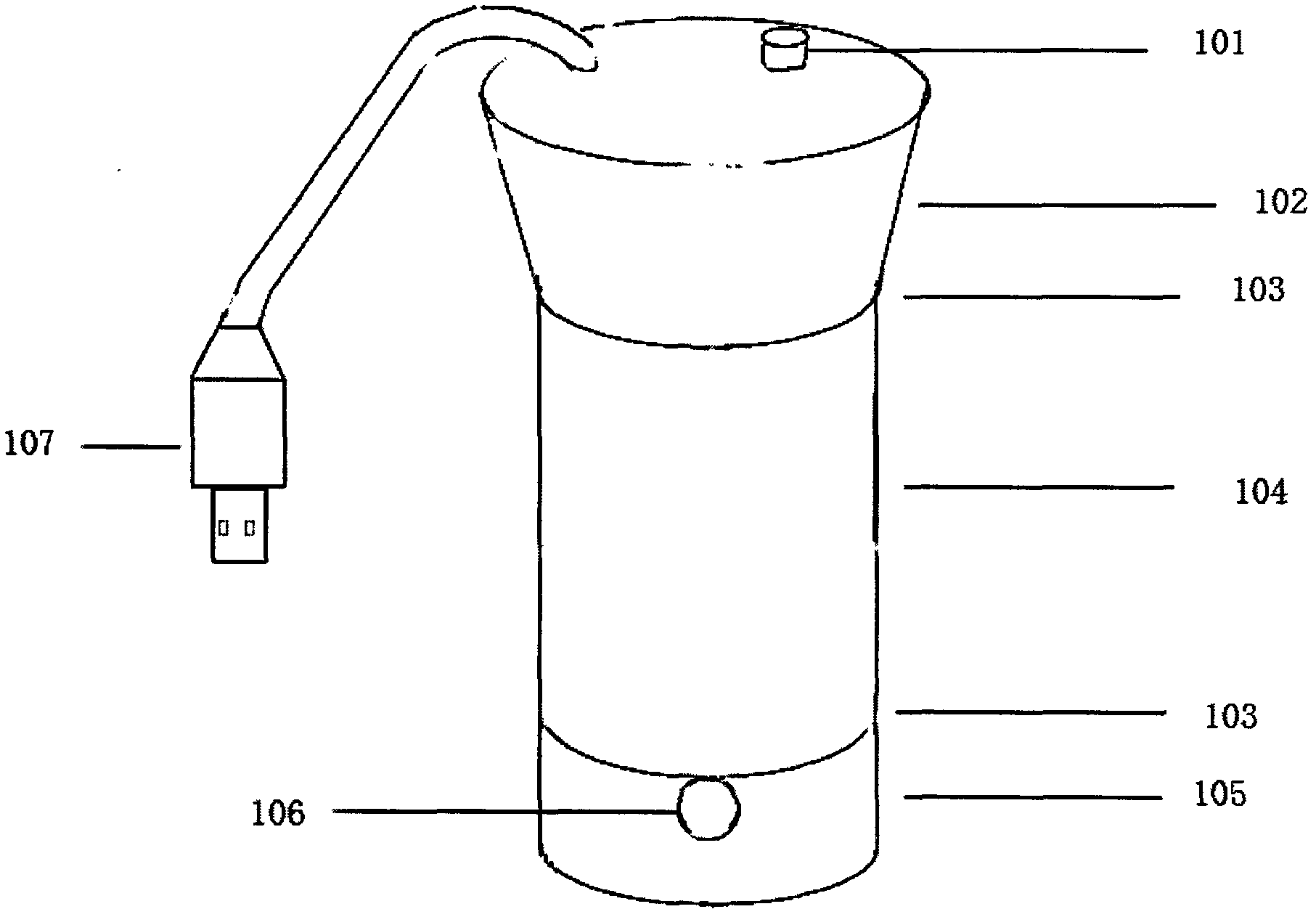

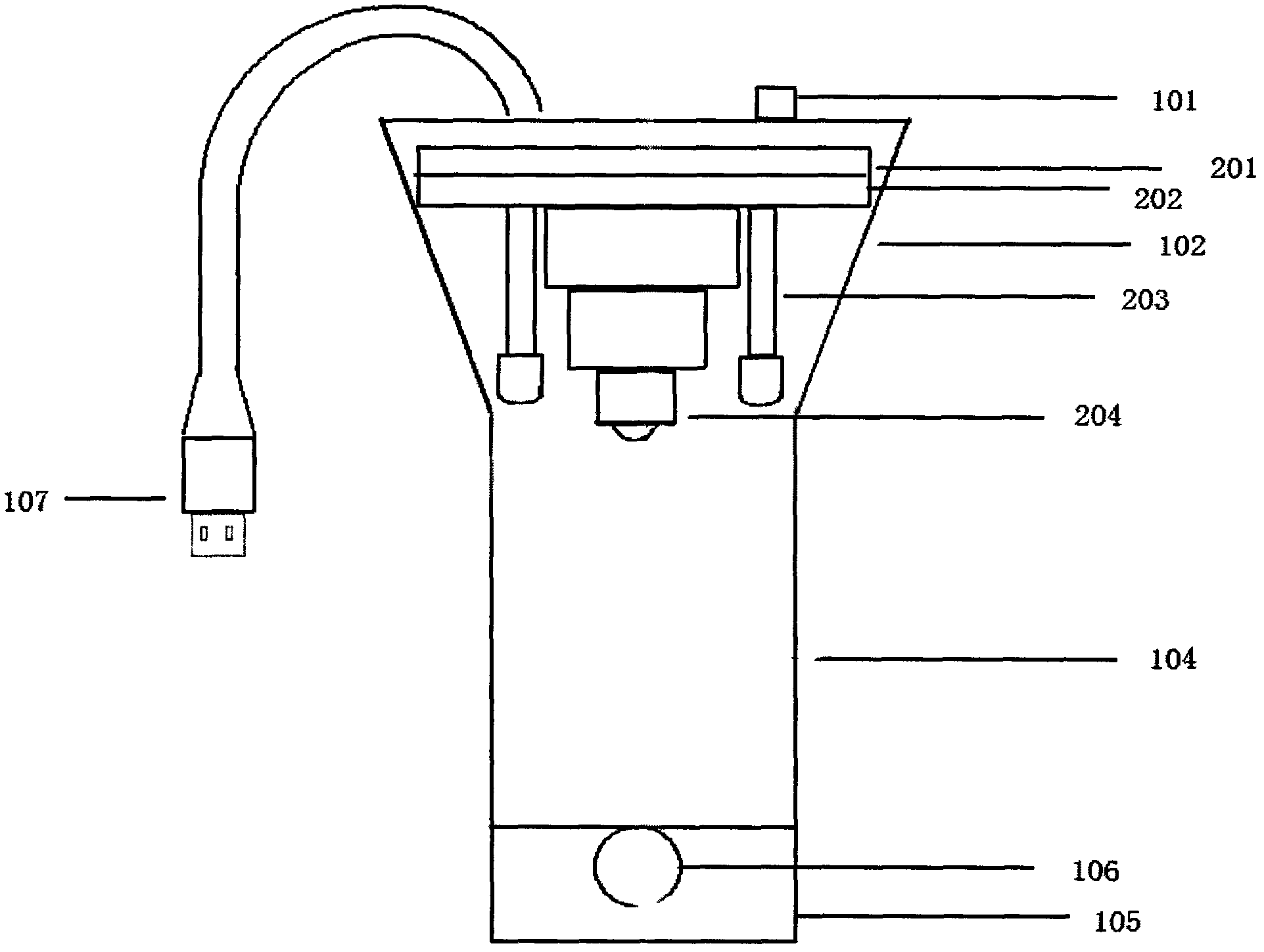

Traditional-Chinese-medicine infantile fingerprint image collection device

InactiveCN103417190AAvoid interferenceAvoid blurCharacter and pattern recognitionDiagnostic recording/measuringSilica gelLED lamp

The invention discloses a traditional-Chinese-medicine infantile fingerprint image collection device which adopts a barrel-type closed structure comprising an upper portion, a middle portion and a lower portion. A camera and a white-light LED lamp are arranged on the upper portion, a switch and a USB (universal serial bus) interface are arranged at the top, a collection barrel is arranged on the middle portion, black sand paper is adhered in the collection barrel to absorb reflected light, an infantile finger fixing support is arranged on the lower portion, finger dies are formed by transparent silica gel to fix infantile fingers, and the three portions are closed. After the camera collects images, the images are transmitted into a computer through a USB line, analysis and diagnosis of traditional-Chinese-medicine infantile fingerprint images are performed through fingerprint analysis and diagnosis software which is designed by independent research and development, and then analysis results are output.

Owner:HUNAN UNIV OF CHINESE MEDICINE

Common sintered brick prepared from casting waste

ActiveCN109942279AHigh carbon contentGuarantee the appearance qualityCeramic materials productionClaywaresBrickPrill

The invention relates to the field of building sintered bricks and particularly relates to a common sintered brick prepared from casting waste. The common sintered brick contains the following raw materials in parts by weight: 70-95 parts of the casting waste, 3-20 parts of an adhesive and 1-20 parts of an enhancer, wherein the casting waste contains sand processed ash, waste black sand and electric furnace ash in a ratio of (5-6) to (4-7) to (4-6). The casting waste is taken as the main raw material, the carbon contents of the sand processed ash and the electric furnace ash are relatively high, and carbon powder particles reach a micron level, so that the adequate combustion is easily realized in the internal combustion process, and sufficient heat is released; meanwhile, by virtue of ignition loss of the carbon powder, the unit weight of the sintered brick can be decreased, and the texture of a green brick is lightened; the main component of waste black sand is silicon dioxide, and silicon dioxide plays a role of a skeleton in the common sintered brick, so that the fluidity of the raw material of the green brick in the compression process can be effectively improved, meanwhile, the air permeability of the green brick is improved, and the adequate combustion of a fuel is promoted; and on the other hand, the sintering shrinkage of the green brick can be reduced, and the deformation can be reduced, so that the appearance quality of the common sintered brick is guaranteed.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

