Patents

Literature

64results about How to "Increase the amount of interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

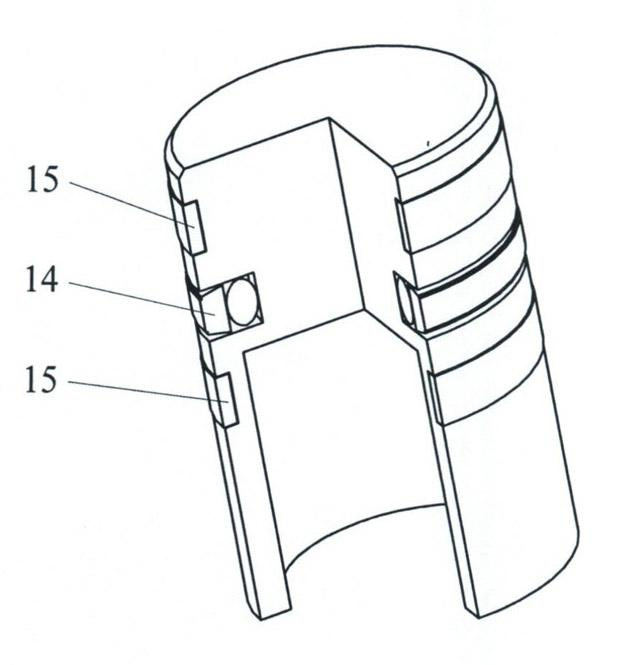

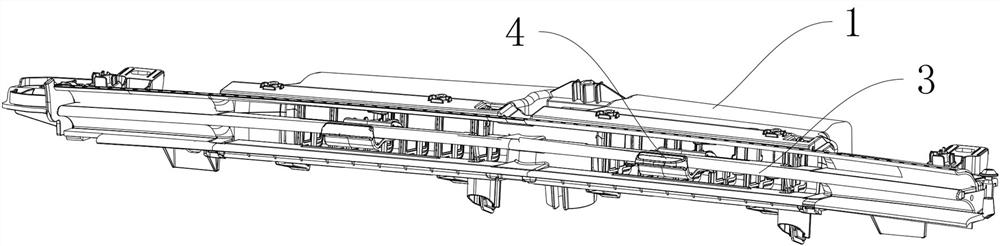

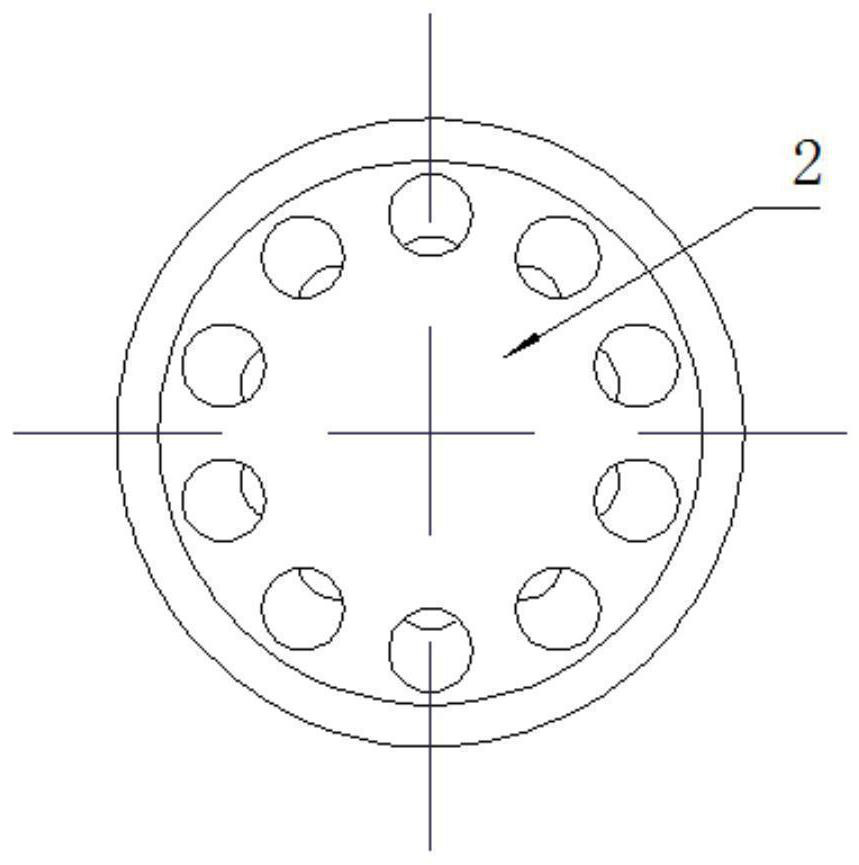

Cylindrical driven clamping type piezoelectric wriggle linear motor

ActiveCN103762887AReduce volumeReduce axial sizePiezoelectric/electrostriction/magnetostriction machinesEngineeringLinear motor

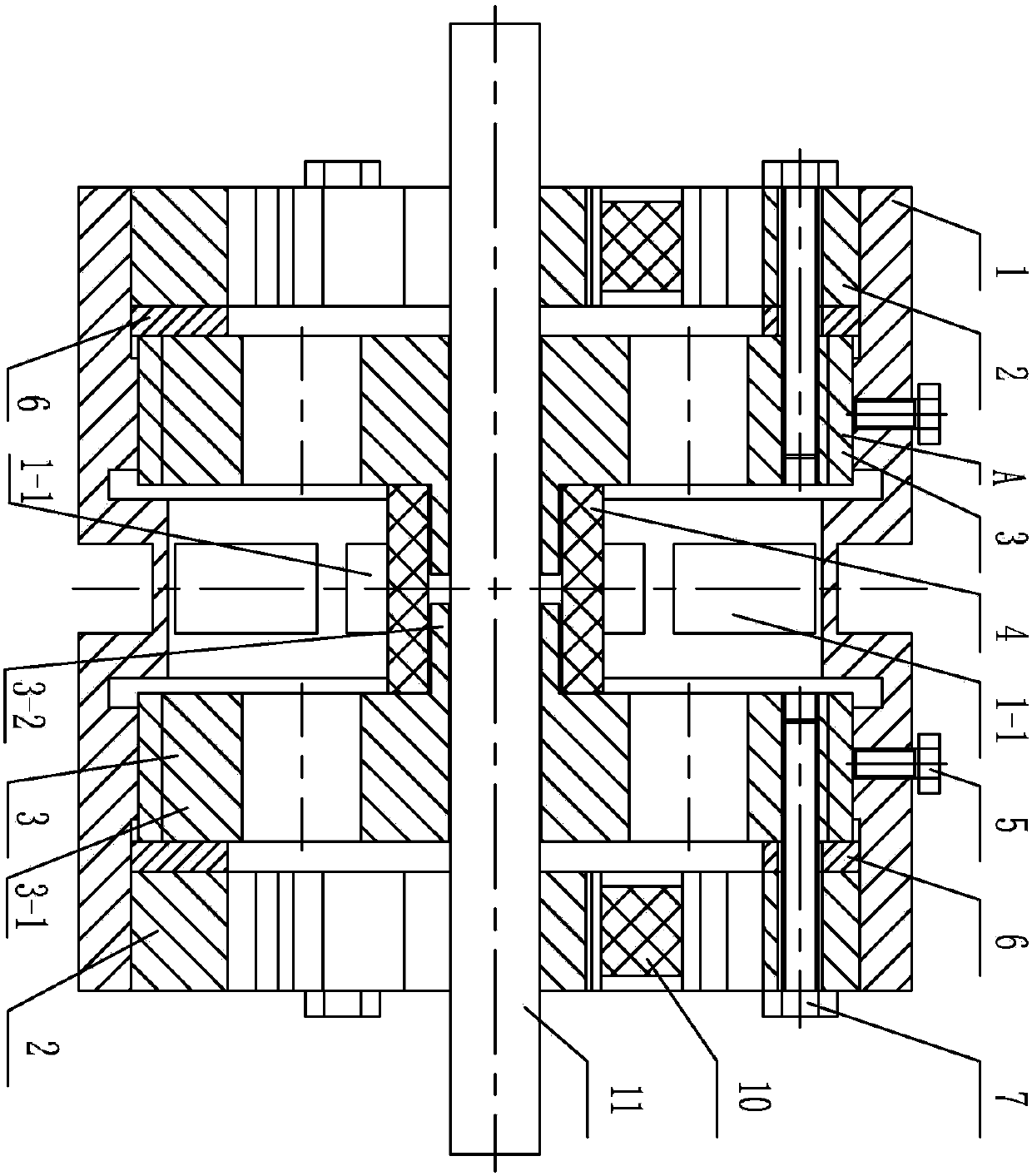

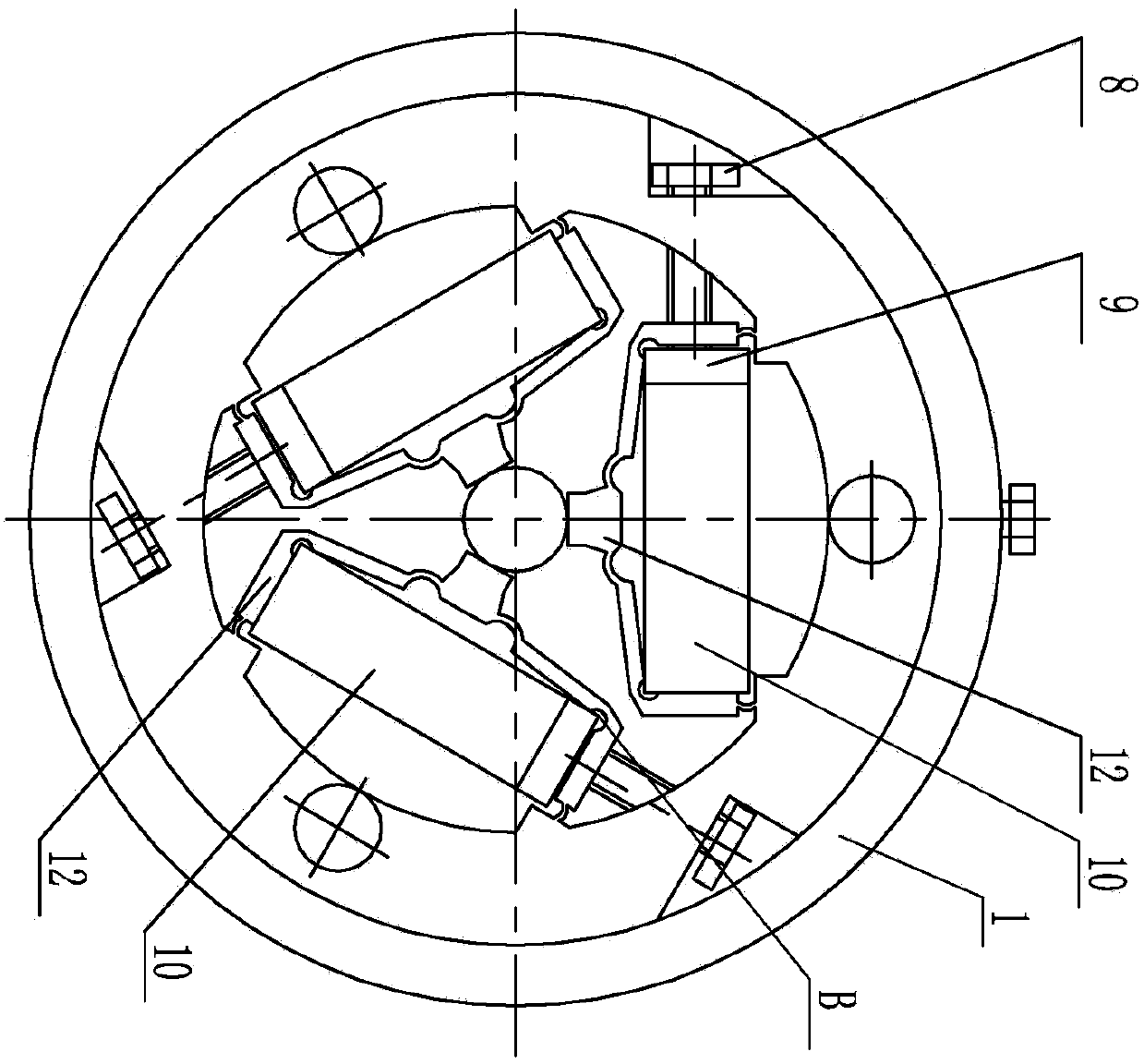

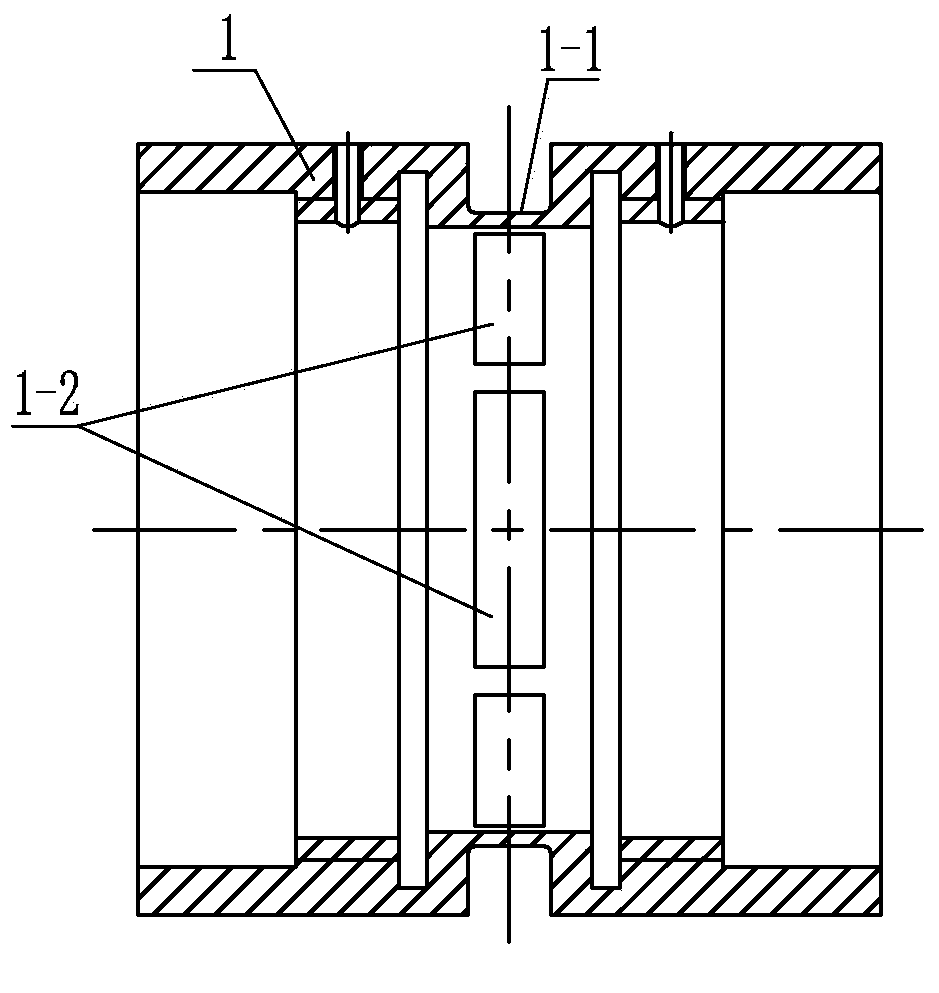

The invention relates to a piezoelectric drive device, in particular to a cylindrical driven clamping type piezoelectric wriggle linear motor to solve the problems that an existing drive clamping type wriggle motor cannot be powered off or self-locked and is not suitable for a compact, thin and long motion mechanism, and a driven clamping type wriggle motor is large in axial size and low in concentricity and control precision and needs an independent guide mechanism. The cylindrical driven clamping type piezoelectric wriggle linear motor comprises a guide rail, a drive mechanism, two annular gaskets and two sets of clamping mechanisms. The drive mechanism comprises a drive sleeve, a first piezoelectric stack and two clipping bodies. Each set of clamping mechanism comprises a clamping body, three second piezoelectric stacks and three flexible bodies. The middle of the drive sleeve is provided with the first piezoelectric stack, the clipping bodies, the gaskets and the clamping bodies are installed inside the drive sleeve from interior to exterior in a left-and-right symmetrical mode, the clipping bodies are in threaded connection with the drive sleeve, and the three flexible bodies are respectively and evenly distributed on the inner surfaces of the clamping bodies in the circumferential direction of the clamping bodies. The piezoelectric drive device is applied to the precise positioning and driving field.

Owner:HARBIN INST OF TECH

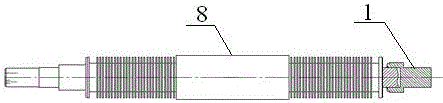

Production process of insulation pull rod

The invention discloses a production process of an insulation pull rod. The production process comprises an insulation pipe blank pipe curing and molding phase, an insulation pipe blank pipe machining phase and a connector bonding phase, wherein in the insulation pipe blank pipe curing and molding phase, fiber materials are dried in vacuum; resin is impregnated under a vacuum environment and the fiber materials are subjected to primary curing; after de-molding, the fiber materials are subjected to secondary curing to obtain an insulation pipe blank pipe; the insulation pipe blank pipe is machined; the insulation pipe blank pipe is bonded with a connector by adopting a heat-expansion and cold-contraction principle; and finally, the insulation pull rod is obtained. According to the production process of the insulation pull rod, the technical defects of a production process of the insulation pull rod that air gaps, micro-cracks, concentrated stress and layering are easy to generate, the connection of the connector is not reliable, the air gaps are easy to generate in a bonding layer of the connector and the insulation pipe and the like are overcome.

