Patents

Literature

33results about How to "Soft and malleable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for using soft attapulgite ceramic powder

The invention discloses a method for using soft attapulgite ceramic powder. The method comprises the following steps of: putting the soft attapulgite ceramic powder into a container; slowly adding hot water to the soft attapulgite ceramic powder, stirring the powder in time and kneading into a strip-shaped mud cake; coating methyl silicone oil onto the outer surface of the strip-shaped mud cake and kneading once again; and pressing the strip-shaped mud cake into soft attapulgite ceramic mud. The soft attapulgite ceramic powder comprises purified attapulgite clay, bentonite, sepiolite, calcium chloride, sodium polyacrylate, sodium carboxymethylcellulose and sodium stearoyl lactate. The soft attapulgite ceramic mud prepared by adding the water and the methyl silicone oil to the soft attapulgite ceramic powder has the characteristics of high viscosity, good soft plasticity, small shrinkage, no deformation, hardening after natural drying, no need of roasting, no cracks, no mildew, no deterioration, no irritation to skin, no toxicity, no corrosivity and no oily feel. The using method of the soft attapulgite ceramic powder is suitable for manufacturing the soft attapulgite ceramic mud on site by adopting the soft attapulgite ceramic powder.

Owner:JIANGSU DAHAI PLASTIC

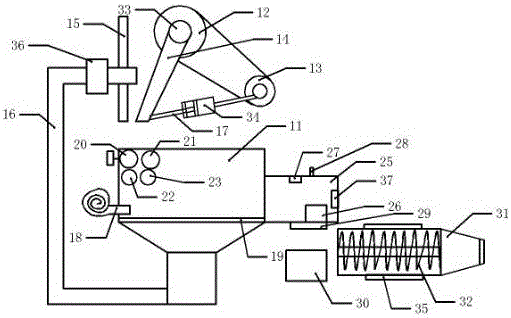

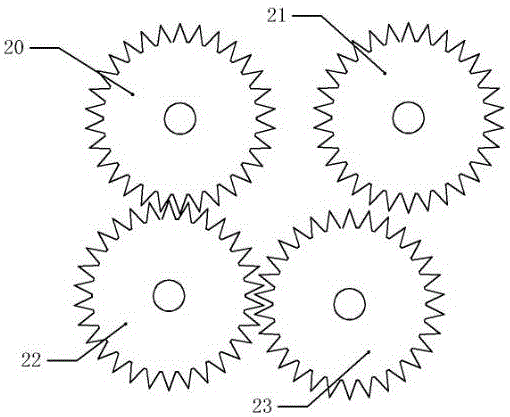

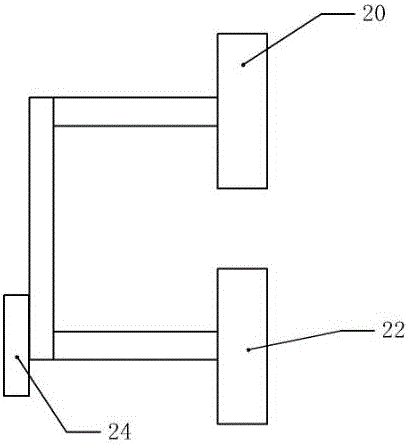

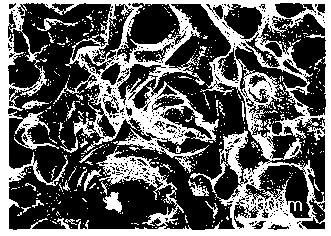

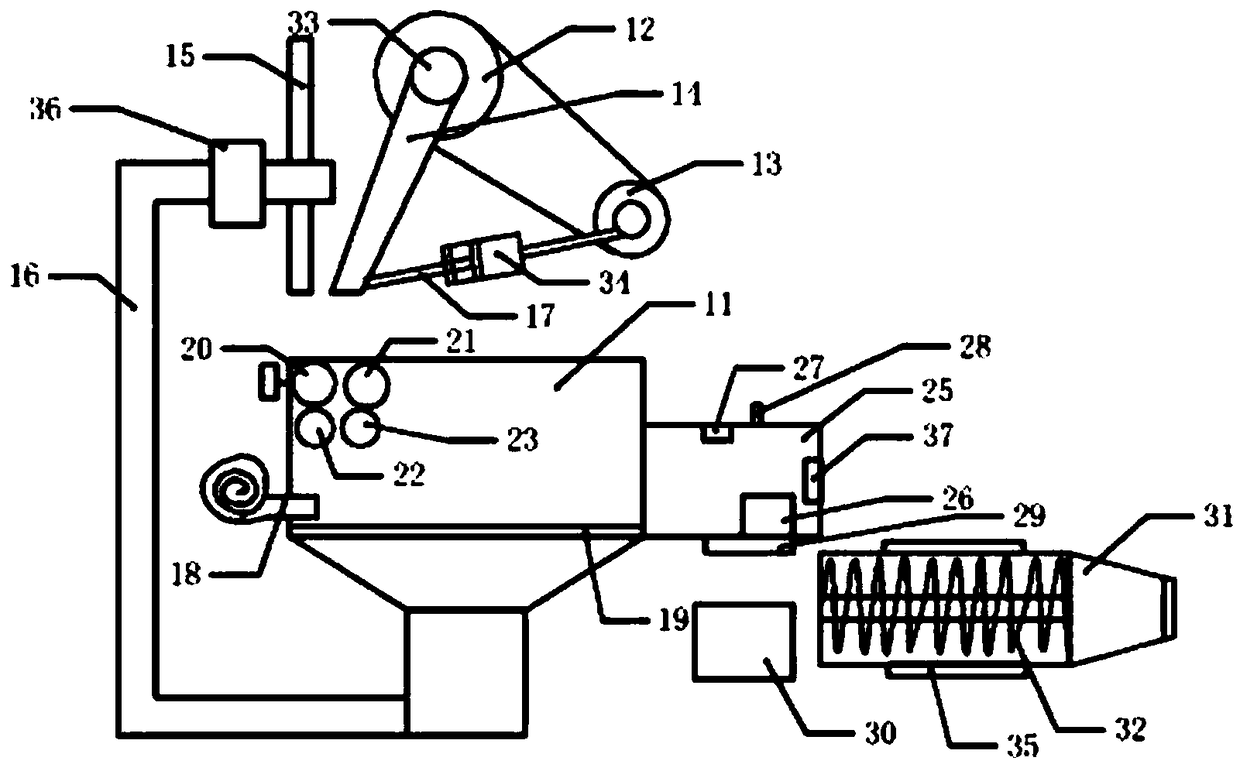

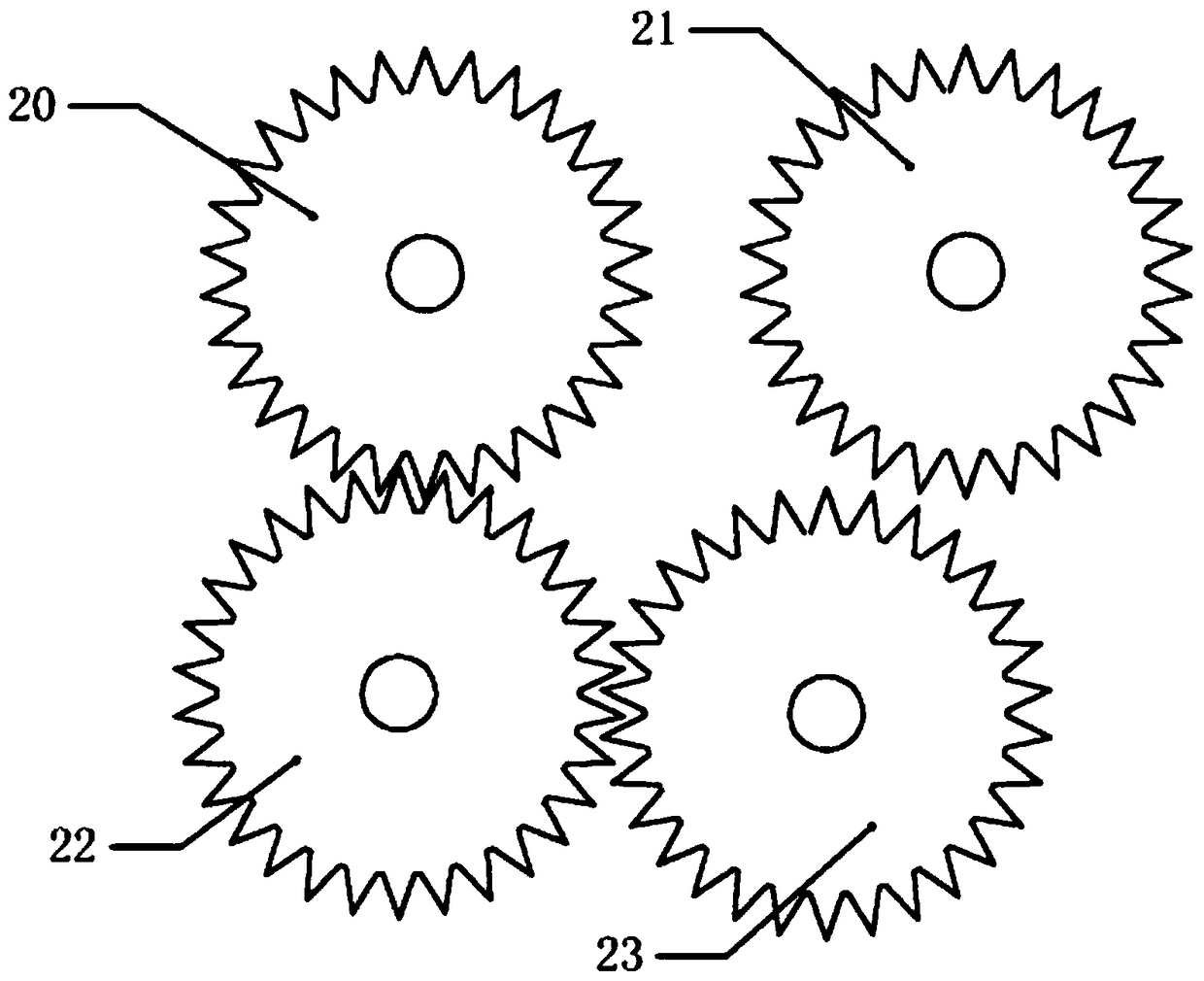

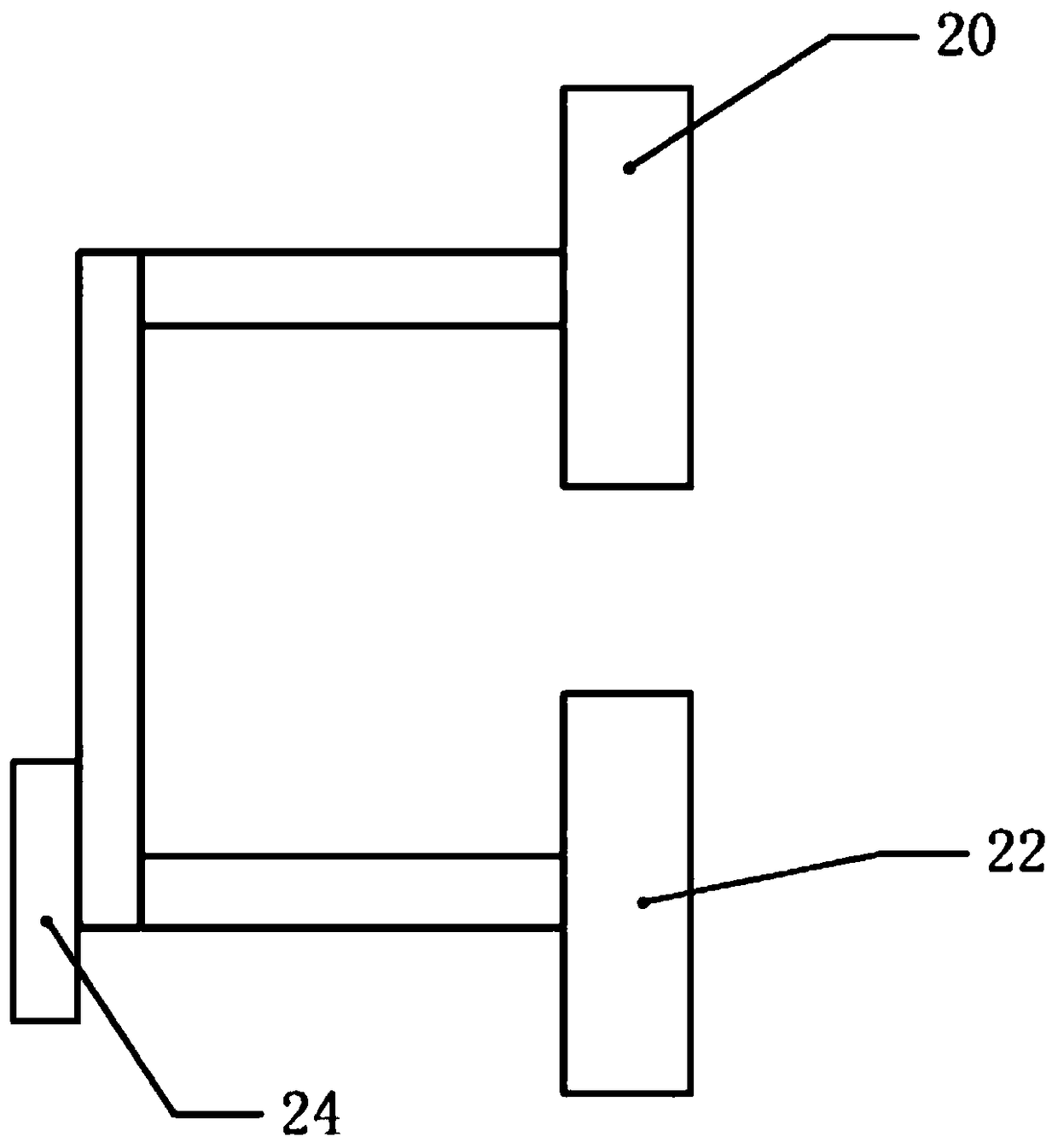

Oil sludge recovery device

ActiveCN106734094AGood viscosityIncreased softness and plasticitySolid waste disposalMagnetic separationScrapMagnet

