Production method of high-strength alloy welded pipe

A production method and technology for welded pipes, applied in welding equipment, metal processing equipment, laser welding equipment, etc., can solve the problems of "frame wear, unreliable welded pipe quality, unstable welded pipe forming, etc., so as to reduce losses and improve service life. And the effect of working stability and molding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

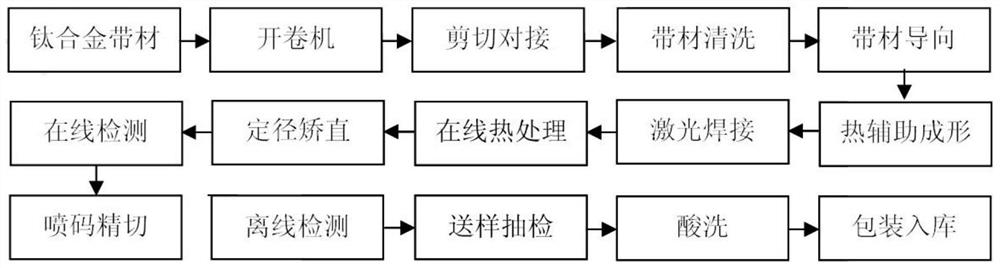

[0045] Specific embodiment: a kind of preparation method of high-strength titanium alloy welded pipe, concrete steps are as follows:

[0046] Step 1) Heat-assisted forming of the high-strength titanium alloy strip to obtain a titanium alloy tube blank.

[0047] For duplex titanium alloy TC4, according to the national standard GB / T 3621, the yield strength of TC4 titanium alloy strip is greater than 830MPa, the tensile strength is greater than 895MPa, the elongation is about 10%, the Young's modulus is 109-112GPa, and the melting point is 1630-1650 ℃, phase transition point 995±15℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com