Patents

Literature

36results about How to "Reduce springback deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for processing polymer film surface microstructure based on roll-to-roll hot rolling

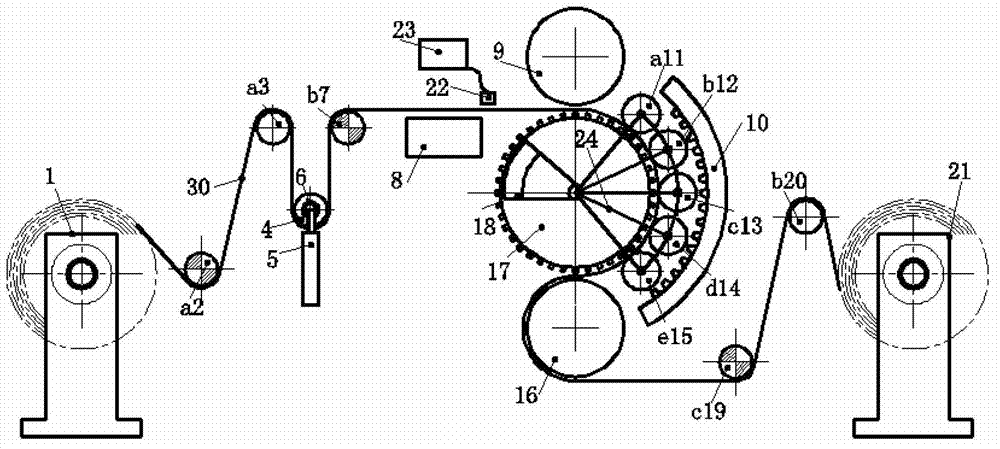

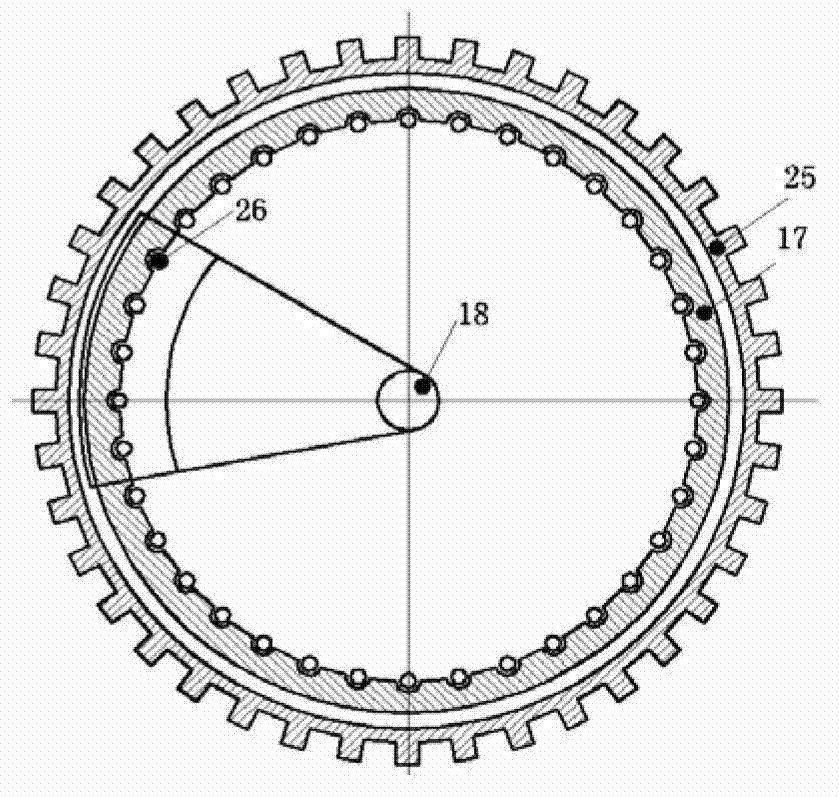

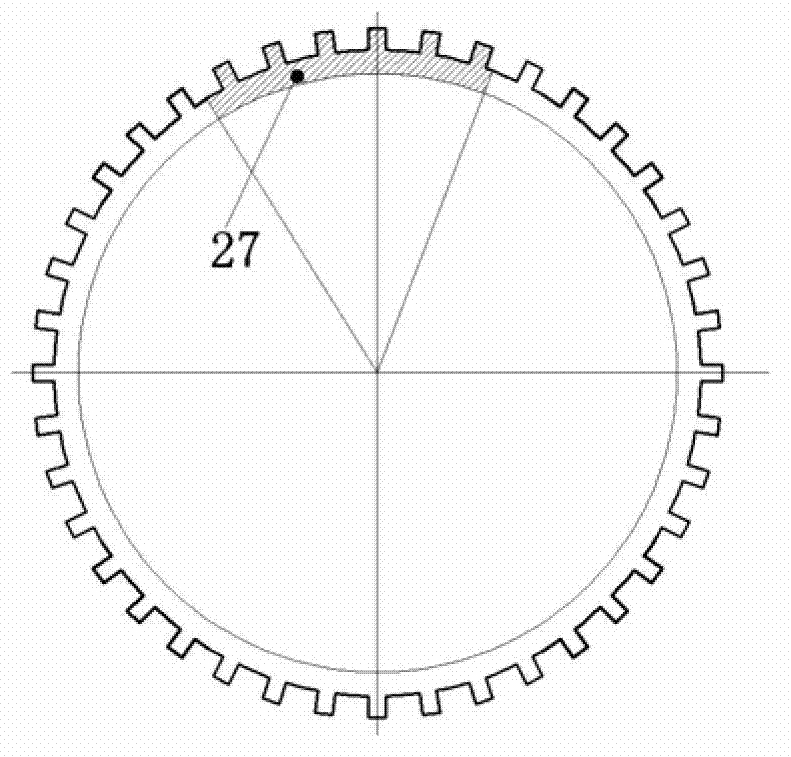

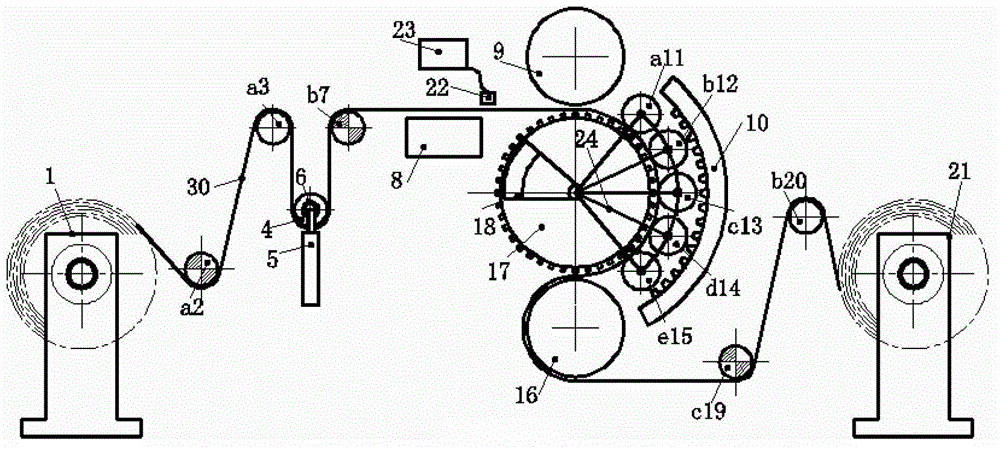

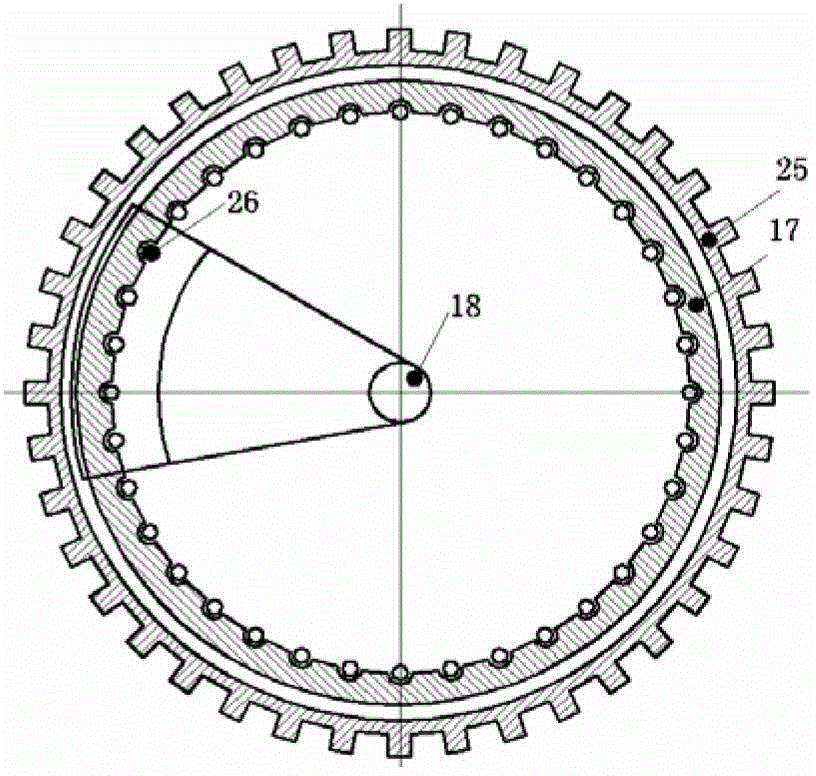

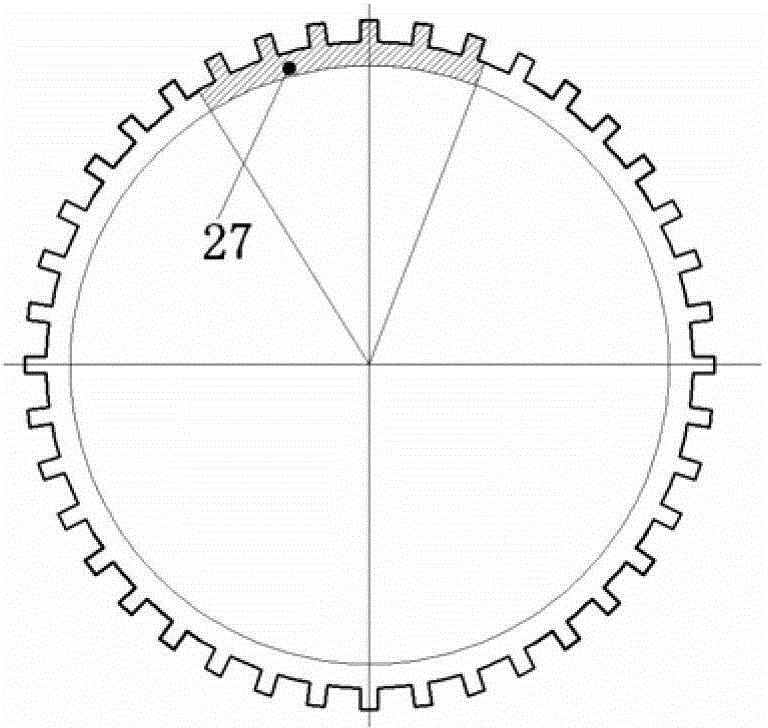

The invention relates to device and method for processing a polymer film surface microstructure based on roll-to-roll hot rolling. The method comprises the following six steps: unrolling, pre-heating, hot-rolling, conforming, cooling and rolling. The unrolling step includes continuously drawing a polymer film from a rolled material and removing static electricity on the surface of the film. After the pre-heating step, the polymer film is heated to a temperature below the glass transition temperature thereof to get ready for the hot-rolling step. The local heating treatment is conducted on a plate roller to allow only the temperature of the stamping surface to rise above the glass transition temperature, so as to roll-form the preheated film. The conforming step enables the rolled film in close contact with the surface of the plate roller, so that the film is completely deformed. The formed film is subjected to both cooling and conforming to cause rapid curing of the surface microstructure and reduce rebound. Compared with the prior art, the device and method have the advantages of reducing the risk of rebound and deformation, improving the forming precision of the microstructure, making demoulding easier and increasing the processing efficiency.

