Patents

Literature

146 results about "Plasticine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasticine, a brand of modelling clay, is a putty-like modelling material made from calcium salts, petroleum jelly and aliphatic acids. Plasticine is used extensively for children's play, but also as a modelling medium for more formal or permanent structures. Because of its non-drying property, it is a popular choice of material for stop-motion animation, including several Oscar-winning films by Nick Park. The brand-name clay is sometimes mentioned in British music, such as the "plasticine porters" in the Beatles' "Lucy in the Sky with Diamonds", the Oasis songs "Little James" and "Shakermaker", and the Placebo song "Plasticine".

Permanently plastic plasticine for fire-protection applications, methods for its preparation and its use

InactiveUS20050032934A1Reduce the probability of burningHigh inflation pressureOther chemical processesSpecial tyresFire protectionThermal insulation

A permanently plastic Plasticine for fire-protection applications is described, comprising a matrix composition, which contains fire-protection additives and conventional auxiliary materials and is based on organic polymers, and a method for its preparation and its use for the fire-protecting sealing of openings, cable and pipe bushings in walls, floors and / or ceilings, of joints between ceiling parts and wall parts, between masonry openings and construction parts, which are to be installed, such as window frames and door frames, between ceilings and walls and between exterior walls and curtaining facades, for the purpose of thermal insulation and / or fire protection, are described.

Owner:HILTI AG

Processing technology of silicon rubber mould

The invention provides a silicone rubber mold manufacturing process, the process is: 1. labeling a layer clay or plasticine on one side surface of exemplar prototype mouldjoint and producing a template frame of semi-mold; 2. casting the gypsum slurry into template frame; 3. removing the clay or plasticine layer from exemplar prototype mouldjoint after the gypsum slurry congealing, and cleaning the cavity; 4. deploying the silicone rubber uniformly and debubbling at vacuum, pouring it in the cavity of gypsum and exemplar prototype surface, and sulfidizating the silicone rubber materials; 5. Removing the exemplar prototype and cleaning the cavity; 6. producing another semi-mold through the above steps. The process of the invention only cast one layer of silicone rubber material on the mold cavity surface, reduces silicone rubber material consumption, reduces the mold production costs, while the product is easy to be taken out from the thin-walled silicone rubber mold, it overcomes the product quality problem caused by the poured product by traditional silicon rubber mold is different be taken out in the demolding process, it improves the life of silicone rubber mold.

Owner:SHANDONG UNIV

Glass flake plasticine coating

InactiveCN1789351AImprove heat resistanceImprove mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsVinyl esterCoating

The invention provides a glass flake clay paint, whose constituents include (by weight ratio) vinyl ester 55-65%, glass flake 25-35%, and addition agent 0.001-10%. The paint has good tenacity, fatigue resistance, antiseep property and hermeticity.

Owner:吴凡 +1

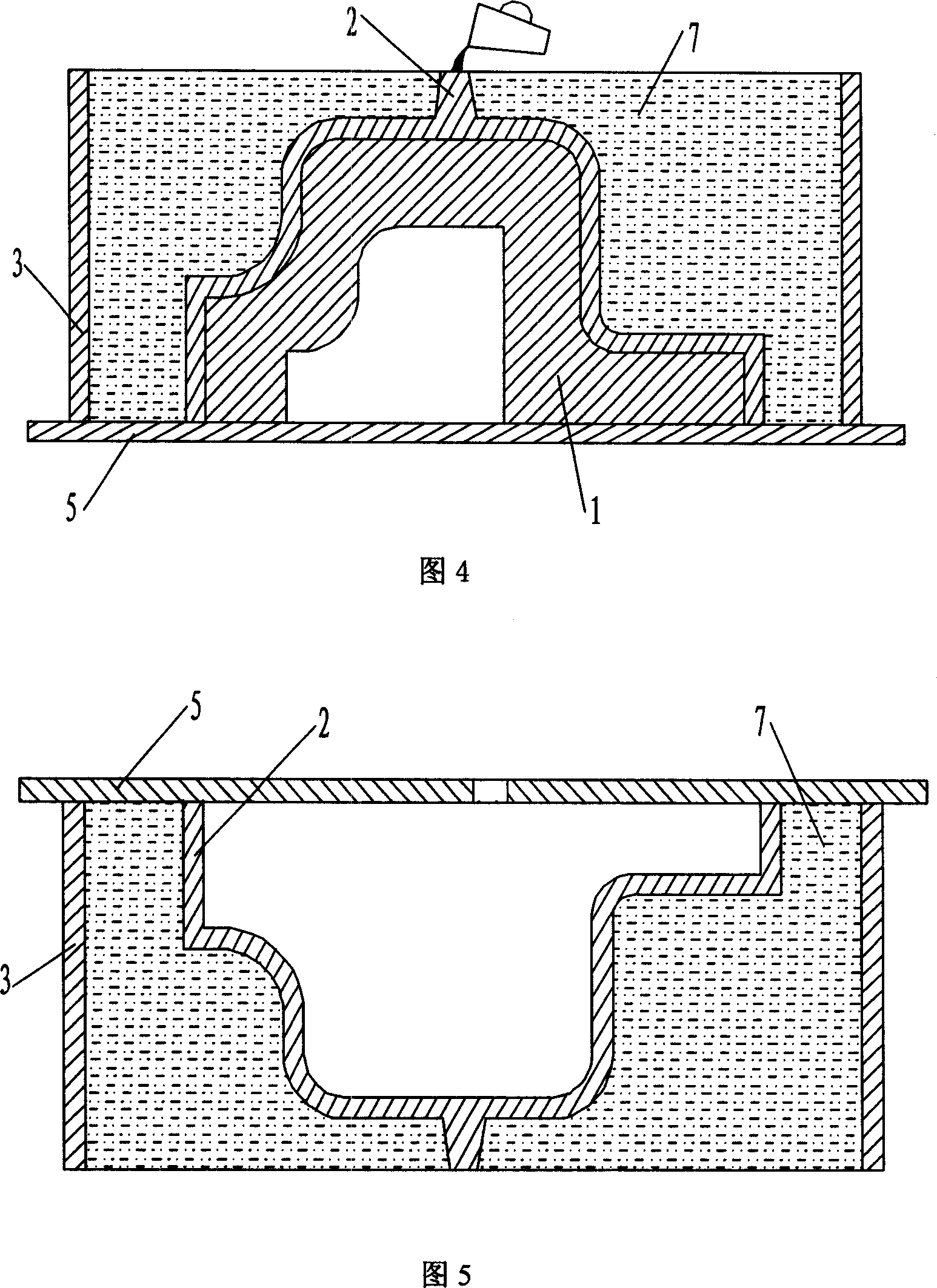

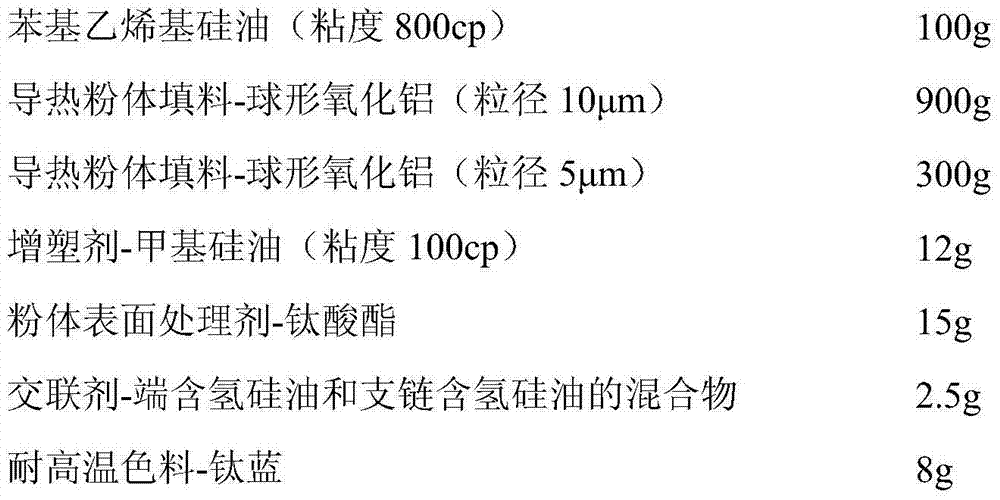

High-thermal-conductivity organosilicone mud and preparation method thereof

ActiveCN104497575AIncrease filling volumeReduce molecular forcesHeat-exchange elementsHeat conductingTemperature resistance

The invention discloses a high-thermal-conductivity organosilicone mud. The high-thermal-conductivity organosilicone mud is prepared from the following raw materials: 100 parts of silicone oil and 1000-1200 parts of heat-conducting powder filler in parts by weight, 0.5-1wt% of plasticizer and 1-3wt% of powder surface treating agent in terms of the heat-conducting powder filler, and 1-3wt% of cross-linking agent, 5-10wt% of high temperature resistant pigment and 0.01-0.015wt% of platinum catalyst in terms of the silicone oil. Besides, the invention also discloses a preparation method of the high-thermal-conductivity organosilicone mud. The high-thermal-conductivity organosilicone mud product has the advantages of high thermal conductivity, stable heat transfer property, excellent high temperature resistance, plasticity just as plasticine and the like; the preparation method of the high-thermal-conductivity organosilicone mud is simple; a better thermal-conductivity solution way can be provided for electronic heating components and radiating or other cooling devices.

Owner:GUANGZHOU BAIYUN CHEM IND

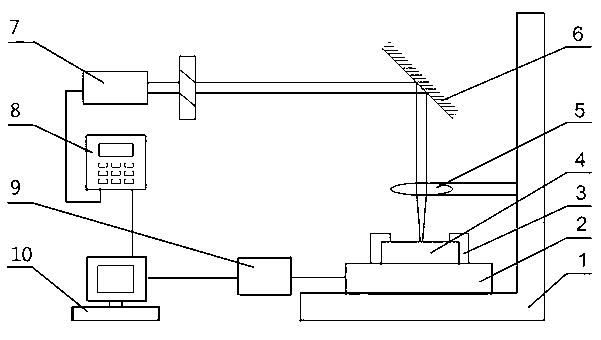

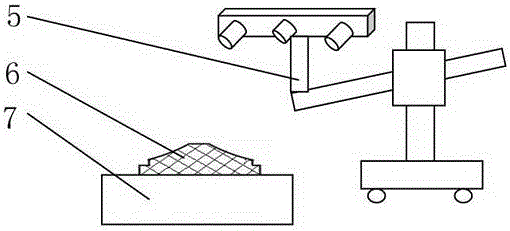

Object volume non-contact measuring method and device based on reflection mirror secondary imaging

ActiveCN104215178AImprove edge contrastImprove sharpnessUsing optical meansCamera lensTelecentric lens

The invention relates to an object volume non-contact measuring method and device based on reflection mirror secondary imaging. The device comprises a rotary carrier table, wherein a first parallel light source is flatly arranged on the rotary carrier table, a plane reflection mirror forming a 45-angle included angle in the vertical direction is arranged above the rotary carrier table, a second parallel light source is vertically arranged beside the rotary carrier table, a double-side telecentric lens rightly facing the second parallel light source is arranged beside the rotary carrier table and installed on a CCD video camera, and a laser device for horizontally transmitting laser to the plane reflection mirror so as to reflect the laser to the center of the rotary carrier table is arranged above the CCD video camera. Compared with conventional methods, a great breakthrough on time and accuracy is achieved, and the device is simple in structure, diffuse reflection can be measured, complicated object surfaces similar to plasticine and the like can be measured, and the reliable technical device and method is used for non-contact accurate object volume measurement.