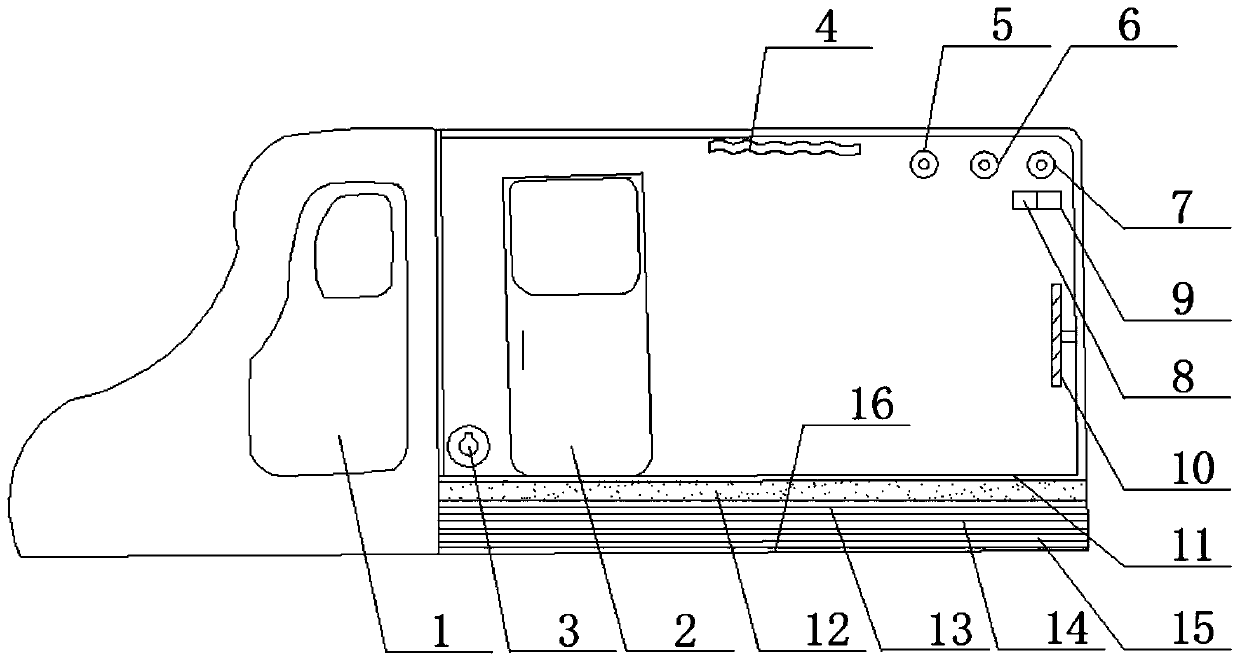

Sand physiotherapy bag

The invention discloses a sand physiotherapy bag and relates to the technical field of rehabilitation treatment tools. The sand physiotherapy bag comprises an upper layer, a middle layer, a bottom layer, sand barriers, iron tourmaline black sand, a traditional Chinese medicine mixture, a heating chip and a temperature controller, wherein the upper layer, the middle layer and the bottom layer are sequentially fixed from top to bottom, the sand barriers are uniformly distributed in the upper layer and the bottom layer in parallel, the iron tourmaline black sand is arranged in the sand barriers on the upper layer, and the traditional Chinese medicine mixture is arranged in the sand barriers on the bottom layer; and the heating chip is arranged in the middle layer and is connected with the external temperature controller through a wire. The sand physiotherapy bag integrates thermal therapy, magnetic therapy, massage and medical therapy, and has good effects on treatment of diseases such asfatigue, limb aching and tiring, chronic lumbocrural pain, sciatica, angiitis, chronic digestive tract diseases, gynecological diseases, scapulohumeral periarthritis, soft tissue injury and hypertension.

Owner:新疆火焰沙健康科技有限公司

A kind of halogen-free black sand and preparation method thereof

The invention provides halogen-free black sand and a preparation method thereof. The halogen-free black sand is prepared from the following ingredients in percentage by weight: 30 to 50 percent of carbon black, 5 to 15 percent of lignite wax, 25 to 40 percent of diatomite, 5 to 10 percent of epoxidized soybean oil, 3 to 7 percent of fatty alcohol-polyoxyethylene ether, 3 to 5 percent of ammonium polyphosphate, 2 to 5 percent of fatty acid calcium salt, 0.1 to 0.5 percent of inorganic salt copper sulfate and 3 to 5 percent of coupling agents. A preparation process comprises the following stepsof sequentially adding formula raw materials into an internal mixer to be mixed for 20 minutes; obtaining a pre-finished product after the heating and grinding; transferring the pre-finished product into a butterfly type low-speed stirring machine for shearing and shaping the pre-finished product; obtaining a particular primary finished product of the black sand; filtering the particular primary finished product of the black sand to obtain a finished product. The black slurry produced by the method has the advantages of color spreading performance, high coloring capability and good flowability; the blackness degree and the brightness degree of the plastic products can be enhanced; a halogen-free and environment-friendly formula is used; phenomena of color spots, poor color vein dispersionand the like cannot occur; in the processing process, the mixing is firstly performed, and then, the grinding is repeatedly performed for three times, so that the carbon black, plasticizers and the like are uniformly scattered; the obtained black sand has the uniformly scattered color and luster and pigment figure.