Owner:MOTIC XIAMEN ELECTRIC GRP

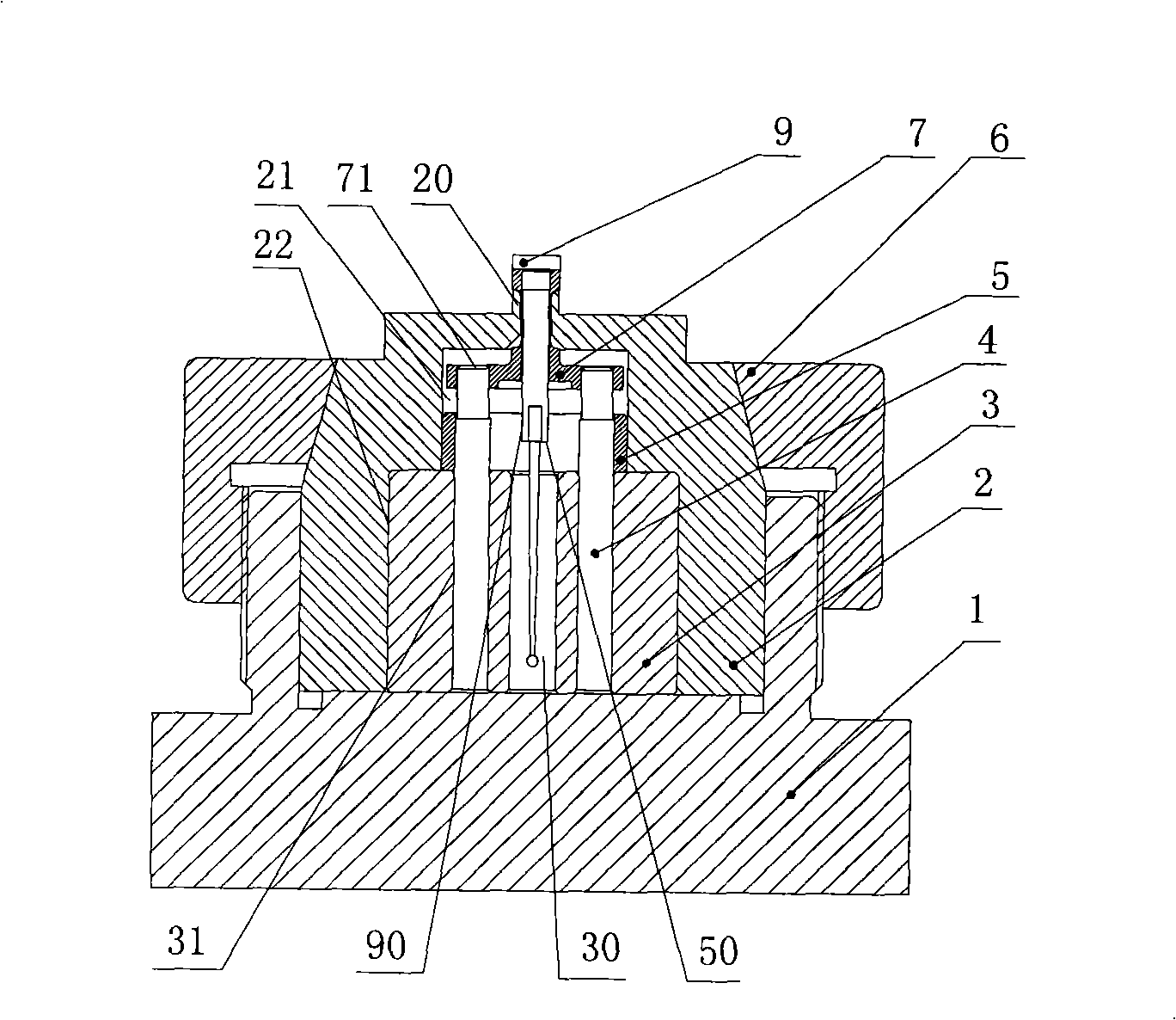

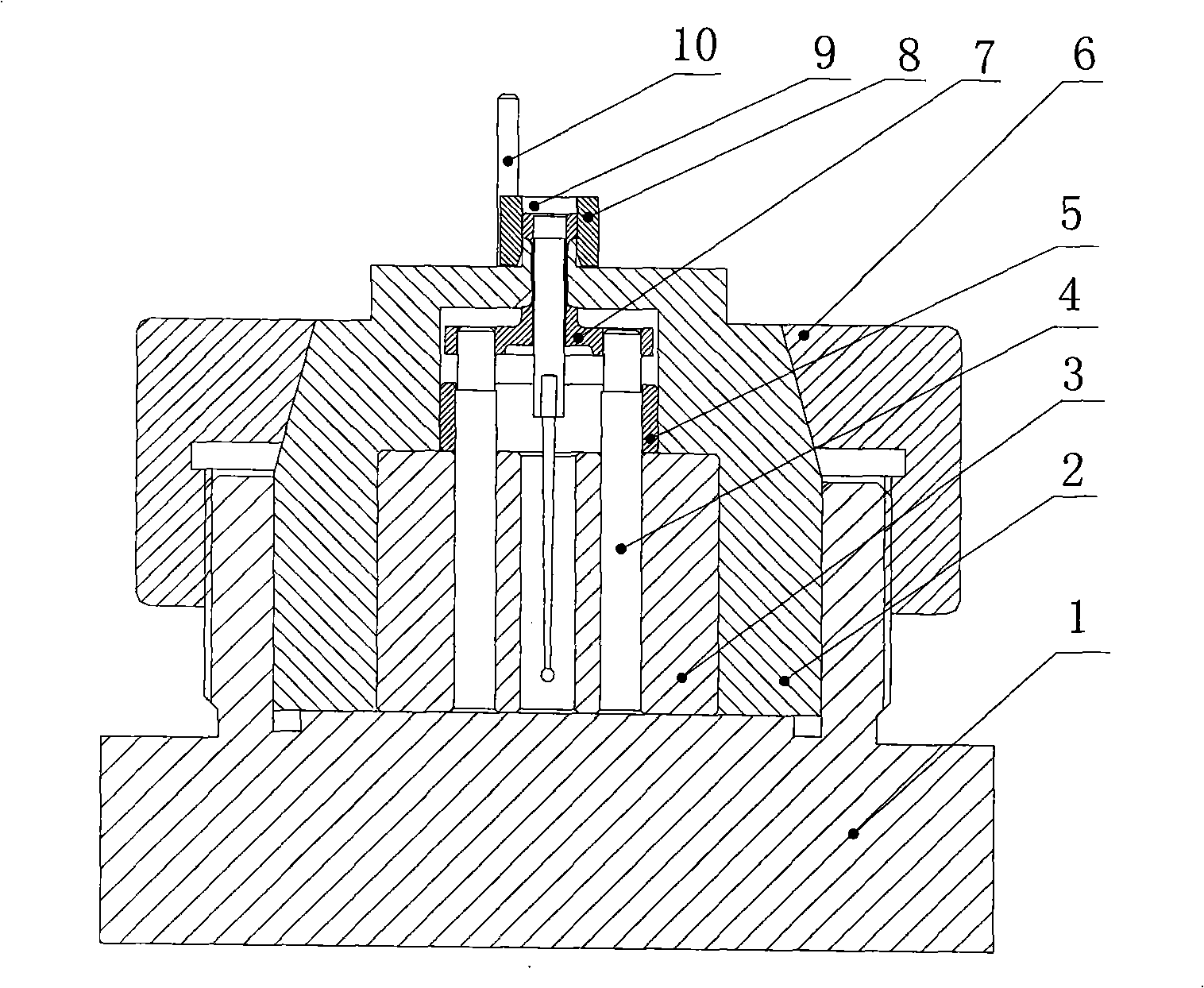

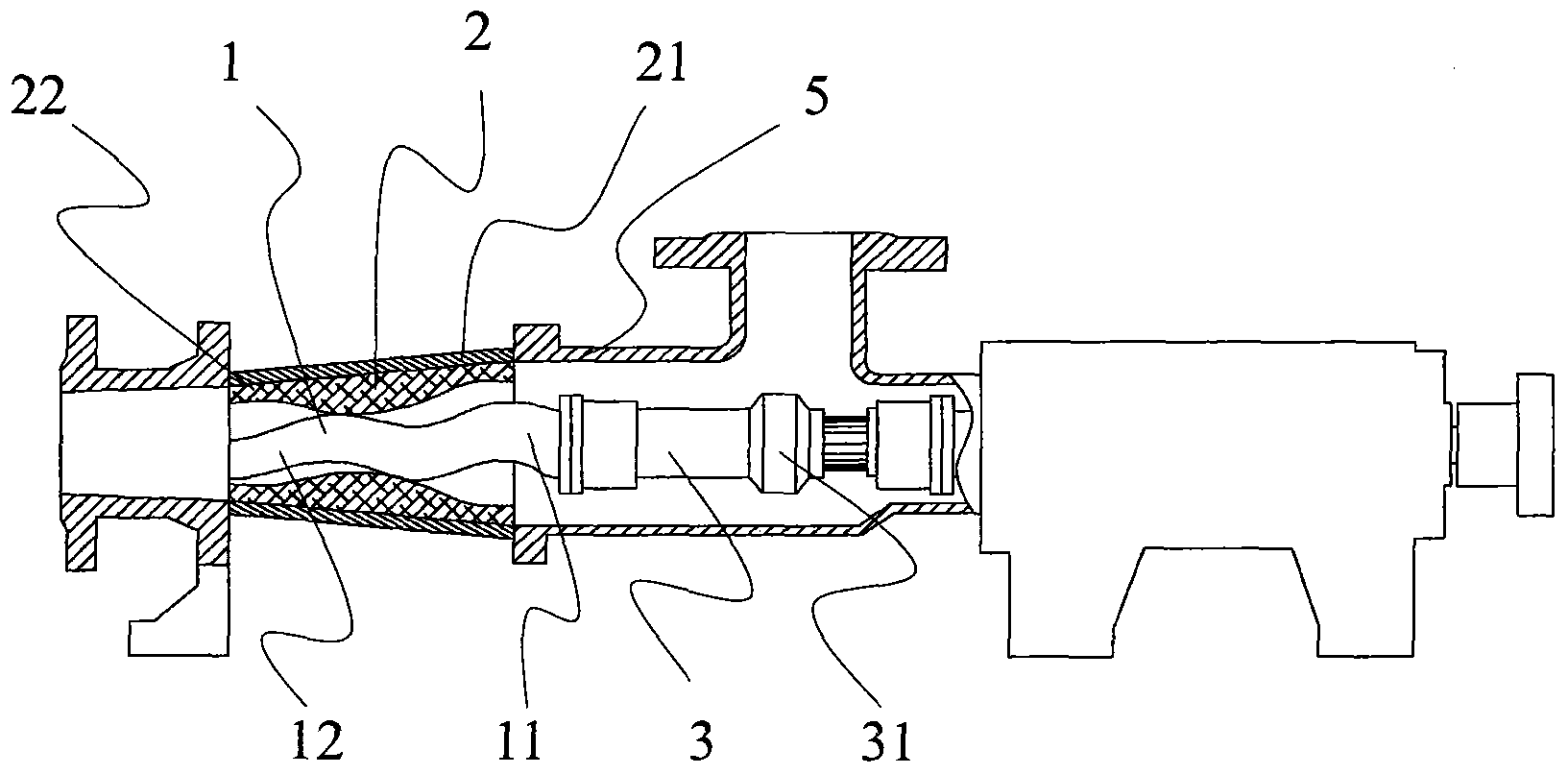

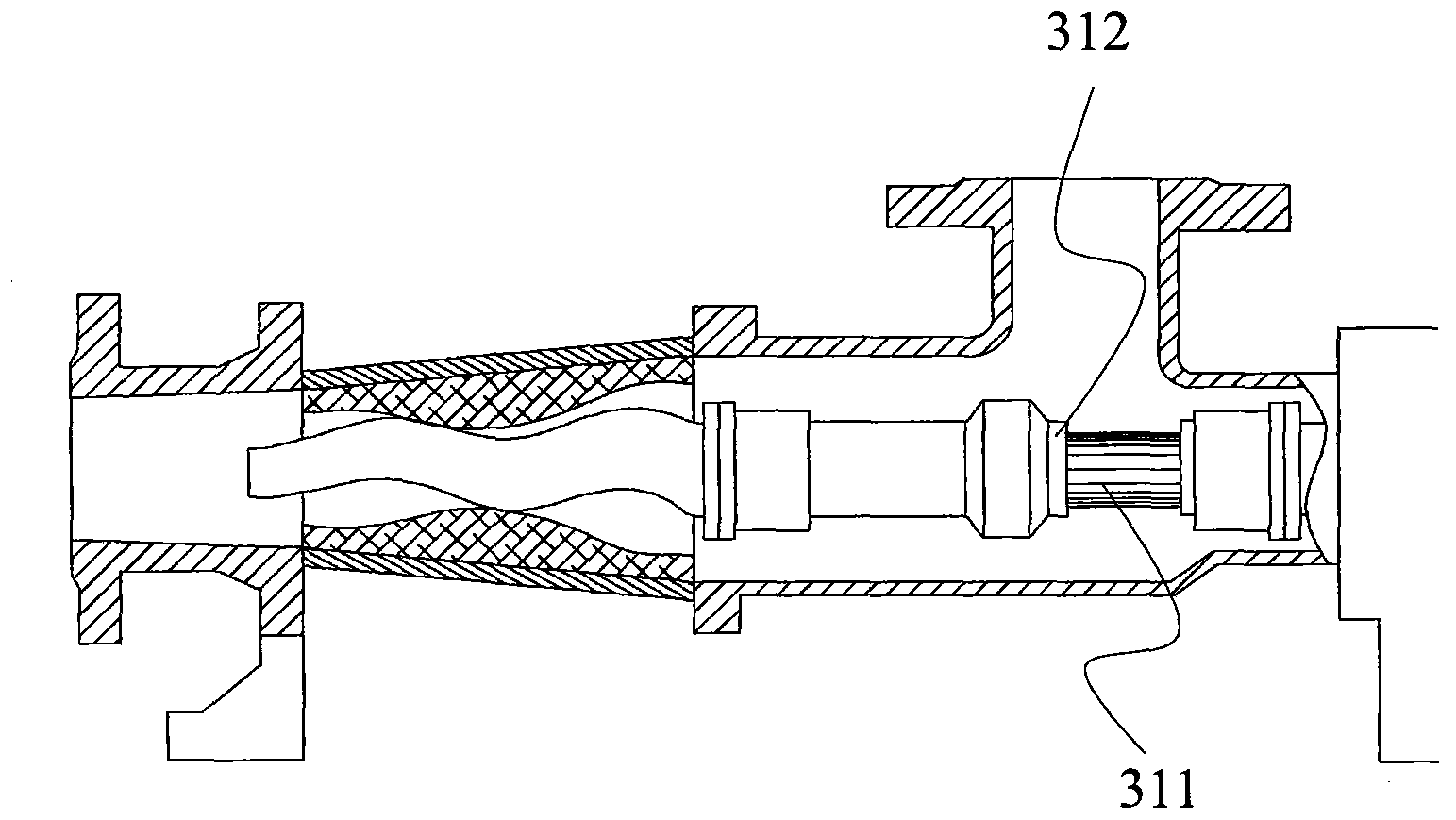

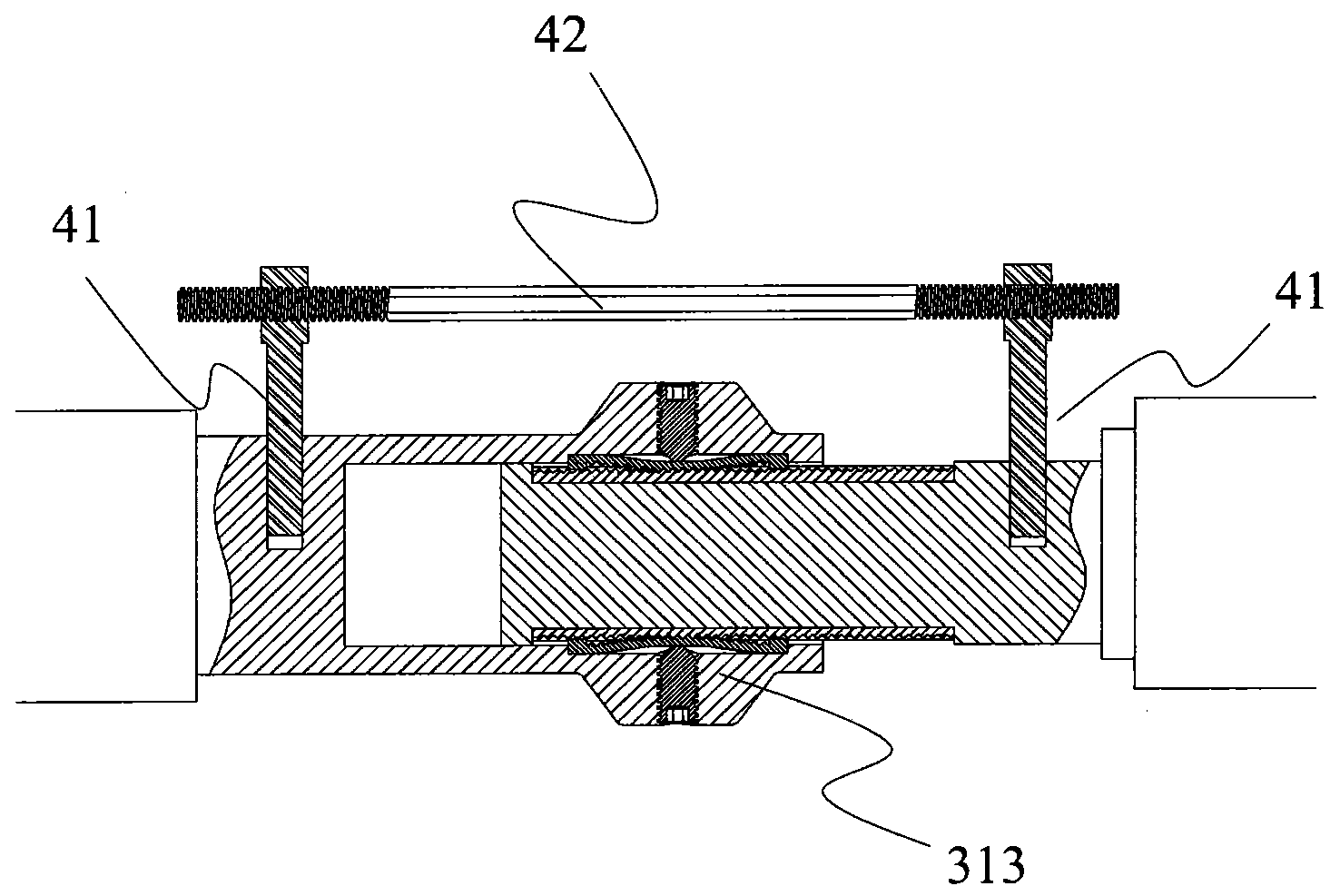

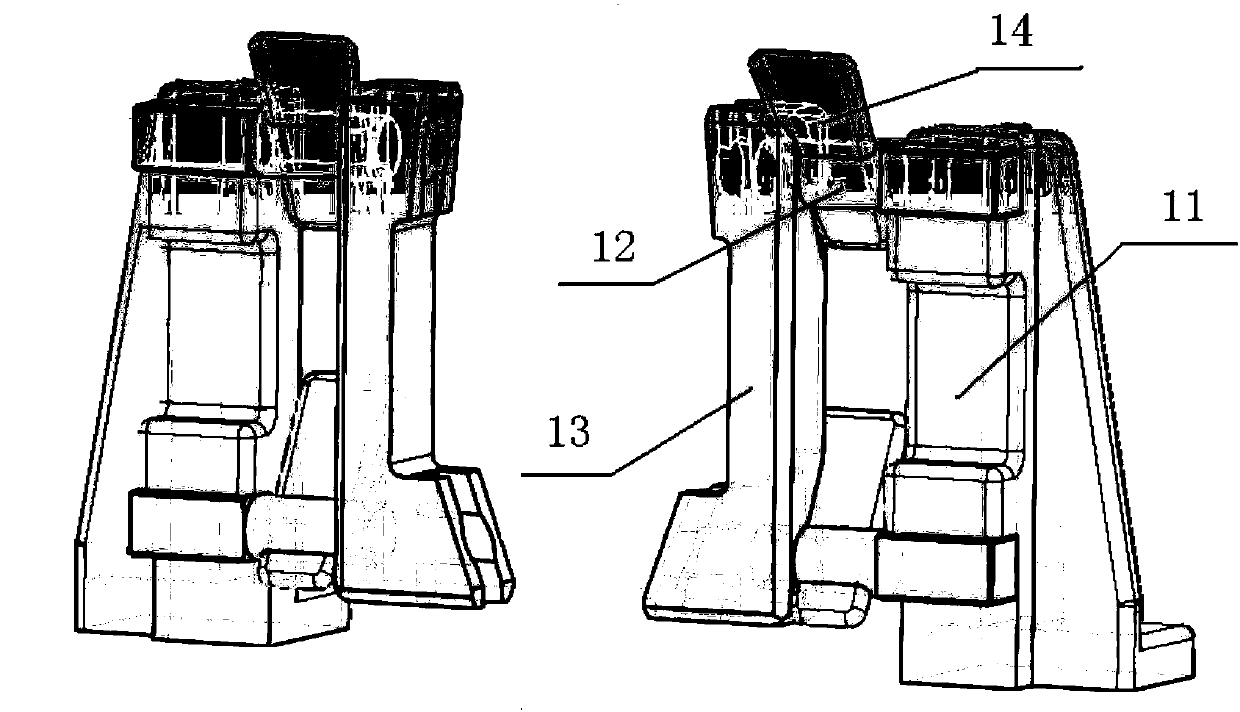

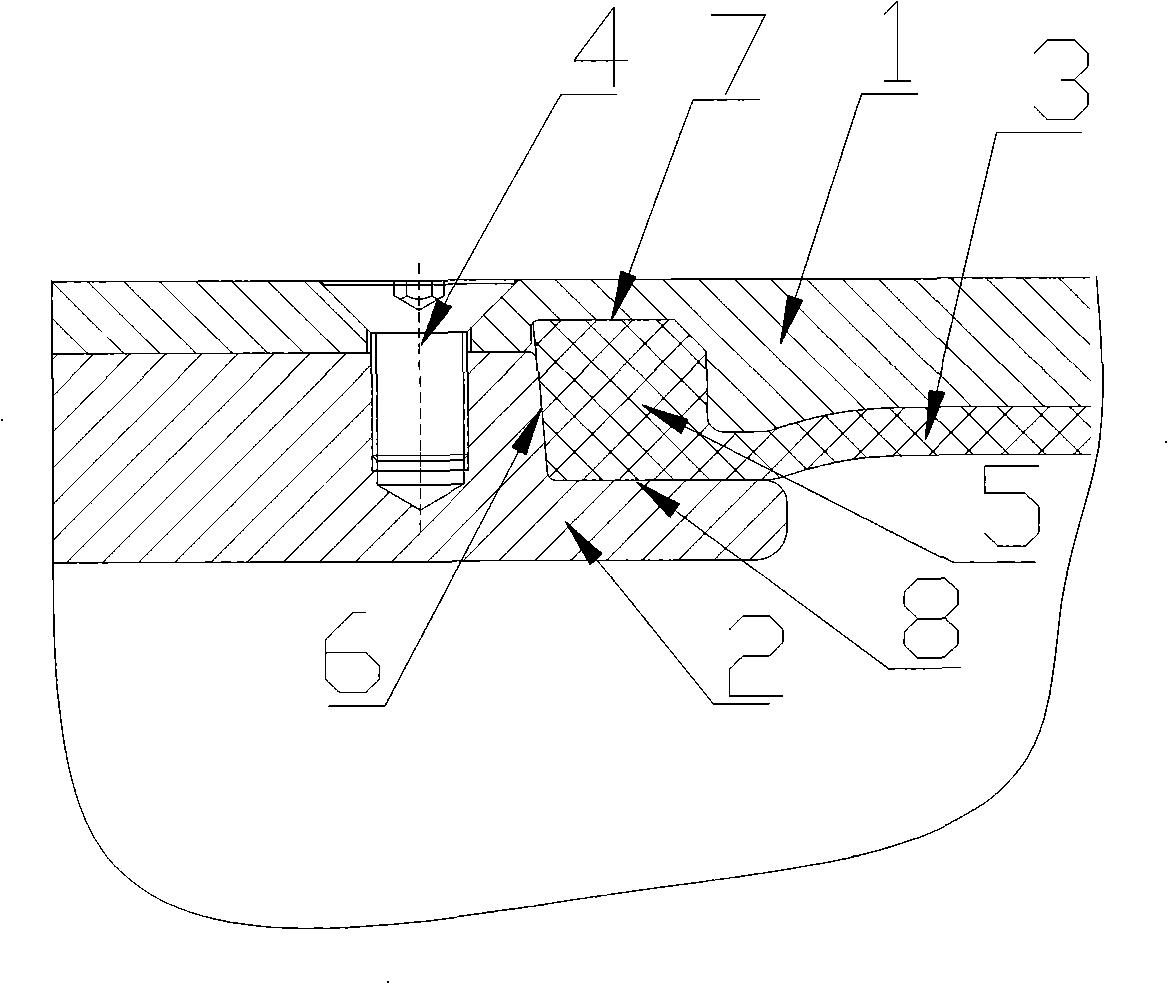

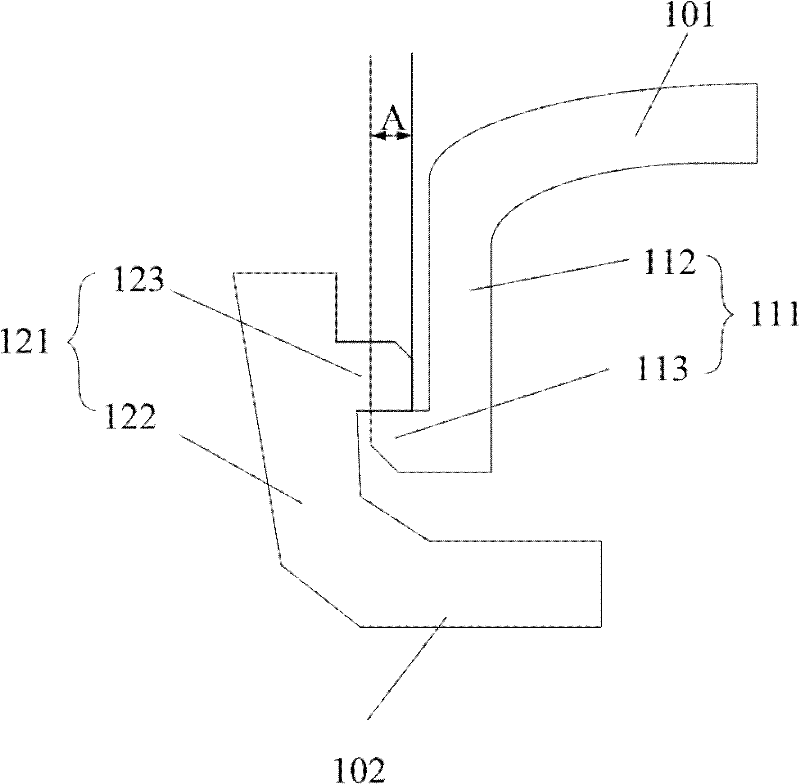

Assembly fixture of armature assembly for electrohydraulic servo valve

InactiveCN101310932AAchieve reliabilityImprove shape and position accuracyServomotor componentsWork holdersEngineeringLocknut

The invention discloses an assembling jig used in an armature component of an electrohydraulic servo valve. The armature component consists of a baffle feedback rod, a tubular spring with a shaft shoulder and an armature; the assembling jig comprises a mounting base, two left and right blocks, a positioning shaft and two first positioning pins used for guiding the tubular spring, a baffle positioning sleeve, a locknut and two second positioning pins used for positioning the armature. The assembling jig used in the armature component of the electrohydraulic servo valve of the invention is adopted, namely,, by virtue of the left and right blocks, a positioning hole on the positioning shaft, the positioning pins of the tubular spring and the positioning pins of the armature, the assembling jig can accurately position the working directions of a baffle surface of a baffle feedback rod, a mounting hole of the tubular spring and the armature, thus realizing comparatively high the accuracy of form and position. The assembling jig can realize parallelism of the work plane of the armature and the bottom face of the tubular spring and also can realize the larger magnitude of interference and the reliability of assembly when in use.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

