Mould for forming side push bending beam for passenger train

A technology for railway passenger cars and side roofs, applied in the directions of forming tools, manufacturing tools, vehicle components, etc., can solve the problem of large rebound deformation, affecting the quality of welding and installation of side roof curved beams, and the flatness of both sides of the side roof curved beams. Difficult to meet the standard and other problems, to achieve the effect of reducing springback deformation, ensuring flatness, and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

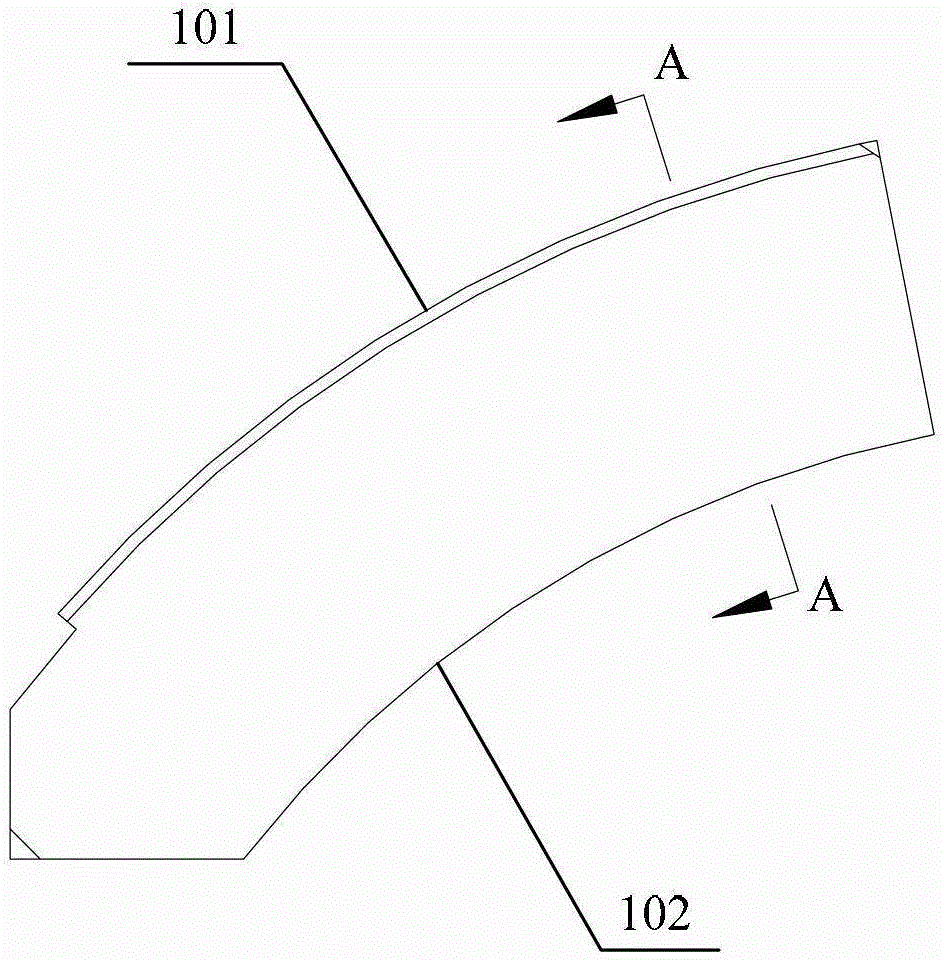

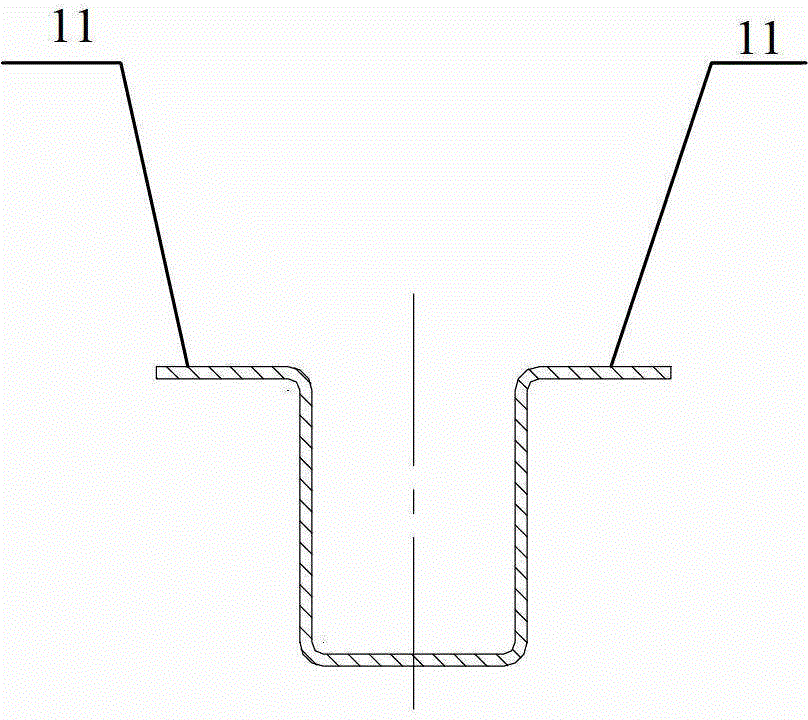

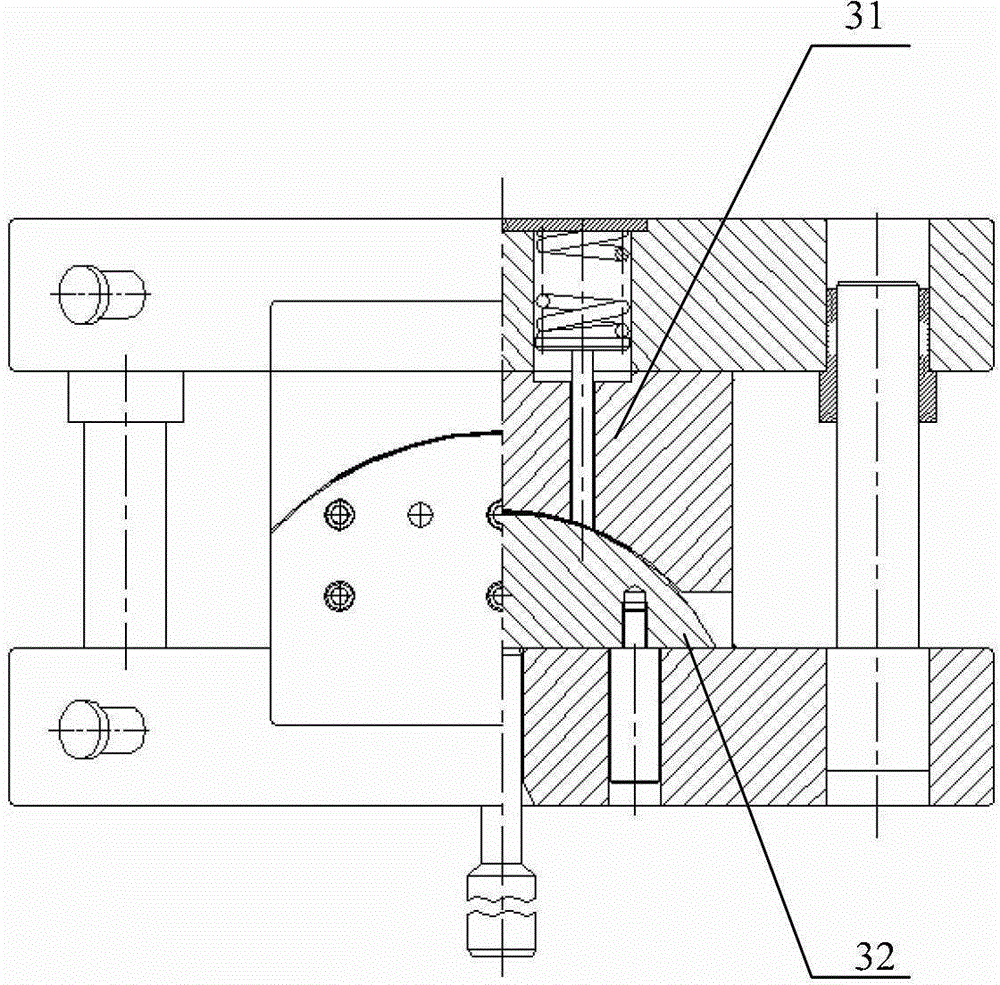

[0020] Figure 4A It is the front view of the embodiment of the mold for forming the side roof curved beam of the railway passenger car of the present invention; Figure 4B for Figure 4A Middle B-B sectional view; Figure 4C top view; see Figure 4A-Figure 4C , the present embodiment provides a mold for forming the side roof of a railway passenger car, comprising: a lower mold 41 fixedly arranged on the working platform and an upper mold 42 arranged above the lower mold 41, the upper mold 42 can be opposite to the lower mold 41 Move up and down; the top surface of the lower mold 41 is fixedly provided with a lower limit block 43, and the lower limit block 43 is provided with a binder plate 44; The second concave arc surface 430 (such as Figure 7A and Figure 7B shown), the bottom surface of the upper mold 42 is a first convex arc-shaped surface 420 matching the outer arc surface of the side top curved beam, and the top surface of the binder plate 44 is formed with a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com