Owner:SHANGHAI JIAO TONG UNIV

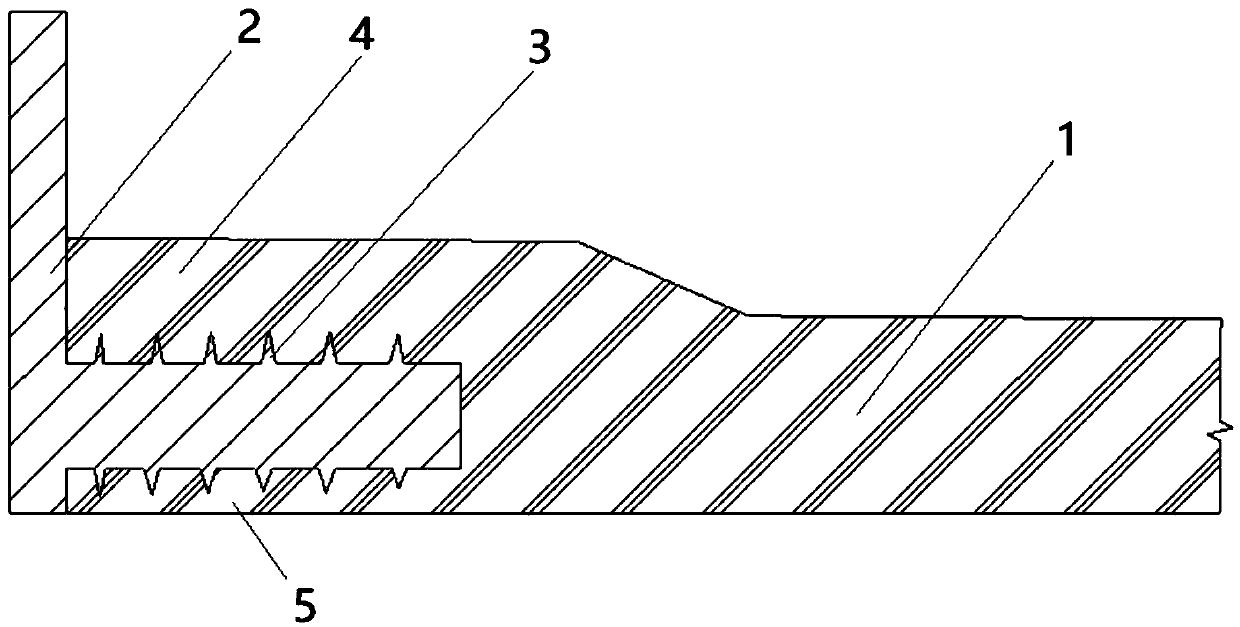

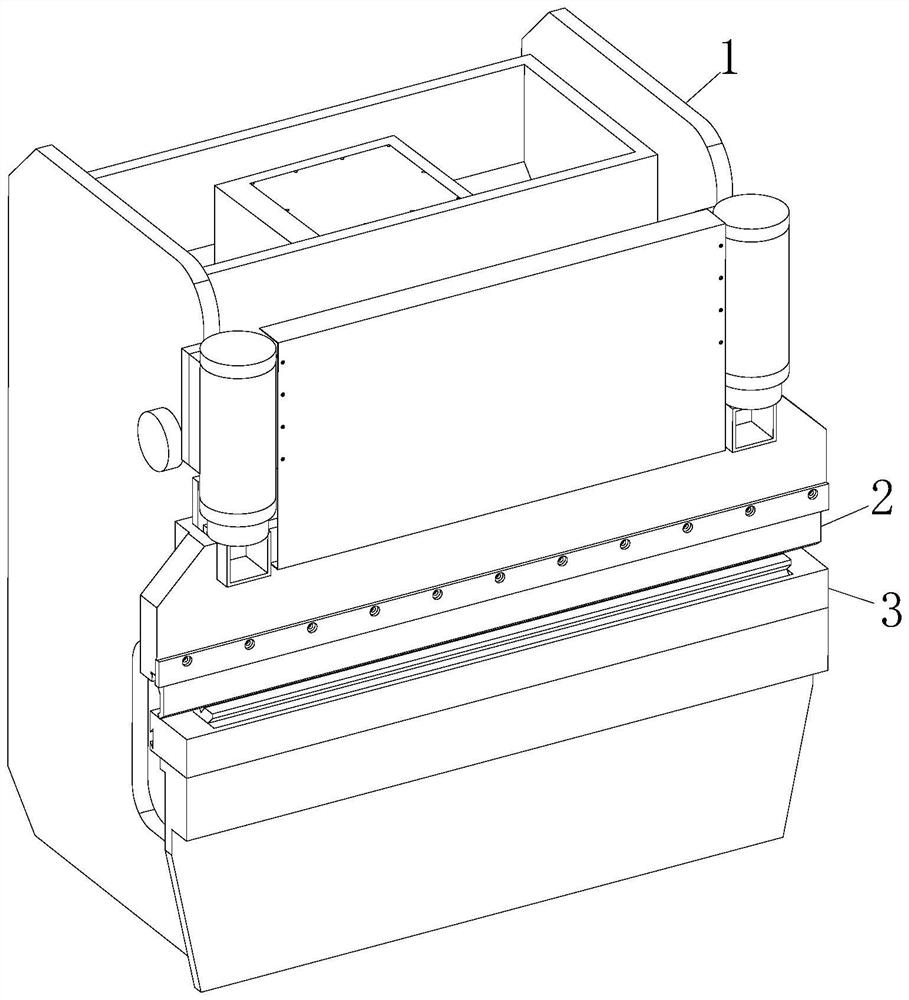

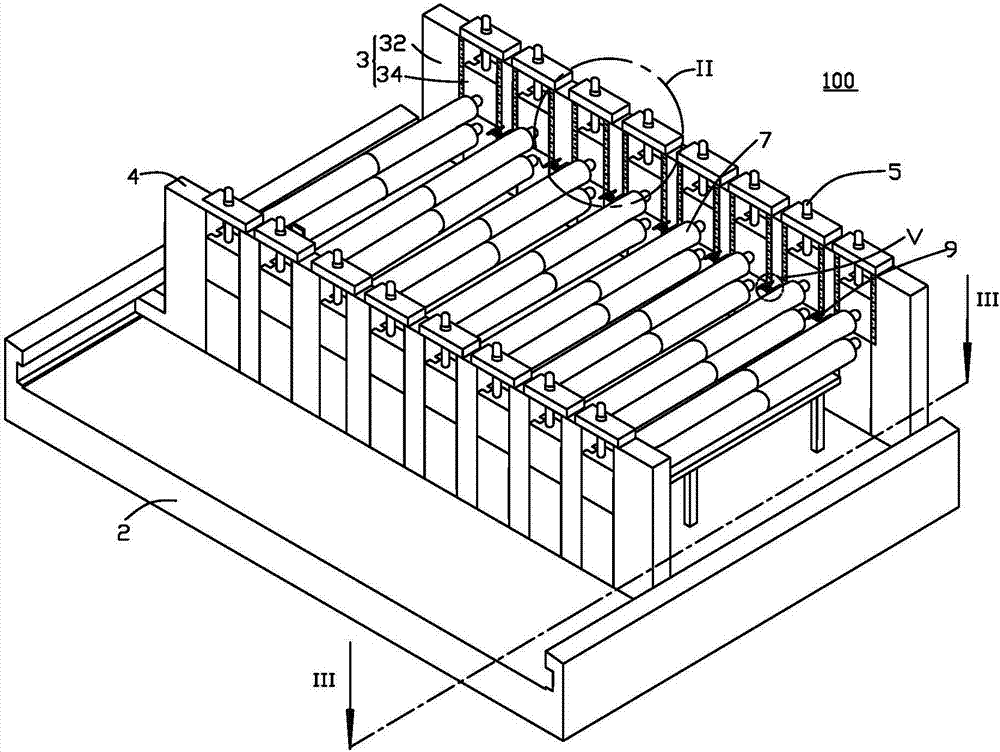

Plate rolling bending machine

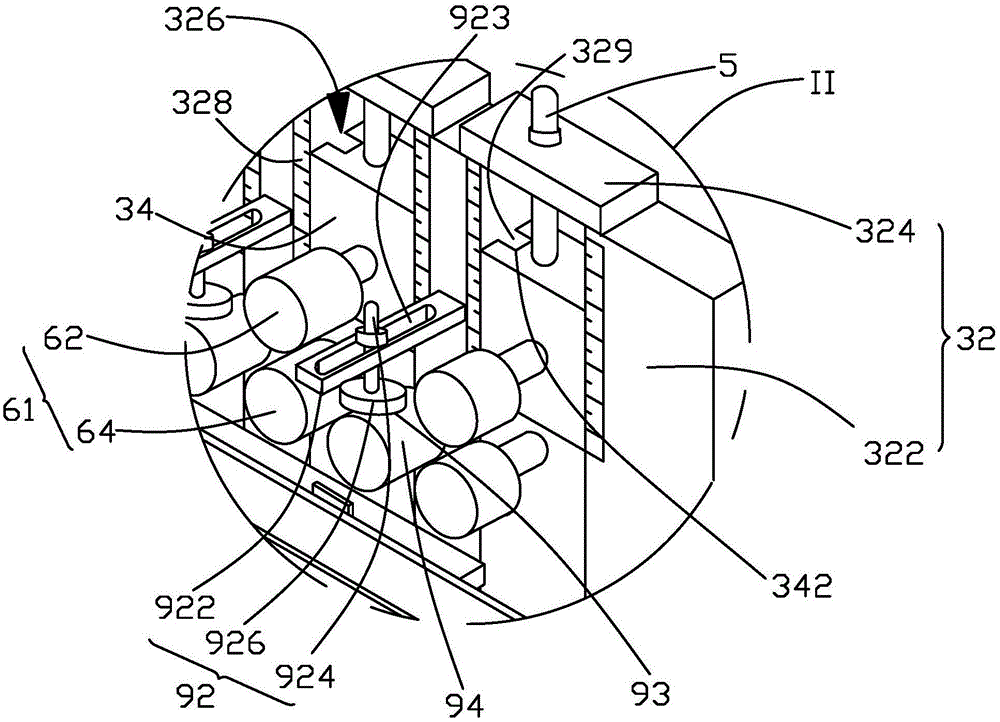

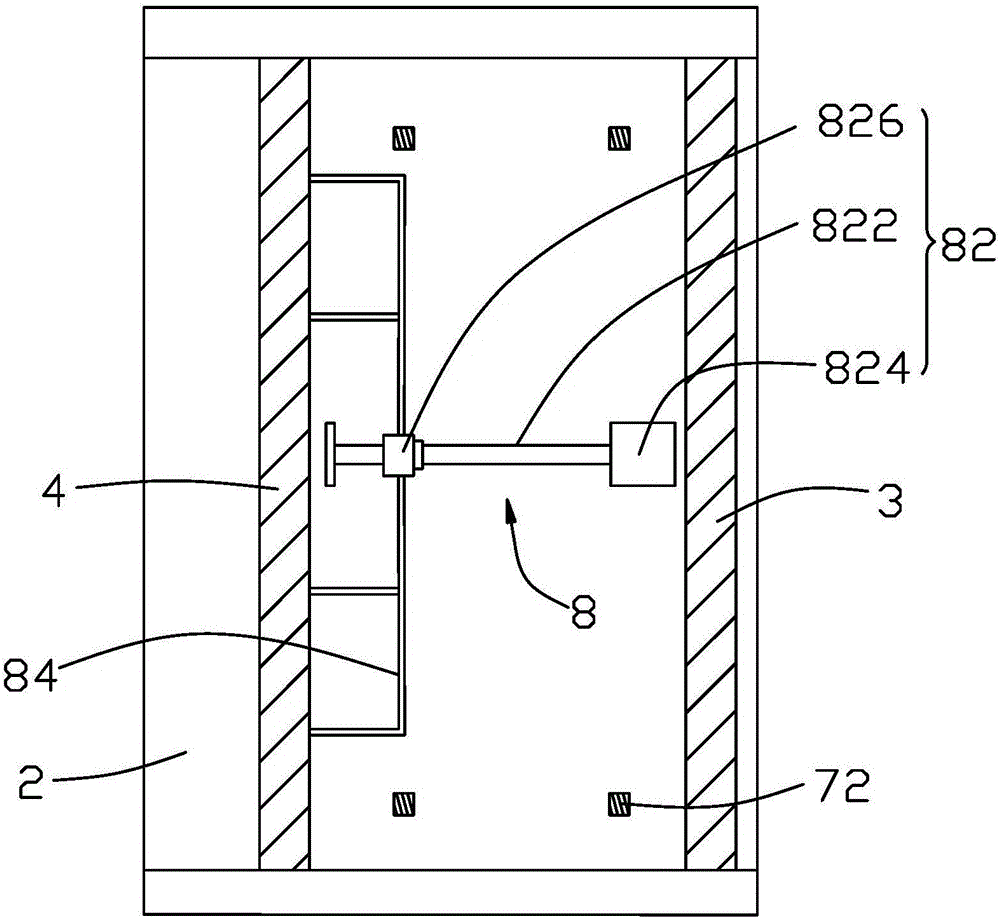

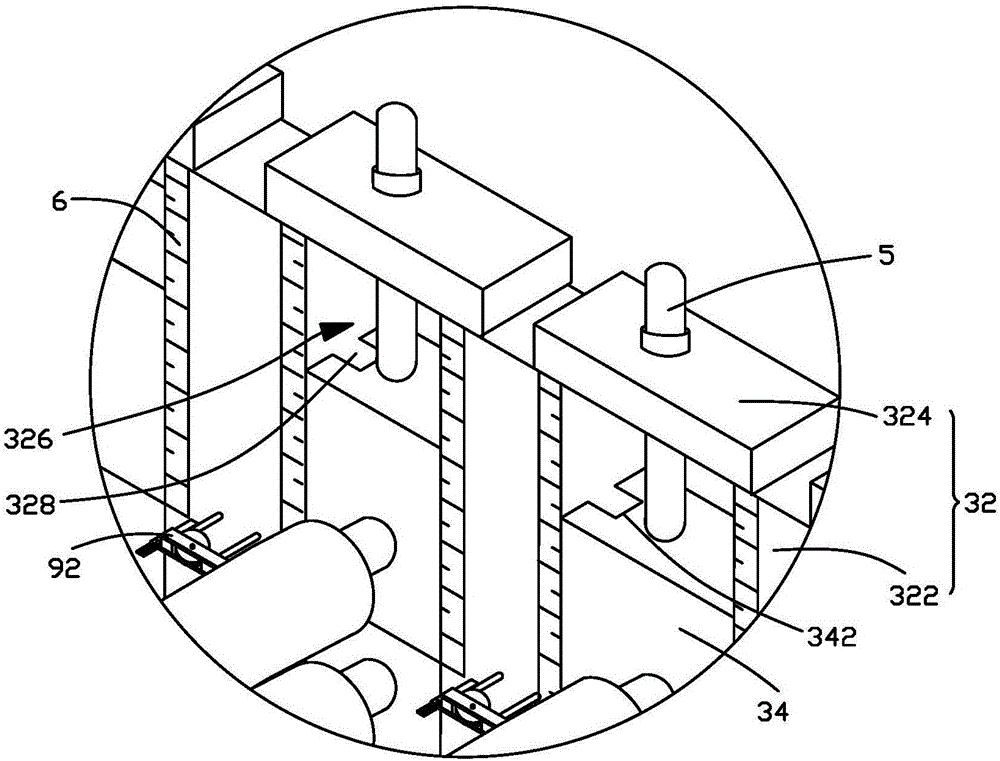

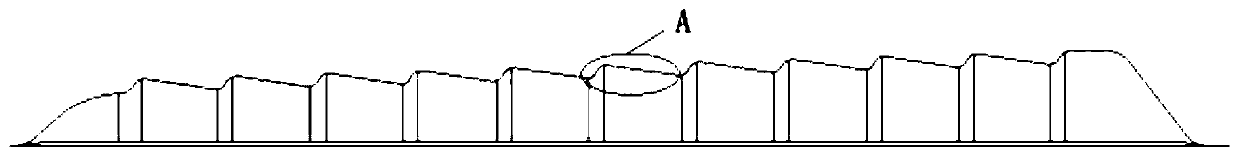

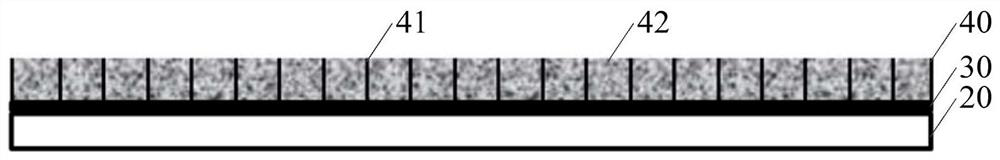

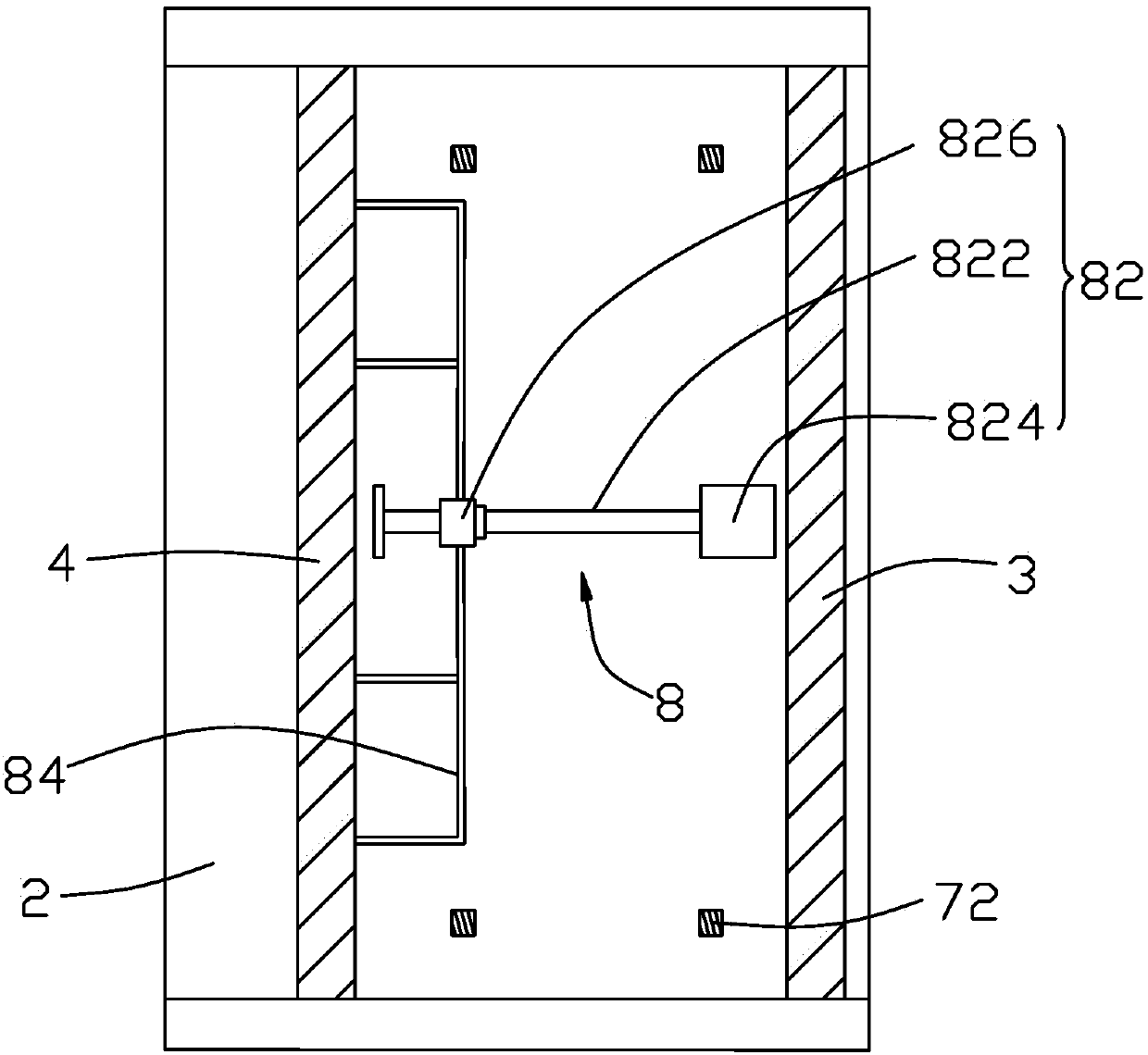

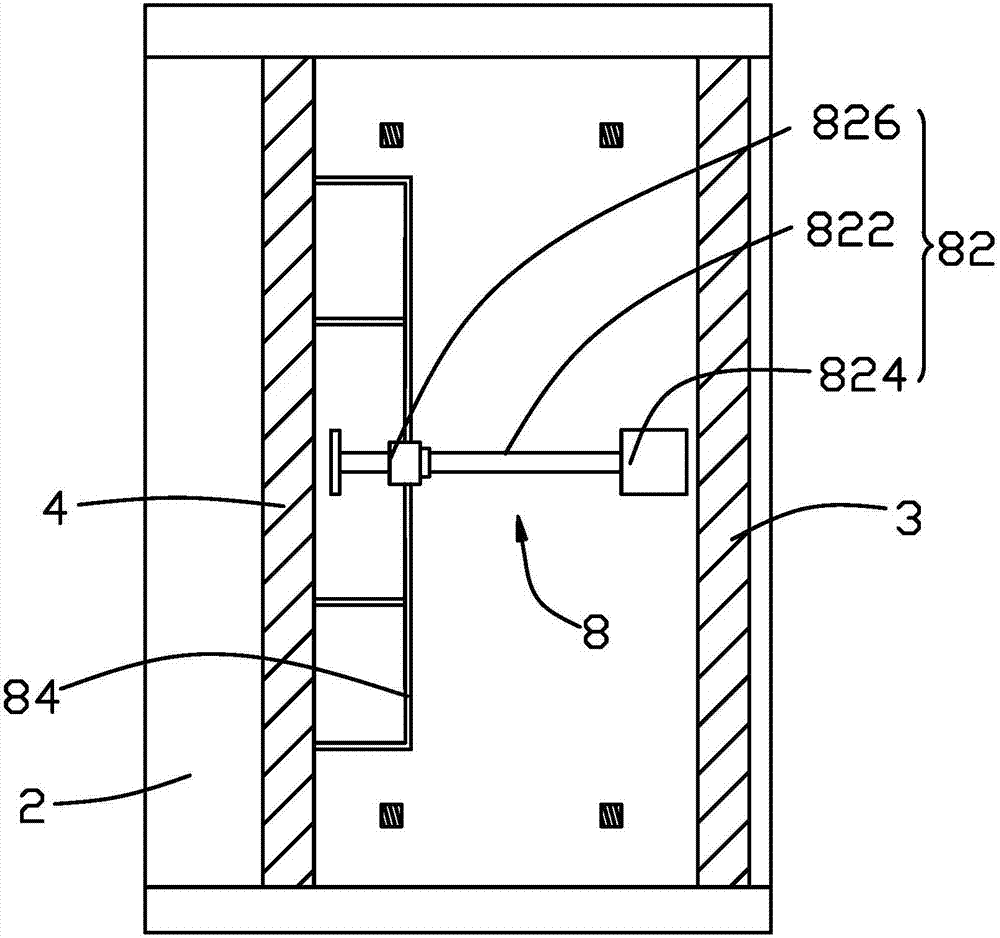

ActiveCN106077179AReduce springback deformationHigh precisionMetal-working feeding devicesPositioning devicesMechanical engineeringSupporting wall

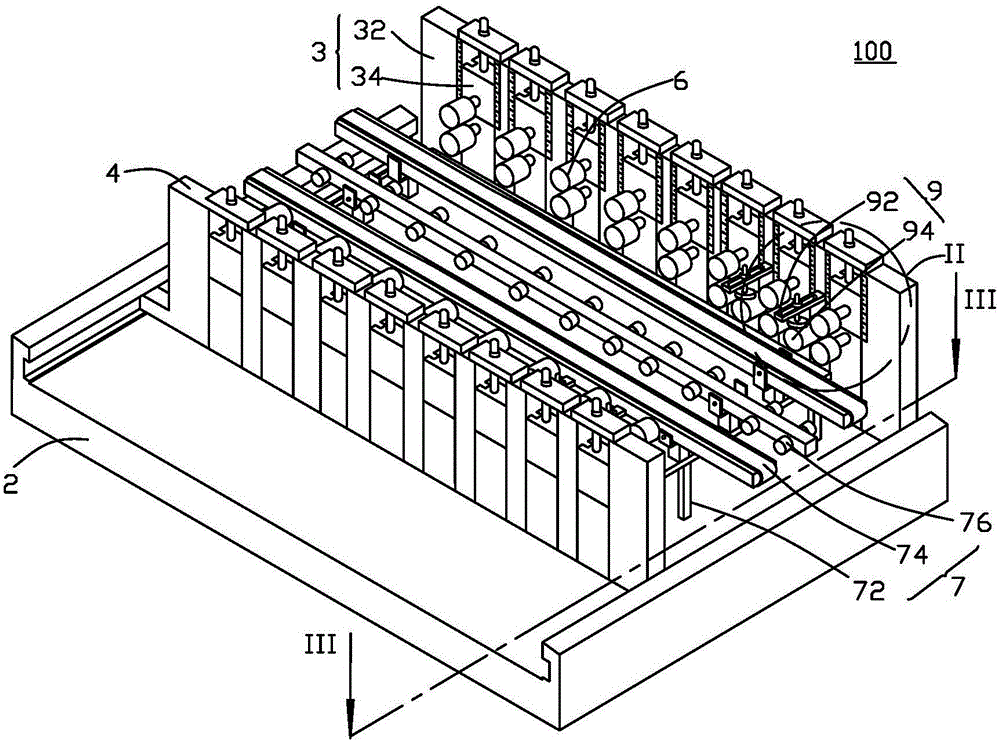

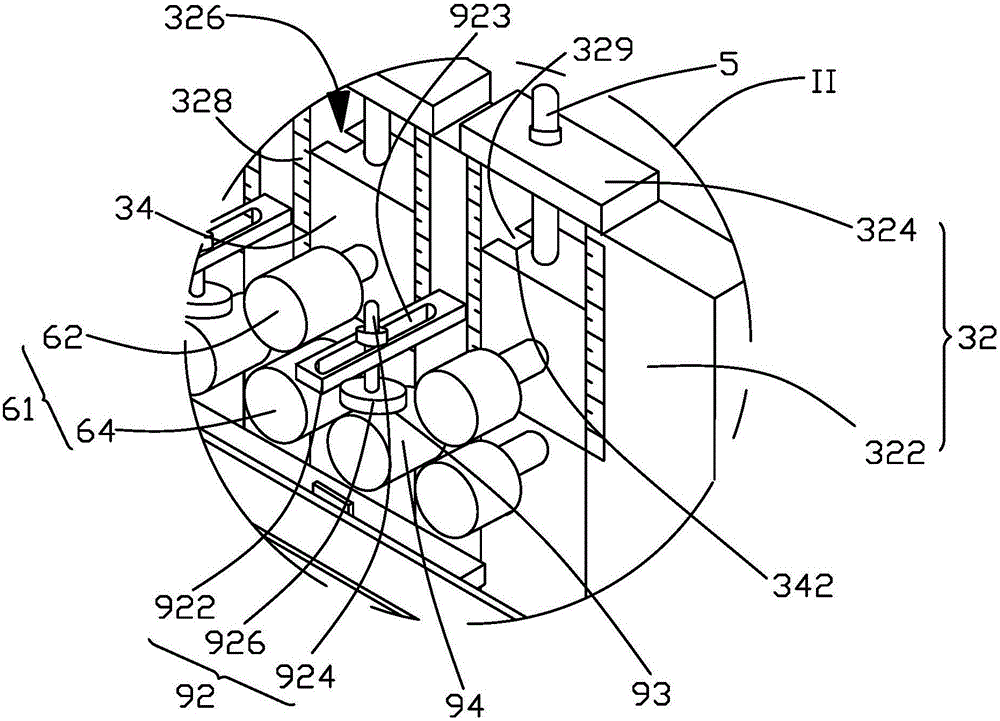

The invention provides a plate rolling bending machine used for bending the two opposite sides of a plate by a preset angle theta. The plate rolling bending machine comprises two oppositely-arranged supporting walls, two rows of forming roller sets arranged on the two supporting walls correspondingly, and a conveying mechanism located between the two rows of forming roller sets. The conveying mechanism is used for conveying the plate. Each row of forming roller sets comprises a plurality of forming roller sets arranged in the conveying direction of the plate at intervals. Each forming roller set comprises an upper roller and a lower roller which are arranged oppositely. The upper rollers and the lower rollers are both rotationally arranged on the corresponding supporting walls. The peripheral wall of each upper roller and the peripheral wall of the corresponding lower roller are correspondingly provided with bending surfaces used in cooperation. The angle formed by the bending surfaces and the axes of the forming rollers ranges from 0 degree to theta, and the angle gradually increases to the preset angle theta in the conveying direction of the plate. The plate rolling bending machine can improve the bending precision and forming effect of the plate.

Owner:广西田阳至恒门业有限公司

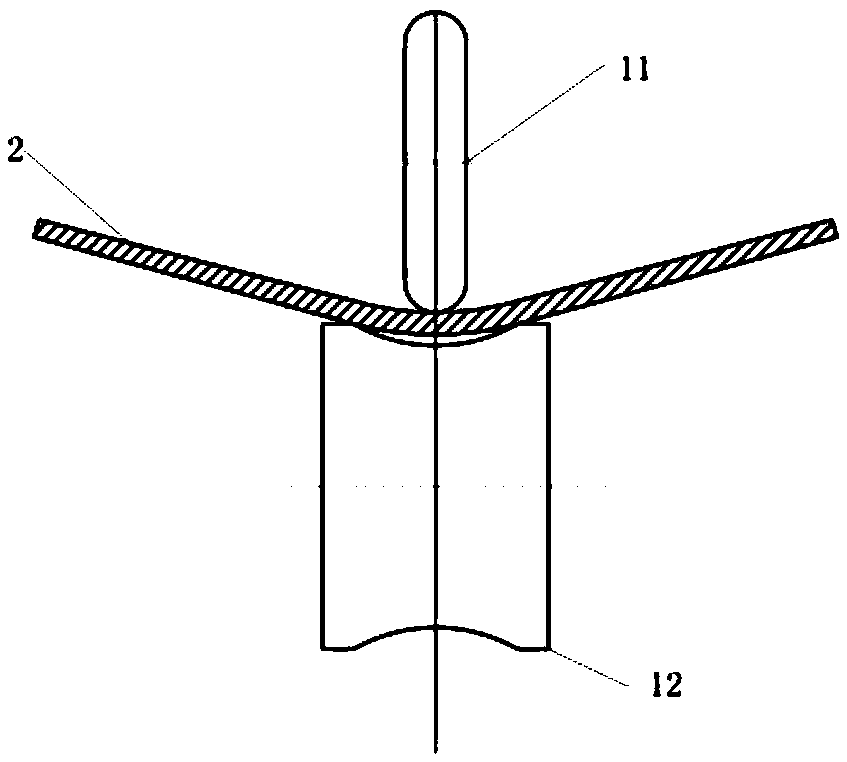

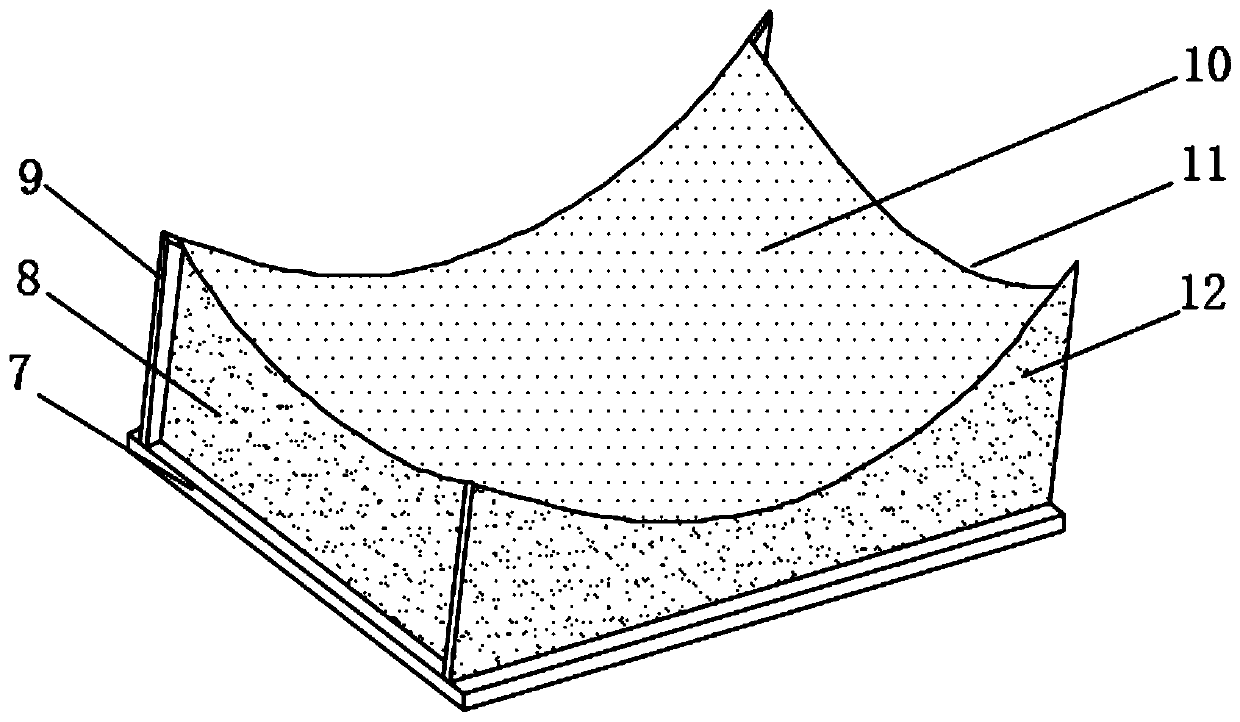

Viscous medium pressure forming method for local curvature sudden change thin-wall coverage piece

The invention belongs to the field of aerospace equipment thin-wall coverage piece manufacturing, and particularly relates to a viscous medium pressure forming method for a local curvature sudden change thin-wall coverage piece. According to the method, a plunger in a viscous medium bin is pushed, so that viscous media load the viscous medium pressure P to a plate blank from the viscous medium bin, under the action of the viscous medium pressure P, the plate blank is gradually attached to a cavity of a die, and at the cavity curvature sudden change position, a plate is promoted to flow throughthe viscous attaching stress tau of the viscous media, shape local sudden change area materials are supplemented, the area wall thickness is prevented from being reduced, the wall thickness uniformity is improved, finally, the plate blank is completely attached to the surface of the cavity of the die, and accordingly a good forming effect is achieved. According to the viscous medium pressure forming method, the forming technology is simple, the quality is stable, reliability is high, cost is low, and the viscous medium pressure forming method is suitable for forming machining of high-strengthheat resisting alloy local curvature sudden change thin-wall coverage pieces.

Owner:HARBIN INST OF TECH

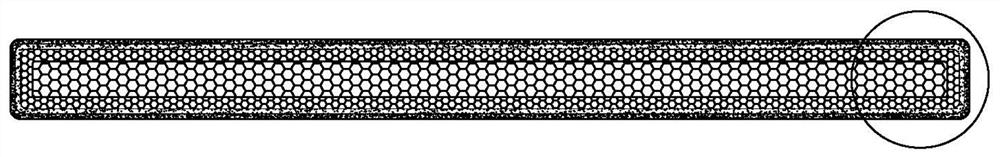

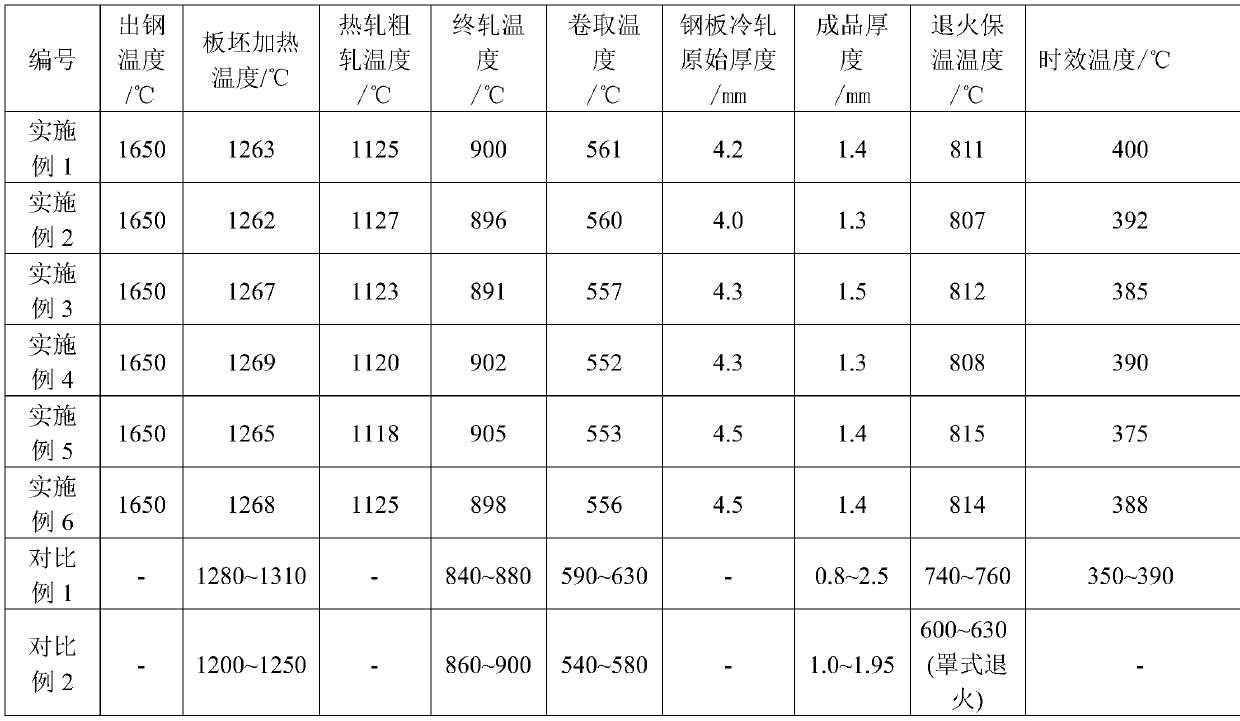

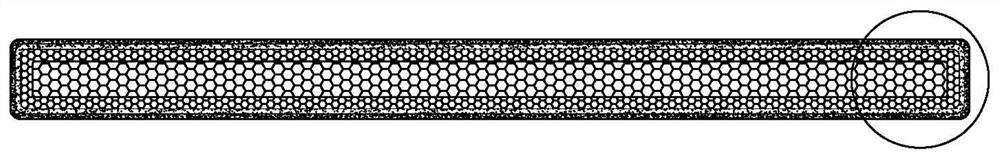

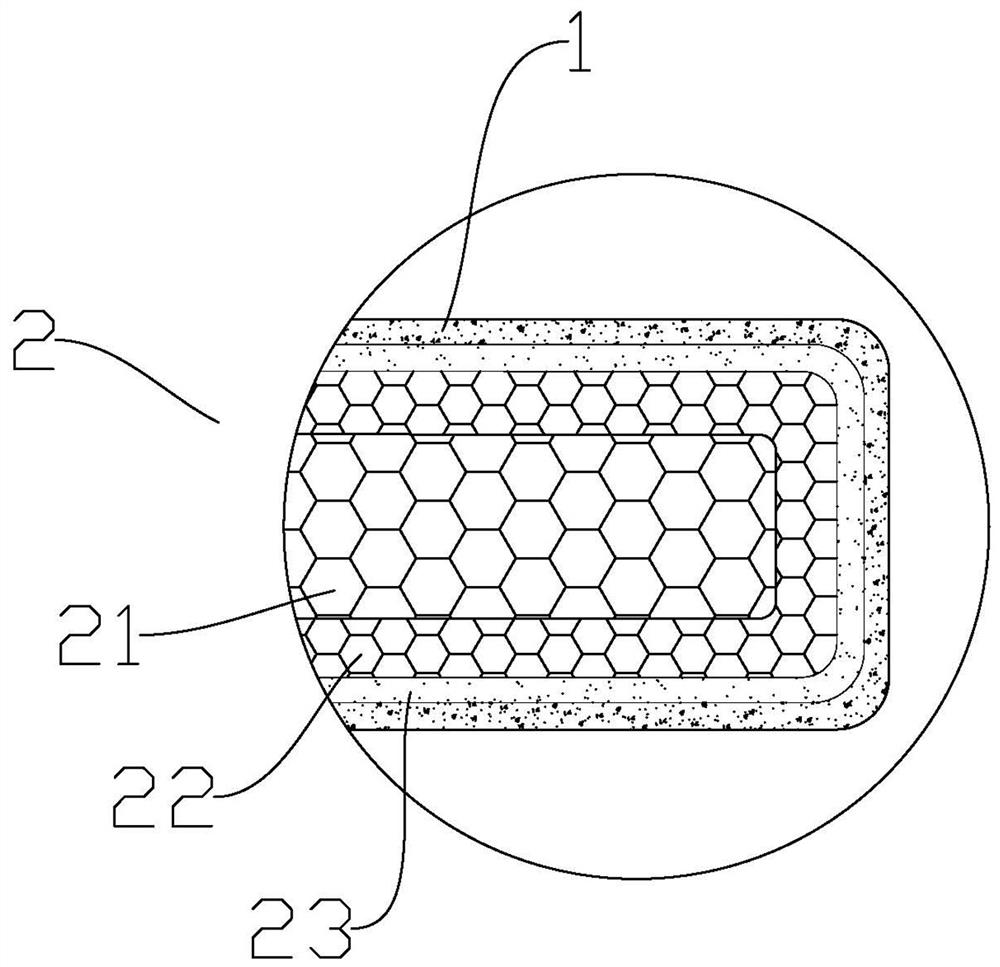

PVC co-extrusion foaming floor and preparation method thereof

ActiveCN112443120AAchieve light weightAchieving cohesionLamination ancillary operationsSynthetic resin layered productsPolymer scienceHigh density

The invention relates to a PVC co-extrusion foaming floor and a preparation method thereof, and belongs to the technical field of PVC foaming floors. The PVC co-extrusion foaming floor comprises a PVCfoaming core and a plastic surface layer, wherein the PVC foaming core comprises a first foaming layer, a second foaming layer and a skinning layer, the second foaming layer wraps the first foaming layer, the skinning layer wraps the second foaming layer, and all the layers of the PVC foaming core are integrally connected; the plastic surface layer wraps at least the upper surface of the skinninglayer; the first foaming layer is a low-density foaming layer, and the second foaming layer is a high-density foaming layer; and wood textures are formed in the plastic surface layer. According to the PVC co-extrusion foaming floor and the preparation method thereof, one-time forming is achieved through an improved foaming process, so that compared with a PVC foaming core in the prior art that the first foaming layer and the second foaming layer are not obviously distinguished and the skinning layer is thin, the PVC foaming core has the advantages of being clearer in structural hierarchy andhigher in overall strength; and the PVC foaming core is more suitable for wrapping the plastic surface layer.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

