Oil sleeve joint and oil sleeve assembly

A technology for oil casing and external threaded joints, applied in casing, drill pipe, drilling equipment and other directions, can solve the problems of poor resistance to composite loads, low connection strength of threaded joints, and high production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

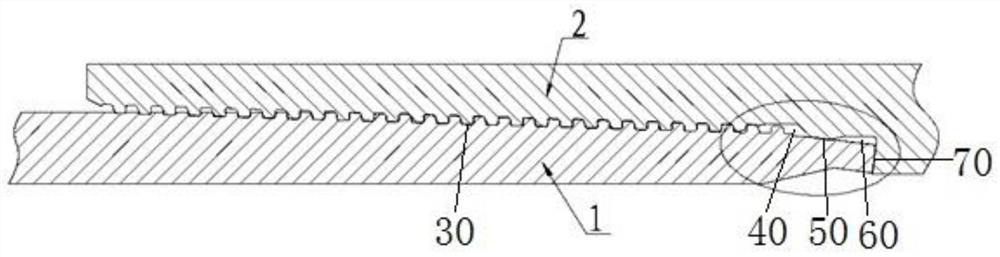

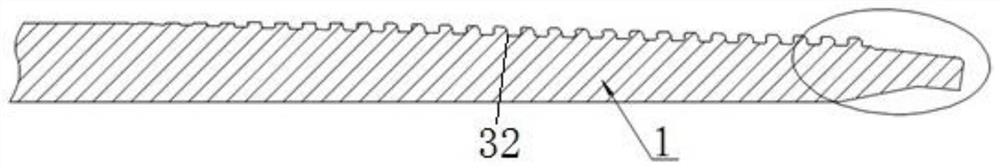

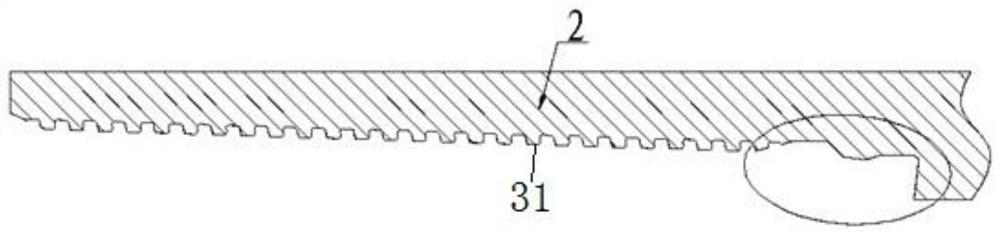

[0040] Such as Figure 1 to Figure 5 As shown, in the embodiment of the present invention, the oil-casing joint includes an externally threaded joint 1 and an internally threaded joint 2, and the internally threaded joint 2 is threadedly connected to the externally threaded joint 1; wherein, along the direction parallel to the axis of the oil-casing joint A threaded structure 30 , a first groove 40 , a sealing structure 50 , a second groove 60 and a shoulder structure 70 are sequentially provided between the externally threaded joint 1 and the internally threaded joint 2 , and the sealing structure 50 includes a first sealing tapered surface 11 And the second sealing cone surface 21 that is sealingly matched with part of the first sealing cone surface 11, the first sealing cone surface 11 is set on a part of the outer wall surface of the external threaded joint 1, and the second sealing cone surface 21 is set on a part of the internal threaded joint 2 on the inner wall.

[00...

Embodiment 2

[0075] The difference between Embodiment 2 and Embodiment 1 is that, as Figure 6As shown, in the second embodiment, the groove surface includes a first outer bevel 22 and a second cylindrical surface 23, from the thread structure 30 to the direction of the shoulder structure 70, the second sealing tapered surface 21, the first outer bevel 22, the second Cylindrical surface 23 and the fourth arc R 22 connected in sequence, and the first outer bevel 22 gradually moves away from the axis of the oil-casing joint, and there is an angle β between the first outer bevel 22 and the axis of the oil-casing joint 2 .

[0076] In the above setting, the groove surface includes a first outer slope 22 and a second cylindrical surface 23, the first outer slope 22, the second cylindrical surface 23, the fourth arc R 22 1, part of the inner shoulder surface 24 and part of the first sealing tapered surface 11 jointly form a second groove 60, the second groove 60 can store excess thread grease,...

Embodiment 3

[0081] The difference between Embodiment 3 and Embodiment 1 is that, as Figure 7 and Figure 8 As shown, in the third embodiment, the outer shoulder surface 12 includes a plurality of second outer slopes 121 connected in sequence, and the inner shoulder surface 24 includes a plurality of third outer slopes 241 corresponding to the plurality of second outer slopes. In the direction of the thread structure 30 to the shoulder structure 70, the multiple second outer slopes 121 and the multiple third external slopes 241 are gradually away from the axis of the oil-casing joint, and the adjacent two second external slopes 121 and the oil-casing joint The included angles between the axes are different, and the included angles between two adjacent third outer slopes 241 and the axis of the oil-casing joint are different.

[0082] In the above settings, the outer shoulder surface 12 of the externally threaded joint 1 is a composite shoulder surface structure composed of multiple surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com