Owner:东莞市从墨塑胶材料有限公司

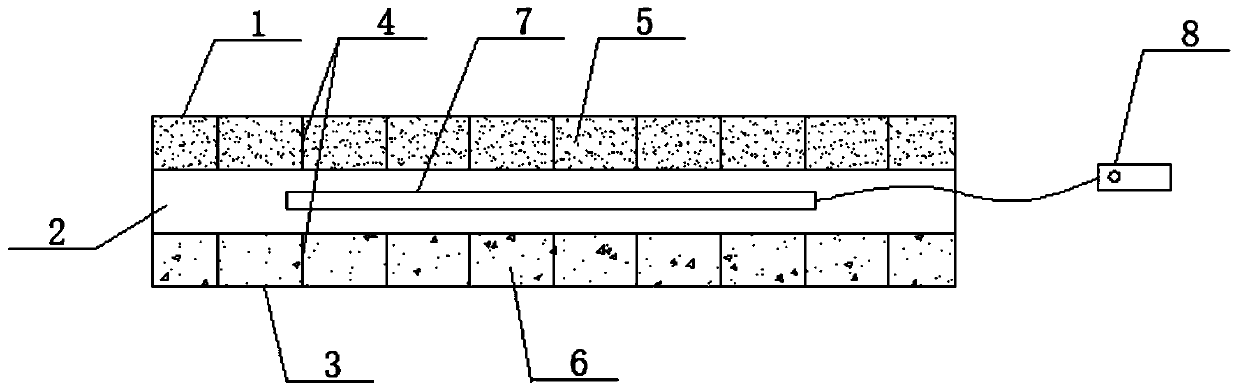

Novel influenza virus killing shelter

PendingCN111472575AEasy to disinfectImprove the bactericidal effectLavatory sanitoryProtective buildings/sheltersAntiseptic sterilizationSprayer

The invention provides a novel influenza virus killing shelter and relates to the technical field of sterilization chambers. A front shelter door and a rear shelter door are arranged at the front andrear parts of the shelter respectively. An air inlet is formed in one side of the rear shelter door. An ultraviolet disinfection lamp, an air purifier and a negative chloride ion generator are installed at the top of the inside of the shelter body. A warming agent sprayer, a shelter temperature regulator and a shelter bottom temperature controller are installed on the inner side wall of the shelter body. An air outlet is formed in the upper end of the shelter body. A cotton mattress sheet is arranged at the bottom of the shelter body, tourmaline black sand is arranged below the cotton mattresssheet, and a partition plate, a magnetic cable heating mat, an insulation board and a bottom plate are sequentially arranged below the tourmaline black sand. The novel influenza virus killing sheltercan conveniently kill influenza viruses on human bodies, thereby well controlling infectivity of the influenza viruses.

Owner:新疆火焰沙健康科技有限公司

Production method of black attapulgite polymer clay

InactiveCN101973062AHigh viscositySoft and malleableCeramic shaping apparatusCooking & bakingPolymer science

The invention discloses a production method of black attapulgite polymer clay. The technical scheme of the method is characterized by comprising the following steps: adding black sand-like attapulgite mixture to an operating horizontal flour-mixing machine, slowly adding sodium polyacrylate gel solution into the black sand-like attapulgite mixture, and then stirring to obtain black clod-like attapulgite mixture; spraying methyl silicone oil on the black clod-like attapulgite mixture, kneading to obtain the semi-finished product of black attapulgite polymer clay; and finally pressing the semi-finished product into a flat shape, sealing and packaging to obtain a finished product. The black attapulgite polymer clay has the characteristics of high viscosity, good soft plasticity, small shrinkage rate, no need of baking, no cracking, no corrosion and no greasy feeling, and can be hardened after natural drying. When the black attapulgite polymer clay is mixed with attapulgite polymer clay in other colors for use, artware with clear patterns, bright colors and vivid effect can be shaped, and the black attapulgite polymer clay is applicable to the shaping of patterns, molds and artware.

Owner:南通江涌投资开发有限公司

Method for producing bricks from silt and sludge

InactiveCN101830687BWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primarystirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

Upper arch effect demonstrating instrument

InactiveCN100454358CObserve the soil arching phenomenonUnderstand the interactionEducational modelsRubber membraneSoil arching

The invention discloses a soil arching effect demonstrator. There is a half cylindrical rubber airbag in the center of the bottom of Perspex box. Outside the airbag there is flexible rubber membrane. They are fixed at the bottom of Perspex box. From bottom to top, the Perspex box is filled with yellow sand and black sand; tube of the airbag is connected with inflatable bag outside the Perspex box; in the tube of inflatable bag, there is release valve and forward one-way valve; there is one backward one-way valve in the inflatable bag. By giving air and releasing air, the soil arching can be directly observed.