Owner:CHONGQING TENGTONG IND DESIGN

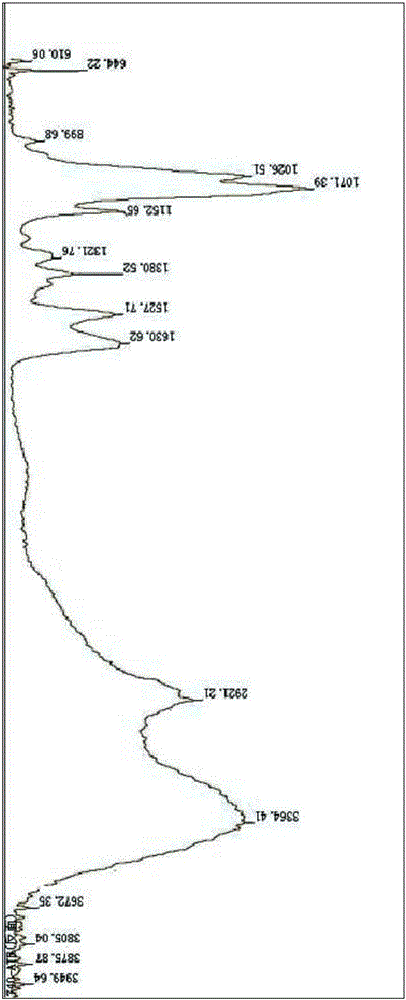

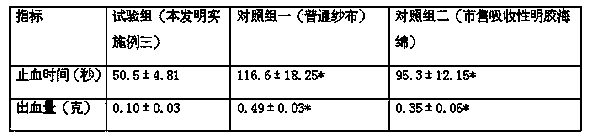

Chitosan sponge surgical dressing and preparation method thereof

ActiveCN103341202AEasy to demouldEasy to wrapAbsorbent padsBandagesFoaming agentWater soluble chitosan

The invention discloses a chitosan sponge surgical dressing and a preparation method thereof. The chitosan sponge surgical dressing includes, by mass, 0.1% to 10% of water-soluble chitosan or a salt thereof, 0.001% to 5% of a foaming agent and 0.05% to 8% of a humectant. The chitosan sponge surgical dressing provided by the invention has a good foaming effect, high adsorption capacity, powerful moisture retention, softness and good plasticity and fills a gap in excellent surgical dressings.

Owner:JIANGSU DIWO BIOLOGICAL PROD

Yellow attapulgite polymer clay powder

The invention discloses a yellow attapulgite polymer clay powder. The yellow attapulgite polymer clay powder is characterized by being prepared from purified attapulgite clay, white bentonite, sepiolite, iron oxide yellow, organic pigment yellow, calcium chloride, rutile titanium dioxide, sodium polyacrylate, carboxymethyl cellulose sodium and sodium stearoyl lactylate. The yellow attapulgite polymer clay powder is prepared by the following steps of: mixing ingredients of the yellow attapulgite polymer clay powder; transferring the ingredients into a pulverizer for pulverization; transferring the pulverized mixture into a powder grinder for grinding; and packaging to obtain finished products of the yellow attapulgite polymer clay powder. The yellow attapulgite polymer clay prepared by adding water and methyl silicone oil to the yellow attapulgite polymer clay powder has the advantages of high viscosity, softness and good plasticity, low shrinkage and no corrosivity or greasiness. The yellow attapulgite polymer clay stiffens after air drying and is not required to be baked. The invention has the advantages of simple production process, low cost and convenient use and is beneficial to popularization. The yellow attapulgite polymer clay powder is suitable for making yellow attapulgite polymer clay on the spot.

Owner:南通江涌投资开发有限公司

Production method of skin-moistening moisture-keeping paper special for mothers and infants

PendingCN108642966AGentle to the touchIncrease humidityNon-fibrous pulp additionSpecial paperFiberStart stop

The invention discloses a production method of skin-moistening moisture-keeping paper special for mothers and infants. The skin-moistening moisture-keeping paper comprises the following component: a bleached soft wood and broadleaf wood pulp plate. The skin-moistening moisture-keeping paper is prepared through the following steps: S1, taking the bleached soft wood and broadleaf wood pulp plate asslurry, and respectively dispersing the slurry into long-fiber slurry and short-fiber slurry by a hydraulic pulper; S2, beating the long-fiber slurry to a beating degree of 19-22 degrees SR through adisc mill, defibering the short-fiber slurry through a high-frequency defibering machine, mixing the defibered short-fiber slurry with the long-fiber slurry according to a proportion of 60:40, and beating the obtained mixture to a beating degree of 26-30 degrees SR through a leveling mill; S3, adding a softening agent of 0.8-1.2 kg / T; S4, enabling the prepared slurry to form original paper; S5, carrying out spraying by a spraying device; S6, linking the start-stop of the spraying device with a rewinder program, and reeling up a coiled paper roll by a rewinder; and S7, carrying out packaging. According to the invention, plant extracts are used as raw materials, skins are not damaged easily, the preparation is simple, and the product quality is improved.

Owner:ZHEJIANG JINGXING PAPER

Preparation method of high-adsorbability ion exchange resin for sewage treatment

InactiveCN107759825AHigh adsorption activityUniform and suitable pore sizeOther chemical processesWater/sewage treatment by sorptionWater bathsIce water

The invention discloses a preparation method of a high-adsorbability ion exchange resin for sewage treatment. The preparation method comprises the following steps: sending macroporous chloromethylatedpolystyrene resin into a piperazine aqueous solution for swelling, adding 2-aminoethanol, carrying out heating, stirring, cooling and washing, adding modified guar gum, stirring the mixture uniformly, and carrying out filtering, washing and drying to obtain pretreated polystyrene resin; and dropwise adding thionyl chloride into the pretreated polystyrene resin in an ice water bath, adjusting thetemperature, keeping the temperature, carrying out cooling, washing and filtering, sending the mixture into nitrobenzene for swelling, and adding trimethylamine for reaction to obtain the high-adsorbability ion exchange resin with for sewage treatment. The modified guar gum is prepared by the following processes: mixing chitosan and glacial acetic acid uniformly, adding water, stirring the materials uniformly, adding polyethylene glycol, carrying out heating and stirring, then carrying out heating, adding guar gum and bamboo charcoal powder and stirring the materials to obtain the modified guar gum.

Owner:ANHUI WANDONG CHEM

Preparation method of pollution-free edible children plasticine

The invention discloses a preparation method of pollution-free edible children plasticine, belonging to the field of preparation of children toys. The preparation method comprises the following steps: washing polished round-grained rice and sticky rice to be clean, mixing the washed polished round-grained rice and sticky rice, soaking the mixed rice by adopting fresh milk after lactobacillus fermentation, so that the ageing resistance of the product is improved, carrying out ball-milling on the soaking solution and the soaked rice to obtain rice milk, carrying out microwave heating gelatinization, carrying out homogenizing treatment, regulating the pH till the pH is neutral, carrying out centrifugal dewatering, carrying out drying, and mixing the dry matter with beewax, glycerinum and the like at a certain ratio, thus obtaining the pollution-free edible children plasticine. According to the preparation method, the adopted raw materials are pollution-free non-toxic materials, so that the obtained plasticine is stable in chemical property, free of toxic and side effects and good in plasticity, can be repeatedly used without deterioration, and can be digested for absorption by the digestive system after being put into the mouth, and no adverse effects are caused to the growth and development of children.