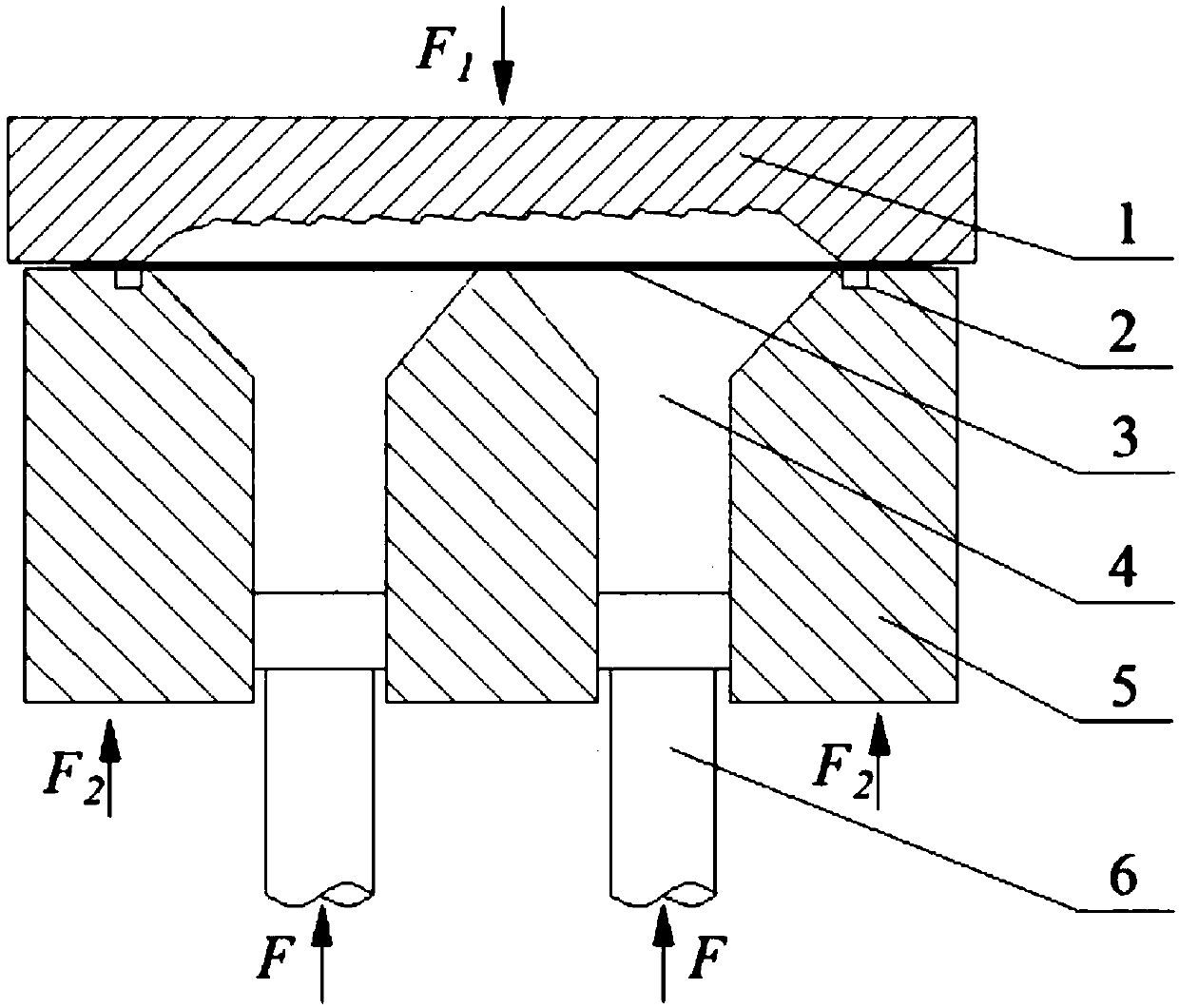

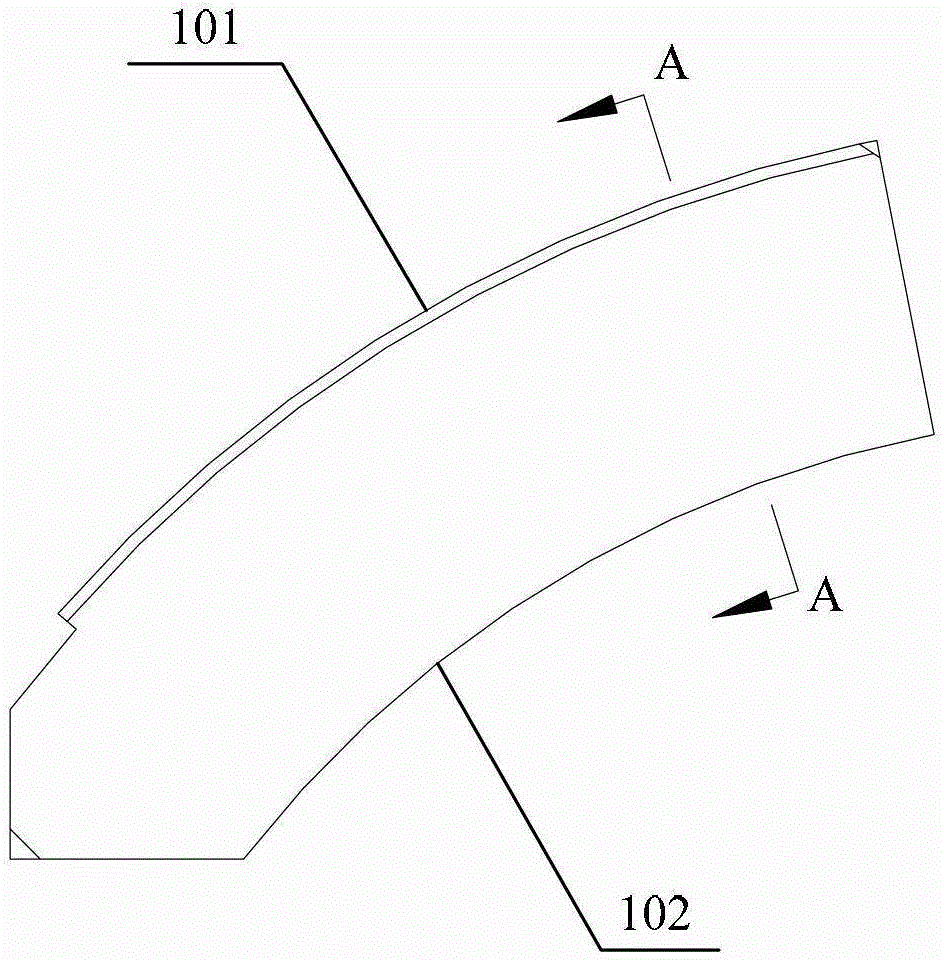

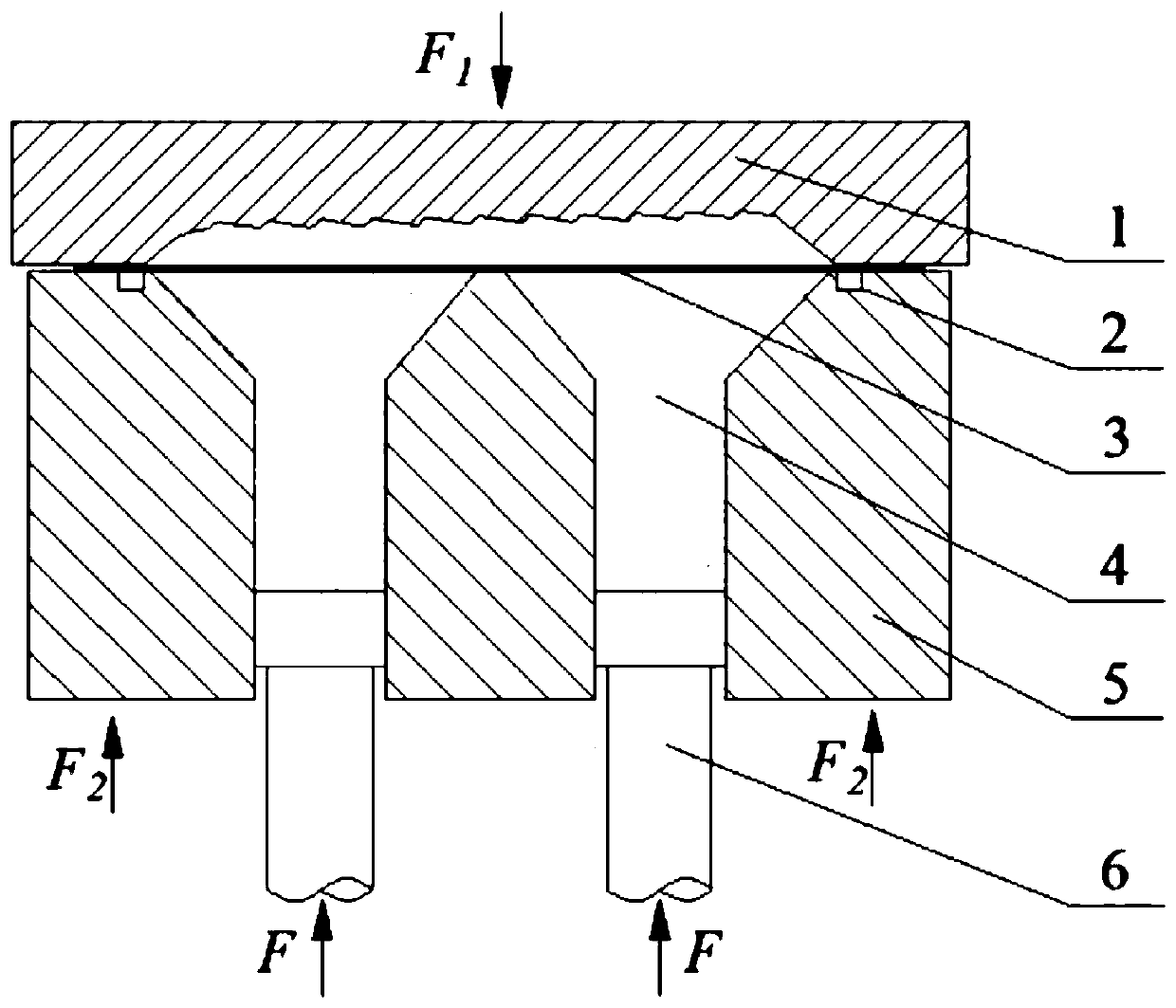

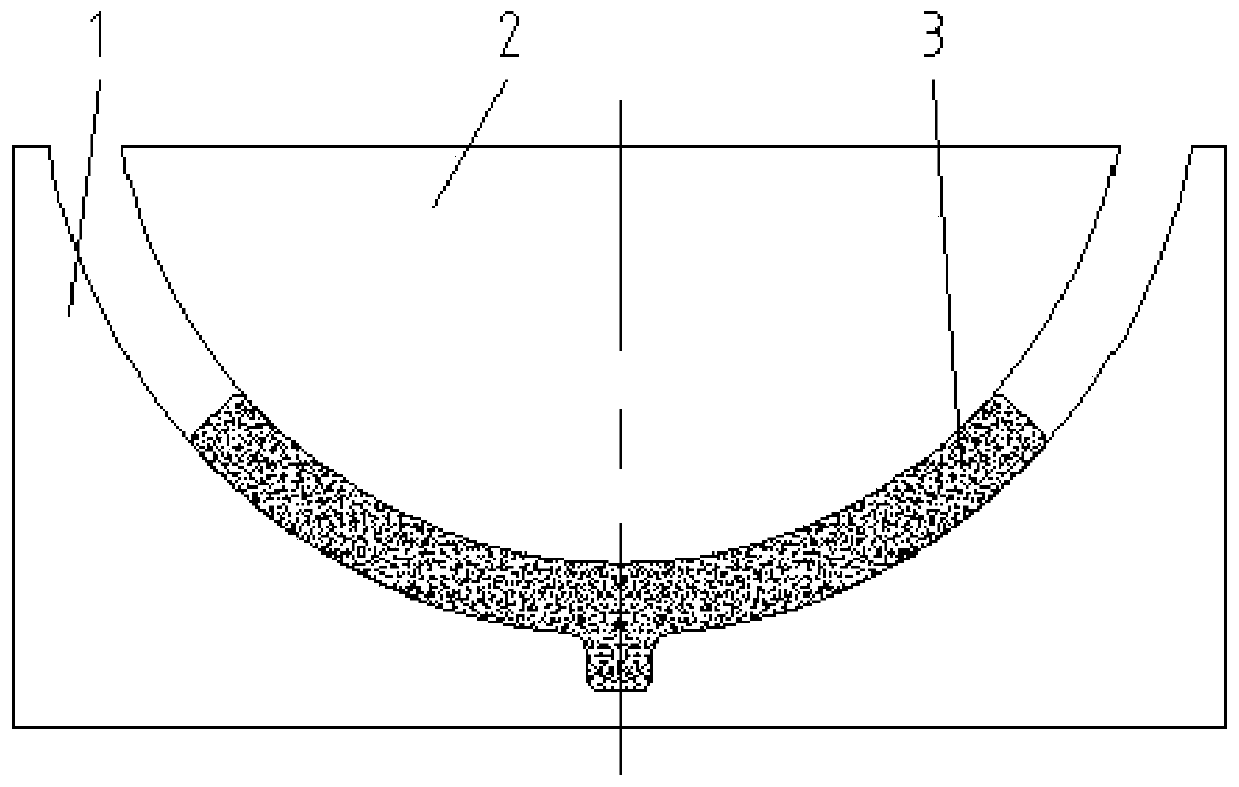

Mould for forming side push bending beam for passenger train

InactiveCN102974698AGuaranteed flatnessReduce springback deformationShaping toolsVehicle componentsLower limitRailway passenger car

The invention provides a mould for forming a side push bending beam for a passenger train. The mould comprises an upper mould and a lower mould arranged up and down. The upper mould can move relative to the lower mould. A lower limiting block is fixedly arranged on the lower mould, and a pressure plate is sleeved on the lower limiting block. A second concave arc-shaped face is formed on a top face of the lower limiting block, the bottom face of the upper mould is a first convex arc-shaped face, and a first concave arc-shaped face attached to the bottom face of the upper mould is formed on the top face of the pressure plate. A groove corresponding to the lower limiting block is formed on the bottom face of the upper mould. The groove is internally provided with an upper limiting block. The bottom face of the upper limiting block is a second convex arc-shaped face matched with the second convex concave arc-shaped face. The pressure plate under the effect of a limiting drive device is positioned on a first work position under the effect of a limiting drive device, and the upper mould moves downward to the pressure plate and is attached to the top face of the pressure plate so as to drive the pressure plate to move downward relative to the lower positioning block so that the lower limiting block enters into the groove. According to the mould, formed rebound deformation can be effectively reduced and the forming quality is improved through the arrangement of the moveable pressure plate.