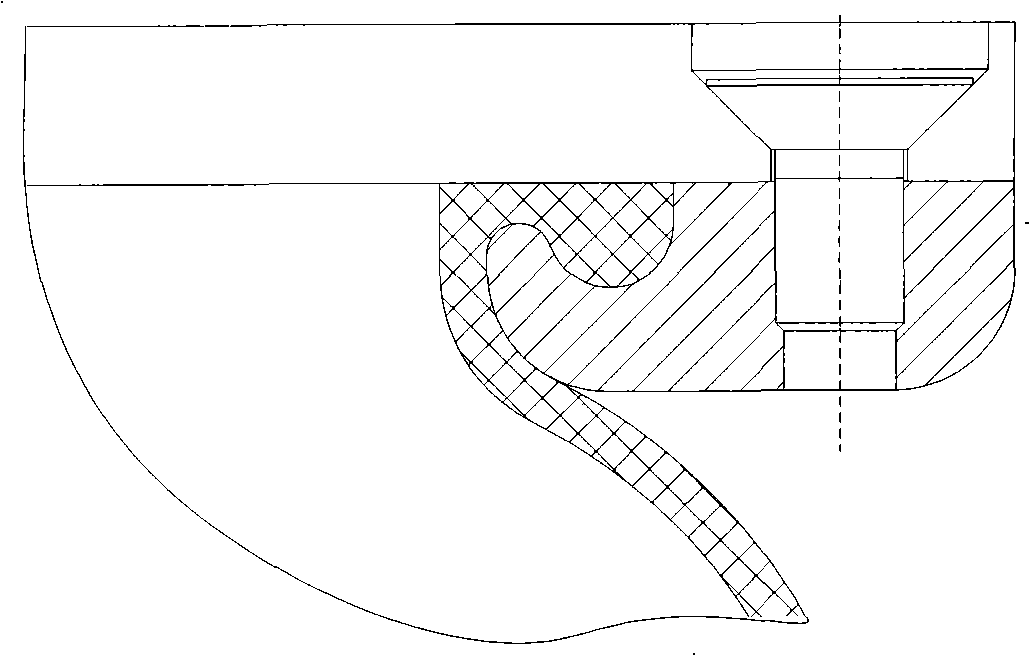

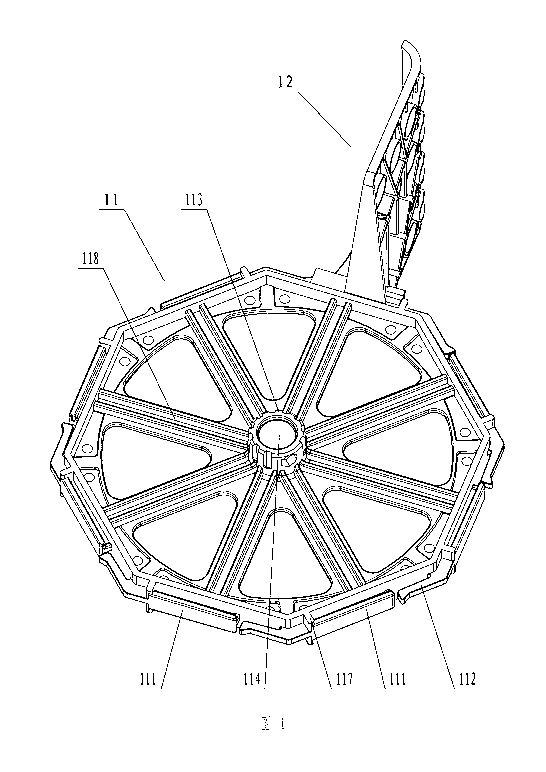

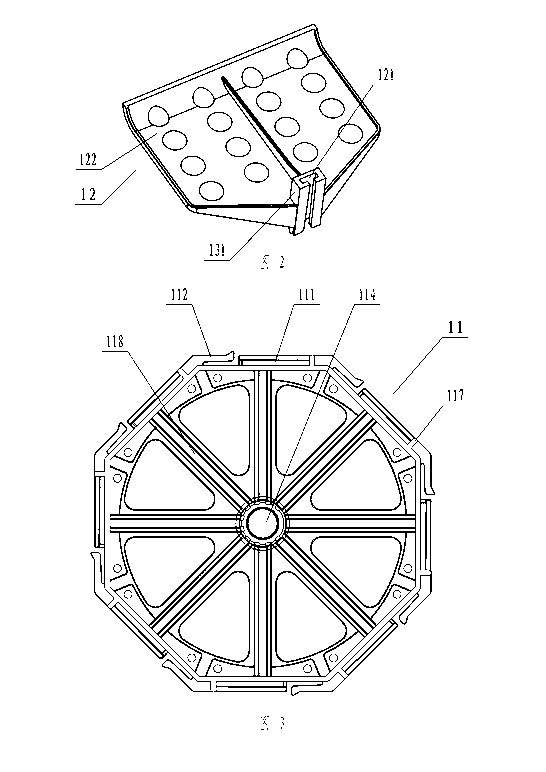

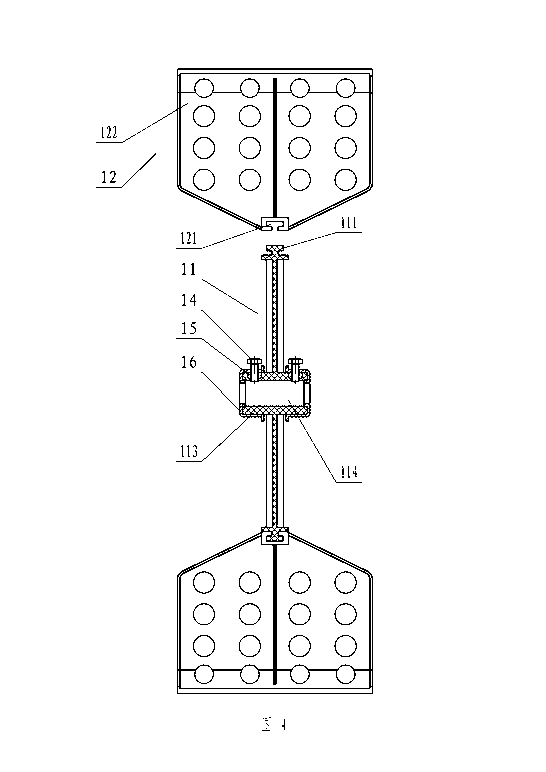

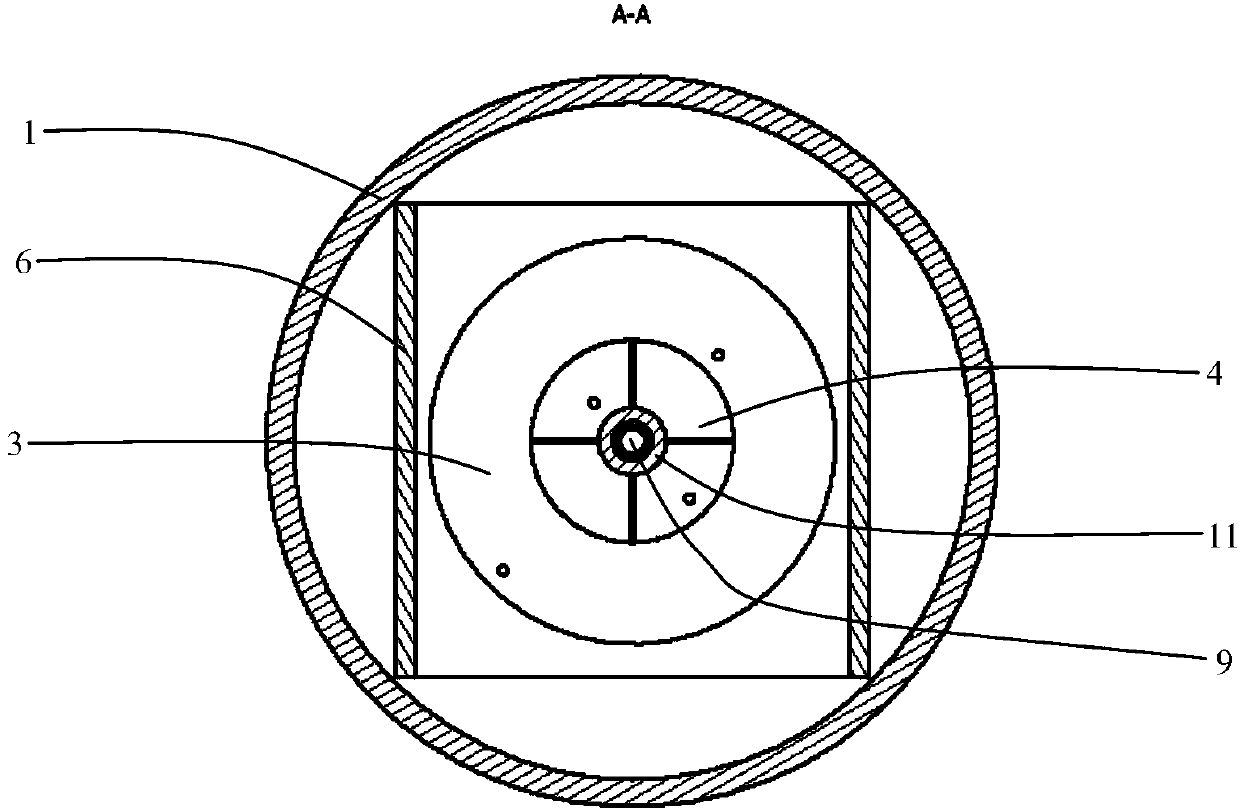

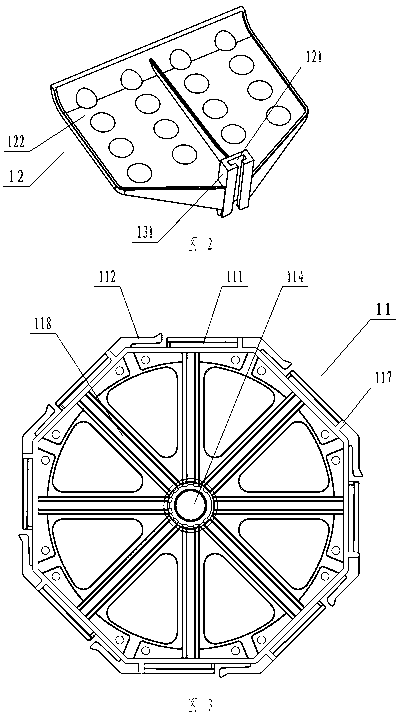

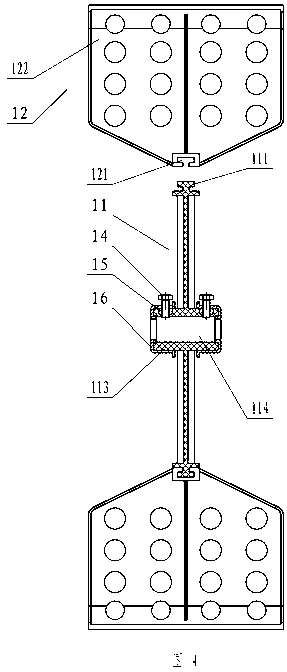

Waterwheel-type aerator

ActiveCN102687686AOutstanding FeaturesHighlight significant progressClimate change adaptationWater aerationImpellerDrive shaft

The invention belongs to an aquaculture machine and relates to a waterwheel-type aerator. The waterwheel-type aerator comprises an impeller, a floating body, a main machine, a transmission shaft and a bearing seat, wherein the floating body is connected by virtue of a thin-wall stainless steel square tube; the square tube is provided with holes through which bolts cab pass; more than two floatingboats are combined by passing the bolts through square tube holes so as to form the floating body; a reinforcing plate is arranged above the square tube holes; two sides of the floating boats are provided with grooves and the bolts are fixed in the grooves; the impeller is composed of a blade and an impeller disc; the impeller disc is provided with a retaining mechanism which is molded by injection; one end of an elastic retaining strip and the straight edge of the impeller disc are molded into a whole body by virtue of injection and the other end of the elastic retaining strip is suspended; and after the blade is assembled in place, the retraining strip is reset and the blade is prevented from being moved out.

Owner:ZHEJIANG FORDY MACHINERY

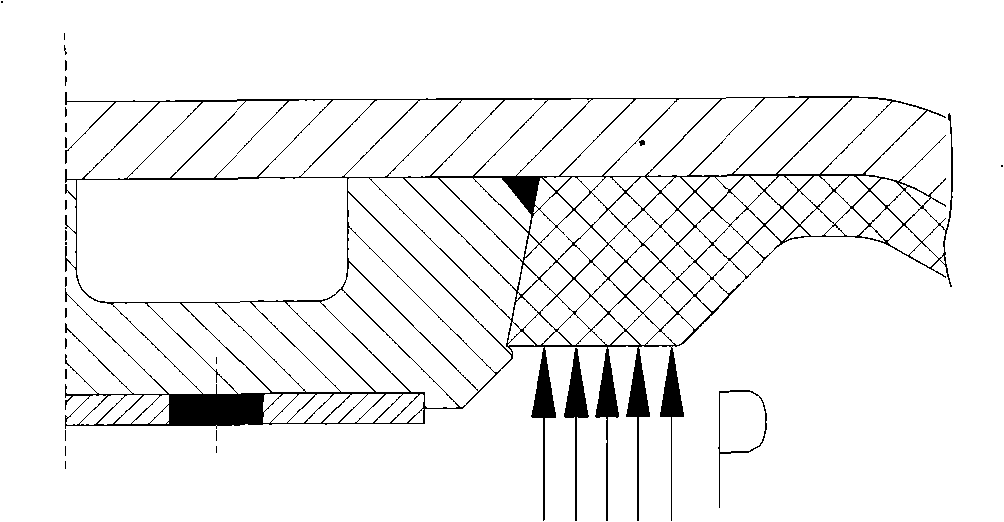

Wear-resistance high-pressure single-screw pump

InactiveCN104047846AIncrease the amount of interferenceRotary piston pumpsRotary piston liquid enginesHigh pressureWear resistance

The invention relates to a wear-resistance high-pressure single-screw pump. An existing single-screw pump has the problems that the rotor interference is reduced, the pressure bearing capacity of the pump is lowered and the leakage amount is increased because a stator rubber bush is easy to wear during usage. The invention discloses an improved scheme, in which a screw and a bush cavity of the single-screw pump are remodel to a cone like shape with a wide feed end and a thin discharge end, and a position adjusting device is arranged on a connecting part between the screw and a bush; when the screw and the bush are worn, the screw moves towards the discharge end so as to increase the interference among the rotors, namely compensate the wear; the screw and the bush are meshed with each other to form a sealed cavity the volume of which is gradually reduced during transverse motion, so that the pressure is increased; the length of the screw bush is lengthened by multiple times of the screw pitch and the wear is equivalent to connecting multiple screws in series, and thus the maximum pumping pressure can be greatly increased.

Owner:无锡市恒烽水煤浆有限公司 +1

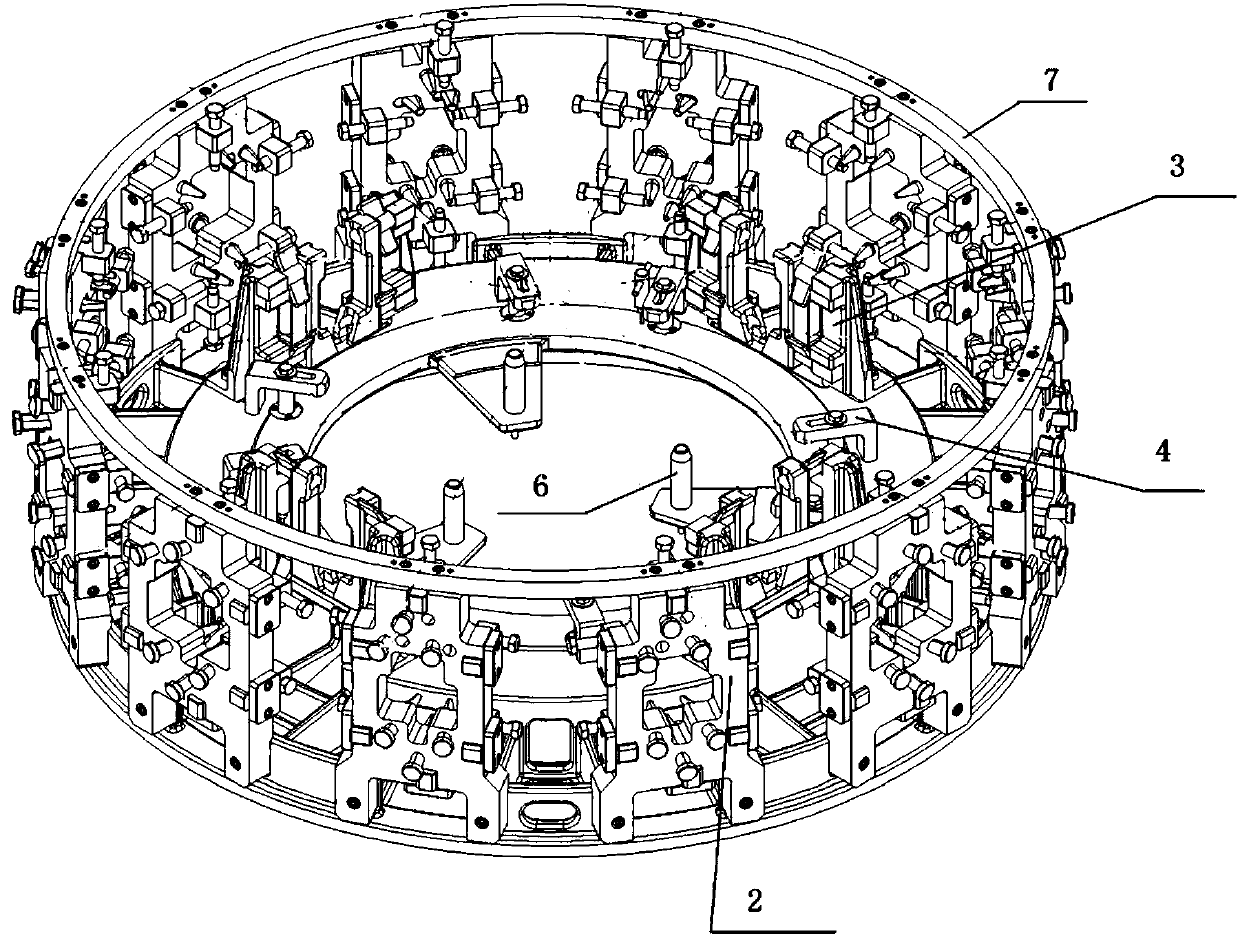

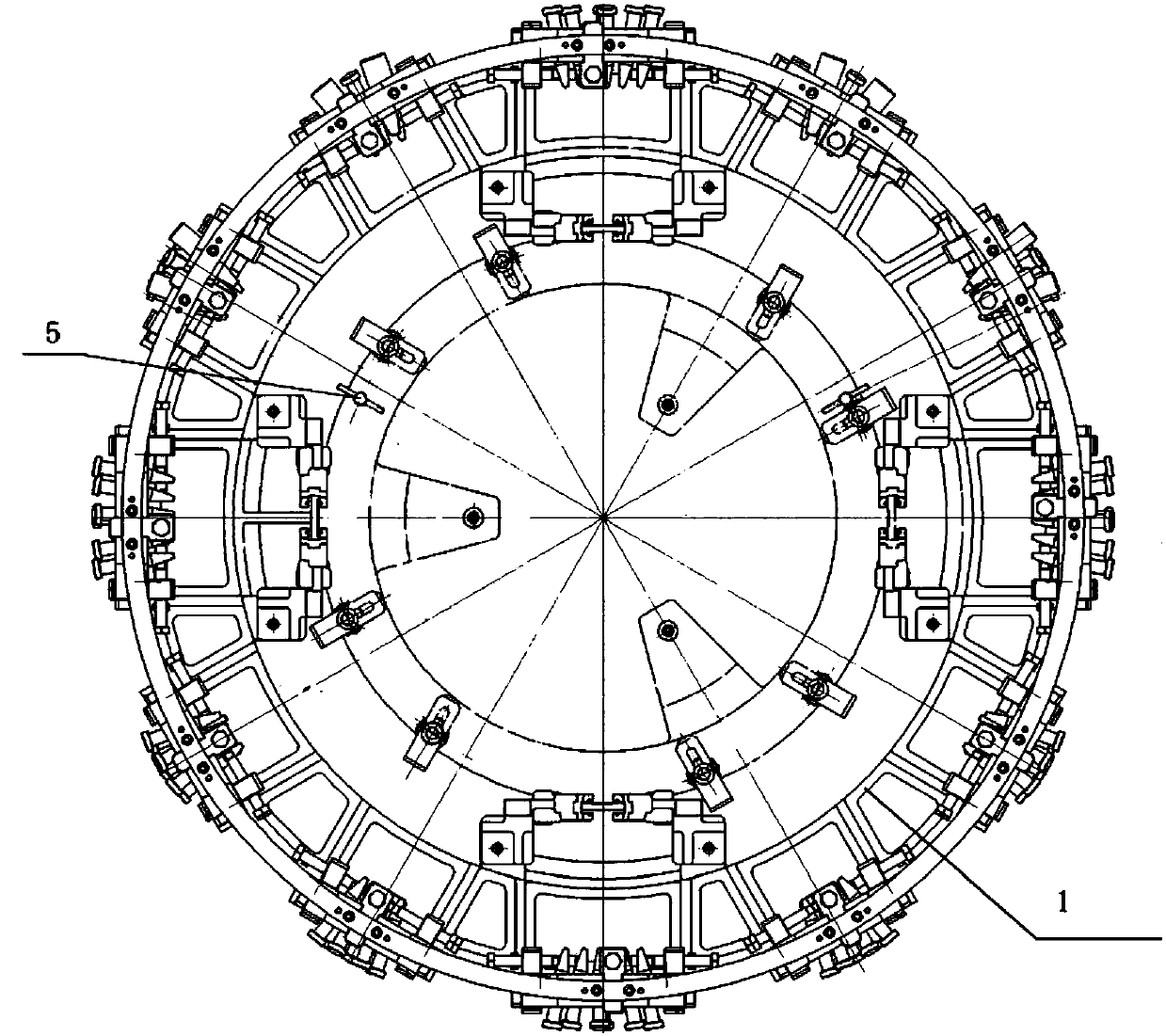

Tool capable of controlling heat treatment distortion of high pressure turbine static case

ActiveCN107739803AEasy to take outIncrease the amount of interferenceFurnace typesHeat treatment furnacesHigh pressureTurbine

The invention discloses a tool capable of controlling the heat treatment distortion of a high pressure turbine static case. The tool structurally comprises a base plate, no less than 2 first kind of locating pins used for locating the case and positioned on the base plate, no less than 3 axis seats used for locating the axis of the case, no less than 4 pressing plate components used for tightly pressing and fixing the case, connecting plate fixing devices used for fixing blade connecting plates, blade body fixing devices used for fixing support plate blade bodies and a top ring used for connecting all the connecting plate fixing devices integrally, wherein the number of the connecting plate fixing devices is the same as that of the blades; and the number of the blade body fixing devices isthe same as that of the support plate blades. With the adoption of the tool for controlling the heat treatment distortion of a fan framework component, the problems as follows are solved: a constrainbetween the tool and the parts has gaps, the constraining function is ineffective or the constraining force is too large, so that the parts get stuck in the tool and cannot be taken out easily.