Owner:FUJIAN NORMAL UNIV

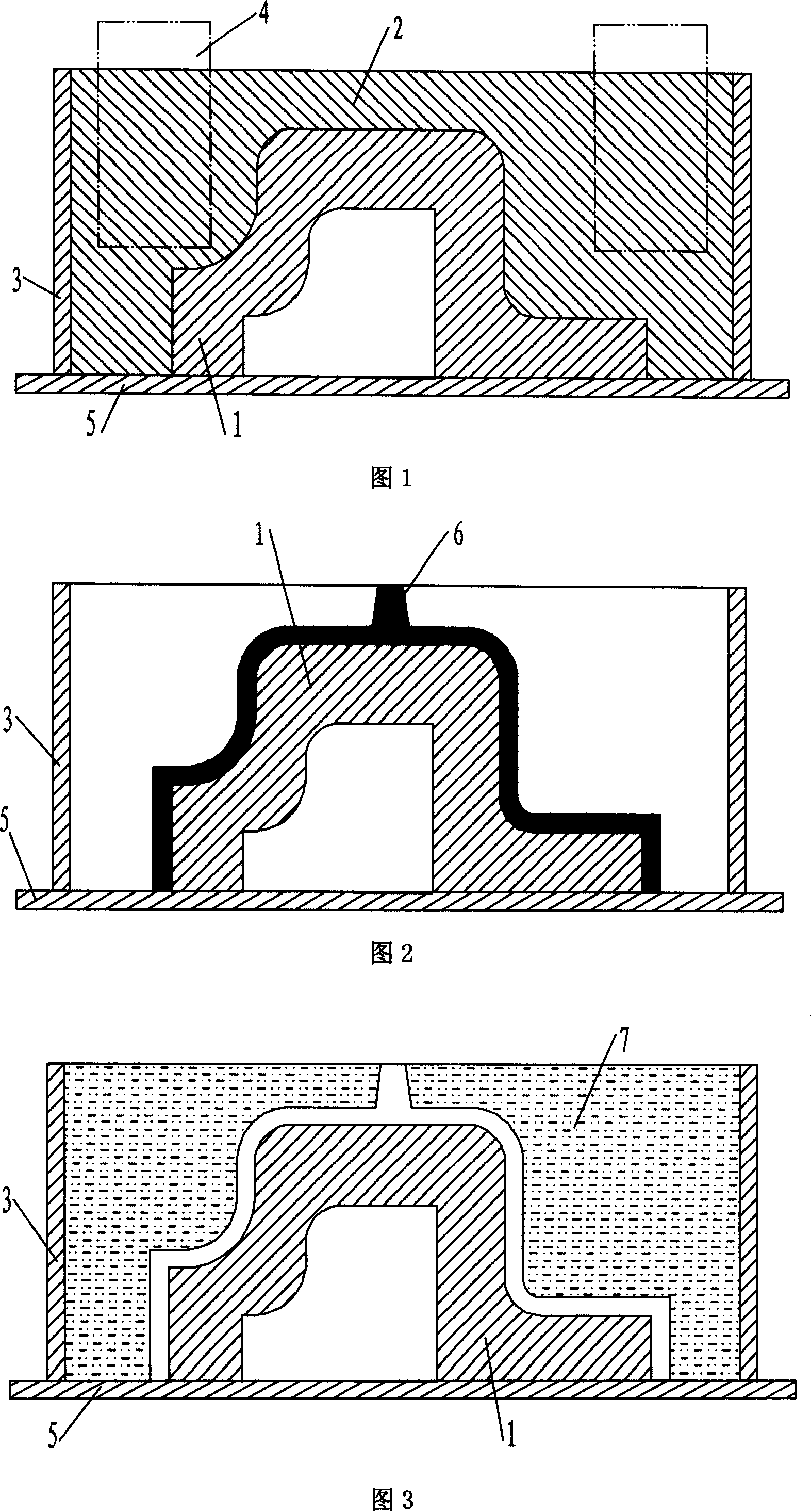

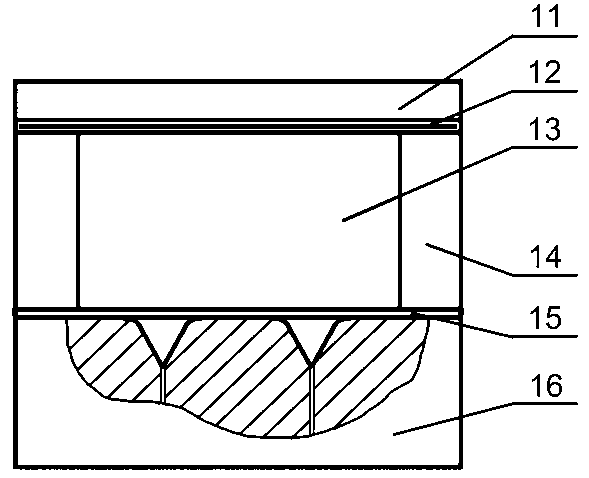

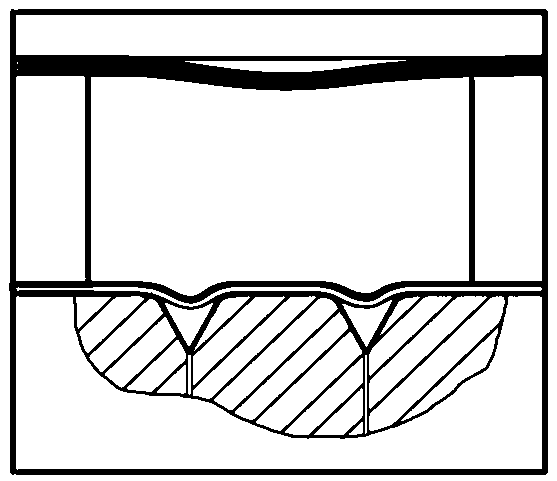

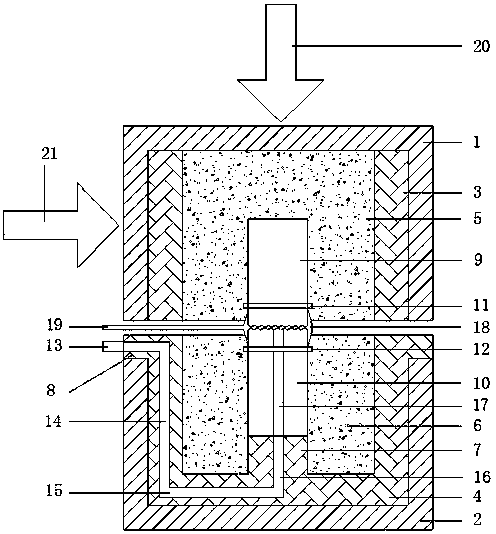

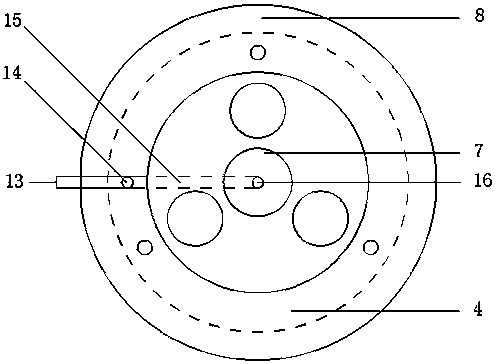

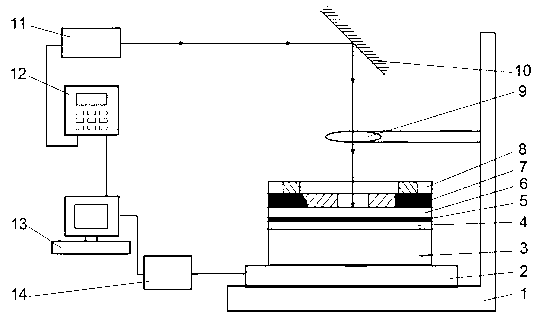

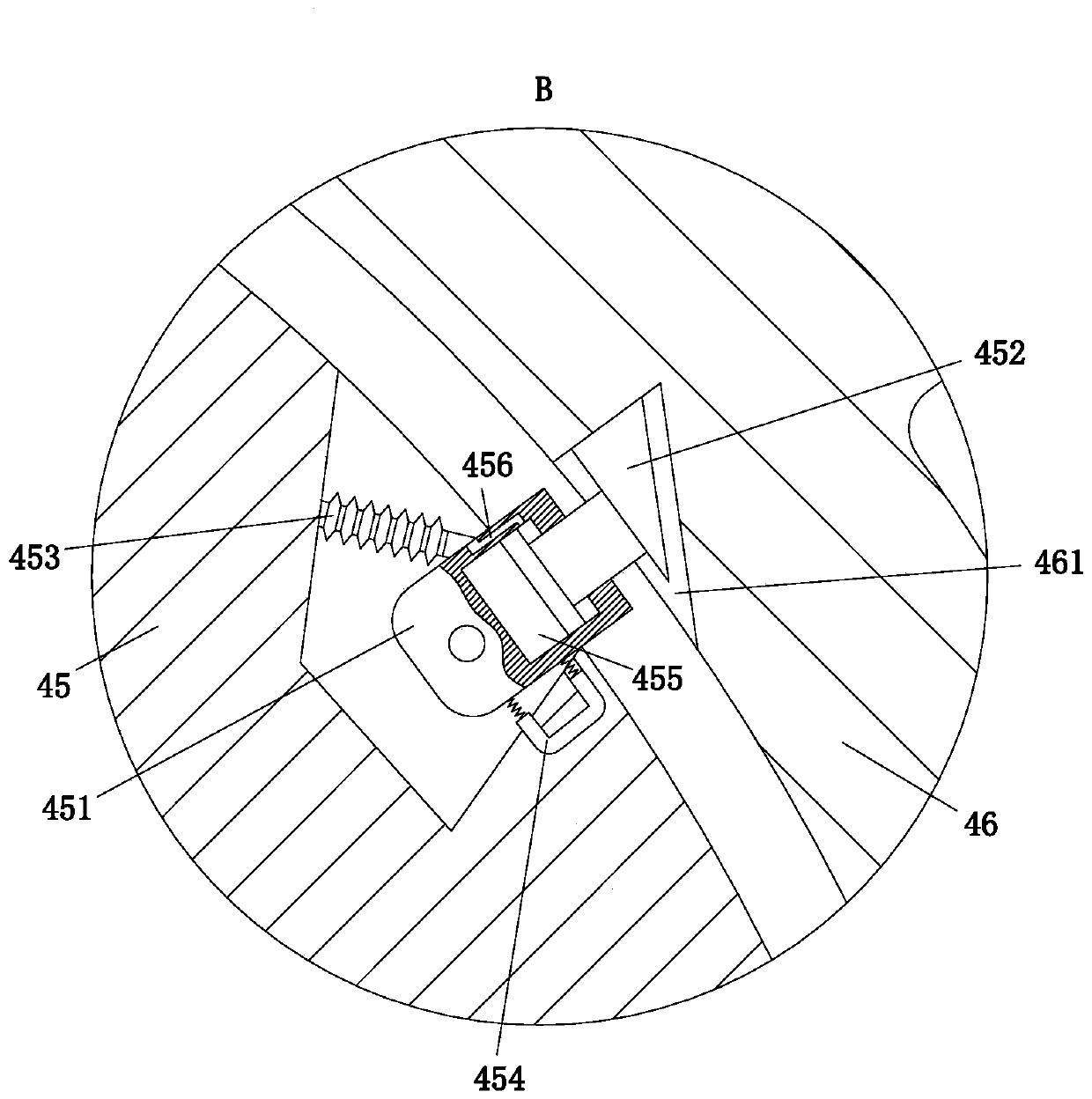

Precise micro-forming device and method thereof based on laser continuous stamping plasticine technology

InactiveCN103252588APrevent springbackEven by forceLaser beam welding apparatusComputer control systemNanosecond laser

The invention discloses a precise micro-forming device and a method thereof based on a laser continuous stamping plasticine technology. The device comprises a laser loading system, a plastic forming system and a computer control system. The laser loading system comprises a nanosecond laser, a reflection mirror and a focusing lens. The plastic forming system comprises a sample system, a clamp body, a three-dimensional moving platform and a base. The computer control system comprises a three-dimensional moving platform controller, a laser controller and a computer. According to the device and the method, plasticine is used for transmitting impact force, in a multi-time impact process, the plasticine and a workpiece are attached together gradually, stress on the workpiece is even, scratching cannot happen, surface quality of the workpiece is improved, and meanwhile according to the characteristic that the plasticine deforms in an plastic mode after being stressed, the workpiece and a micro mould can be attached with each other, rebounding of the workpiece is avoided, and forming precision of the workpiece is guaranteed.

Owner:JIANGSU UNIV

Non-toxic plasticine and preparation method thereof

The invention discloses a non-toxic plasticine and a preparation method thereof. The non-toxic plasticine is prepared from an edible flour material and water which are used as a base material, wherein the non-toxic plasticine contains collagen and nanogold sol, is excellent in elasticity, not easy to crack, environmental-friendly, non-toxic and harmless, has good moulding property and good drying resistance effect and relatively strong antibacterial action, and is suitable for being used by children. The preparation method provided by the invention is simple, convenient and easy to operate.