Owner:CRRC TANGSHAN CO LTD

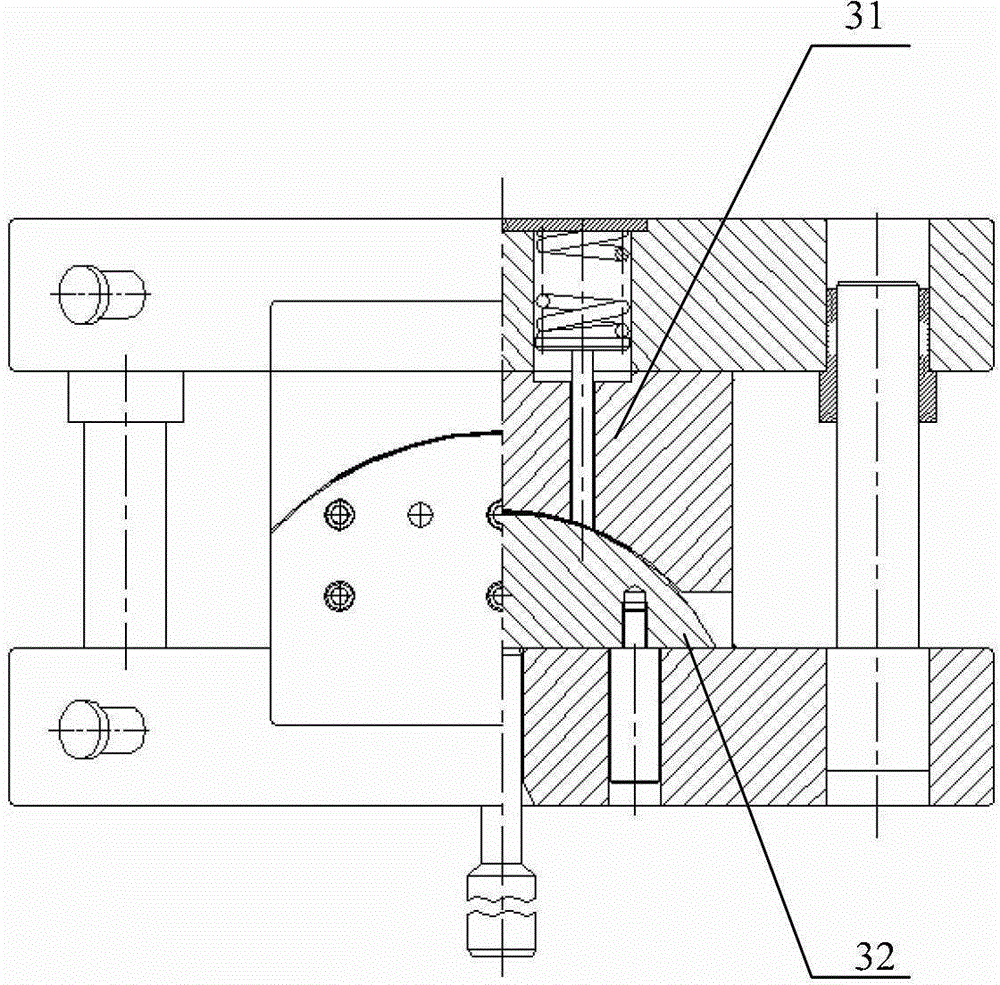

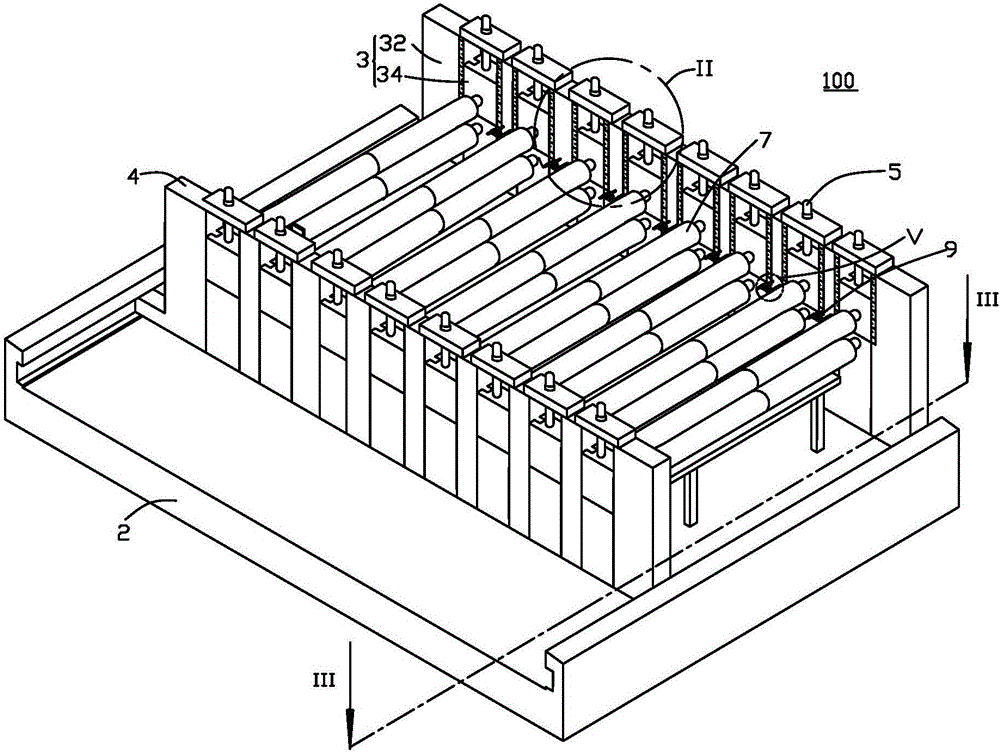

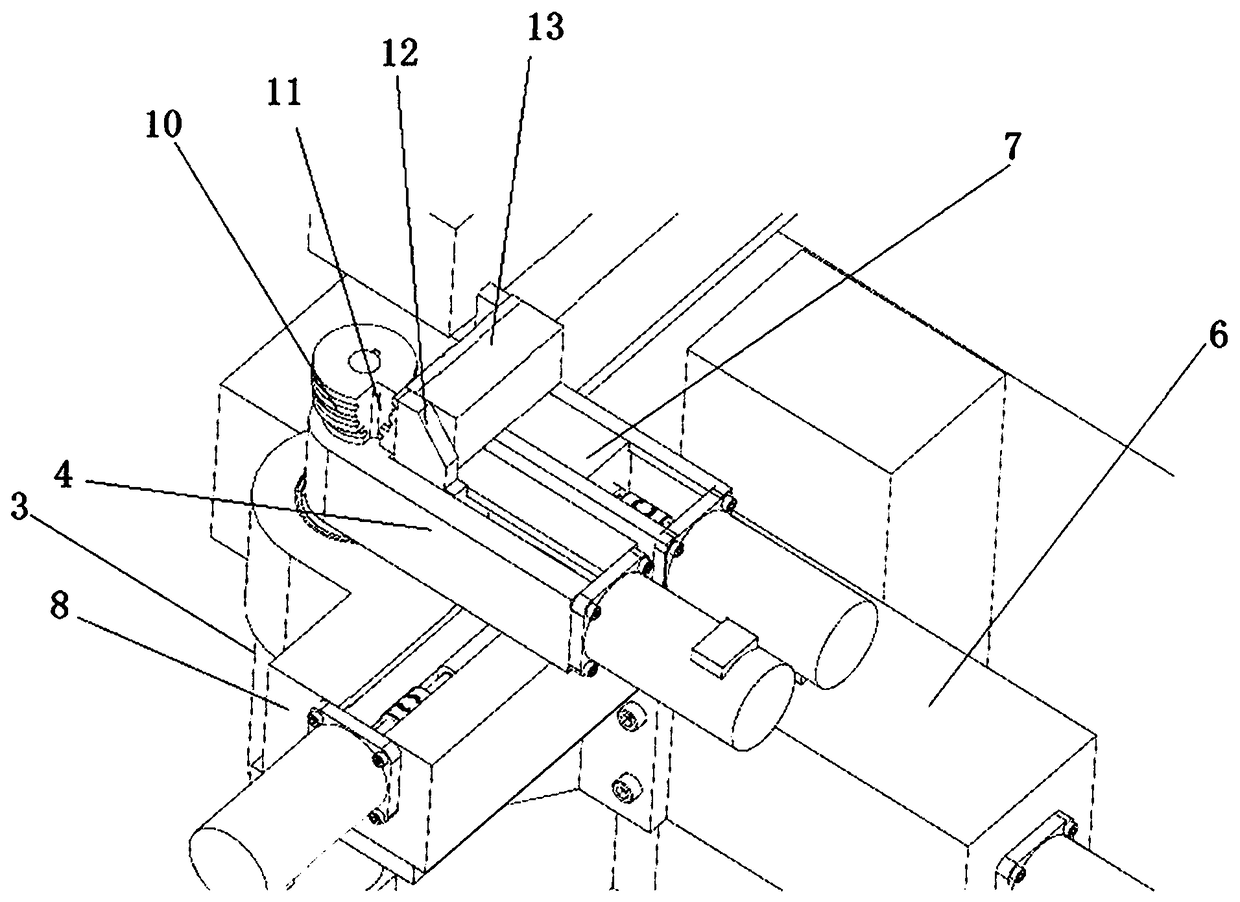

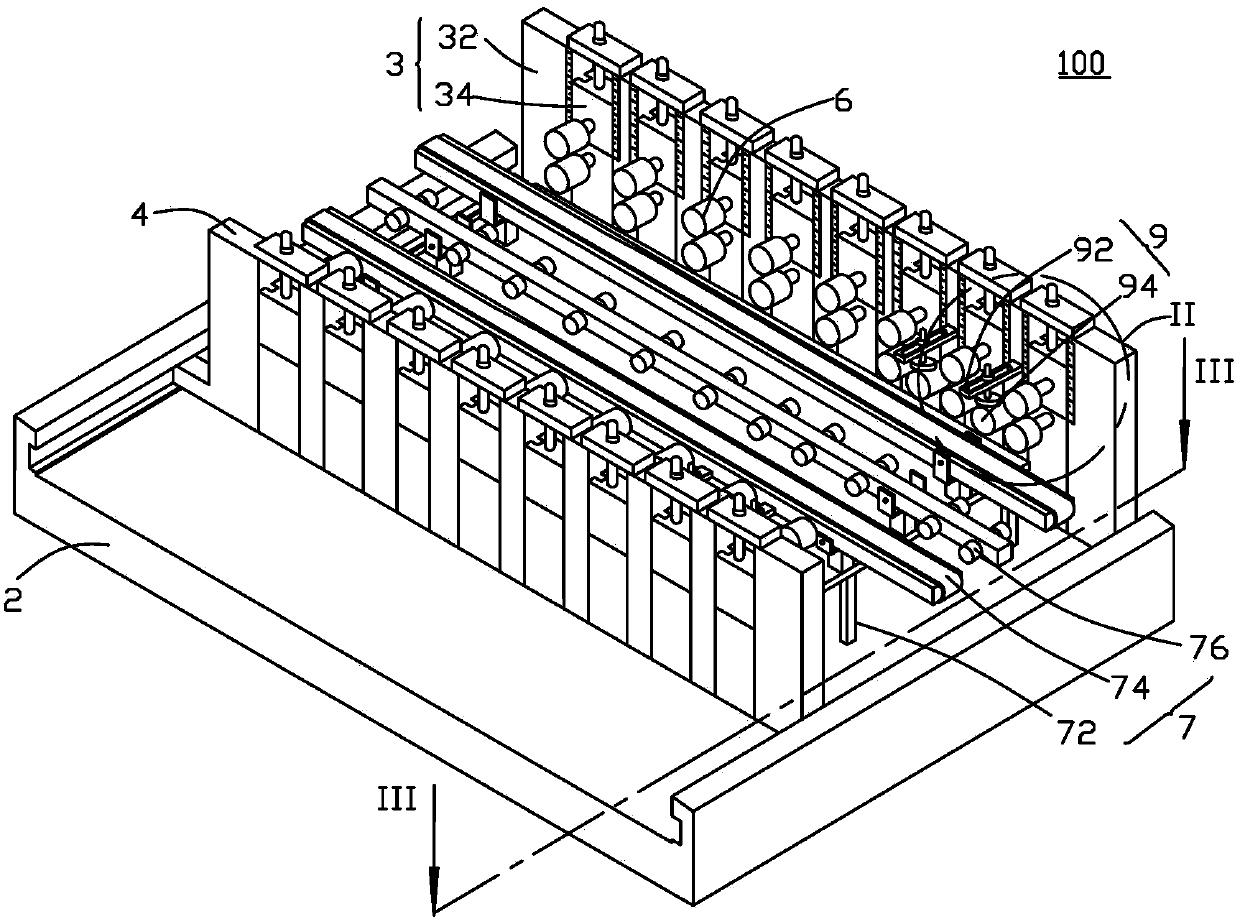

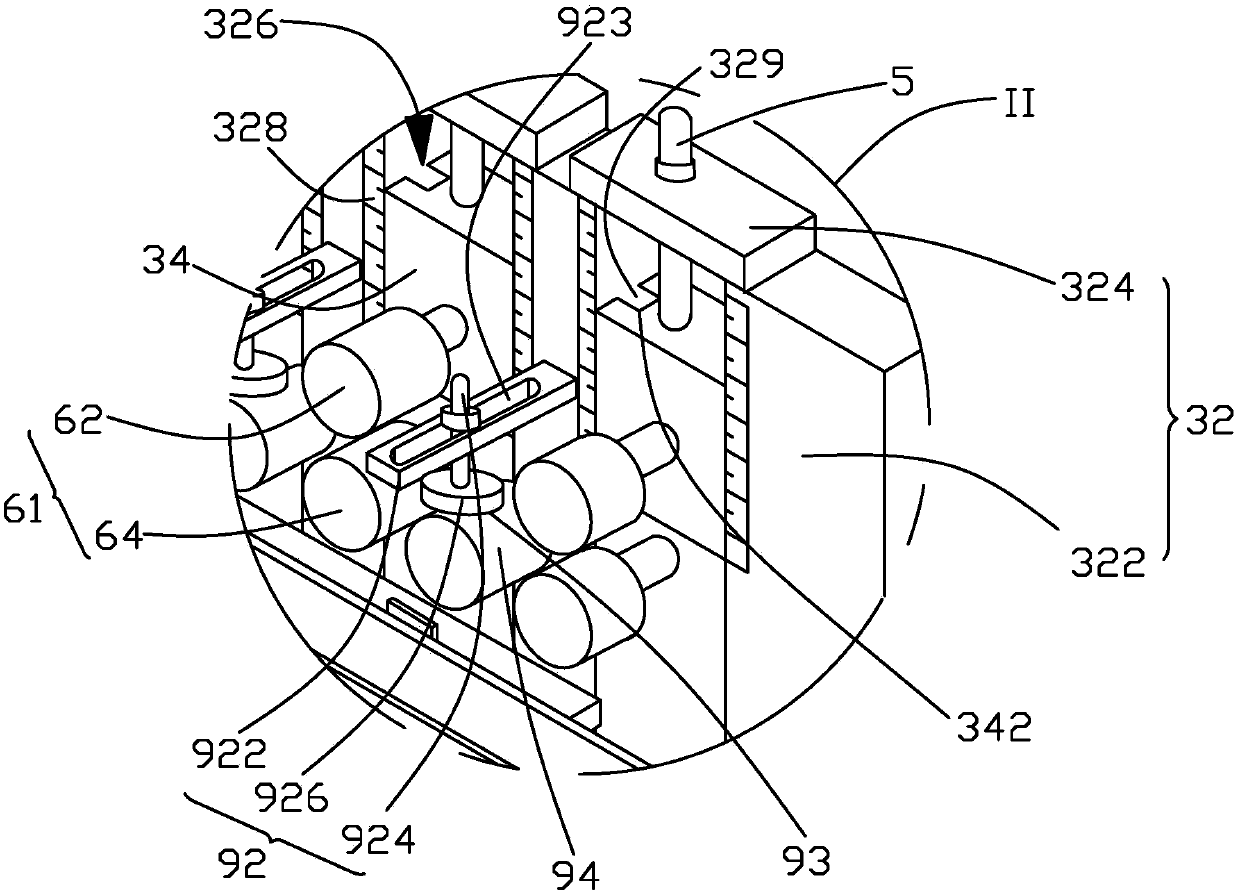

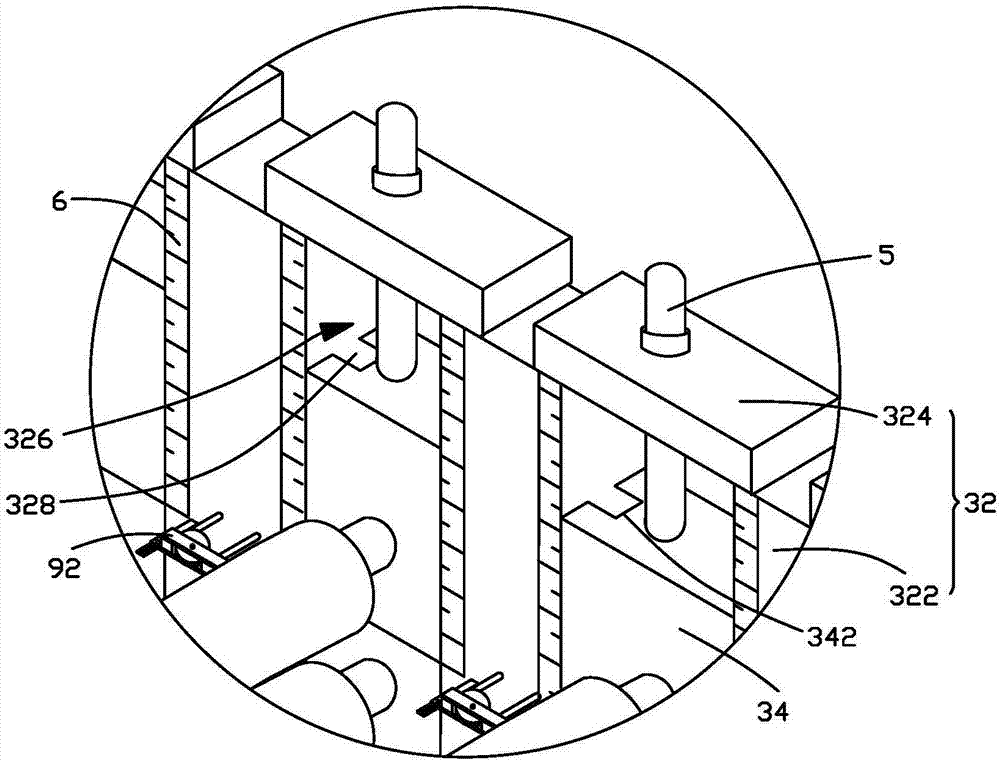

Plate rolling and bending machine

ActiveCN105964743AEasy to useAdjustable distanceMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

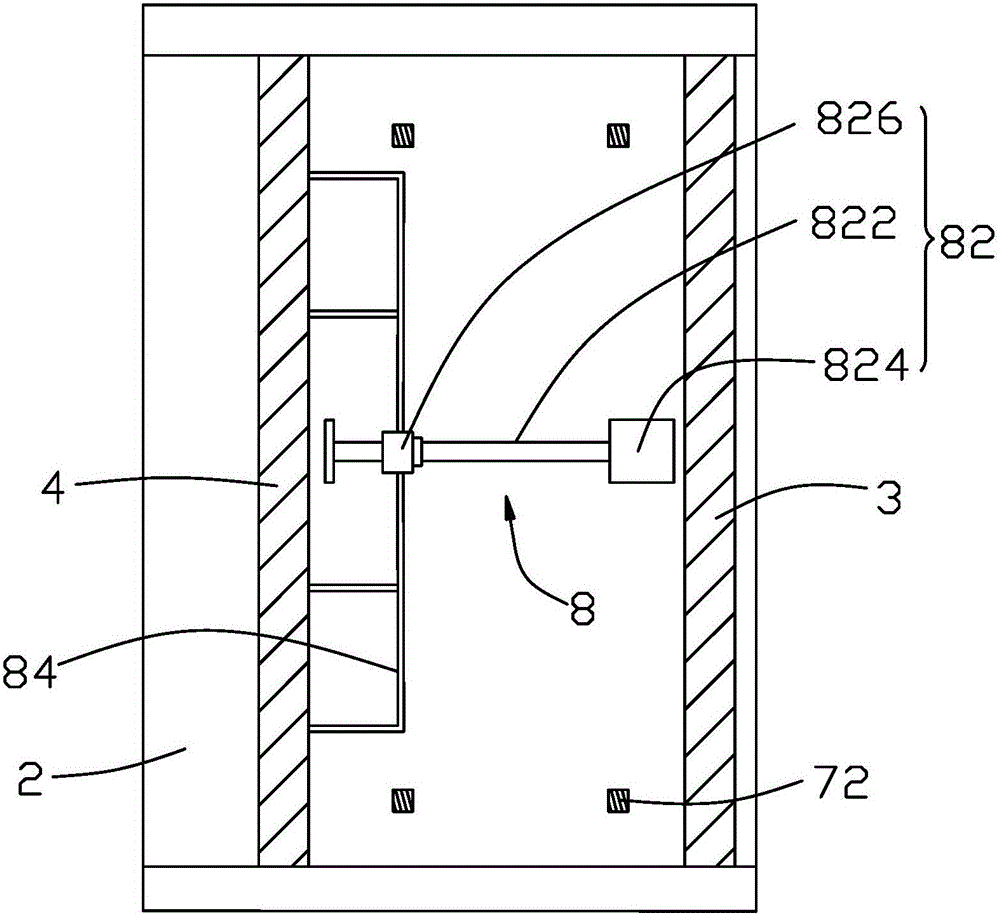

The invention provides a plate rolling and bending machine. The plate rolling and bending machine comprises two opposite supporting walls, a plurality of forming roller sets arranged in the conveying direction of a plate at intervals, a base, a screw rod driving mechanism and a connecting rod, wherein one supporting wall is fixed to the base, and the other supporting wall is movably installed on the base. Each forming roller set comprises an upper roller and a lower roller, the upper roller and the lower roller are oppositely arranged in the vertical direction, and each of the upper roller and the lower roller comprises a telescopic shaft and a roller body fixedly arranged on the telescopic shaft in a sleeving mode. The screw rod driving mechanism comprises a screw rod, a motor driving the screw rod to rotate and a screw rod nut connected to the screw rod in a screwed mode. The connecting rod is connected to the screw rod nut and the supporting wall movably installed so that the two supporting walls can get close or get away from each other, the distance between the two supporting walls can be adjusted for adapting to the bending operation of plates of different widths through the telescoping motion of the telescopic shafts of the forming roller sets, and use is convenient.