Owner:CHENGDU ENGINE GROUP

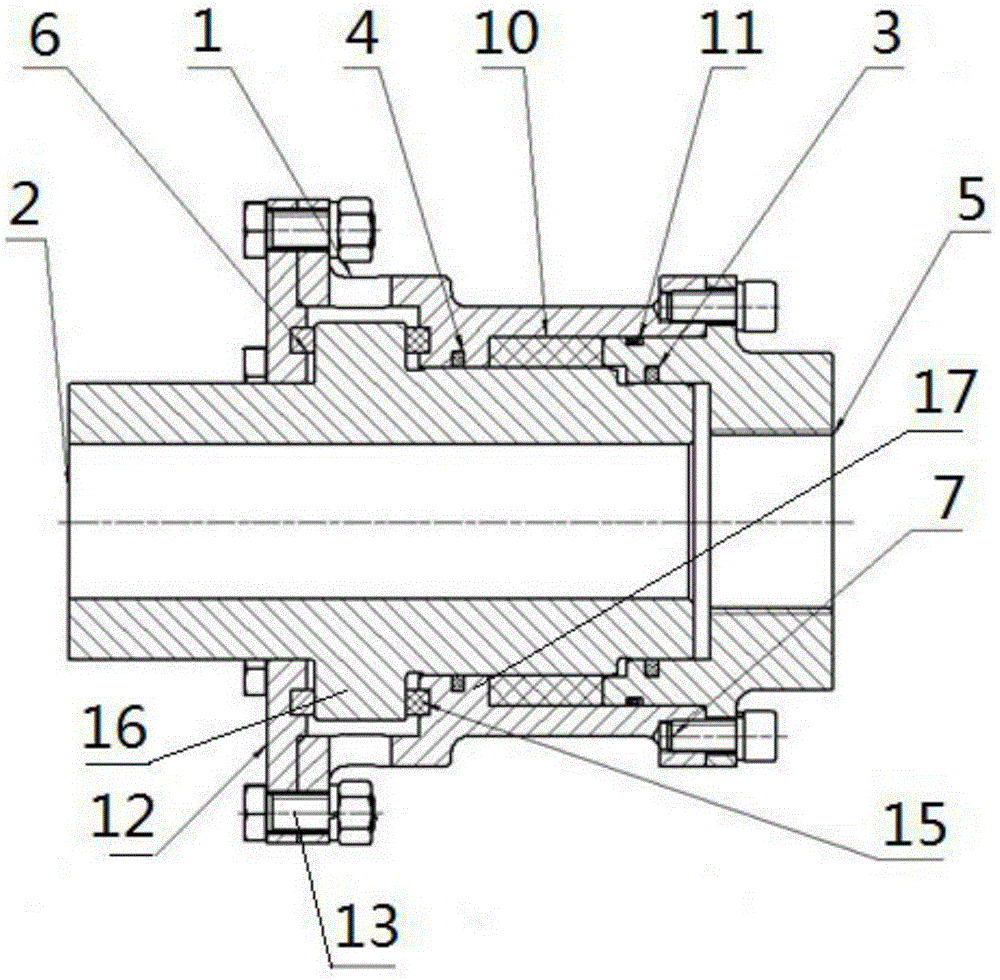

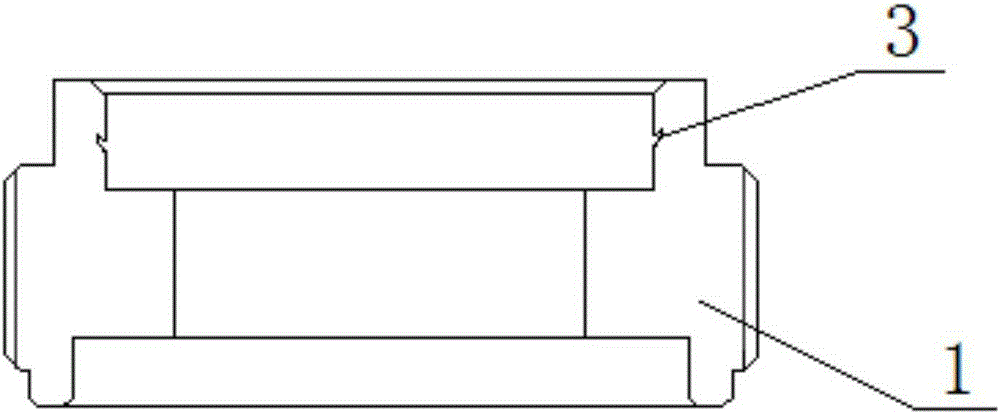

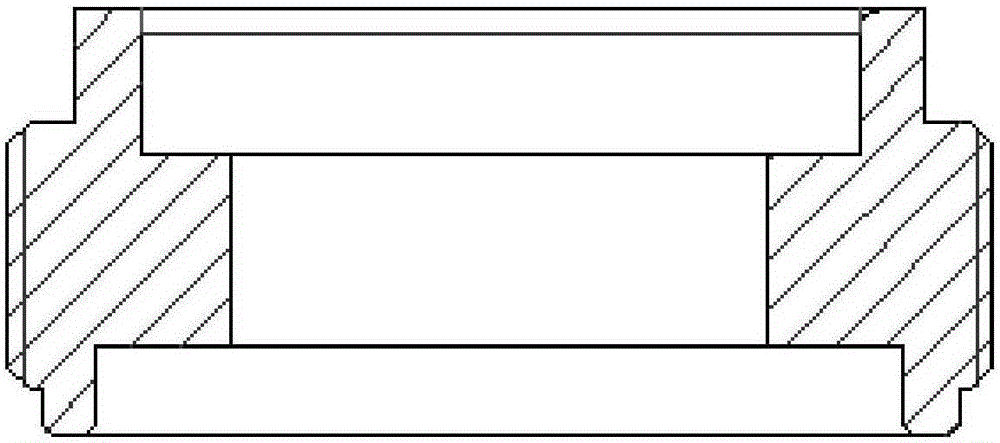

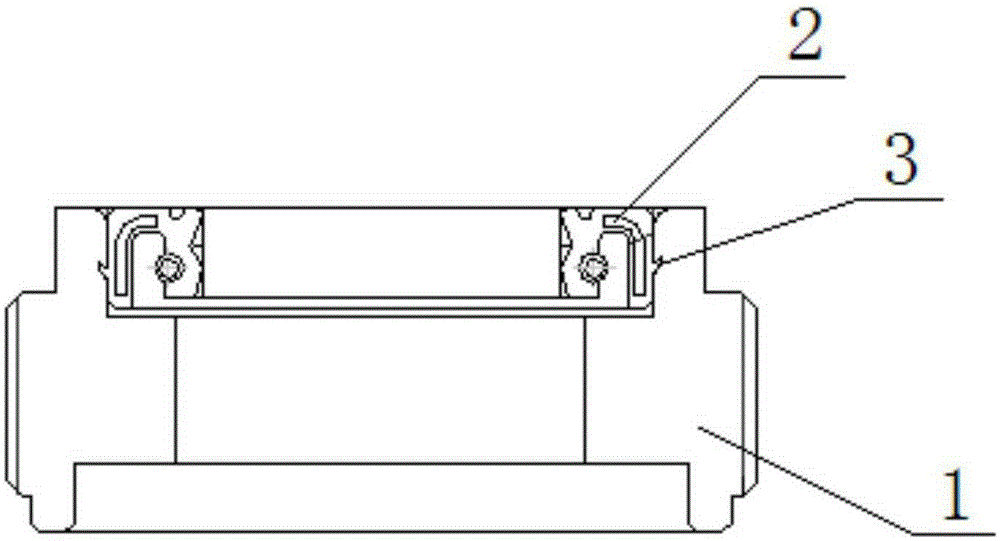

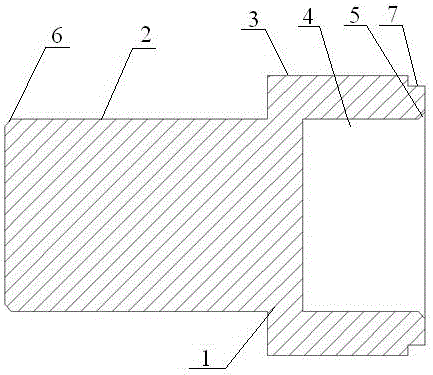

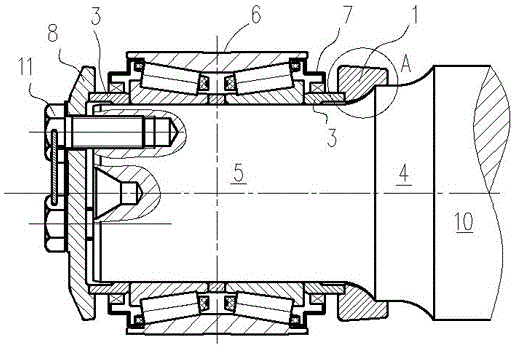

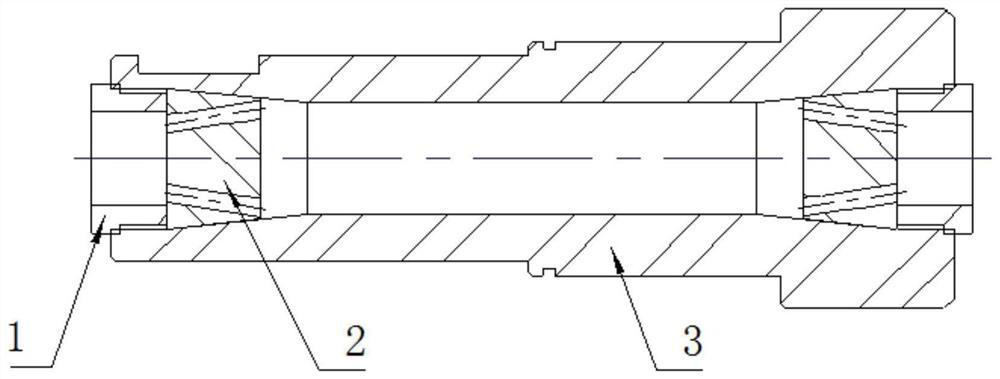

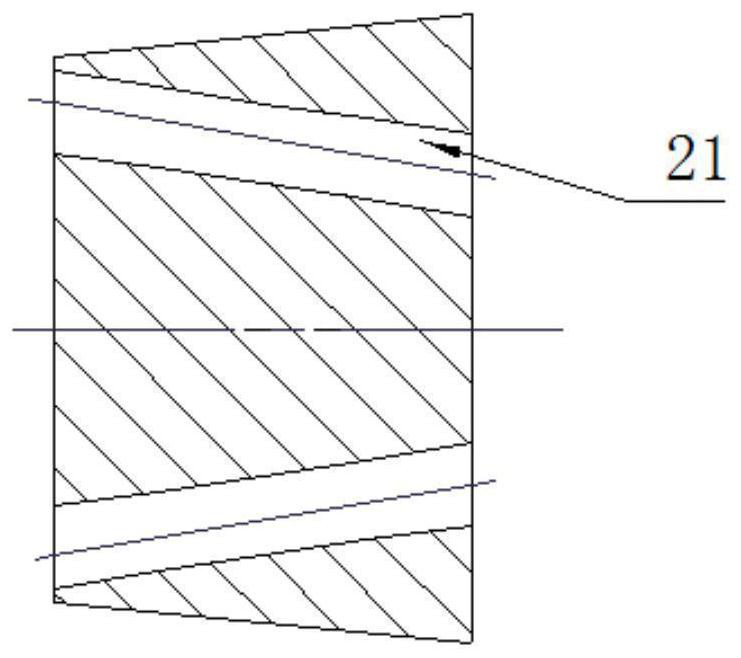

High-speed spindle with tapered hole capable of being automatically locked

InactiveCN102513553AImprove joint stiffnessGuaranteed stiffnessMetal-working apparatusInterference fitHydraulic cylinder

The invention provides a high-speed spindle with tapered hole capable of being automatically locked. The high-speed spindle comprises a spindle, an expansion wall, hydraulic cylinders and an oil path and is characterized in that: an inner hole at the shaft end of the spindle is fixedly linked with the expansion wall with the tapered hole through interference fit; two oil cavities are disposed on the outer surface of the expansion wall; a liquid medium is filled in the oil cavities; two sets of the hydraulic cylinders consisting of a cylinder body component and a piston are symmetrically arranged on the spindle with respect to the axis of the spindle; the cylinder body components are communicated with the oil cavities through the oil path; and a spring is arranged at the bottom of each piston. The high-speed spindle disclosed by the invention has the advantages that: the magnitude of the interference fit between the tapered surface of the knife handle and the tapered hole of the spindle is subjected to automatic compensation. Furthermore, the compensation amount is increased when a rotation speed is increased. The linkage rigidness and the positioning precision of the knife handle and the spindle are ensured at any rotation speed, and the limit rotation speed is improved. The deformation coaxiality generated by the expansion wall is very high, so that the good radial position precision can be ensured. The liquid medium can supply great damping, the power absorbers consist of the piston and the spring, so that the two have vibration absorption effects on the spindle.

Owner:YANSHAN UNIV

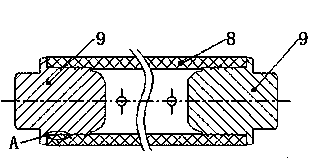

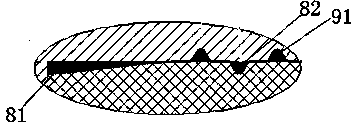

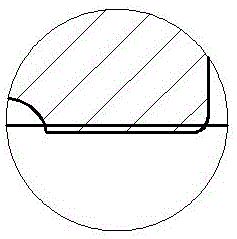

Sub-mouth sealing mode and device of air spring

The invention relates to a sealing way of the tire bead on an air spring and a device thereof; the tire bead of a rubber balloon is placed in a tire bead groove which is formed by the combination of an upper cover plate and a friction plate; the tire bead of the rubber balloon is placed in the tire bead groove which is formed by the upper cover plate and the friction plate; and then sealing for the tire bead of the rubber balloon is formed by the joint compression of the upper cover plate and the friction plate. The sealing structure for the tire bead of the rubber balloon is as follows: a groove-shaped gap is arranged on the upper cover plate; a cone-shaped gap is also arranged on the friction plate; the groove-shaped gap on the upper cover plate is combined with the gap on the friction plate to form a cone-shaped cavity with an opening at one edge; the upper cover plate and the friction plate are connected together by a fastener. The tire bead of the rubber balloon is placed in the cone-shaped cavity; the side edge of the rubber balloon is lead out from the side edge opening of the cone-shaped cavity; and the rubber balloon extends outwards from the center by the opening.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

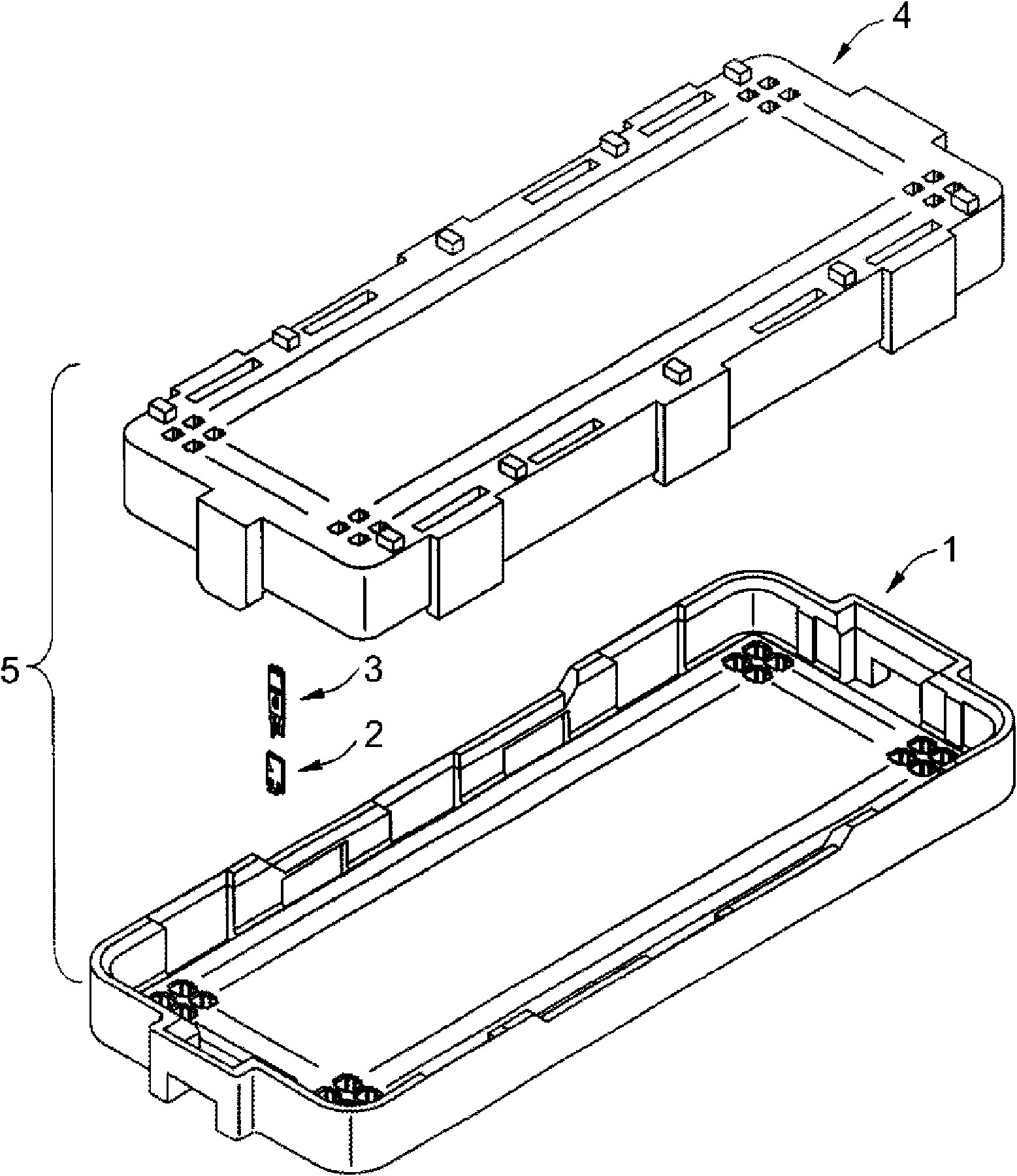

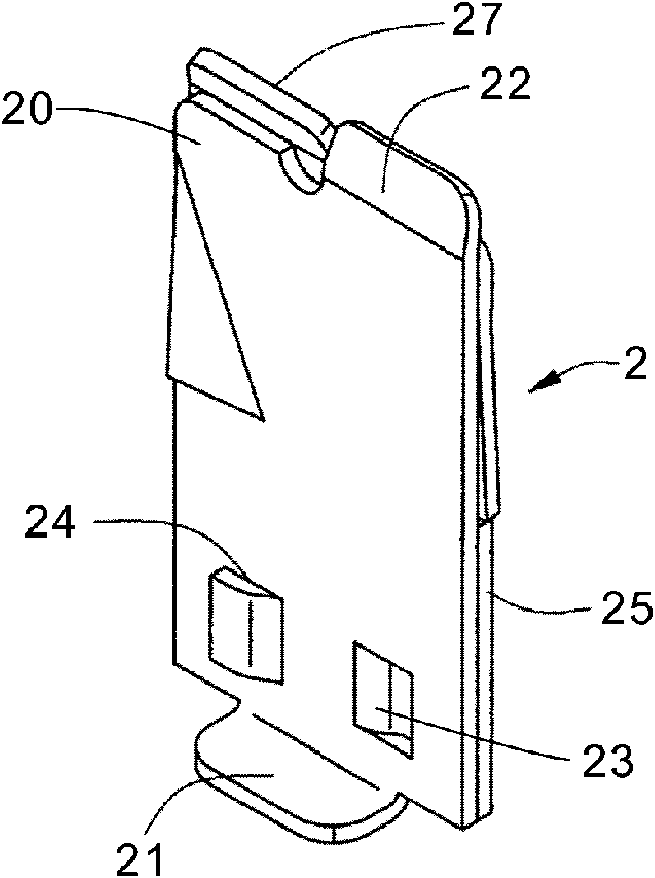

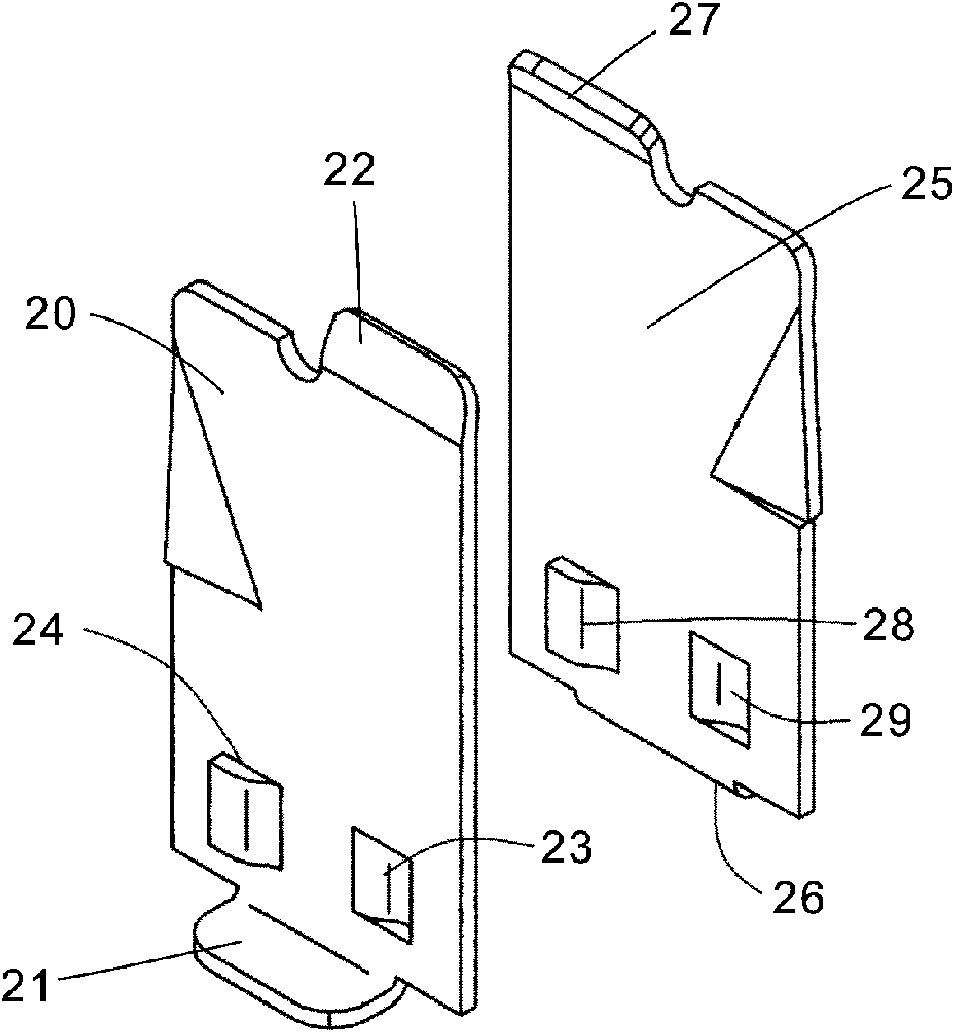

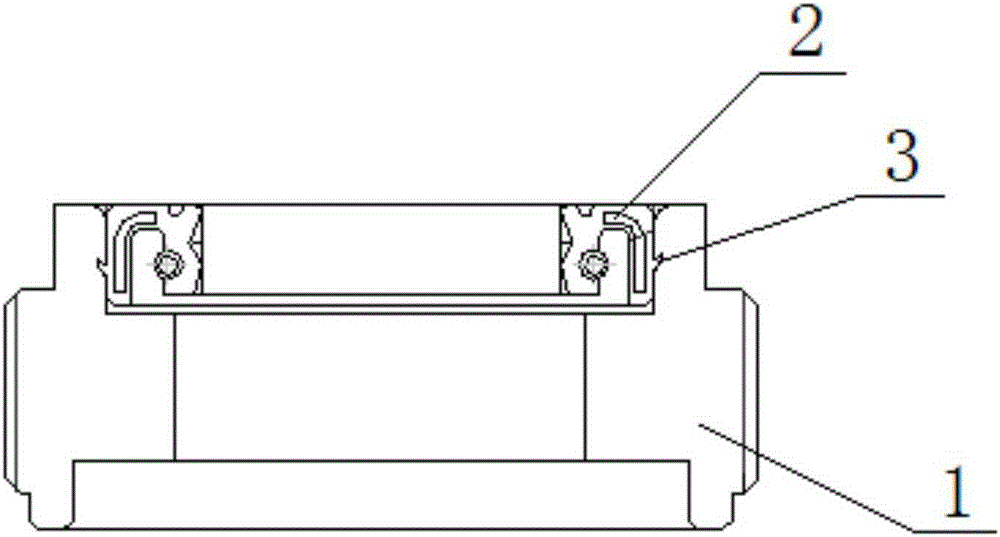

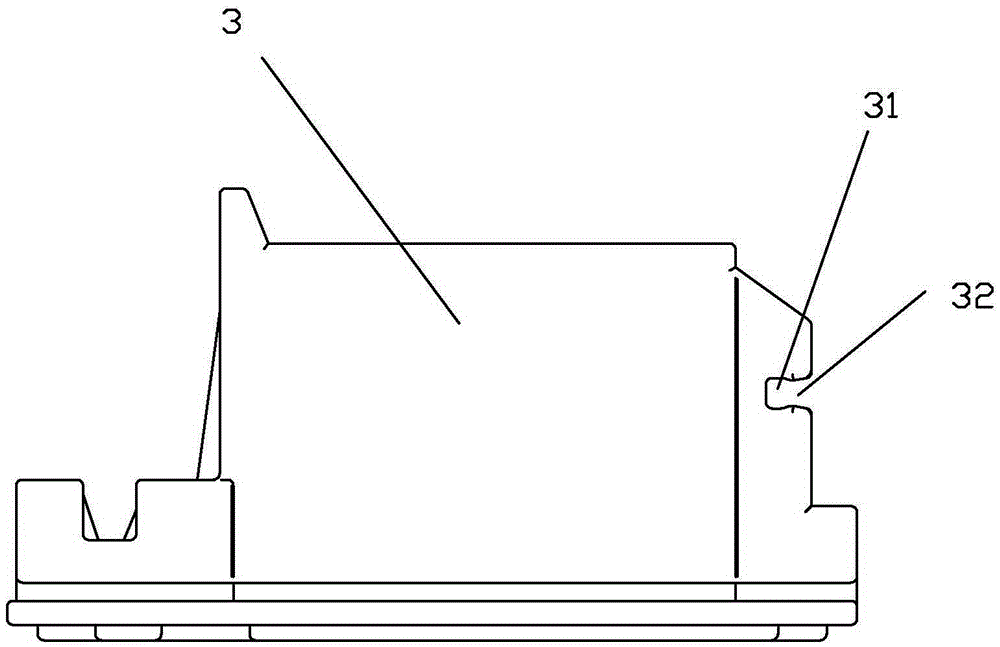

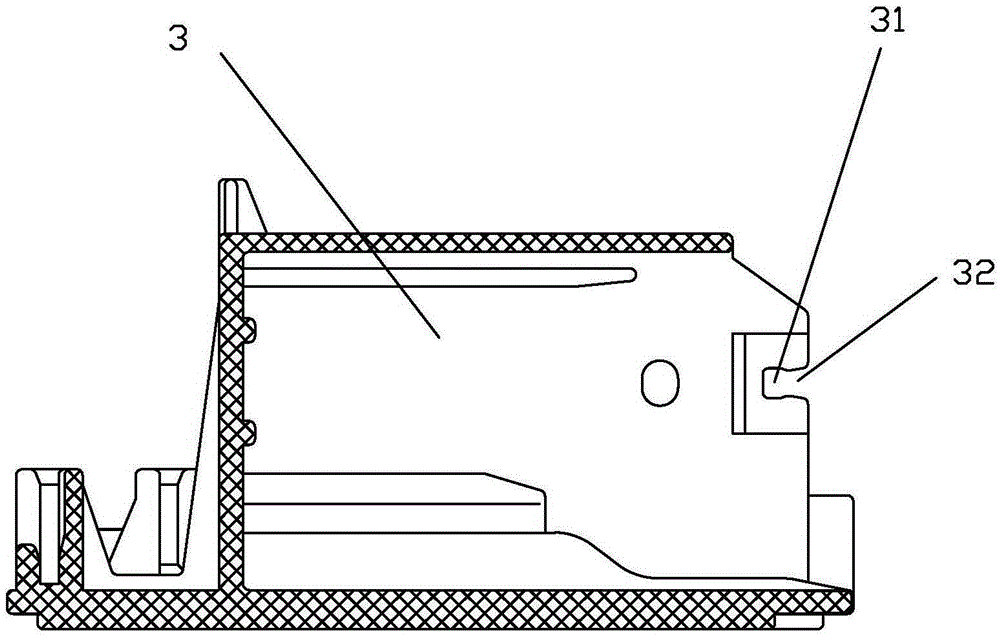

Protection cover and electric connector assembly

ActiveCN106711685AIncrease the amount of interferenceNot easy to looseCouplings bases/casesEngineeringMechanical engineering

Provided is a protection cover, which is installed to a chip connector. The protection cover comprises a main body portion and first clamping buckle portions arranged to the main body portion. Each first clamping buckle portion has a U-shaped clamping hook for buckling around an object to be buckled. Each clamping hook of the protection cover is designed to be in a U shape, thereby facilitating increasing interference amount between the clamping hook and a skirt hemline portion and enabling the clamping hook and the skirt hemline portion to be buckled more stably and firmly, and furthermore, allowing the protection cover not to get loose from a fixation base easily.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