Owner:ZHEJIANG UNIV

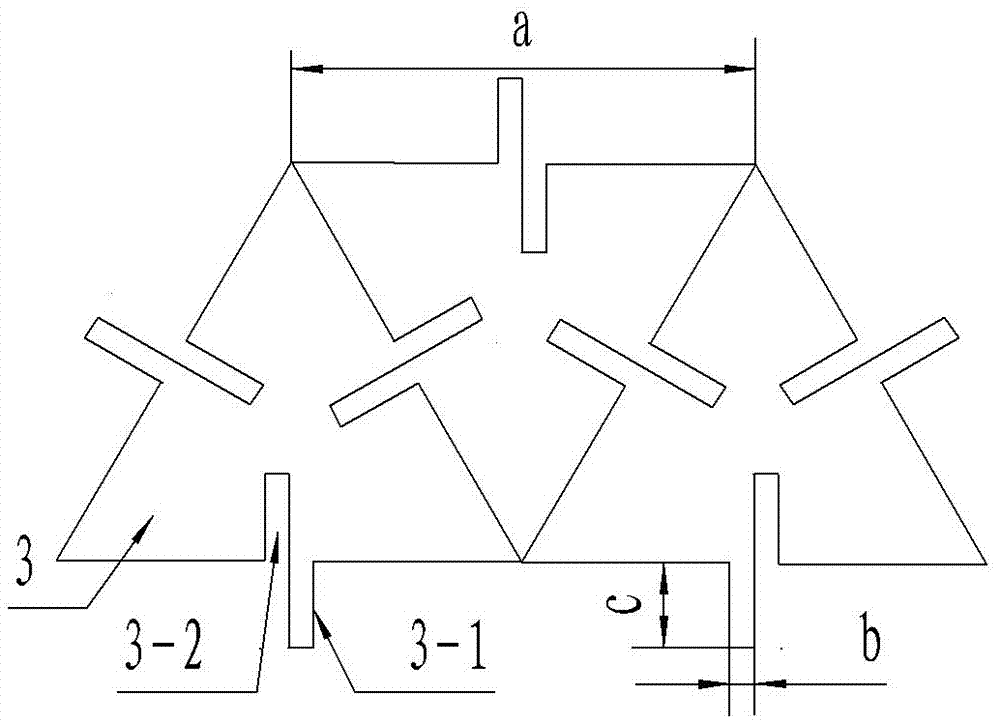

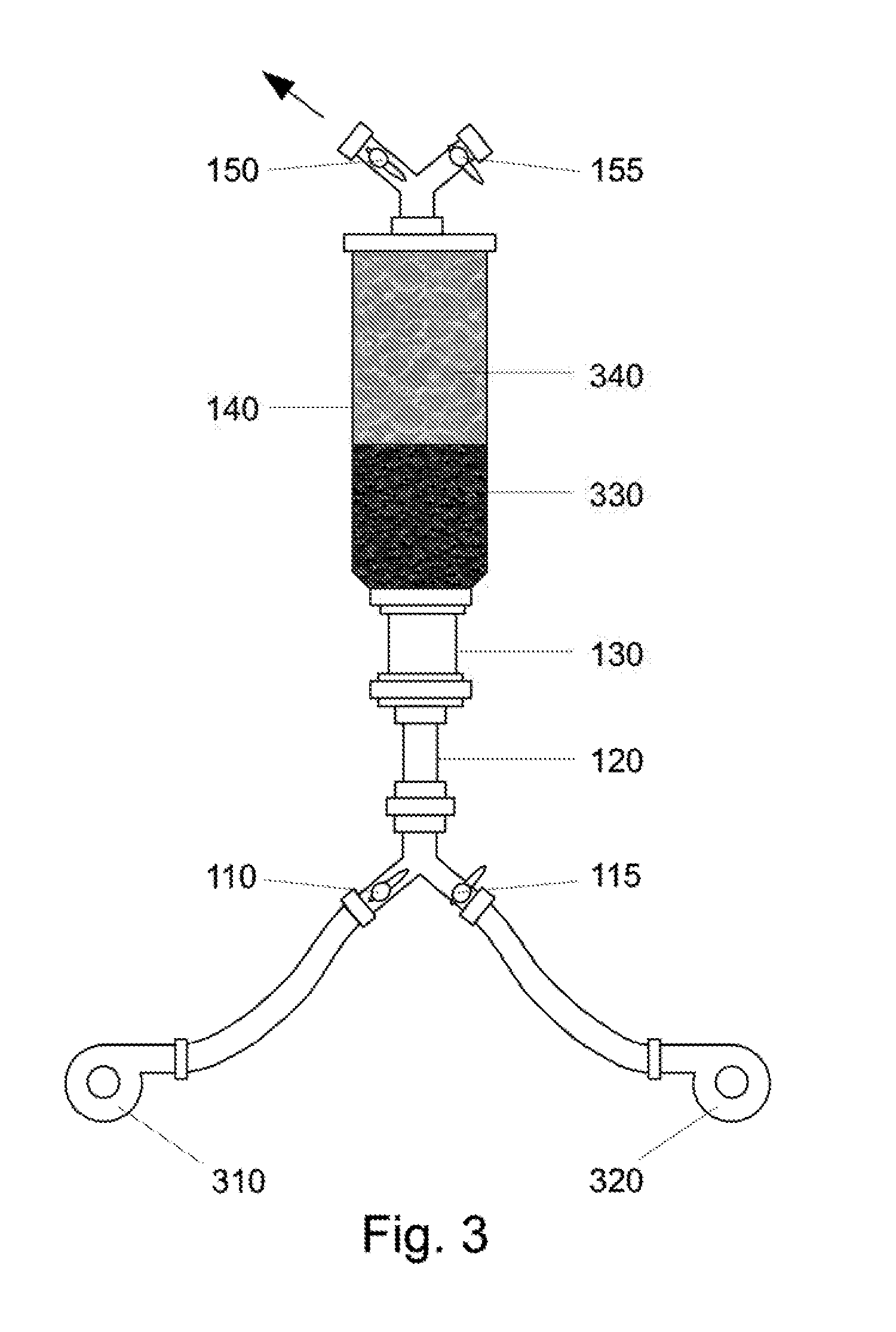

Forward Wash Filter Cleaning

InactiveUS20160243468A1Performed simply and quicklyLittle has been producedDispersed particle filtrationTransportation and packagingParticulatesWater filter

Flow of water is in the same direction during a water-filtering cycle and a filter-cleaning cycle. That feature leads to an especially simple, economical and effective system for (a) producing filtered water and (b) cleaning, during a filter-cleaning cycle, the filter that cleans the water of particulates. No backwash is needed.Forward wash filter cleaning makes use of principles of physics, man-made equipment, and attraction of black sand (e.g., sand containing magnetite) to magnets. Those elements are combined in a novel way to (a) constrain the sand in a compact but permeable filtering layer and (b) allow a forward wash filter-cleaning cycle by simply flowing water through a layer of particulate-laden black sand after the layer has been made less compact by being disrupted during the filter-cleaning cycle. In other words, particulates previously trapped during a water-filtering cycle are washed away in forward-flowing, particulate-laden water during the filter-cleaning cycle.

Owner:MANAUGH THOMAS SCOTT +1

Simulated granite external wall panel and preparation method for same

InactiveCN106381969AReasonable formulaLow priceCovering/liningsLaminationIron oxide blackGranolithic