Owner:浙江盛博澳工贸有限公司

Method for producing white attapulgite soft clay

InactiveCN101973059AHigh viscositySoft and malleableCeramic shaping apparatusSodium polyacrylateSoft clay

The invention discloses a method for producing white attapulgite soft clay. Key points of the technical scheme comprise the following steps of: adding a white sand-grain attapulgite mixture into an operating horizontal flour mixing machine, slowly adding solution of sodium polyacrylate gel into the white sand-grain attapulgite mixture and stirring so as to obtain a white clod-shaped attapulgite mixture; and spraying methyl silicone oil onto the white clod-shaped attapulgite mixture, kneading the white clod-shaped attapulgite mixture into semi-finished white attapulgite soft clay, pressing the semi-finished white attapulgite soft clay into flat-plate white attapulgite soft clay, sealing and packaging so as to obtain a finished product. The white attapulgite soft clay has high viscosity, softness and plasticity and small contractibility rate, becomes hard after natural drying, does not need baking, does not crack and has no corrosion and greasy handfeel. After different colors are added into the white attapulgite soft clay, a plurality of colored soft clay can be produced and handicraft articles with clear patterns, bright colors and vivid effects can be made by using attapulgite soft clay with different colors. The white attapulgite soft clay is suitable for molding patterns, molds and handicraft articles.

Owner:南通江涌投资开发有限公司

Method for producing red attapulgite soft clay

The invention discloses a method for producing red attapulgite soft clay. The technical scheme thereof includes the key points that: red sand-like attapulgite mixture is added into an operative horizontal type flour mixing machine, sodium polyacrylate gel solution is slowly added into the red sand-like attapulgite mixture, mixing is carried out, thus obtaining red mud-like attapulgite mixture; methyl silicon oil is sprayed onto the red mud-like attapulgite mixture, and rubbing is carried out, thus obtaining red attapulgite soft clay semi-finished product, and finally pressing is carried out, thus obtaining flat red attapulgite soft clay, and sealing and packaging are carried out, thus obtaining the finished product. The red attapulgite soft clay has high viscosity and is soft and fictile; and the invention has the characteristics that contractibility rate is low, the clay is hard after natural drying, no baking is required, no crack is produced, and the clay is non-corrosive and is not oily. The red attapulgite soft clay can be mixed with attapulgite soft clay of other colours, craft with clear pattern, bright lustre and realistic effect can be made, and the red attapulgite soft clay is applicable to moulding of pattern, mould and craft.

Owner:南通江涌投资开发有限公司

Preparation method of edible plasticene

The invention discloses a preparation method of edible plasticine. The method comprises the following steps: step 1: using fresh milk and deionized water to obtain a fermentation mixture; step 2: adding japonica rice and glutinous rice to the fermentation mixture for fermentation Soaking; step 3: put the material obtained in step 2 into a ball mill, and perform homogenization; step 4: adjust the pH of the material after step 3 homogeneous treatment, and perform dehydration treatment to obtain base material powder; step 5: put The base material powder is mixed with beeswax, glycerin, sodium citrate and deionized water to obtain the final edible plasticine, which is pure white, high in viscosity, and good in flexibility and plasticity.

Owner:华蓥市红军小学

Method for producing yellow attapulgite polymer clay mud

InactiveCN101973065AGood water dispersibilityGood optical performanceCeramic shaping apparatusPolymer scienceSilicone oil

The invention discloses a method for producing yellow attapulgite polymer clay mud, which is characterized by comprising the following steps: adding yellow granular attapulgite mixture into a running horizontal flour-mixing machine, and slowly adding sodium polyacrylate gel solution into the yellow granular attapulgite mixture, then stirring the obtained products so as to obtain yellow mud block shaped attapulgite mixture; spraying methyl-silicone oil on the yellow mud block shaped attapulgite mixture, and kneading the attapulgite mixture so as to obtain a semi-finished product of yellow attapulgite polymer clay mud; finally, pressing the semi-finished product of yellow attapulgite polymer clay mud into flattening yellow attapulgite polymer clay mud, and carrying out sealed package on the obtained flattening yellow attapulgite polymer clay mud so as to obtain the finished product of the yellow attapulgite polymer clay mud. The yellow attapulgite polymer clay mud produced by using the method of the invention has the characteristics of high viscosity, good soft plasticity, low shrinkage rate, no baking in the process of hardening after air drying, no cracking, no corrosivity, and no greasy feeling. When the yellow attapulgite polymer clay mud is mixed with the attapulgite polymer clay mud in other colors, handicraft products with clear patterns, bright colors and lifelike effects can be produced; and the yellow attapulgite polymer clay mud is suitable for shaping patterns, moulds and handicraft products.

Owner:JIANGSU DAHAI PLASTIC

Production method of fluorescent colour attapulgite clay

InactiveCN101973060AHigh viscositySoft and malleableCeramic shaping apparatusFluorescenceSodium polyacrylate

The invention discloses a production method of fluorescent colour attapulgite clay. The method comprises the following main steps of: adding a fluorescent colour sand attapulgite mixture into a running horizontal type flour-mixing machine, slowly adding sodium polyacrylate gel solution into the fluorescent colour sand attapulgite mixture, and stirring to form a fluorescent colour blocky attapulgite mixture; and spraying methyl silicone oil onto the fluorescent colour blocky attapulgite mixture, kneading to form a semi-finished product of fluorescent colour attapulgite clay, finally pressing to form flat plate type fluorescent colour attapulgite clay, and sealing and packaging the flat plate type fluorescent colour attapulgite clay to obtain the product. The fluorescent colour attapulgite clay has high viscosity and good flexible plasticity, and has the characteristics of low contractibility rate, capability of becoming hard after naturally drying without baking, no generated crack, no corrosivity and no greasy feel. The fluorescent colour attapulgite clay can bring a charming fluorescent visual effect and is suitable for making fluorescent colour patterns, moulds and handiworks.

Owner:南通久通建筑机械有限公司

Economic benefit-increasing sheep feed

InactiveCN107212164ARaise the ratioThe ingredients are scientific and reasonableFood processingAnimal feeding stuffIntestinal structureAnimal science

The invention discloses economic benefit-increasing sheep feed. The sheep feed includes the following ingredients in parts by weight: 10-20 parts of peanut meal, 15-25 parts of potato protein powder, 10-20 parts of fermented blood meal, 10-20 parts of earthworm powder, 20-40 parts of clamworm powder, 6-12 parts of dried cabbageworm powder, 110-120 parts of plant-based main materials, 0.5-0.8 part of an intestine-improving agent, 4-8 parts of corn oil, 4-8 parts of shell powder, 2-4 parts of zeolite powder and 8-16 parts of an attapulgite compound. The sheep feed provided by the invention has the advantages of a simple formula, scientific and reasonable components, easily available ingredients and low cost. The sheep feed also can increase economic benefits and improve the mutton quality of captive sheep without influencing the ecology.

