Bush roller chain model convenient to demount, mount and close

A sleeve roller chain, a technology for easy disassembly and assembly, applied in the chain field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

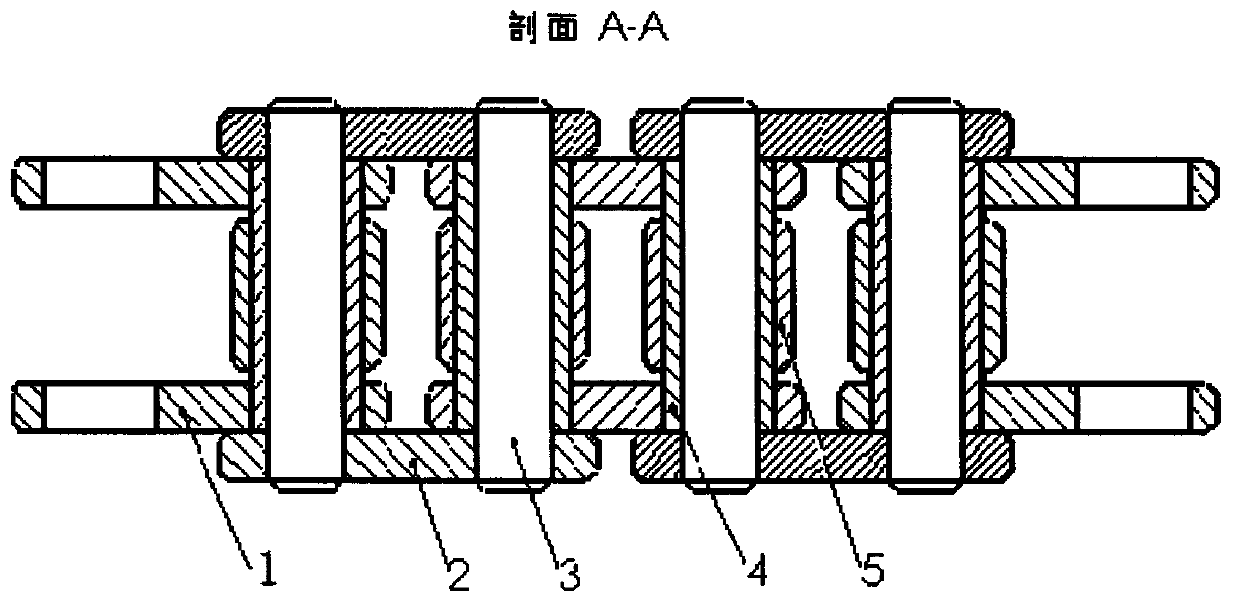

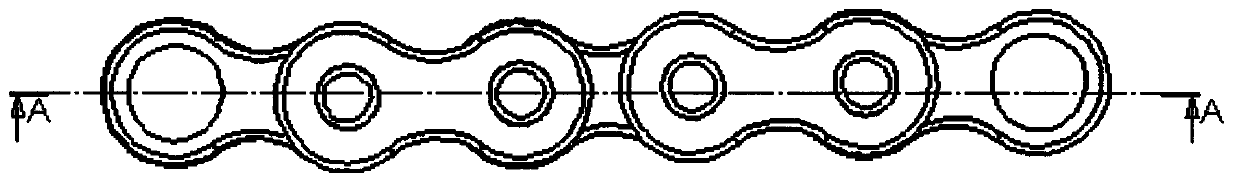

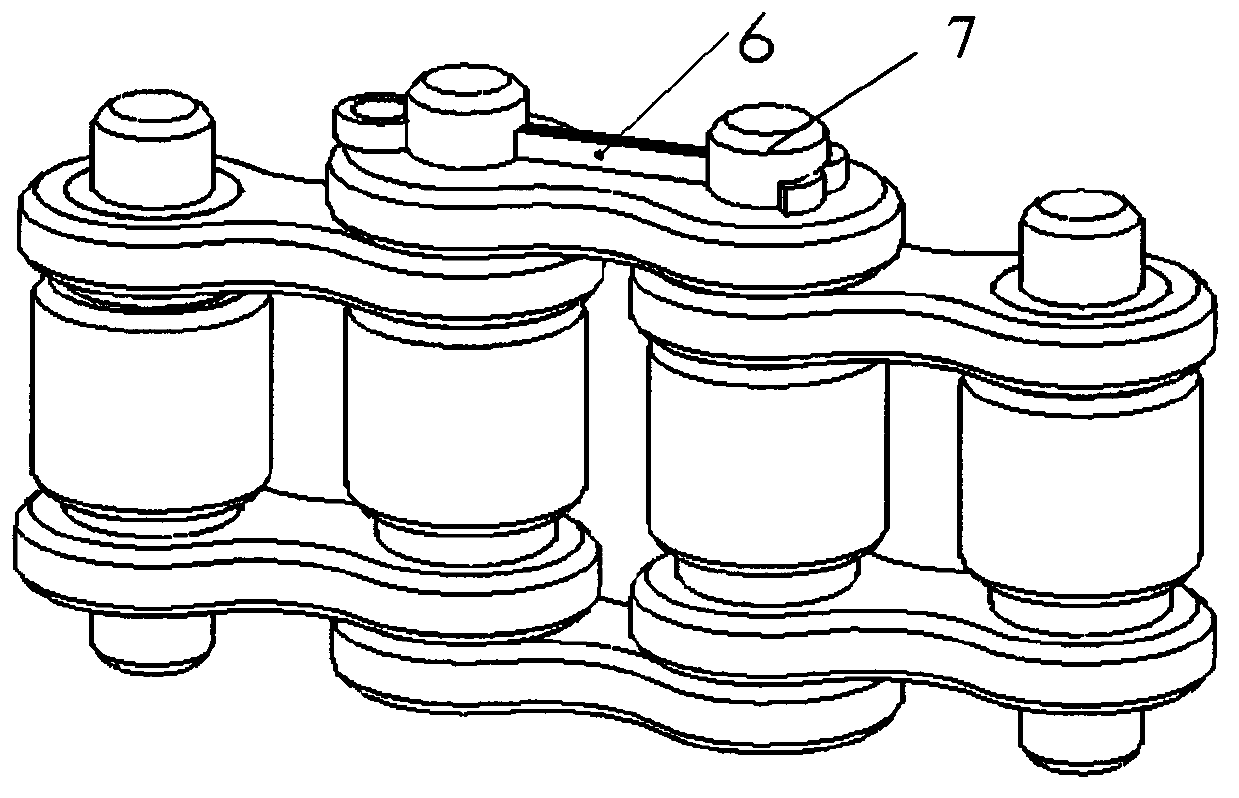

[0011] Below in conjunction with accompanying drawing, the technical scheme of a kind of sleeve roller chain model that is convenient to disassemble and close of the present invention will be further explained: its structure is shown in accompanying drawing, and it is composed of inner chain plate 1, outer chain plate 2, Pin shaft 3, sleeve 4, roller 5, cotter pin 6, open-hole type transition chain link 7, spring clip 8, slotted type transition chain link 9 and transition chain plate 10 constitute. It is characterized in that: each of the two cylindrical holes on the outer chain plate 2 is equipped with a pin shaft 3, and each of the pin shafts 3 is covered with a sleeve 4 of the inner chain plate 1 at one end, and a sleeve 4 is respectively set outside the sleeve 4. 5, the other end of the sleeve 4 is equipped with an inner chain plate 1, and the other end of the bearing pin 3 is equipped with an outer chain plate 2, so that a chain is assembled, and a chain can be formed by r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com