The invention discloses a simulated granite external wall panel and a preparation method for the same. The simulated granite external wall panel comprises a base material layer, a middle material layer and a surface material layer, wherein middle material layer is arranged between the base material layer and the surface material layer; the base material layer is mainly composed of the following raw material: cement, silica fume, coal ash, silica sand, polypropylene fiber and additives; the middle material layer is mainly made of the following raw material of cement, silica fume, coal ash, construction waste powder, polypropylene fibers, magnesium oxide, talcum powder, bamboo fibers, diatomite, coal gangue, calcined kaolin, gypsum and additives; and the surface material layer is made of the following raw material of cement, silica fume, coal ash, black sand, white sand, iron oxide red, iron oxide black, master slices, silver slices and additives. The simulated granite external wall panel has excellent product performance and beautiful and elegant appearance; the material used requires low cost, so production cost can be reduced; and the preparation method is simple and can be easily applied; and production period can be shortened and production efficiency can be improved.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

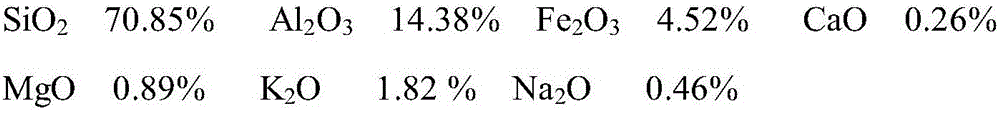

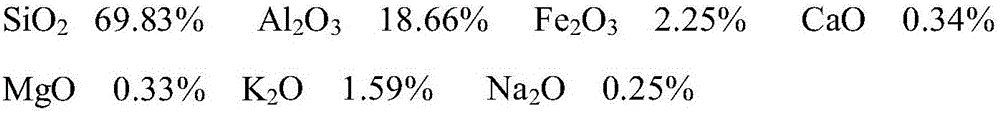

Heat-resistant black sand cooking device and preparation process method thereof

ActiveCN106542801ASatisfy the requirements of thermal deformation resistanceOptimizing thermal deformation resistanceClaywaresActivated carbonThermal deformation