Owner:郑其全

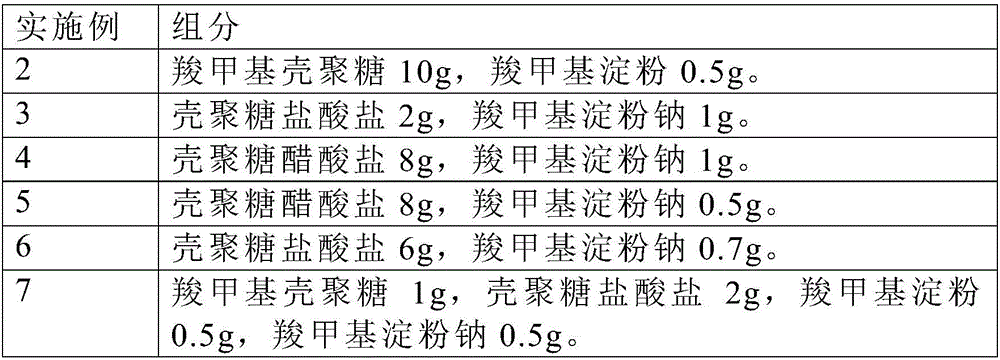

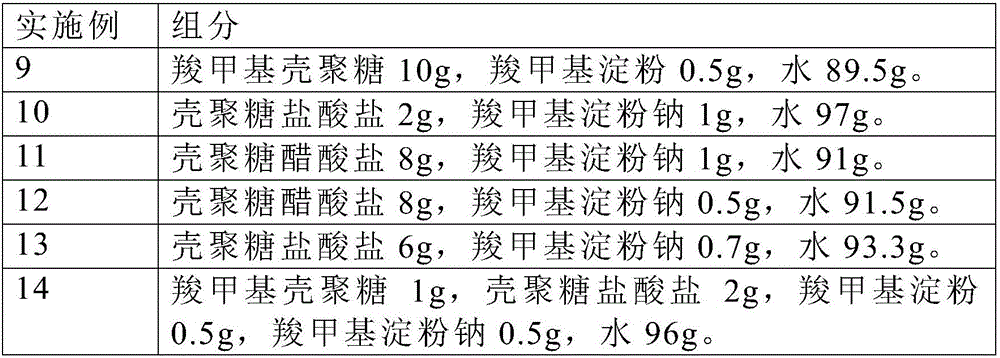

Medical composite chitosan functional dressing and preparation method thereof

The invention belongs to the technical field of a medical article, and relates to a medical composite chitosan functional dressing and a preparation method thereof. The method comprises the following steps of A, weighing a certain amount of water-soluble chitosan or salts and carboxymethyl starch or sodium starch glycolate; putting the materials into a stirring device; adding a certain amount of water; performing stirring so that the solution foams and expands to obtain a preparation solution; B, weighing the preparation solution; injecting the preparation solution into a silicon rubber mold disc; pressing a cap for sealing; then, putting the materials into a -20 DEG C refrigerator for quick freezing and forming; C, putting a quick freezing and forming product in the step B into a vacuum freeze drying machine for freeze drying; performing sterilization and packaging after the demoulding; then performing preparation to obtain the composite chitosan functional dressing. The preparation method provided by the invention has the advantages that the process is simple; the method is suitable for industrial production; the prepared composite chitosan functional dressing has high adsorption capability, high moisture preservation performance and high softness plasticity.

Owner:HANGZHOU YINGJIAN BIOTECHNOLOGY CO LTD

A kind of preparation method of green edible plasticine for children

Owner:浙江盛博澳工贸有限公司

Method for producing green attapulgite polymer clay

InactiveCN101973064AGood water dispersibilityGood optical performanceCeramic shaping apparatusCooking & bakingPolymer science

The invention discloses a method for producing green attapulgite polymer clay, the technical scheme thereof is characterized by adding green sand-grain shaped attapulgite mixture to a running horizontal type flour-mixing machine, slowly adding sodium polyacrylate sol-gel to the green sand-grain shaped attapulgite mixture, and stirring the mixture to obtain green massive attapulgite mixture; spraying methyl silicon oil on the green massive attapulgite mixture, and rubbing the sprayed mixture to obtain the semi-finished product of the green attapulgite polymer clay; and finally suppressing the green attapulgite polymer clay to form the flat green attapulgite polymer clay, and sealing and packaging the flat green attapulgite polymer clay to obtain the finished product. The green attapulgite polymer clay has the advantages of high viscosity, good soft plasticity, and small contractibility rate; in addition, the green attapulgite polymer clay is hardened after being subject to air dry, in no need of baking, and has nonoccurrence of cracks, no corrosiveness and non-greasy feeling. The green attapulgite polymer clay is mixed with other colorific attapulgite polymer clay for use, thus being capable of shaping artwares with clear patterns, fresh and lovely luster and vivid effect; and the green attapulgite polymer clay is suitable for the shaping of patterns, moulds and artwares.

Owner:南通江涌投资开发有限公司

Green attapulgite polymer clay powder

InactiveCN101973741AHigh viscositySoft and malleableSodium polyacrylateSodium carboxymethylcellulose

The invention discloses a green attapulgite polymer clay powder, which is prepared by using purified attapulgite clay, white bentonite, sepiolite, ferric oxide green, organic pigment green, calcium chloride, titanium dioxide anatase, sodium polyacrylate, sodium carboxymethylcellulose and sodium stearoyl lactate as raw materials through the steps of mixing the raw materials above; conveying the obtained mixture into a crusher to crush; then conveying the crushed mixture into a pulverizing mill to pulverize; and packaging the obtained product so as to obtain the finished product of the green attapulgite polymer clay powder. Green attapulgite polymer clay mud prepared by adding water and methyl silicone oil into the green attapulgite polymer clay powder has the advantages of high viscosity, good soft plasticity, low shrinkage rate, no baking in the process of hardening after air drying, no cracking, no corrosivity, and no greasy feeling. The invention is simple in production process, low in cost, easy to use, and beneficial for popularization; and the green attapulgite polymer clay powder is suitable for the field preparation of green attapulgite polymer clay mud.

Owner:南通江涌投资开发有限公司

Production method of black attapulgite polymer clay

InactiveCN101973062AHigh viscositySoft and malleableCeramic shaping apparatusCooking & bakingPolymer science

The invention discloses a production method of black attapulgite polymer clay. The technical scheme of the method is characterized by comprising the following steps: adding black sand-like attapulgite mixture to an operating horizontal flour-mixing machine, slowly adding sodium polyacrylate gel solution into the black sand-like attapulgite mixture, and then stirring to obtain black clod-like attapulgite mixture; spraying methyl silicone oil on the black clod-like attapulgite mixture, kneading to obtain the semi-finished product of black attapulgite polymer clay; and finally pressing the semi-finished product into a flat shape, sealing and packaging to obtain a finished product. The black attapulgite polymer clay has the characteristics of high viscosity, good soft plasticity, small shrinkage rate, no need of baking, no cracking, no corrosion and no greasy feeling, and can be hardened after natural drying. When the black attapulgite polymer clay is mixed with attapulgite polymer clay in other colors for use, artware with clear patterns, bright colors and vivid effect can be shaped, and the black attapulgite polymer clay is applicable to the shaping of patterns, molds and artware.

Owner:南通江涌投资开发有限公司

Cable for frequency-control shield tunneling machines

InactiveCN107216554AGood weather resistanceIncreased durabilityInsulated cablesInsulated conductorsMicrocrystalline waxEngineering

The invention discloses a cable for a variable frequency speed regulating shield machine, which comprises a cable core and a sheath layer wrapped on the outside of the cable core. The sheath layer raw materials by weight include: 100-110 parts of main materials, benzene petroleum sulfonate 1-2 parts of ester, 2.5-4.5 parts of coupling agent, 20-40 parts of pine tobacco compound, 5-15 parts of bamboo powder, 2-8 parts of aramid fiber, 3-10 parts of barium sulfate whisker, microcrystalline fiber 5-12 parts of calcium, 2-6 parts of microencapsulated red phosphorus, 0.5-1.5 parts of dioctyl phthalate, 1-1.8 parts of microcrystalline paraffin, 1-2 parts of UV absorber RMB, acrylonitrile-butanedi 1-2 parts of ethylene-styrene copolymer. The invention can resist tensile, deformation and external force, and has excellent weather resistance and durability, can protect the metal material inside the cable for a long time, prevent oxidation corrosion, and also has very high mechanical strength.

