Patents

Literature

66results about How to "Reduce the amount of interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sealing device

ActiveCN101883941APrevent intrusionSmall slip torqueEngine sealsShaftsMechanical engineeringEngineering

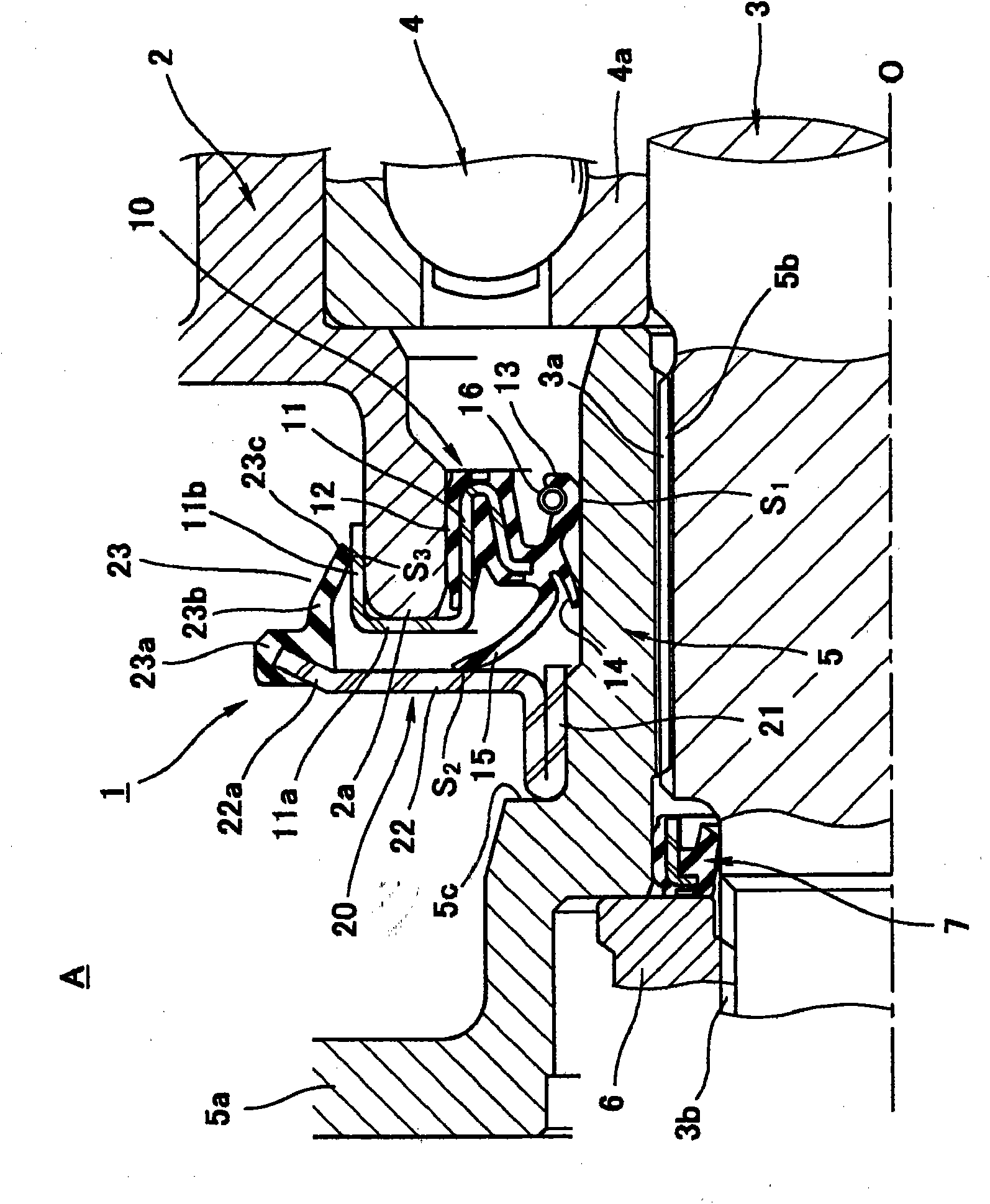

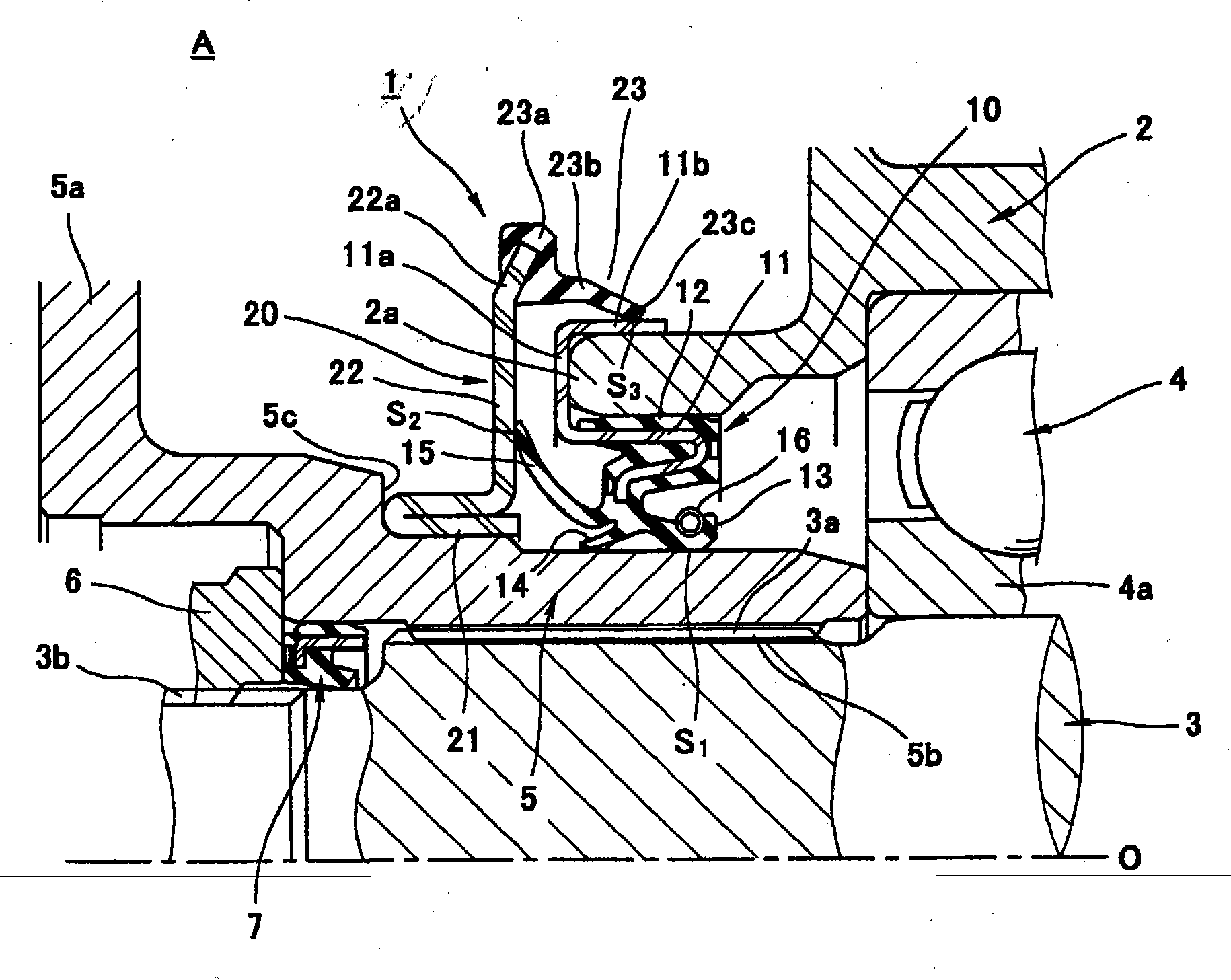

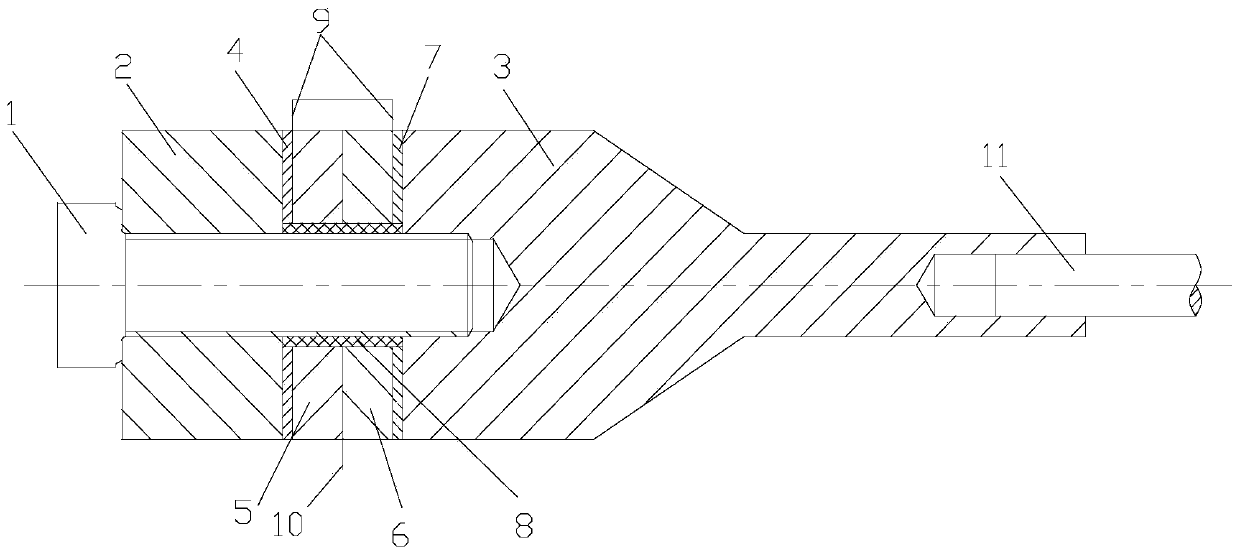

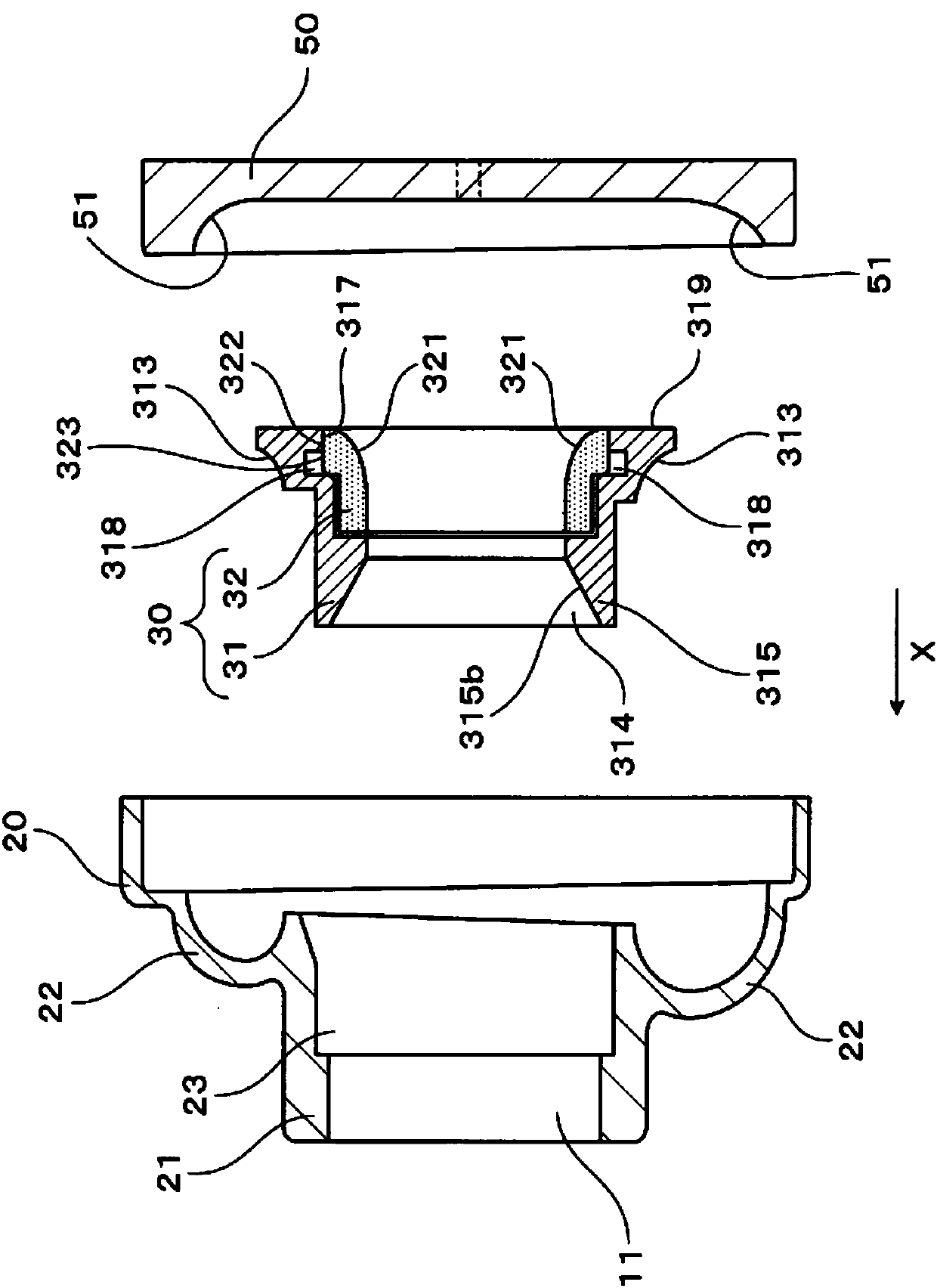

A sealing device (1) for sealing the periphery etc. of a shaft of a portion likely to be exposed to muddy water etc. coming from the outside (A). The sealing device (1) prevents as far as possible entry of muddy water etc. into a sliding section (S1) of an oil seal lip (13). To achieve this, the sealing device (1) has an oil seal (10) mounted on the inner peripheral surface of an opening end (2a) of a non-rotating housing (2), and also has a slinger (20) mounted on a rotating body (5), inserted through the housing (2), so as to be located on the axially outward side of the oil seal (10). The oil seal (10) is formed from a rubber-like elastic material and integrally with a metal reinforcement ring (11). The oil seal (10) has the oil seal lip (13) in intimate slidable contact with the outer peripheral surface of the rotating body (5), and also has a side lip (15) in intimate slidable contact with the slinger (20). The reinforcement ring (11) has a sliding tube section (11b) located on the outer diameter side of a sliding section (S2) of the side lip (15) in a manner exposed from the rubber-like elastic material. An external seal lip (23) provided on an outer diameter section (22a) of the slinger (20) is in intimate slidable contact with the outer peripheral surface of the sliding tube section (11b).

Owner:NOK CORP

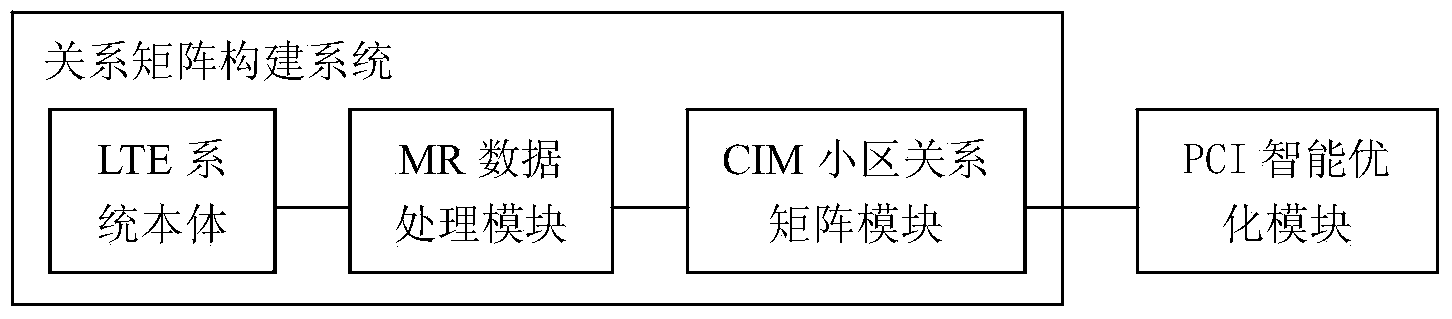

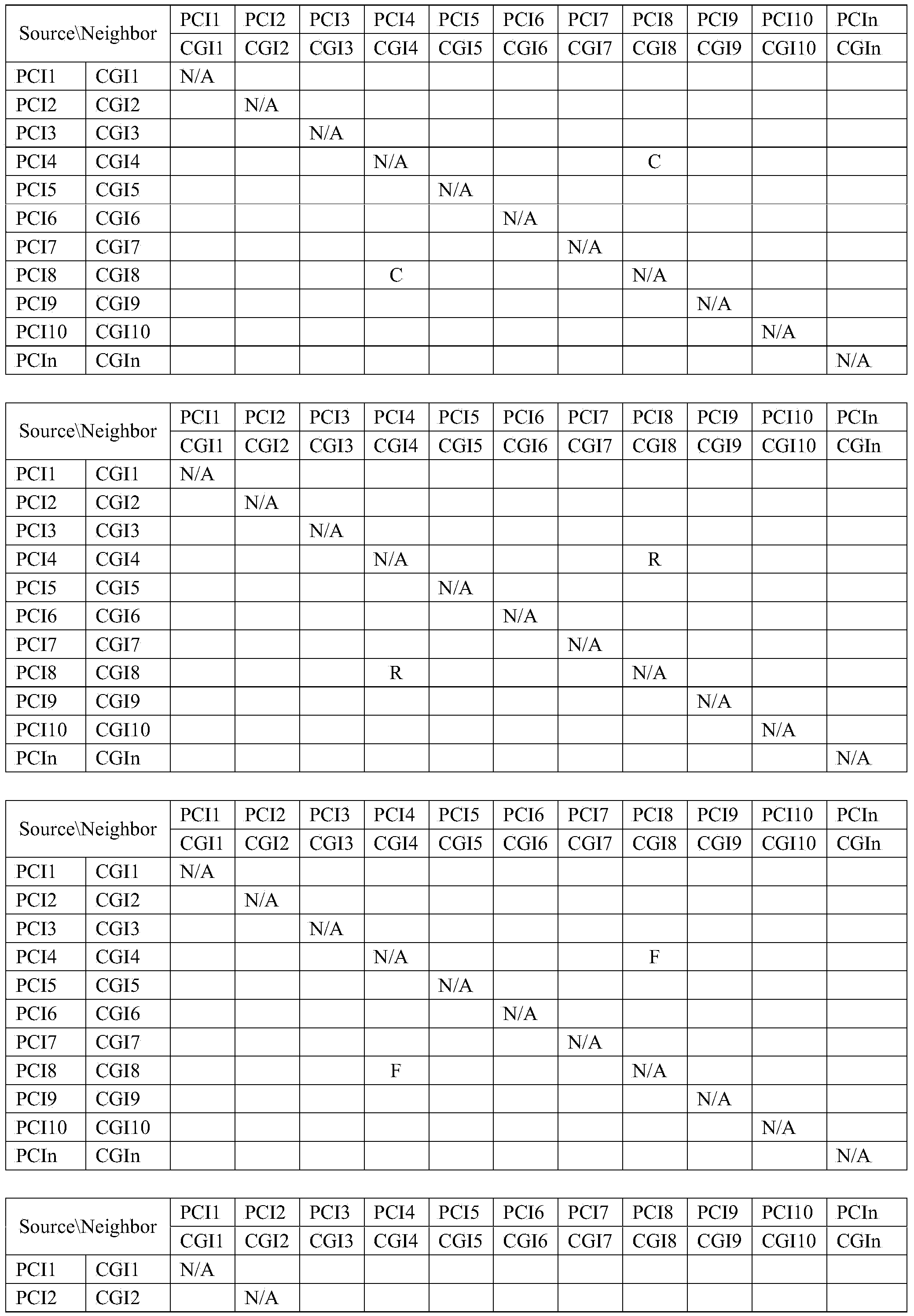

Relation matrix establishment system and method and PCI intelligent optimization system and method

ActiveCN103906078AQuality improvementReduce operating costsNetwork planningCommunications systemSystems analysis

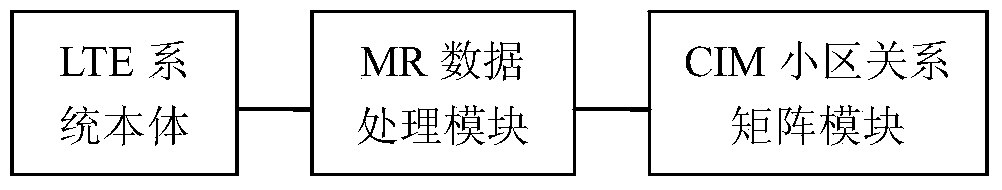

The invention relates to intelligent analysis and intelligent optimization of an LTE mobile communication system. The problem that the coverage relation, the switching relation and the interference relation among cells cannot be accurately quantified and analyzed in an existing LTE system is solved, the problem that the degree of intelligence and the degree of automation are low in an PCI optimization method of the existing LTE system is also solved, and a relation matrix establishment system and method and a PCI intelligent optimization system and method are provided. According to the technical scheme, the relation matrix establishment system is formed by the way that an MR data processing module is connected with an LTE system body, and a CIM cell relation matrix module is connected with the MR data processing module; the PCI intelligent optimization system is formed by the way that a PCI intelligent optimization module is connected with the CIM cell relation matrix module in the cell relation matrix establishment system. The relation matrix establishment system and method and the PCI intelligent optimization system and method have the advantages of being capable of not only quantifying the inference relation among the cells, but also planning and optimizing PCI setting of the cells, suitable for LTE system analysis and wireless optimization and also suitable for 4G service providers to improve operation efficiency.