Owner:江西荣妍科技有限公司

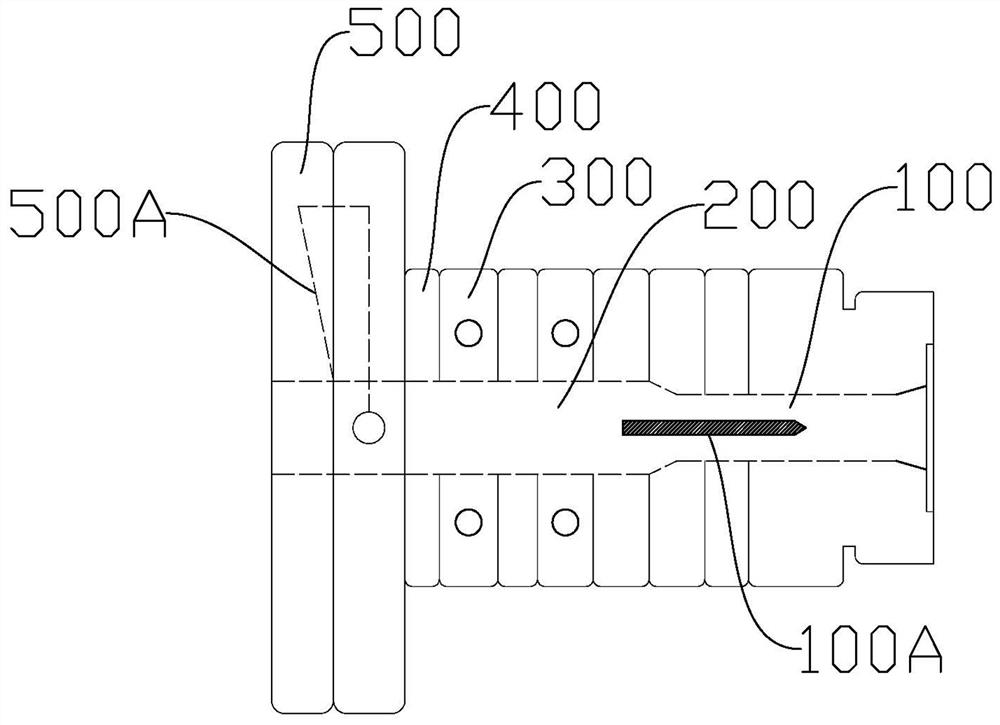

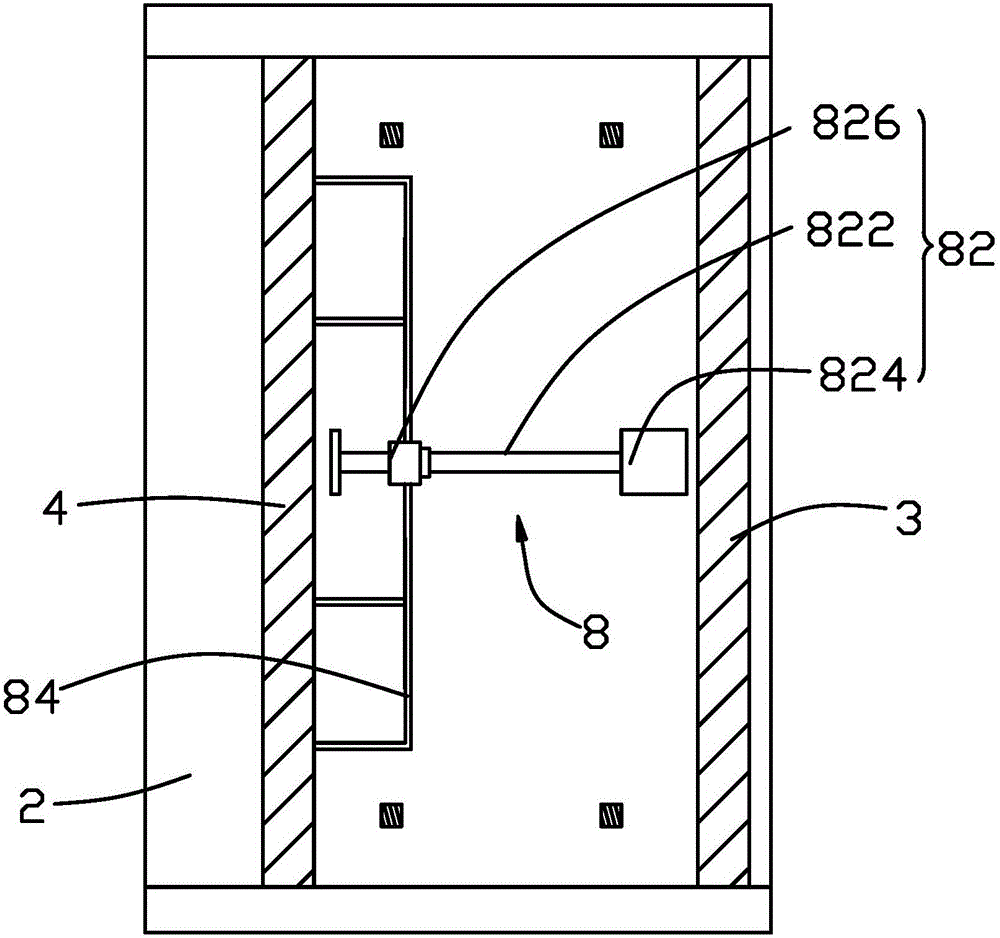

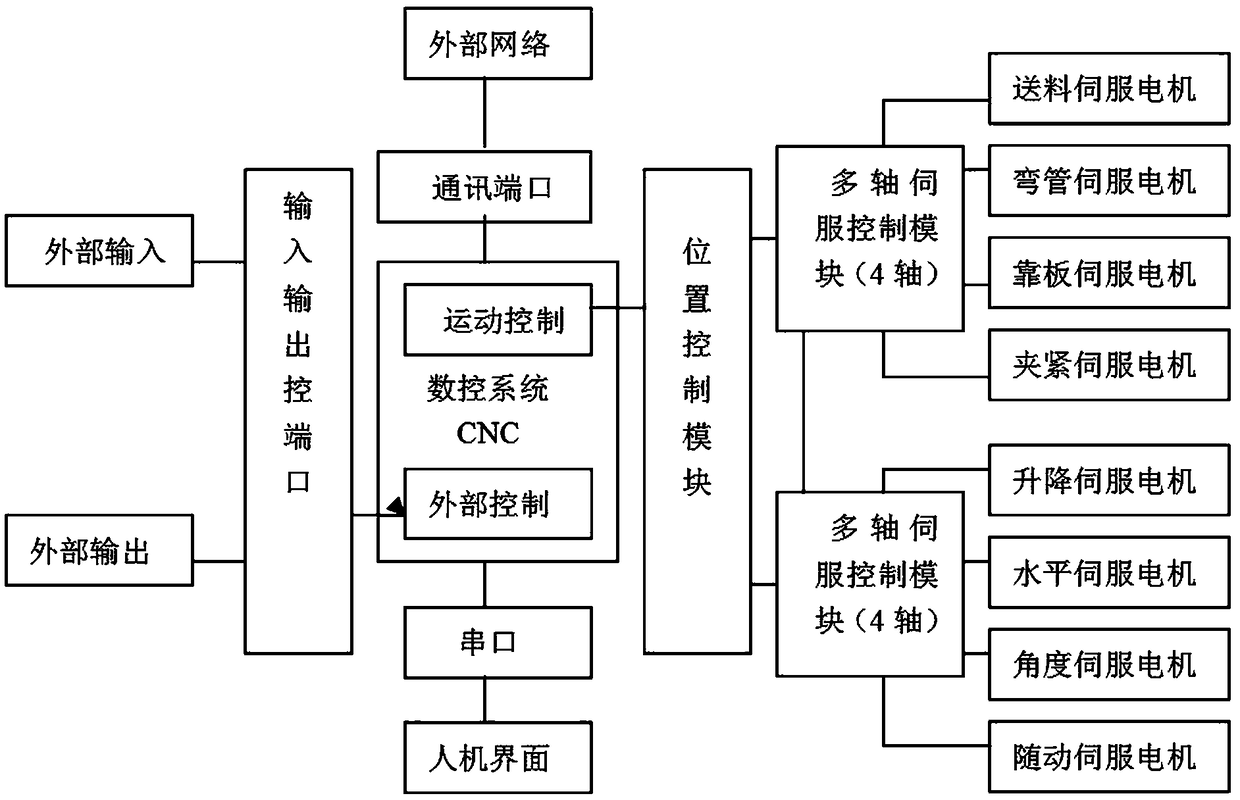

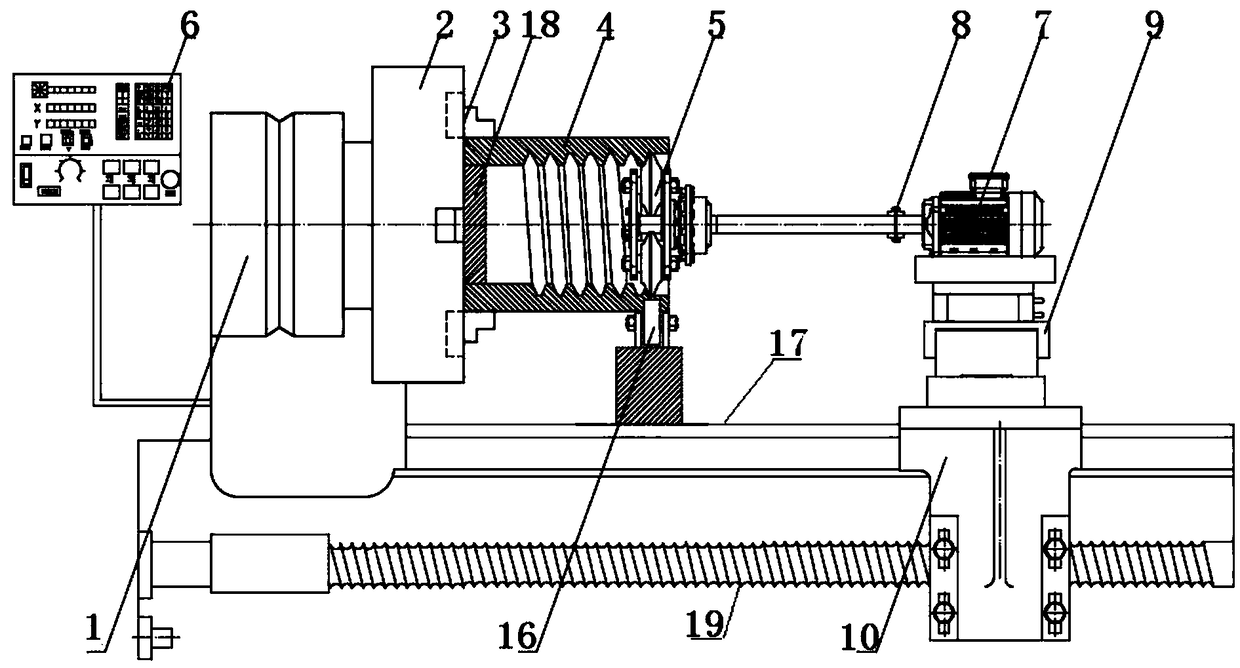

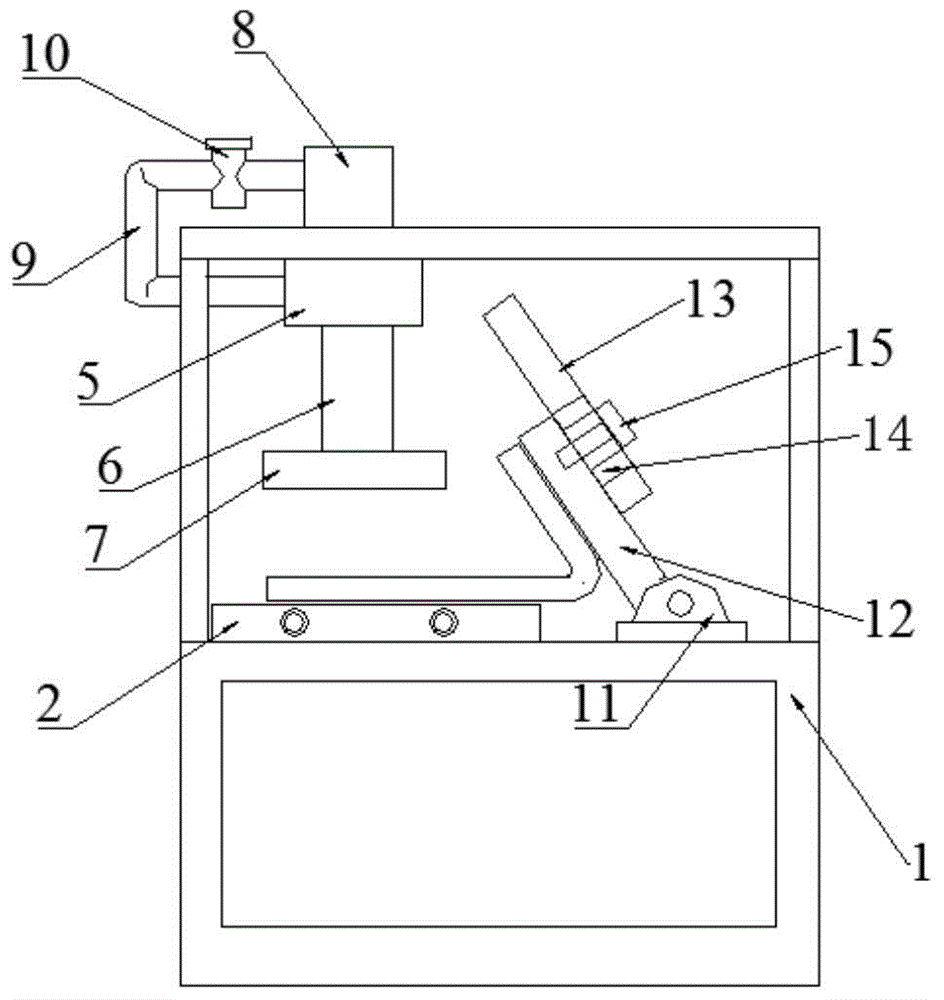

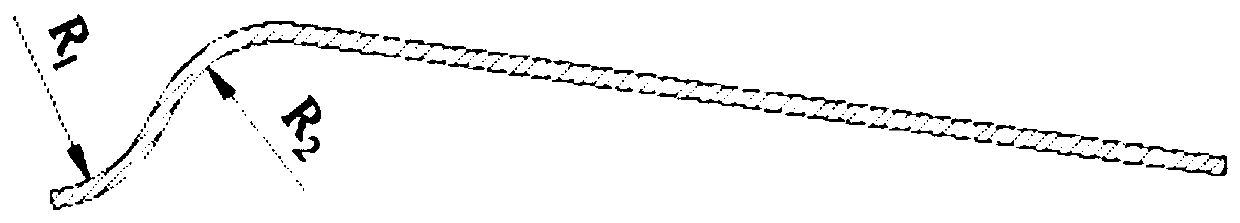

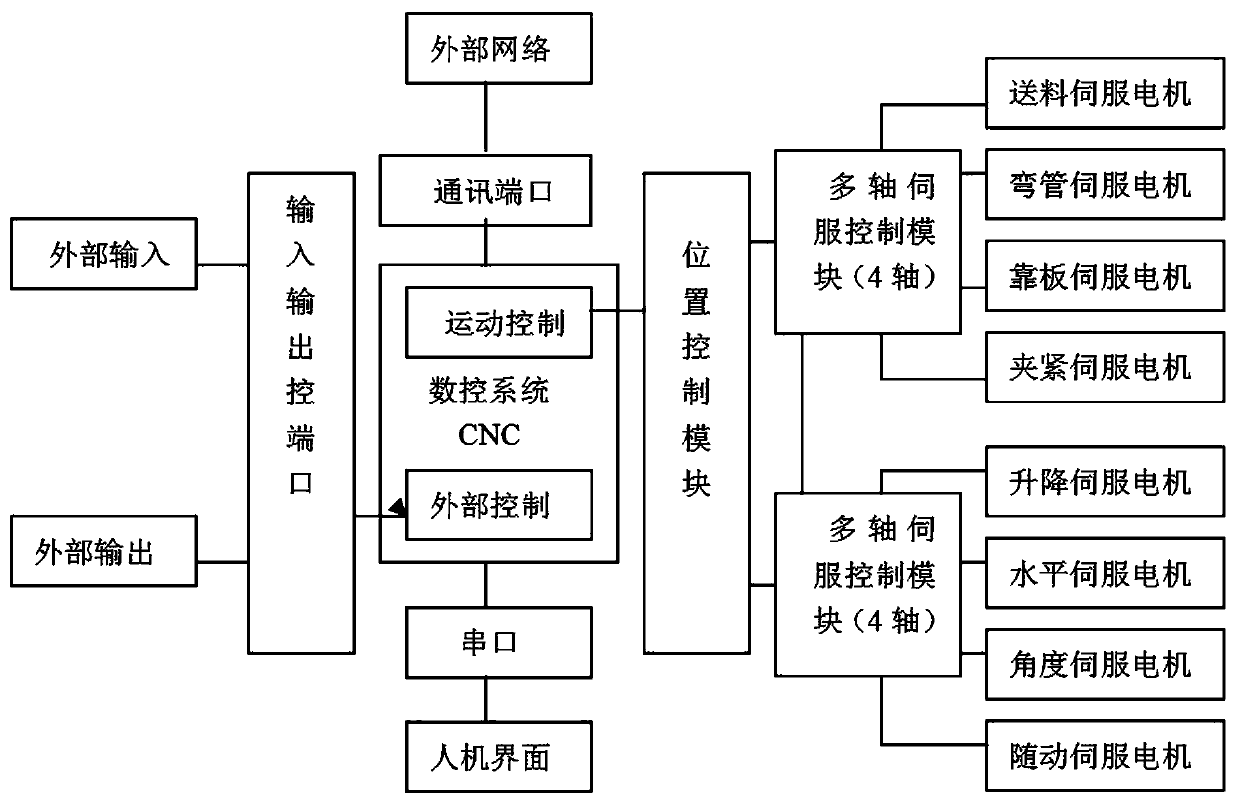

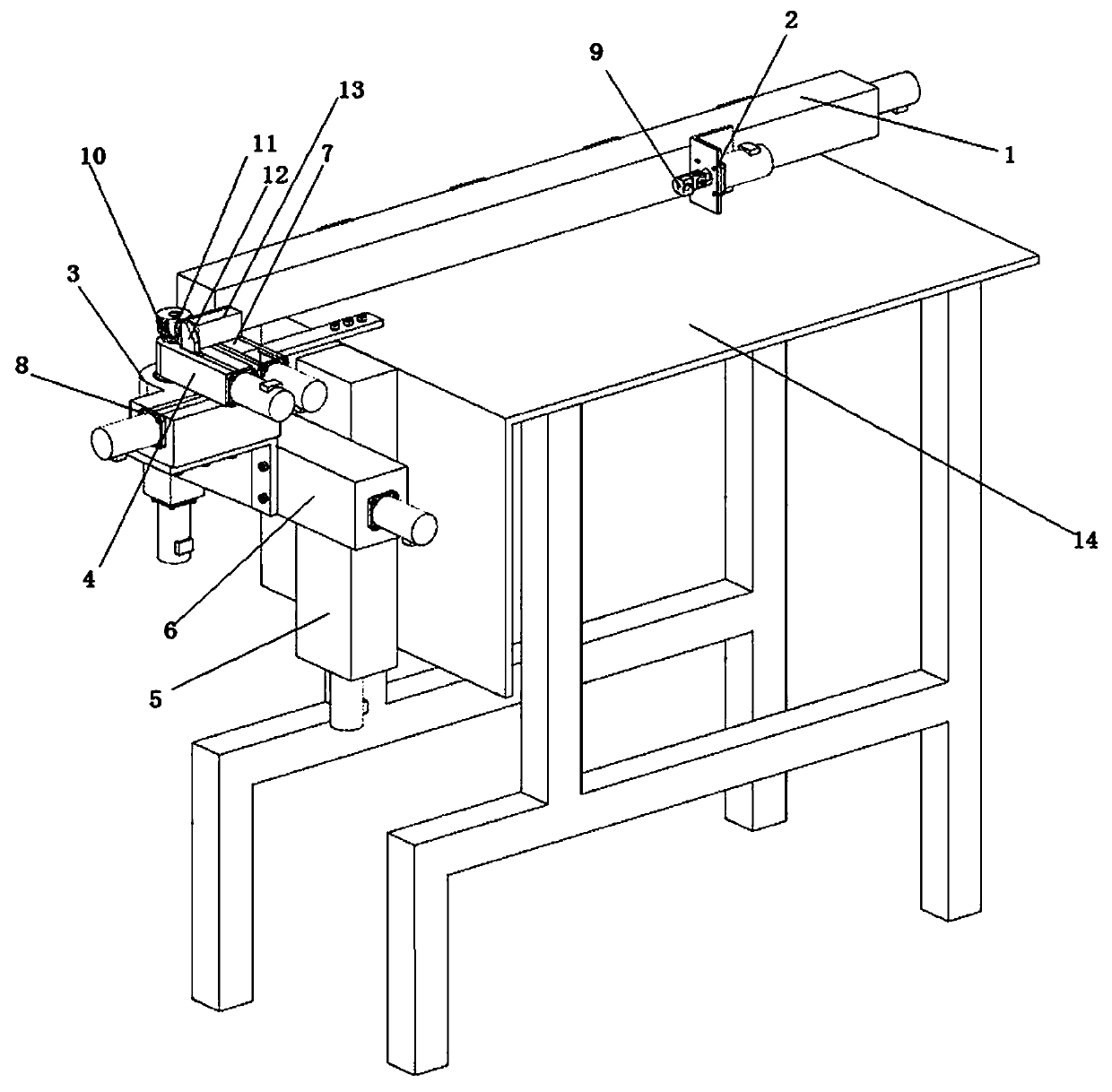

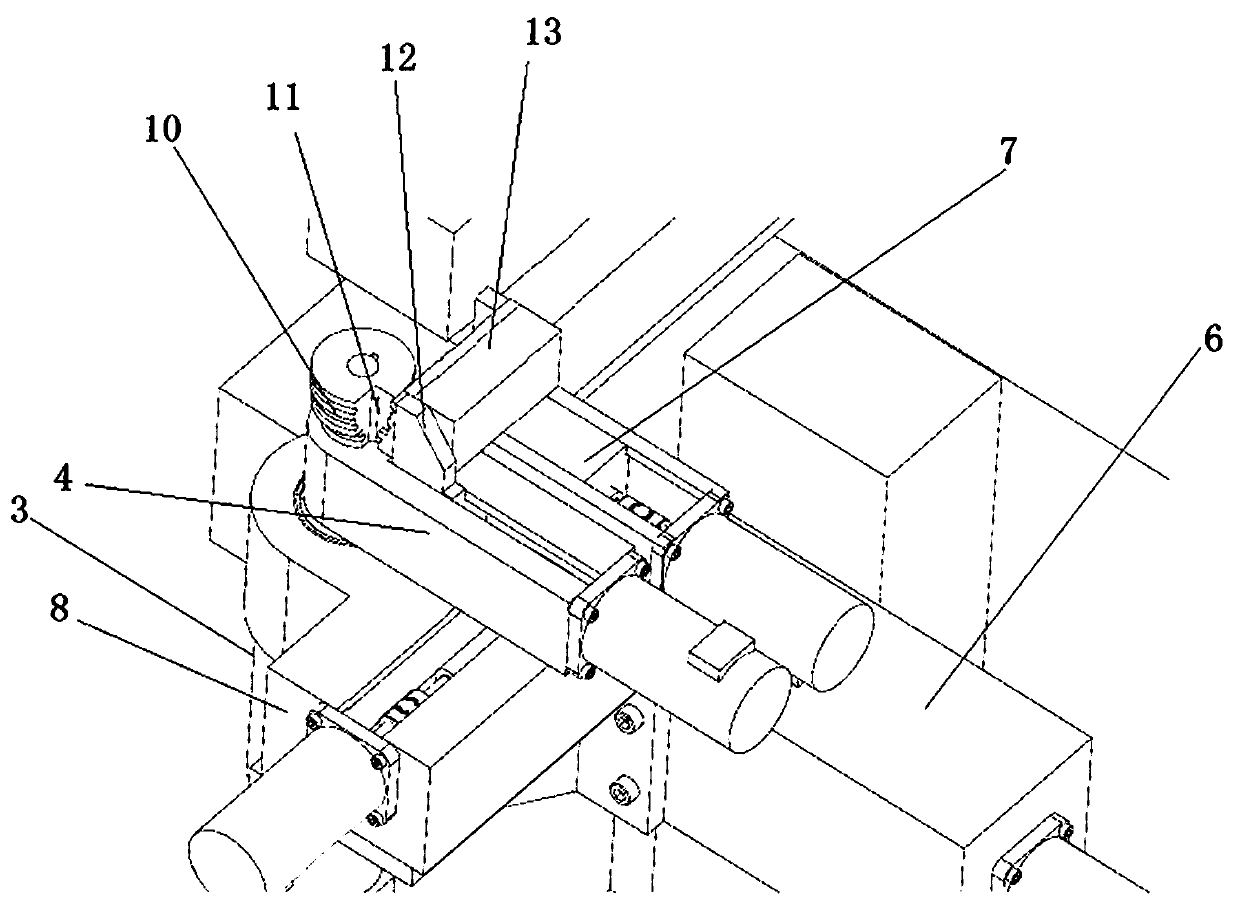

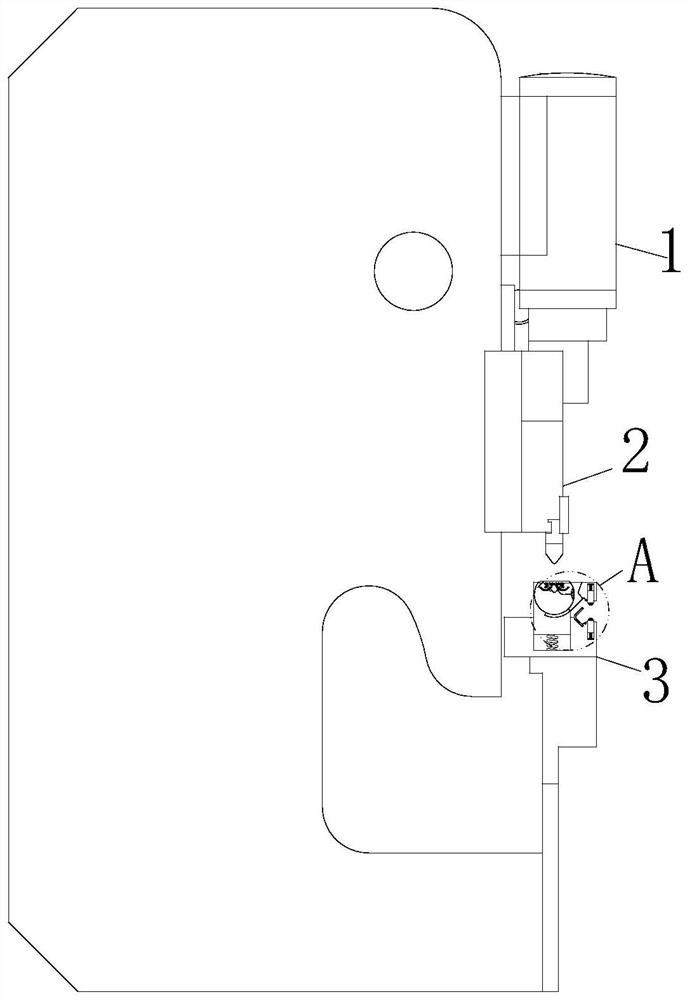

Numerical control pipe-bending machine control system

InactiveCN109127812AReduce springback deformationEnsure consistencyMetal-working feeding devicesPositioning devicesNumerical controlMachine control

The invention discloses a numerical control pipe-bending machine control system, and relates to the technical field of pipe bending machining. The numerical control pipe-bending machine control systemcomprises a central controller, external inputting equipment, external outputting equipment and a pipe-bending machine executing part. The pipe-bending machine executing part comprises a feeding servo mechanism, an angle rotating servo mechanism, a pipe-bending servo mechanism, a clamping servo mechanism, a lifting servo mechanism, a horizontal moving servo mechanism, a plate backing servo mechanism and a follow-up servo mechanism. According to the numerical control pipe-bending machine control system, moving at different angles and positions is completed through eight-axis servo control, bending machining at any angle and radius can be achieved, and the machining precision is guaranteed; and meanwhile, quick replacing of a pipe-bending mold and a feeding clamp can be structurally achieved, and thus, a pipe-bending machine has the function of welding prior to bending.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

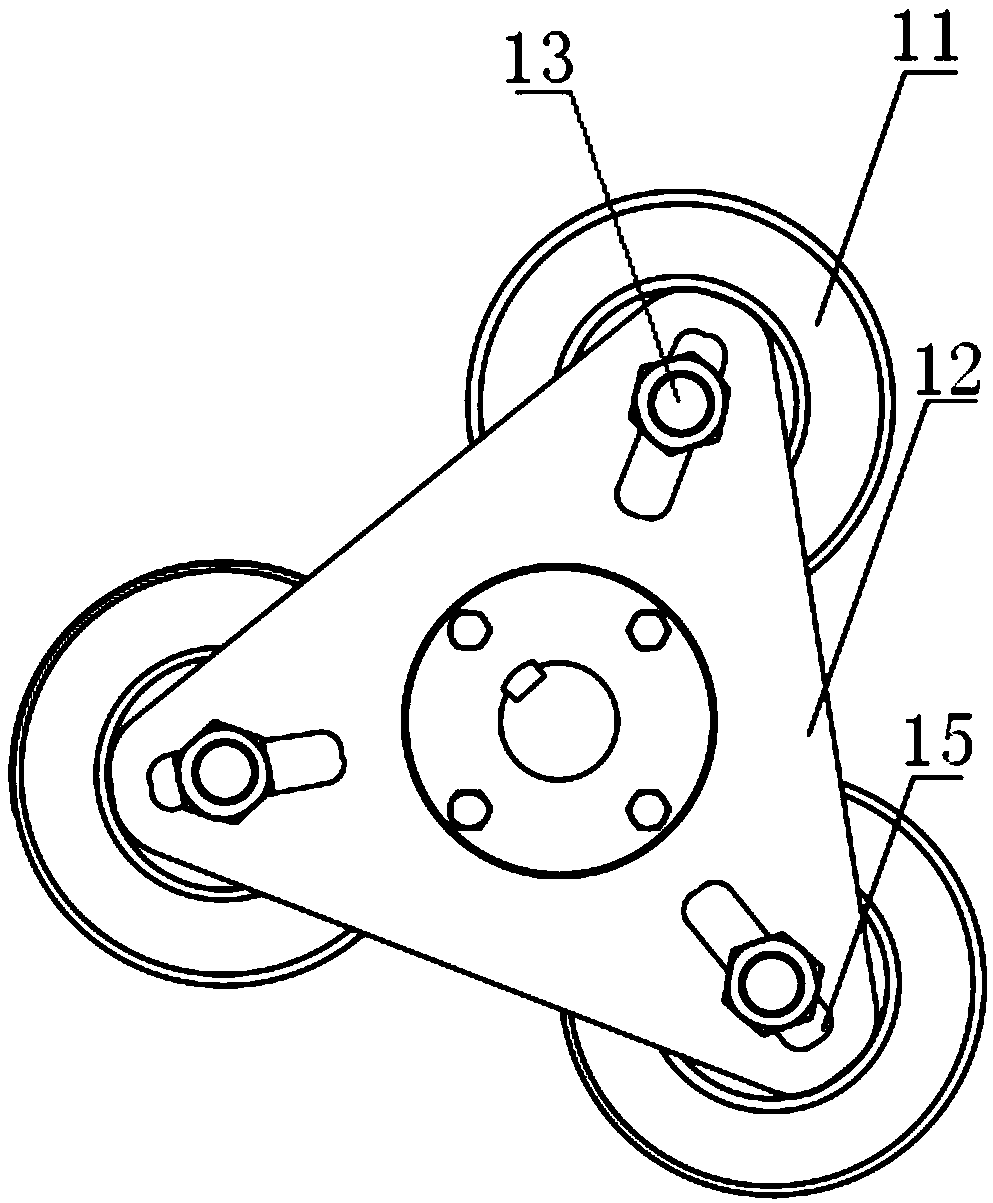

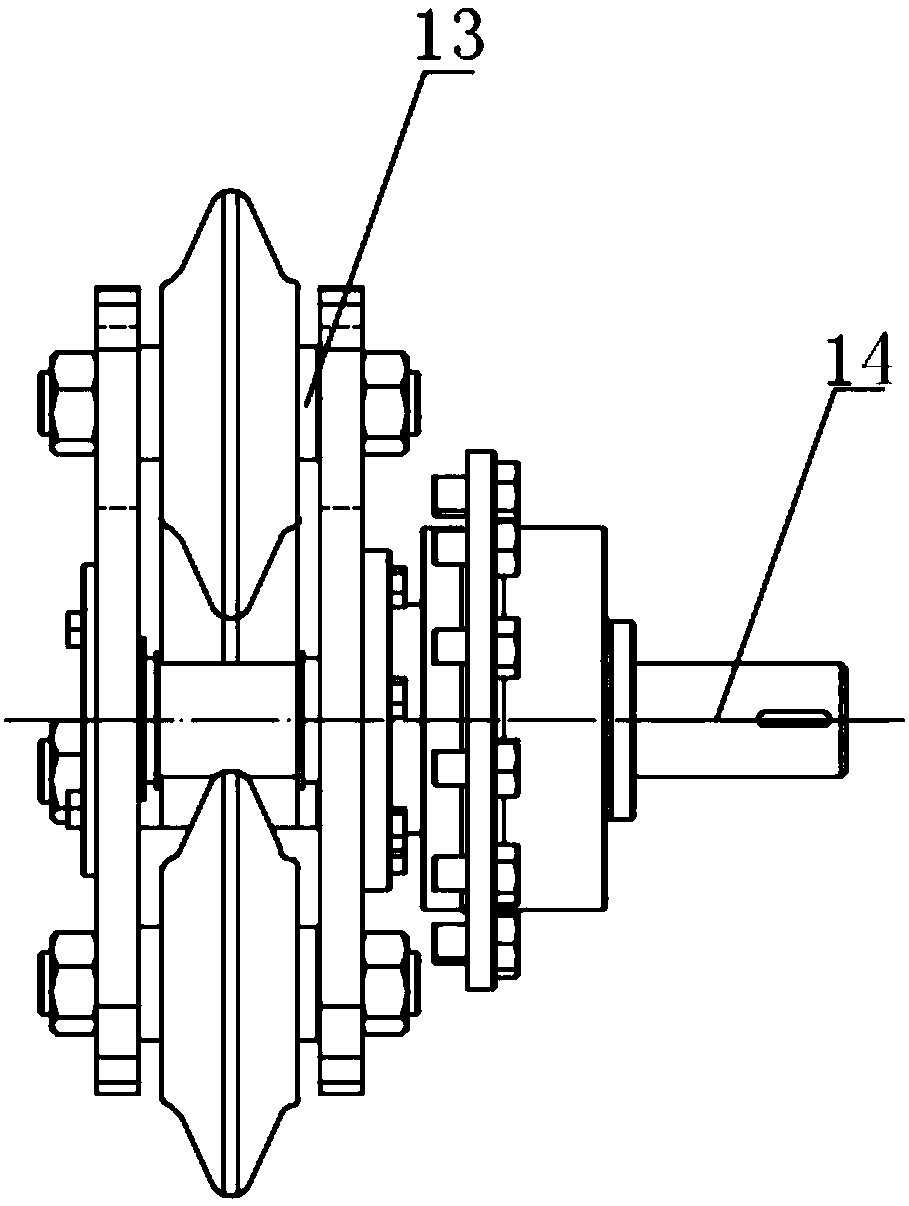

Pipe fitting internal thread incremental rolling-extruding forming device

InactiveCN108994130AImprove surface qualityImprove mechanical propertiesNumerical controlPipe fitting

The invention discloses a pipe fitting internal thread incremental rolling-extruding forming device. The pipe fitting internal thread incremental rolling-extruding forming device comprises an electricspindle box body of a numerically-controlled machine tool, a centring chuck is connected to one side of the electric spindle box body, a clamping jaw is fixed to one side of the centring chuck, a pipe fitting sample is fixed into the clamping jaw, a rolling-extruding forming tool wheel is arranged in the pipe fitting sample, a driving device is connected to one end of the rolling-extruding forming tool wheel, and a numerical control device of the numerically-controlled machine tool is connected to the electric spindle box body. The problem of low quality of an internal thread formed by current milling is solved.

Owner:XIAN UNIV OF TECH

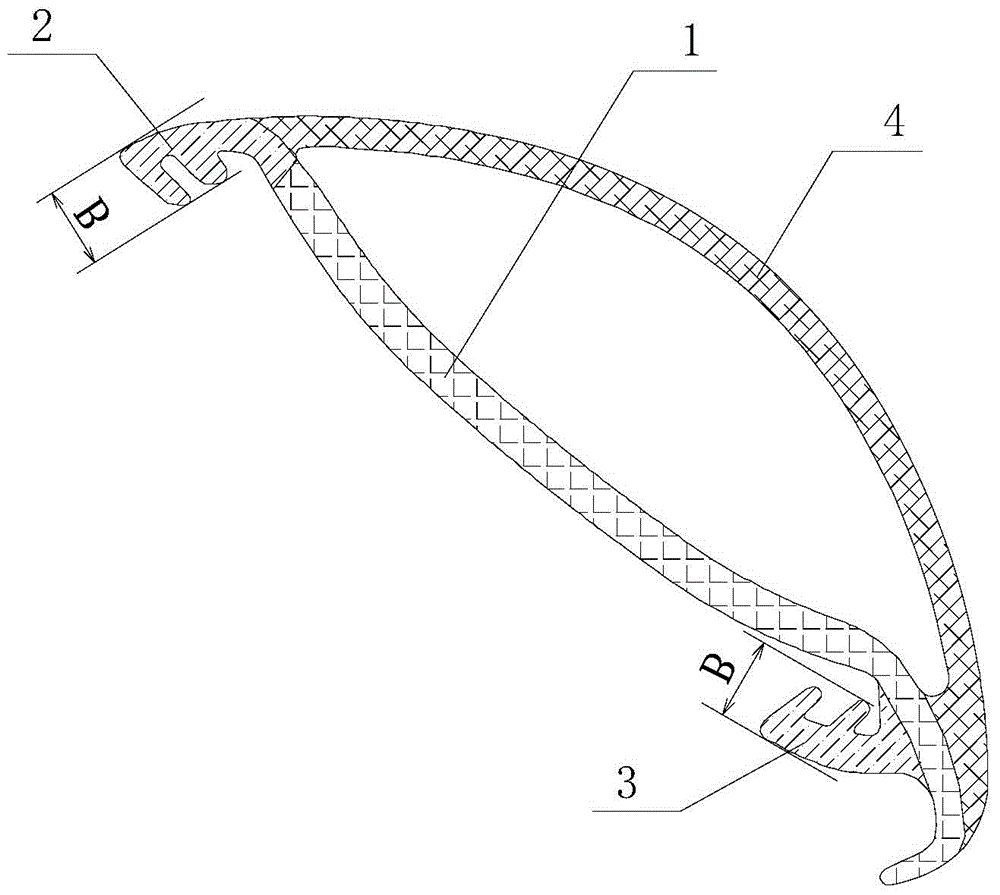

Rubber sealing strip used for outer protective plate of automobile door

ActiveCN104589977AAvoid deformation failureReduce the amount of interferenceEngine sealsVehicle sealing arrangementsHardnessCo extrusion

The invention provides a rubber sealing strip used for an outer protective plate of an automobile door. The rubber sealing strip used for the outer protective plate of the automobile door is composed of a middle plate-shaped supporting portion, a first insertion claw portion, a second insertion claw portion and an outer arc protruding portion. The two insertion claw portions are located on the two sides of the plate-shaped supporting portion respectively, and the outer arc protruding portion is located on the two sides of the plate-shaped supporting portion. The rubber sealing strip is characterized in that a multi-body co-extrusion forming technology is adopted by the rubber sealing strip, and the hardnesses of the two insertion claw portions, the hardness of the plate-shaped supporting portion and the hardness of the outer arc protruding portion become smaller gradually. According to the rubber sealing strip, the hardnesses of the materials of different portions are adjusted by utilizing the multi-body co-extrusion technology, the two insertion claw portions have high hardness, so that the tension of the two insertion claw portions in the installation groove become larger, enough anti-disengagement strength is guaranteed, curling deformation caused in the assembly process is reduced, the assembly speed is increased, it is guaranteed that the rubber sealing strip can be installed in place, and the assembly quality is improved; the plate-shaped supporting portion has the moderate hardness, and therefore ineffectiveness caused by deformation of the sealing strip is avoided; the hardness of the outer arc protruding portion is low, so that the fit performance between the outer arc protruding portion and a metal plate of a door frame is improved, and therefore the leakproofness between the automobile door and the door frame is improved.

Owner:天津华涛汽车塑料饰件有限公司

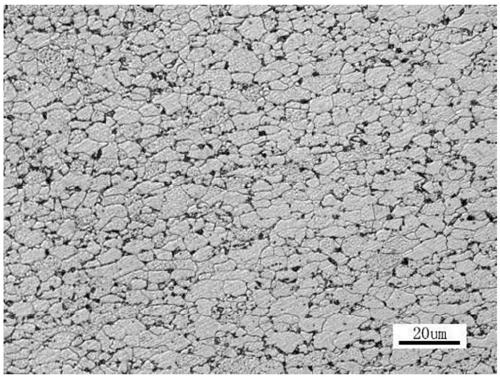

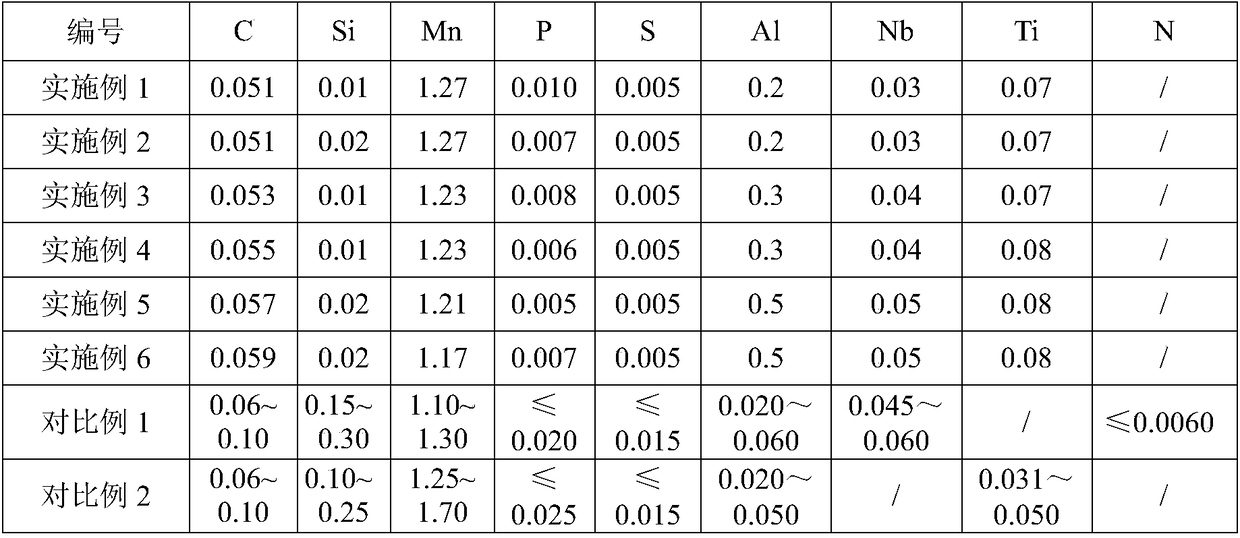

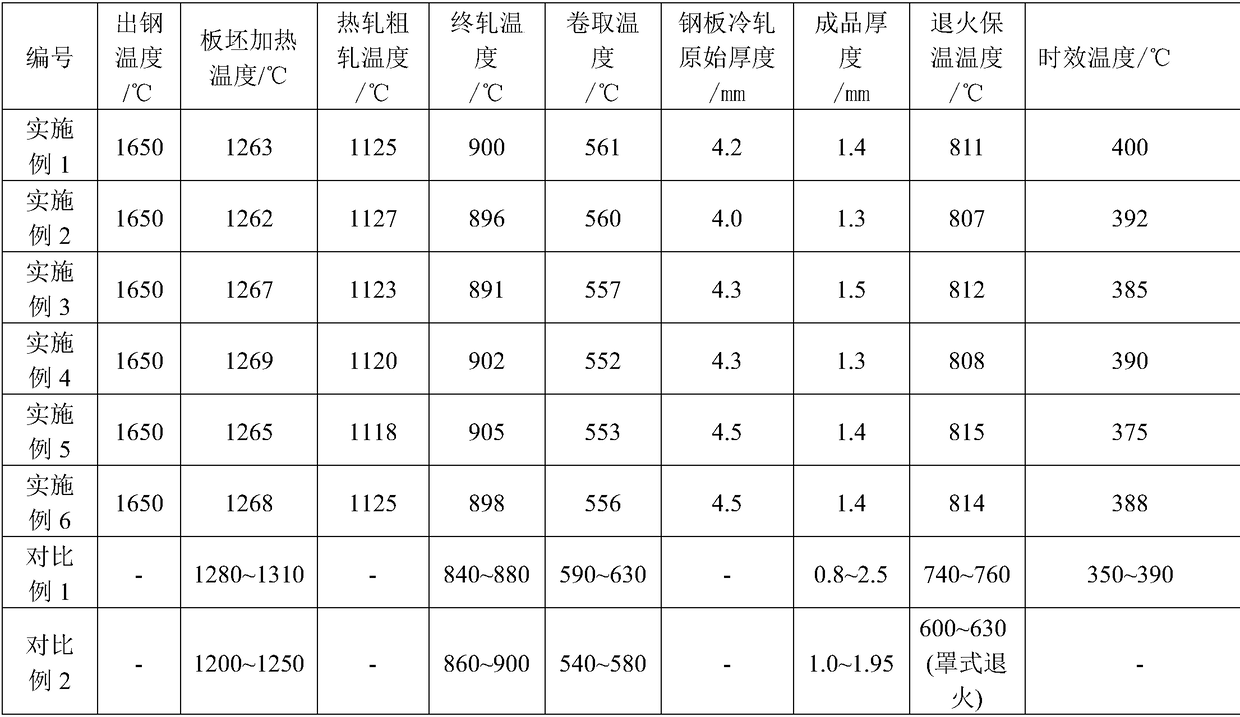

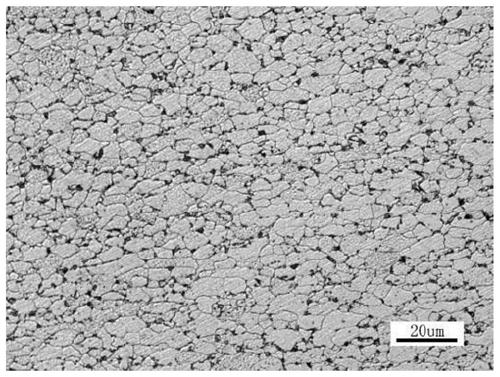

460MPa grade cold-rolled microalloy high strength steel, and manufacturing method thereof