Owner:ANHUI ELECTRIC GRP SHARES

Production method of purple attapulgite soft ceramic clay

The invention discloses a production method of purple attapulgite soft ceramic clay. The technical scheme has the key points of: adding a purple attapulgite mixture into a horizontal flour-mixing machine in operation, slowly adding a sodium polyacrylate gel solution into the purple attapulgite mixture, and mixing into a purple clay and attapulgite mixture; sprinkling methyl silicone oil on the purple clay and attapulgite mixture, and kneading into a semi-finished product of purple attapulgite soft ceramic clay; and finally pressing into a flat plate type purple attapulgite soft ceramic clay, sealing and packaging into a finished product. The purple attapulgite soft ceramic clay has the characteristics of high viscosity, good soft plasticity, small shrinkage rate, hardening after natural drying, no need of roasting, no production of crazing, no corrosiveness and no greasy taste. The purple attapulgite soft ceramic clay is used together with other colors of attapulgite soft ceramic clay, and artworks with clear patterns, right color and vivid effect can be molded. The purple attapulgite soft ceramic clay is applicable to the molding of patterns, molds and artworks.

Owner:南通江涌投资开发有限公司

Method for producing luminous attapulgite polymer clay

InactiveCN101973731AHigh viscositySoft and malleableLuminescent compositionsLuminous paintPolymer science

The invention discloses a method for producing luminous attapulgite polymer clay. The key points of the technical scheme of the method comprise the following steps of: adding a sand-like attapulgite mixture into a horizontal dough kneading machine which has run, slowly adding gel solution of sodium polyacrylate into the sand-like attapulgite mixture and mixing to obtain a mud block-shaped attapulgite mixture; spraying luminous paint and methyl silicone oil on the mud block-shaped attapulgite mixture; kneading to obtain the luminous attapulgite polymer clay half-finished product; and finally pressing to obtain planar luminous attapulgite polymer clay and hermetically packaging to form the finished product. The luminous attapulgite polymer clay has the characteristics of high viscosity, high softness and plasticity and small shrinkage rate, becomes hard by natural drying, does not crack and does not have corrosion or greasy feel. The luminous attapulgite polymer clay can emit light for over 6 hours after absorbing light on a bright part for 10 to 30 minutes, so that the appreciation of handicraft articles is greatly improved; and the luminous attapulgite polymer clay is suitable for molding a luminous pattern, a mould and the handicraft articles.

Owner:JIANGSU DAHAI PLASTIC

A sludge recovery device

ActiveCN106734094BFully filteredHigh viscositySolid waste disposalMagnetic separationWaste oilOil sludge

The invention belongs to the technical field of oil sludge recovery and particularly relates to an oil sludge recovery device. An oil sludge recovery bin is fixedly provided with a jaw crusher; the oil sludge recovery bin is provided with a rolling compaction device below the jaw crusher; a sludge outlet located below the oil sludge recovery bin is a tapered opening; the large-caliber end of the tapered opening is movably provided with a filter plate; the upper layer surface of the filter plate is provided with a magnet; a plurality of filter holes are formed in the filter plate; the small-caliber end of the tapered opening is connected with a return pipe communicating with a feeding hole of the jaw crusher; the oil sludge recovery bin is fixedly provided with a blast blower; an air outlet of the blast blower is located below the rolling compaction device; the outer side of the oil sludge recovery bin is connected with an impurity removal box which is opposite to a wind gap of the blast blower and communicates with the oil sludge recovery bin; the impurity removal box is internally provided with a magnet block; and an extrusion device is arranged below the impurity removal box. The problems that the surface of an oil sludge model prepared from oil sludge is easily enabled to be rough and the visual effect of the oil sludge model is poor when waste oil sludge with scrap iron is secondarily used are solved.

Owner:CHONGQING TENGTONG IND DESIGN

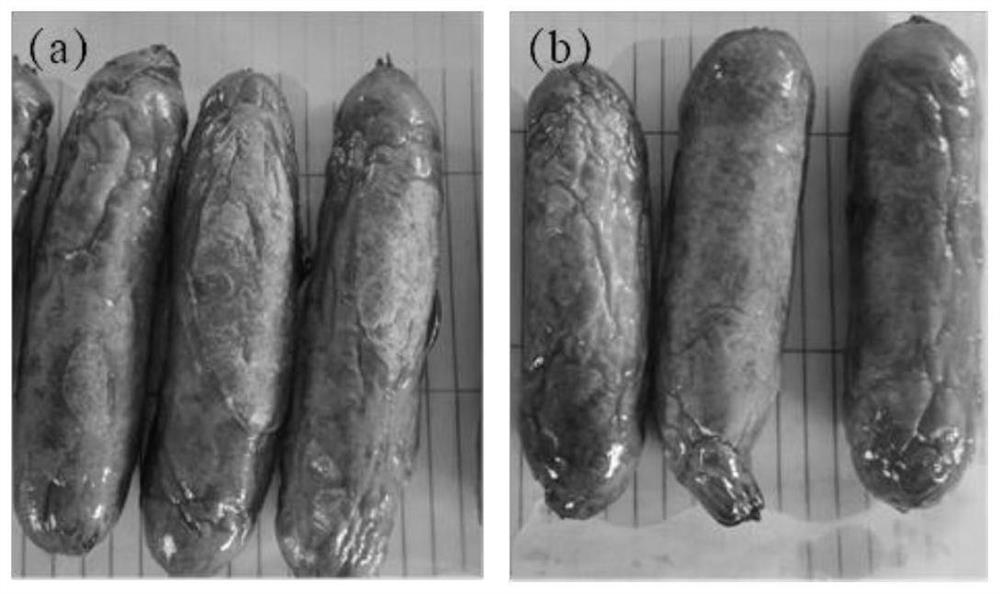

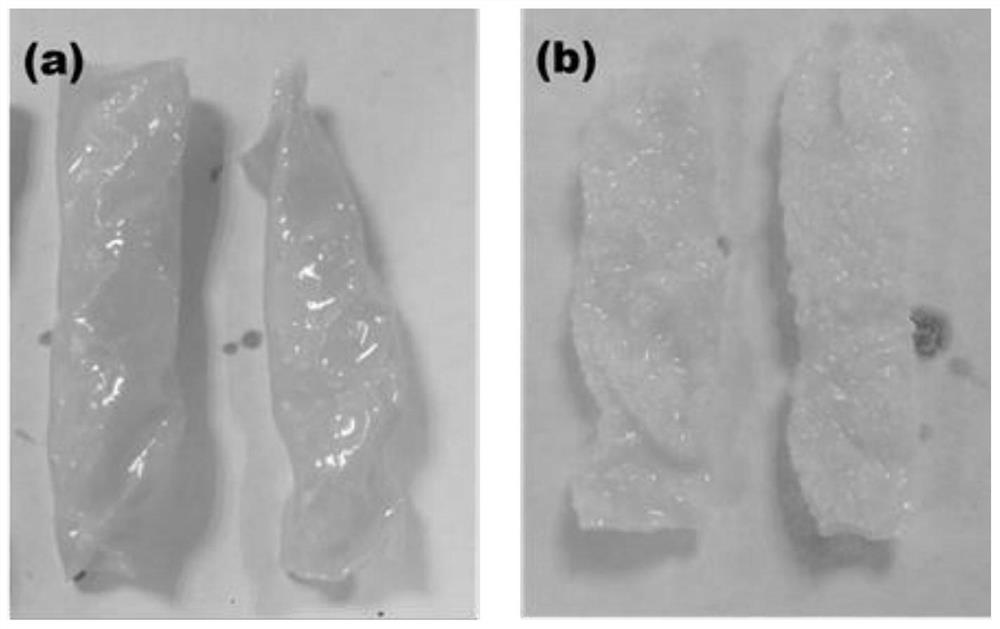

Method for preparing deep-fried collagen casings by wet soaking

The invention provides a method for preparing deep-fried collagen casings by wet soaking. The method comprises the following steps: mincing cowhide, pickling for the first time, homogenizing, curing, cross-linking, washing, plasticizing, drying and rewetting to obtain the deep-fried collagen casings. The deep-fried collagen casings prepared by the method have the advantages that the taste, the viscosity and the deep-frying characteristic are obviously improved.