Owner:南京北福泉圣环保科技有限公司

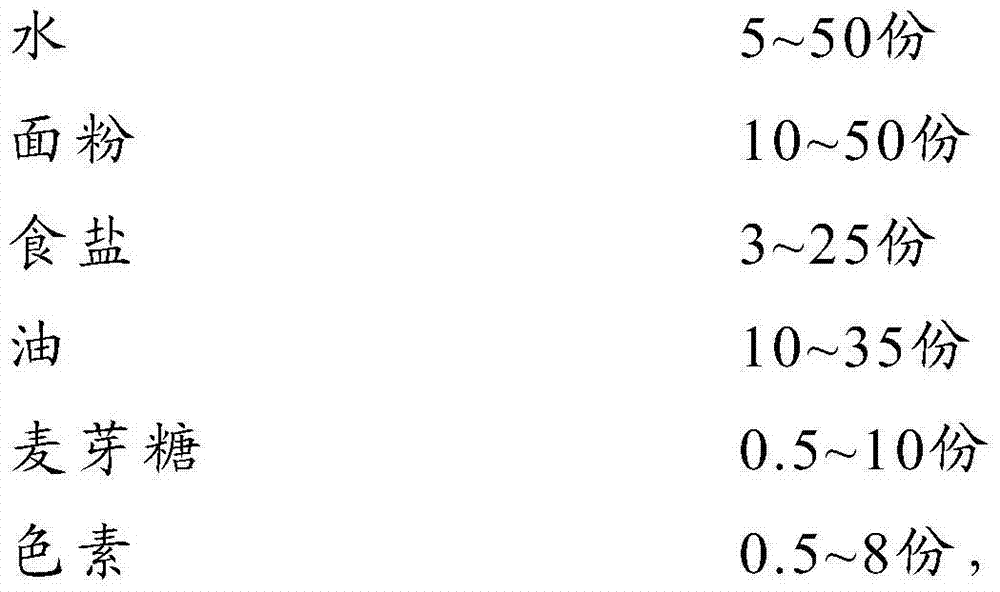

Non-toxic colored plasticine and preparation method thereof

The invention discloses non-toxic colored plasticine. The non-toxic colored plasticine contains the following ingredients: wheat flour, glutinous rice flour, plant protein powder, starch, carrageenan, clay, maltose, refined salt, edible oil, berberine hydrochloride, a humectant, vitamin E, potassium sorbate and water. The invention further discloses a corresponding preparation method of the non-toxic colored plasticine. According to the non-toxic colored plasticine and the preparation method thereof, the formula is reasonable, and natural raw materials are adopted, so that the non-toxic colored plasticine is non-toxic, odorless, environmentally friendly and pollution-free, is high in plasticity, good in toughness and bright-colored in color and does not stick hands; children are prevented from mistakenly eating the plasticine, and the safety is guaranteed.

Owner:潘承恩

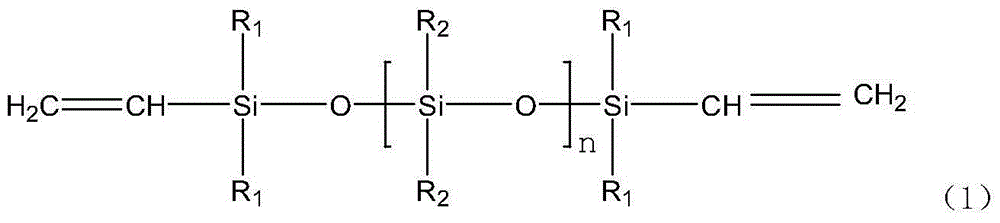

Two-component organosilicone plasticine

The invention relates to a plasticine product, in particular to two-component organosilicone plasticine. The plasticine comprises a component A and a component B, wherein the component A and the component B are prepared from raw materials in percentage by weight. The component A comprises vinyl polysiloxane, a filler, a platinum catalyst, a pigment and silicone oil; and the component B comprises vinyl polysiloxane, a filler, a pigment, silicon oil, a crosslinking agent and a speed control agent. The two-component organosilicone plasticine is good in usability and non-staining property, and is free of oil leakage, free of staining property, safe and stable.

Owner:深圳市楚鹰新材料有限公司

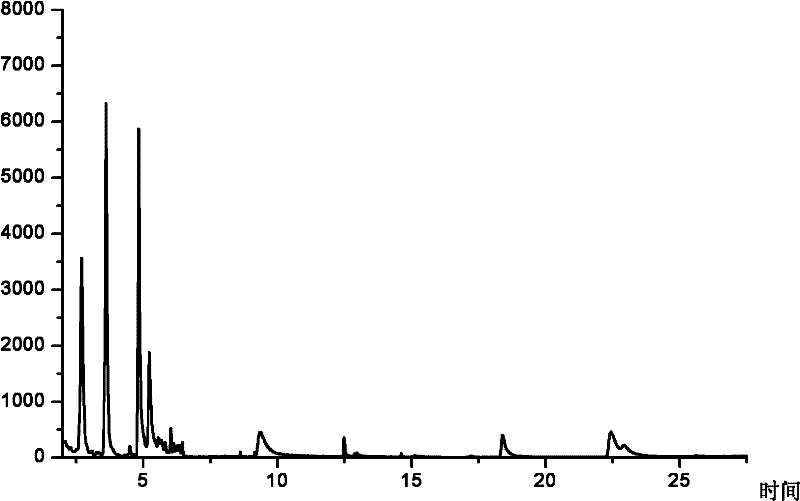

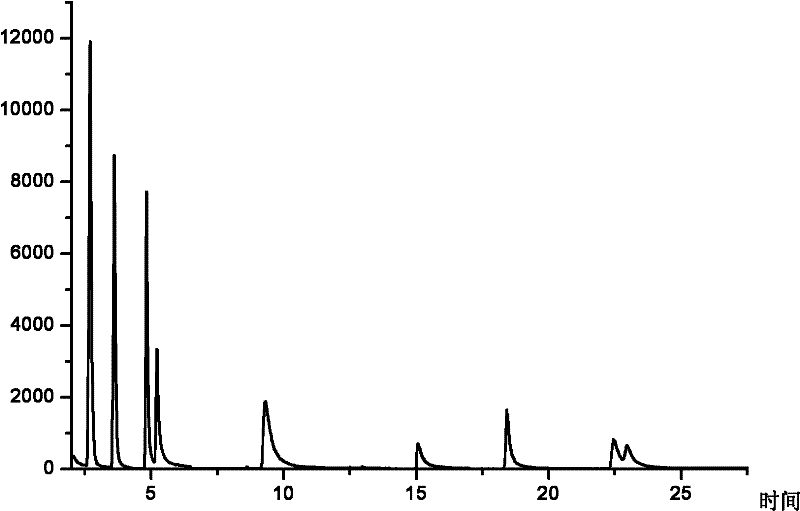

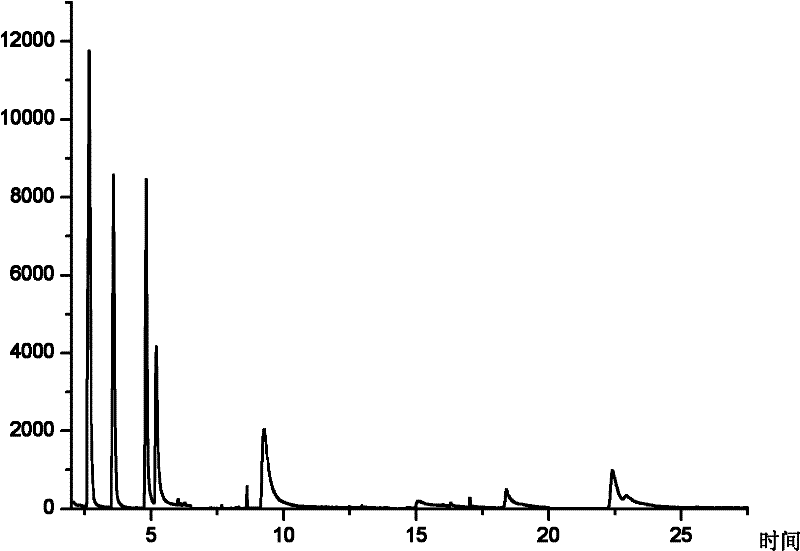

Method for measuring aromatic amine in plasticine

InactiveCN102213696AAvoid matrix interferenceComponent separationPreparing sample for investigationOrganic solventGas phase

The invention discloses a method for measuring aromatic amine in plasticine, which comprises the following steps of: cutting the plasticine into small pieces, and performing ultrasonic extraction on the small plasticine pieces by using methanol, ethanol, isopropanol or acetonitrile to obtain extracting solution; removing organic solvent in the extracting solution, and adding sodium hyposulfite solution to perform a reduction reaction at the temperature of between 60 and 80 DEG C; after the reaction is finished, regulating the pH value of reaction solution to be between 10 and 12, purifying bya solid phase extraction column, and eluting to obtain eluent; and allowing the eluent to enter a gas chromatograph-mass spectrometer to measure the aromatic amine. The method for measuring the aromatic amine in the plasticine fills the blank of the technology, and the problem of matrix interference caused by other ingredients in the plasticine is solved effectively; and due to the adoption of a common detection device, the method is easy to popularize.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