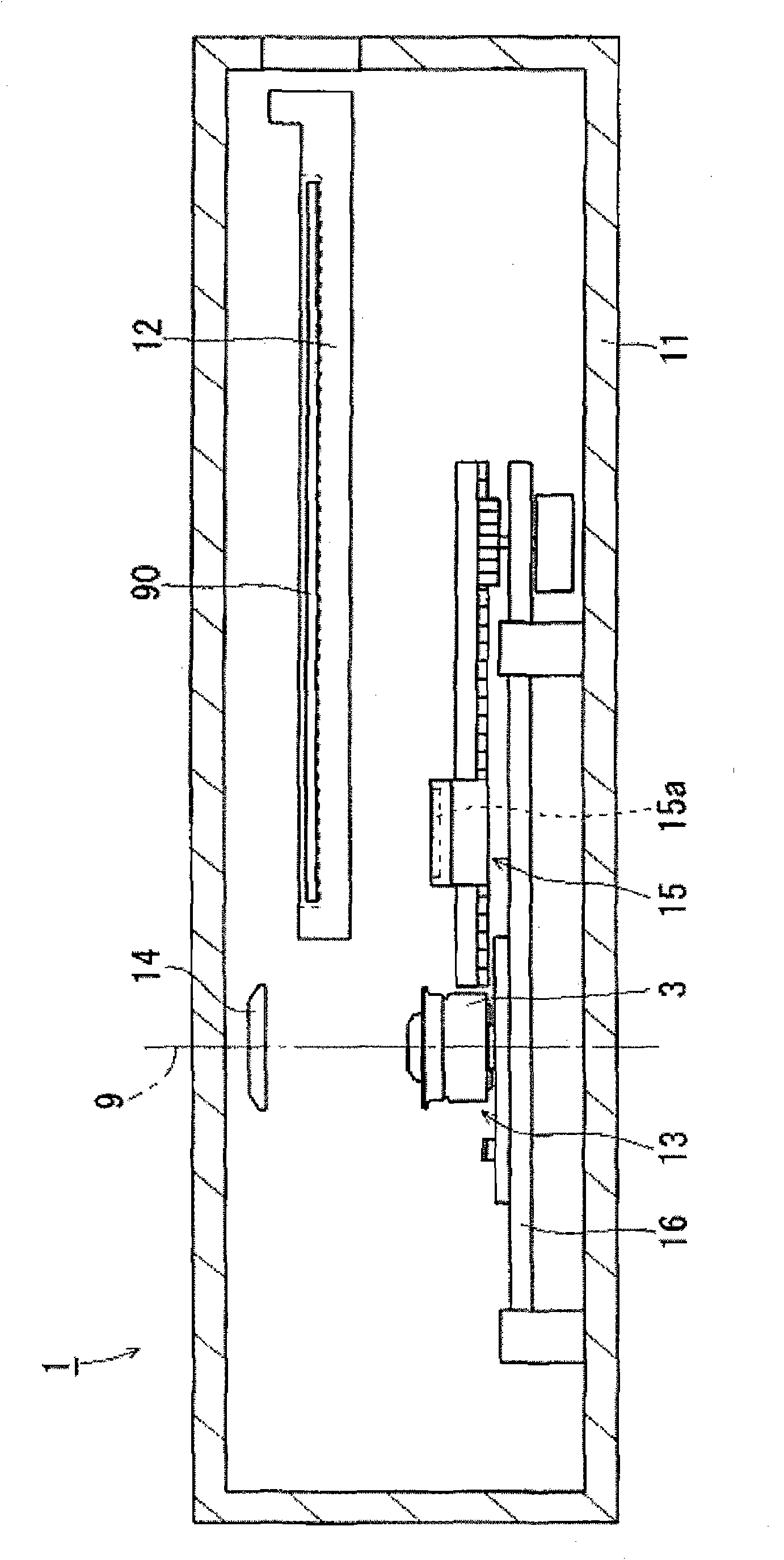

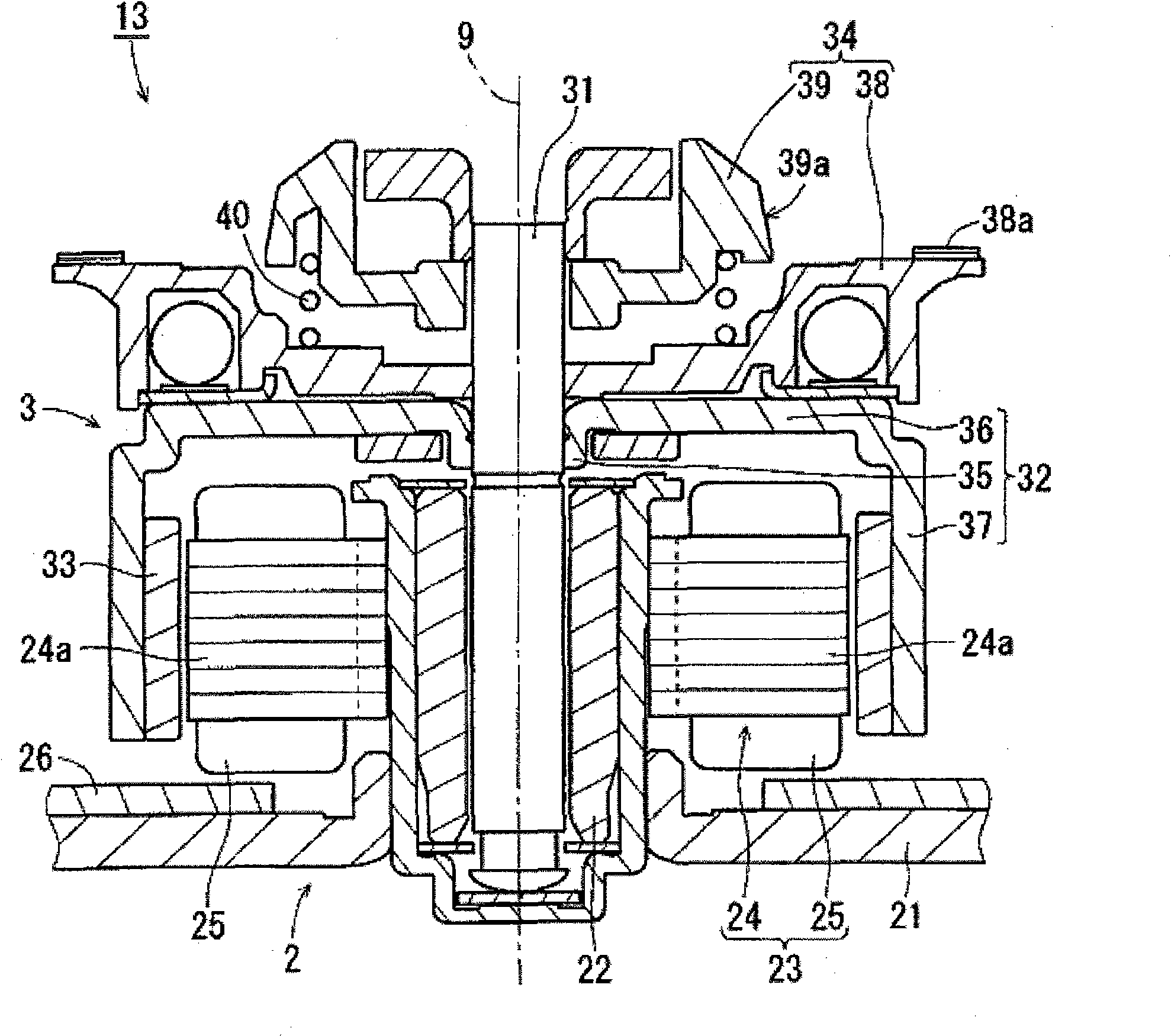

Motor, disc drive device, rotor yoke manufacturing method and motor manufacturing method

InactiveCN102064623AInhibitionImprove fastnessMagnetic circuit rotating partsRecord information storageRotor magnetsMagnetic flux

The invention provides a motor, a disc drive device, a rotor yoke manufacturing method and a motor manufacturing method. The motor has a stationary portion and a rotating portion which, in a state of being capable of rotating with a central shaft extending up and down as the center, is supported by the stationary portion. The stationary portion has a stator which generates magnetic flux. The rotating portion is provided with a shaft configured along the central shaft, a rotor yoke which has a cylindrical fastened portion fastened to the shaft by pressing, and a rotor magnet which is fixed to the rotor yoke and is opposite to the stator in the radial direction. The shaft has a portion extruding up and down from the fastened portion. In addition, the inner circumferential surface of the fastened portion forms a concave portion. When the shaft is pressed into the fastened portion of the rotor yoke, flash which is generated because the inner circumferential surface of the fastened portion is stroked is received in the concave portion, so that the generation of axial end flash of the fastened portion is restrained. Moreover, in this way, due to no use of adhesives, the press-in interference is increased, and the shaft and the rotor yoke can be firmly fastened.

Owner:NIDEC CORP

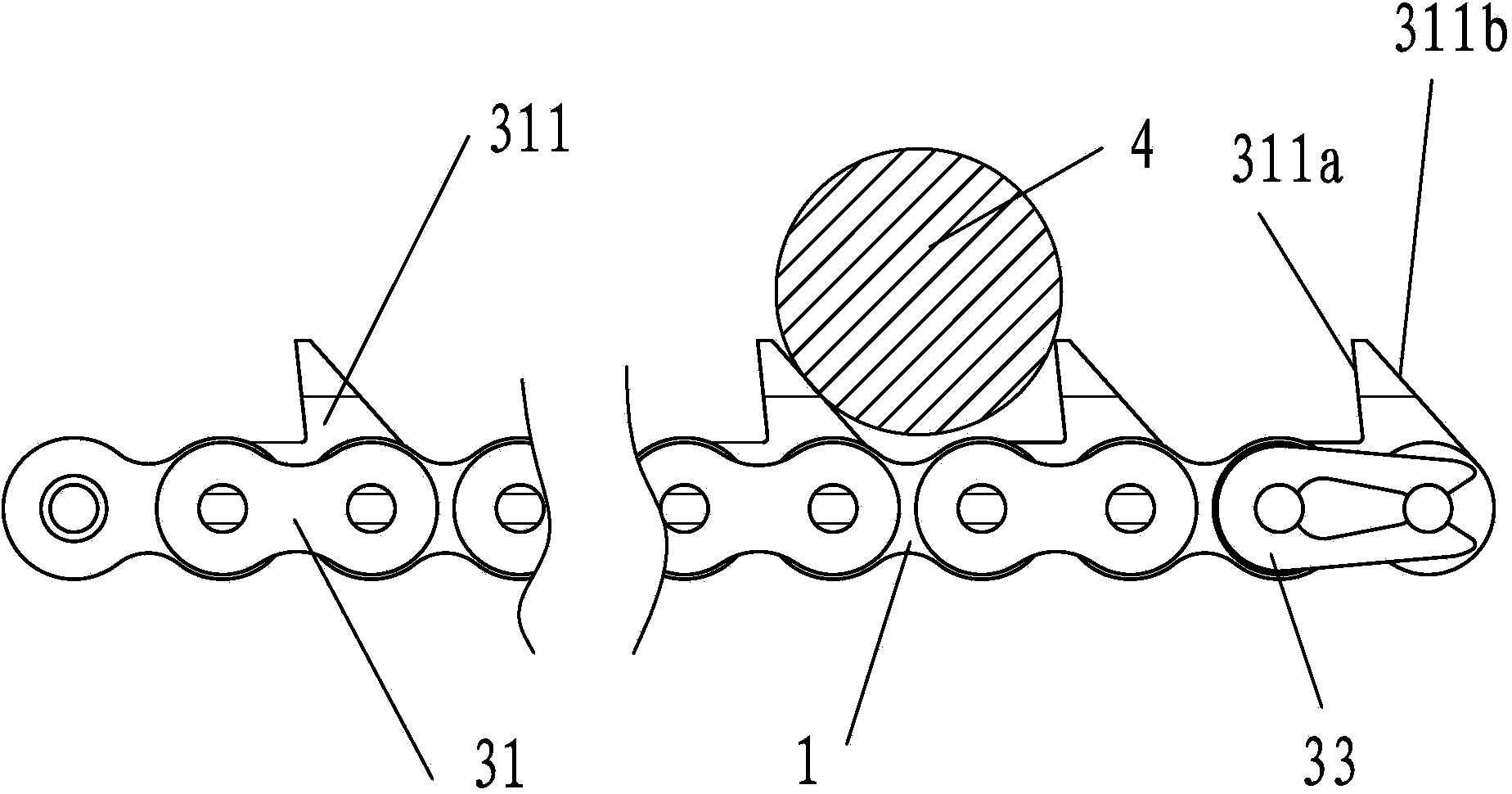

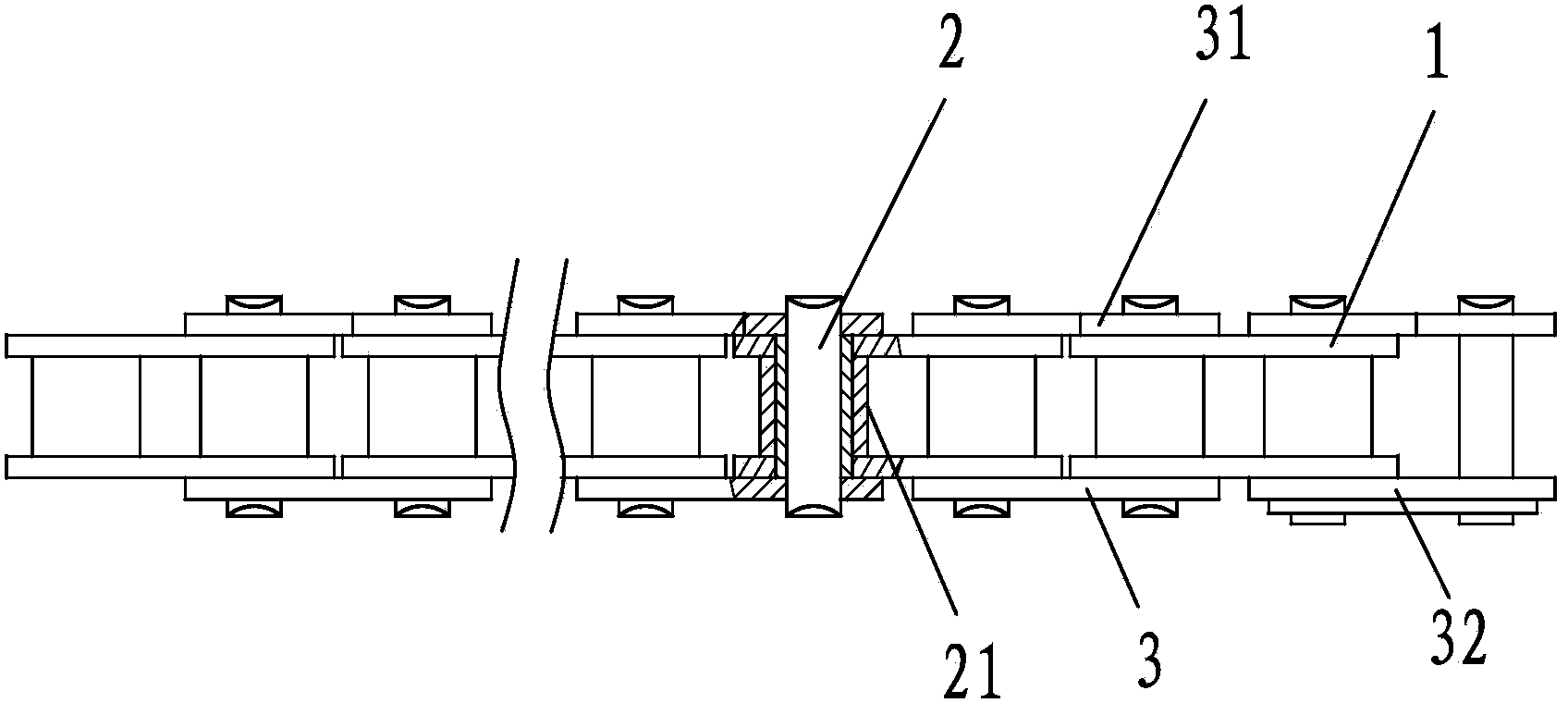

Chain special for conveying wood

InactiveCN104163316APrevent backward rolloverIncrease the amount of interferenceConveyorsInterference fitSharp tooth

The invention discloses a chain special for conveying wood. The chain comprises inner chain plates, every two inner chain plates are distributed left and right and fixedly connected through a hinge pin, a roller is arranged outside each hinge pin in a sleeved mode, outer chain plates are arranged on the outer sides of every two inner chain plates and provided with two through holes, each hinge pin penetrates through the two corresponding through holes and is fixed to the corresponding outer chain plates in an interference fit mode, and at least one of every two outer chain plates is a sharp-tooth outer chain plate; each sharp-tooth outer chain plate comprises a sharp-tooth part, wherein the sharp-tooth part comprises a small slope and a large slope which incline toward the same direction, one piece of wood is placed between the small slopes and the large slopes between every two sharp-tooth outer chain plates to be conveyed, the side direction of each sharp-tooth part is in a wedge shape, and therefore the problems that when conveying the wood, a traditional chain can not convey the wood stably or grab the wood tightly are solved.