Owner:JIANGNAN UNIV

Production method of black attapulgite polymer clay

InactiveCN101973062BHigh viscositySoft and malleableCeramic shaping apparatusCooking & bakingPolymer science

The invention discloses a production method of black attapulgite polymer clay. The technical scheme of the method is characterized by comprising the following steps: adding black sand-like attapulgite mixture to an operating horizontal flour-mixing machine, slowly adding sodium polyacrylate gel solution into the black sand-like attapulgite mixture, and then stirring to obtain black clod-like attapulgite mixture; spraying methyl silicone oil on the black clod-like attapulgite mixture, kneading to obtain the semi-finished product of black attapulgite polymer clay; and finally pressing the semi-finished product into a flat shape, sealing and packaging to obtain a finished product. The black attapulgite polymer clay has the characteristics of high viscosity, good soft plasticity, small shrinkage rate, no need of baking, no cracking, no corrosion and no greasy feeling, and can be hardened after natural drying. When the black attapulgite polymer clay is mixed with attapulgite polymer clay in other colors for use, artware with clear patterns, bright colors and vivid effect can be shaped, and the black attapulgite polymer clay is applicable to the shaping of patterns, molds and artware.

Owner:南通江涌投资开发有限公司

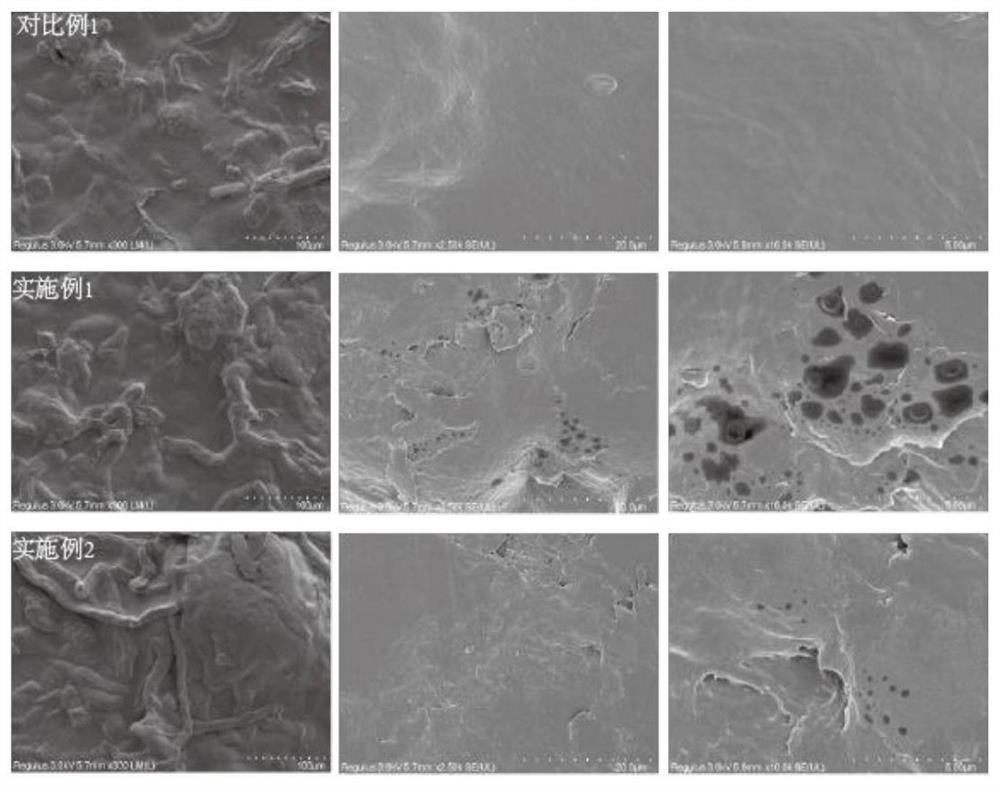

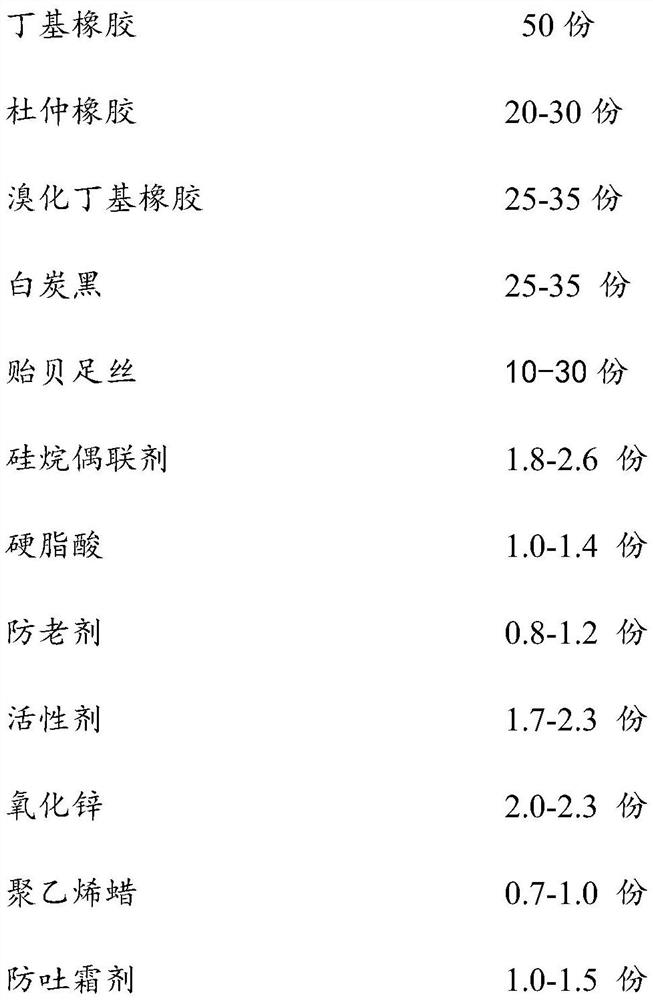

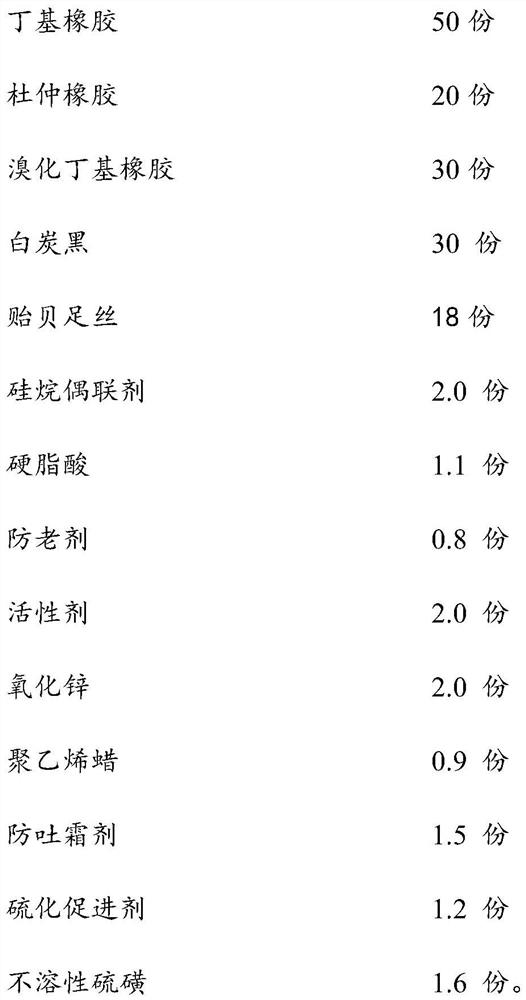

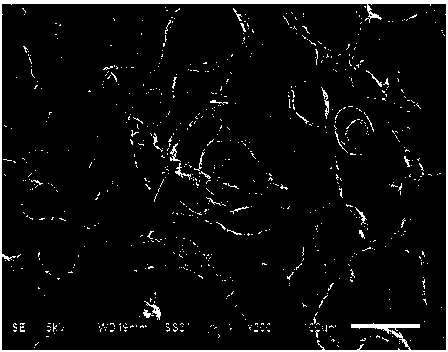

Preparation method of mussel byssus antiskid rubber sole

The invention discloses a mussel byssus antiskid rubber sole and a preparation method thereof. The sole is prepared from eucommia ulmoides rubber, butyl rubber, brominated butyl rubber, white carbon black, an anti-aging agent, mussel byssus, a silane coupling agent, stearic acid, an anti-aging agent, an active agent, zinc oxide, polyethylene wax, an anti-frosting agent, sulfur and a vulcanization accelerator, wherein the mussel byssus is taken from fresh mussels and comprises a stem part, a silk thread part and a root part which are connected in sequence, so that a three-dimensional support structure is formed. The waste byssus in the mussel processing process is fully utilized as a biological raw material, and the toughness of the rubber sole base material is improved.

Owner:MAOTAI FUJIAN SOLES CO LTD +1

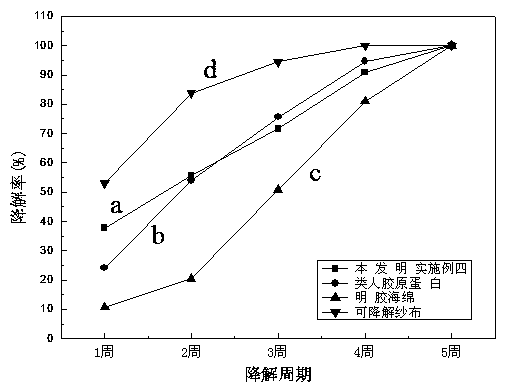

Starch-derived absorbable medical sponge and preparation method thereof

The invention discloses a starch-derived absorbable medical sponge and a preparation method thereof. The starch-derived absorbable medical sponge is a composition comprising the following components by mass percent: 0.08-12% of absorbable starches, 0.0001-6% of foaming agents and 0.005-9% of moisturizing agents. According to the preparation method, the absorbable starches are utilized to prepare the starch sponge with better water-absorbing property and hemostasis property, and zoogenous extracts are unnecessary to be added. The starch sponge overcomes the defect that the existing starch sponge has fragile texture, and the starch sponge is loose and porous and has uniform holes and better hemostatic effect and internal degradation rate.

Owner:JIANGSU DIWO BIOLOGICAL PROD

Chitosan sponge surgical dressing and preparation method thereof

ActiveCN103341202BEasy to demouldEasy to wrapAbsorbent padsBandagesFoaming agentWater soluble chitosan

Owner:JIANGSU DIWO BIOLOGICAL PROD

Production method for blue attapulgite soft clay