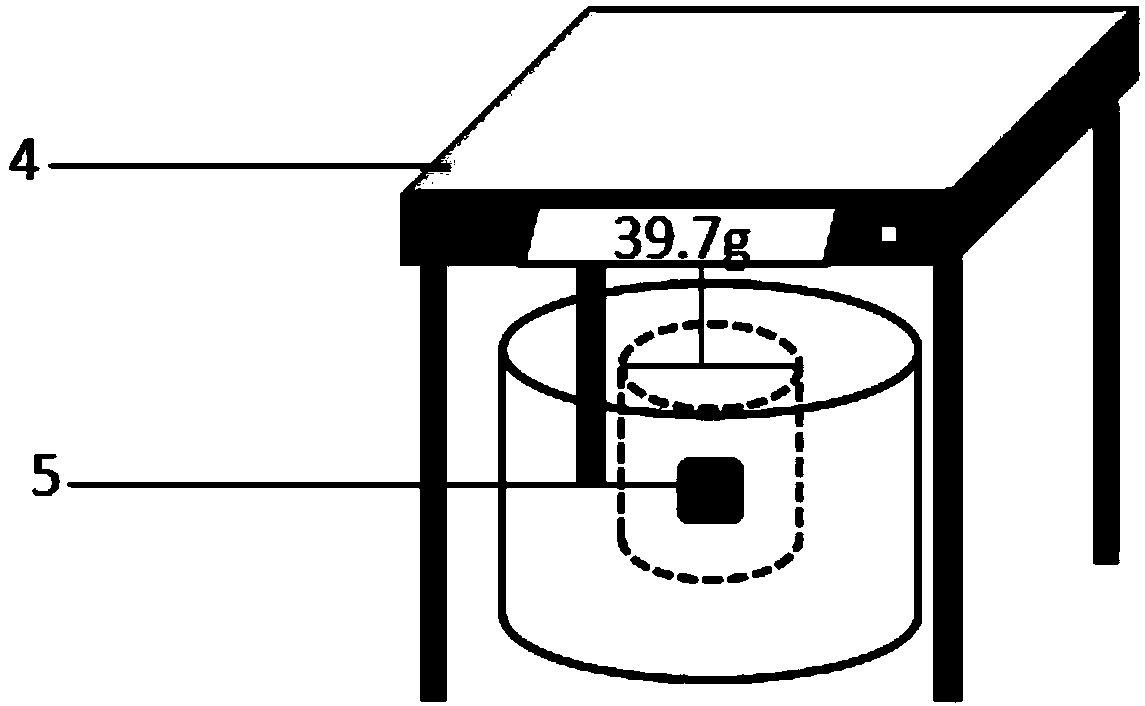

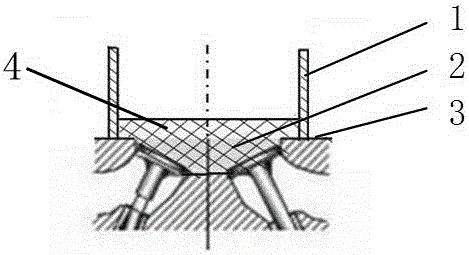

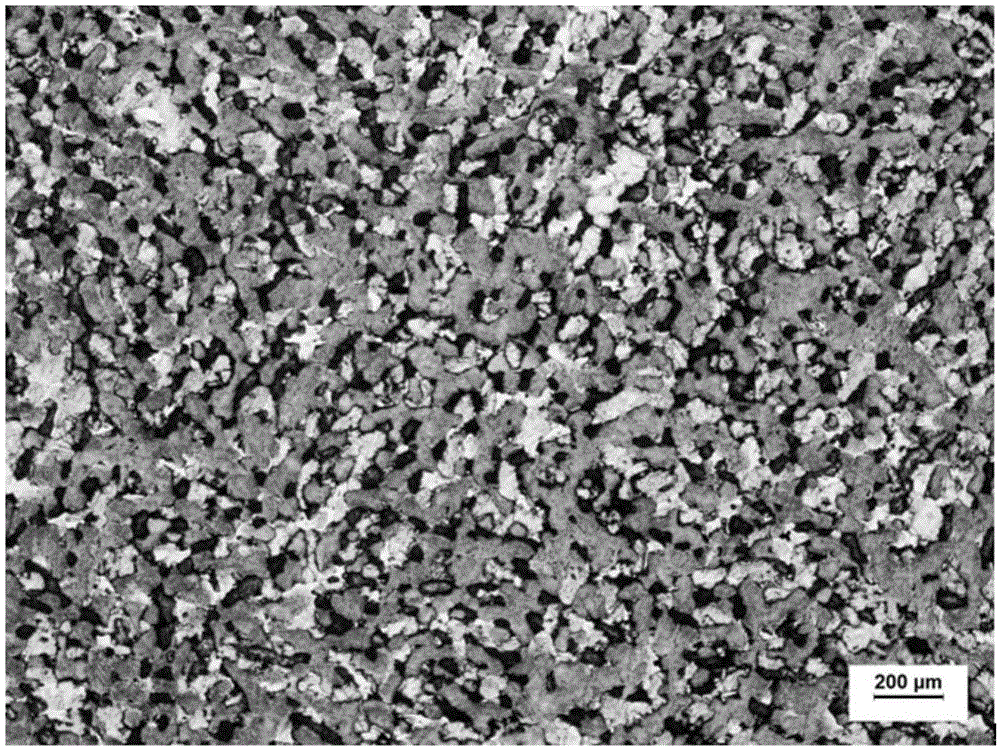

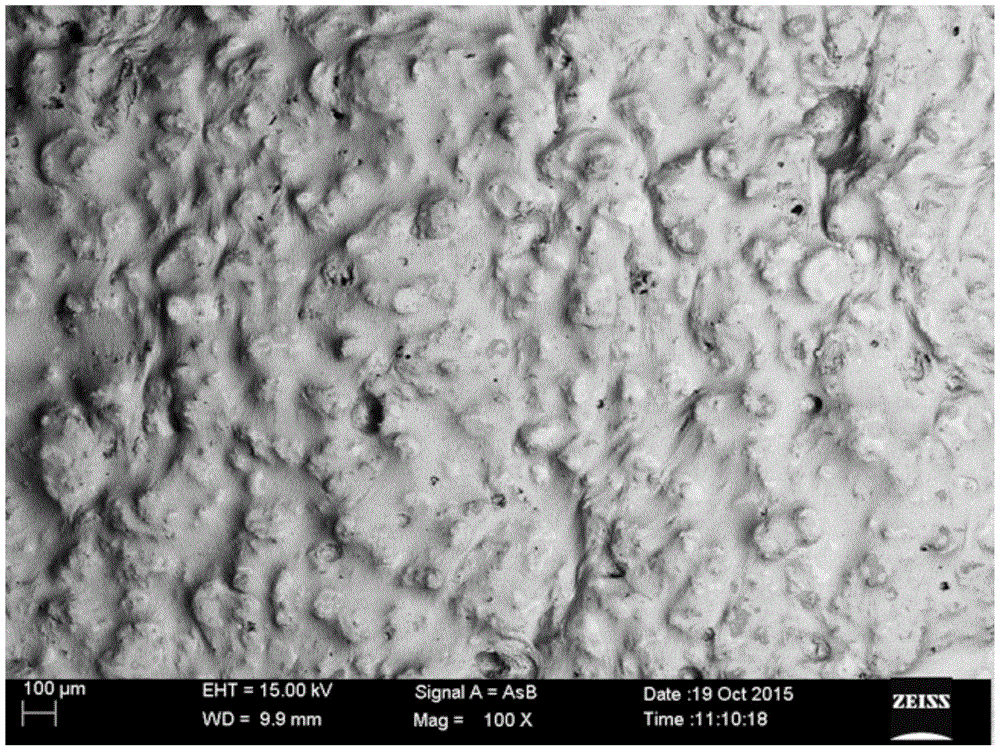

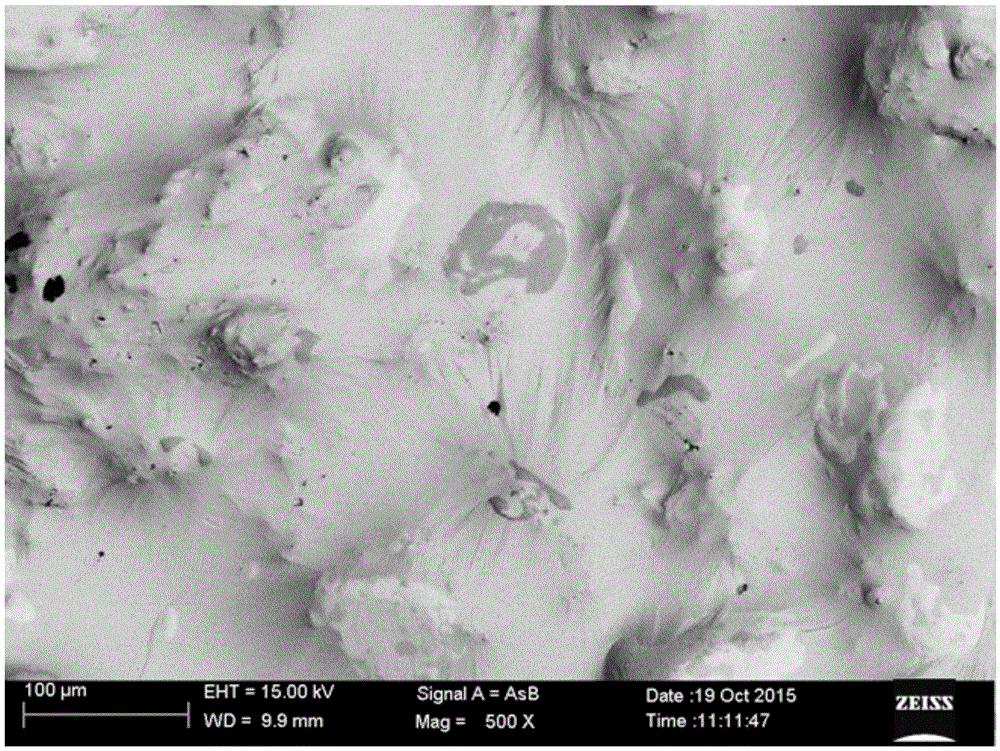

Roughness detecting method for combined surface of concrete prefabricated part

ActiveCN107621250AEffective means of controlFast measurementMeasurement devicesDistilled waterSurface roughness

The present invention discloses a roughness detecting method for the combined surface of a concrete prefabricated part. The method comprises the following steps of 1) cleaning sundries on the surfaceof a to-be-measured part before the test, selecting a suitable area, painting a layer of demoulding oil on the selected area, and fixing a stainless steel square frame on the area; 2) filling the stainless steel square frame by adopting the plasticine to enabling the parallel and level state of the surface of the stainless steel square frame; 3) removing the stainless steel square frame, and taking down the plasticine attached on the surface of the part; 4) kneading the plasticine into a whole block, weighing the plasticine in the air as m1 and accurate to 0.01 g, placing the plasticine in a mesh basket, placing the plasticine in the distilled water together with the mesh basket, weighing the plasticine in the water as m2 and accurate to 0.01 g, and calculating the roughness of the plasticine. According to the roughness detecting method for the combined surface of the concrete prefabricated part, the roughness of the concrete prefabricated part, in the horizontal, vertical and inclineddirections, can be tested.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Rock fracture shear seepage test device and test method thereof

InactiveCN107860697AEasy to analyzeThe test parameters are accuratePermeability/surface area analysisWater leakageRock sample

The invention discloses a rock fracture shear seepage test device and a test method of the device and relates to the technical field of rock mechanical tests. The test device comprises an upper shearbox, a lower shear box, an upper shear ring and a lower shear cylinder, wherein a sealed small hole is formed in the lower shear cylinder and connected with a water supply pipeline to apply water pressure onto a rock sample. The test method comprises the steps of mounting a fracture sample in the upper shear ring and the lower shear cylinder by cement placement and plasticine isolation, wrapping the side face of the fracture sample with a rubber sleeve to avoid water leakage between the side face of the sample and the rubber sleeve, putting a combination of the upper shear ring and the lower shear cylinder in the lower shear box and the upper shear box, connecting with the water supply pipeline and a water collecting pipeline, measuring load, displacement and seepage quantity, and collecting measured data and drawing a form via a computer, wherein a water outlet is formed in the rubber sleeve. The device and the method are used for achieving the rock fracture shear seepage test, and studying the change in rock fracture seepage quantity in a shear process.

Owner:HENAN POLYTECHNIC UNIV

High-moisturizing food-grade plasticine powder and preparation method thereof

The invention discloses high-moisturizing food-grade plasticine powder. The high-moisturizing food-grade plasticine powder is prepared from the following raw materials in parts by mass: 88 to 96 parts of base materials, 5 to 10 parts of modifier, 0.1 to 0.5 part of additive and 0.1 to 0.5 part of pigment. The invention discloses a preparation method of the high-moisturizing food-grade plasticine powder at the same time. According to the high-moisturizing food-grade plasticine powder and the preparation method, disclosed by the invention, plasticine which has the excellent characteristics of tack-free performance, oil-free performance, good moisturizing performance, good flexibility and good plasticity can be obtained through scientific and reasonable raw material selection, the durability of the good performance is good, and the high-moisturizing food-grade plasticine powder is a toxic-free and environment-friendly plasticine raw material.

Owner:苏州冰心文化用品有限公司

Colored plasticine and preparation method thereof

The invention discloses colored plasticine and a preparation method thereof. The colored plasticine is prepared from wheat starch, rice flour, glycerol, edible refined salt, purple sweet potato whole flour suspension, nipagin compound sodium acetate, saturated citric acid solution or citric acid buffer solution. The preparation method comprises the following steps: taking the wheat starch, the rice flour and the edible refined salt according to the weight parts, placing the taken components into a container, grinding, uniformly mixing the obtained powder, and screening to obtain mixed flour; adding the saturated citric acid solution or citric acid buffer solution into the prepared purple sweet potato whole flour solution, and thus obtaining a mixed solution; dropwise adding glycerol and nipagin compound sodium acetate into the mixed flour, adding the mixed solution into the mixed flour under stirring, afterwards taking out the mixture, kneading uniformly, uniformly smearing glycerol on the surface of the finished product obtained through kneading, and packaging the finished product with glycerol through a preservative film. According to the colored plasticine and the preparation method thereof, the raw materials are low in cost, the preparation method is simple and feasible, the colors are controllable, and the colored plasticine is non-toxic and harmless, and easy to popularize.

Owner:SHANXI UNIV

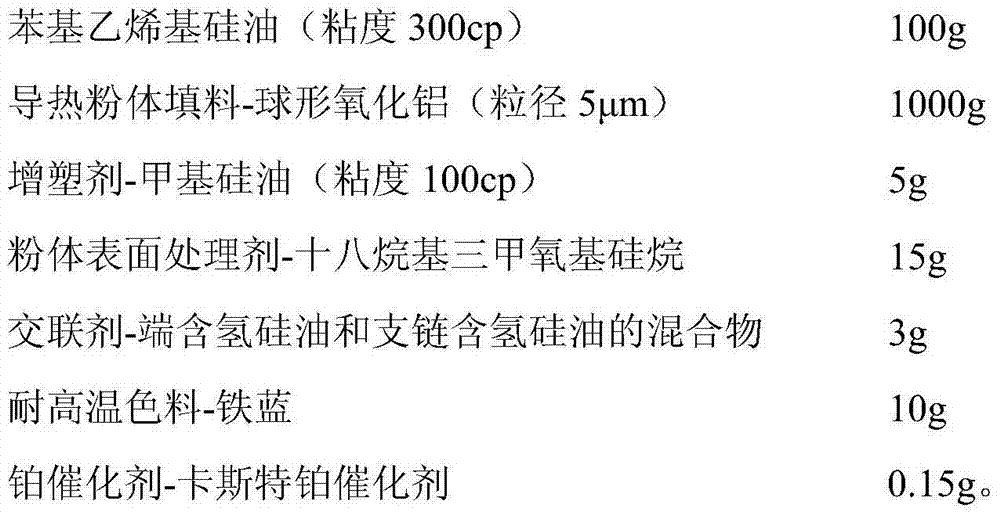

Laser mask shock forming device based on plasticine mould and method of laser mask shock forming device

InactiveCN103317227AReduce hardnessReduce springback deformationLaser beam welding apparatusControl systemEngineering

The invention discloses a laser mask shock forming device based on a plasticine mould and a method of the laser mask shock forming device. The device comprises a laser loading system, a platform moving system, a forming system and a control system, the forming system comprises plasticine serving as a mould, a workpiece, an absorbing layer film, an optical medium, a mask and an annular pressing block, the workpiece is arranged on the plasticine, the transparent optical medium serving as a restraint layer is attached to the upper side of the workpiece in a pressing manner, the absorbing layer film is arranged between the optical medium and the workpiece, the mask for changing the size and the shape of a laser spot is arranged above the optical medium, the annular pressing block is arranged above the mask, and the mask, the optical medium, the absorbing layer film, the workpiece and the plasticine are fastened on the platform moving system through the annular pressing block. The device is low in cost, rapid, precise and repeatable and can be used for laser mask shock forming of conventional difficultly formed materials based on the plasticine mould, mould designing and manufacturing expenses can be reduced, and machining precision and working efficiency are improved.

