Rubber sealing strip used for outer protective plate of automobile door

A technology of rubber sealing strip and outer guard plate, which is applied in the direction of engine sealing, sealing device, vehicle parts, etc., can solve the problems of lowering assembly quality, large curling deformation of claws, and increasing assembly resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

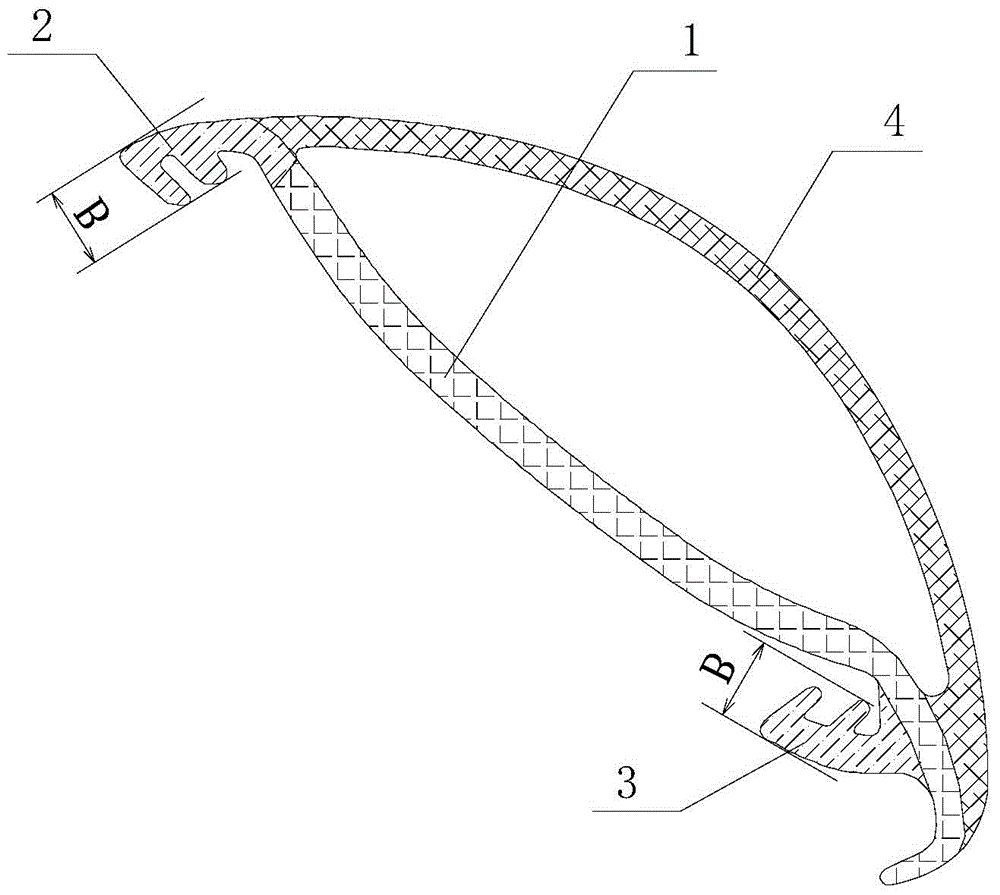

[0013] refer to figure 1 , a rubber sealing strip used on the outer guard of the car door, which is composed of a plate-shaped support part 1 arranged in the middle, a first claw part 2, a second claw part 3 and an arc-shaped outer convex part 4. The two claw parts are arranged on one side of the plate-shaped supporting part near two ends thereof, and the arc-shaped outer convex part is arranged on the other side of the plate-shaped supporting part. The rubber sealing strip is formed by a multi-body co-extrusion process, and the hardness of the two claw parts is higher than that of the plate-shaped support part, and the hardness of the plate-shaped support part is higher than that of the arc-shaped outer convex part. Specifically, this rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com