The invention discloses a production method for blue attapulgite soft clay, which has a technical scheme as follows: adding the mixture of the blue sand-shaped attapulgite into an operating horizontal type flour-mixing machine; slowly adding sodium polyacrylate gel solution into the mixture of the blue sand-shaped attapulgite, and stirring to obtain another mixture of the blue sand-shaped attapulgite; spraying methylsiliconeoil on the mixture of the blue sand-shaped attapulgite; rubbing into a semi-finished product of the blue attapulgite soft clay; and finally pressing into a plane-shaped blue attapulgite soft clay, and sealing and packing into a finished product. The blue attapulgite soft clay has high viscosity, good soft plasticity, small contractibility rate, changes hard after beingdried naturally, does not need baking, does not generate checking, and is corrosiveness-free and has no greasy feeling. The blue attapulgite soft clay can be mixed with the attapulgite soft clay withother colors for shaping handiworks which have clear pattern, bright color and vivid effect; and the blue attapulgite soft clay is applied to shape patterns, moulds and handiworks.

Owner:南通江涌投资开发有限公司

Method for producing red attapulgite soft clay

The invention discloses a method for producing red attapulgite soft clay. The technical scheme thereof includes the key points that: red sand-like attapulgite mixture is added into an operative horizontal type flour mixing machine, sodium polyacrylate gel solution is slowly added into the red sand-like attapulgite mixture, mixing is carried out, thus obtaining red mud-like attapulgite mixture; methyl silicon oil is sprayed onto the red mud-like attapulgite mixture, and rubbing is carried out, thus obtaining red attapulgite soft clay semi-finished product, and finally pressing is carried out, thus obtaining flat red attapulgite soft clay, and sealing and packaging are carried out, thus obtaining the finished product. The red attapulgite soft clay has high viscosity and is soft and fictile;and the invention has the characteristics that contractibility rate is low, the clay is hard after natural drying, no baking is required, no crack is produced, and the clay is non-corrosive and is not oily. The red attapulgite soft clay can be mixed with attapulgite soft clay of other colours, craft with clear pattern, bright lustre and realistic effect can be made, and the red attapulgite soft clay is applicable to moulding of pattern, mould and craft.

Owner:南通江涌投资开发有限公司

Production method of purple attapulgite soft ceramic clay

The invention discloses a production method of purple attapulgite soft ceramic clay. The technical scheme has the key points of: adding a purple attapulgite mixture into a horizontal flour-mixing machine in operation, slowly adding a sodium polyacrylate gel solution into the purple attapulgite mixture, and mixing into a purple clay and attapulgite mixture; sprinkling methyl silicone oil on the purple clay and attapulgite mixture, and kneading into a semi-finished product of purple attapulgite soft ceramic clay; and finally pressing into a flat plate type purple attapulgite soft ceramic clay, sealing and packaging into a finished product. The purple attapulgite soft ceramic clay has the characteristics of high viscosity, good soft plasticity, small shrinkage rate, hardening after natural drying, no need of roasting, no production of crazing, no corrosiveness and no greasy taste. The purple attapulgite soft ceramic clay is used together with other colors of attapulgite soft ceramic clay, and artworks with clear patterns, right color and vivid effect can be molded. The purple attapulgite soft ceramic clay is applicable to the molding of patterns, molds and artworks.

Owner:南通江涌投资开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com