Owner:JIANGSU UNIV

Modeling composition and its use

A modeling composition consisting of a wax-based and oil-based binder, a filler, and a coloring agent, wherein the filler is substantially a light filler comprised of hollow microbeads. The binder is comprised of solid wax, pasty wax, and a liquid component of a wax base, an oil base, or a wax and oil base. The binder is present in the modeling composition in an amount of 45 to 90% by weight. The modeling composition can be used as play dough for children or as a therapeutic composition in the medical field for training and rehabilitation.

Owner:J S STAEDTLER

Natural plasticine

The invention discloses a natural plasticine which is prepared from the following raw materials in parts by weight: 10-15 parts of wheat flour, 10-15 parts of starch, 5-10 parts of glutinous rice flour, 3-5 parts of waxy corn starch, 5-7 parts of clay, 6-15 parts of liquid paraffin, 4-8 parts of glycerol, 3-5 parts of sodium chloride, 5-8 parts of vegetable oil, 3-5 parts of xanthan gum, 2-6 parts of quartz powder, 1-3 parts of edible pigment and 20-30 parts of water. By adopting the natural raw materials, the natural plasticine has the advantages of high safety, environment friendliness, no pollution, moderate hardness and high plasticity.

Owner:QINGDAO DAFANG WISDOM NETWORK TECH CO LTD

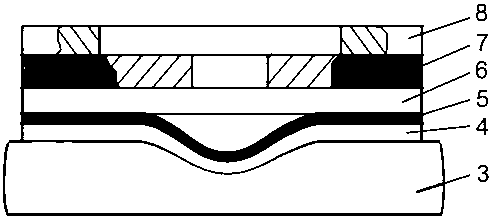

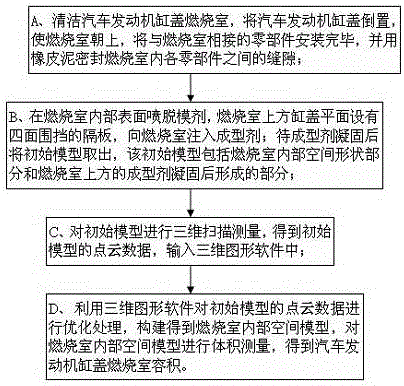

Automobile engine cylinder head combustion chamber volume measurement method

InactiveCN106225677AAccurately find the volume sizeAvoid errorsUsing optical meansCombustion chamberPoint cloud

The present invention provides an automobile engine cylinder head combustion chamber volume measurement method. The method comprises the following steps: A, cleaning an automobile engine cylinder head combustion chamber, inverting the automobile engine cylinder head, completing the installation of parts connected with the combustion chamber, and sealing the slits between the parts of the combustion chamber by using the plasticine; B, spraying a release agent at the inner surface of the combustion chamber, arranging clapboards closed at four sides at the plane of the cylinder head of the upper portion of the combustion chamber, injecting the molding into the combustion chamber, taking out an initial model after the molding is solidified; C, performing three-dimensional scanning measurement of the initial model, obtaining the point cloud data of the initial model, and inputting the point cloud data in the three-dimensional graphic software; and D, performing optimization process of the point cloud data of the initial model by employing three-dimensional graphic software, constructing the inner space model of the combustion chamber and performing the volume measurement, and obtaining the volume of the automobile engine cylinder head combustion chamber. The measurement method overcomes the defects of easy leakage and big error of the liquid in the current technology, and the operation is easy and the precision is high.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

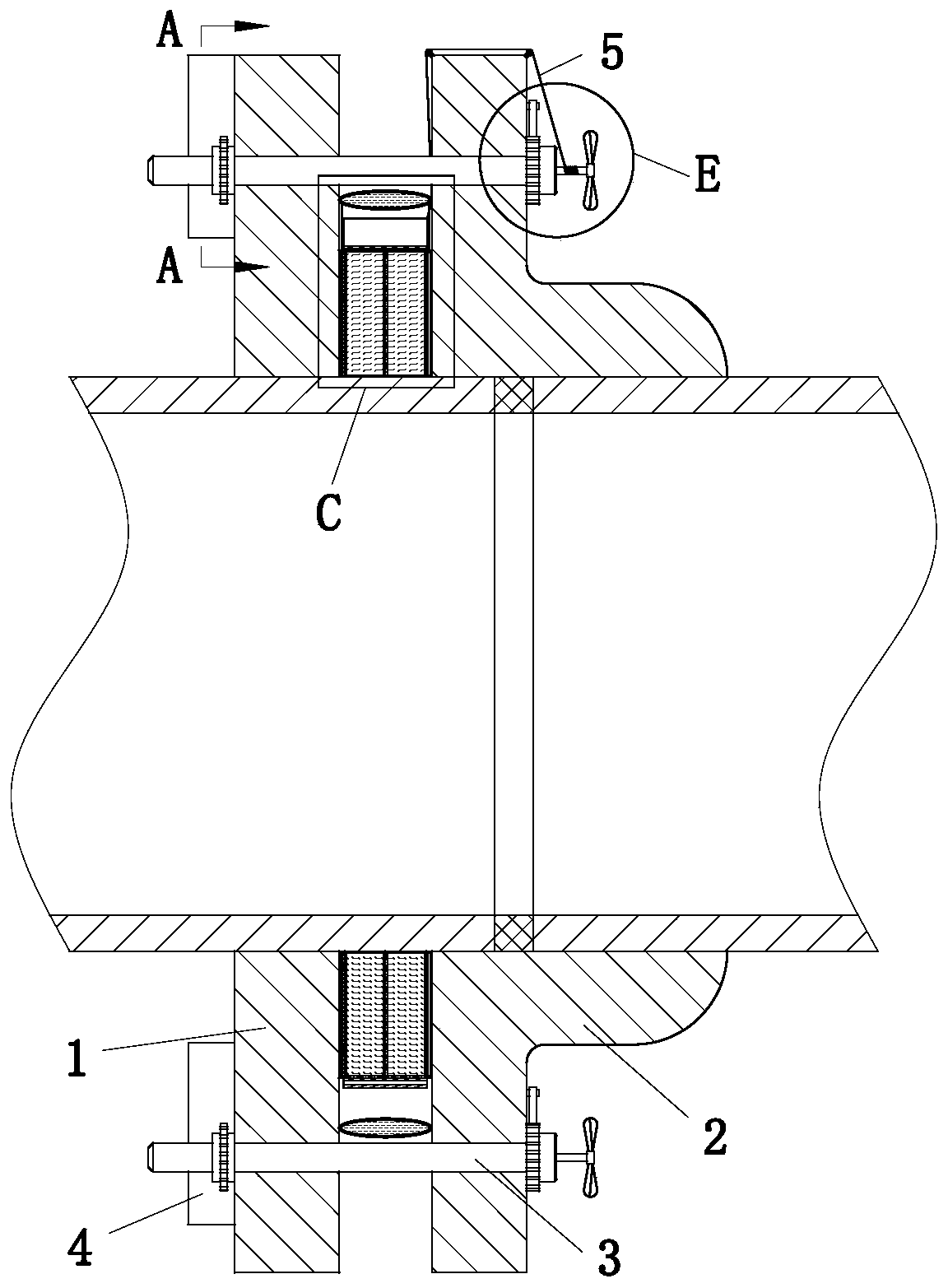

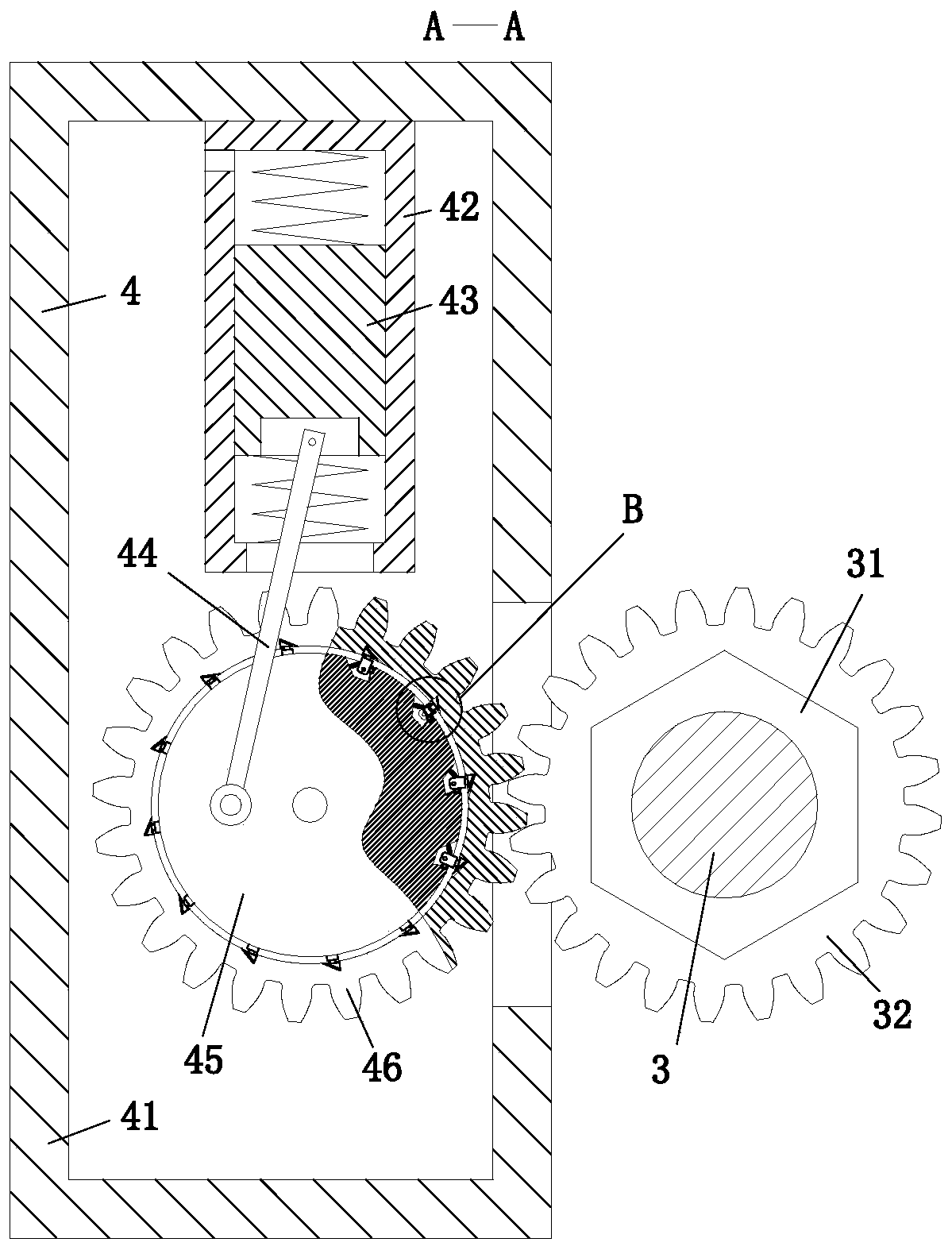

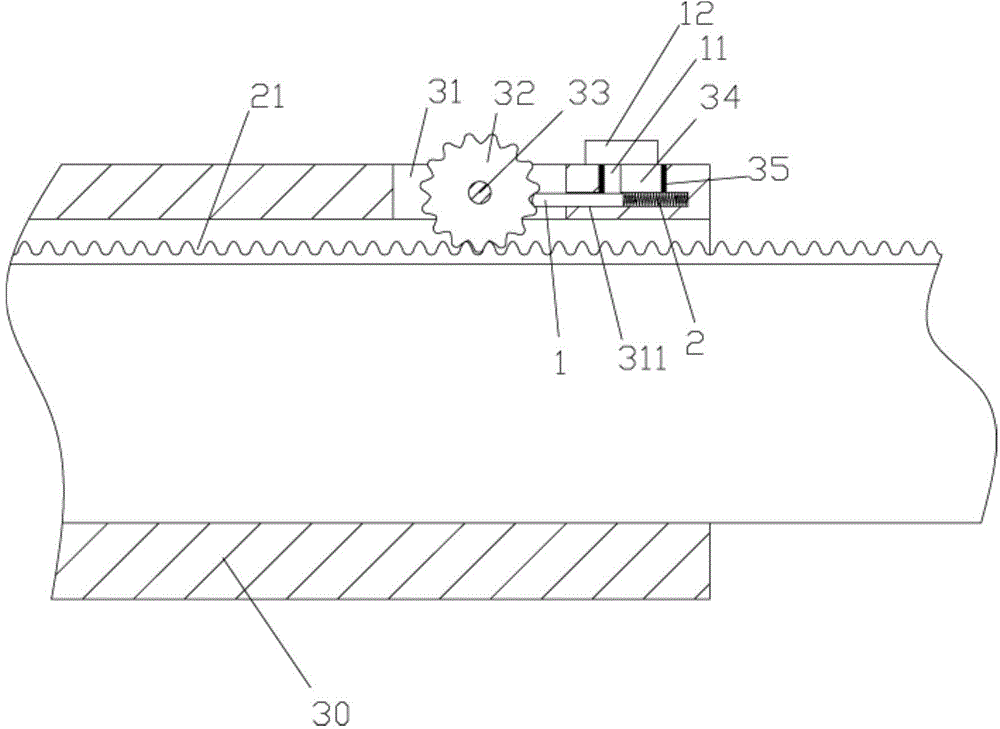

Leakproof gas pipeline flange

ActiveCN109780349AImprove sealingImprove the efficiency of automatic lockingFlanged jointsEngineeringFlange