Owner:ZHEJIANG CHANGXING XILIN CHAIN & SPROCKET

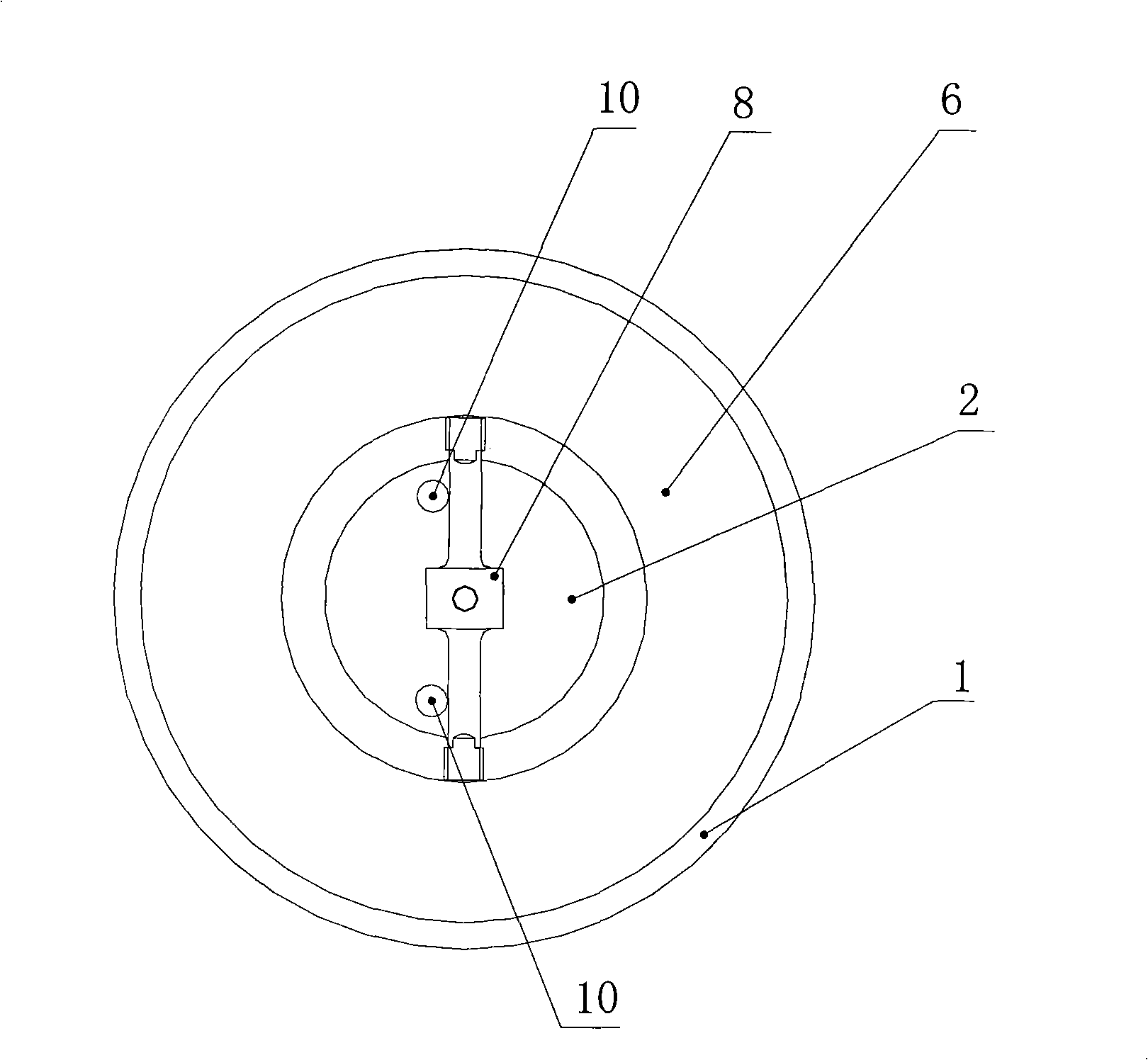

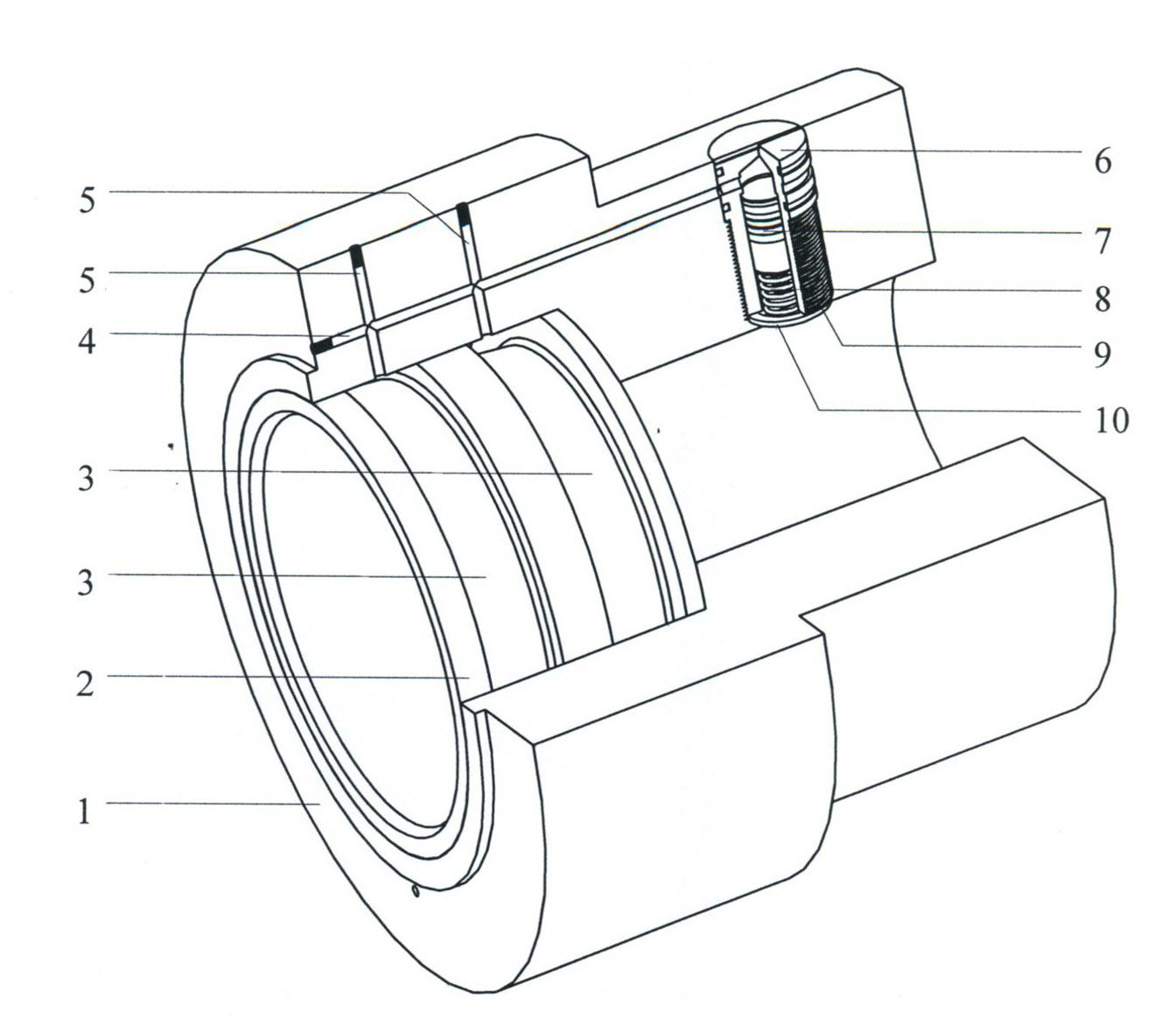

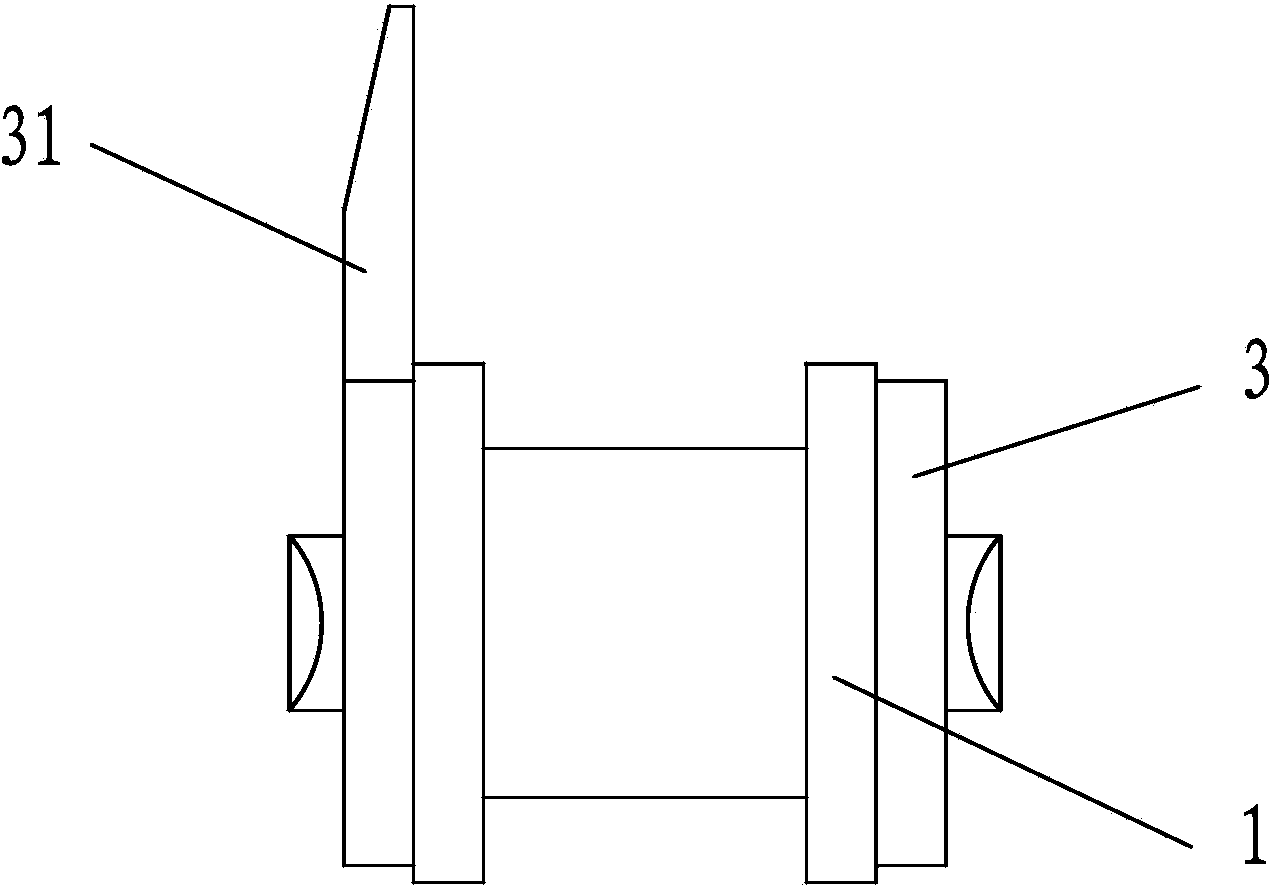

Low-speed rotary sealing device

InactiveCN105387209AImprove the sealing effectIncrease the amount of interferenceEngine sealsEngineeringHigh pressure

The invention discloses a low-speed rotary sealing device which comprises a shell, a rotary shaft, a fixed shaft, an end cover, a rough sealing gasket and a main sealing ring. The rotary shaft and the fixed shaft are sleeved with the shell. The rotary shaft is sleeved with the end cover. The end cover presses one end face of a boss I arranged on the outer circle of the rotary shaft and is connected with one end face of the shell. A flange plate connected with the other end face of the shell is arranged on the outer circle of the fixed shaft. A boss II is arranged on the inner circle of the shell. One end face of the boss II is in sealing fit with the other end face of the boss I through the rough sealing gasket. The rotary shaft is sleeved with the main sealing ring which is pressed between the rotary shaft and the shell. Three seals are arranged according to use conditions. The rough sealing gasket is designed at the position, communicated with the outside world, of the device and mainly used for solving the problem that particles in the outside world enter the main sealing ring to cause damage; and auxiliary sealing rings are designed at the two ends of the main sealing ring and can effectively reduce the pressure produced after inner high-pressure liquid permeates out, so that the sealing effect of the main sealing ring is improved.

Owner:CHONGQING UNIV

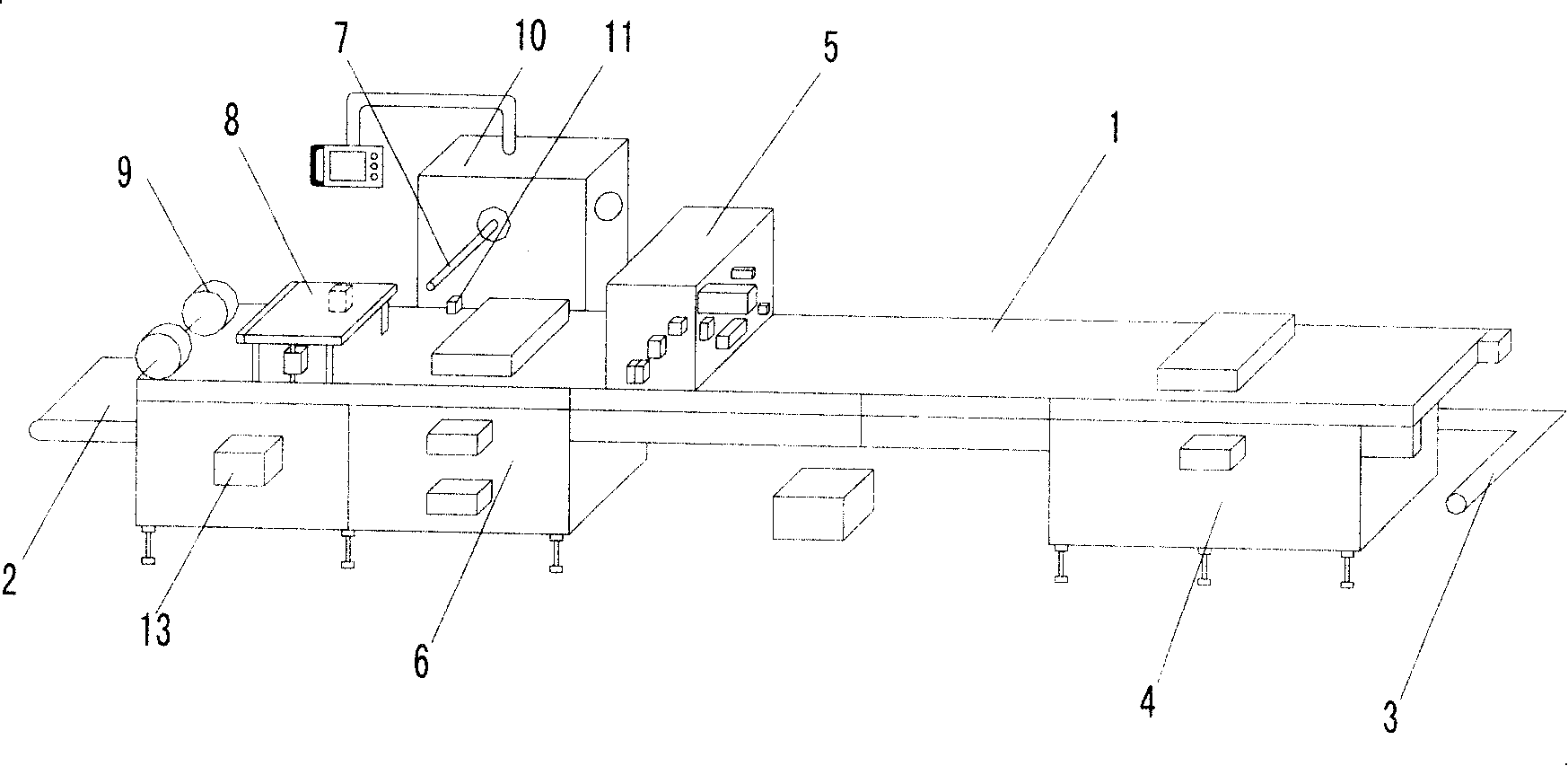

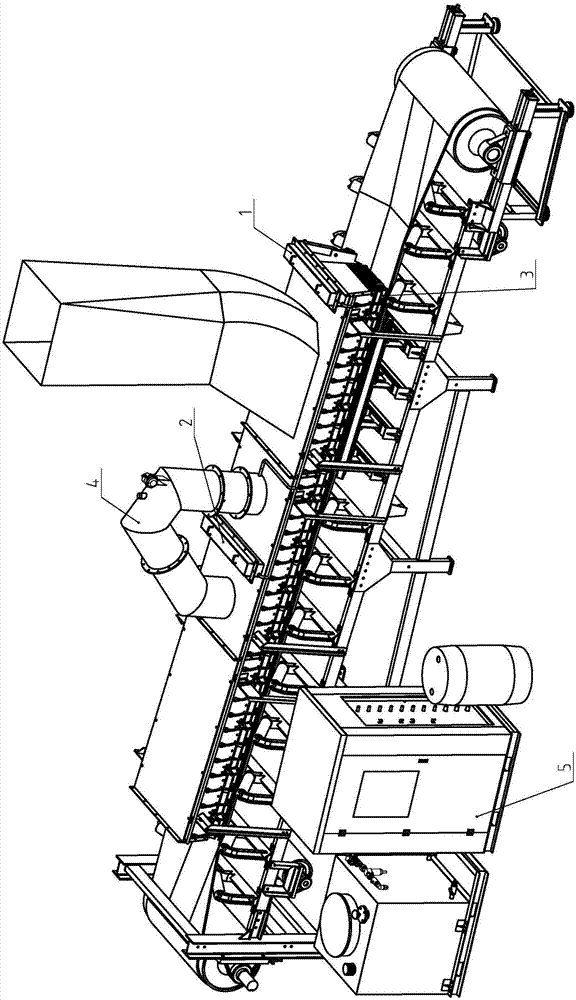

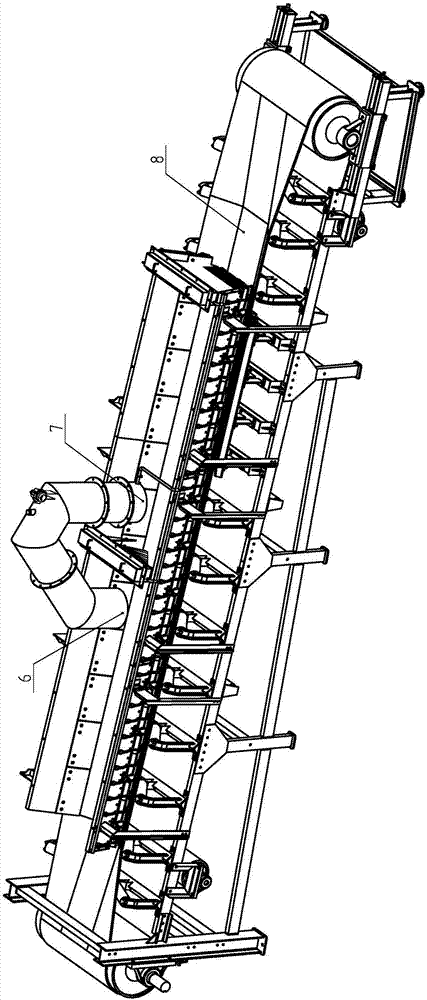

Suction plastic packing machine

ActiveCN101209755AImprove stabilityAccelerateWrapping material feeding apparatusTemperatue controlGas consumptionTemperature control

The invention relates to a plastic suction sack filler; wherein, a temperature control mechanism adopts a PID mode to control a temperature control instrument; a knife rest in a longitudinal shutdown mechanism is an integrated knife rest; the lifting cylinders in a plastic suction mechanism and a heat seal mechanism are respectively provided with a gasket with a thickness of 40mm; a guide plate is arranged on a color control patch detecting mechanism; a solenoid pilot actuated valve in a power mechanism is arranged adjacent to the cylinder in the plastic suction mechanism; clutches in a film unreeling mechanism and a paper unreeling mechanism adopt electromagnetic clutches; a die sealing mechanism on a lower die in the plastic suction mechanism and the heat seal mechanism is formed by a rectangle groove arranged around the lower die and a heteromorphic joint strip embedded in the groove. The invention can control the heating temperatures of the plastic suction mechanism and the heat seal mechanism within an accurate and proper range, thus greatly improving the stability of plastic suction forming and heat seal forming, reducing gas consumption and effectively improving the productivity effect of the whole machine.

Owner:SHANGHAI KANGDELAI ENTERPRISE DEV GRP CO LTD

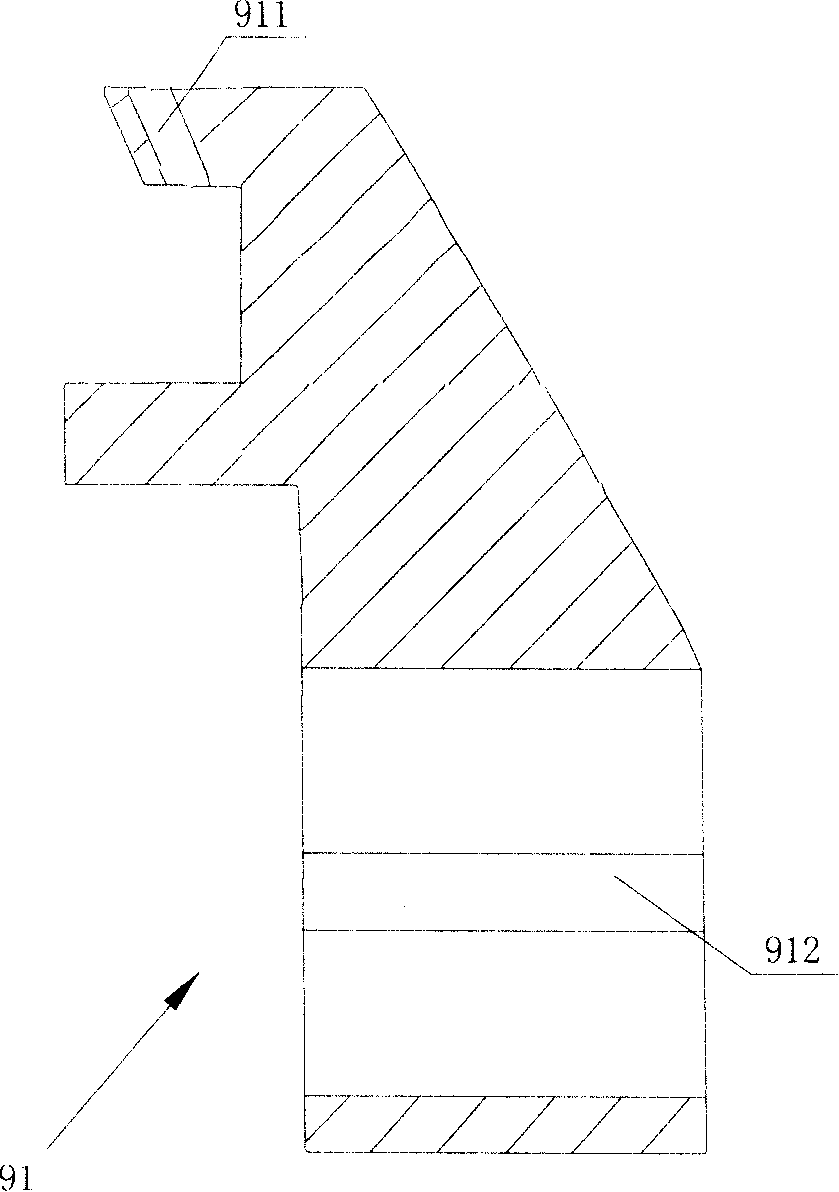

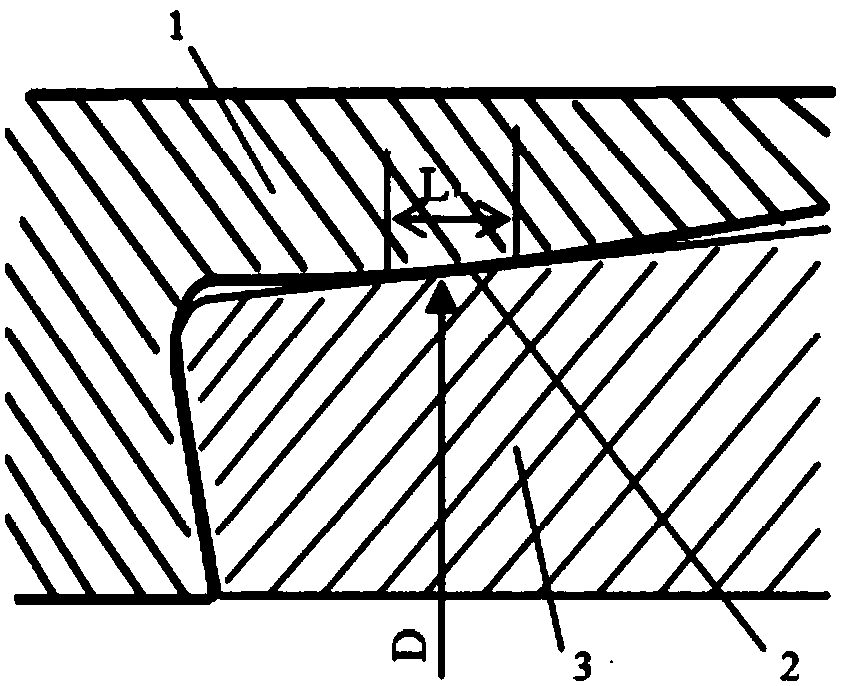

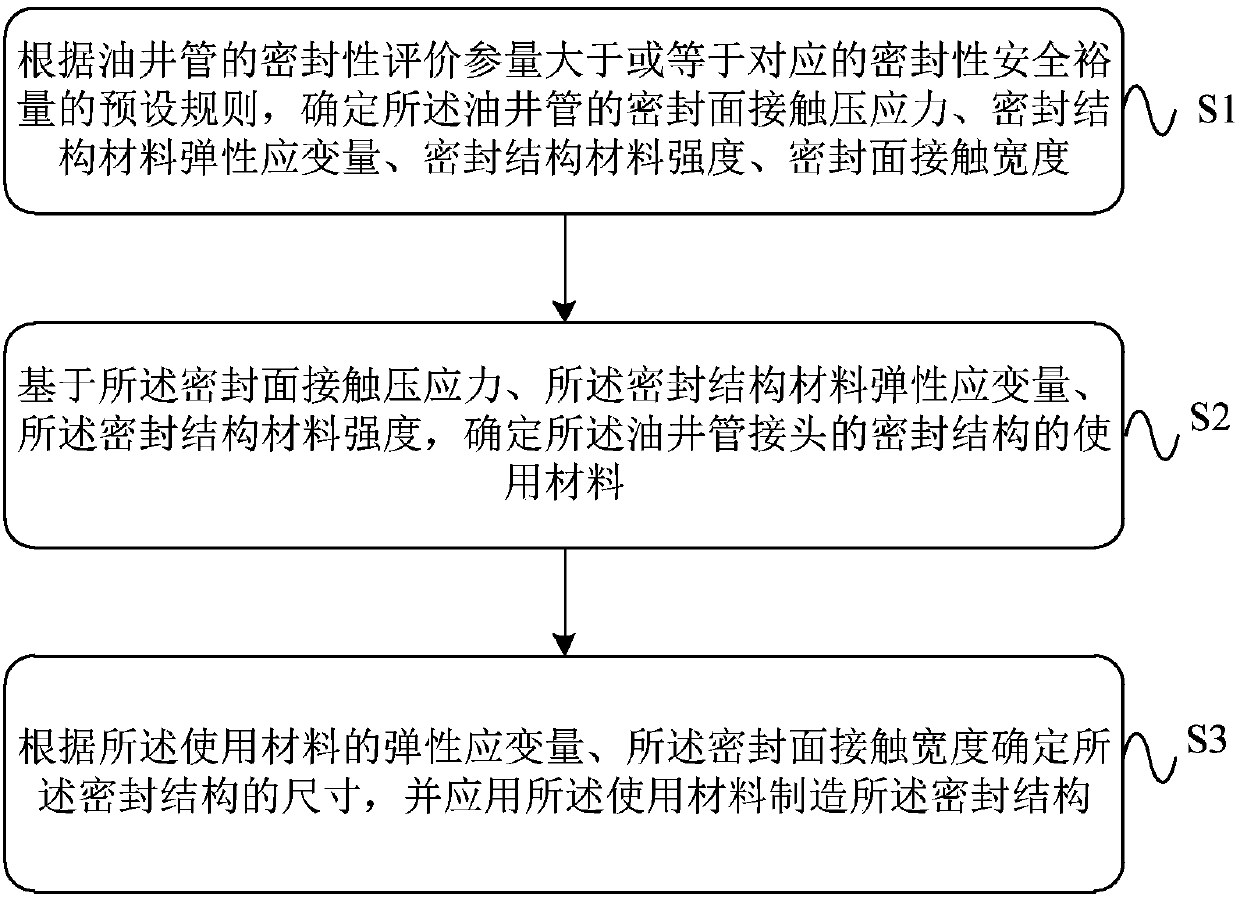

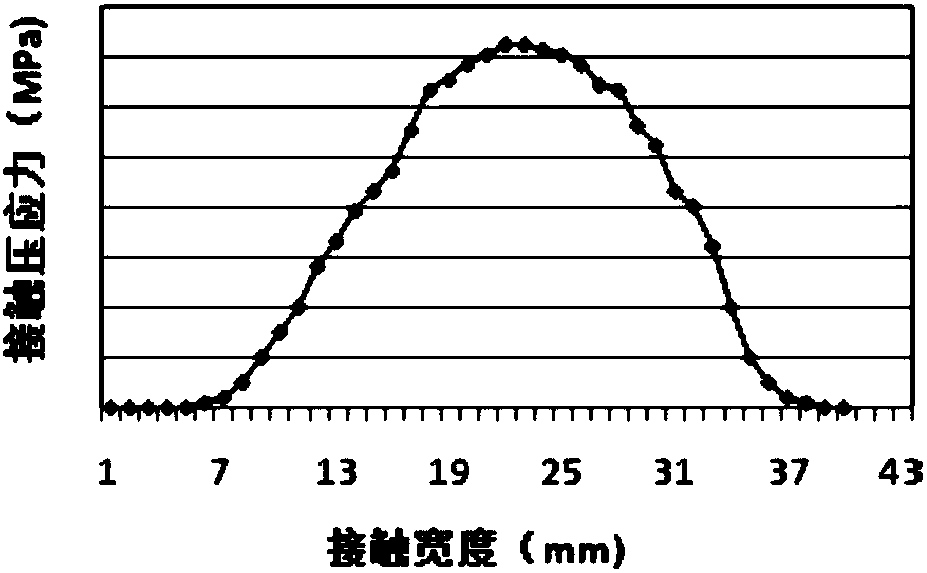

Designing and manufacturing method and sealing method of sealing structure of oil well pipe joint

ActiveCN110359858AImproves sealing reliabilityIncrease the amount of interferenceDrilling rodsDesign optimisation/simulationContact pressureAlloy

The invention provides a designing and manufacturing method and a sealing method of a sealing structure of an oil well pipe joint. The manufacturing method comprises the steps of according to a presetrule that a sealing performance evaluation parameter is larger than or equal to a corresponding sealing performance safety allowance of an oil well pipe, determining a sealing surface contact pressure stress, a sealing structure material elasticity strain capacity, sealing structure material strength and a sealing surface contact width of the oil well pipe; according to the sealing performance safety allowance of the oil well pipe, enabling the sealing structure material elasticity strain capacity to be larger than 0.5%; according to the sealing surface contact pressure stress, the sealing structure material elasticity strain capacity and the sealing structure material strength, determining a used material of the sealing structure; according to the determined sealing structure material elasticity strain capacity, determining the used material of the sealing structure as a hyperelastic alloy material with the elasticity strain capacity being larger than 0.5%; and manufacturing the sealing structure according to the used material and the elasticity strain capacity thereof. By utilizing the designing and manufacturing and the sealing method of the sealing structure of the oil well pipe joint provided by the embodiment of the invention, the reliability of a sealing performance of the oil well pipe joint is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