Owner:成都爱德华兹通信技术有限公司

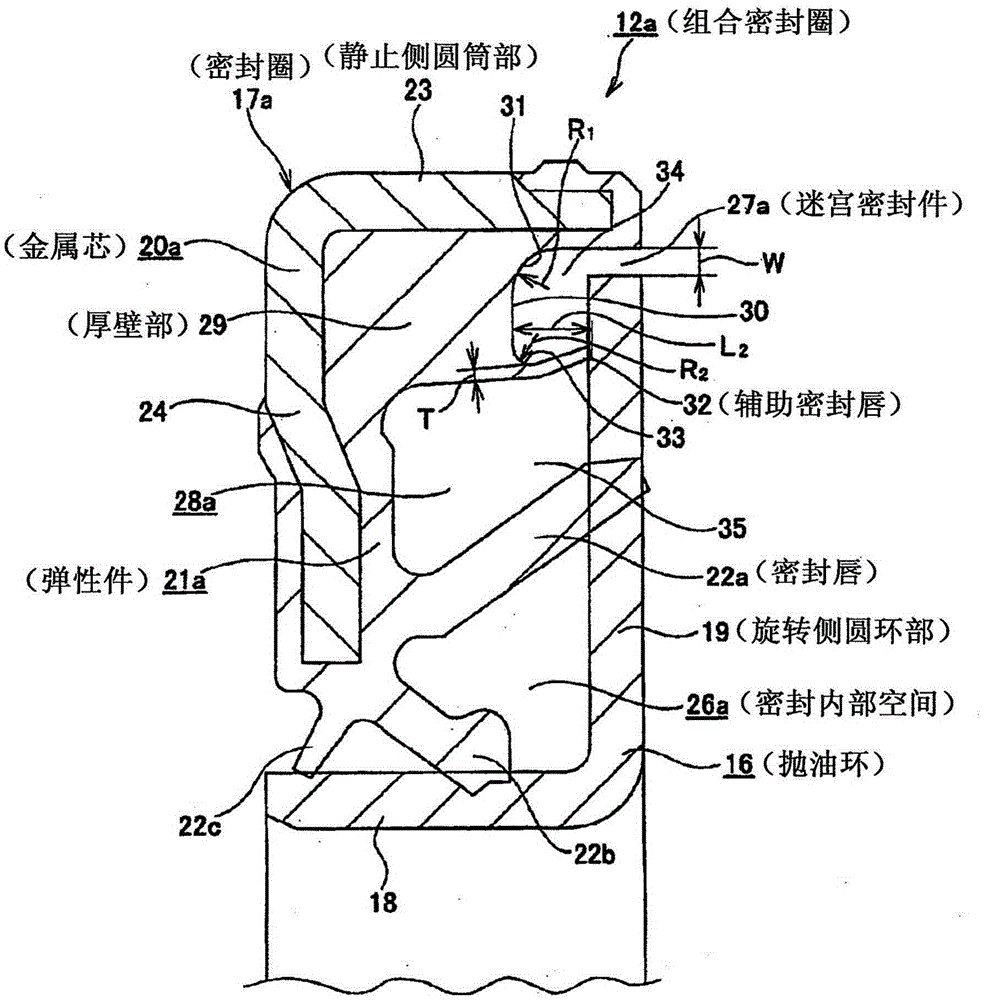

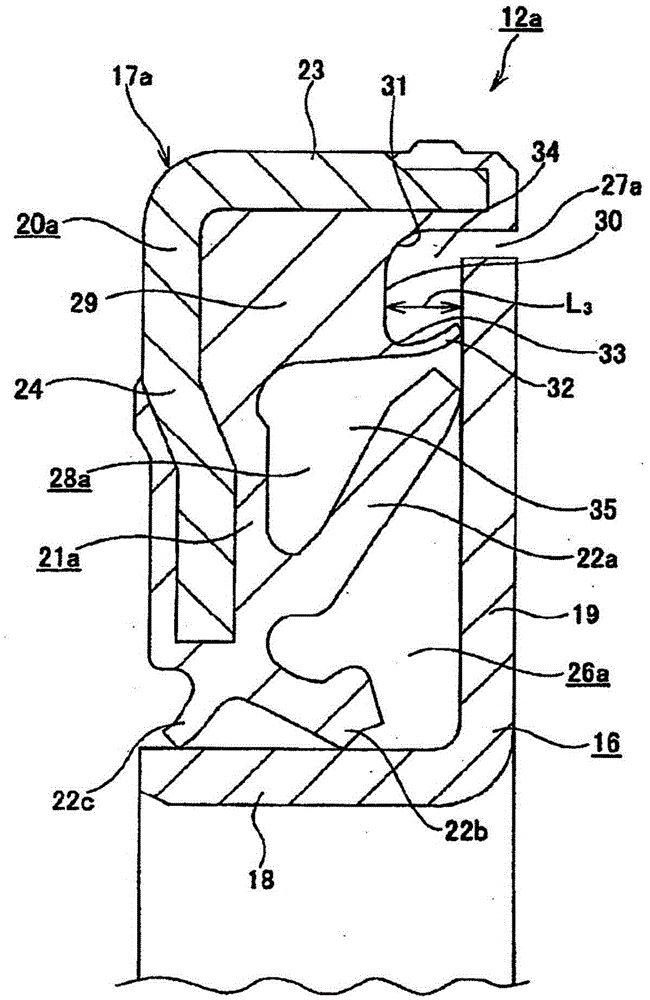

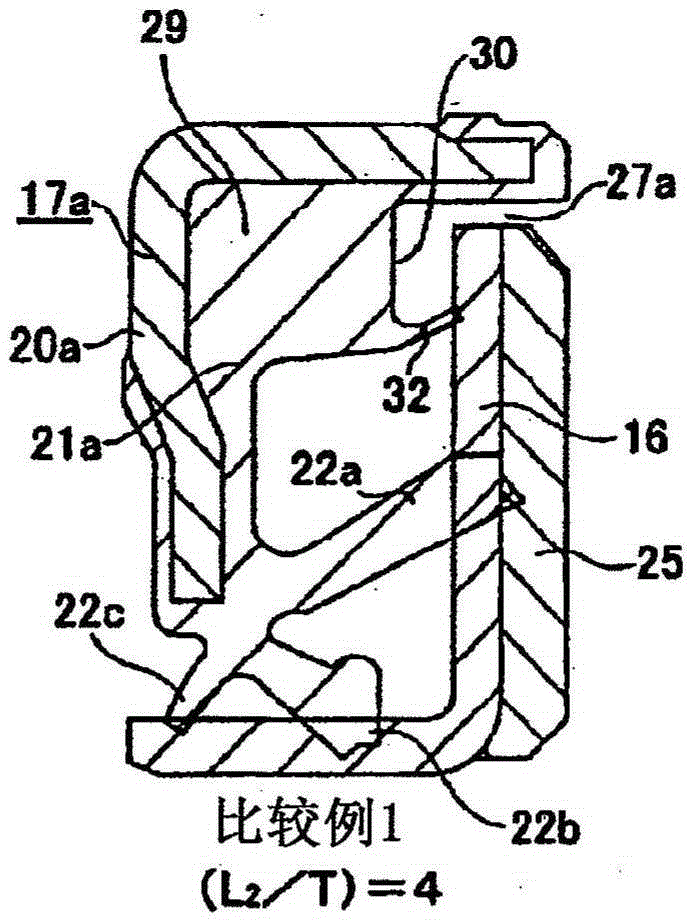

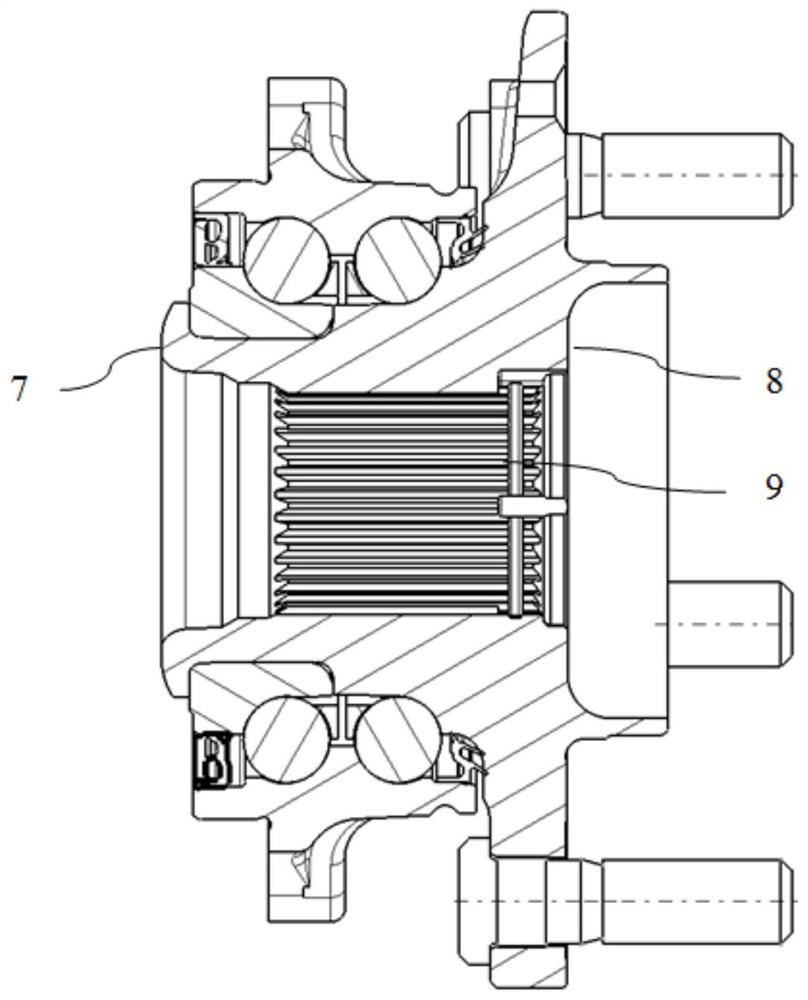

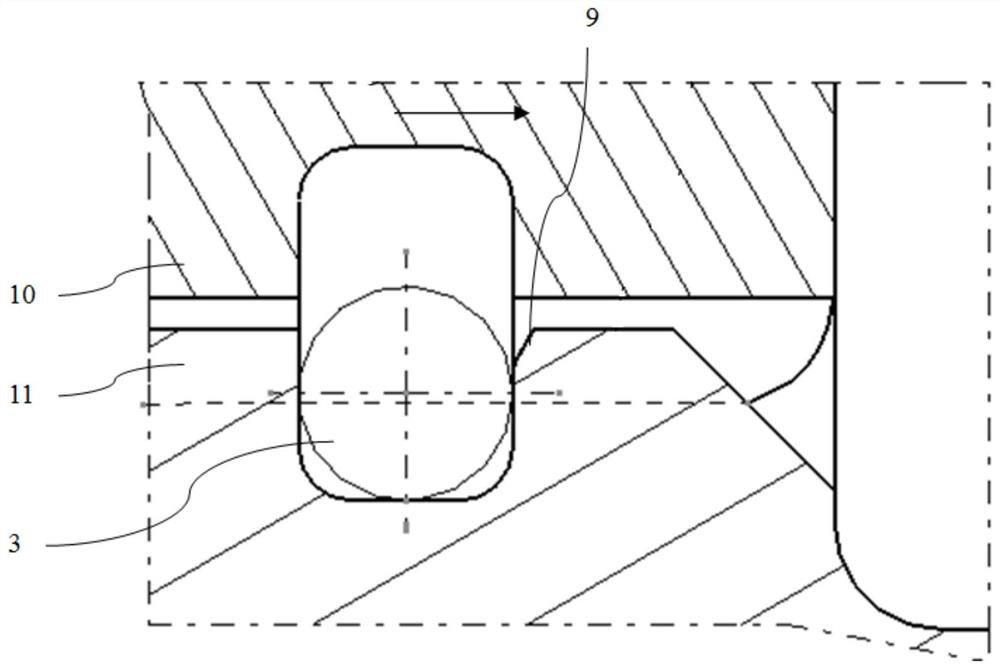

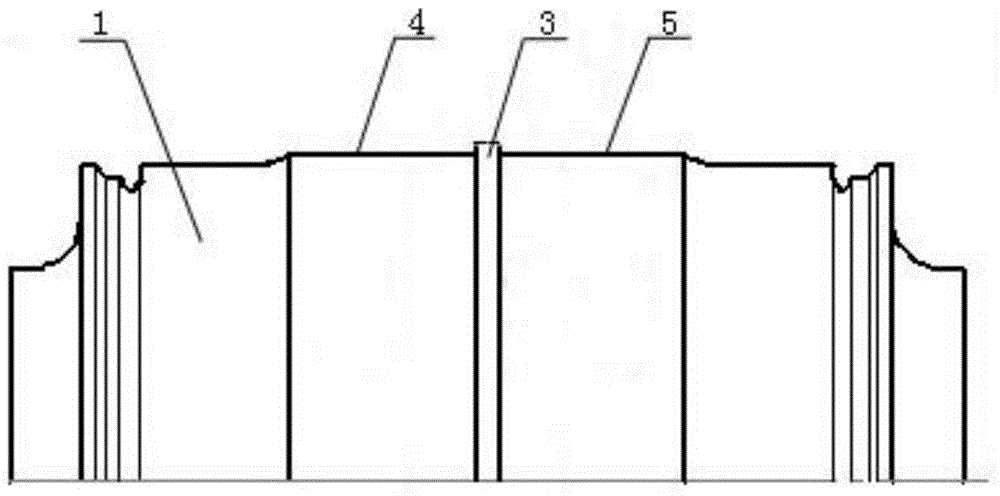

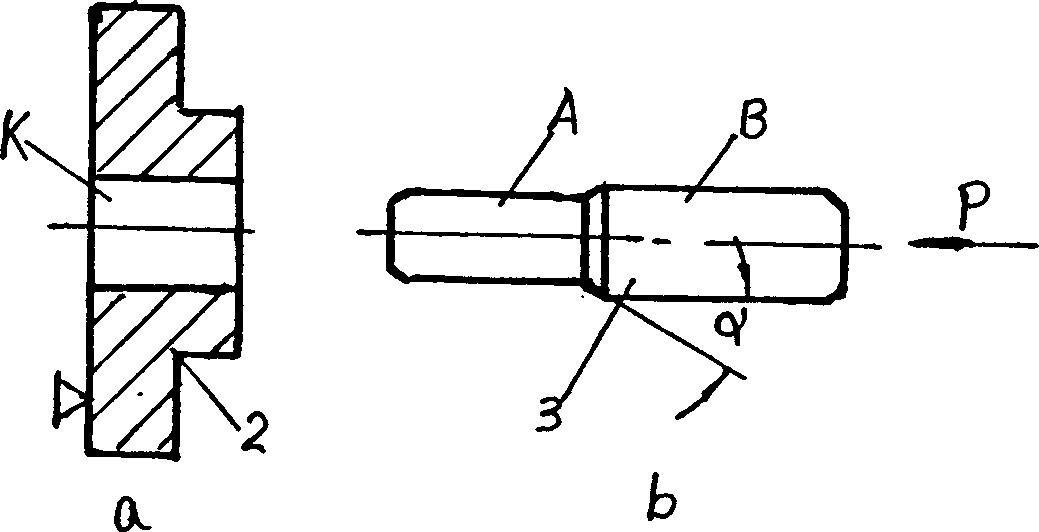

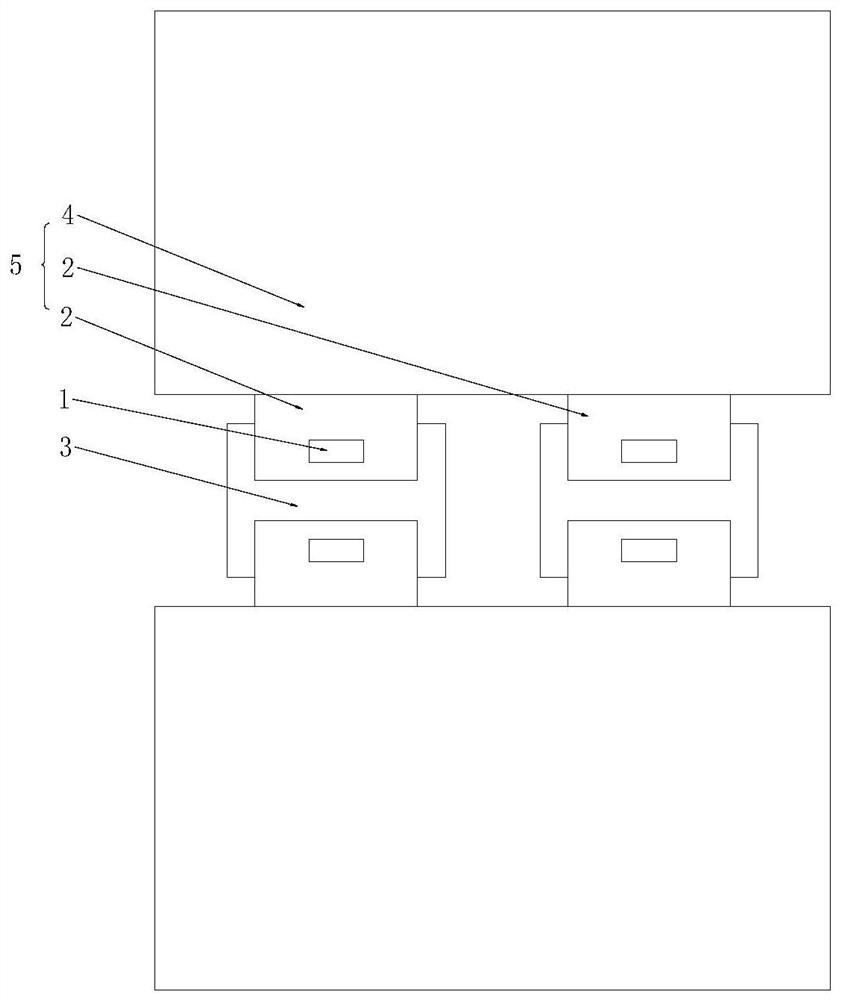

Rolling bearing unit with combination seal ring

InactiveCN105358851AExtend your lifeSuppresses low sliding torqueEngine sealsRolling contact bearingsForeign matterInterior space

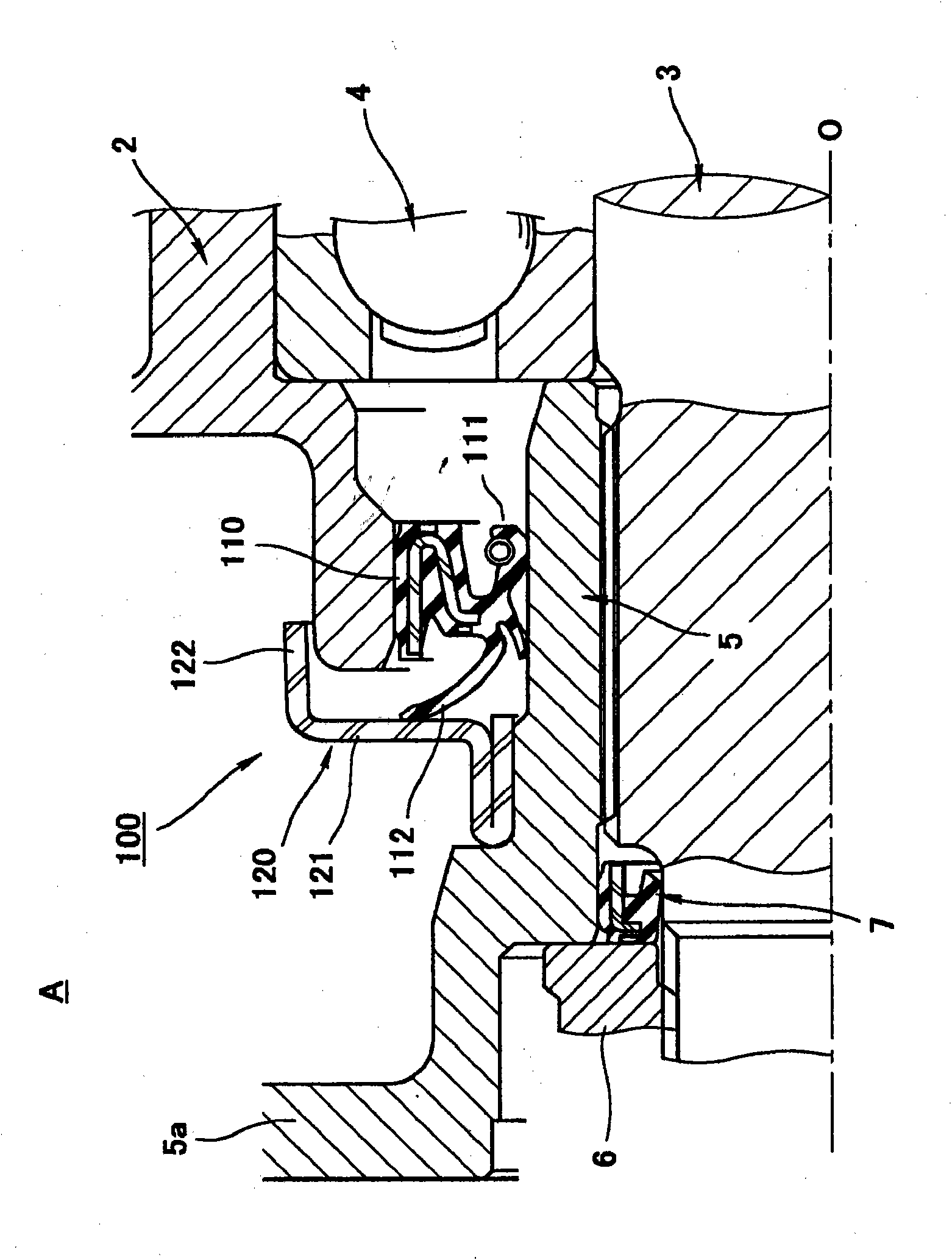

In order to implement a structure capable of ensuring the movement of a seal lip (22a) provided in a seal ring (17a) by preventing the entry of foreign matter into a seal interior space (26a) between a slinger (16) and the seal ring (17a) which constitute a combination seal ring (12a), a labyrinth seal (27a) is provided between the outer peripheral edge of a rotation-side circular ring section (19) constituting the slinger (16) and the inner peripheral surface of a stationary side cylindrical section (23) of a cored bar (20) constituting the seal ring (17a). Further, in a portion which is a part of an elastic material (21a) constituting the seal ring (17a) and is located between the labyrinth seal (27a) and the seal lip (22a) being a side lip, an auxiliary seal lip (32) having lower rigidity than the seal lip (22a) is provided. The total axial length of the auxiliary seal lip (32) in a free state is set to 5.5 to 7.5 times the thickness thereof, and the proportion of an interference is set to the range of 0-20% of the total axial length in a free state.