The invention belongs to the technical field of flanges, and particularly relates to a leakproof gas pipeline flange which comprises a left flange, a right flange, a locking module and a seal module.The left flange and the right flange are arranged oppositely; multiple bolts are arranged between the left flange and the right flange; hexagon nuts are arranged on the tail parts of the bolts; No.1 gears are fixedly connected onto the hexagon nuts; the seal module is arranged between the left flange and the right flange; and the locking module is arranged on the left flange. According to the leakproof gas pipeline flange provided by the invention, by utilizing the vibration of a pipe body, a heavy block pushes a rocking bar to move up and down, a rotating plate is rotated so as to enable a No.2 gear to rotate unidirectionally through a pulling block and a right-angle slot, and the No.2 gear re-screws the hexagon nuts through the No.1 gears, so that the automatic locking efficiency of thehexagon nuts is improved, and the sealing efficiency is favorably improved; and by utilizing the mutual extrusion of two annular seal bags, plasticine in the two annular seal bags flows so as to fillgaps among the left flange, the right flange and a pipe body, so that a seal effect of the pipe body is effectively improved.

Owner:肇庆佛燃天然气有限公司

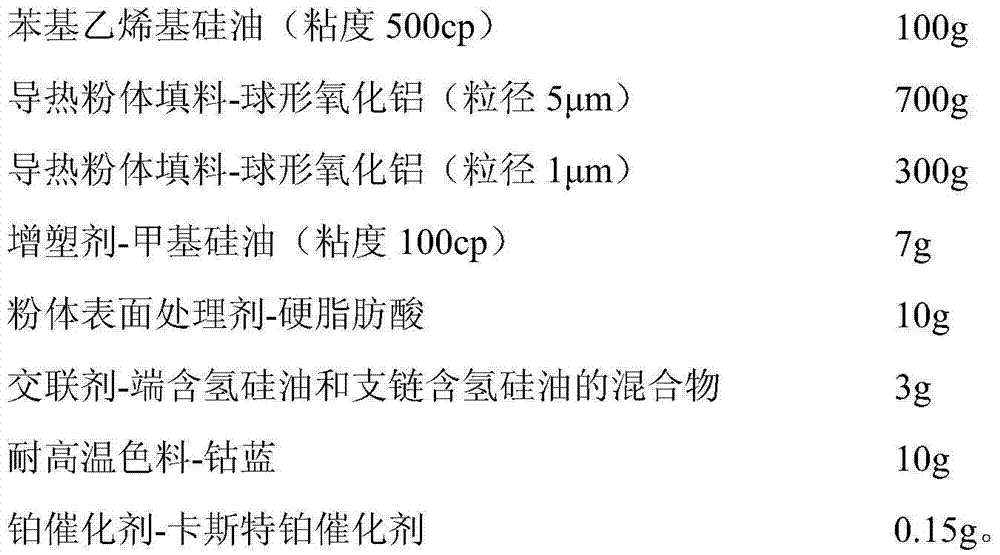

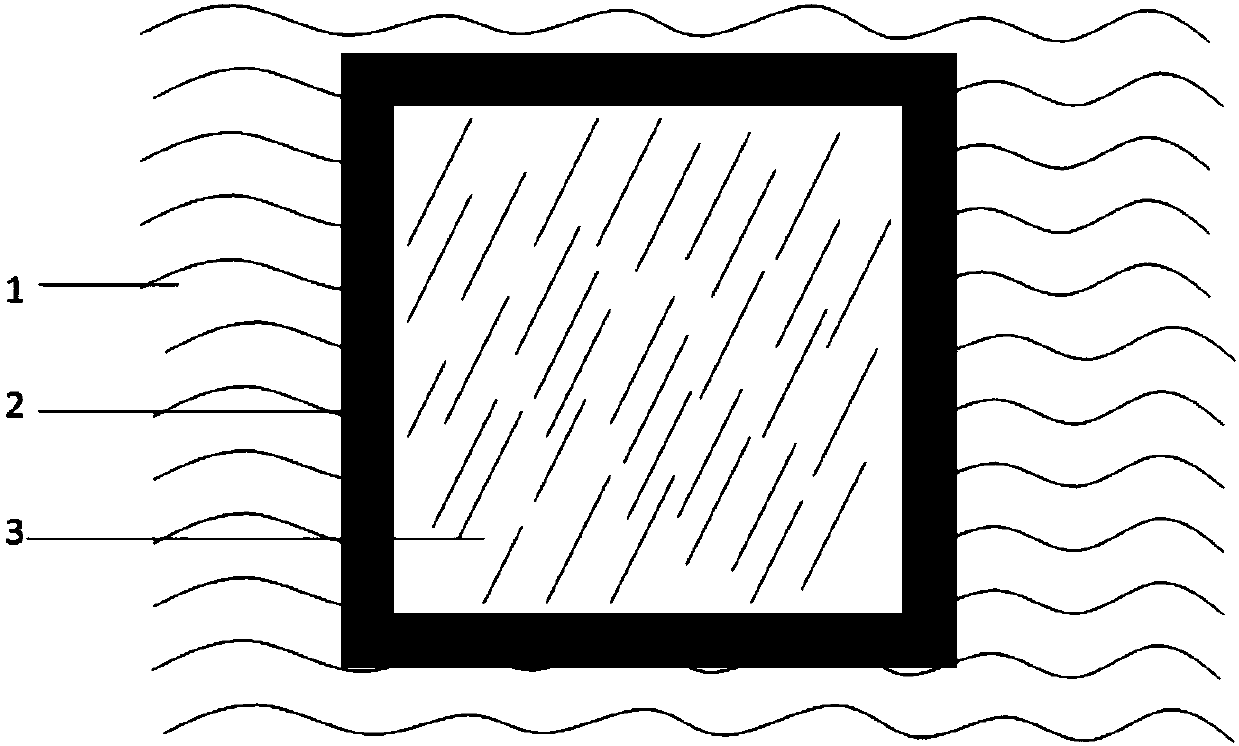

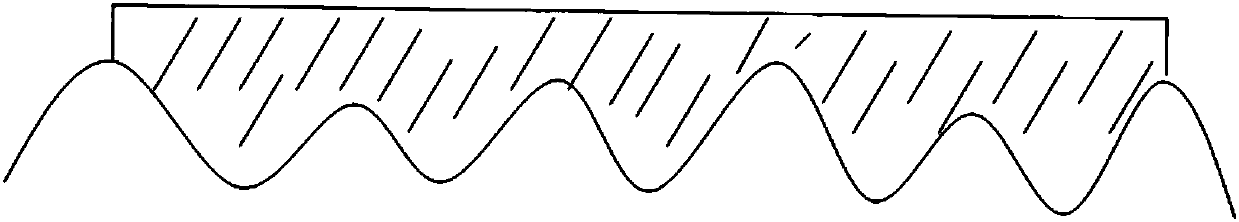

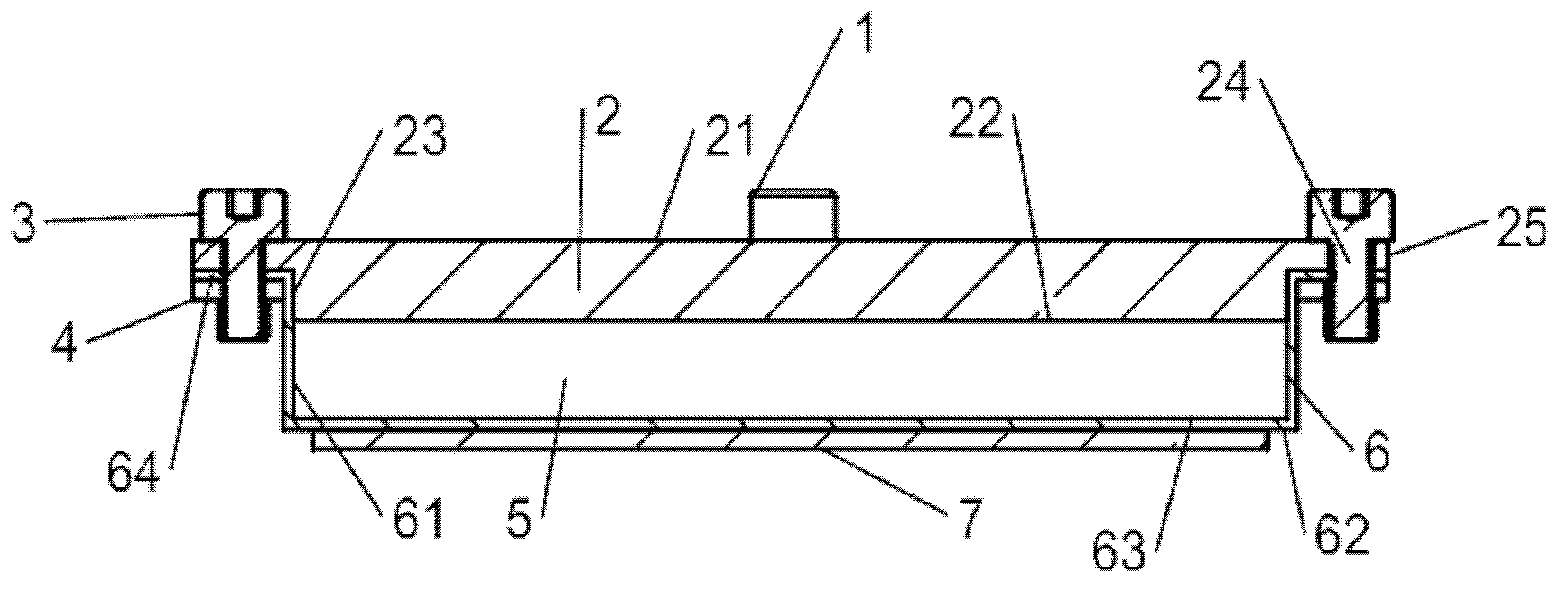

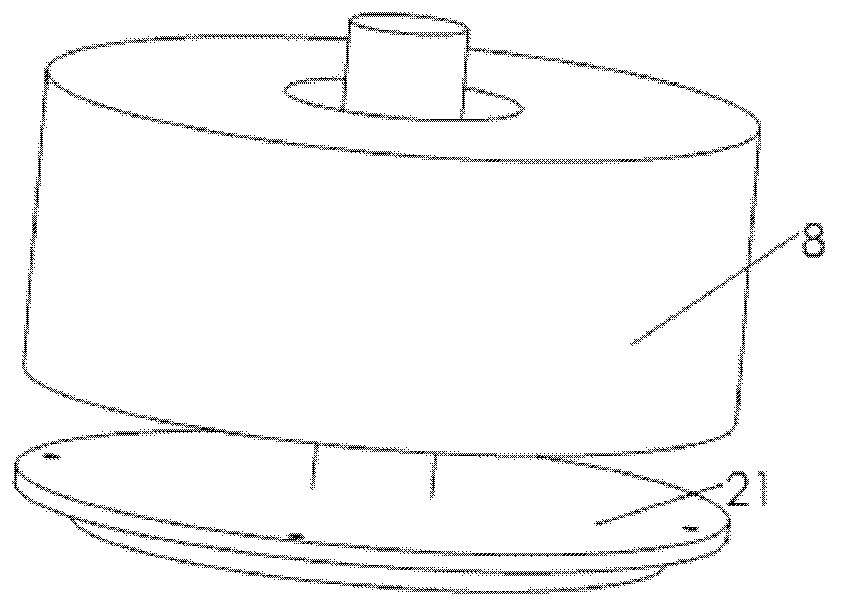

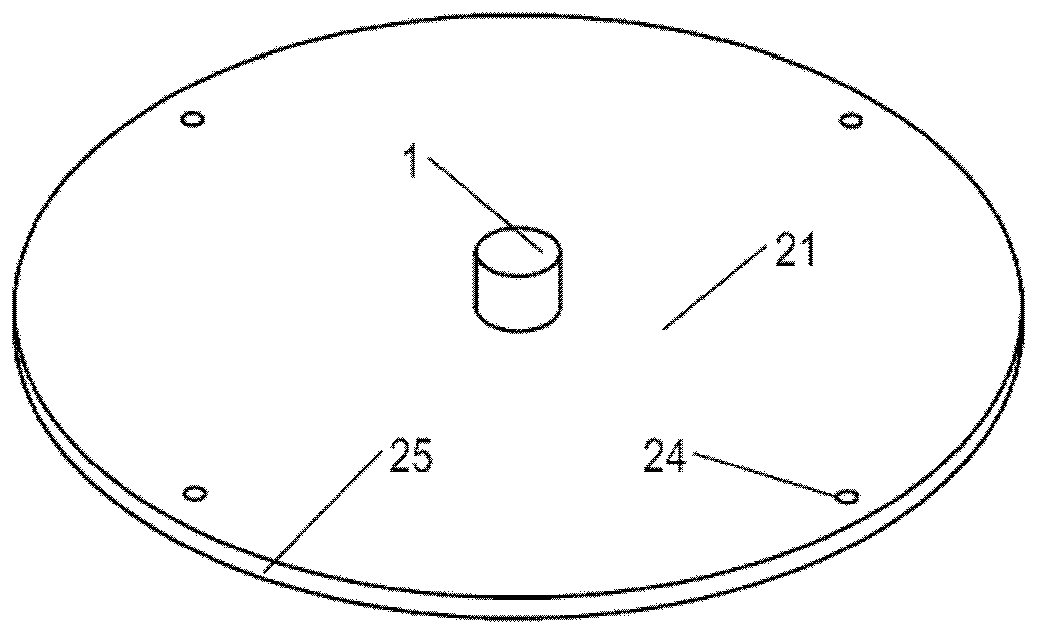

Polishing grinding disc for restraining full-band error of optical surface

InactiveCN103302604AIncreased Grinding RemovalControl polishing pressure distributionOptical surface grinding machinesGrinding devicesEngineeringDiaphragm seal

The invention relates to a polishing grinding disc for restraining a full-band error of an optical surface. The polishing grinding disc is provided with a rotating shaft connecting end, a base, a flange ring, a diaphragm seal membrane, magnetorheological plasticine, a polishing pad, and a magnetic field generator, wherein the rotating shaft connecting end is located in a central position of an external upper part of the base; the base is provided with an annular boss; the annular boss is located on the outer side of a side wall; a group of fixedly connected screw holes are formed in the annular boss, and are centrosymmetric to the rotating shaft connecting end; the flange ring is an annular cylinder and is provided with a group of fixedly connected screw holes; the diaphragm seal membrane is in a bucket-shaped structure with the upper end opened; the magnetorheological plasticine is placed in a seal cavity formed by an inner wall and an upper surface of the diaphragm seal membrane as well as the bottom of the base; a boss of the diaphragm seal is fixedly connected with the annular boss of the base by the flange ring and bolts; the polishing pad is fixedly connected with a lower surface of the diaphragm seal membrane; and the magnetic field generator is placed on the upper surface of the external upper part of the base outside the grinding disc, controls magnetic field distribution in the seal cavity, generates a magnetic field parallel to a direction of a rotating shaft, and adjusts and controls a storage modulus and a loss modulus of the magnetorheological plasticine.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Silicon boron polymer and preparation method therefor and application thereof

ActiveCN105175732AIncrease viscosityInhibit and solve the problem of too fast responseTwo stepMethyl group

The invention discloses a silicon boron polymer and a preparation method therefor and an application thereof. The preparation method for the silicon boron polymer comprises two steps: firstly carrying out a reaction between 30-40 parts of a boron-containing compound and 20-30 parts of polyol to prepare a polyol ester; and then carrying out a reaction between 3-20 parts of the boronized polyol ester, 1-10 parts of methylsilicone oil, 60-100 parts of hydroxyl silicone oil, 0.1-15 parts of white carbon black and 0.01-0.5 part of a plasticizer unsaturated fatty acid to obtain the silicon boron polymer. Plasticine made from the synthetic silicon boron polymer has good bounce and stretchability; the elongation at break reaches 1000-2000%; the tensile strength is just 1-2 MPa; and the T type peel strength is just 0.1-1 kN / m. The preparation method disclosed by the invention is simple in process, short in preparation period and strong in operating controllablity; the stability of product performance can be improved; and the energy consumption is reduced, so that large-scale production is further facilitated. The prepared silicon boron polymer can be widely applied to the fields of toys for children, artistic molding, industrial molding and the like.