The present invention discloses a heat-resistant black sand cooking device and a preparation process method thereof, wherein the main raw material components comprise, by mass, 40-45% of spodumene, 10-35% of ancient city mud, 10-30% of white mud, and 10-25% of kaolin. The specific process steps comprise: carrying out ore dressing on the raw materials; crushing to achieve 60-120 mesh; preparing the material; adding water and carrying out stirring mixing; aging for 7 days; carrying out vacuum mud forming; carrying out rolling pressing molding; finishing the billet; drying; checking the billet; sizing; firing; taking the glaze and carbonizing; and carrying out inspection packaging. According to the present invention, on the basis of the original black sand device raw materials, the low-expansion material spodumene is introduced; the thermal-deformation resistance of the product is optimized by carrying out the grading treatment on various component powder particles of the raw materials; the firing temperature is controlled at 1210-1230 DEG C; the water absorption of the product is controlled at 3-5%; the 800-20 DEG C thermal-deformation resistance is achieved, such that the thermal-deformation resistance requirement of the family cooking on the black sand device is met; the low-expansion glaze is achieved, such that the nonstick pan is achieved, and the odour tainting cannot be generated; and the natural gas is used as the medium so as to endow the product with the water purification with active carbon.

Owner:SICHUAN ZHUANGWANG BLACK SAND CO LTD

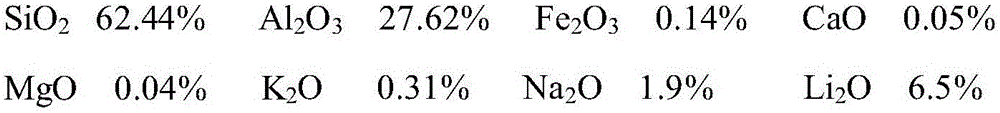

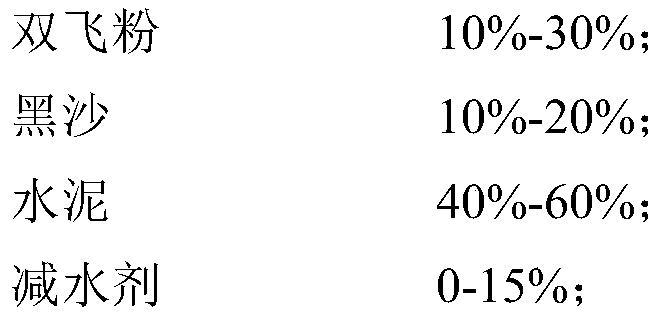

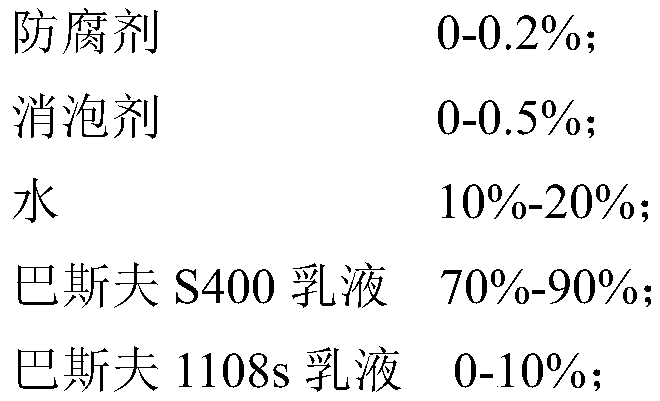

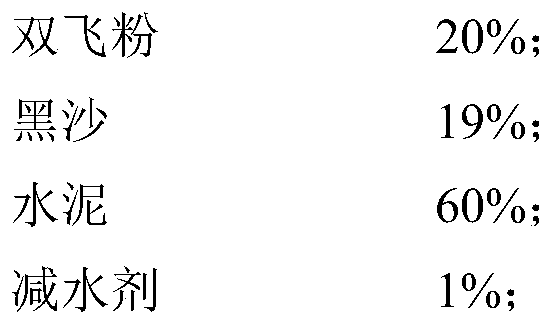

Flexible waterproof slurry

The invention discloses a flexible waterproof slurry. The flexible waterproof slurry comprises a powder and a liquid, and is characterized in that the powder comprises the following components in percentage by mass: 10-30% of heavy calcium carbonate powder; 10%-20% of black sand; 40%-60% of cement; and 0-15% of a water reducing agent; and the liquid comprises the following components in percentageby mass: 0-0.2% of a preservative; 0-0.5% of a defoaming agent; 10%-20% of water; 70%-90% of BASF S400 emulsion; and 0 to 10 percent of BASF 1108s emulsion; the powder and the liquid are mixed according to the mass ratio of 1: 0.6-0.68. The flexible waterproof slurry disclosed by the invention is high in bonding strength, high in impermeable pressure and good in flexibility.