Owner:NSK LTD

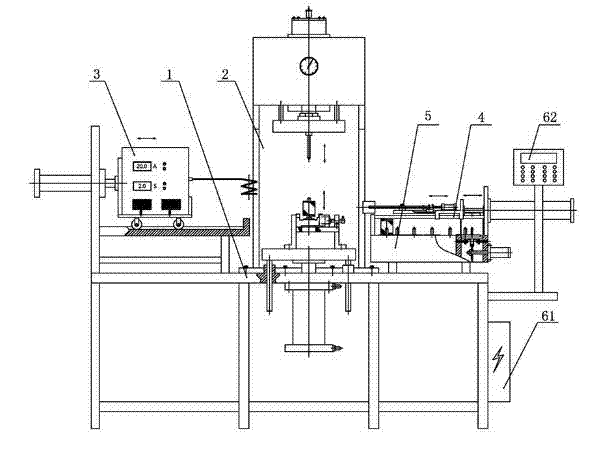

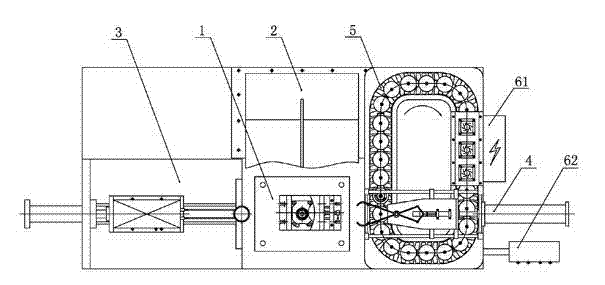

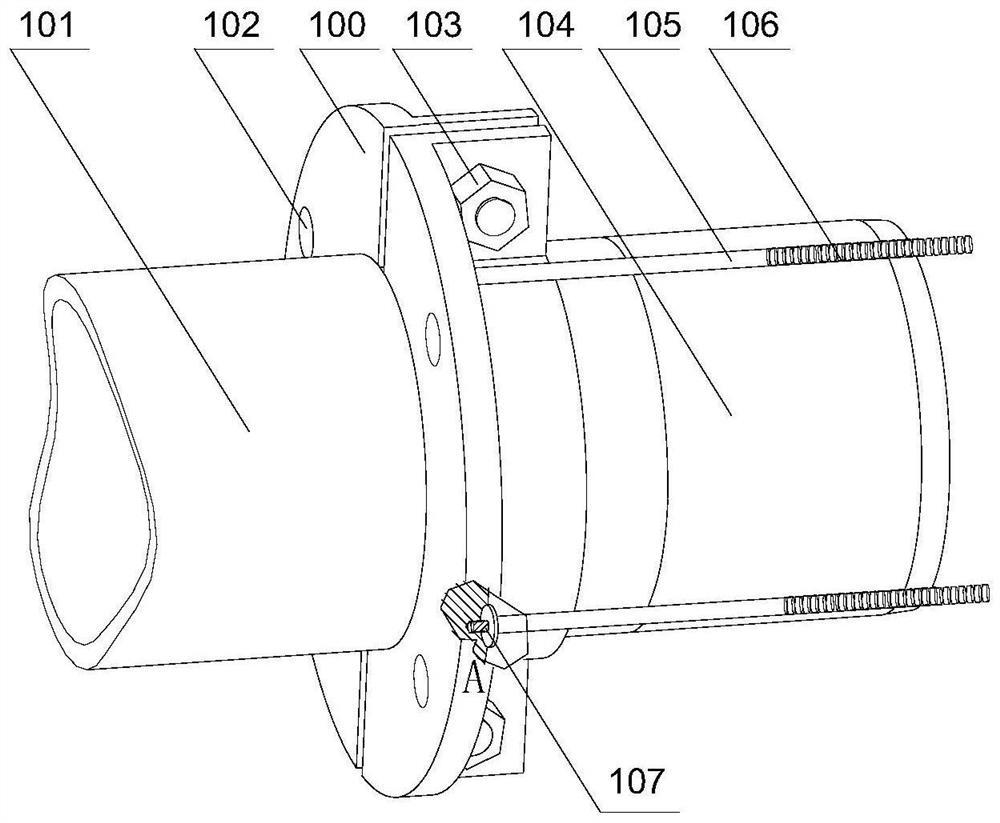

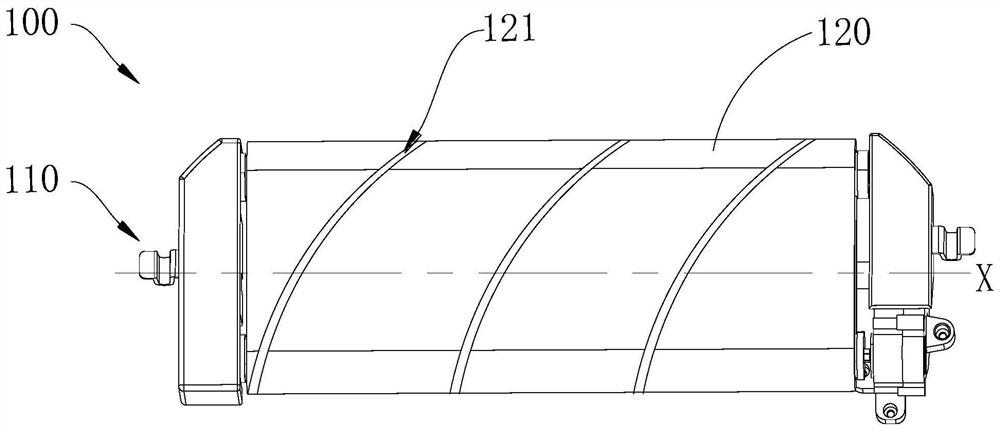

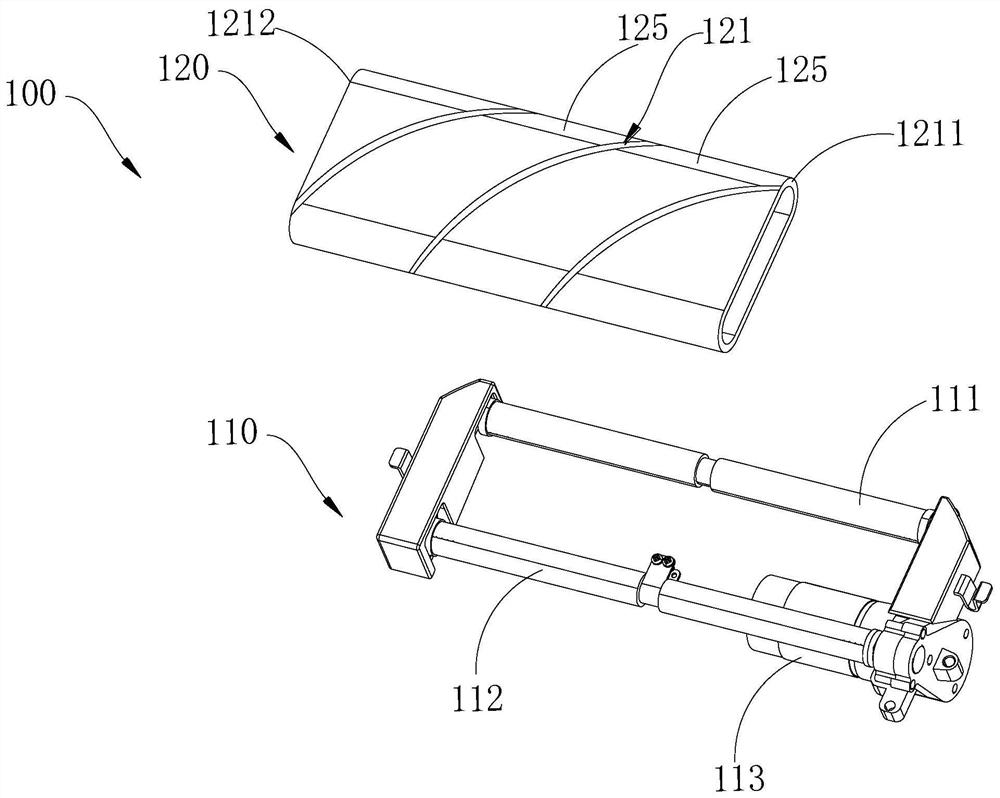

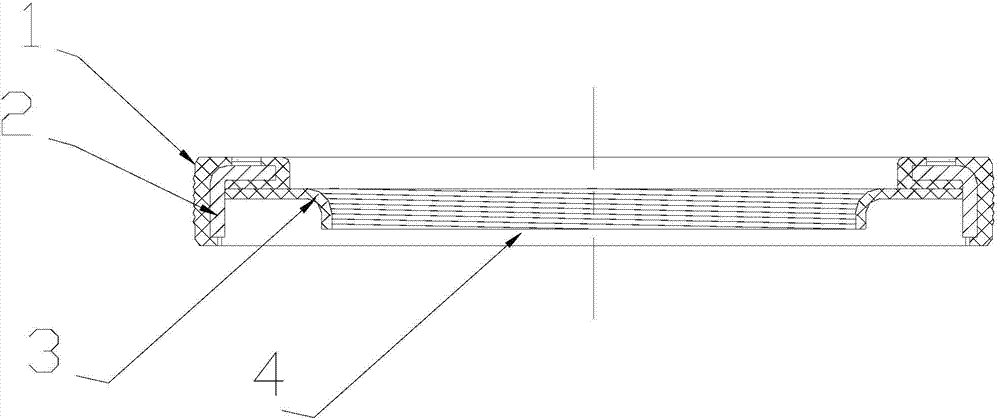

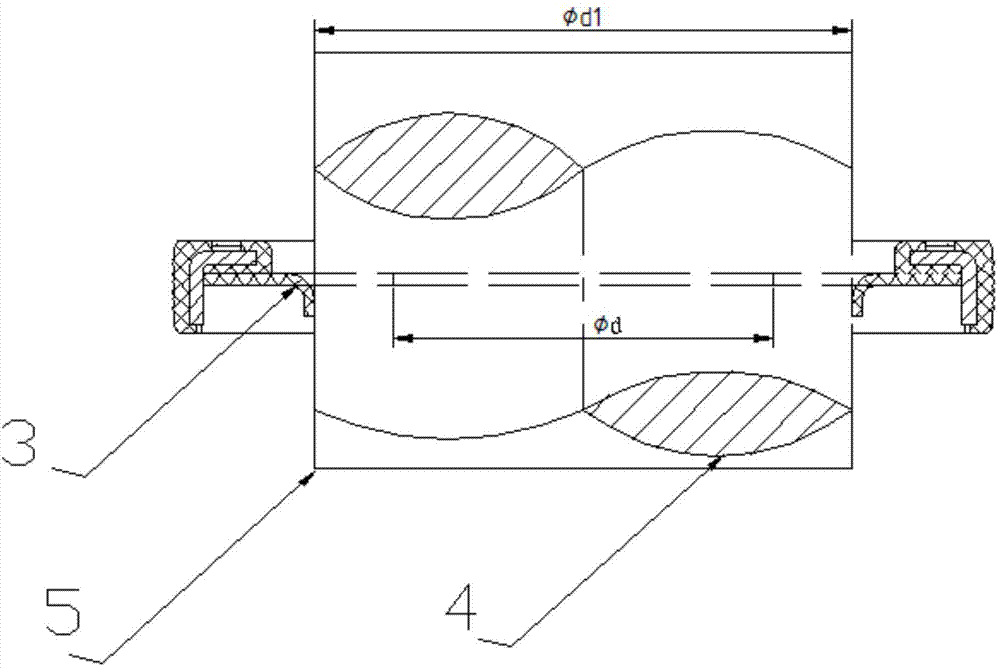

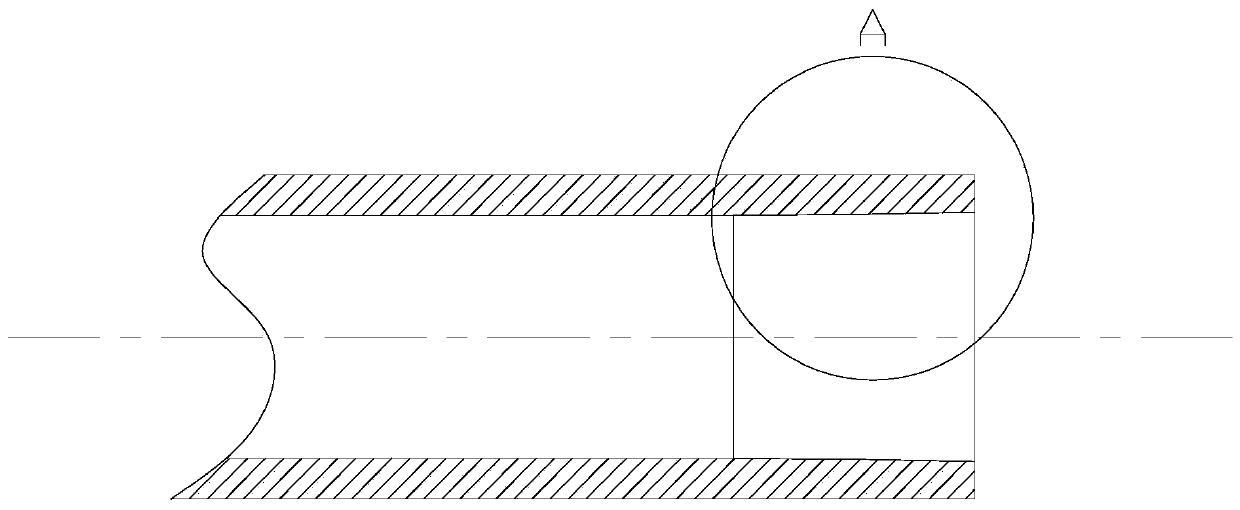

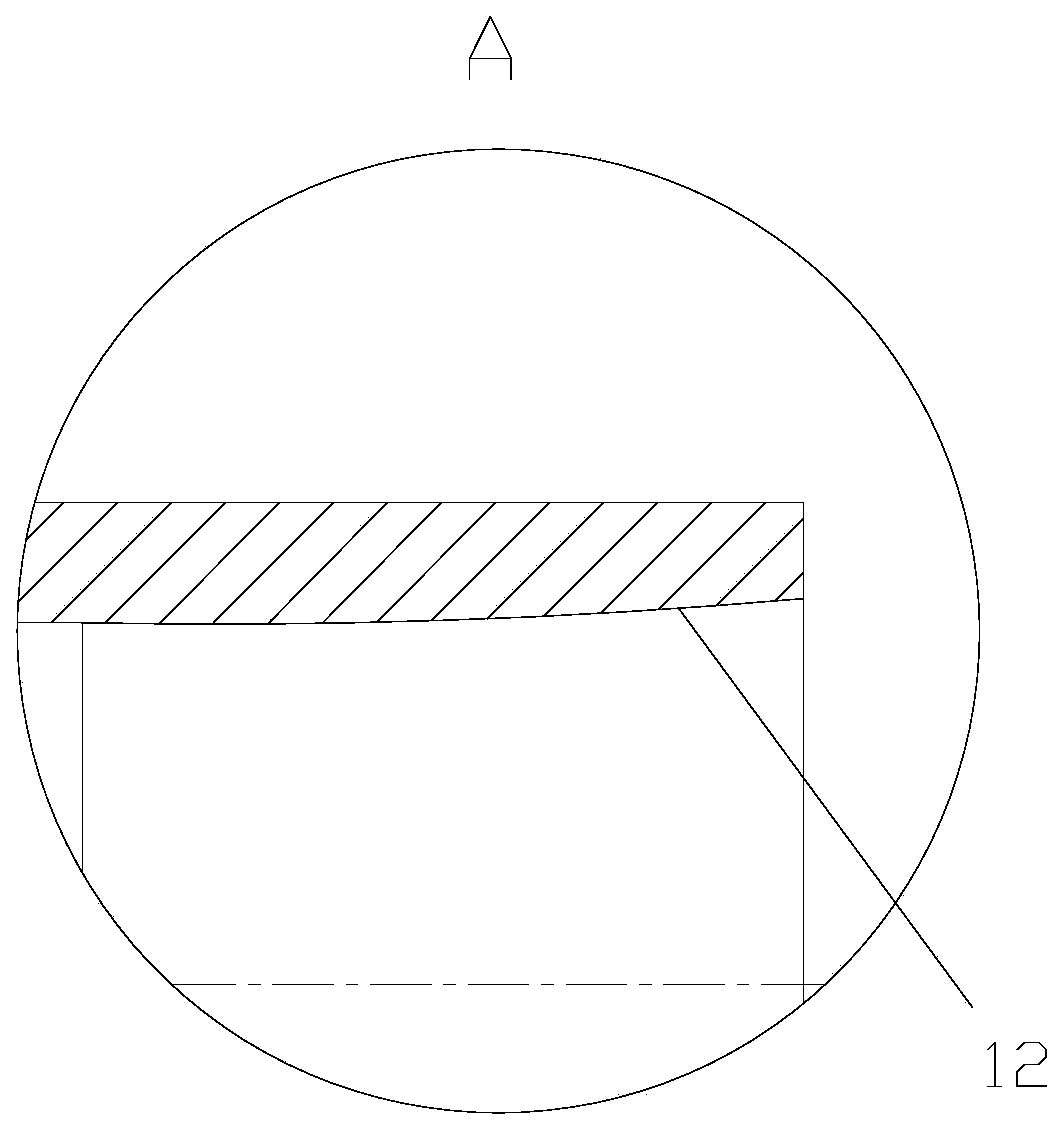

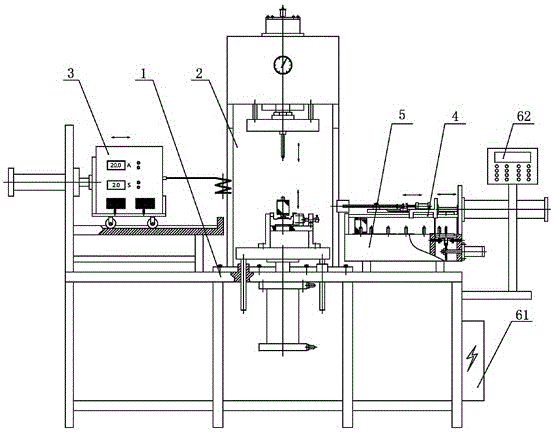

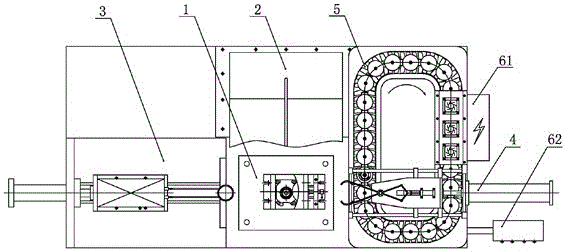

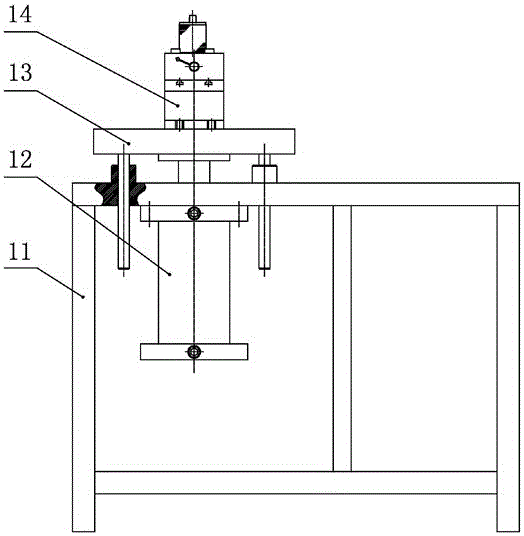

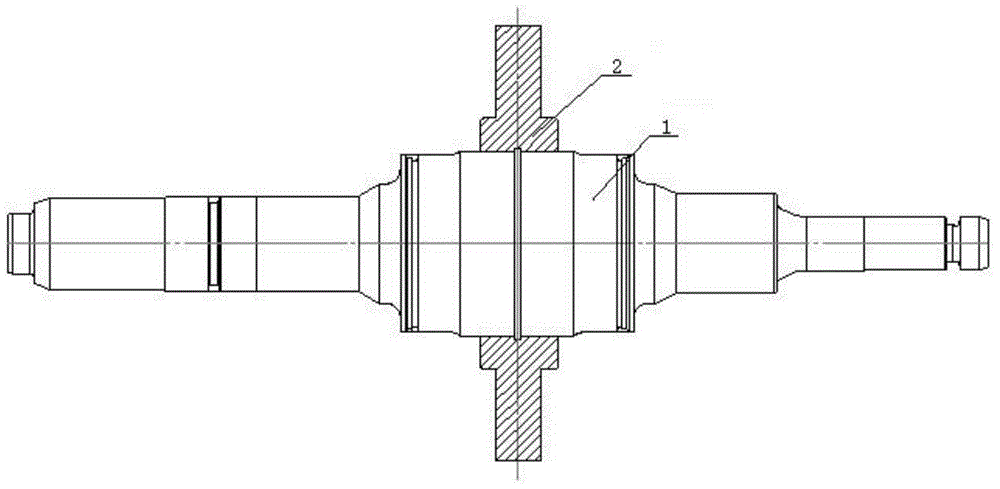

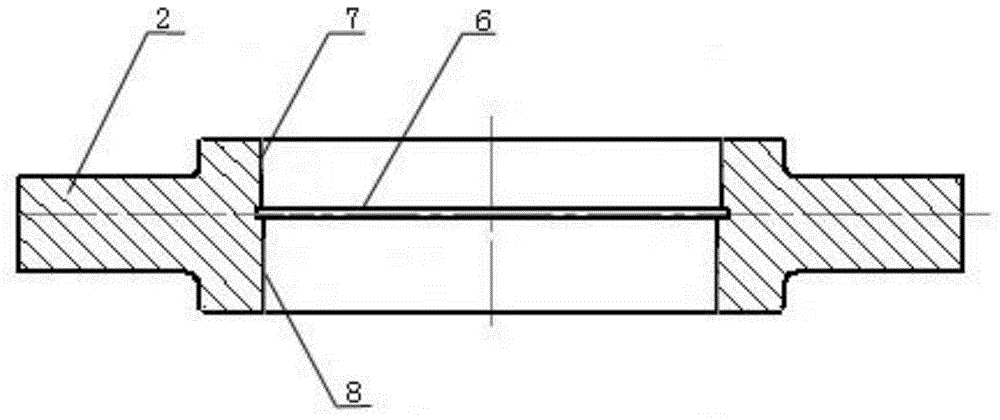

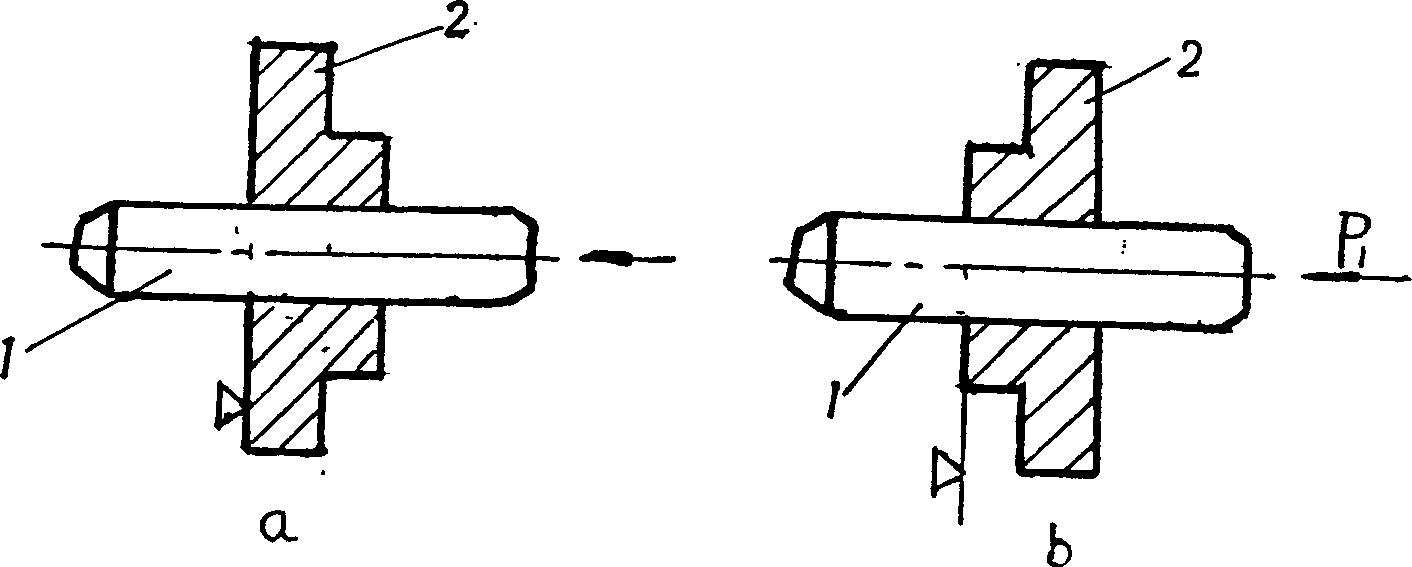

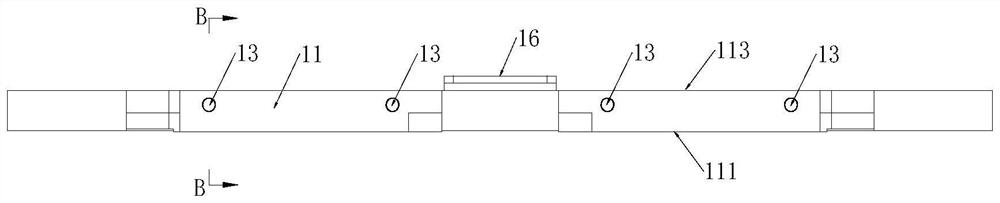

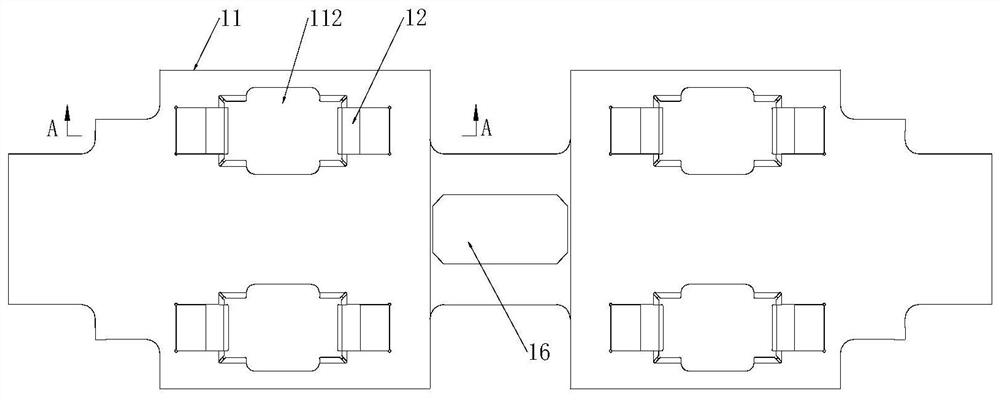

Damage-free compressor rotor heat jacket assembly disassembling device

ActiveCN103203585AReduce the amount of interferenceReduce ejection forceMetal working apparatusEngineeringReusability

The invention discloses a damage-free compressor rotor heat jacket assembly disassembling device. The damage-free compressor rotor heat jacket assembly disassembling device is provided with a jacking mechanism which is capable of lifting vertically, a clamp jig capable of clamping a workpiece is arranged at the top of the jacking mechanism, a high frequency heating device used for heating the workpiece and capable of moving leftwards and rightwards is mounted on the upper left portion of the jacking mechanism, a hydraulic ejection mechanism capable of ejecting out a crankshaft is mounted above the jacking mechanism and the high-frequency heating device, a pressure center of the hydraulic ejection mechanism is coincided with the center of the jacking mechanism, a rotor shifting mechanism capable of clamping a rotor to move leftwards and rightwards is mounted on the upper right portion of the jacking mechanism and below the hydraulic ejection mechanism, a rotor cooling mechanism capable of cooling a rotor shifted from the rotor shifting mechanism is mounted below the rotor shifting mechanism, and the jacking mechanism, the high-frequency heating device, the hydraulic ejection mechanism, the rotor shifting mechanism and the rotor cooling mechanism are connected with a controlling mechanism. The damage-free compressor rotor heat jacket assembly disassembling device has the advantages of simplicity in operation, high disassembling efficiency, small damage to disassembled parts, and good reusability.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

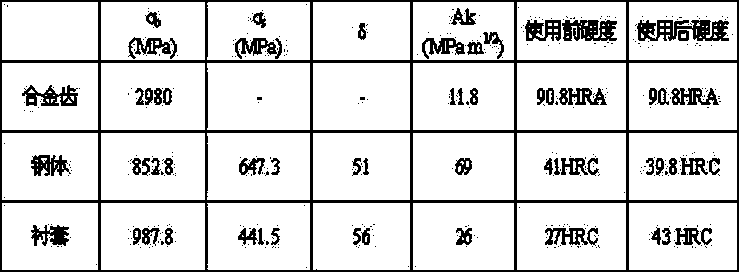

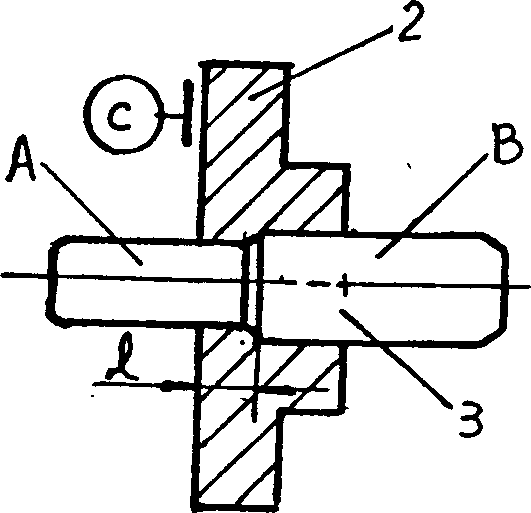

Process for inlaying alloy teeth of rock drilling bit

ActiveCN103850652AReduces the chance of broken (broken) teethLarge joint surfaceDrill bitsInterference fitAlloy

The invention discloses a process for inlaying alloy teeth of a rock drilling bit. The process comprises the steps of 1, selecting a good-quality high manganese round steel and processing the good-quality high manganese round steel into a liner bushing; 2, carrying out vacuum water quenching, tempering and heat preservation on the processed liner bushing, and then carrying out air-cooling treatment; 3, carrying out finish machining on an inner hole of the linear bushing; 4, performing thermal treatment on the linear bushing machined with the inner hole, and pressing the alloy teeth into the linear bushing under appropriate conditions; 5, performing high-speed shot blasting treatment on the teeth-inlaid linear bushing; 6, accurately grinding the outer circular surface of the teeth-inlaid linear bushing; 7, enabling the teeth-inlaid linear bushing to be in interference fit with teeth holes. The process for inlaying the alloy teeth of the rock drilling bit has the advantages that the liner bushing is arranged to sleeve the alloy teeth, so that the holding force is enhanced by enlarging the effective combination surface by increasing the length, and the magnitude of interference can be reduced appropriately without increasing the alloy cost, and therefore, the teeth can be fixed firmly, and also the drilling bit body and the alloy teeth can be protected against damage; meanwhile, under the protection action of the liner bushing, because the stress is basically eliminated in the process of inlaying the teeth in the linear bushing, the phenomena of alloy tooth breakage and steel body collapse are reduced remarkably, and the service life of the drill bit is prolonged.

Owner:ZHUZHOU SUNSHINE CEMENTED CARBIDE TOOLS

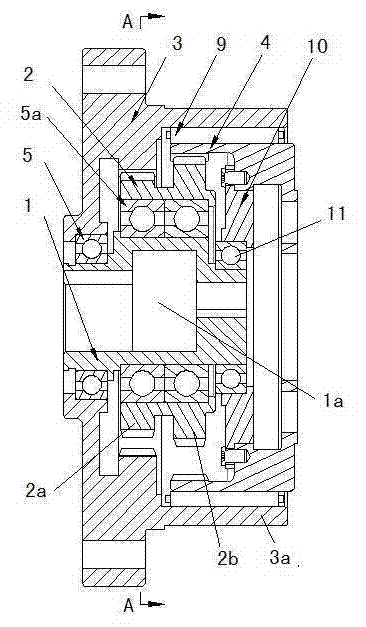

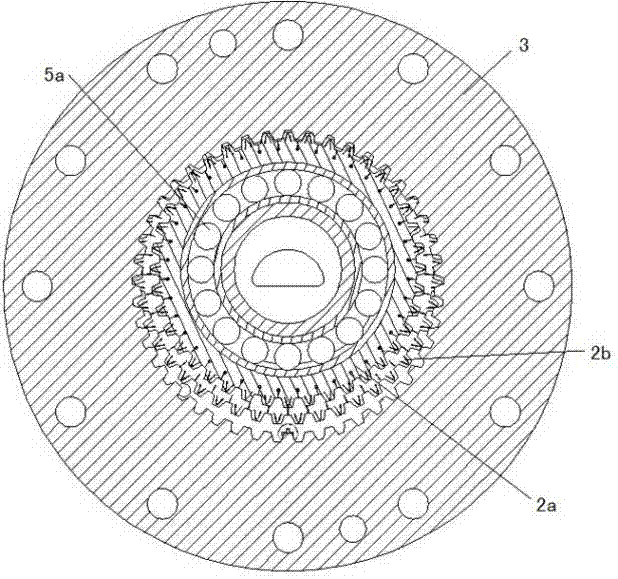

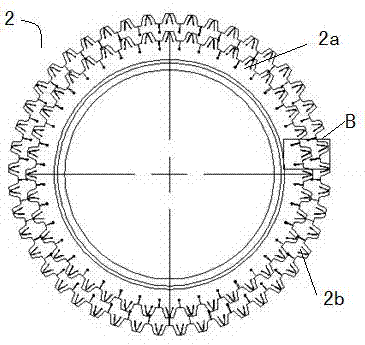

Filtering reducer with high reliability and precision

The invention discloses a filtering reducer with high reliability and precision, which comprises an eccentric power input shaft, a duplicate gear, an internal fixing gear and an internal power output gear, wherein an eccentric section is arranged on the eccentric power input shaft; the duplicate gear comprises an external gear I and an external gear II, and rotationally matched with and mounted on the eccentric section in a sleeving manner; the internal fixing gear and the external gear I form a small tooth difference engagement pair I; the internal power output gear and the external gear II form a small tooth difference engagement pair II; and elastic grooving filtering structures are arranged in the small tooth difference engagement pair I and the small tooth difference engagement pair II, and comprise gear tooth grooves formed in gear teeth of the gears. Each gear tooth groove comprises two curved gear tooth grooves and a straight gear tooth groove, wherein the curved gear tooth grooves and tooth outlines of gear teeth form equidistant curves respectively; and each straight gear tooth groove is formed between a tooth crest of each gear tooth and a joint of every two curved gear tooth grooves; and / or, the elastic grooving filtering structures comprise gear grooves formed in tooth grooves of the gears; the gear grooves comprise straight gear grooves formed in the tooth grooves symmetrically; and the gear tooth grooves and the gear grooves are filled with elastomer.