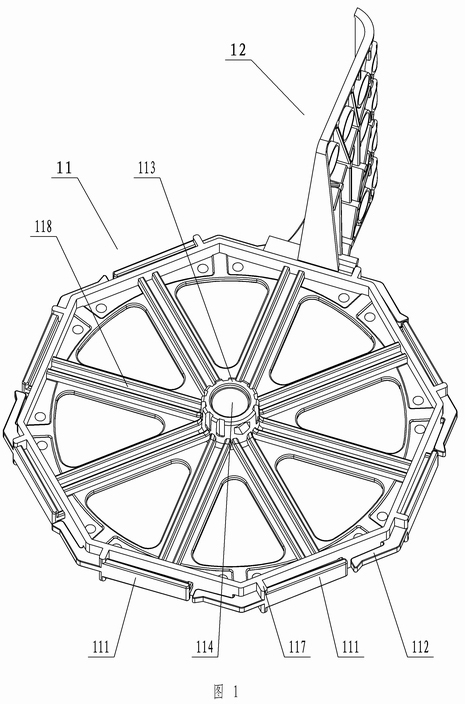

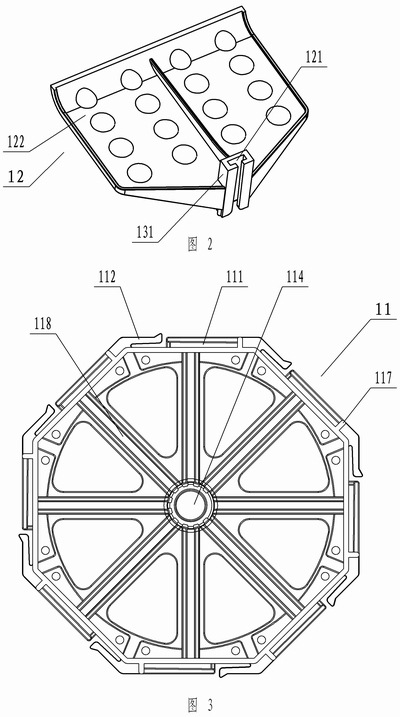

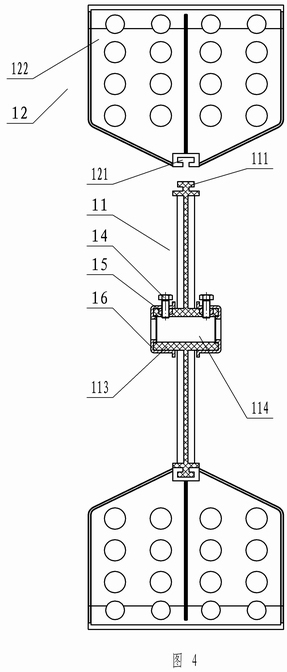

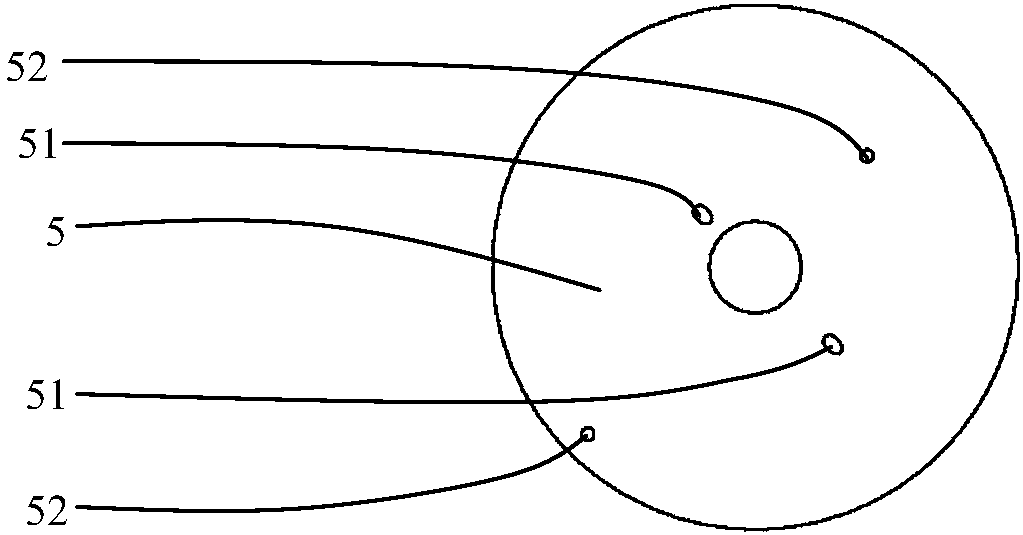

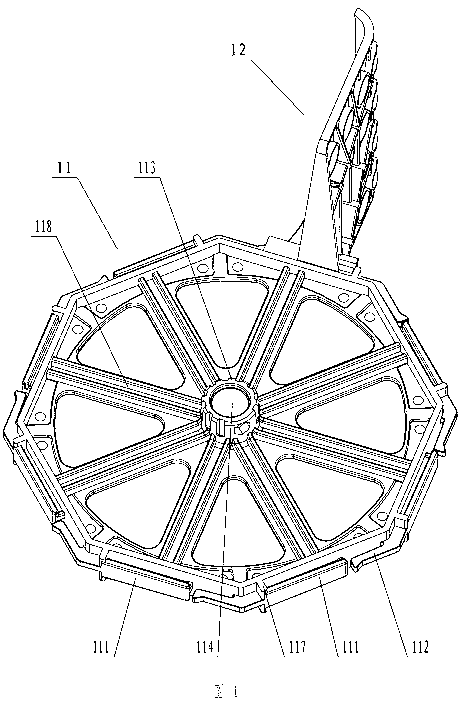

Impeller with retaining mechanism on impeller disk and water-wheel aerator with retaining mechanism impeller

ActiveCN102823538AEasy to assembleIncreased load-bearing capacityPisciculture and aquariaImpellerThin walled

The invention belongs to an aquacultural machine and relates to an impeller with a retaining mechanism on an impeller disk. The impeller is composed of a blade and the impeller disk; the retraining mechanism formed in an integral injecting way together is arranged on the impeller disk; one end of an elastic retaining strip and the straight edge of the impeller disk are injected into a whole; the other end of the elastic retaining strip is suspended; the retraining strip resets and prevents the blade from retreating after the blade is assembled at a proper position; a water-wheel aerator with a retaining mechanism impeller comprises a floating body, a main machine, a transmission shaft and a bearing block; the floating body is connected by a thin-wall stainless steel square tube; a hole passing through bolts is arranged on the square tube; more than two floating boats are combined into the floating body through square tube holes via the bolts; a reinforcing plate is arranged above the square tube holes; grooves are arranged at the two sides of the floating boats, and the bolts are fixed inside the grooves.

Owner:ZHEJIANG FORDY MACHINERY

Electric connector terminal and manufacturing method thereof

InactiveCN102044773AFit tightlyEasy to separateContact member manufacturingElectrically conductive connectionsInterference fitElectricity

The invention relates to an electric connector terminal and a manufacturing method thereof, and belongs to the field of electric connectors. The electric connector terminal is provided with two conductive sheets which are tightly attached to each other, wherein the two corresponding ends of each conductive sheet are respectively provided with a platform and a conductive connecting part; one conductive sheet is provided with more than one bump and / or more than one groove, and the other conductive sheet is provided with more than one groove and / or more than one bump with the number and shape corresponding to those of the bump and / or the groove formed on one conductive sheet; and the bumps correspond to and are matched with the grooves one by one, and the bumps on one conductive sheet stretch into the grooves on the other conductive sheet to form interference fit. The manufacturing method comprises the following steps of: molding the two conductive sheets, attaching, punching to mold the bumps and the grooves, and calendering the bumps. The electric connector terminal has a firm structure and is convenient to assemble; and by the method, the two conductive sheets can be punched at one time and the bumps and the grooves on the two conductive sheets can be molded simultaneously, so that molding times is reduced.

Owner:奕东电子科技股份有限公司

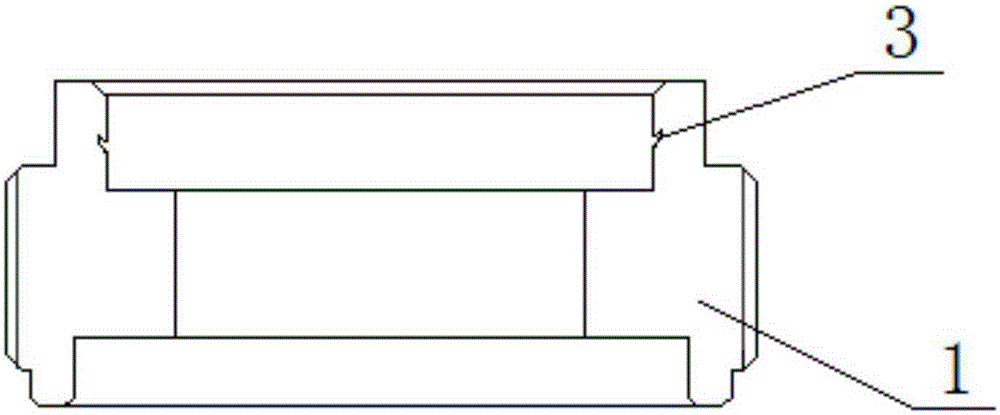

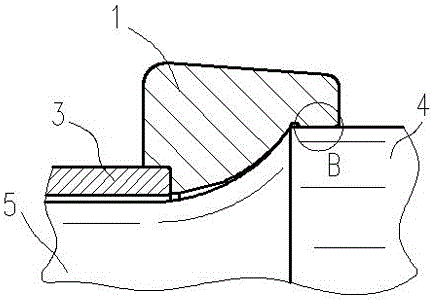

Sealing structure of gear and rack steering device

InactiveCN105240531AAct as a barbIncrease the amount of interferenceEngine sealsEngineeringMachining

The invention discloses a sealing structure of a gear and rack steering device. The sealing structure comprises a gear shaft adjusting plug screw (1) and a dust seal (2) matched with the gear shaft adjusting plug screw (1). The dust seal (2) is installed in the gear shaft adjusting plug screw (1) and closely attached to the inner wall of the gear shaft adjusting plug screw (1). A groove (3) is formed in the portion, matched with the dust seal (2), of the inner wall of the gear shaft adjusting plug screw (1). According to the sealing structure of the gear and rack steering device, a groove structure is designed at the high-low pressure oil seal portion or the dust seal assembling portion; and after a high-low pressure oil seal and the dust seal are completely assembled to be in place according to the existing machining accuracy requirement and under the assembling technical condition, the groove structure portion can have the barb function when bearing large axial component force, the interference magnitude and the resistance of sealing piece rubber and the matched portion are increased, and then the problem that a sealing piece disengages from the matched portion after working for a long time is solved.

Owner:WUHU HENGLONG AUTO STEERING SYST

Rack and pinion steering gear sealing structure

InactiveCN105197097AIncreased interference and resistanceReduce investment in human resourcesEngine sealsMechanical steering gearsEngineeringMechanical engineering

The invention discloses a rack and pinion steering gear sealing structure which comprises a gear shaft adjusting screw plug (1) and a dust seal (2) matched with the gear shaft adjusting screw plug (1), wherein the dust seal (2) is mounted in the gear shaft adjusting screw plug (1), and is clung to the inner wall of the gear shaft adjusting screw plug (1); a groove (3) is formed in the inner wall of the gear shaft adjusting screw plug (1) and in the position corresponding to the dust seal (2). According to the rack and pinion steering gear sealing structure adopting the structure, through the design of the groove structure at the high-low pressure oil seal part or the dust seal assembling part, when a high-low pressure oil seal and the dust seal are completely assembled in place according to the conventional processing precision requirement and assembly process condition, under a relatively strong axial component force, the groove structure can play a barb role, and the magnitude of interference and the resisting force of sealing part rubber and the coordinated part are increased, so that the problem that the sealing part is divorced from the coordinated part after being used for a long time is solved.

Owner:WUHU HENGLONG AUTO STEERING SYST

Fast repair spare part of shaft end of cooling table roller way and use method thereof

InactiveCN105964708AThe overall structure is simple and reliableEasy to manufactureCooling bedsMetal rolling arrangementsInterference fitEngineering

The invention relates to a fast repair spare part of a shaft end of a cooling table roller way and a use method thereof. The fast repair spare part of the shaft end comprises a shaft end body, and the shaft end body comprises a shaft rod and a shaft end base, wherein the shaft rod and the shaft end base are integrally formed, and the outer diameter of the shaft end base is greater than the outer diameter of the shaft rod. A cylindrical shaft end inner hole is formed in the middle of one end of the shaft end base, an inner chamfer is arranged at the open end of the shaft end inner hole, and an outer chamfer is arranged at the end of the shaft rod. In the use process, the spare part of the shaft end is preheated at high temperature, then is installed on a cutting shaft section of the old cooling table roller way in an interference fit assembly mode at high temperature and is fast cooled by cooling water, and finally electric-arc welding is carried out on the connection part for firm connection. The spare part of the shaft end is simple and reliable in structure, the old roller way can be quickly and effectively repaired, the maintenance time is greatly reduced, and the repaired old cooling table roller way is simple and good in practical effect like a new cooling table roller way.

Owner:JIANGSU YONGGANG GROUP CO LTD

Electronic device shell with deformable hook

InactiveCN102548282AIncrease the amount of interferenceEasy to disassembleCasings/cabinets/drawers detailsEngineering

Owner:QISDA SUZHOU

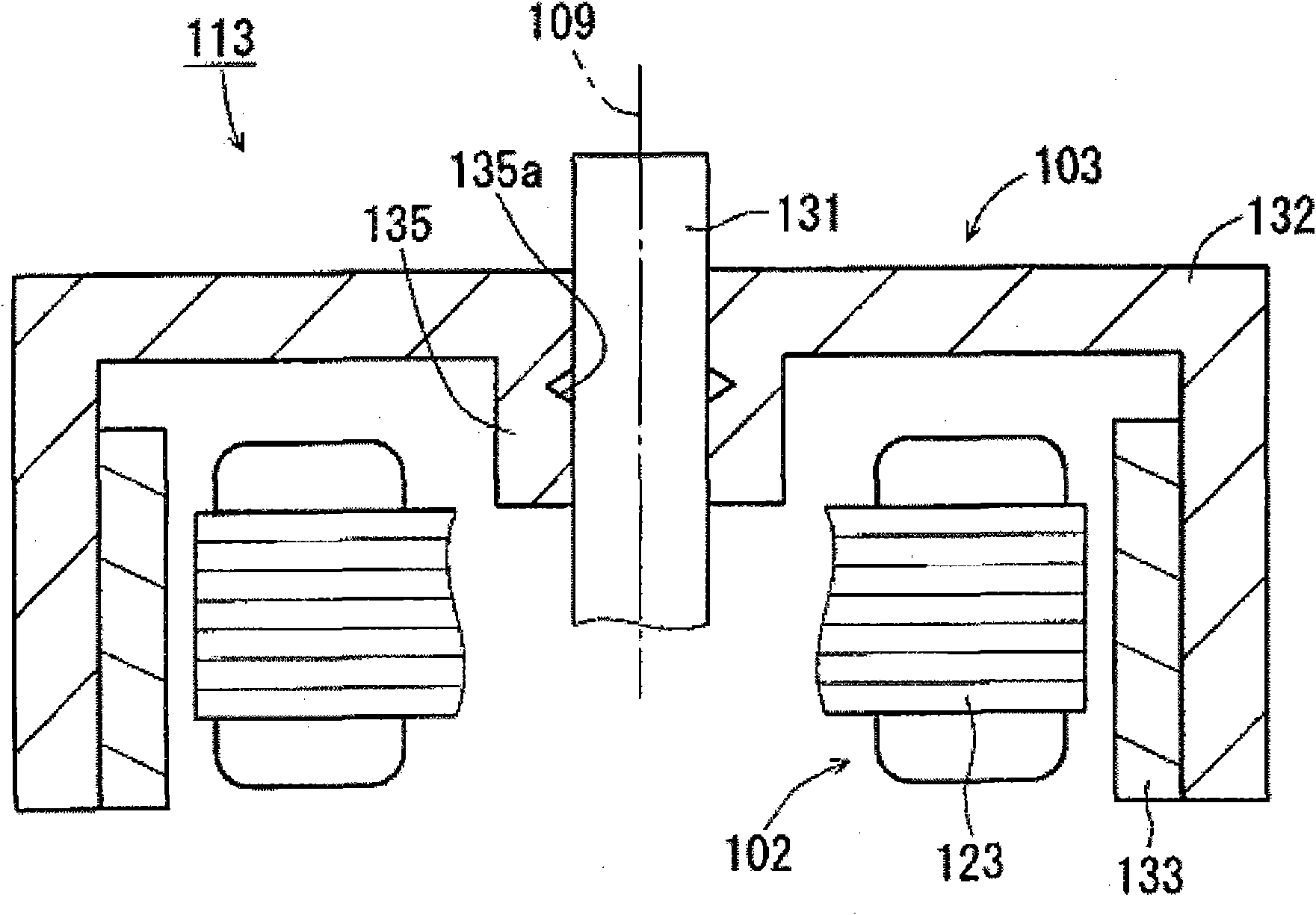

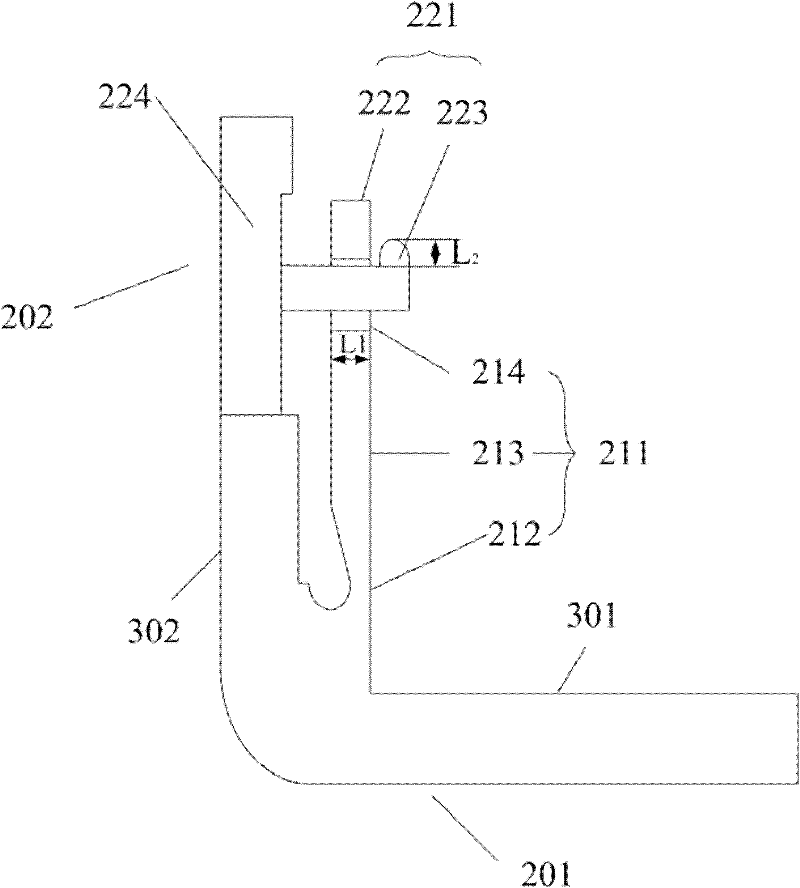

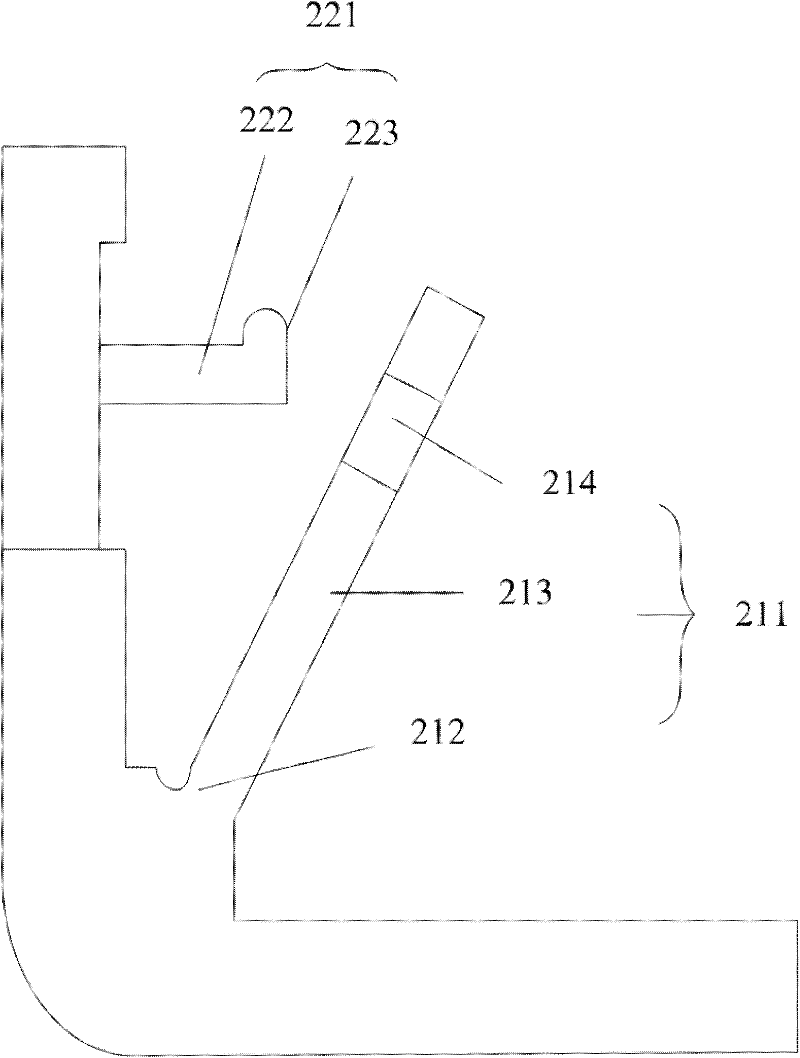

Connection structure of armature portion and pedestal of magnetic latching relay

The present invention discloses a connection structure of an armature portion and a pedestal of a magnetic latching relay. The connection structure comprises an armature portion and a pedestal; the armature portion is provided with a rotating shaft, and the pedestal is provided with a shaft hole, wherein the shaft hole is provided with an opening part; the height of the opening part is smaller than the height between the upper top wall and the lower bottom wall of the pedestal; and when the rotating shaft of the armature portion is disposed in the shaft hole of the pedestal along with the opening part, the rotating shaft is provided with an abdicating part at the height direction to allow the rotating shaft to be in microscale interference fit with the opening part after the abdicating part is reduced, and when the rotating shaft rotates to a resetting stabilization position or a setting stabilization position, the magnitude of interference of the rotating shaft is gradually increased up to the maximum between the height direction and the opening part, so that the rotating shaft is prevented from quitting from the shaft hole. According to the invention, it is ensured that the rotating shaft of the armature portion is not easy to take off after being installed into the hole of a pedestal, so that the reliability of products is improved, and plastic soft flocks generated in the process of installing the rotating shaft of the armature portion into the hole of the pedestal are small, so that the stability of relay parameters is ensured.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