Owner:NINGBO PASCO UNITED IND

A method of using black sand waste to make environmentally friendly bricks

ActiveCN108675764BAvoid pollutionSimple processCeramic materials productionClaywaresMaterials preparationBrick

Owner:荥经县朱氏砂器有限公司

Pump part production process

ActiveCN113664153ANot easy to stickIncrease productivityFoundry mouldsFoundry coresWaxInvestment casting

The invention relates to a pump part production process, which relates to the field of part production, and comprises the following steps: a, preparing a moulding sand mould; b, preparing a black sand mould; c, performing pouring; d, performing desanding; e, performing recycling; and f, performing surface treatment. According to the production process in the invention, precoated sand and black sand are used for preparing a part; wax melting and roasting processes in an investment casting process are reduced; the process is simplified; the production period is shortened; therefore, the part production efficiency is improved; furthermore, energy consumed by wax melting and roasting is reduced; the effects of energy conservation and emission reduction are achieved; compared with wax, the black sand is not easy to adhere to the surface of the part, so that sand cleaning is more convenient; therefore, the production efficiency of the part is further improved; and mass production of the part is facilitated.

Owner:WENLING NEWIMPETUS CASTINGANDMACHINING CO LTD

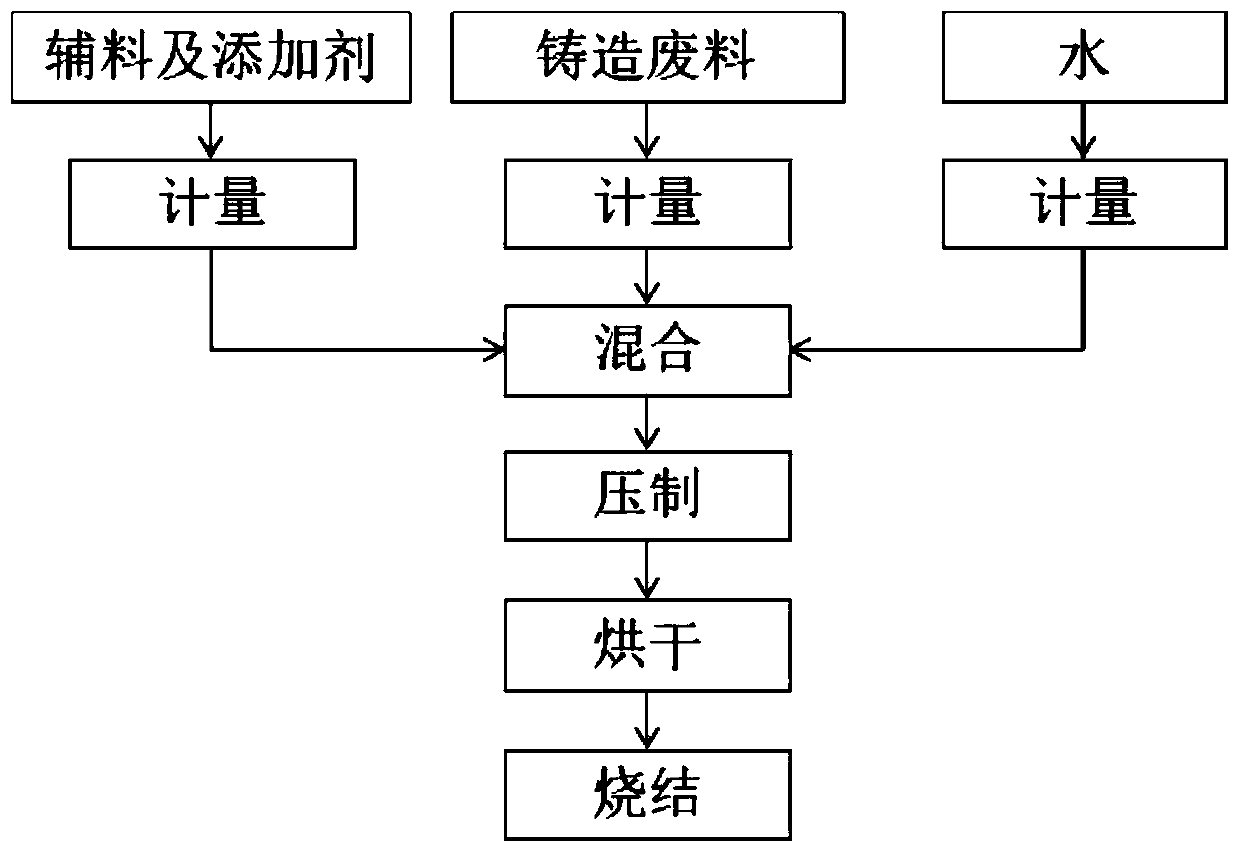

Method for making environmental-friendly brick by black sand waste materials

ActiveCN108675764AAvoid pollutionSimple processCeramic materials productionClaywaresMaterials preparationBrick

The invention discloses a method for making an environmental-friendly brick by black sand waste materials. The method sequentially comprises the following steps of crushing, material proportioning, mud material preparation, mold pressing shaping, drying, slurry spraying, firing and cooling. The method has the advantages that the process is simple; the operation is convenient; black sand waste materials generated in the black sand industry can be used for producing environmental-friendly bricks, so that the black sand waste materials which are always useless in many years are changed into valuable materials; the pollution of the black sand waste materials on the peripheral environment is effectively avoided; the treatment cost is reduced; the environmental-friendly effect is good.

Owner:荥经县朱氏砂器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com