Owner:SICHUAN UNIV

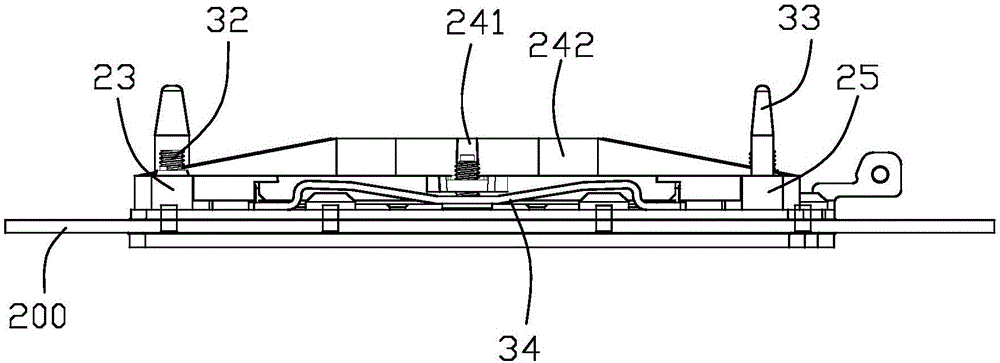

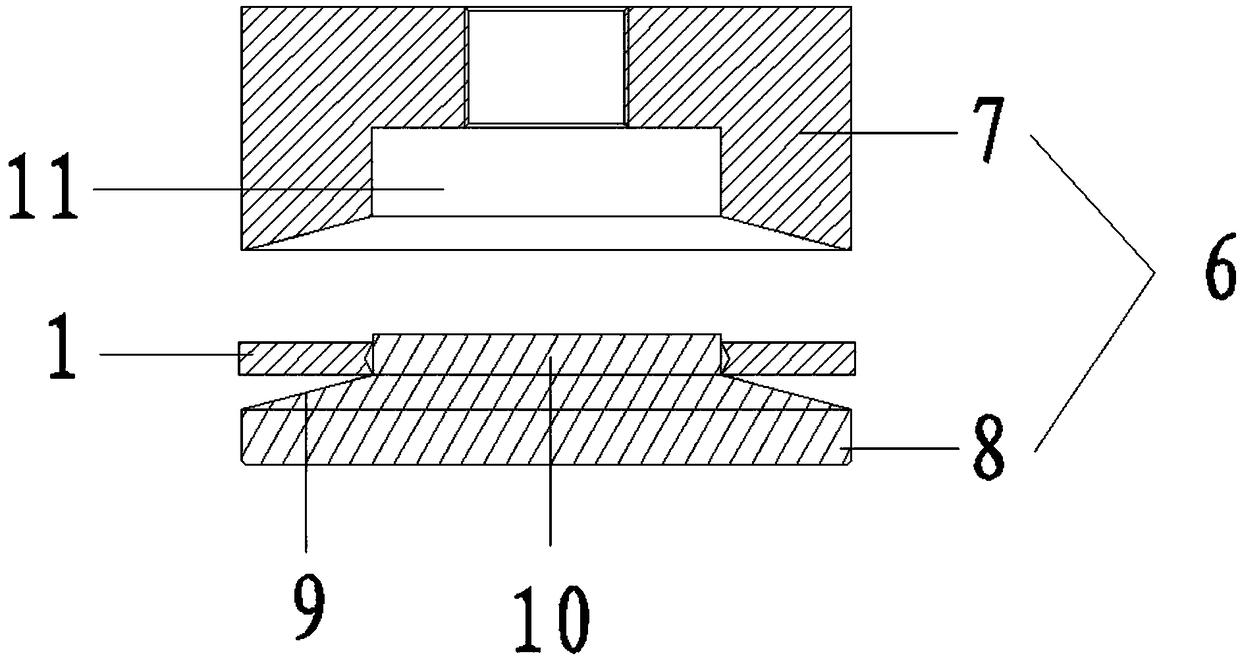

Electric connector component

ActiveCN106848717AReduce the amount of interferenceReduce friction lossCouplings bases/casesElectricityEngineering

An electric connector component comprises an electric connector, a protective cover and a fixing seat. The electric connector comprises an insulating body and a plurality of conducting terminals fixed to the insulating body, the insulating body is provided with a chip containing cavity, the conducting terminals stretch into the chip containing cavity, the protective cover comprises a flat plate, a first fastener and an operation portion, the flat plate covers the upper portions of the conducting terminals, the first fastener is connected with the flat plate, the operation portion stretches upwards from the flat plate, the fixing seat is provided with a second fastener which is positioned beside the insulating body and matched with the first fastener in a fastened manner, and the first fastener and the second fastener are mutually fastened vertically when the protective cover is mounted on the fixing seat. When the protective cover is disassembled, the operation portion is horizontally twisted to drive the first fastener to keep away from the second fastener, so that the protective cover is conveniently taken out of the fixing seat.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Electric-melted pipeline press-fitting process, press-fitting tool and press-fitting tool manufacturing process

PendingCN113635258ADifficult and easy to affectSize Difficulty AffectedMetal-working hand toolsPipe fittingPipe

An electric-melted pipeline press-fitting process comprises the following steps of performing oxide layer removing and polishing operation on the surface of an electric-melted pipeline inserting part, polishing an extremely thin surface layer, and keeping the cylindricity precision of the polished part basically unchanged; selecting a pressing disc, an electric-melted direct pipe fitting, an elbow pressing frame and a tee pressing frame pressing tool which are matched with the pipeline and the pipe fitting which are to be assembled, and mounting the pipeline and the pipe fitting on the pressing tool; and synchronously rotating a nut, and driving the pipeline and the pipe fitting to move oppositely in a relative spiral rotation mode to finish spiral press-fitting assembly of the pipeline and the pipe fitting. And then electrifying and welding are conducted. The invention further relates to a press-fitting tool and a manufacturing method of the press-fitting tool; after the press-fitting tool is used, the welding quality can be guaranteed through the assembly interference magnitude of the electric-melted pipeline and the pipe fitting, the welding quality cannot be affected by the small interference magnitude, and the threshold value of the interference magnitude is much larger than that of the prior art; and the press-fitting tool has the advantages that the whole device is simple, the operation is convenient, the process is suitable for space-limited and high-altitude environment operation, and the application range is wide.

Owner:江西铜业集团(贵溪)防腐工程有限公司

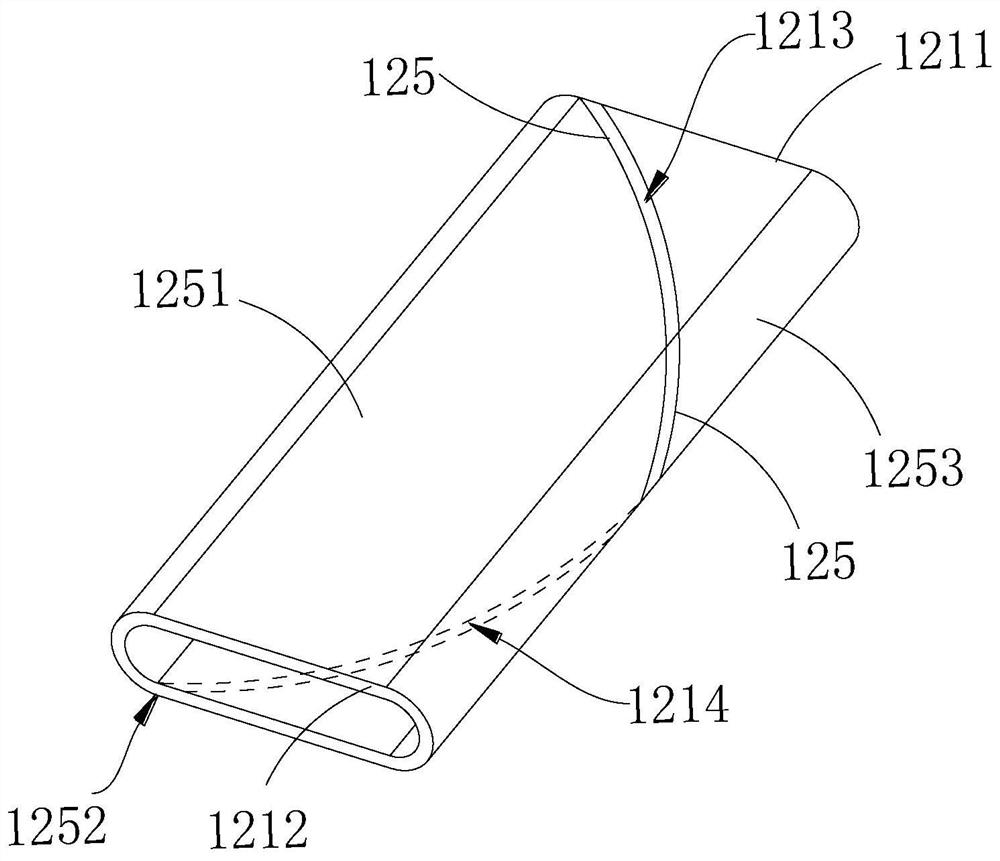

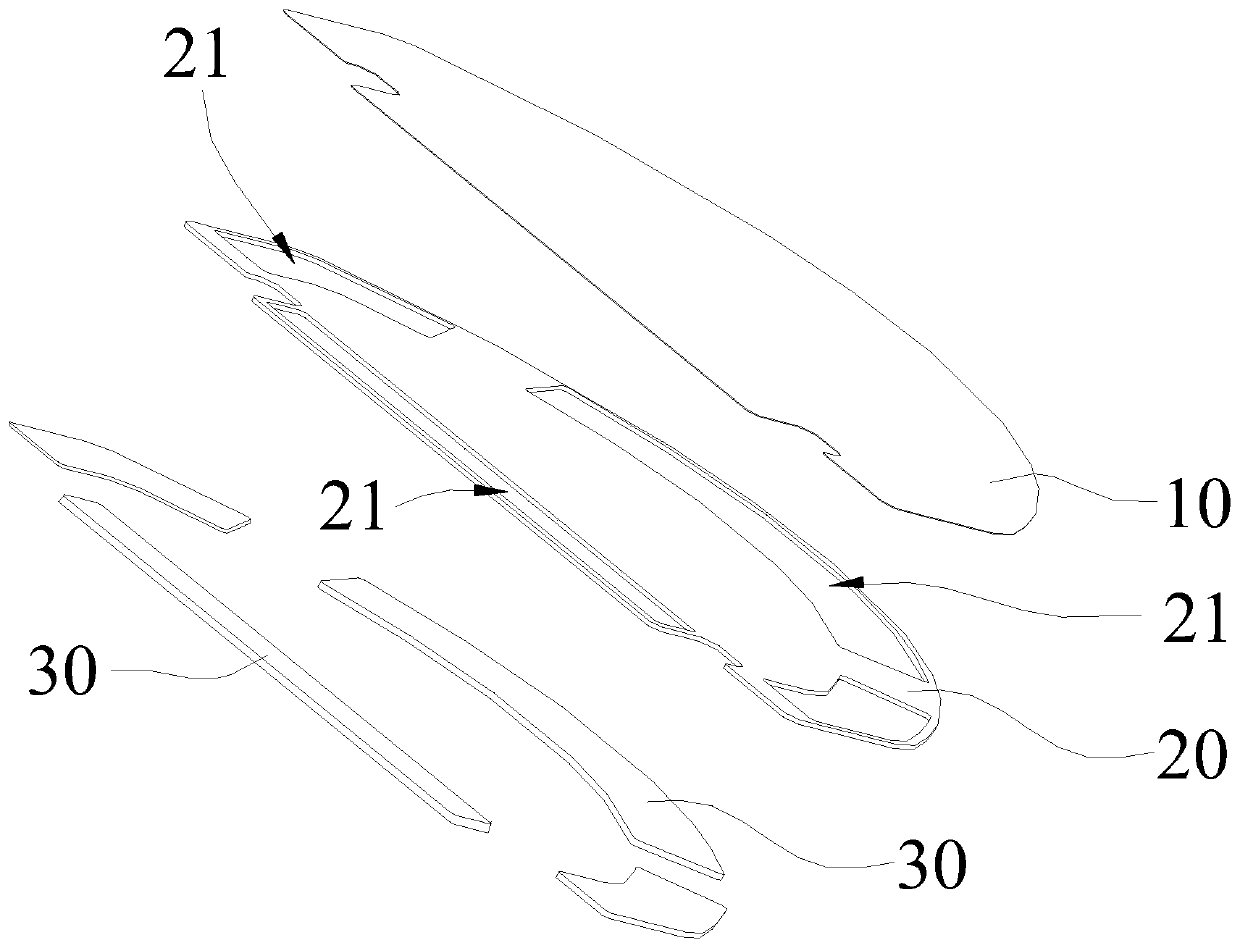

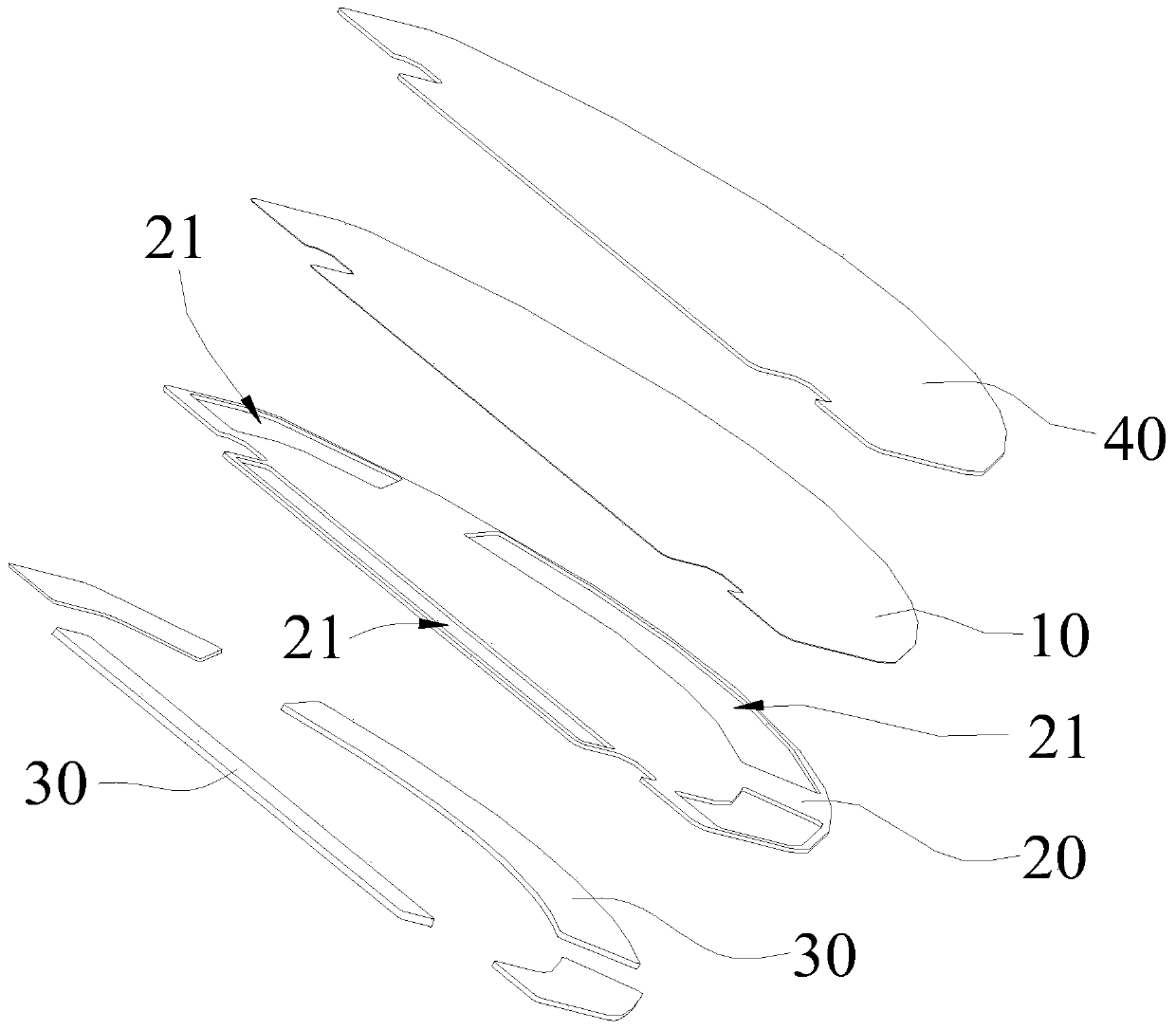

Mop, mop mechanism, intelligent cleaning device and handheld cleaning device

PendingCN113455971ASmooth rotationReduce the amount of interferenceCarpet cleanersFloor cleanersHand heldEngineering

The invention provides a mop, a mop mechanism, an intelligent cleaning device and a handheld cleaning device. The mop is suitable for the mop mechanism, the mop mechanism is provided with a rotating axis, the mop is provided with two or more mop parts, a gap is formed between every two adjacent mop parts, and the gaps are suitable for being arranged around the periphery of the mop; and at least part of the gap is spirally arranged. At least part of the gap of the mop is spirally arranged, so that when a scraping strip conducts dirt scraping operation on the mop, the whole scraping strip cannot be in contact with the edge, located in the gap, of the mop at the same time, a small part of the scraping strip makes contact with the edge, located in the gap, of the mop at the same time, and the contact area between the whole scraping strip and the edge, located in the gap, of the mop at the same time is reduced; the interference amount between the scraping strip and the mop is reduced, so that the whole mop is more stable in the rotating process.

Owner:SHENZHEN ZBEETLE INTELLIGENCE CO LTD

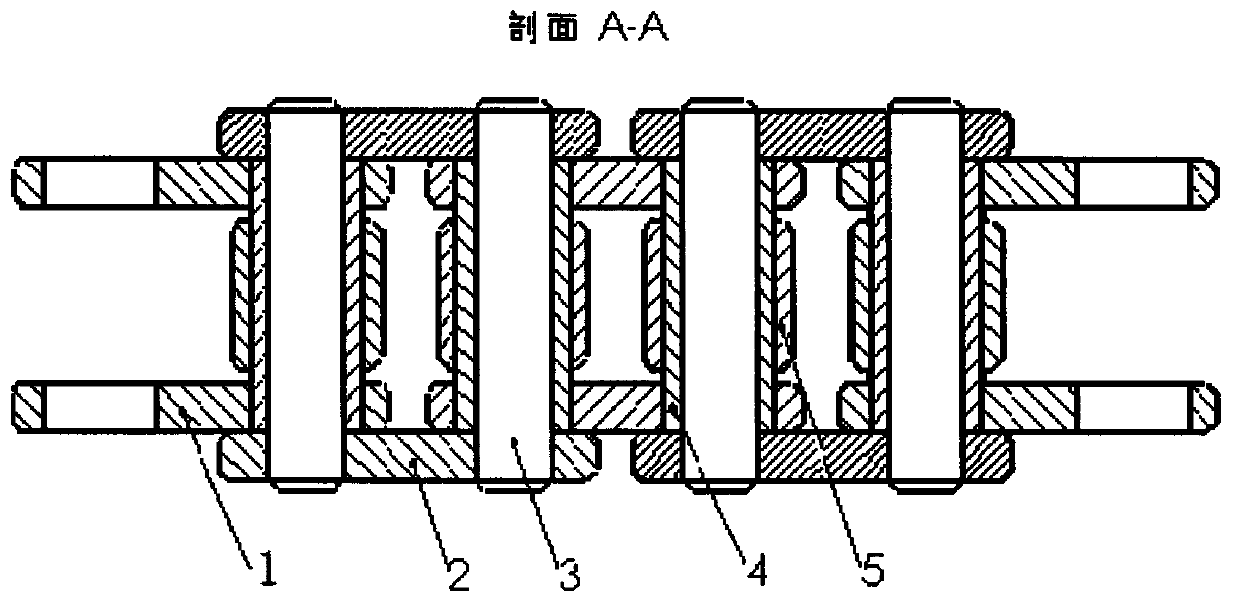

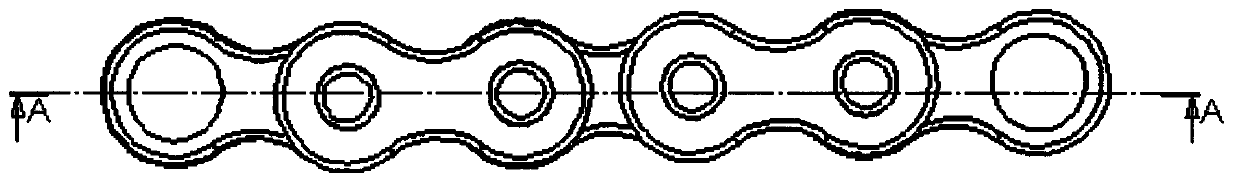

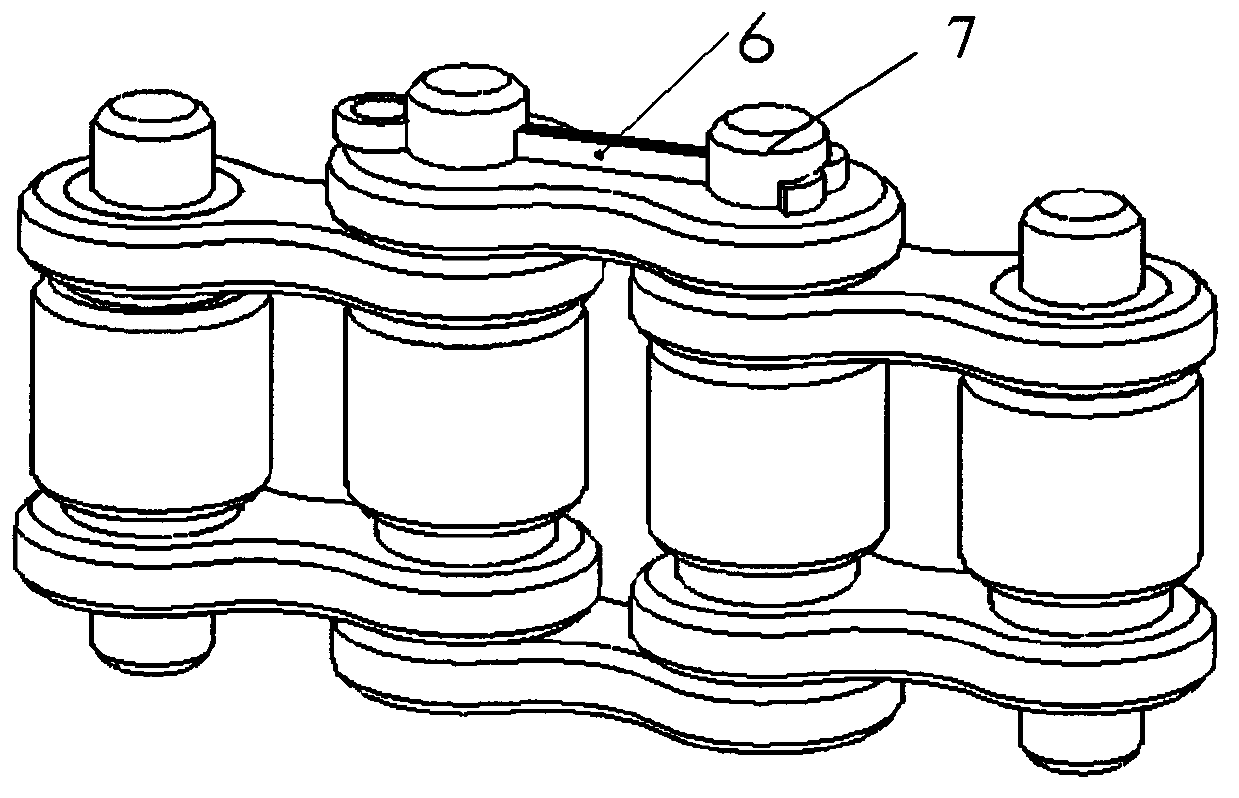

Bush roller chain model convenient to demount, mount and close

InactiveCN104235266AReduce the amount of interferenceReduce weightChain linksDriving chainsEngineeringRoller chain

The invention belongs to a chain, discloses a bush roller chain model convenient to demount, mount and close and aims at solving the technical problem of manually demounting and mounting a bush roller chain and closing to form an annular chain and helping to know internal structure and assembling method of the bush roller chain. The bush roller chain model is composed of pin shafts, bushes, rollers, inner chain plates, outer chain plates, grooved transition chain links, holed transition chain links, transition chain plates, spring clamps and cotters. The bush roller chain model is characterized in that one pin shaft is mounted in each of two holes of each outer chain plate, one bush with the inner chain plates mounted at two ends sleeves each pin shaft in a hollow manner, one roller sleeves each bush in a hollow manner, one outer chain plate is mounted at the other end of each pin shaft, one chain link is assembled, and a chain can be formed by repeating the above action; two ends of the chain are connected by using the transition chain link or the transition chain plate and can be closed to form the annular chain. Each of the above parts is in size of a standard member of a large-pitch bush roller chain, the bush roller chain is completely made by plastic, thereby being light in weight, large in size and convenient to demount, mount and close.