Owner:东莞九天量子科技有限公司

Method for manufacturing fiber cross section slices

InactiveCN104198235ASatisfy cross-section inspectionGood dispersionPreparing sample for investigationAdhesiveSingle fiber

The invention discloses a method for manufacturing fiber cross section slices. The method comprises the following steps: adding quickly-dried adhesive to the bottom part of a holding container, putting single fiber or one beam of fibers on the surface of the quickly-dried adhesive or putting the fibers on the surface of the quickly-dried adhesive along the length direction of the holding container after the quickly-dried adhesive is slightly dried, and embedding two ends of the fibers into plasticine at two ends of the holding container; then continuing to dropwise add the quickly-dried adhesive until the fiber is covered by the adhesive; removing the holding container and the plasticine after the quickly-dried adhesive is cured so as to obtain fiber-coated adhesive rods; slicing the adhesive rods to obtain the fiber cross section slices. The method for manufacturing the fiber cross section slices has the advantages that the fibers are coated by the quickly-dried adhesive, so that the requirements on detecting cross sections of a slight amount of fibers or a single fiber can be met; the fibers in the fiber cross section slices manufactured by the method are good in dispersion properties and clear and accurate in shape of the cross sections; the method is simple and convenient and high in practicability, and can be widely used in field of forensic science at home and abroad.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

Measurement method of mould closing margin of stamping mould

ActiveCN109248939AImprove accuracyImprove reliabilityShaping toolsMetal working apparatusData treatmentMaterials science

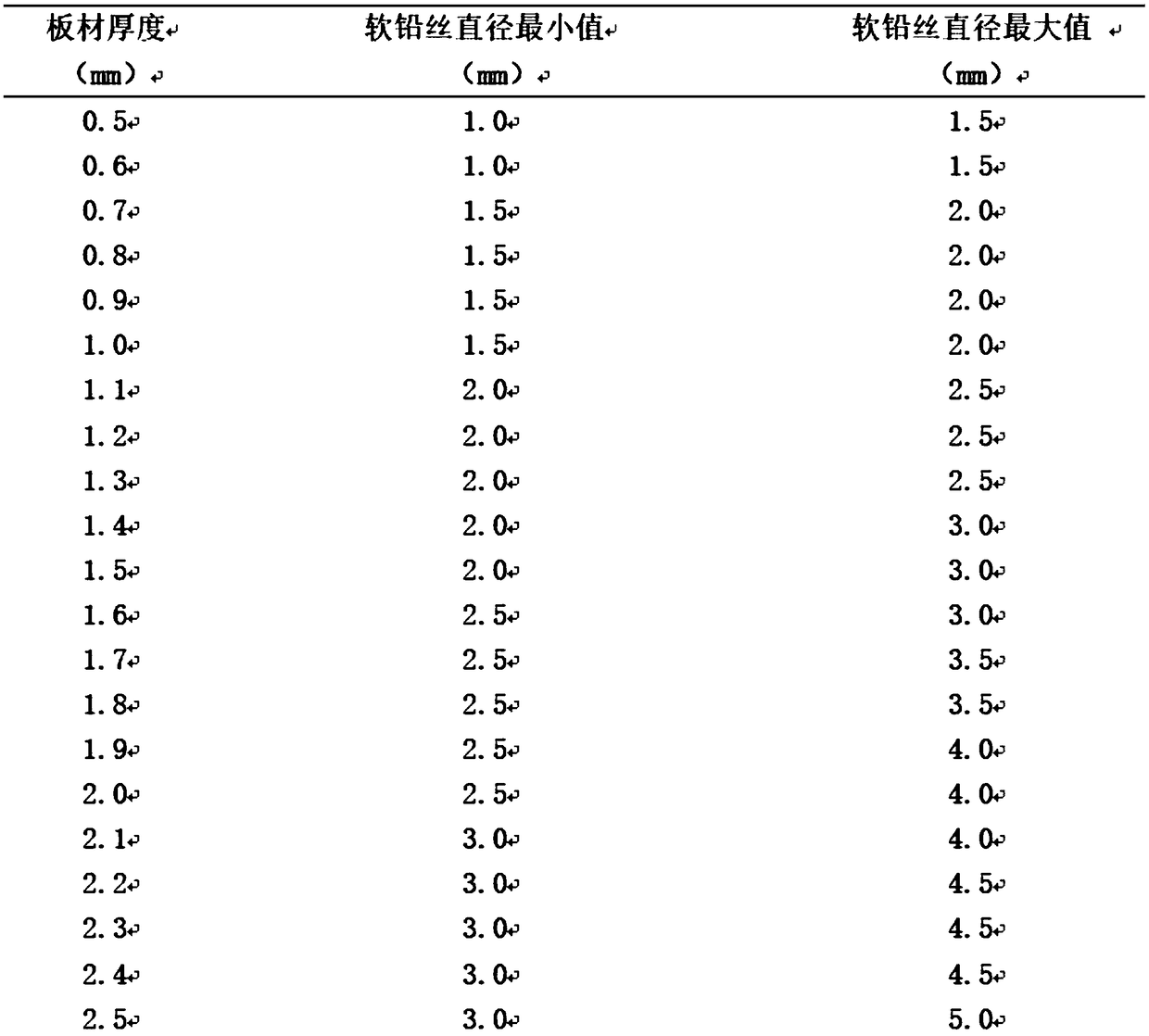

The invention discloses a measurement method of a mould closing margin of a stamping mould. The method comprises the following steps that a mould blank holder state is checked and adjusted, a mould balance state is checked and adjusted, mould closing height is set, the to-be-measured mould is used for pressing a workpiece, opening treatment is conducted on the workpiece, all opened positions are subjected to double numbering, filler is prepared, the filler is prepared from industrial plasticine and soft steel wires, the workpiece is placed on the upper surface of a mould lower die, one group of filler is placed at each opened position, the soft metal wires, the industrial plasticine and the mould are stacked from top to bottom in sequence, the mould is closed, the filler is pressed, the thickness of an opened piece of the workpiece subjected to opening and the thickness of the soft metal wires subjected to pressing are measured, and for the opened positions, data processing is conducted on areas which need to be subjected to heavy coloring and light coloring separately, so that the mould closing margin of the stamping mould is obtained. Through the measurement method, the mould closing margin can be measured accurately and reliably.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

Furniture making-replica method

ActiveCN105773782AIncrease the sense of simplicityConsistent material colorNatural patternsIrregularity removal devicesSolubilityAmmonium hydroxide

The invention discloses a furniture making-replica method. The furniture making-replica method includes the step a of dipping and the step b of filling up of flaws, wherein according to the step a of dipping, kaolin is added with water to form slurry with the weight ratio of kaolin to water being 30%-40%, furniture is dipped in the slurry for 30-50 min and then taken out, the slurry attached to the furniture is removed, a mixed solution is formed by mixing 5-9 parts of hydrogen peroxide with the solubility being 20%-28% and 1 part of ammonium hydroxide with the concentration being 18%-20%, all the outer surfaces of the furniture are coated with the mixed solution for 20-30 times at the environment temperature of 30-60 DEG C, the surfaces of the furniture are coated with an alcoholic solution with the concentration being 30%-50% for 3-5 times, and the surfaces of the furniture are heated for 5-8 min with charcoal fire at 60-80 DEG C; and according to the step b of filling up of flaws, the flaws of the furniture are filled up with plasticine so that the surfaces of the furniture can be flat. The furniture making-replica method can achieve the technical purpose of how to conduct making-replica treatment on the furniture.