ActiveCN108929987AImprove mechanical propertiesHigh strengthFurnace typesHeat treatment furnacesSocial benefitsManufacturing technology

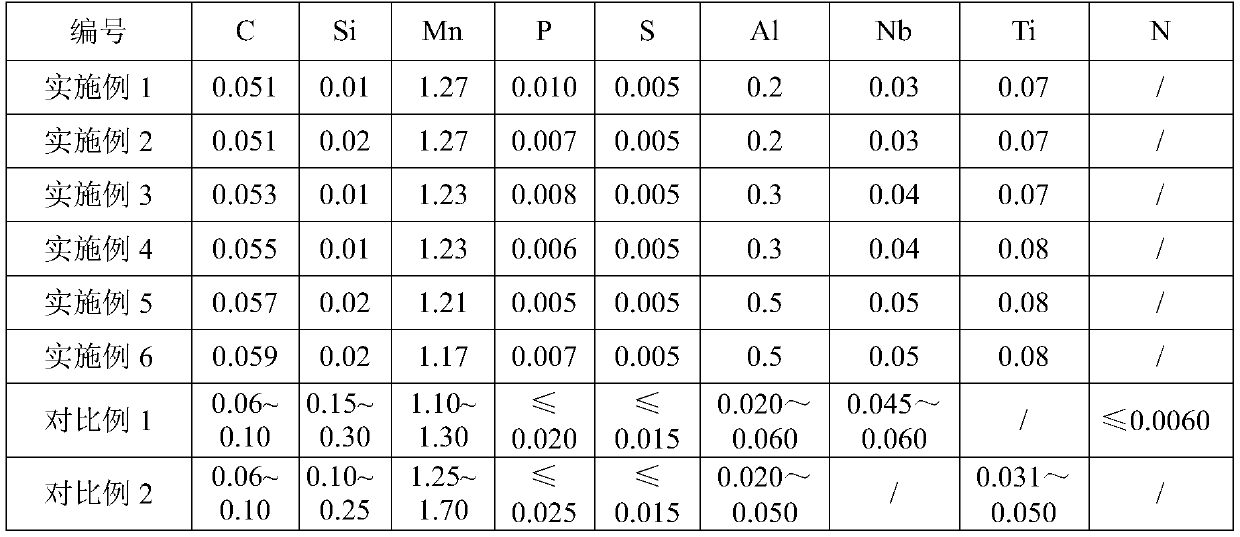

The invention discloses 460MPa grade cold-rolled microalloy high strength steel. The 460MPa grade cold-rolled microalloy high strength steel comprises, by mass, 0.051 to 0.059% of C, 0.01 to 0.02% ofSi, 1.17 to 1.27% of Mn, 0.2 to 0.5% of Al, P<=0.010, S<=0.006, 0.03 to 0.05% of Nb, 0.07 to 0.08% of Ti, and the balance Fe and unavoidable impurities. A manufacturing method is combined with component design and manufacturing technology improvement, so that the obtained steel products are high in strength, percentage elongation, spot welding performance, and moulding performance, excellent platability is achieved, rebound deformation performance is small, problems in the prior art such as poor formation performance, weldability, and rebound performance of high strength steel of the same grade are solved, and obvious social benefit and economic benefit are achieved.

Owner:武汉钢铁有限公司

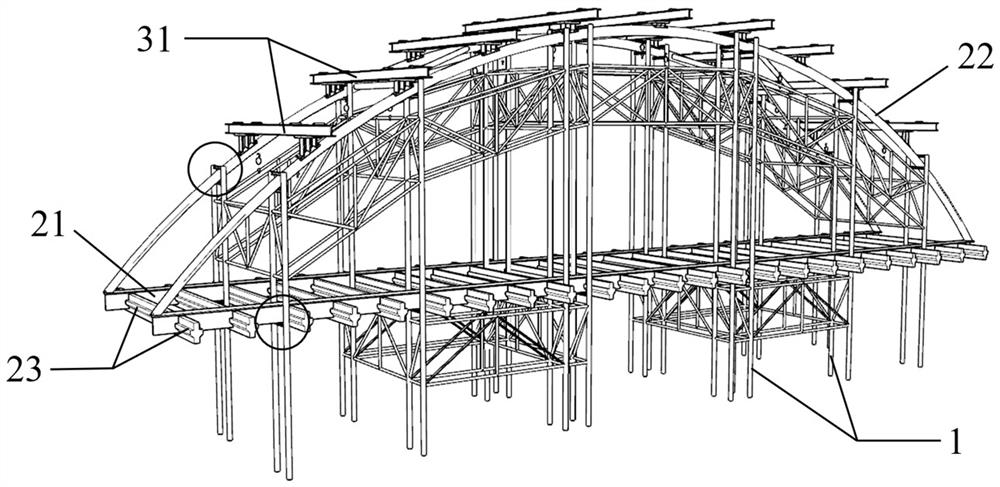

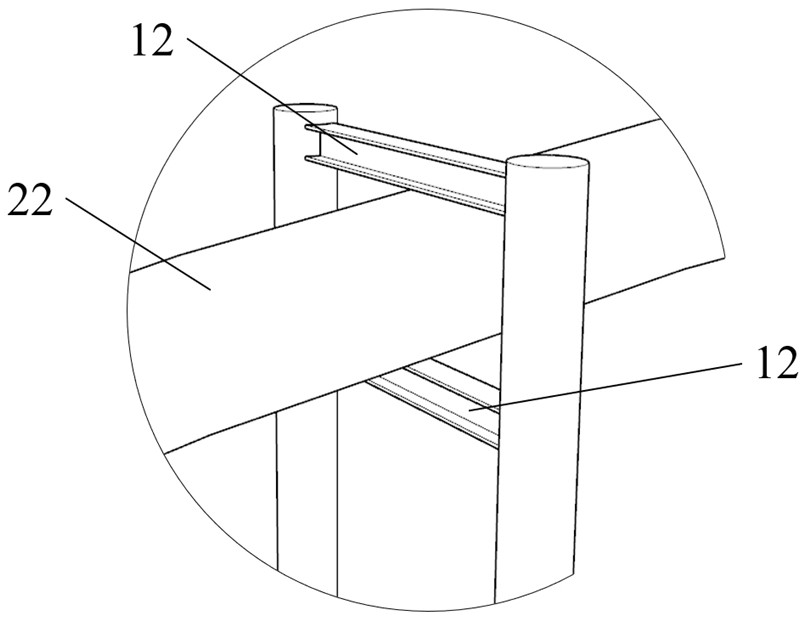

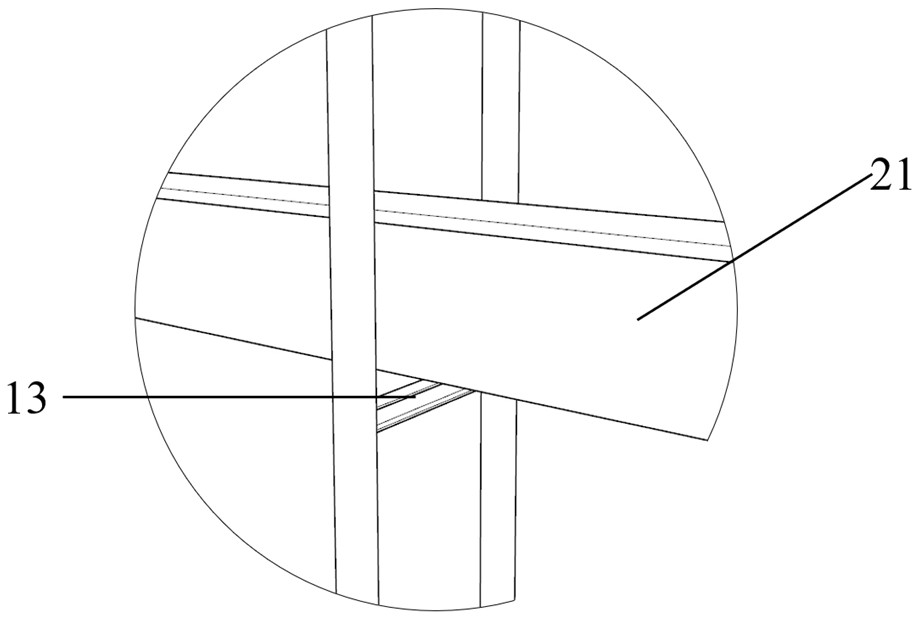

Arch bridge deck structure dismantling device based on arch rib supporting stress

ActiveCN113802478AReduce sinking deformationEasy to moveBuilding repairsBridge structural detailsArchitectural engineeringBridge deck

The invention relates to the technical field of bridge construction, in particular to an arch bridge deck structure dismantling device based on arch rib supporting stress. The device comprises a bracket and a hoisting mechanism; the bracket comprises a pair of steel pipe pile sets symmetrically arranged on the two sides of an arch bridge body, and each steel pipe pile set comprises four or more supporting piers distributed in the direction of the arch bridge body. Each supporting pier at least comprises two steel pipe piles; the hoisting mechanism comprises supporting beams which are uniformly distributed on the arc-shaped sections of the arch ribs, each supporting beam is transversely arranged in parallel to the arch bridge, the lower end of each supporting beam is fixedly connected with the upper end of the corresponding arch rib through a pair of supporting mechanisms, and an electric hoist crane is hung on each supporting beam to hoist all demolition parts of the bridge floor structure of the arch bridge. Therefore, the original bearing capacity of the arch rib of the old arch bridge is fully utilized, the supporting force of the suspension beam of the electric hoist crane is provided, bridge deck structure dismantling operation is carried out, use of large mechanical equipment is reduced, and the device has important significance on dismantling of the bridge deck structure of the arch bridge.

Owner:HEFEI UNIV OF TECH +1

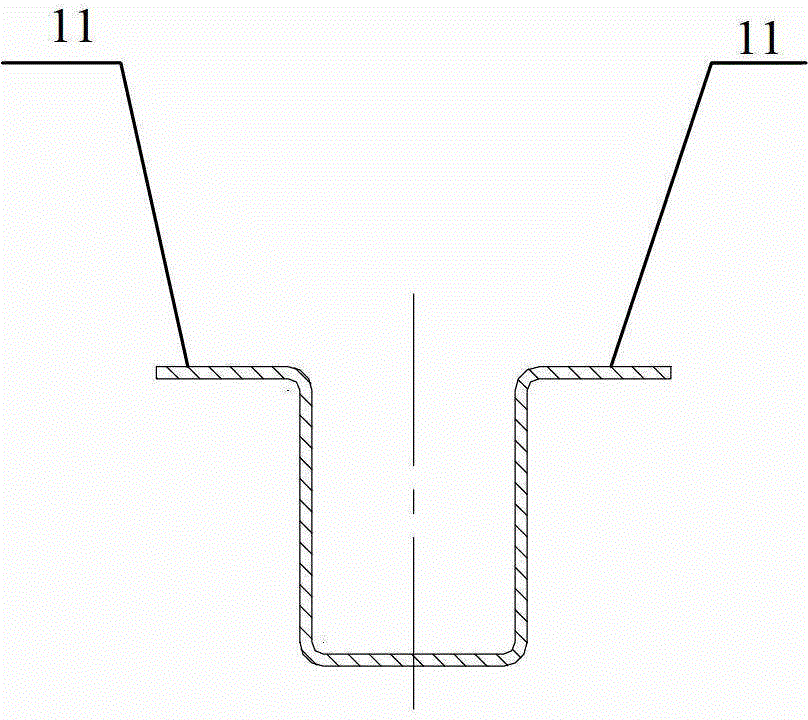

Plate rolling and bending machine

ActiveCN106111768AImprove bending accuracyThe amount of adjustment is the sameEngineeringMechanical engineering

The invention provides a plate rolling and bending machine. The plate rolling and bending machine comprises two supporting walls which are oppositely arranged, a plurality of adjustment screws, two rows of forming roller sets arranged on the two supporting walls correspondingly, and a conveying mechanism located between the two rows of forming roller sets. Each supporting arm comprises a supporting plate and a plurality of sliding blocks, wherein a plurality of sliding grooves are formed in the supporting plate at intervals, and each sliding block is slidably arranged in the corresponding sliding groove. Each adjustment screw is connected to the corresponding supporting plate in a screwed mode and connected with the corresponding sliding block. At least one side of each sliding groove is provided with a scaleplate. Each row of forming roller sets includes a plurality of sets of forming rollers which are arranged at intervals in the plate conveying direction. Each forming roller set includes an upper roller and a lower roller which are oppositely arranged, wherein one end of the upper roller is rotatably connected to the corresponding sliding block, and the lower roller is rotatably installed on the corresponding supporting plate. According to the plate rolling and bending machine, the vertical positions of the sliding blocks and the upper rollers are measured through the scaleplates, so that the consistency of the adjustment quantity of the upper rollers on the same supporting wall is guaranteed, and the plate bending precision is improved accordingly.

Owner:广西田阳至恒门业有限公司

Production method of high-strength alloy welded pipe

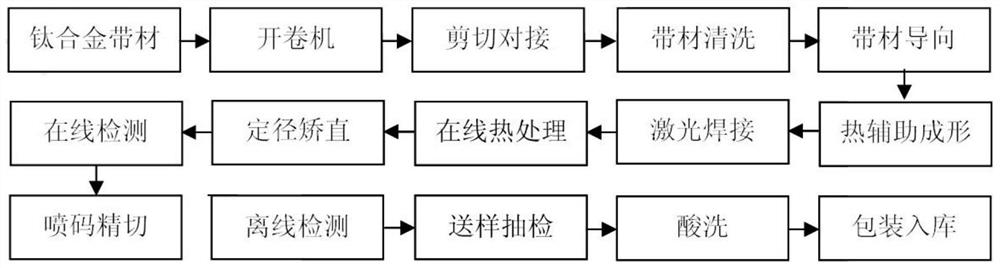

PendingCN114406622ALower resistanceReduce springback deformationLaser beam welding apparatusMolding machineWeld seam

The invention discloses a production method of a high-strength alloy welded pipe. The production method comprises the following steps that an uncoiled strip is heated and then enters a pipe blank forming unit to be progressively formed into a pipe blank; a laser main welding arc auxiliary welding mode is adopted, so that the pipe blank entering the welding chamber is welded and formed into a welded pipe; the diameter of the welded pipe is preset, and then online annealing heat treatment is conducted to obtain a low-stress welded pipe; and carrying out secondary sizing, straightening and detection treatment on the low-stress welded pipe. According to the production method, a heat-assisted titanium alloy incremental forming pipe blank technology is designed, the strength of the high-strength titanium alloy is reduced by heating the strip, the plasticity and deformation capacity of the high-strength titanium alloy are improved, meanwhile, a laser main welding arc auxiliary welding mode is adopted, the area and the grain size of a titanium alloy welding seam melting area can be remarkably reduced, and the welding quality is improved. The low-stress laser welding and on-line heat treatment processes are utilized, the stress of the welded pipe can be effectively reduced, comprehensive regulation and control of forming, tissue, stress and performance are achieved, and finally the high-quality high-strength titanium alloy welded pipe is obtained.

Owner:HUNAN XIANGTOU GOLDSKY NEW MATERIALS CO LTD

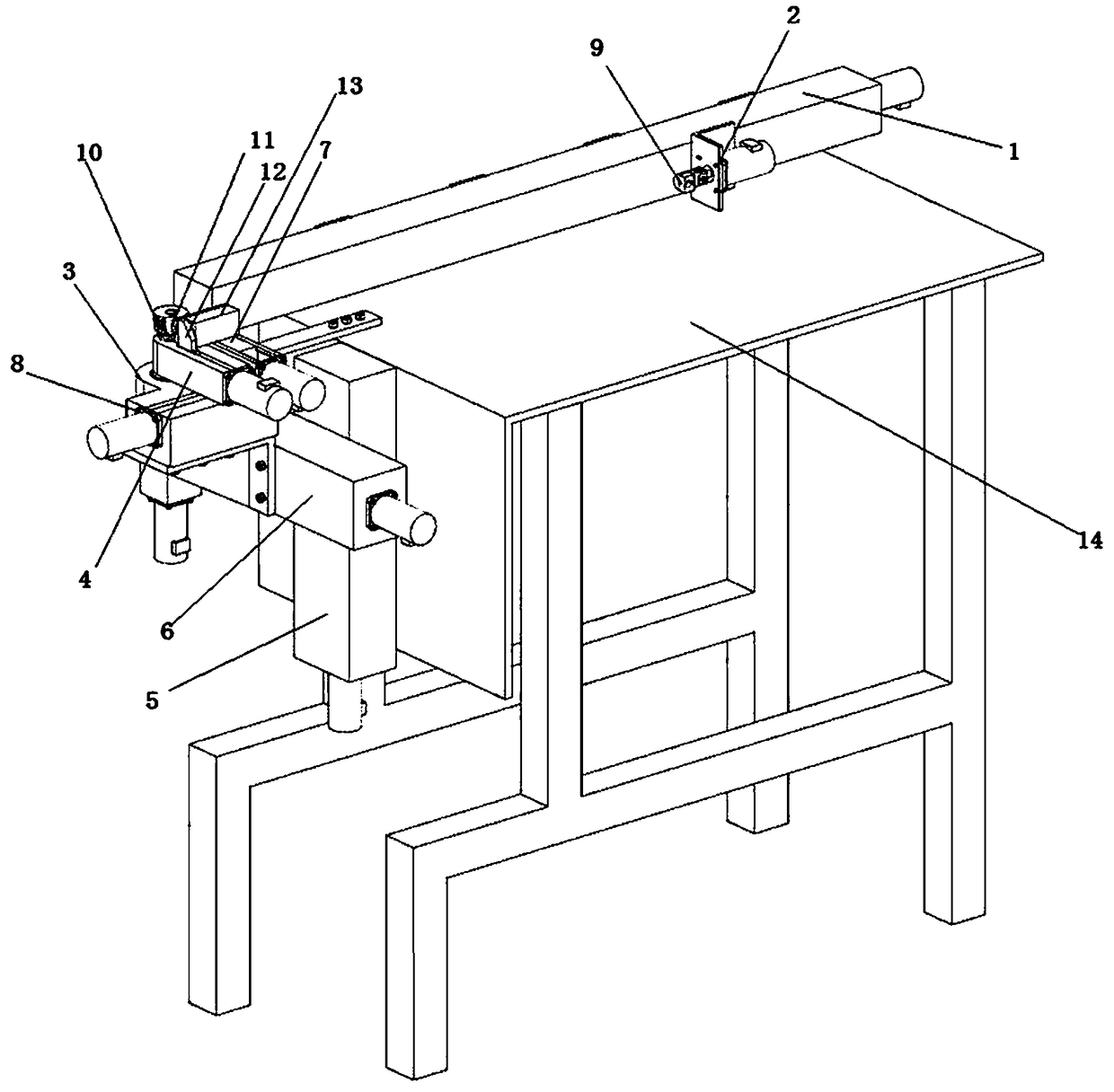

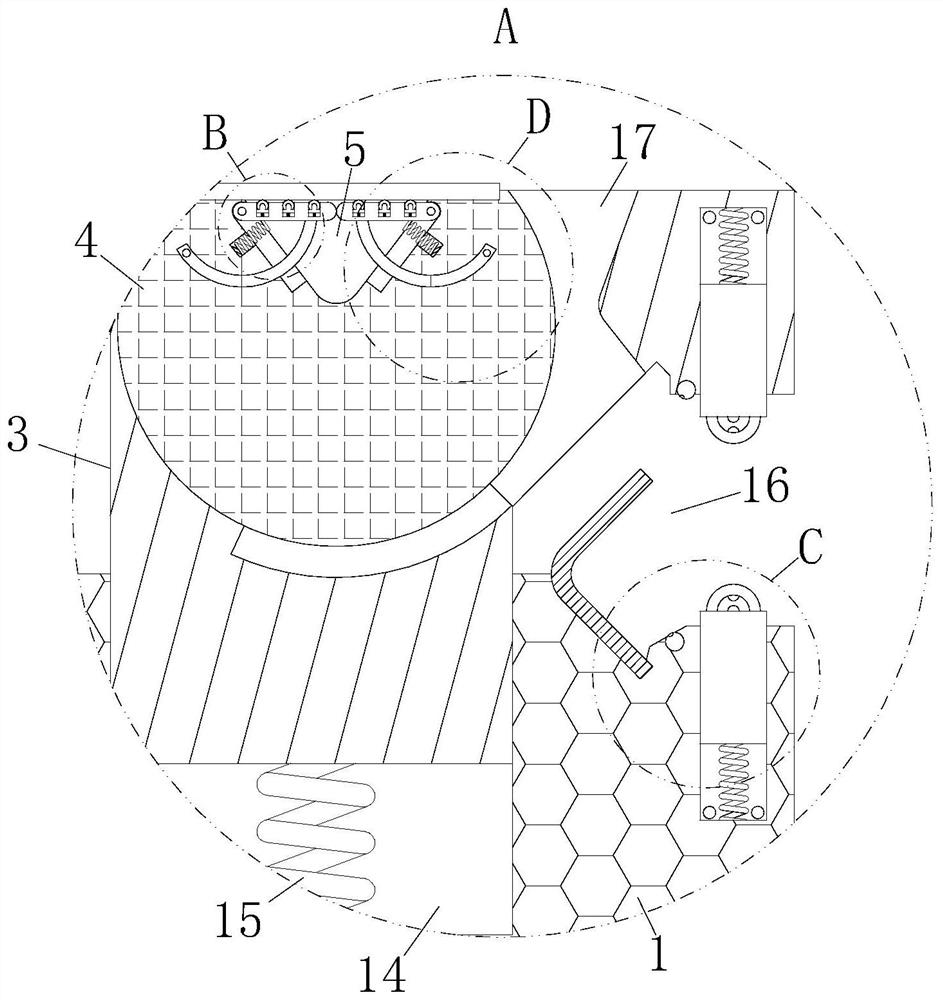

Novel transformer insulation plate bending device

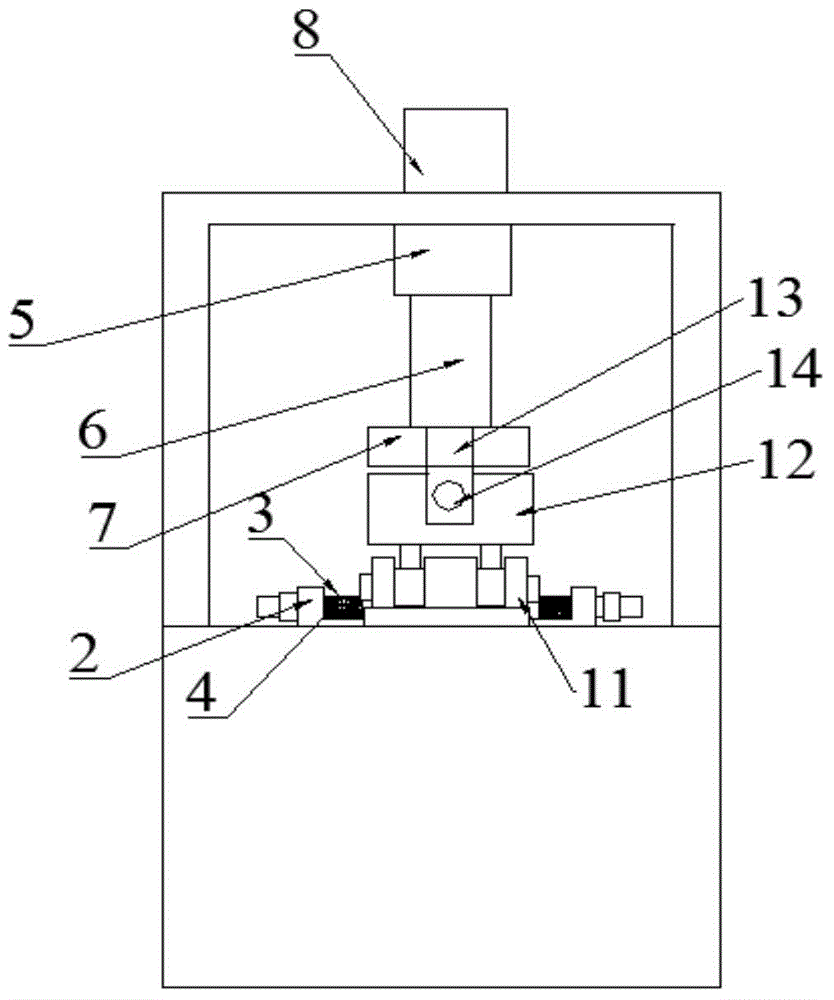

InactiveCN104999710AReduce labor intensityReduce springback deformationMechanical working/deformationEngineeringTransformer

The invention provides a novel transformer insulation plate bending device, which comprises a stock, a clamping part, and a bending part, wherein the clamping part comprises a fixing plate, a leadscrew nut mechanism, a cylinder mechanism and a lower pressing plate, the middle of the fixing plate is provided with a rectangular placement groove along the length direction, the left side and the right side of the placement groove are convex, the leadscrew nut mechanism transversely passes through the convex part of the placement groove, the cylinder mechanism is fixed on the top wall of the stock, and the lower pressing plate is located at the upper part of the placement groove and fixed on the cylinder mechanism; and the bending part comprises a supporting shaft seat, a rotating pressing plate and a handle, the rotating pressing plate and the supporting shaft seat are hinged and connected, and the handle is fixed on the rotating pressing plate. The level principle is used for realizing bending operation on the insulation plate, multidirectional positioning is carried out on the insulation plate during the bending process, the insulation plate is stably fixed, labor intensity is reduced, and the problem of rebound deformation of the insulation plate can be effectively reduced.