Owner:NANJING COLLEGE OF CHEM TECH

Anti-interference gear and rolling cutter thereof used for machining

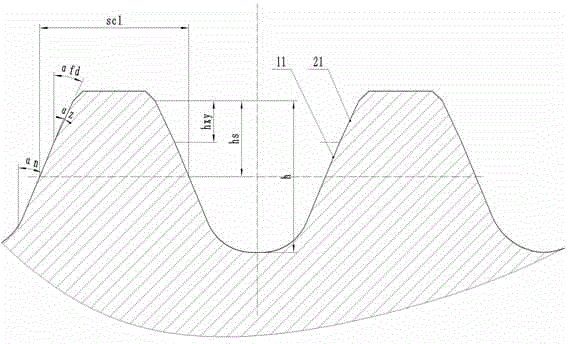

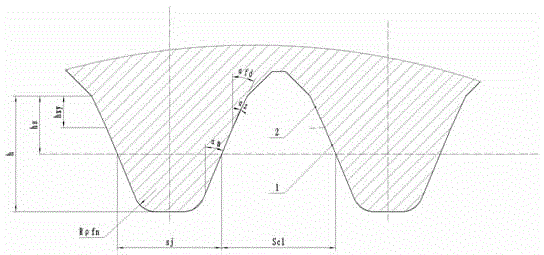

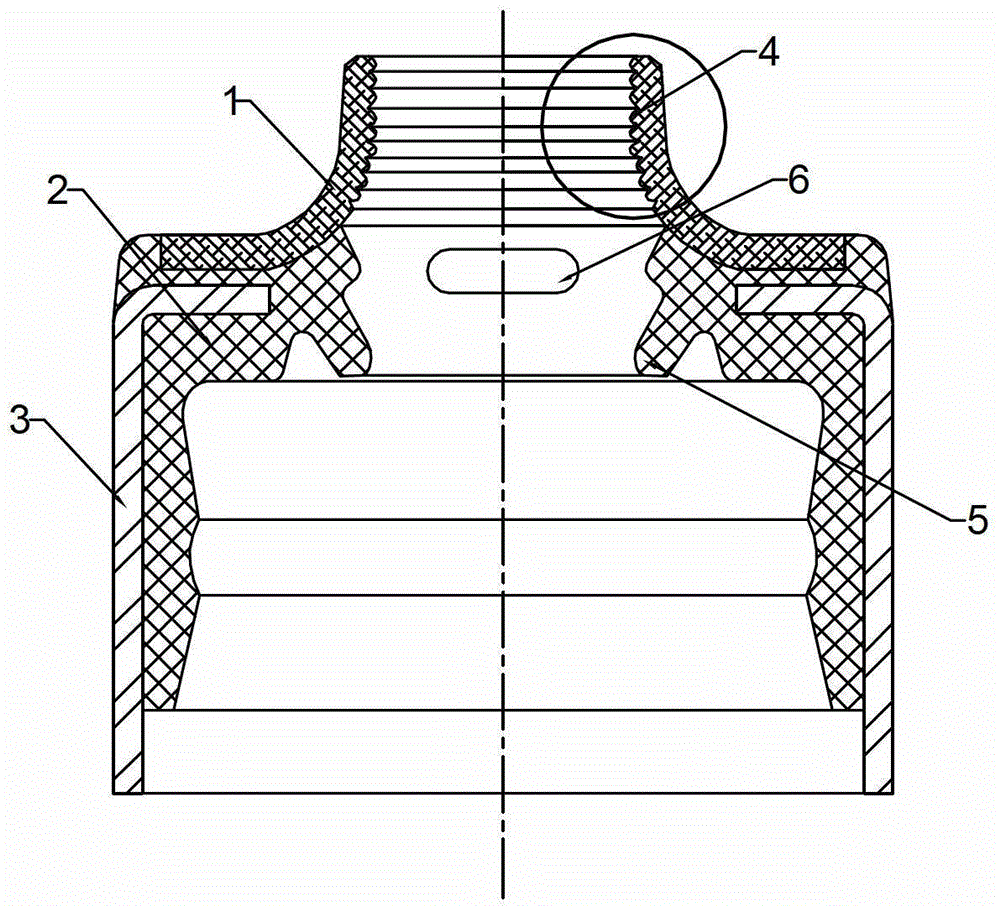

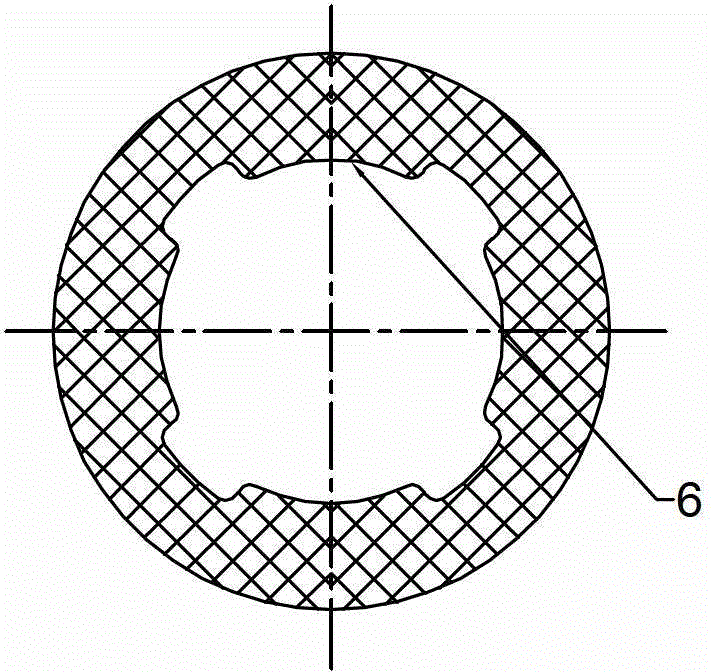

InactiveCN105626819ASimple structureReduce the amount of interferencePortable liftingGear teeth manufacturing toolsString lengthEngineering

The invention discloses an anti-interference gear and a rolling cutter thereof used for machining capable of reducing interference amount of gear engagement. The tooth shape comprises following parameters: h-whole depth of tooth, h-xy: tip relief; hs-tooth addendum; sc1- arc tooth thickness; sj-string length; an-a pressure angle; afd-a tip relief angle; az-an increasing angle; and Rpfn-circular angles. An included angle, az, is formed by a first tooth surface and a second tooth surface. An included angle, afd, is formed by the second tooth surface and a vertical surface is a tip relief angle. The relations among the pressure angle am, the tip relief angle afd and the increasing angle az is afd equal to arctan(tan(an)+Delta / tan (0.4m) ); az is equal to afd-an. In the formula, m is the module of gears, delta is anti-interference amount of gears. The value range is 0.02 to 0.09. The anti-interference gear and the rolling cutter thereof used for machining have following beneficial effects: a simple structure is obtained; anti-interference amount of gear engagement is greatly decreased to facilitate using and improve service lifetime of gears.

Owner:QIJIANG DALISHEN GEAR

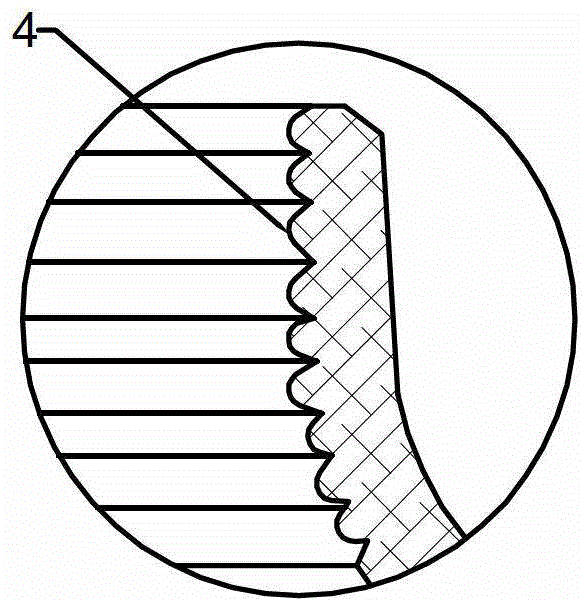

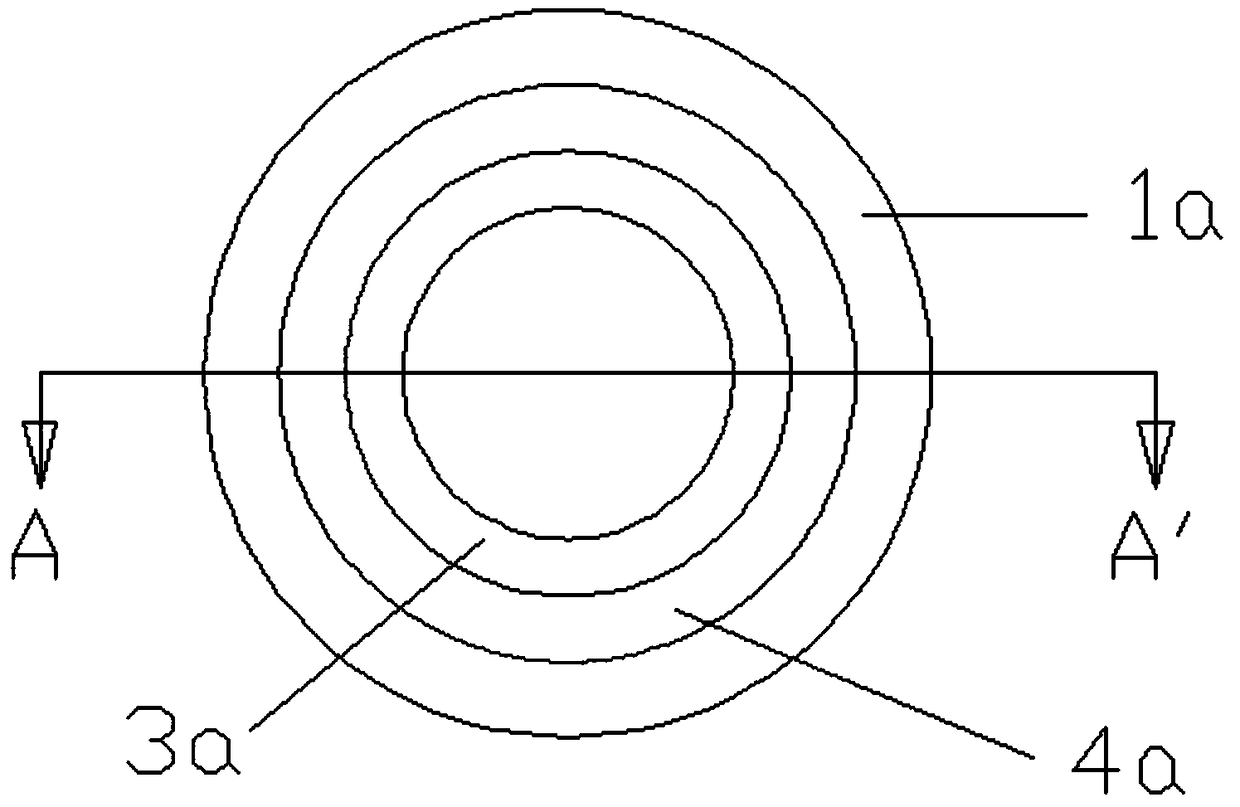

High wear-resistant valve pressurizing oil seal

InactiveCN102979591AReduce the amount of interferenceNot easy to wearMachines/enginesLift valveInterference fitVulcanization

The invention disclose a high wear-resistant valve pressurizing oil seal of an engine. The oil seal comprises a rubber body, a framework and a PTFE (polytetrafluoroethylene) patch, and is shaped by vulcanization bonding by three different materials. After shaping, a main lip port which is in interference fit with a valve rod is generated on the PTFE patch; the lip port of the PTFE patch is in a circular jagged shape; and a pressure-bearing air lip which is in interference fit with the valve rod is generated on the rubber body. Four convex plates which are annularly distributed are arranged on the rubber body 2; and the surface of the convex plate is in clearance fit with the valve rod. Because the PTFE patch has a circular jagged multi-lip port structure, the PTFE patch can be used under high-speed and high-pressure working condition for a long time and is difficult to wear; the pressure-bearing air lip is arranged at the lower part of the lip port of the PTFE patch, the oil leakage amount of the engine can be effectively prevented from entering a cylinder under a turbo charging condition, and the cylinder is prevented from carbon deposition; and four convex plates which are annularly distributed are arranged from the lip port of the PTFE patch to the middle part of the pressure-bearing air lip, when the valve rod works, the valve rod has auxiliary guiding and protection functions, and the service life is prolonged.

Owner:广东天诚密封件股份有限公司

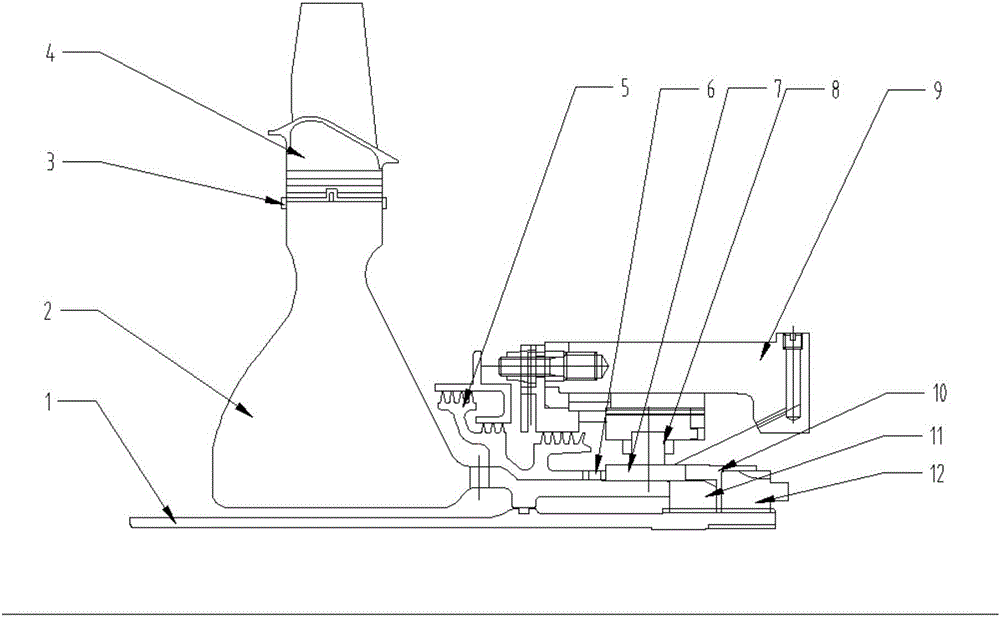

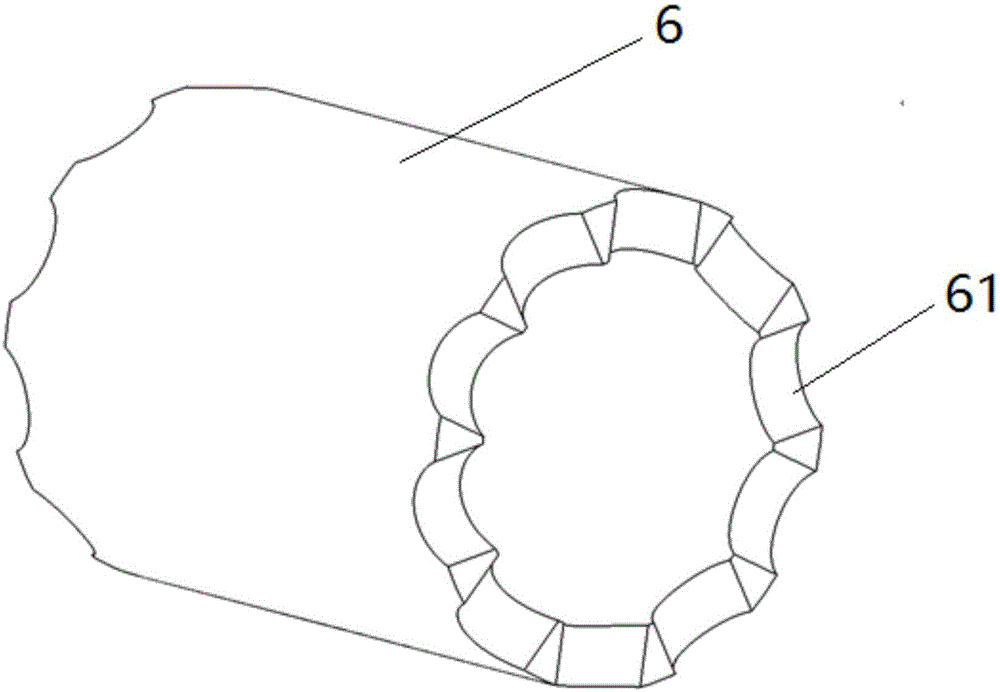

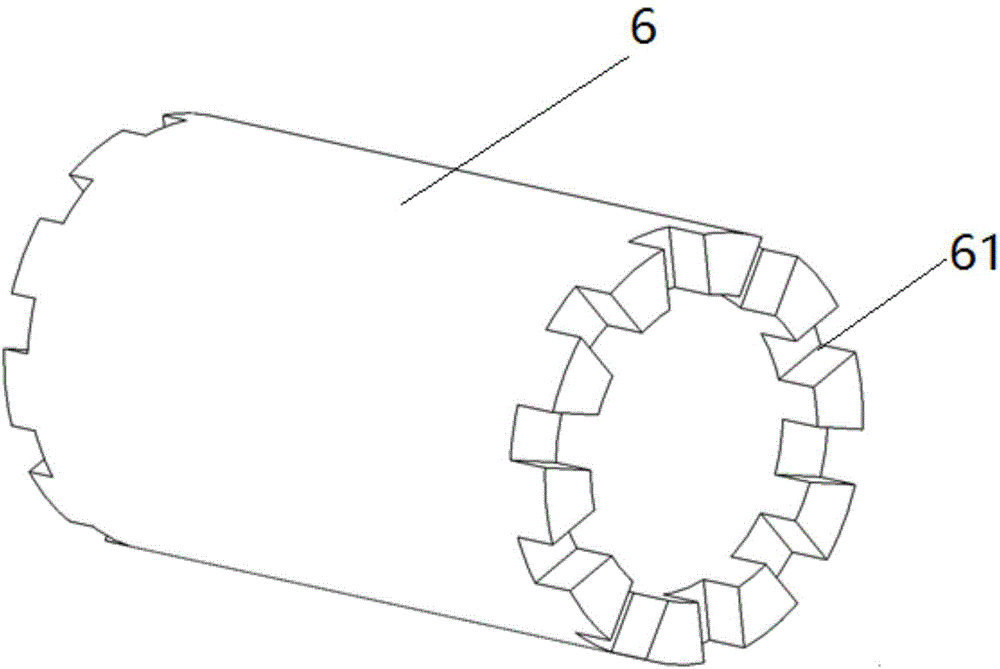

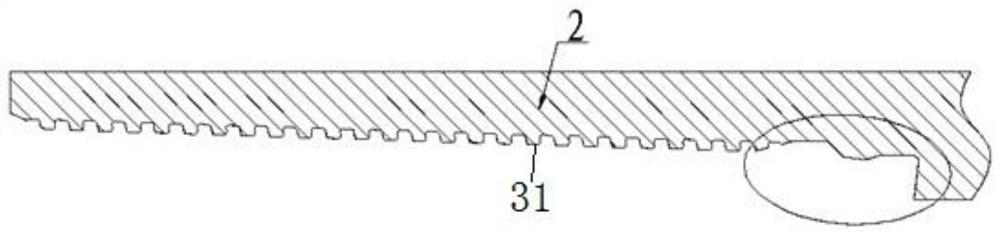

Adjustable pad structure used in high-temperature side bearing cavity of engine

ActiveCN106677904AReliable supplyLow thermal conductivityTurbine/propulsion lubricationDual effectEngineering

The invention relates to an adjustable pad structure used in a high-temperature side bearing cavity of an engine, and the adjustable pad structure can be widely applied to such fields as ground-based gas turbines, aero-engines and the like. A bearing, an adjustable pad and a sealing labyrinth ring which are arranged on a turbine shaft in a sleeving manner are arranged in the high-temperature side bearing cavity of the engine, one end surface of the adjustable pad is propped against the sealing labyrinth ring, the other end surface of the adjustable pad is propped against a bearing track inner ring, and a hot-end turbine rotating part is arranged on the inner side of the sealing labyrinth ring. The adjustable pad structure is characterized in that a plurality of toothed grooves are formed at least in the end surface, propped against the bearing track inner ring, of the adjustable pad. Compared with a traditional adjustable pad, the adjustable pad structure provided by the invention has the advantages of simple structure, low processing cost and complete function, can achieve dual effects of reducing heat conduction of high-temperature parts and providing lubricating oil required by cold start of the engine, can control the temperature of the bearing inner ring more effectively and meets the demand for supplying the lubricating oil required by cold start of the engine.

Owner:中科航星科技股份有限公司

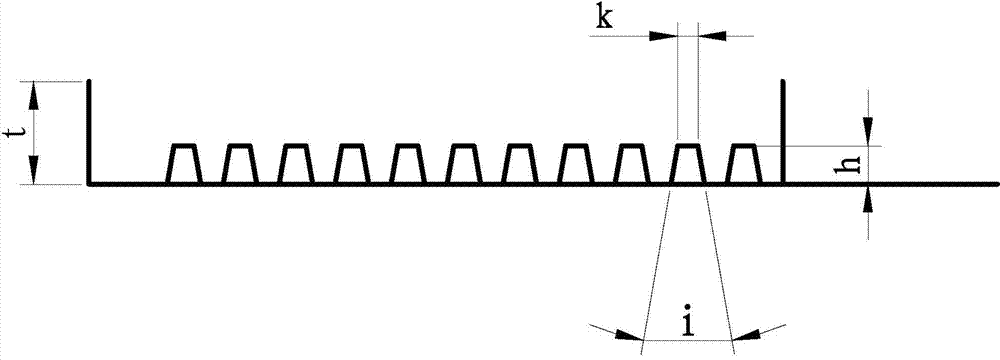

PTFE (polytetrafluoroethylene) oil seal of multi-group oil return lines

ActiveCN104847899AReduce thicknessReduce the amount of interferenceEngine sealsHelix anglePolytetrafluoroethylene

The invention discloses a PTFE (polytetrafluoroethylene) oil seal arranged with multi-group oil return lines and made of a PTFE material; a contact face between a sealing lip slice PTFE of the PTFE oil seal and a shaft piece is provided with multiple groups of oil return lines; meanwhile, parameter of oil return line grooves and a rotating space between the oil return lines are improved. By comparing with a traditional PTFE oil seal, the thickness of the PTFE sealing lip is reduced by about 1 / 3, and the magnitude of interference between an inner hole of the PTFE sealing lip and the rotating shaft is also correspondingly reduced; therefore, the radial force is reduced by about a half, and the requirements on saving energy and reducing emission are realized. Width, space and depth of spiral oil return grooves are reduced by about 1 / 3; for adopting a combined structure of multi-group spiral oil return grooves, it is guaranteed that the oil return grooves and the surface of the rotating shaft have enough contact length and enough helix angles; therefore, the oil seal has enough oil returning ability. The oil seal is longer in service life, and able to greatly reduce the risk of failure of an oil seal piece.

Owner:CHENGDU SHENGBANG SEALS

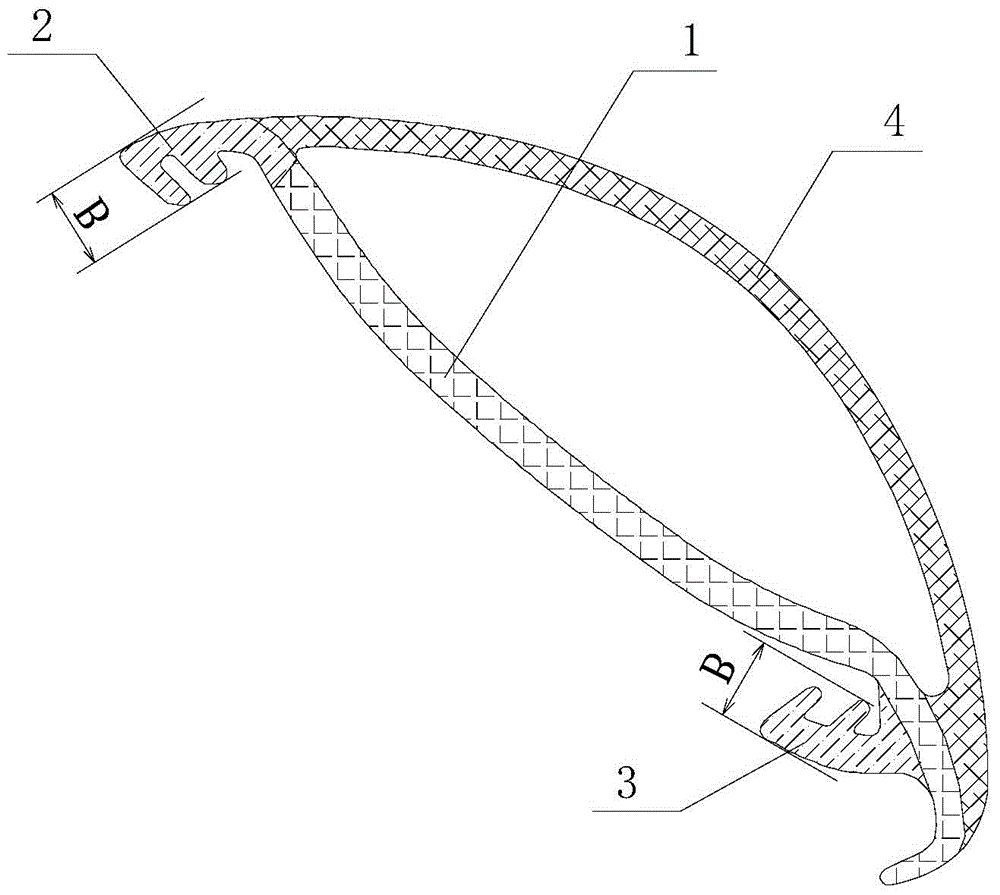

Rubber sealing strip used for outer protective plate of automobile door

ActiveCN104589977AAvoid deformation failureReduce the amount of interferenceEngine sealsVehicle sealing arrangementsHardnessCo extrusion

The invention provides a rubber sealing strip used for an outer protective plate of an automobile door. The rubber sealing strip used for the outer protective plate of the automobile door is composed of a middle plate-shaped supporting portion, a first insertion claw portion, a second insertion claw portion and an outer arc protruding portion. The two insertion claw portions are located on the two sides of the plate-shaped supporting portion respectively, and the outer arc protruding portion is located on the two sides of the plate-shaped supporting portion. The rubber sealing strip is characterized in that a multi-body co-extrusion forming technology is adopted by the rubber sealing strip, and the hardnesses of the two insertion claw portions, the hardness of the plate-shaped supporting portion and the hardness of the outer arc protruding portion become smaller gradually. According to the rubber sealing strip, the hardnesses of the materials of different portions are adjusted by utilizing the multi-body co-extrusion technology, the two insertion claw portions have high hardness, so that the tension of the two insertion claw portions in the installation groove become larger, enough anti-disengagement strength is guaranteed, curling deformation caused in the assembly process is reduced, the assembly speed is increased, it is guaranteed that the rubber sealing strip can be installed in place, and the assembly quality is improved; the plate-shaped supporting portion has the moderate hardness, and therefore ineffectiveness caused by deformation of the sealing strip is avoided; the hardness of the outer arc protruding portion is low, so that the fit performance between the outer arc protruding portion and a metal plate of a door frame is improved, and therefore the leakproofness between the automobile door and the door frame is improved.

