Laser mask shock forming device based on plasticine mould and method of laser mask shock forming device

A technology of impact forming and plasticine, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems affecting the accuracy of workpieces, achieve the effects of improving mechanical properties, precise and controllable laser parameters, and reducing springback deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings.

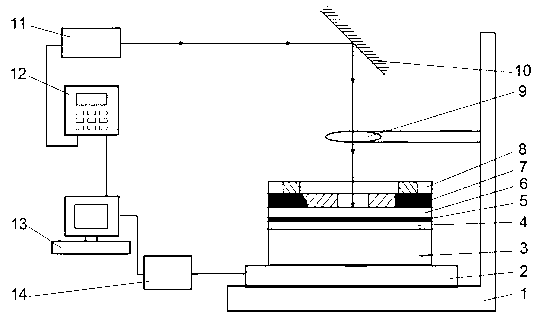

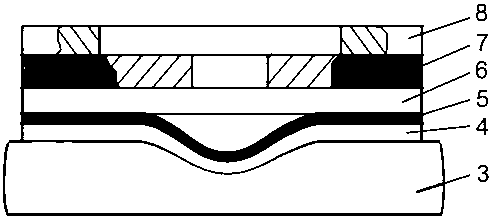

[0027] The structure of the laser mask impact forming device based on the plasticine mold of the present invention is as follows figure 1 Shown, including laser loading system, platform moving system, forming system, control system connection. The laser loading system consists of a nanosecond laser 11, a reflector 10, and a focusing lens 9. The laser beam emitted by the nanosecond laser passes through the reflector 10 and the focusing lens 9 and directly enters the forming system; the forming system includes a ring press block 8, a mask 7. Optical medium 6, absorption layer film 5, work piece 4 and plasticine 3, the forming system is placed on the platform moving system through the ring pressing block 8; the platform moving system is composed of the three-dimensional moving platform 2 and the L-shaped base 1; the three-dimensional moving platform 2 is fixed on the L-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com