Owner:TIANJIN TONGAN TRANSFORMER

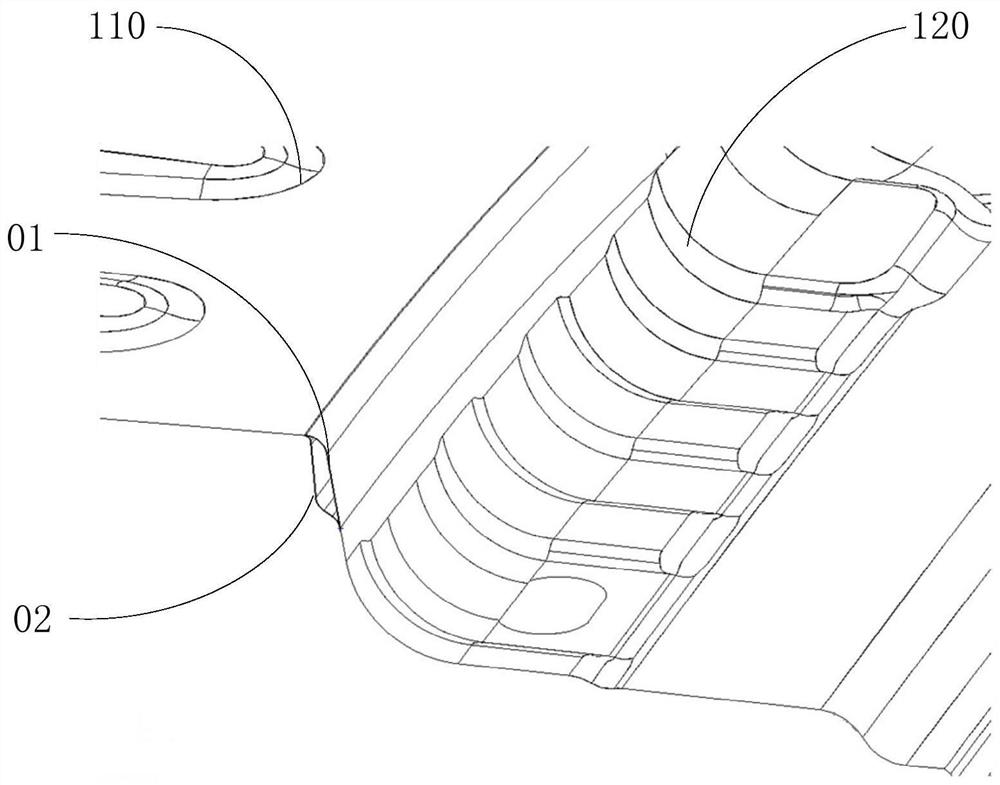

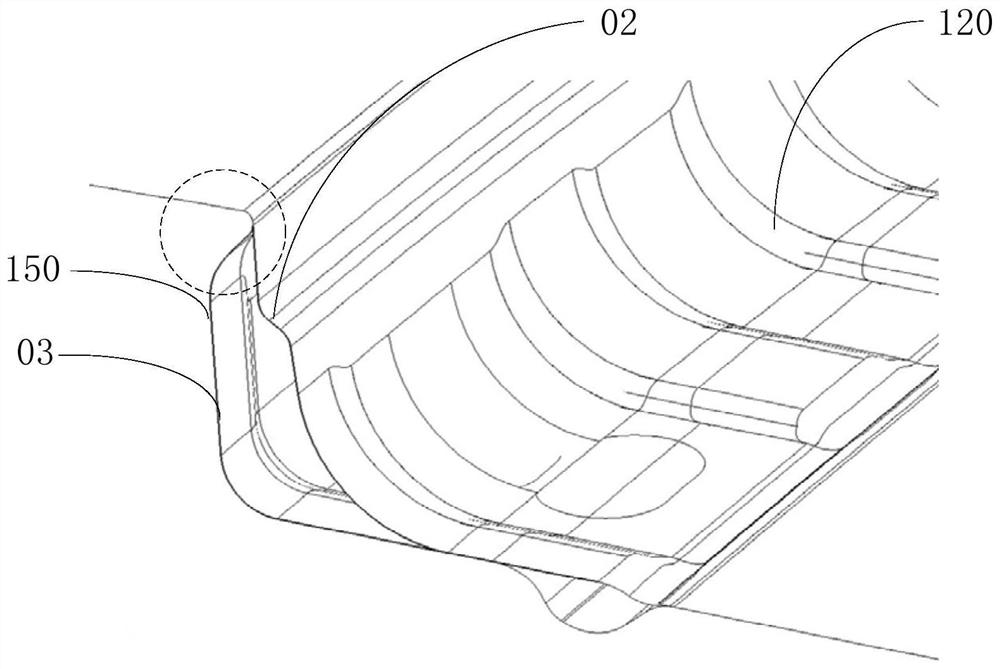

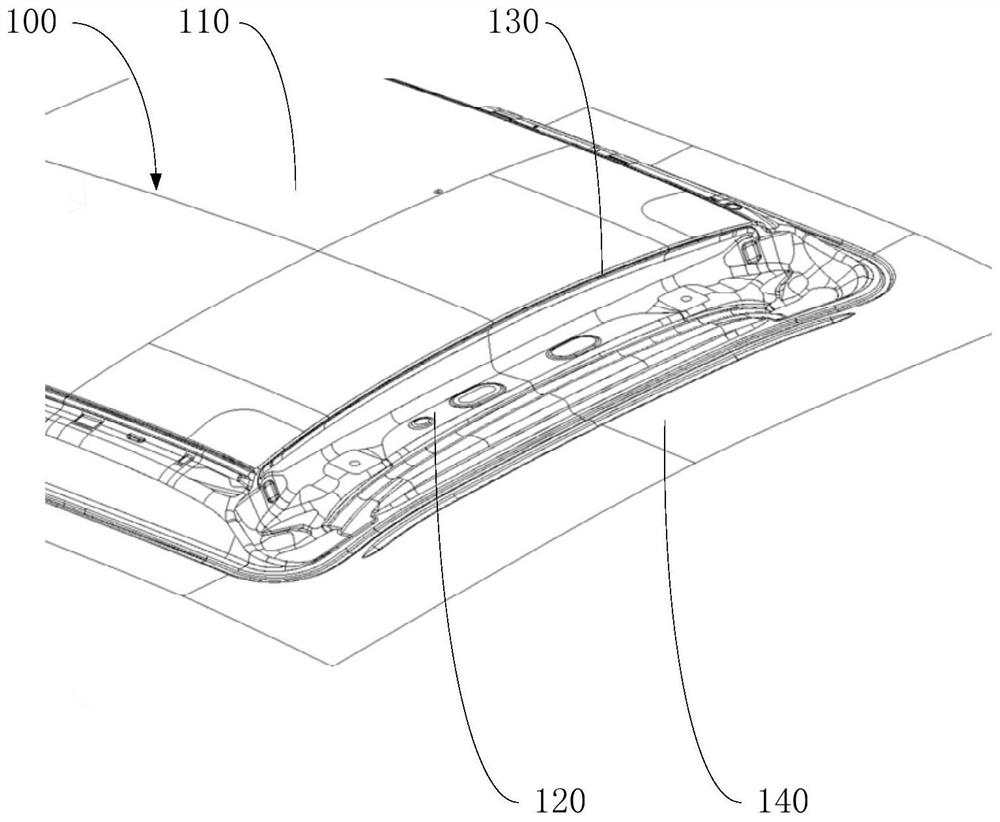

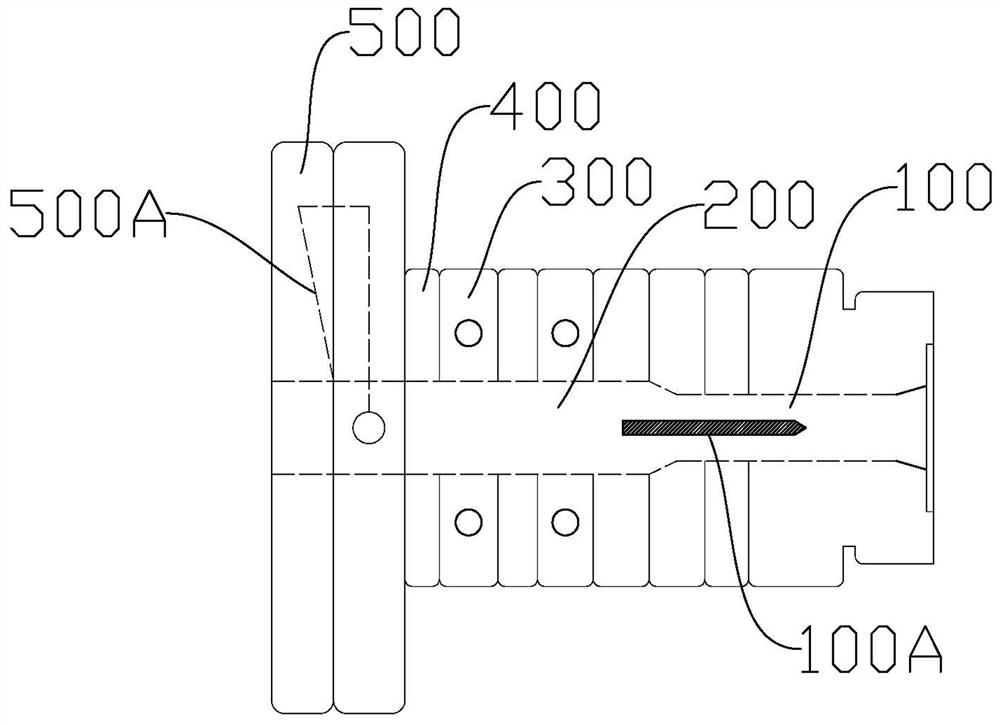

Automotive roof plastic mold and forming method thereof

ActiveCN113083941BReduce pulling deformationReduce dent deformationShaping toolsSupport surfaceManufacturing engineering

The invention provides an automobile roof shaping mold and a molding method thereof. The automobile roof shaping mold includes a lower mold and an upper mold. The lower mold is formed with an upper support surface for supporting the top section and a side molding surface for forming the tail section. 1. The rounded connecting surface connecting the upper supporting surface and the side forming surface and the side supporting surface used to support the edge blanking section of the process; the upper mold correspondingly includes a positive pressing block, a positive fillet pressing block, a side shaping pressing block and Side pressing blocks. When closing the mold, the positive pressing block corresponds to the top section of the pressing, the side pressing block corresponds to the edge section of the pressing process, the side trimming block trims the tail section sideways, and the side trimming block and the positive rounded corner pressing block are used for Co-molding fillet connection segments. Since the positive fillet pressure block is introduced at the later stage of the side shaping tail section to positively shape the fillet connection section, the situation of no compression in the fillet connection section is avoided, and at the same time, the deformation of the top section caused by side shaping is positively shaped, so that The junction between the top section and the fillet connection section has stable characteristics, and the top section has no concave deformation.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A viscous medium pressure forming method for thin-walled coverings with sudden changes in local curvature

The invention belongs to the field of aerospace equipment thin-wall coverage piece manufacturing, and particularly relates to a viscous medium pressure forming method for a local curvature sudden change thin-wall coverage piece. According to the method, a plunger in a viscous medium bin is pushed, so that viscous media load the viscous medium pressure P to a plate blank from the viscous medium bin, under the action of the viscous medium pressure P, the plate blank is gradually attached to a cavity of a die, and at the cavity curvature sudden change position, a plate is promoted to flow throughthe viscous attaching stress tau of the viscous media, shape local sudden change area materials are supplemented, the area wall thickness is prevented from being reduced, the wall thickness uniformity is improved, finally, the plate blank is completely attached to the surface of the cavity of the die, and accordingly a good forming effect is achieved. According to the viscous medium pressure forming method, the forming technology is simple, the quality is stable, reliability is high, cost is low, and the viscous medium pressure forming method is suitable for forming machining of high-strengthheat resisting alloy local curvature sudden change thin-wall coverage pieces.

Owner:HARBIN INST OF TECH

A kind of 460mpa grade cold-rolled micro-alloy high-strength steel and its manufacturing method

ActiveCN108929987BImprove mechanical propertiesHigh strengthFurnace typesHeat treatment furnacesSocial benefitsManufacturing technology

The invention discloses 460MPa grade cold-rolled microalloy high strength steel. The 460MPa grade cold-rolled microalloy high strength steel comprises, by mass, 0.051 to 0.059% of C, 0.01 to 0.02% ofSi, 1.17 to 1.27% of Mn, 0.2 to 0.5% of Al, P<=0.010, S<=0.006, 0.03 to 0.05% of Nb, 0.07 to 0.08% of Ti, and the balance Fe and unavoidable impurities. A manufacturing method is combined with component design and manufacturing technology improvement, so that the obtained steel products are high in strength, percentage elongation, spot welding performance, and moulding performance, excellent platability is achieved, rebound deformation performance is small, problems in the prior art such as poor formation performance, weldability, and rebound performance of high strength steel of the same grade are solved, and obvious social benefit and economic benefit are achieved.

Owner:武汉钢铁有限公司

A heat-resistant load-bearing integrated structure for aircraft and its forming method

ActiveCN111805938BConducive to lightweightHigh Rigidity Structural PerformanceDomestic articlesCoatingsHigh stiffnessFlight vehicle

Owner:BEIJING INST OF ELECTRONICS SYST ENG

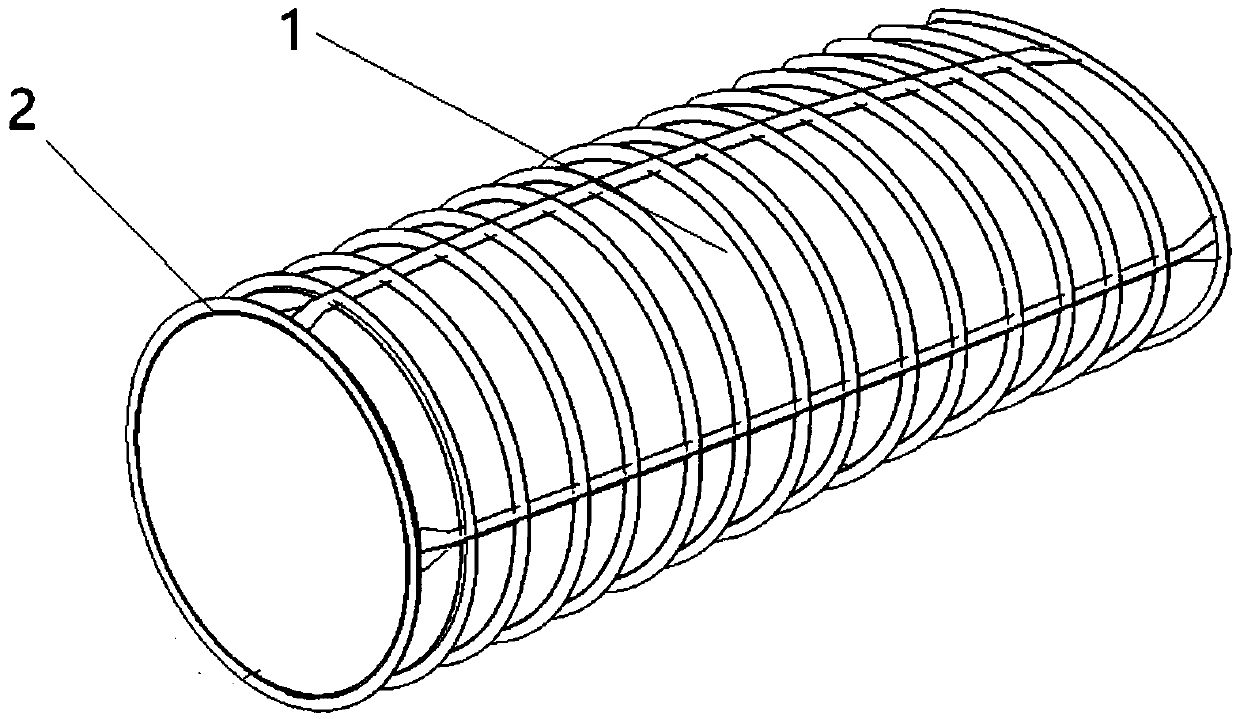

Composite material rotary body butt joint

InactiveCN109552647AReduce deformation springbackGuaranteed inner tolerancePower plant air intake arrangementsForming processesButt joint

A composite material rotary body butt joint comprises a rotary body made of a composite material and a metal butt flange. The rotary end of the metal butt flange is embedded in the end socket of the composite material rotary body during the forming process of the rotary body.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

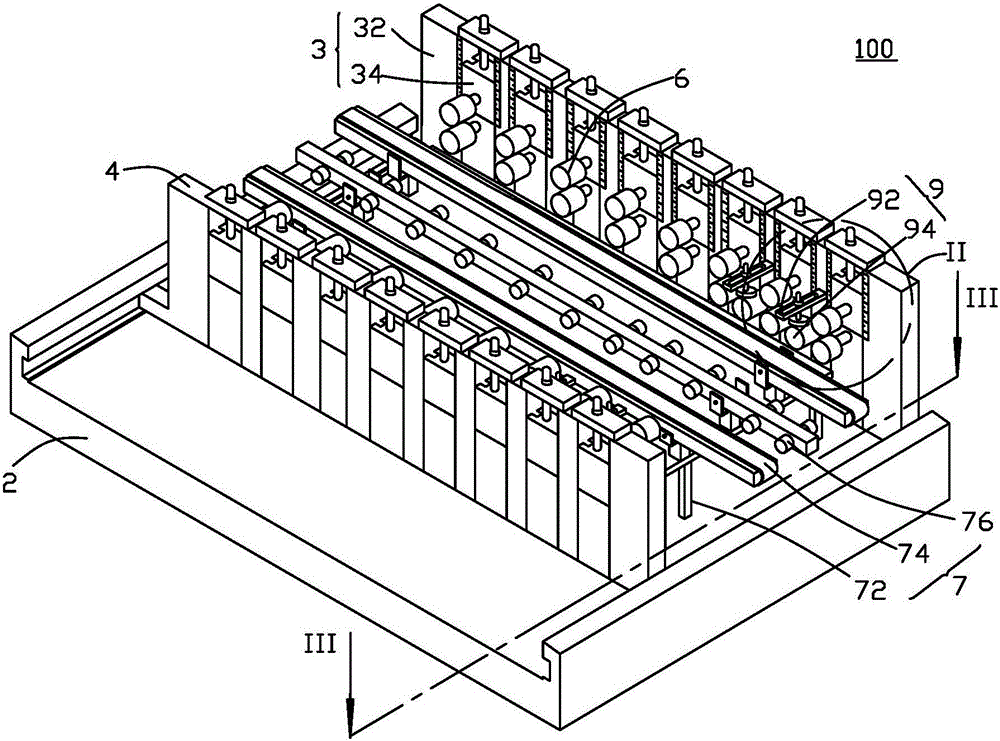

Plate Rolling Bending Machine

ActiveCN106077179BReduce springback deformationHigh precisionMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention provides a plate rolling bending machine used for bending the two opposite sides of a plate by a preset angle theta. The plate rolling bending machine comprises two oppositely-arranged supporting walls, two rows of forming roller sets arranged on the two supporting walls correspondingly, and a conveying mechanism located between the two rows of forming roller sets. The conveying mechanism is used for conveying the plate. Each row of forming roller sets comprises a plurality of forming roller sets arranged in the conveying direction of the plate at intervals. Each forming roller set comprises an upper roller and a lower roller which are arranged oppositely. The upper rollers and the lower rollers are both rotationally arranged on the corresponding supporting walls. The peripheral wall of each upper roller and the peripheral wall of the corresponding lower roller are correspondingly provided with bending surfaces used in cooperation. The angle formed by the bending surfaces and the axes of the forming rollers ranges from 0 degree to theta, and the angle gradually increases to the preset angle theta in the conveying direction of the plate. The plate rolling bending machine can improve the bending precision and forming effect of the plate.

Owner:广西田阳至恒门业有限公司

Plate Rolling Bending Machine

ActiveCN106040794BReduce springback deformationHigh precisionMetal-working feeding devicesPositioning devicesMultiple formsEngineering

The invention provides a plate rolling bending machine used for bending a plate by a preset angle theta. The plate rolling bending machine comprises two oppositely-arranged supporting walls and a plurality of forming roller sets arranged in the conveying direction of the plate at intervals. Each forming roller set comprises an upper roller and a lower roller which are arranged oppositely in the vertical direction. The two opposite ends of each upper roller are rotationally arranged on the two supporting walls correspondingly. The two opposite ends of each lower roller are rotationally arranged on the two supporting walls correspondingly. Bending faces used in cooperation are correspondingly arranged on the peripheral wall of each upper roller and the peripheral wall of the corresponding lower roller. The angle formed by each bending face and the axis of one forming roller ranges from 0 degree to theta. The angles of the multiple forming roller sets are gradually increased to the preset angle theta in the conveying direction of the plate. The plate rolling bending machine can improve the bending precision and forming effect of the plate.

Owner:广州市华顶建材有限公司

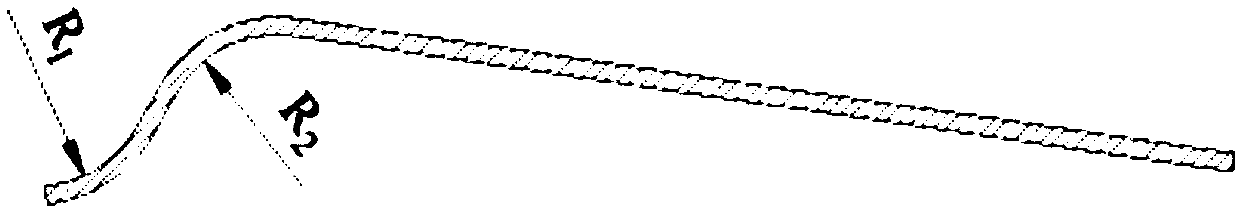

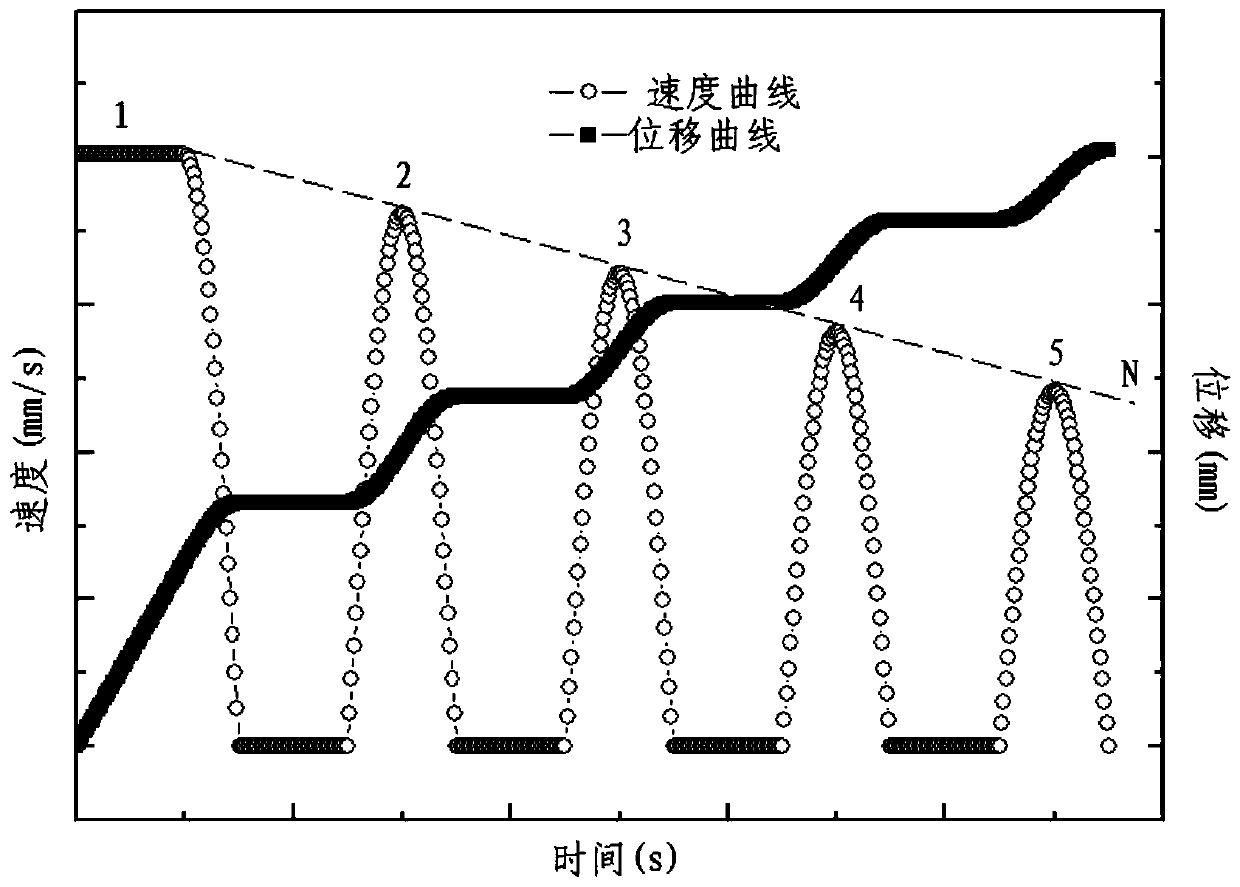

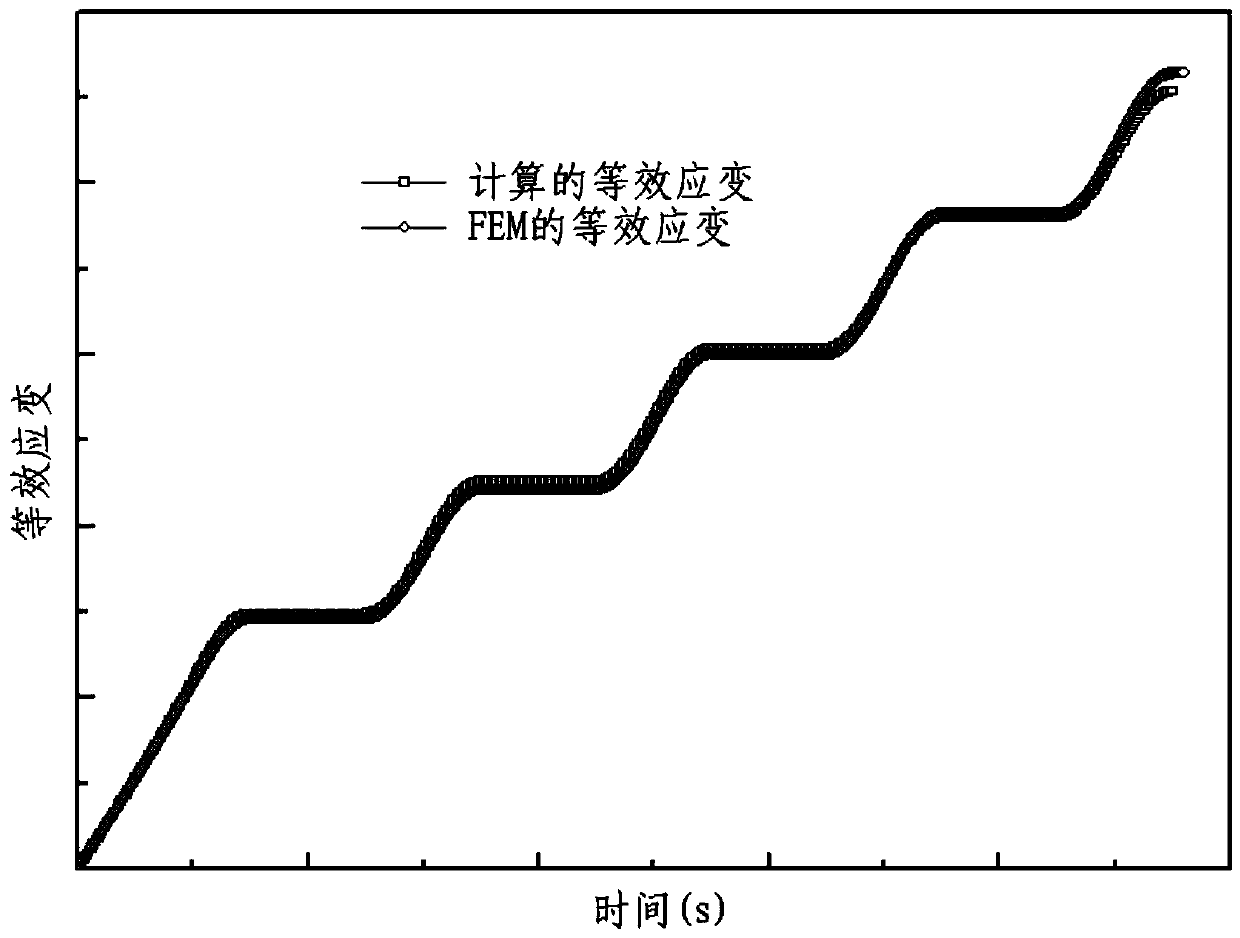

A method of cold extrusion wave shaping for curved parts

ActiveCN108127001BPromote cold extrusion shapingHigh forming precisionExtrusion diesWave shapeEngineering