Owner:天津华涛汽车塑料饰件有限公司

Ultrasound-assisted cutting vibration system

InactiveCN109894684AFirmly connectedReduce assembly accuracyMechanical vibrations separationInterference fitStress concentration

The invention discloses an ultrasound-assisted cutting vibration system which comprises an ultrasonic transducer, an insulation sleeve and an overall superhard cutting tool bar. The insulation sleeveand the overall superhard cutting tool bar are located at the front end of an ultrasonic amplitude transformer; and the front end of the ultrasonic amplitude transformer and the overall superhard cutting tool bar are connected in a hot-charging interference fit way. According to the ultrasound-assisted cutting vibration system provided by the invention, the overall superhard cutting tool bar for shaping and the ultrasonic amplitude transformer for shaping are connected in the hot-charging interference fit way, so that the problems that stress concentration exists in the connecting part, and anoverall superhard cutting tool is easy to break or fragment under high-frequency or large-amplitude ultrasonic vibration are solved. Meanwhile, only one-time fitting-surface connection is adopted, sothat the assembling accuracy of the cutting tool is high, and the high-precision reliable connection for the high-frequency or large-amplitude ultrasonic cutting processing of the overall superhard cutting tool bar is realized.

Owner:DALIAN JIAOTONG UNIVERSITY

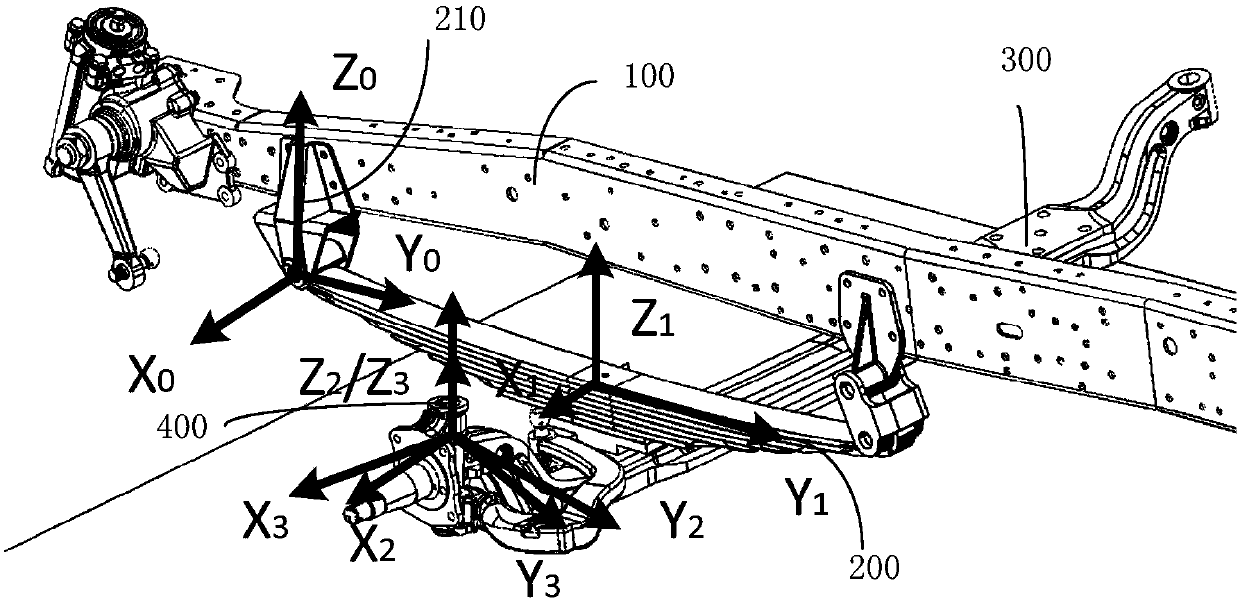

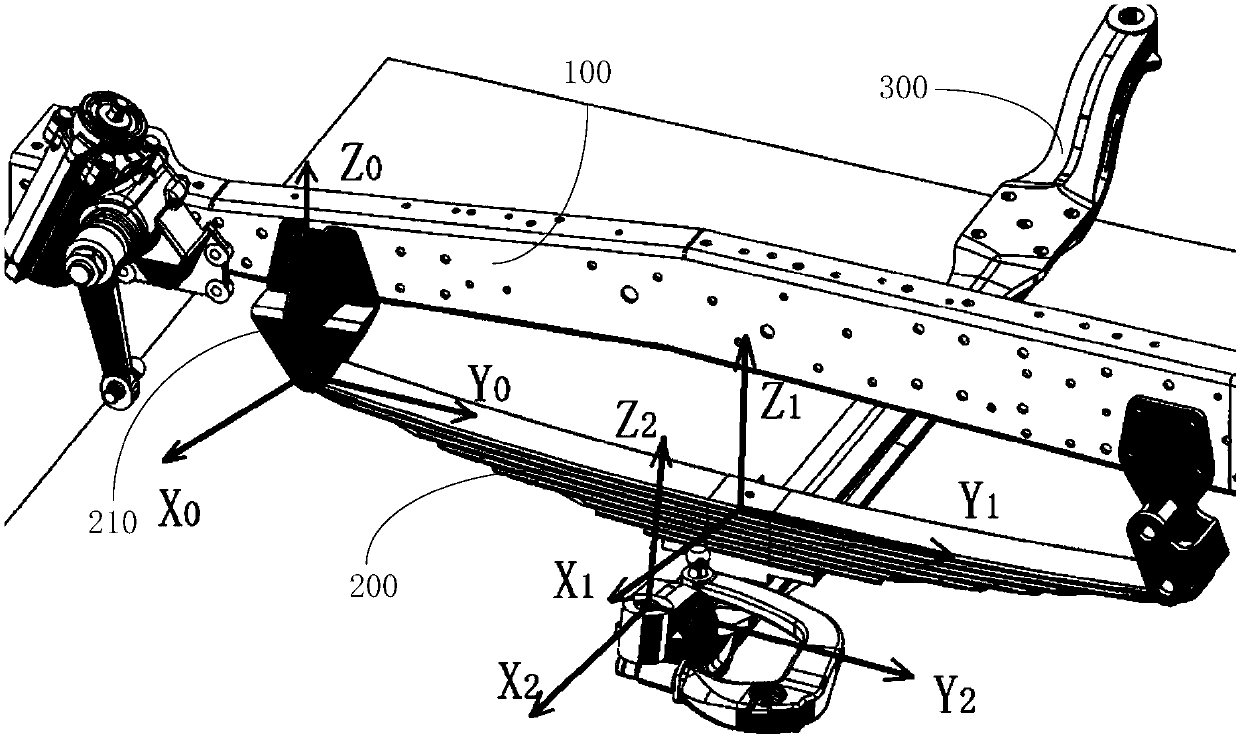

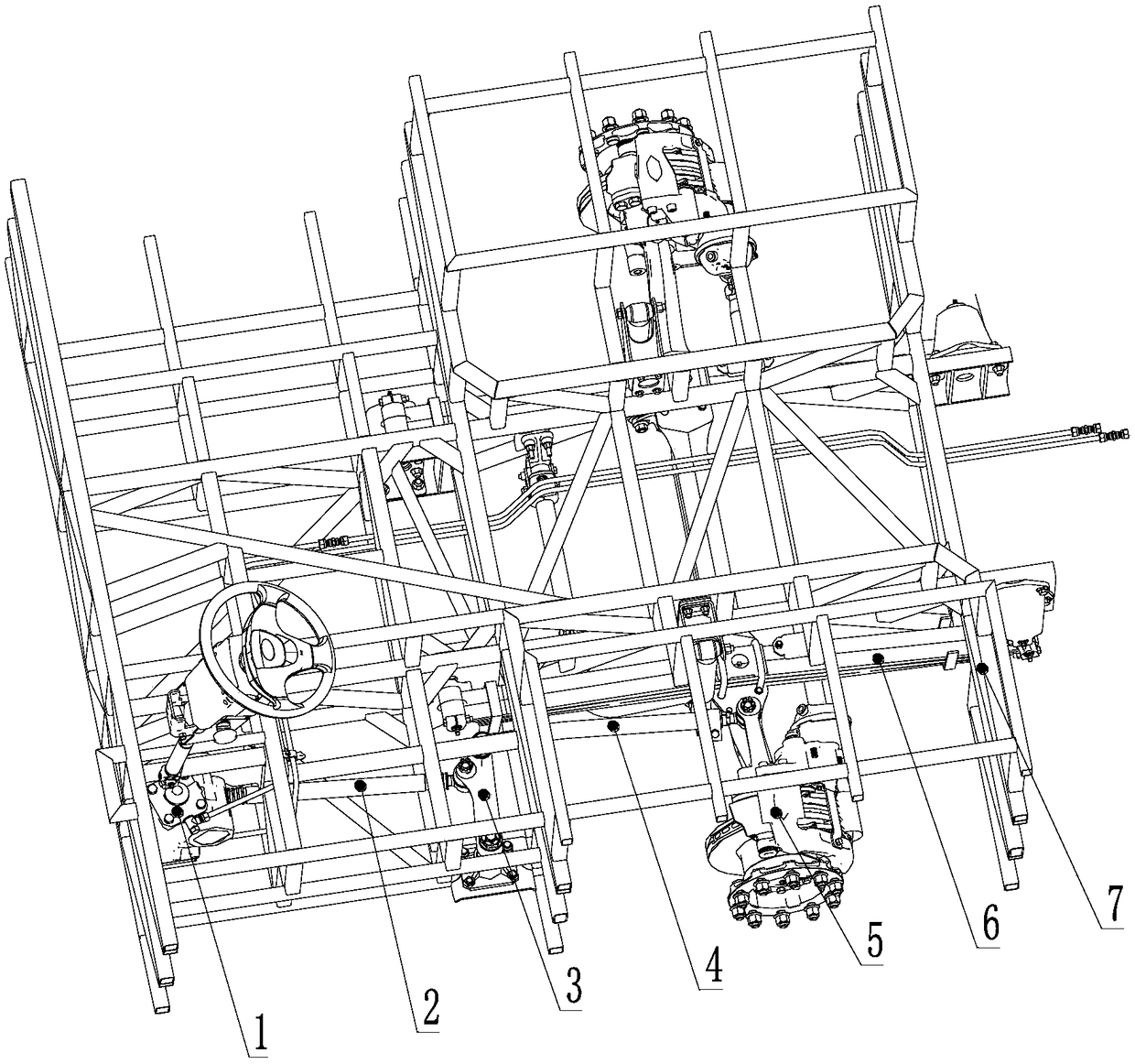

Analysis method of interference amount of truck steering system and suspension system

ActiveCN108229077ASave manpower and material resourcesReduce the amount of interferenceGeometric CADDesign optimisation/simulationTruckSteering system

The invention provides an analysis method of interference amount of a truck steering system and a suspension system, and relates to the technical field of vehicle analogue simulation. A truck comprises the steering system and the suspension system. The analysis method includes the steps: building a plurality of coordinate systems on the steering system and the suspension system; building contact between the steering system and the suspension system through a plurality of different coordinate systems, and giving interference amount corresponding to combination of the suspension system and the steering system. The analysis method solves the technical problems that interference amount of an existing designed truck steering system and a suspension system cannot be calculated in braking, and the range of the interference amount cannot be ensured.

Owner:TIANJIN TRINOVA AUTOMOTIVE TECH CO LTD

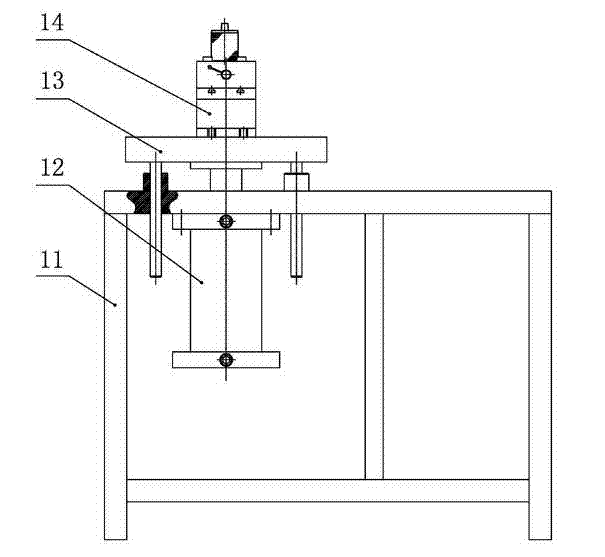

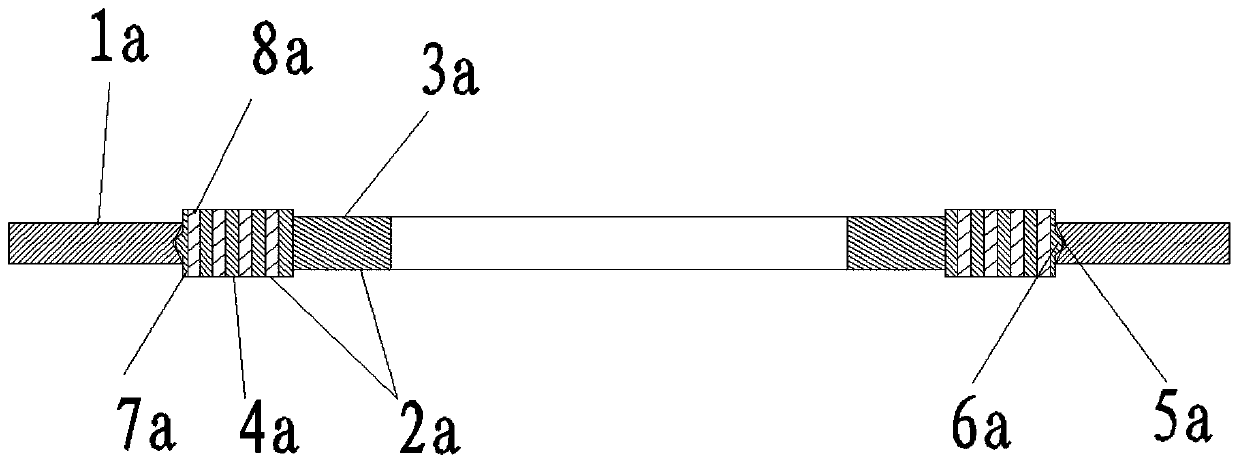

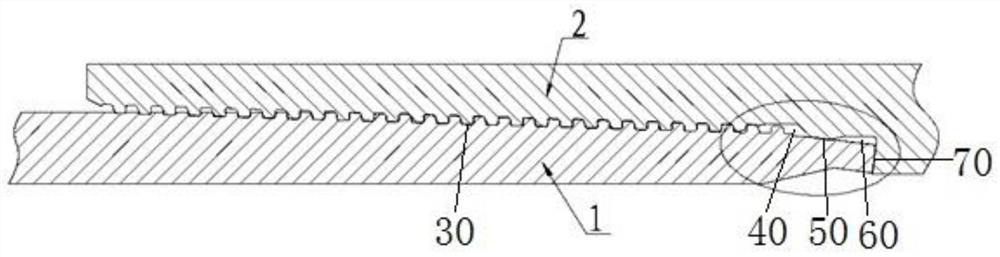

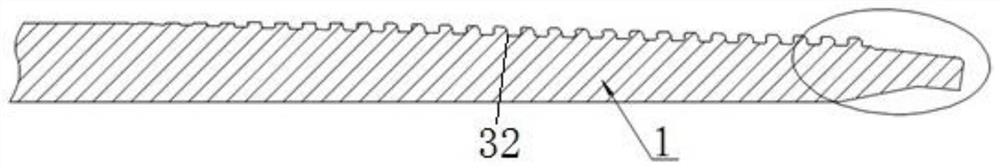

Manufacturing equipment and mold of metal spiral-wound gasket

ActiveCN109093023AEasy to pressEasy to installShaping toolsMetal working apparatusSpiral woundAutomation

The invention discloses manufacturing equipment of a metal spiral-wound gasket. The manufacturing equipment is characterized by comprising an outer ring deformation device and an inner and outer ringautomatic lantern ring leveling device. The outer ring deformation device comprises an outer ring deformation mold used for achieving first deformation of an outer ring, enabling the outer ring to jack up from bottom to top, and expanding the inner diameter of the top of the outer ring. The inner and outer ring automatic lantern ring leveling device comprises a first platform body, a first multistation index plate, a lantern ring mold and an outer ring leveling mold arranged at the first platform body. The lantern ring mold is used for completely compressing an inner ring into the outer ring.The outer ring leveling mold is used for achieving second deformation of the outer ring and leveling the upper and lower surfaces of the outer ring. According to the manufacturing equipment of the metal spiral-wound gasket, during the installation process of the inner ring and the outer ring, annular protrusions at the outer surface of a winding ring of the inner ring are not liable to upwarp or be crushed, flatness and finish degree of the product surface are high, and the automation degree is high. The invention further provides a manufacturing mold of the metal spiral-wound gasket.

Owner:慈溪红叶密封制品有限公司

Passenger vehicle wheel edge spline matching and fastening structure

PendingCN112026438ALow costSimplify the assembly and disassembly processHubsAxle unitsDrive shaftControl theory

The invention belongs to the technical field of riding chassis parts, and particularly relates to a passenger vehicle wheel edge spline matching and fastening structure. The structure comprises a driving shaft, a hub bearing and an elastic check ring, the driving shaft is sleeved with the elastic check ring, the driving shaft is connected into the hub bearing through a spline and connected into the hub bearing in a matched mode through the elastic check ring on the driving shaft, and a plurality of hub bearing disassembling process holes used for disassembling the driving shaft are formed in the right side end face of the hub bearing; the elastic check ring which is convenient to assemble and disassemble is adopted for positioning, a shaft head thread pair is not needed for fastening, endface contact does not exist between the driving shaft and the hub bearing, the assembling and disassembling process is simplified, the purchasing cost is reduced, and the problem of vehicle starting abnormal sound can be solved fundamentally.

Owner:FAW CAR CO LTD

Non-destructive disassembly device for compressor rotor shrink sleeve assembly

The invention discloses a damage-free compressor rotor heat jacket assembly disassembling device. The damage-free compressor rotor heat jacket assembly disassembling device is provided with a jacking mechanism which is capable of lifting vertically, a clamp jig capable of clamping a workpiece is arranged at the top of the jacking mechanism, a high frequency heating device used for heating the workpiece and capable of moving leftwards and rightwards is mounted on the upper left portion of the jacking mechanism, a hydraulic ejection mechanism capable of ejecting out a crankshaft is mounted above the jacking mechanism and the high-frequency heating device, a pressure center of the hydraulic ejection mechanism is coincided with the center of the jacking mechanism, a rotor shifting mechanism capable of clamping a rotor to move leftwards and rightwards is mounted on the upper right portion of the jacking mechanism and below the hydraulic ejection mechanism, a rotor cooling mechanism capable of cooling a rotor shifted from the rotor shifting mechanism is mounted below the rotor shifting mechanism, and the jacking mechanism, the high-frequency heating device, the hydraulic ejection mechanism, the rotor shifting mechanism and the rotor cooling mechanism are connected with a controlling mechanism. The damage-free compressor rotor heat jacket assembly disassembling device has the advantages of simplicity in operation, high disassembling efficiency, small damage to disassembled parts, and good reusability.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Universal mill horizontal roll assembling structure and matching and assembling method

ActiveCN104438345APrevent axial movementPrevent burstMetal rolling stand detailsMetal working apparatusFree coolingEngineering

The invention relates to a universal mill horizontal roll assembling structure which comprises a roll shaft and a roll ring. A boss is arranged on the outer circle surface, in contact with the roll ring, of the roll shaft, and an annular groove matched with the size of the boss is formed in the corresponding inner circle surface of the roll ring. A matching and assembling method of the assembling structure comprises the steps that (1) the assembling size is measured after the roll shaft is machined; (2) the roll ring is matched; (3) the roll ring is heated; (4) preparation is carried out before hot assembling; (5) hot assembling is carried out on the roll shaft; (6) a horizontal roll is naturally cooled. Compared with the prior art, the assembling structure and the method have the advantages that the roll shaft and the roll ring are provided with the boss and the annular groove respectively, and the situation that the assembled roll ring axially moves due to too large interference magnitude is avoided; the roll ring is matched according to the actual size of the roll shaft, the interference magnitude is properly reduced on the premise of guaranteeing close connection of the roll shaft and the roll ring, and the situation that the assembled roll ring is expanded and cracked due to the too large interference magnitude in the use process is avoided; the boss of the roll shaft and the assembling faces on the two sides of the annular groove of the roll ring are designed to be different in size and diameter, and smooth assembling is facilitated.

Owner:鞍钢轧辊有限公司

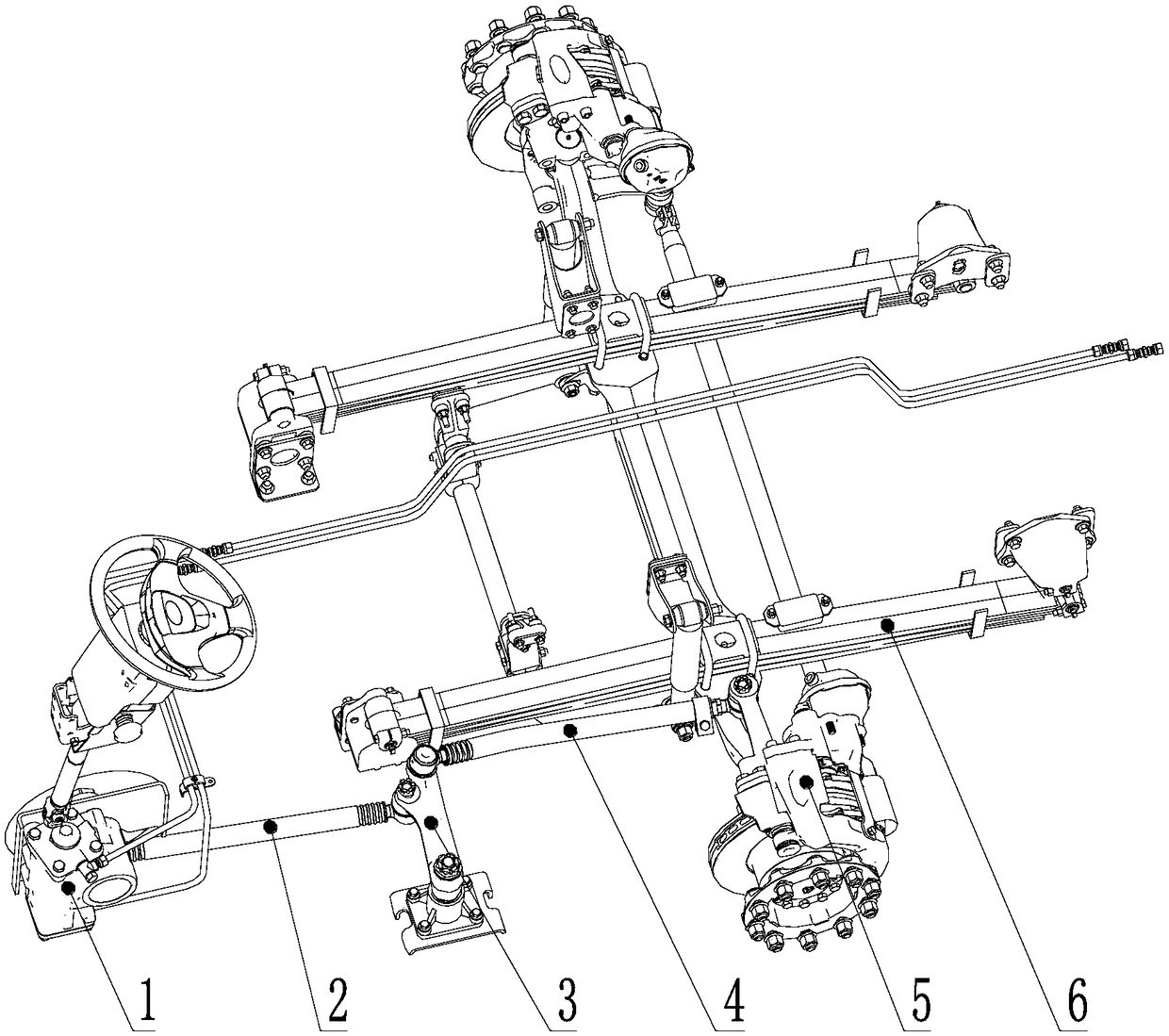

Bus steering system

PendingCN109398480AImprove versatilitySatisfy the richness requirementSteering linkagesResilient suspensionsVehicle frameAgricultural engineering

Disclosed is a bus steering system. The bus steering system comprises a bus frame, a front steering part, a transition swing arm and a rear steering part, wherein the front steering part and the rearsteering part are both arranged on the bus frame from front to back; the front steering part and the rear steering part are connected by the transition swing arm; the front steering part can be stretched according to different front suspension lengths of different bus models; and the rear steering part adopts a modular design. The front steering part can be stretched according to the different front suspension lengths of the different bus models, so that the steering system is suitable for the various bus models and the application range of the steering system is expanded. The rear steering part adopts the modular design so as to improve the universality of the steering system, reduce the production cost and increase the production efficiency.