Owner:浙江亚厦产业园发展有限公司

Adjustable tweezers for multi-hole anti-skidding sleeves

The invention discloses a pair of adjustable tweezers for multi-hole anti-skidding sleeves. The pair of adjustable tweezers comprises a body including a connecting portion and tweezers arms. Multiple stepped through holes are formed in the connecting portion. The inner side wall of a large diameter segment of each stepped through hole is provided with at least two opposite transverse inserting holes, in which clamping springs and steel balls are inserted in a sleeving mode. Limiting plates, close to the inner side walls of the stepped through holes, are fixed with the transverse inserting holes. Middles of the limiting plats are provided with middle through holes. The steel balls are inserted into the middle through holes in a sleeving mode. Front portions of the steel balls stretch out of the middle through holes. One ends of the clamping springs apply forces to bottom ends of the transverse inserting holes and the other ends of the clamping springs apply forces to the steel balls. Circular pieces are inserted into the stepped through holes in a sleeving mode. Middles of the circular pieces are provided with graphic through holes. The anti-skidding sleeves sleeve the tweezers arms. The adjustable tweezers for the multi-hole anti-skidding sleeves have following beneficial effects: when plasticine or glutinous small parts is made, the connecting portion can be directly pressed onto plasticine or a glutinous block so that the small part can be dug out for production; and the anti-skidding requirements of different users can be satisfied due to the fact that the pair of adjustable tweezers has position-adjustable anti-skidding sleeves.

Owner:SHANDONG JUANCHENG ZHIYUAN SCI & TEACHING INSTR CO LTD

Low-melting-point alloy and preparation method thereof

The invention provides low-melting-point alloy and a preparation method thereof. The general formula of the low-melting-point alloy is GaInxSnyCdzMt, wherein M is selected from Pb and / or Zn; x is larger than or equal to 0.5 and smaller than or equal to 2.5; y is larger than or equal to 0.5 and smaller than or equal to 2.5; z is larger than or equal to 1 and smaller than or equal to 3; t is larger than or equal to 1 and smaller than or equal to 3. The preparation method of the low-melting-point alloy includes the following steps that Ga, In, Sn, Cd, Pb and / or Zn are mixed in a specific sequence and then subjected to vacuum melting through a high-frequency induction furnace, and the low-melting-point alloy is obtained. The formula of the low-melting-point alloy is scientific and reasonable, and the preparation method of the low-melting-point alloy is simple and easy to implement. The low-melting-point alloy has the free-deformed property similar to that of plasticine in the room temperature environment and has low melting point and high conduction characteristics.

Owner:DALIAN UNIV OF TECH

Preparation method of leadless high-density plasticine

The invention provides a preparation method of leadless high-density plasticine, and belongs to the technical field of a high-energy radiation shielding material. The leadless high-density plasticine is prepared from the raw materials of tungsten powder, a coupling agent, thermoplastic elastomer and the like. The preparation method comprises the steps: modifying the tungsten powder (or tungsten alloy powder) by the coupling agent, uniformly mixing and processing the tungsten powder (or tungsten alloy powder) and low-melting-point thermoplastic polyurethane (or vinyl acetate resin) mixture utilizing an internal mixer or a screw extruder, and carrying out hot pressing at 100-180 DEG C and pressure of 0.5-2.0MPa to obtain the leadless high-density plasticine composite material. The leadless high-density plasticine composite material prepared by the method is high in density, good in viscosity, good in hand feeling, definite in moulding, difficult in plasticine adhesion and color adhesion on hand, and wide in application temperature range; furthermore, the material has the density more than 10.0g / cm<3>, and has excellent high-energy radiation shielding performance; and in particular, the composite material also has the advantages of being leadless, environment-friendly and the like.

Owner:SHANGHAI UNIV

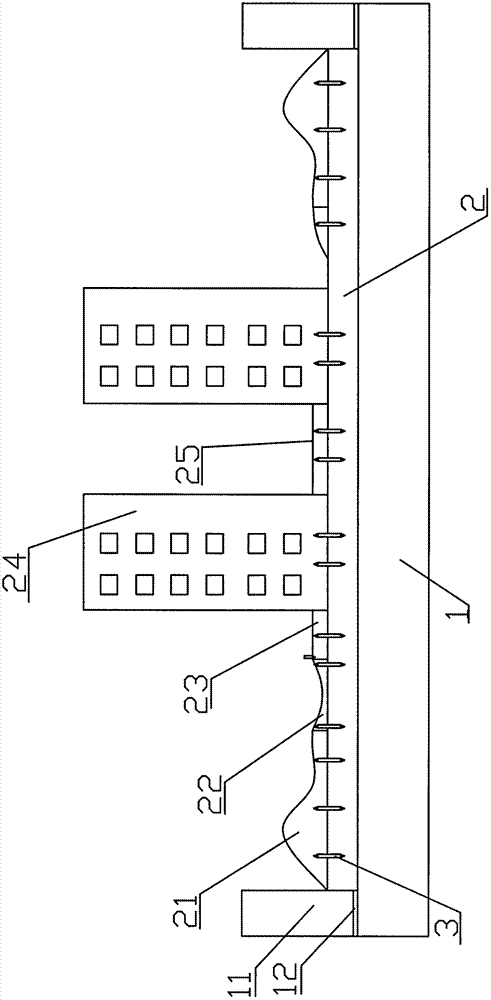

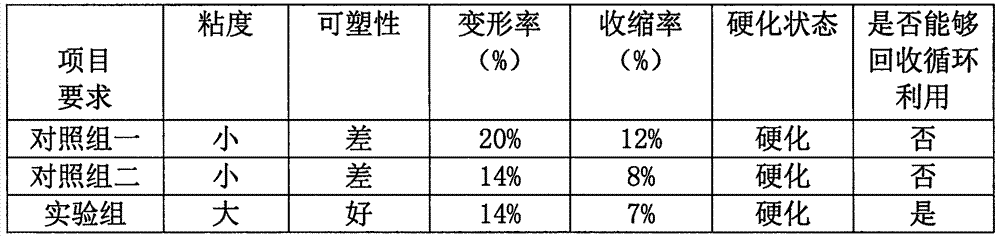

Plasticine and preparation method and reusable sand table using plasticine

The invention belongs to plasticine and a preparation method and a reusable sand table using the plasticine. The reusable sand table comprises a plasticine base disc and a plasticine model which are made of the plasticine. A fixing pin is arranged between the plasticine base disc and the plasticine model, the bottom of the plasticine base disc is provided with a glass base, glass plates are arranged around the glass base respectively, the two ends of the fixing pin are conical, one end of the fixing pin is arranged on the upper portion inside the plasticine base disc, and the other end of the fixing pin is arranged on the lower portion inside the plasticine model. The plasticine model comprises a plasticine rockery model, a plasticine river model, a plasticine sidewalk model, a plasticine house model and a plasticine road model. The reusable sand table has the advantages of being reasonable in design and convenient to use and reuse. The model is mainly made of the plasticine, is high in viscosity and good in soft plasticity, has the advantages of not deforming easily and being low in shrinkage and hardening, and is suitable for sand table manufacture and display.

Owner:HENAN MECHANICAL & ELECTRICAL ENG COLLEGE

Crystal wiredrawing plasticine and preparation method thereof

The invention provides crystal wiredrawing plasticine and a preparation method thereof. The plasticine comprises the following components in parts by weight: 1-3 parts of transparent liquid glue, 1-3parts of white glue, 1-3 parts of shaving foam, 1-3 parts of glycerin, 1-3 parts of borax water, 1-2 parts of clay, and 1-2 parts of snowflake powder; and the preparation method comprises the following steps: preparing the raw materials according to the above weight parts; mixing the transparent liquid glue, the white glue, the shaving foam and the glycerin, putting the mixed material into a stirring machine, and performing stirring for 5 min to obtain a stirred substance A; pouring a suitable ratio of the borax water into the prepared stirred substance A, and performing stirring for 5 min toobtain a stirred substance B; adding the clay into the prepared stirred substance B, and continuing stirring to form plasticine; and adding the prepared plasticine into the infused snowflake powder, and performing kneading molding to obtain the snowflake wiredrawing crystal plasticine. The preparation method provided by the invention is simple, has low costs, is beautiful and elegant, and saves alarge amount of preparation time and preparation costs.

Owner:傅伟伟

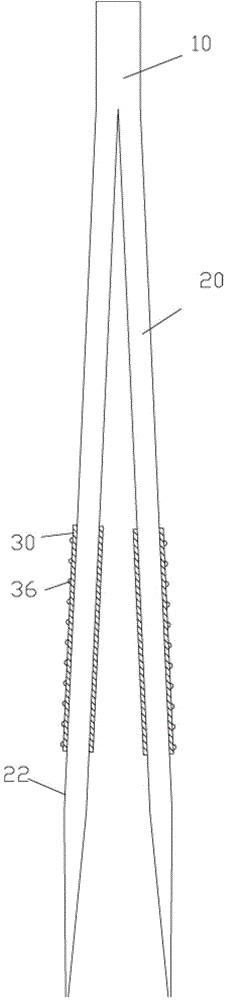

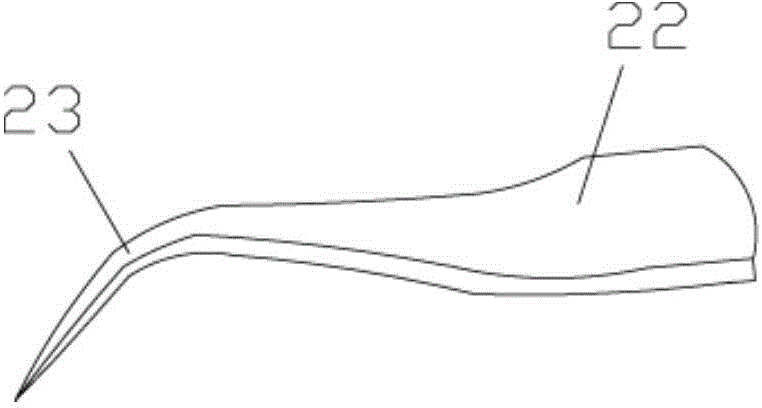

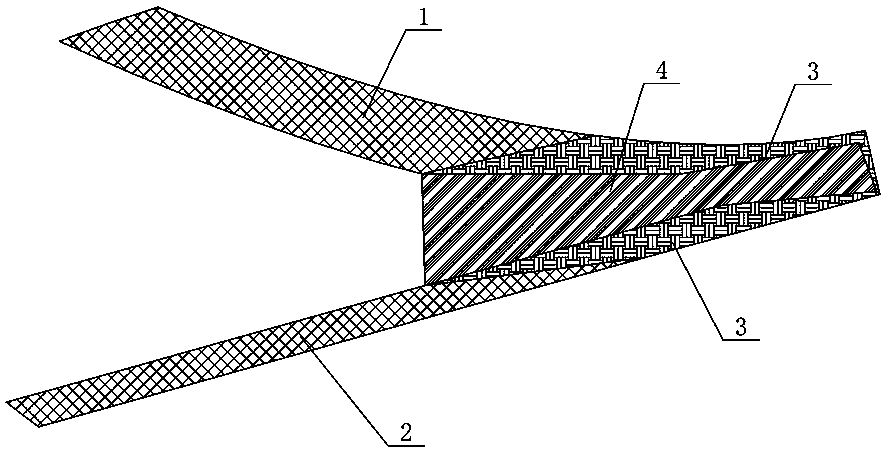

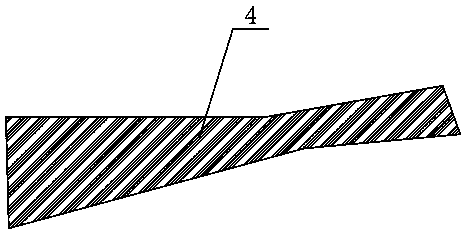

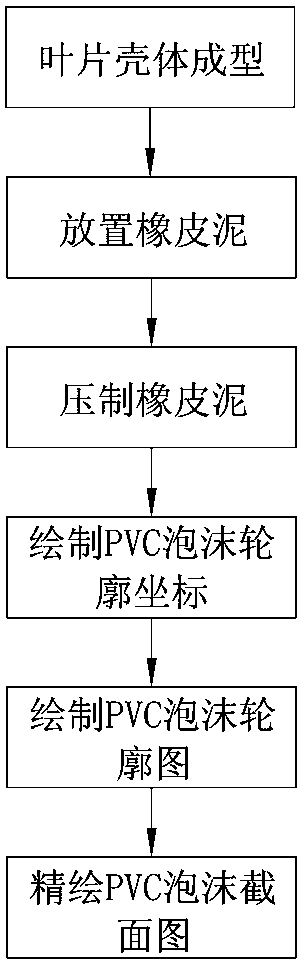

Wind power blade posterior-edge die spotting PVC foam design method

ActiveCN108509663AEasy to operateLow costGeometric CADSpecial data processing applicationsEconomic benefitsEngineering

The invention discloses a wind power blade posterior-edge die spotting PVC foam design method. The method comprises the following steps: S1, forming blade shell bodies; S2, placing plasticine; S3, pressing the plasticine; S4, drawing PVC foam contour coordinates; S5, drawing a PVC foam contour graph; and S6, refinedly drawing a PVC foam section drawing. The method has the advantages that operations are convenient, economic benefits are high, and design costs can be reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com