The invention discloses a cold extruding fluctuation shaping method for an arc-shaped piece. A recombination speed is loaded to an upper cold extruding die, the instantaneous true strain of the recombination speed in each period is controlled, and therefore the speed track path of the recombination speed in each period and shaping amount corresponding to the speed track paths are optimally designed, the upper die is promoted to carry out cold extruding shaping on a blank, and the forming precision of the arc-shaped piece is improved. The recombination speed includes a plurality of periodic recombination speeds, and each periodic recombination speed is formed by adding a fixed speed and a fluctuation speed. The vector direction of the recombination speed is downward along the extruding axisall the time. The amplitudes of the adjacent fluctuation speeds with amplitudes larger than 0 are gradually reduced. By means of the cold extruding fluctuation shaping method for the arc-shaped piece, the rebound deformation of the cold extruding piece during finishing can be effectively reduced, and the cold extruding fluctuation shaping method can be widely applied to products of copper, tantalum, tungsten and other alloys.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

A CNC pipe bending machine control system

InactiveCN109127812BReduce springback deformationEnsure consistencyMetal-working feeding devicesPositioning devicesNumerical controlMachine control

The invention discloses a numerical control pipe-bending machine control system, and relates to the technical field of pipe bending machining. The numerical control pipe-bending machine control systemcomprises a central controller, external inputting equipment, external outputting equipment and a pipe-bending machine executing part. The pipe-bending machine executing part comprises a feeding servo mechanism, an angle rotating servo mechanism, a pipe-bending servo mechanism, a clamping servo mechanism, a lifting servo mechanism, a horizontal moving servo mechanism, a plate backing servo mechanism and a follow-up servo mechanism. According to the numerical control pipe-bending machine control system, moving at different angles and positions is completed through eight-axis servo control, bending machining at any angle and radius can be achieved, and the machining precision is guaranteed; and meanwhile, quick replacing of a pipe-bending mold and a feeding clamp can be structurally achieved, and thus, a pipe-bending machine has the function of welding prior to bending.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

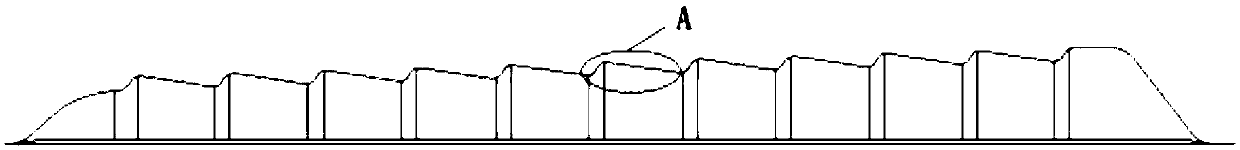

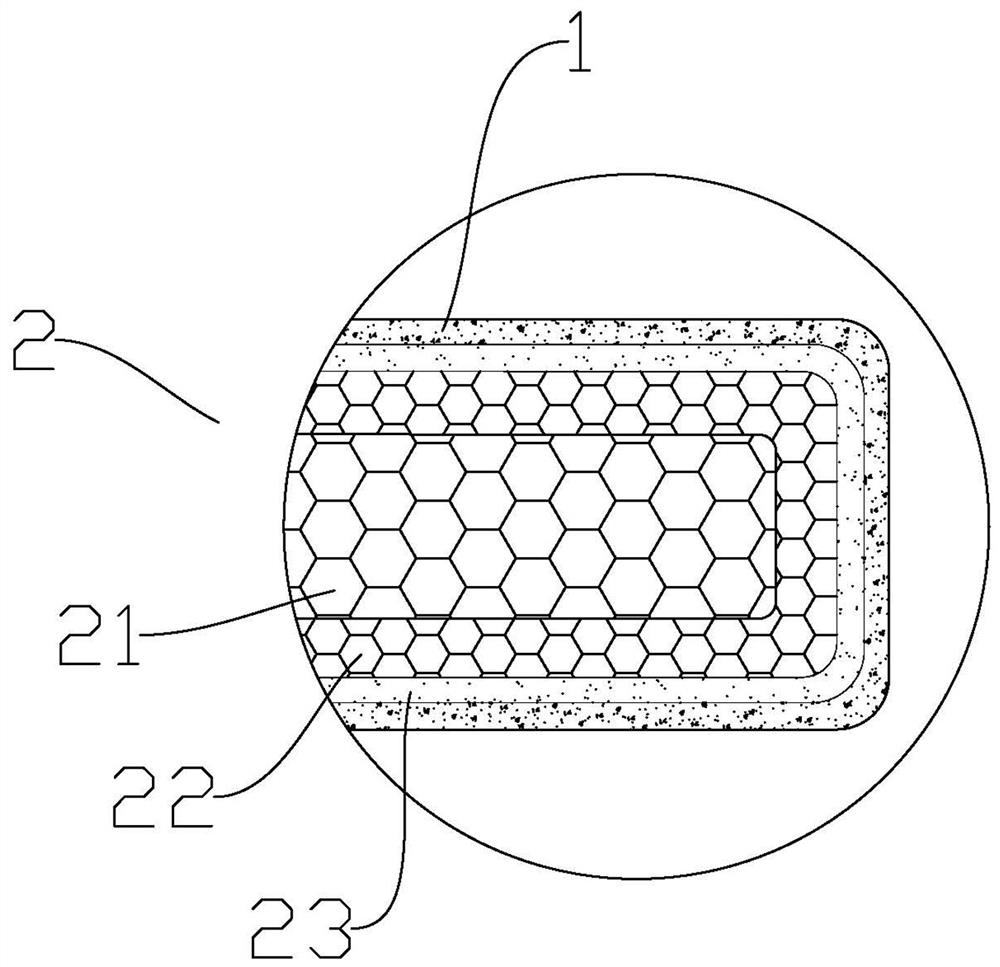

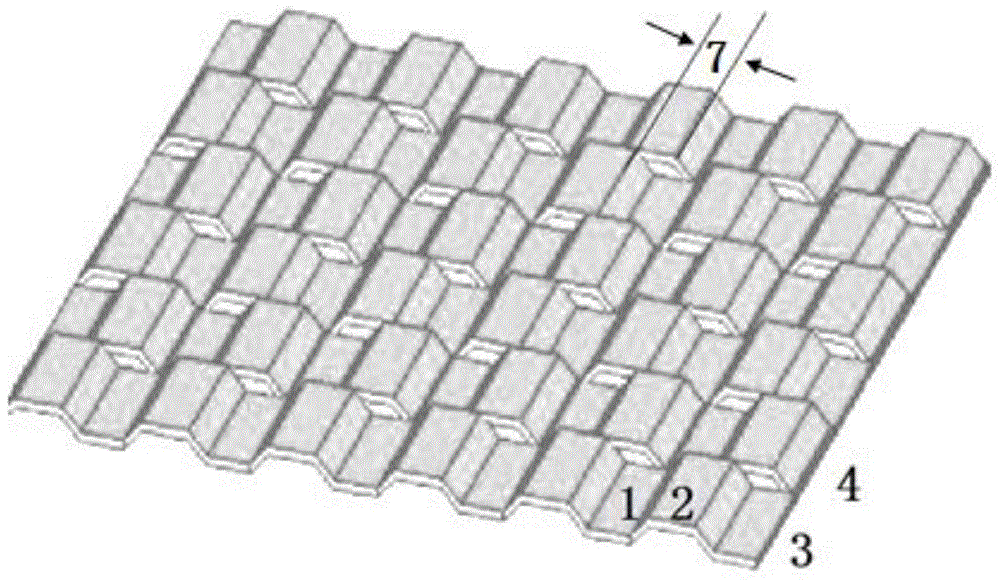

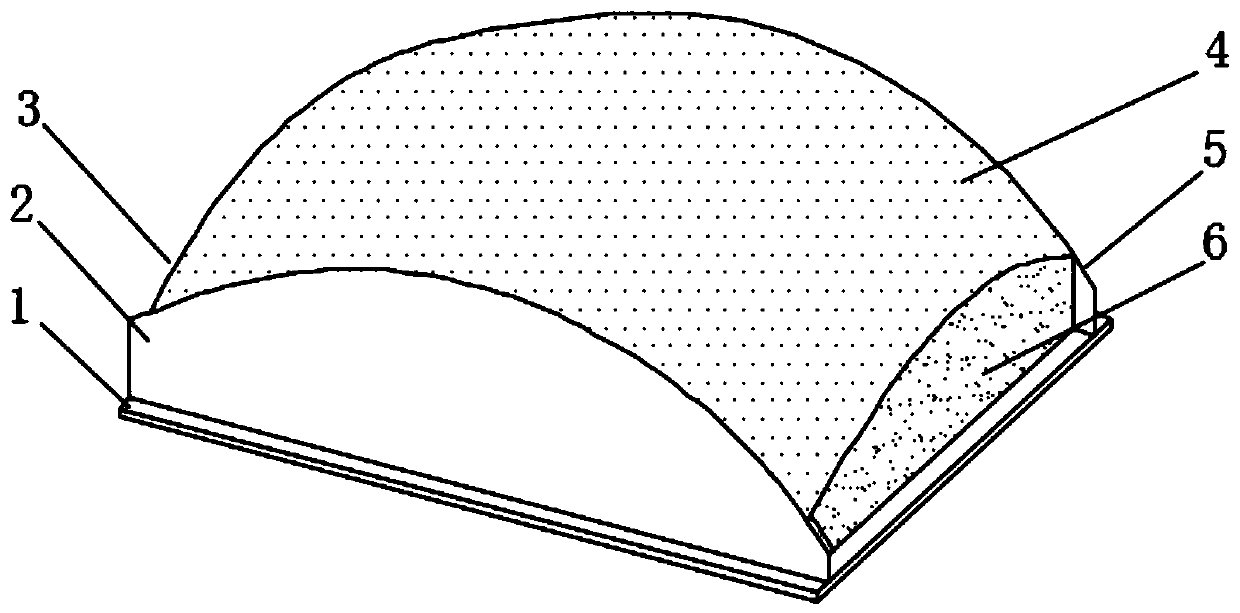

A solid oxide fuel cell cathode gas flow field plate and its preparation method

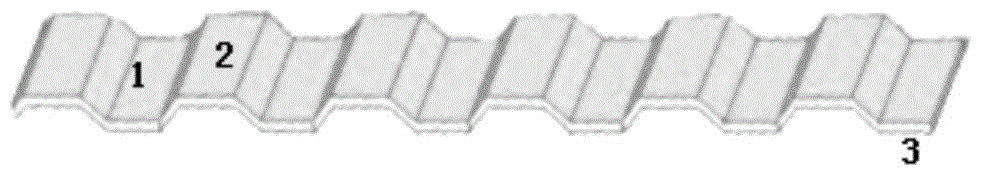

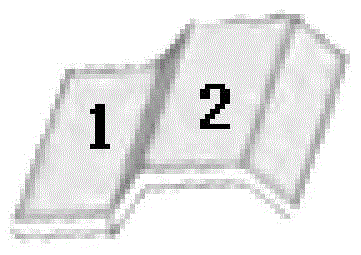

ActiveCN104253280BEfficient use ofFully contactedFinal product manufactureCollectors/separatorsIsosceles trapezoidFuel cells

The invention discloses a solid-oxide-fuel-cell cathode gas flow field plate which is used to uniformly distribute an oxidation gas and collect cathode current. The cathode gas flow field plate is formed by multiple tooth-shaped ripple blocks which are in parallel connection and have same dimension, each tooth-shaped ripple block is formed by two tooth-shaped ripple strips (3 and 4) which are in parallel arrayed connection after being staggered at a distance (7), each tooth-shaped ripple strip (3 and 4) is formed by multiple flat-top bosses (2) and flat plates (1) which are in alternate connection, each flat-top boss (2) has a tooth-shaped contour, the flat plates (1) are connected with the root parts of the flat-top bosses (2) to form tooth-shaped ripples, and the cross section of each flat-top boss (2) has a shape same to the shape of an isosceles trapezoid without a bottom edge. The cathode gas flow field plate of a fuel cell is capable of overcoming the problems that a conventional flow field is large in gas pressure reduction and low in fuel utilization rate. By employing a roll forming technology for preparing the flow field plate, the flow field plate is simple in technology, can be precisely formed and high in product qualified rate.

Owner:HUAZHONG UNIV OF SCI & TECH

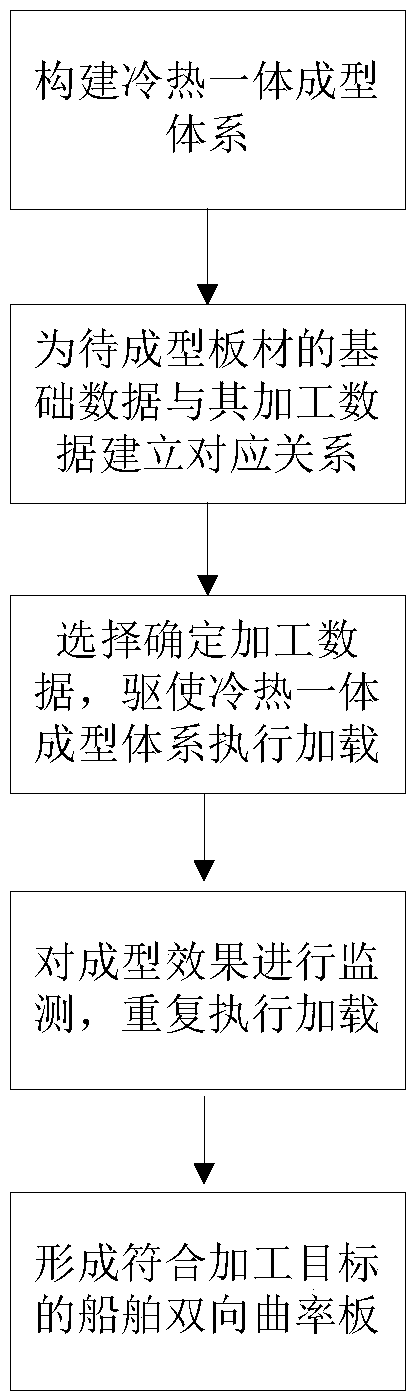

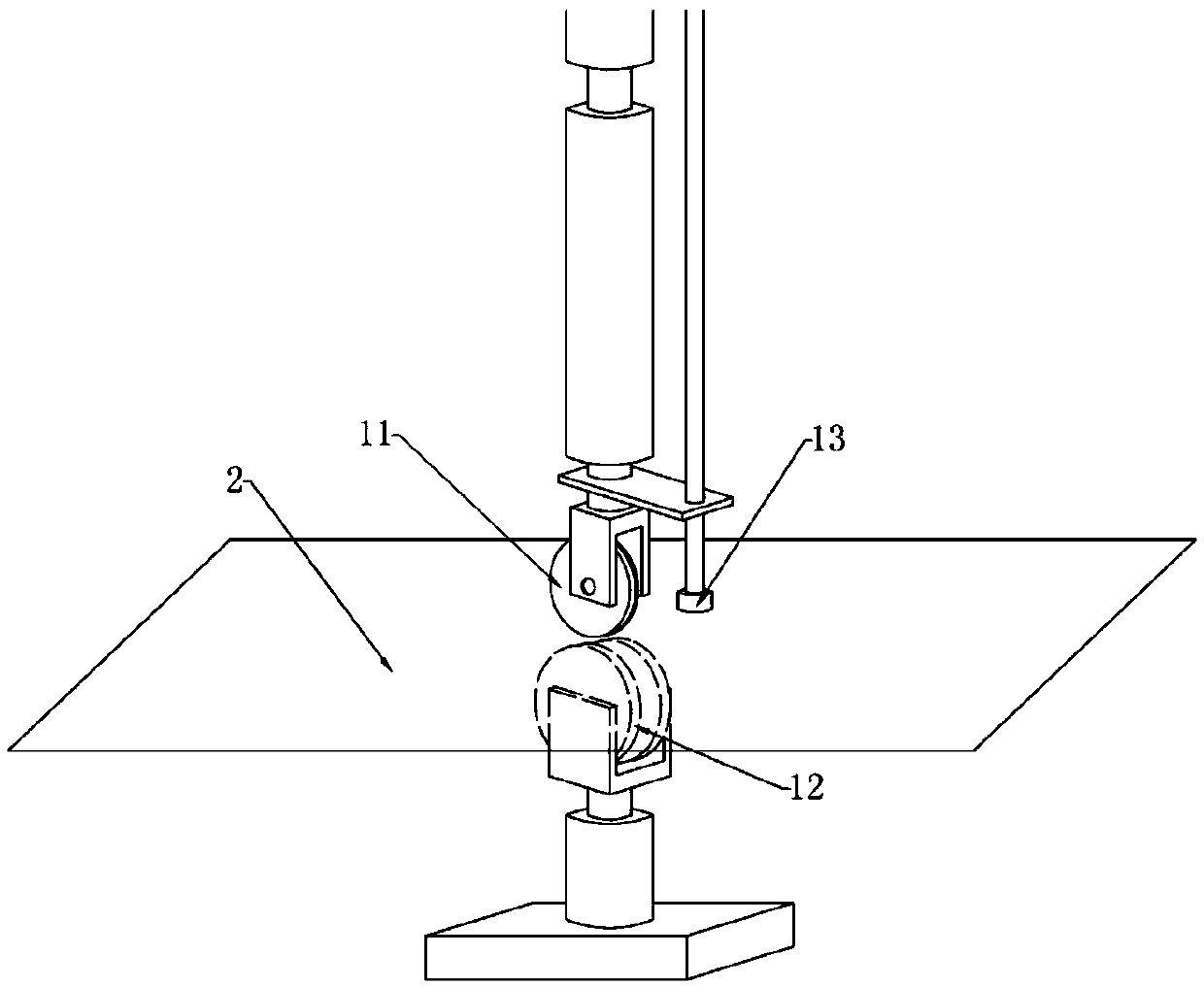

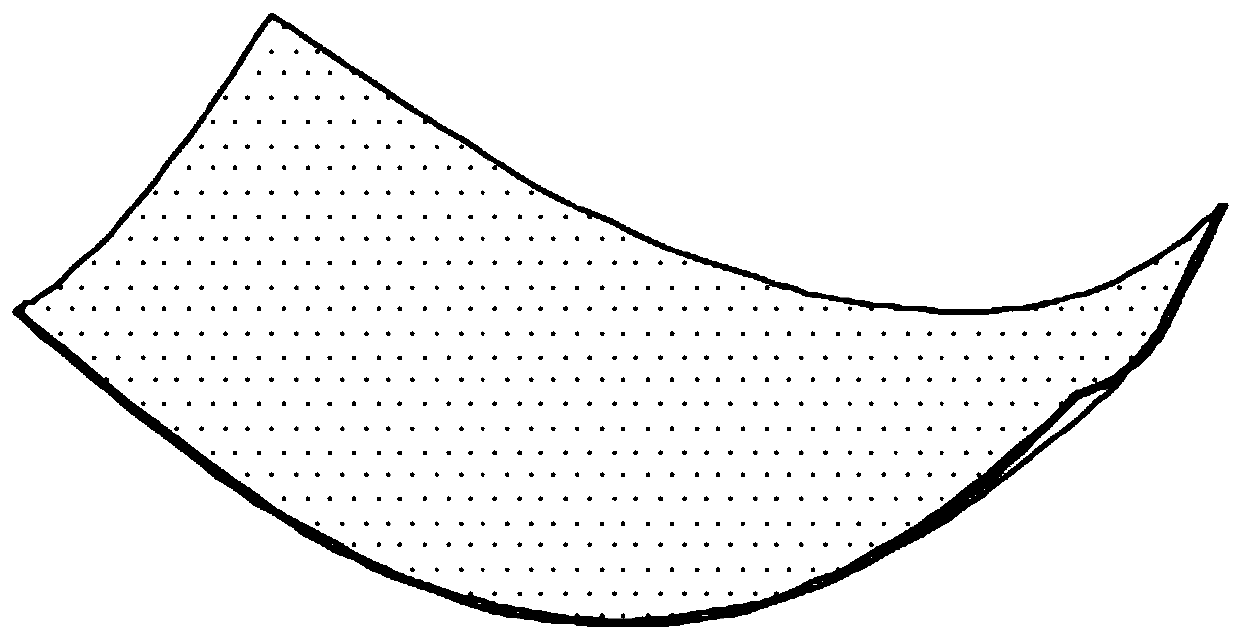

A cold and hot integrated forming method for two-way curvature plates of ships

ActiveCN103639251BReduce adverse effectsOvercome the defect of not being able to process large curvature platesMarine engineeringUltimate tensile strength

The invention discloses a cold-hot integrally forming method for a ship bidirectional curvature plate. The cold-hot integrally forming method for the ship bidirectional curvature plate comprises the steps of (a) establishing a dedicated cold-hot integrally forming system; (b) establishing a corresponding relationship between basic data of a to-be-formed plate and machining data; (c) selecting and determining suitable machining data based on the established corresponding relationship, and correspondingly driving the cold-hot integrally forming system to upload the plate; (d) monitoring the forming effect of the plate, performing comparison and feedback on the difference between the formed effect and a machining target, and performing the steps of selecting, determining, uploading and monitoring again based on the difference until the bidirectional curvature plate meeting with the machining target is formed. The cold-hot integrally forming method for the ship bidirectional curvature plate can reduce negative influence from machining to the performance of the plate while the machining efficiency is improved, can reduce equipment cost, can reduce work intensity of personnel, and can improve forming precision of the ship bidirectional curvature plate remarkably.

Owner:HUAZHONG UNIV OF SCI & TECH

L-shaped aluminum profile arc bending die

ActiveCN114850269AIncrease contact areaReduce local deformationShaping toolsMechanical engineeringPhysics

The invention belongs to the field of arc bending dies, and particularly relates to an L-shaped aluminum profile arc bending die which comprises a machine body, an upper die plate and a lower die plate. The surface of the machine body is in sliding connection with an upper template; a lower template is arranged on the surface of the machine body and at the bottom of the upper template; a block is arranged on the top surface of the lower template; a shape groove is formed in the top surface of the shape block; a rotating groove is formed in the inner surface of the shaped groove; a rotating plate is rotationally connected into the rotating groove; a mounting groove is formed in the groove bottom of the rotating groove; a first spring is fixedly connected to the interior of the mounting groove, and the first spring is fixedly connected with the rotating plate; through rotation of the rotating plate, a large contact area is always kept between the rotating plate and the bottom face of the aluminum template, the problems of local concentrated stress of the aluminum template and change of the local stress position are reduced, then the problems of local deformation of the aluminum template and scratching of the surface of the aluminum template are reduced, and the forming quality of the aluminum template is improved.

Owner:江苏科力西铝业有限公司

A kind of pvc co-extrusion foam floor and preparation method thereof

ActiveCN112443120BLow densityAppropriate wrappingLamination ancillary operationsSynthetic resin layered productsPolymer scienceHigh density

The invention relates to a PVC co-extruded foam floor and a preparation method thereof, belonging to the technical field of PVC foam floors. PVC co-extruded foam floor, including PVC foam core and plastic surface layer, PVC foam core includes first foam layer, second foam layer and crust layer, second foam layer covers first foam layer, knot The skin layer covers the second foam layer, and the layers of the PVC foam core are integrally connected; the plastic surface layer is at least covered on the upper surface of the skin layer; the first foam layer is a low-density foam layer, and the second foam layer is High-density foam layer; wood grain on plastic surface. The present invention is molded at one time through an improved foaming process; the PVC foam core of the present invention is not clearly distinguished from the first foam layer and the second foam layer in the prior art, and the thickness of the crust layer is thin. It has the advantages of clearer structure and higher overall strength; and it is more suitable for covering the plastic surface.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

A method for forming high-strength titanium alloy double-curved thin-walled wide plate

ActiveCN109731975BHigh forming precisionForming accuracy is reasonableMetal working apparatusTitanium alloyThin walled

The invention discloses a novel high-strength titanium alloy hyperboloid thin-wall wide plate forming method. The novel high-strength titanium alloy hyperboloid thin-wall wide plate forming method comprises the following steps that S1, a heat setting mold is manufactured; S2, a titanium alloy hyperboloid plate is formed; and S3, after all the work is completed, the profile modeling and cold forming and heat setting work of the high-strength titanium alloy hyperboloid thin-wall wide plate are completed completely, and has the follow-up assembly process requirements. According to the high-strength titanium alloy hyperboloid thin-wall wide plate profiling compression cold forming and hot setting forming method, cold pressing, hot-pressing or mold-free multi-point forming are taken into consideration, a special field is not needed, the width of the formed hyperboloid plate is doubled, the stress is small, the forming precision is relatively high and the like; the copying and mold pressingcold forming and heat setting are mainly the profiling pressing mold, the manufacturing of the heat setting mold of the titanium alloy hyperboloid plate and the heat setting work in the furnace afterthe titanium alloy plate is formed.

Owner:NANJING BAOSE

Plate Rolling Bending Machine

ActiveCN105964743BEasy to useAdjustable distanceMetal-working feeding devicesPositioning devicesMechanical engineeringEngineering

The invention provides a plate rolling and bending machine. The plate rolling and bending machine comprises two opposite supporting walls, a plurality of forming roller sets arranged in the conveying direction of a plate at intervals, a base, a screw rod driving mechanism and a connecting rod, wherein one supporting wall is fixed to the base, and the other supporting wall is movably installed on the base. Each forming roller set comprises an upper roller and a lower roller, the upper roller and the lower roller are oppositely arranged in the vertical direction, and each of the upper roller and the lower roller comprises a telescopic shaft and a roller body fixedly arranged on the telescopic shaft in a sleeving mode. The screw rod driving mechanism comprises a screw rod, a motor driving the screw rod to rotate and a screw rod nut connected to the screw rod in a screwed mode. The connecting rod is connected to the screw rod nut and the supporting wall movably installed so that the two supporting walls can get close or get away from each other, the distance between the two supporting walls can be adjusted for adapting to the bending operation of plates of different widths through the telescoping motion of the telescopic shafts of the forming roller sets, and use is convenient.

Owner:江西荣妍科技有限公司

Apparatus and method for surface microstructure processing of polymer film based on roll-to-roll hot rolling

ActiveCN102806660BReduce springback deformationHigh forming precisionPolymer thin filmsGlass transition

The invention relates to device and method for processing a polymer film surface microstructure based on roll-to-roll hot rolling. The method comprises the following six steps: unrolling, pre-heating, hot-rolling, conforming, cooling and rolling. The unrolling step includes continuously drawing a polymer film from a rolled material and removing static electricity on the surface of the film. After the pre-heating step, the polymer film is heated to a temperature below the glass transition temperature thereof to get ready for the hot-rolling step. The local heating treatment is conducted on a plate roller to allow only the temperature of the stamping surface to rise above the glass transition temperature, so as to roll-form the preheated film. The conforming step enables the rolled film in close contact with the surface of the plate roller, so that the film is completely deformed. The formed film is subjected to both cooling and conforming to cause rapid curing of the surface microstructure and reduce rebound. Compared with the prior art, the device and method have the advantages of reducing the risk of rebound and deformation, improving the forming precision of the microstructure, making demoulding easier and increasing the processing efficiency.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com