Owner:SINO TRUK JINAN POWER

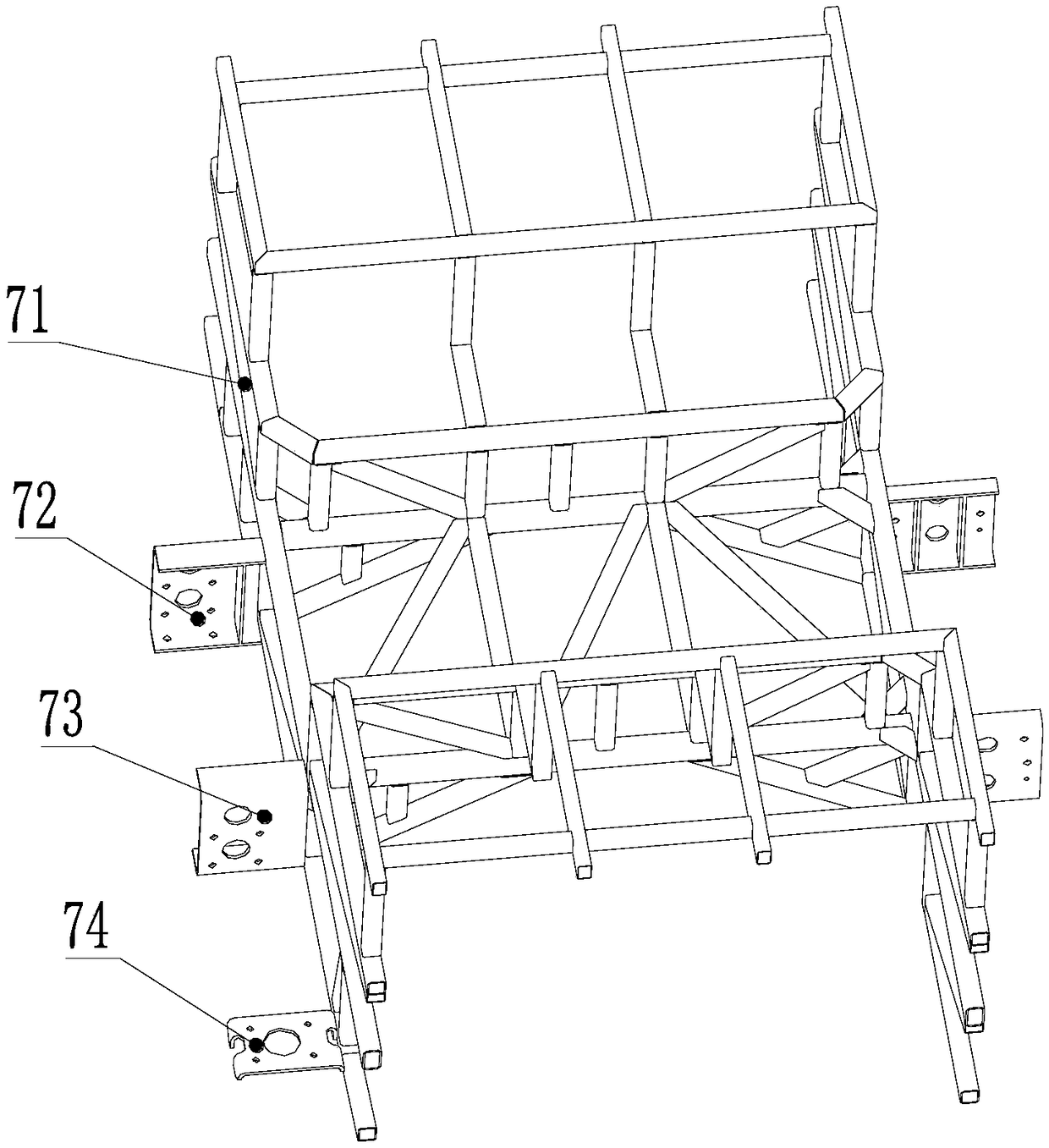

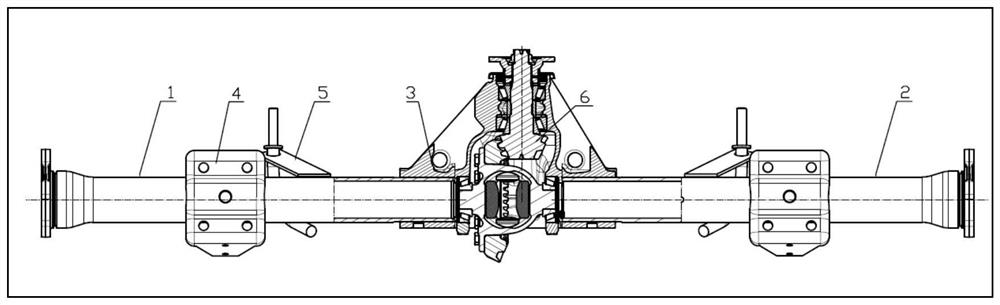

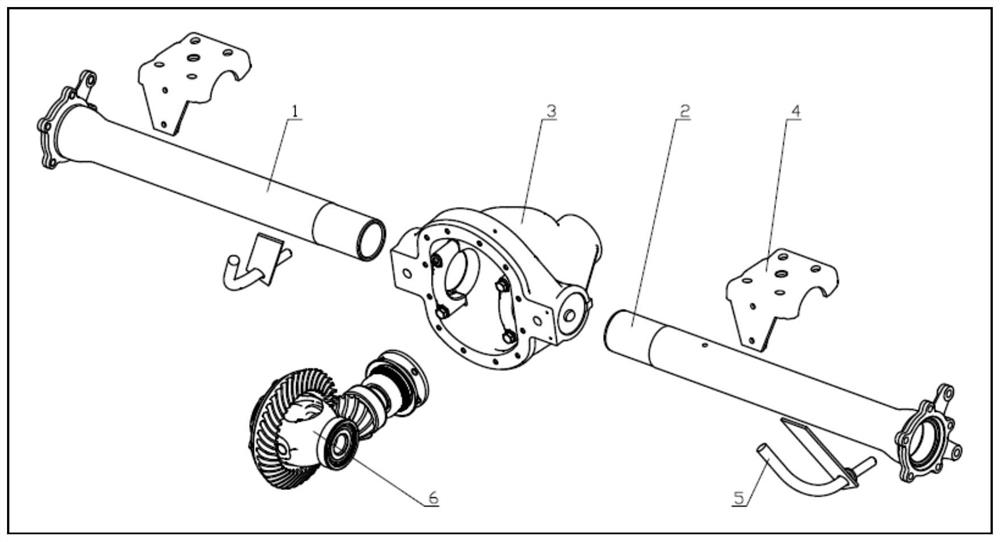

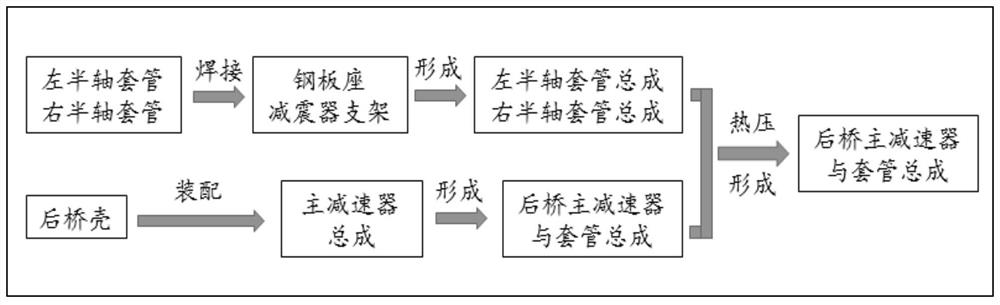

Rear axle main speed reducer and sleeve assembly assembling equipment and assembling process thereof

InactiveCN112059533APrevent outflowReduce volumeMetal working apparatusProcess equipmentReduction drive

The invention discloses commercial vehicle rear axle main speed reducer and sleeve assembly assembling equipment and process. A left half axle sleeve assembly and a right half axle sleeve assembly arepressed into a rear axle shell hole in a rear axle main speed reducer assembly at the same time by adopting a double-end hot pressing process. Double-end hot-pressing process equipment and a corresponding assembling process are adopted for assembling of the rear axle main speed reducer and the sleeve assembly, the problems of press-in depth fluctuation and scrap iron extrusion caused by the left-right pressure difference can be effectively solved, and the product quality stability and performance are guaranteed.

Owner:NANJING NAVECO AUTOMOBILE CO LTD

Method for preventing looseness of ceramic contact pin and metal body fit

InactiveCN1423144AImprove reliabilityGuaranteed verticality requirementsCoupling light guidesInterference fitCeramic

The characteristics of the invention are that the mini step is designed in the mating part between the ceramics contact pin and the metallic body. The step includes the chamfering that is the transition part between the axes with different diameters. The tight fit is adopted between the thick axis and the mating hole of the metallic body. The transition fit is adopted between the thin axis and the mating hole of the metallic body. The assembly of the ceramics contact pin produced by adopting the said method guarantees the fastness and the relaibility of the fit between the ceramics contact pin and the metallic body in various usage environment.

Owner:WUHAN UNICELL TECH CO LTD

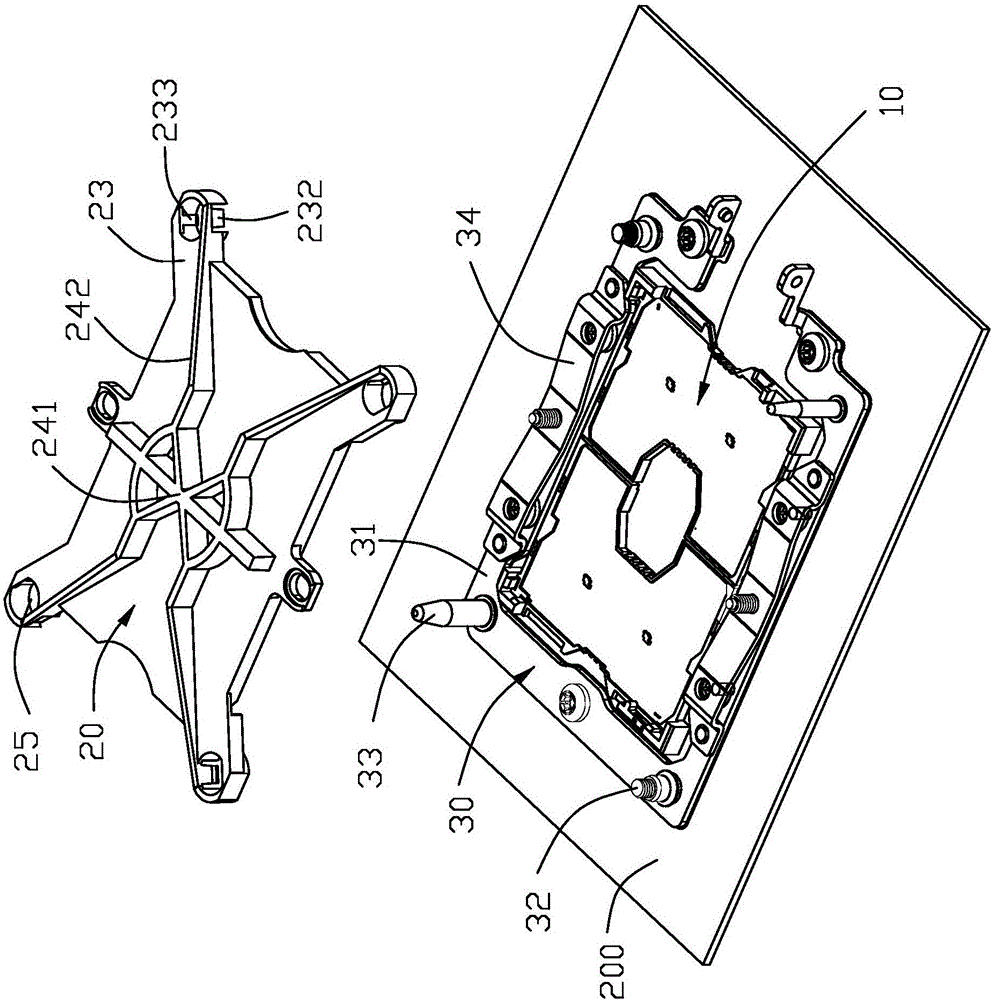

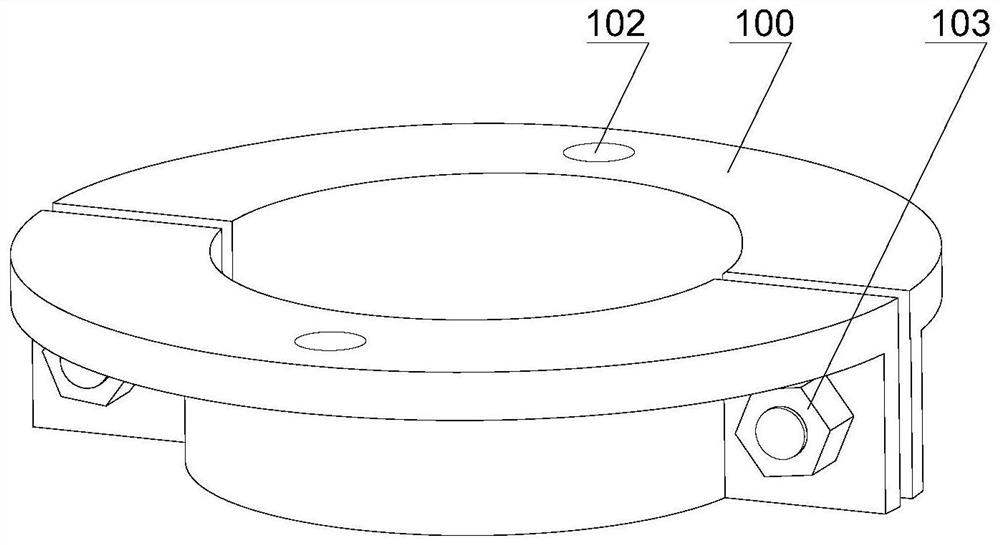

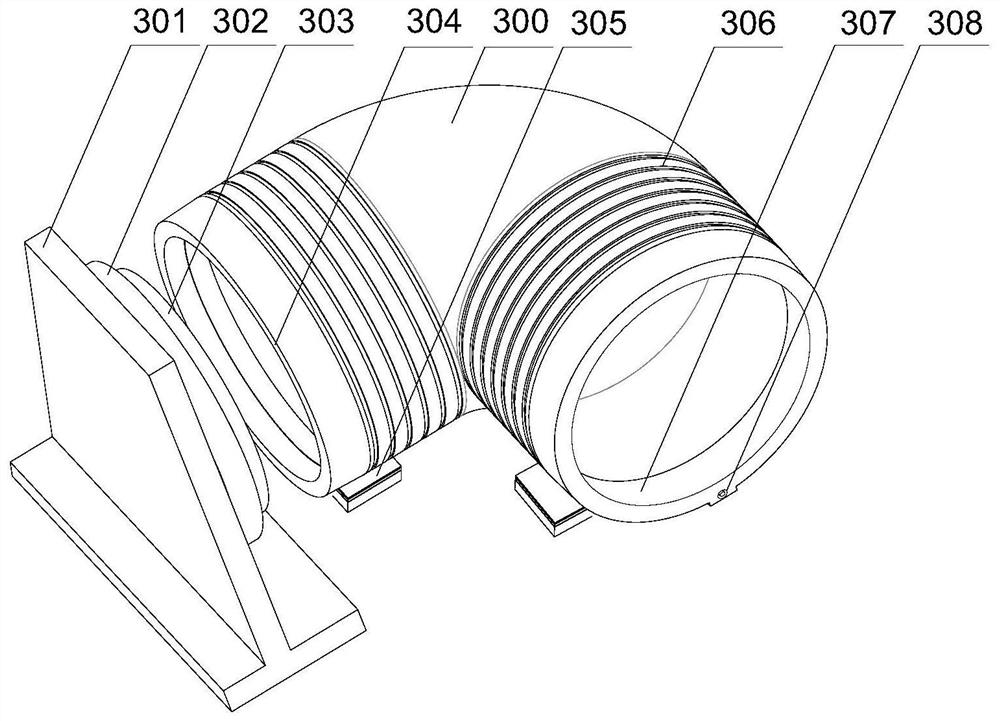

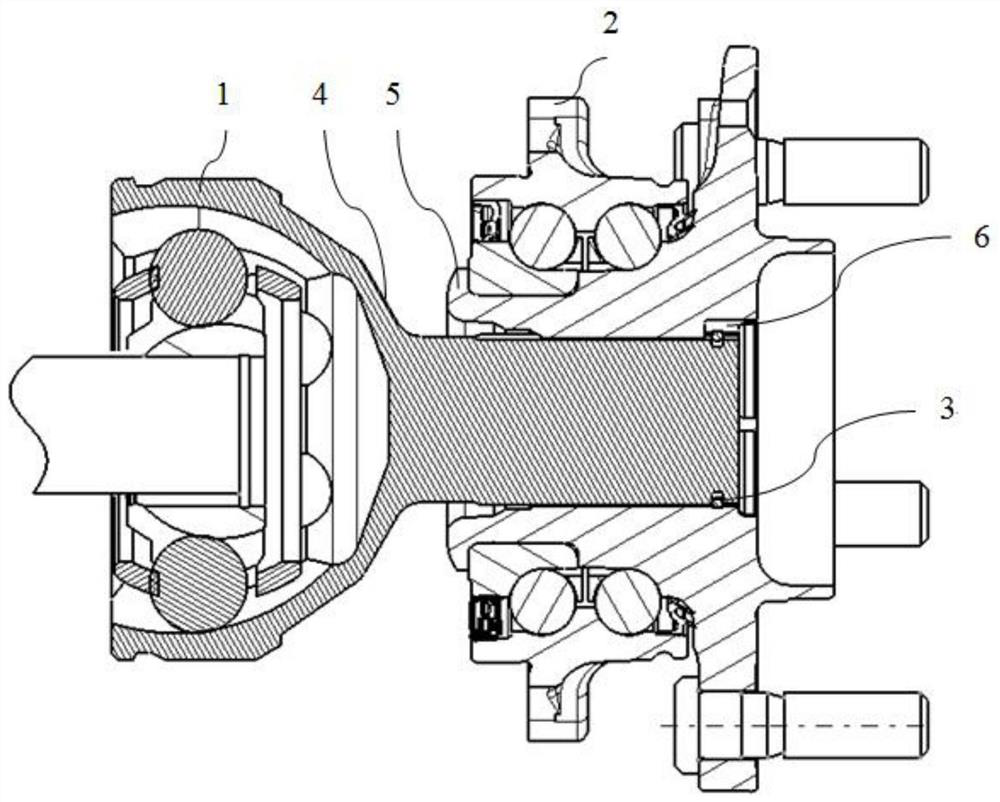

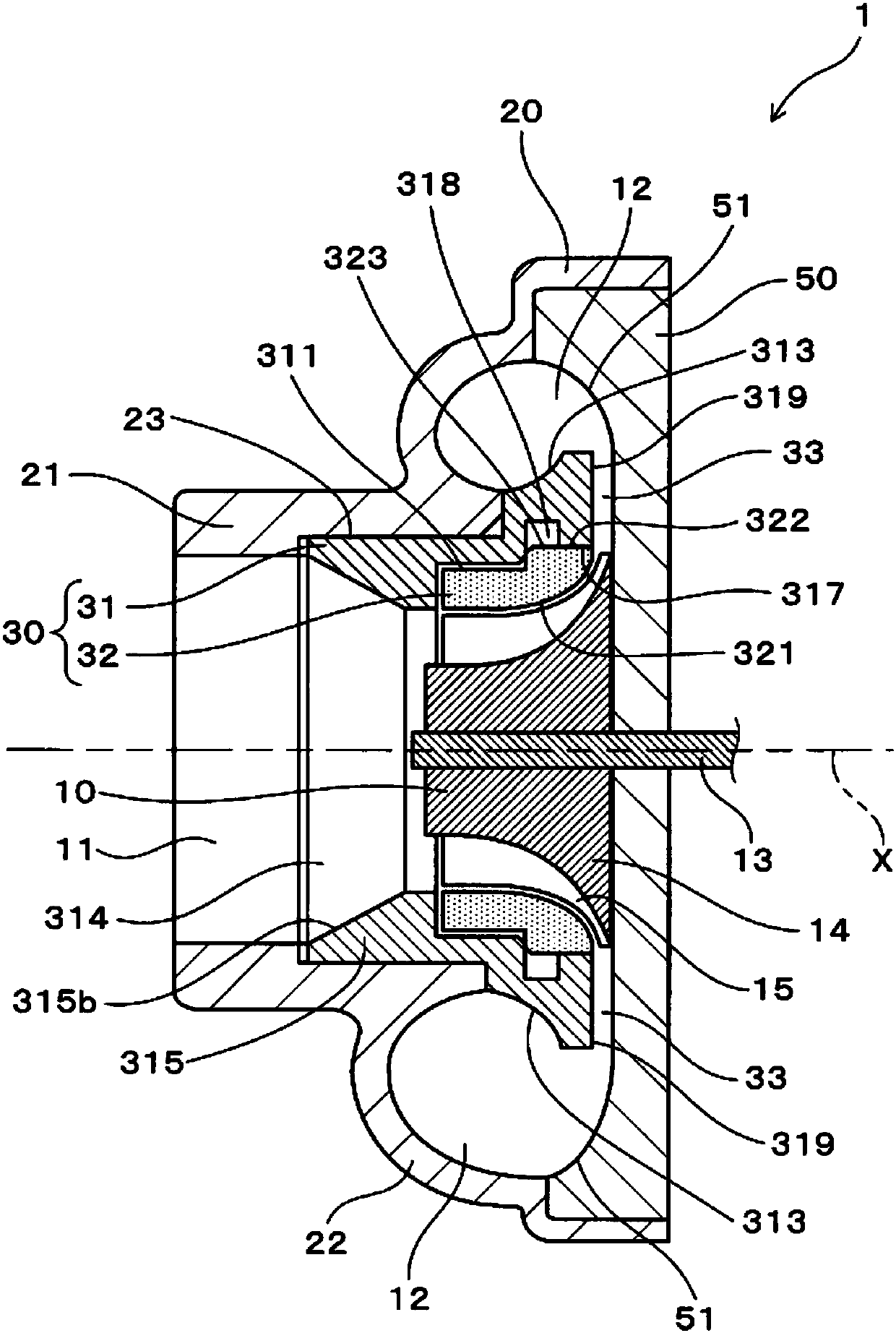

Compressor housing for supercharger

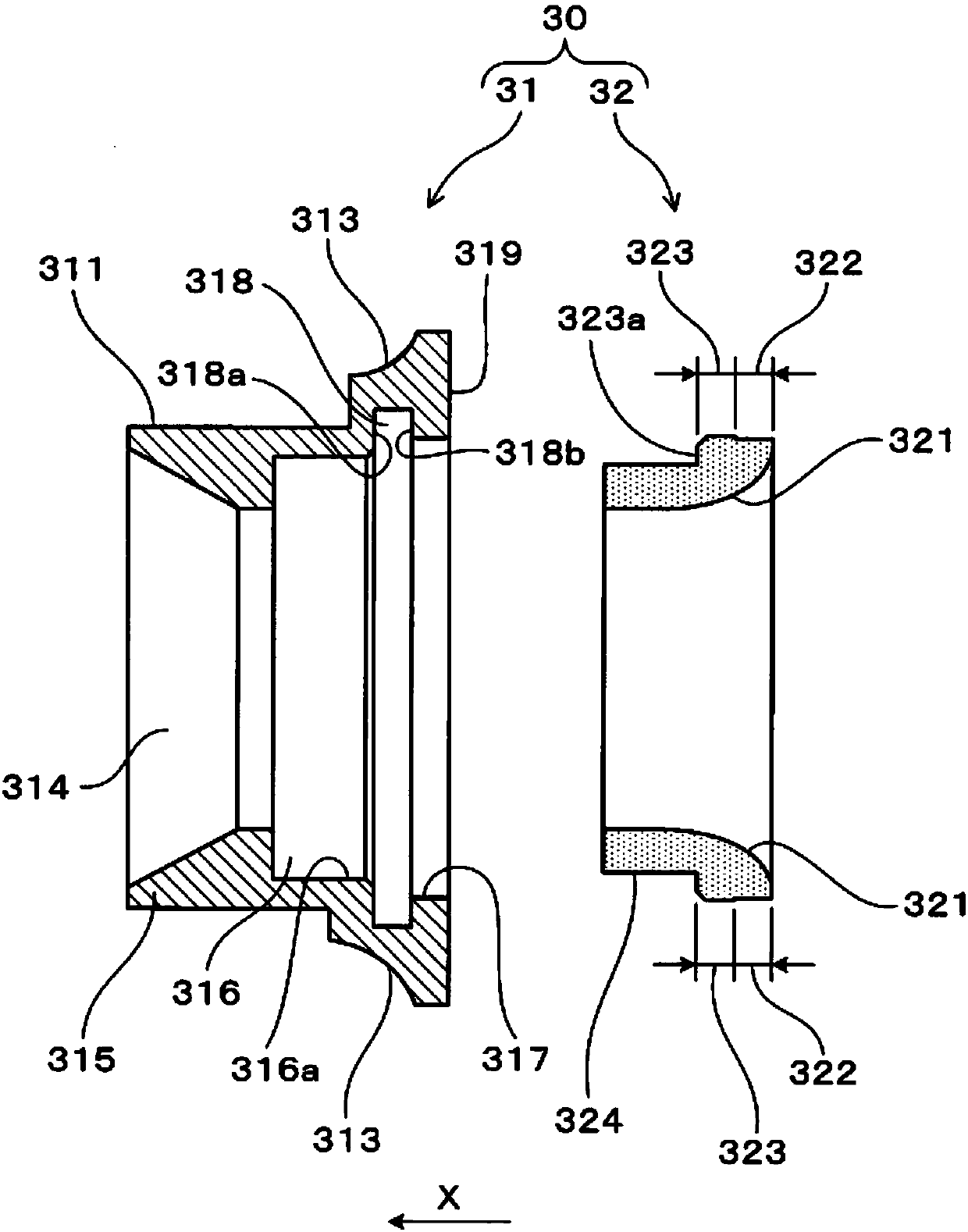

InactiveCN107614848APrevent movementAchieving an anchoring effectPump componentsEngine fuctionsEngineeringMechanical engineering

This invention addresses the problem of providing a compressor housing for a supercharger, which is simple in configuration and with which it is possible to reliably secure a sliding member. To solvethis problem, a compressor housing (1) for a supercharger is provided with a scroll part (20) having a scroll chamber, and a shroud part (30) having a shroud surface (321). The shroud part (30) comprises an annular sliding member (32) which forms the shroud surface (321), and an annular sliding member securing part (31). The sliding member securing part (31) has a press-fitting concavity (317) into which the sliding member (32) is press-fitted, and a groove part (318) formed in the circumferential direction as being recessed diametrically outward in the front side of the sliding member (32) inthe press-fitting direction (X). The sliding member (32) has a press-fitting contact part (322) which comes into contact with the inner peripheral surface of the press-fitting concavity (317), and abulging part (323) which bulges into the groove part (318) in a position of facing the groove part (318).

Owner:株式会社欧德克斯 +1

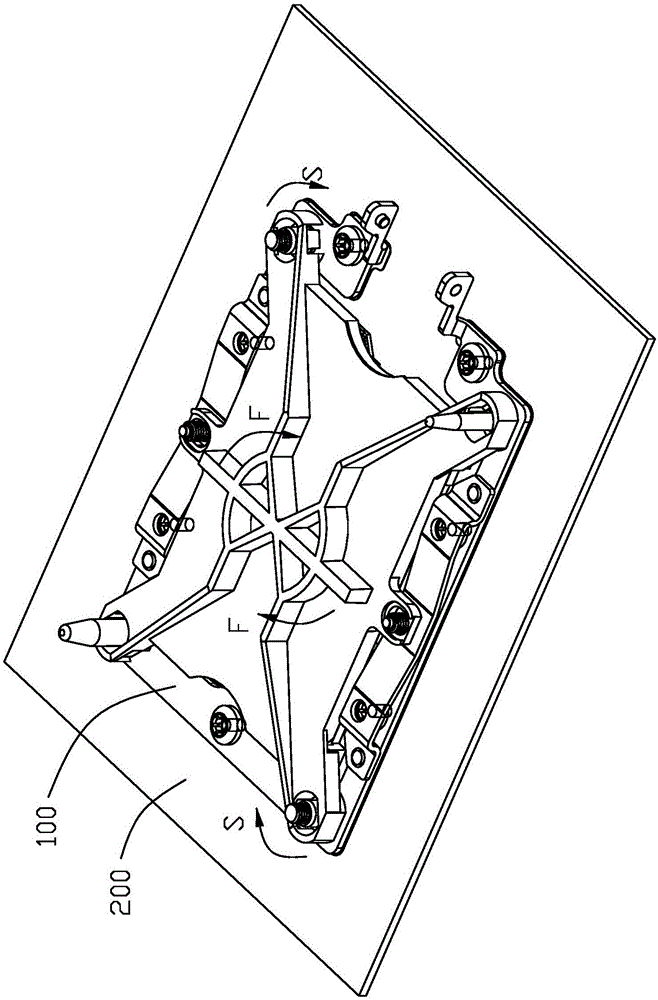

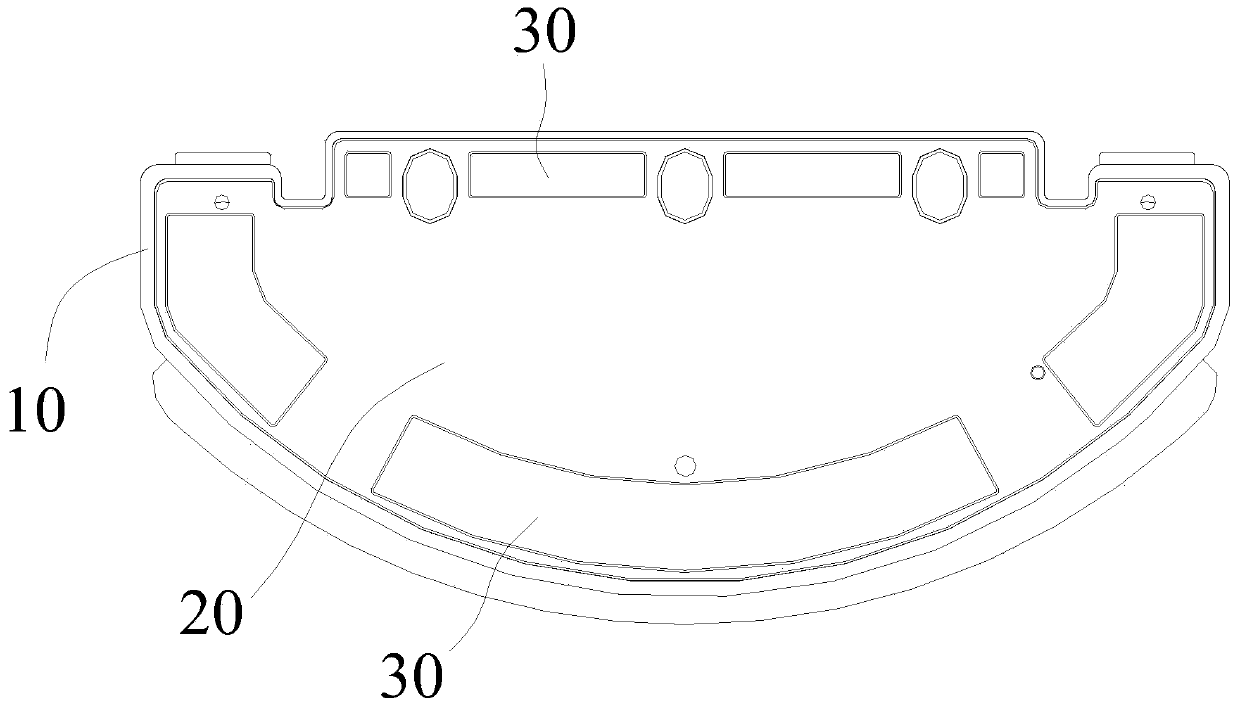

Self-moving robot and rag mounting device

PendingCN111134579AIncrease the amount of interferenceEasy to cleanCarpet cleanersFloor cleanersStructural engineeringMachine

The invention provides a self-moving robot and a rag mounting device. The self-moving robot is provided with a machine body, a water tank is arranged in the machine body, the rag mounting device is arranged at the bottom of the water tank, rags are installed on the outer side of the rag mounting device, the rag mounting device comprises a base material layer and an elastic cushion layer, and the elastic cushion layer is arranged between the base material layer and the rags. The magnitude of interference between the rags and the ground can be dynamically adjusted, or the degree of attachment tightness between the rags and the ground can be dynamically adjusted, so that the self-moving robot is prevented from slipping in the walking process, it is ensured that the self-moving robot can walknormally, and the cleaning efficiency of the self-moving robot is ensured.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Jig and assembly equipment

ActiveCN113199190AIncrease spacingReduce the amount of interferenceWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention provides a jig and assembly equipment, and belongs to the technical field of automatic equipment. The jig comprises a pressing plate and supporting blocks. A receding hole is formed in the pressing plate. The pair of supporting blocks is movably connected to the two opposite sides of the receding hole of the pressing plate and can be switched between a first posture and a second posture. Each supporting block is provided with a bearing portion used for bearing a first part. After the first part is assembled to a second part, the pair of supporting blocks is switched from the first posture to the second posture, so that the distance between the bearing portions of the pair of supporting blocks is increased. When the jig and the second part are separated, the probability that the connection relation between the first part and the second part is damaged can be reduced, and even the connection relation is prevented from being damaged.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

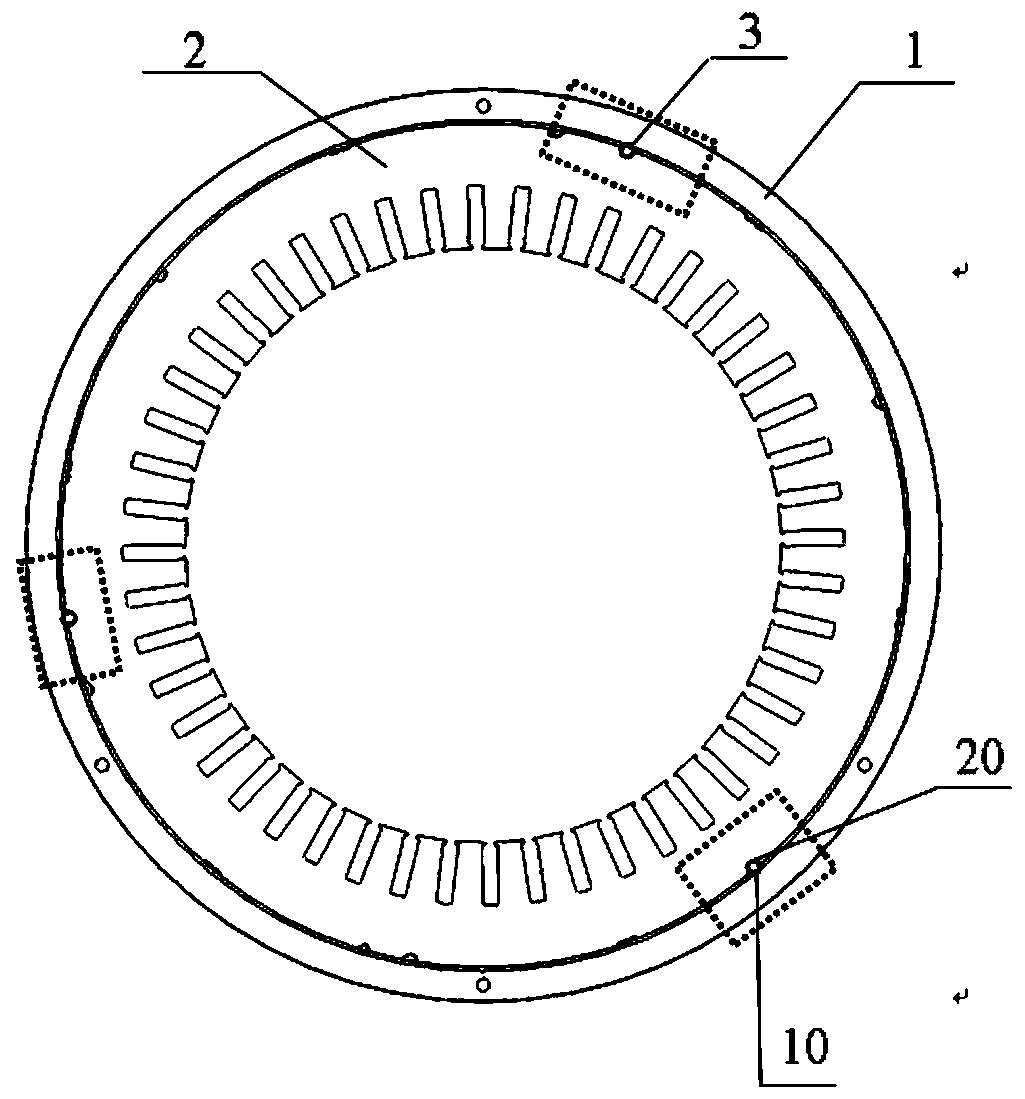

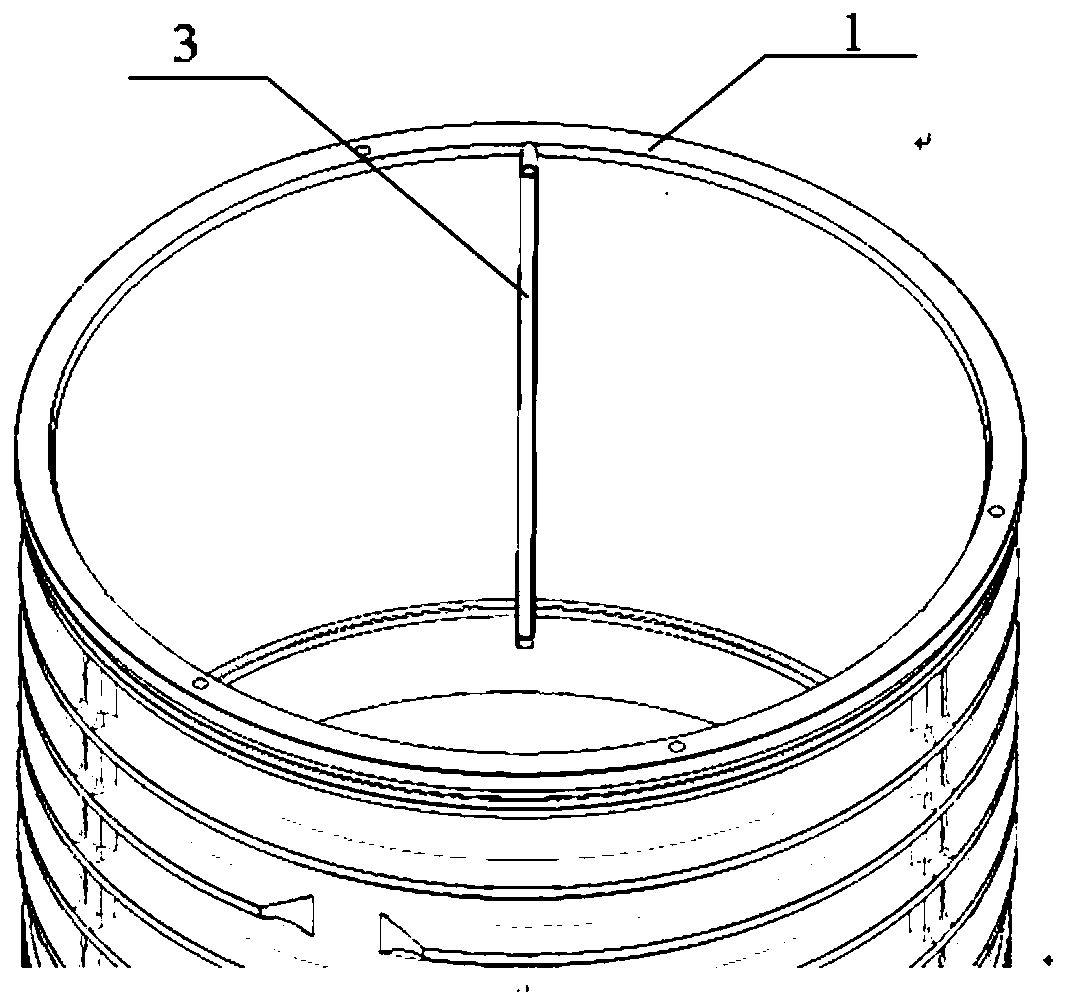

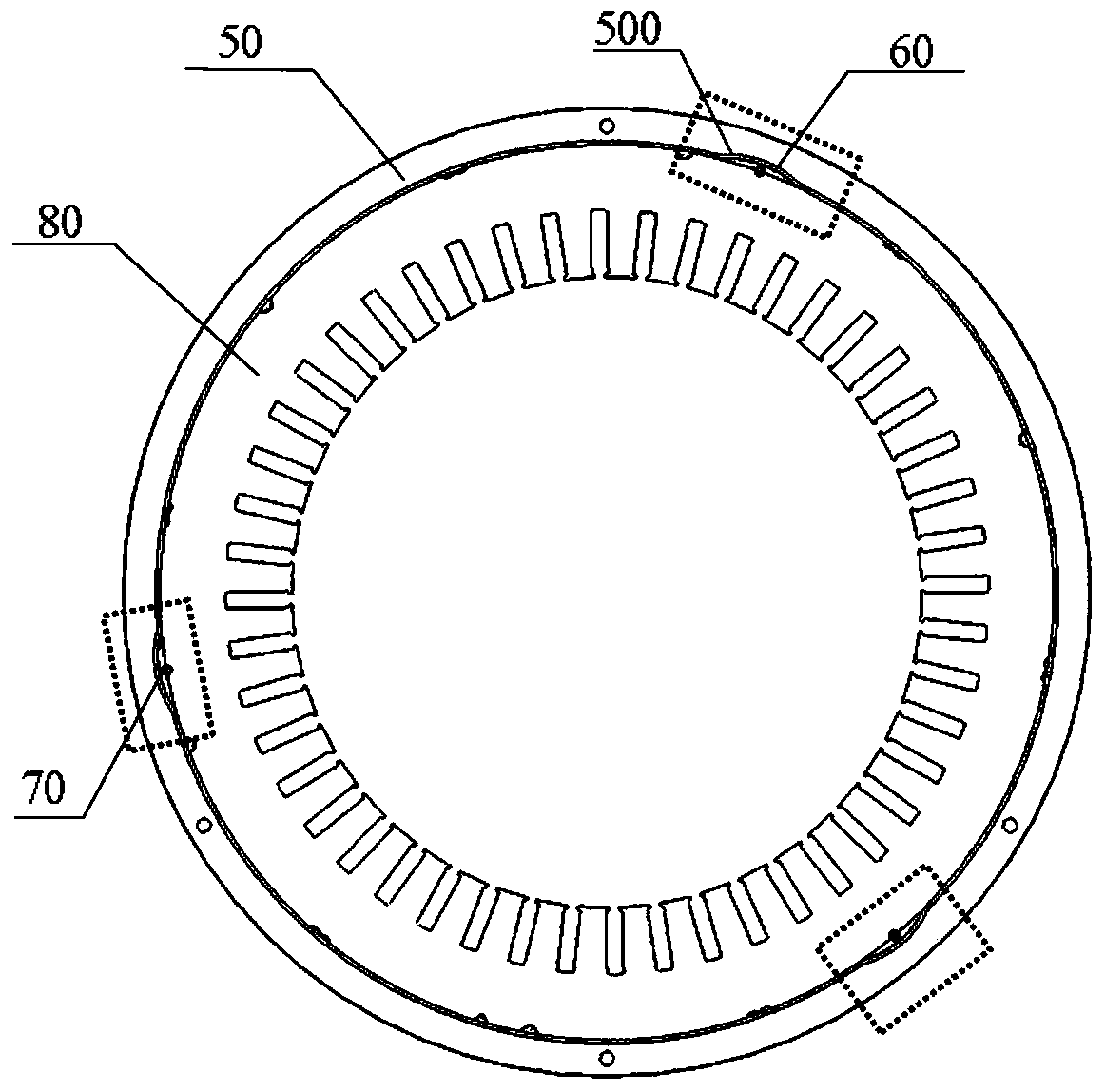

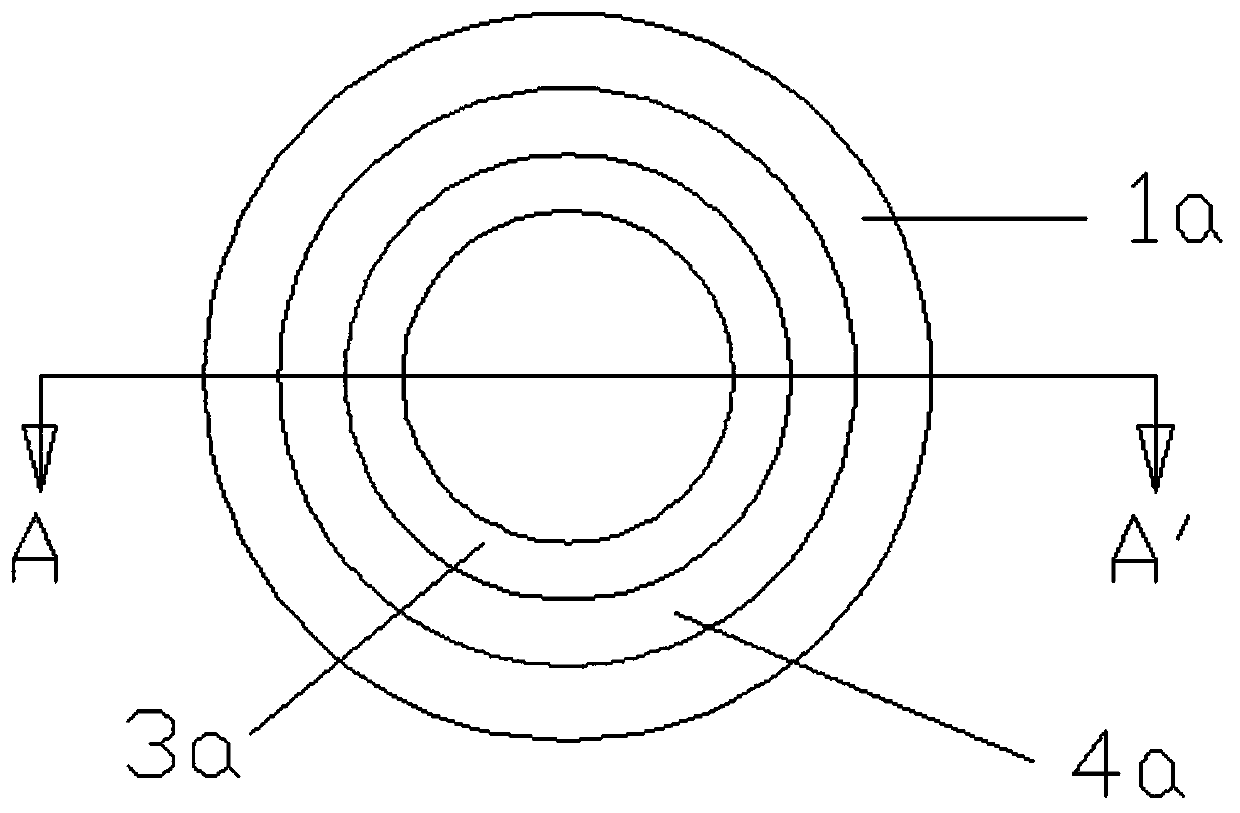

Motor and motor stator cooling structure

InactiveCN109768639AReduce stress concentration effectsGuaranteed normal deliveryMagnetic circuit stationary partsCooling/ventillation arrangementStatorEngineering

The invention relates a motor and a motor stator cooling structure. The motor stator cooling structure comprises a water sleeve and an elastic pin, wherein the water sleeve sleeves an outer ring surface of a motor stator and is in interference fit with the motor stator, a water sleeve groove is formed in an inner ring surface of the water sleeve and extends axially, an intermediate medium is arranged in the water sleeve groove, a positioning hole is formed in the intermediate medium and the outer ring surface of the motor stator, the elastic pin is integrally of an annular structure and is fixed in the positioning hole, the shape of the positioning hole is matched with the shape of the elastic pin, a radial opening is formed in the elastic pin and communicates with the inner ring surface of the elastic pin, and an axial end, along the elastic pin, of the radial opening extends to the other axial end. With the motor and the motor stator cooling structure, provided by the embodiment of the invention, the stress concentrated effect of the water sleeve groove can be reduced, the situation that the water sleeve is deformed caused by the stress at the water sleeve groove exceeds extremeyield strength is prevented, and normal transferring of torque between the motor stator and the water sleeve under a low-temperature environment is favorably ensured.

Owner:SCHAEFFLER TECH AG & CO KG

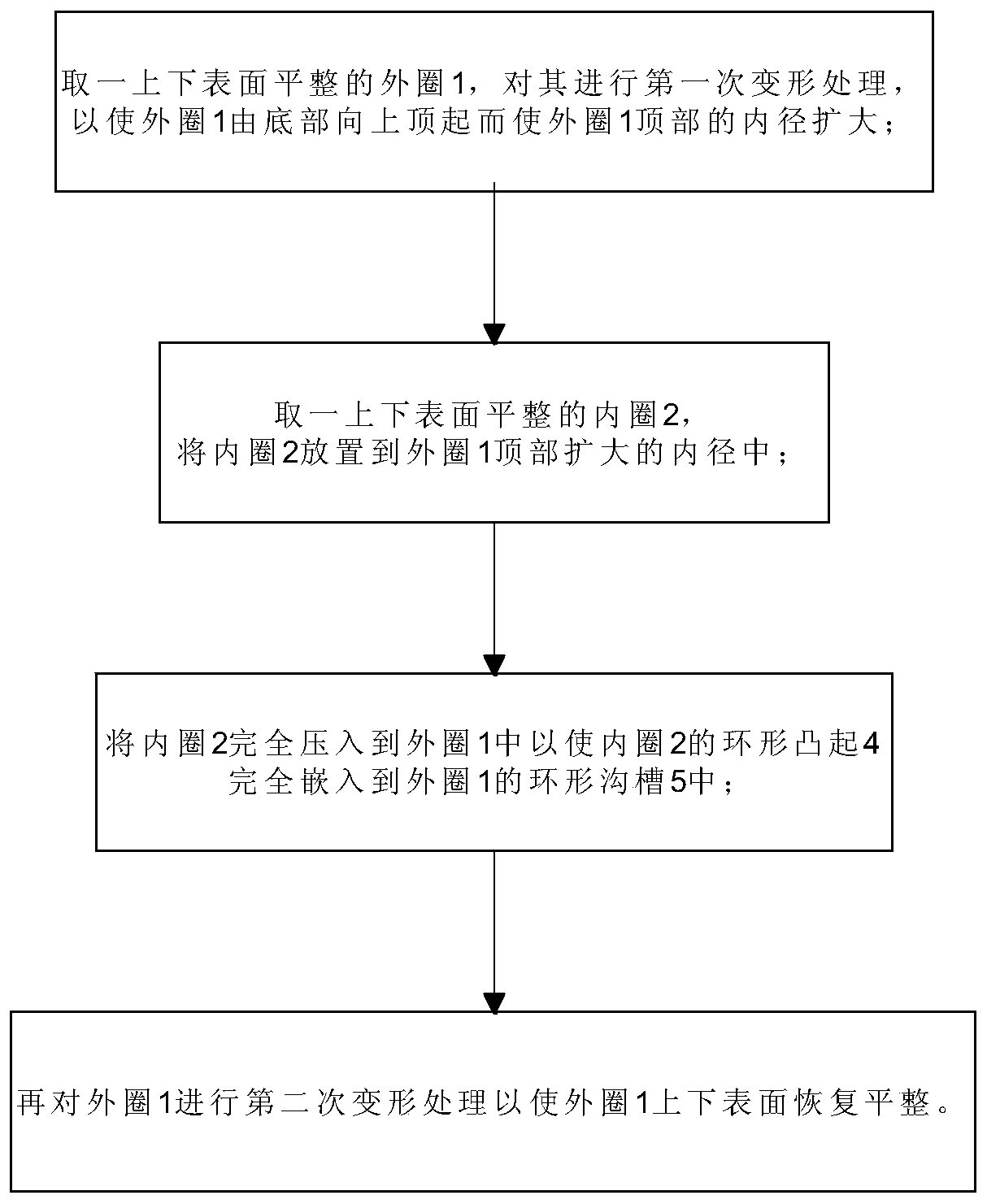

Manufacturing equipment for metal wound gaskets

ActiveCN109093024BEasy to pressReduce the amount of interferenceShaping toolsMetal working apparatusMetalChemistry

The invention provides a manufacturing method for a metal spiral-wound gasket. The manufacturing method for the metal spiral-wound gasket is characterized by comprising the following steps that (1), an outer ring with flat upper and lower surfaces is taken and subjected to first deformation treatment, thus the outer ring is jacked up from the bottom to make the inner diameter of the top of the outer ring enlarge; and (2) an inner ring with flat upper and lower surfaces is taken and pressed into the outer ring from the expanded inner diameter on the top of the outer ring, and the upper and lower surfaces of the outer ring are restored to be flat. According to the manufacturing method for the metal spiral-wound gasket, in the installation process of the inner and outer rings, an annular bulge on the outer surface of a spiral-wound ring of an inner ring is not prone to become warped or crushed to be damaged. In addition, the invention further provides a manufacturing device for the metalspiral-wound gasket, wherein the manufacturing device for the metal spiral-wound gasket has good roughness and fineness on the product surface and high automation level.

Owner:慈溪红叶密封制品有限公司

Oil sleeve joint and oil sleeve assembly

PendingCN113279704AImprove integrityImprove sealingDrilling rodsDrilling casingsScrew threadScrew joint

The invention provides an oil sleeve joint and an oil sleeve assembly. The oil casing joint comprises an external thread joint, and an internal thread joint, wherein the internal thread joint is in threaded connection with the external thread joint; a thread structure, a first groove, a sealing structure, a second groove and a shoulder structure are sequentially arranged between the external thread joint and the internal thread joint in the direction parallel to the axis of the oil sleeve joint, and the sealing structure comprises a first sealing conical surface and a second sealing conical surface in sealing fit with part of the first sealing conical surface; and the first sealing conical surface is arranged on a part of the outer wall surface of the external thread joint, and the second sealing conical surface is arranged on a part of the inner wall surface of the internal thread joint. According to the technical scheme, the oil sleeve joint has excellent stable sealing performance and compression resistance under the action of combined loads.

Owner:衡阳华菱连轧管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com