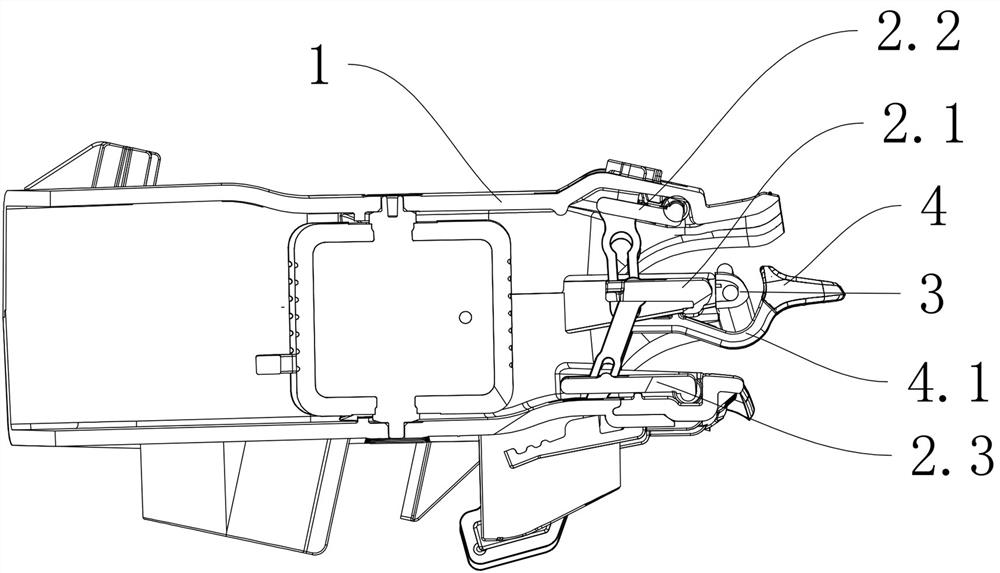

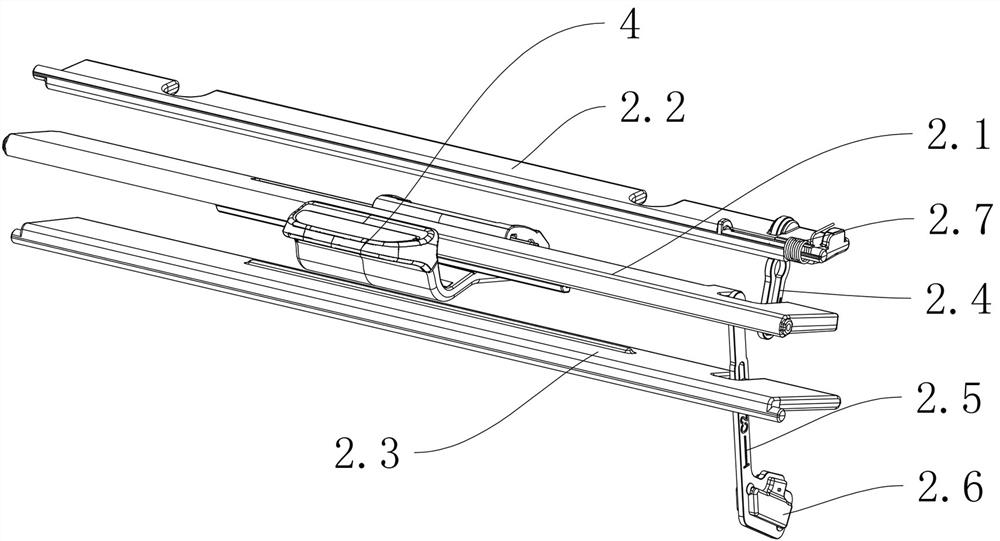

Damping structure of automobile air conditioner air outlet

ActiveCN112060870AIncrease the amount of interferenceStable operating forceAir-treating devicesVehicle heating/cooling devicesPhysicsAutomotive air conditioning

The invention discloses a damping structure of an automobile air conditioner air outlet. The damping structure comprises a shell and an outer-layer air guide blade group arranged in the shell; the outer-layer air guide blade group comprises a main blade, a driven blade and a connecting rod; one end of the connecting rod is connected with the main blade; the other end of the connecting rod is connected with the driven blade; the end, connected with the driven blade, of the connecting rod further extends outwards and is provided with a damping part; a positioning groove matched with the dampingpart is formed in the shell; the damping part extends into the positioning groove; and when the main blade rotates, the connecting rod is driven to move, so that the damping part slides in the positioning groove and generates friction force. According to the damping structure of the automobile air conditioner air outlet, the damping part is arranged on the connecting rod, the positioning groove isformed in the shell, and the damping part is matched with the positioning groove, so that the operating force is stable, and the durability is good.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

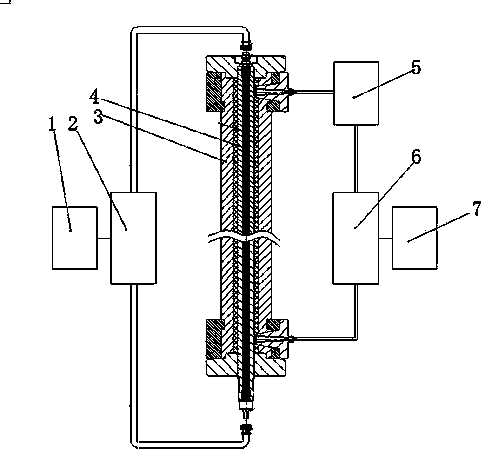

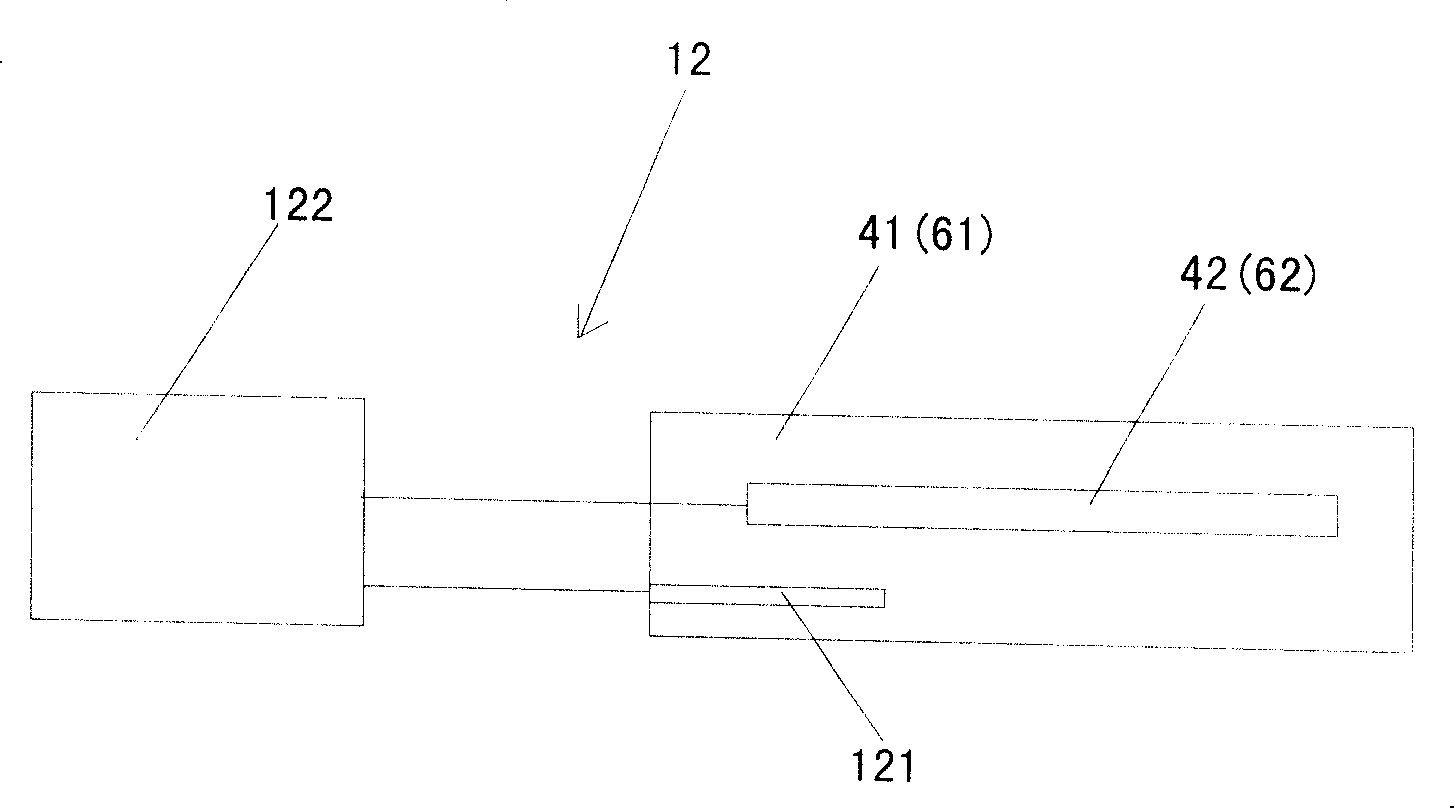

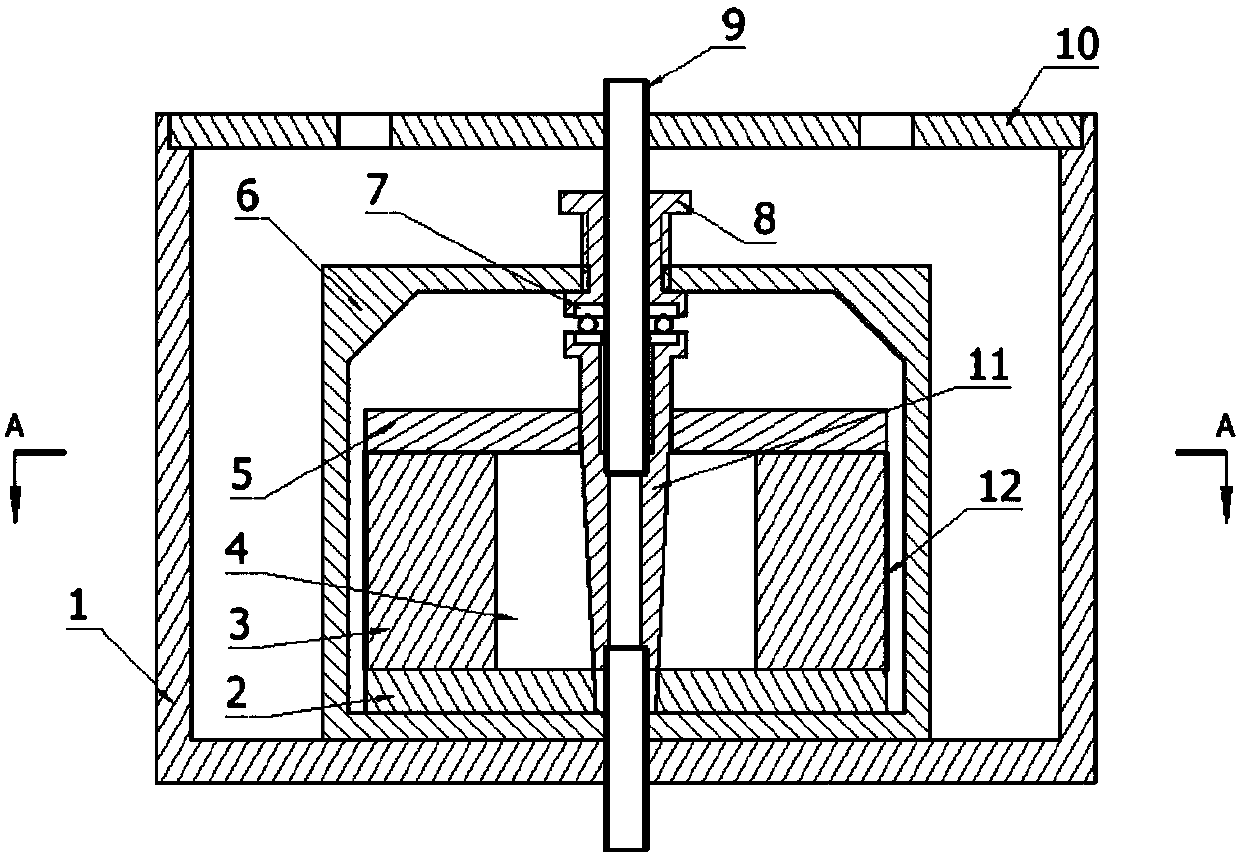

Device and method to study relationship between interference and thermal contact resistance

ActiveCN107796848AStable temperatureIncrease the amount of interferenceMaterial heat developmentTwo temperatureEngineering

The invention provides a device and method to study relationship between interference and thermal contact resistance. The device comprises a cooling conical spindle, a ring and sleeve equal in height,an upper computer, and a support; the outer side of the sleeve is provided with heating film, the outer side of the ring is in contact connection with the inner side of the sleeve, and an inner cavity of the ring fits the lower end of the cooling conical spindle; the ring is radially divided into 2-6 ring units; the cooling conical spindle is connected with a cooling medium circulation pipeline,and the upper end of the cooling conical spindle fits the lower end of a spiral loader; the upper end of the cooling conical spindle is greater than its lower end in diameter; the spiral loader is fixed on the support; the support and the sleeve are fixed to each other, wherein both the sleeve and the ring are axially provided with two temperature detection holes, a temperature sensor is arrangedin each temperature detection hole, and a probe of each temperature sensor is arranged at the corresponding axial center. The device and method have the advantages that magnitude of thermal contact resistance of joint faces of a cylinder and sleeve under different interferences can be measured and data support is provided for completing a thermal network method.

Owner:XI AN JIAOTONG UNIV

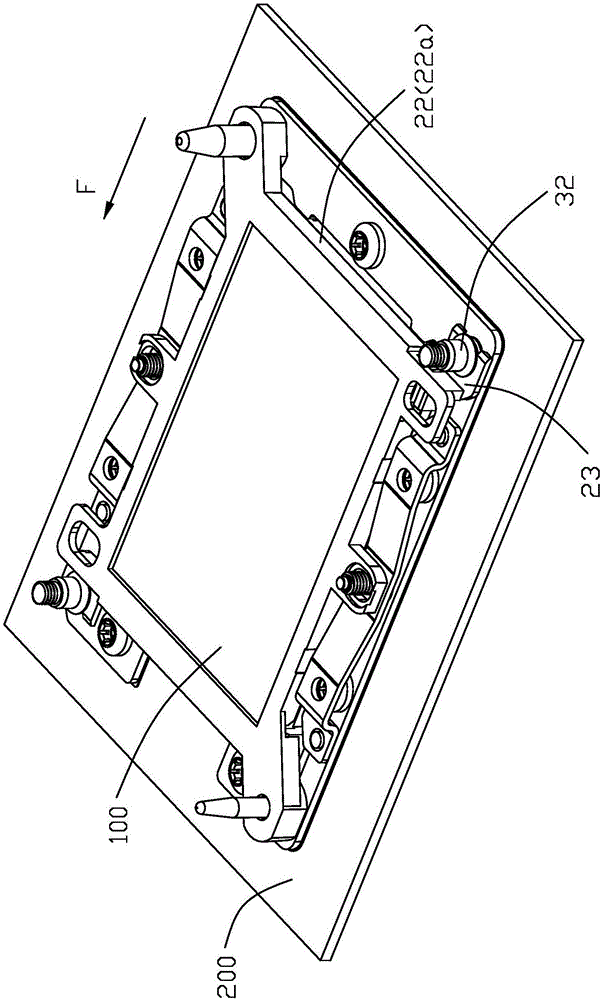

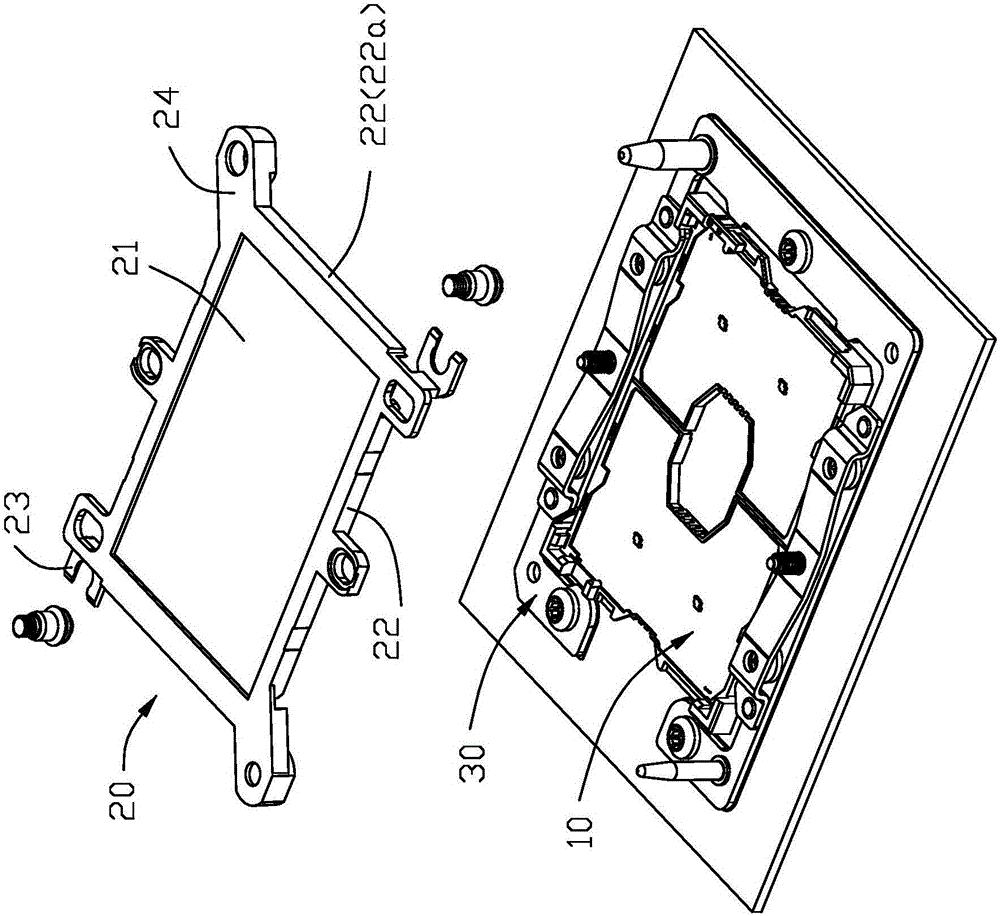

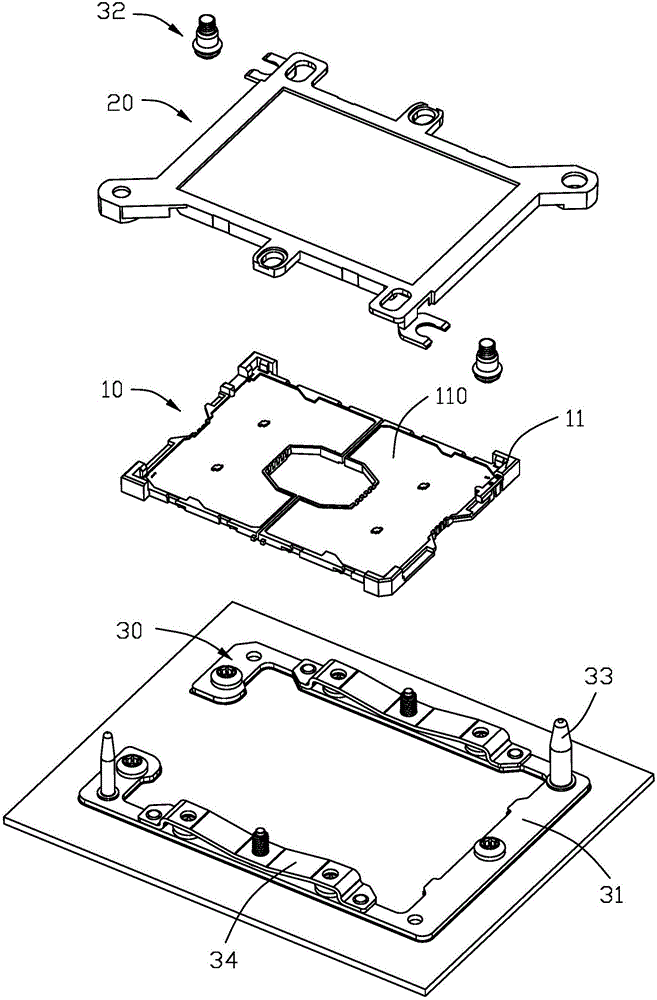

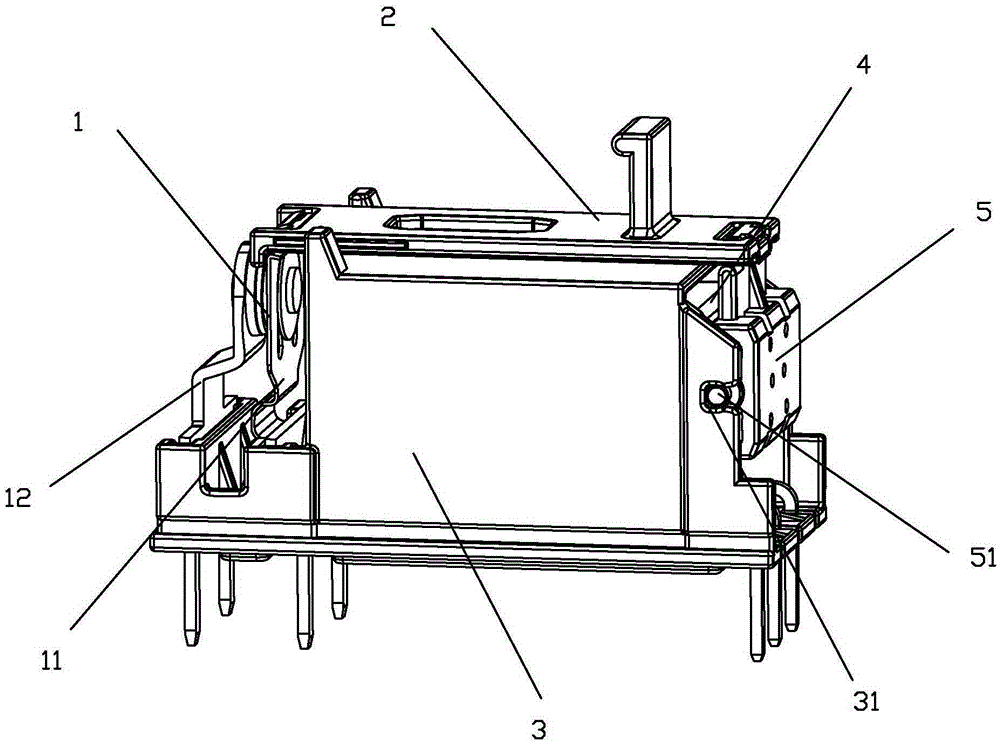

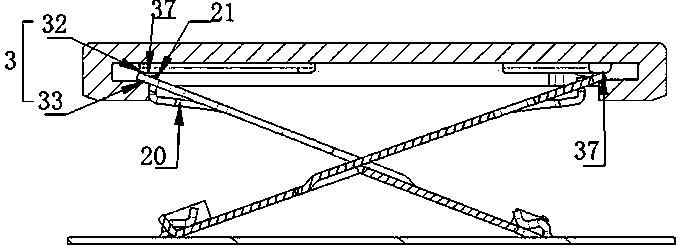

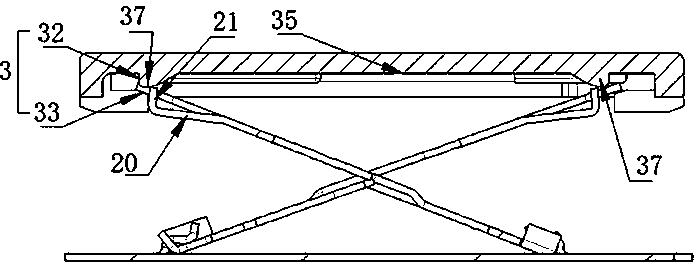

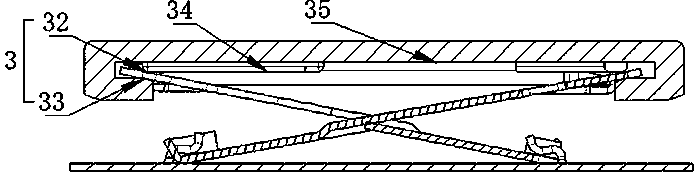

A key switch device supported by sheet metal scissor feet with elastic hook limit structure

ActiveCN105390308BReduce factory defect rateSolve the long-standing problem of losing keysContact operating partsFoot supportsMiniaturization

A key switch device supported by sheet metal scissor feet with a cantilever elastic hook limit structure of the present invention is characterized in that: the scissor foot support 16 is stamped and formed on the metal plate surface; the scissor foot support 16 is formed with elasticity The sheet metal elastic cantilever 20, the scissors foot support 16 has a stamped and formed scissors anti-off structure; the key cap 1 is provided with a key limit boss 45, and the mutually supporting scissors feet support 16 passes through the scissors anti-off structure Cooperate with the key limiting boss 45 of the key cap 1 to prevent the key from coming out or limit the key cap 1 to the upper limit position; the key switch device of the metal scissor foot structure can be widely used in computer keyboards, palmtop computers, various A type of embedded keyboard and a key switch device for keystroke operation. The strength and structural rigidity of the supporting structure of the scissor feet are greatly improved, and the metal scissor feet realizes ultra-light, ultra-thin and further realizes the miniaturization of the key device.

Owner:陈峰

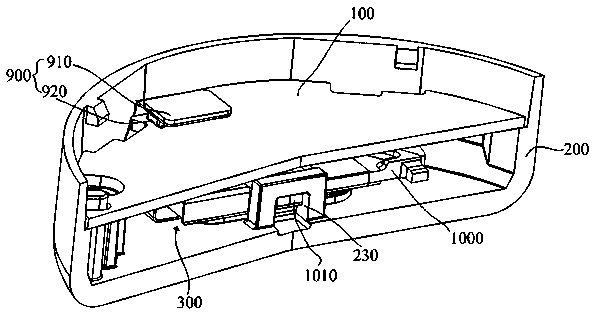

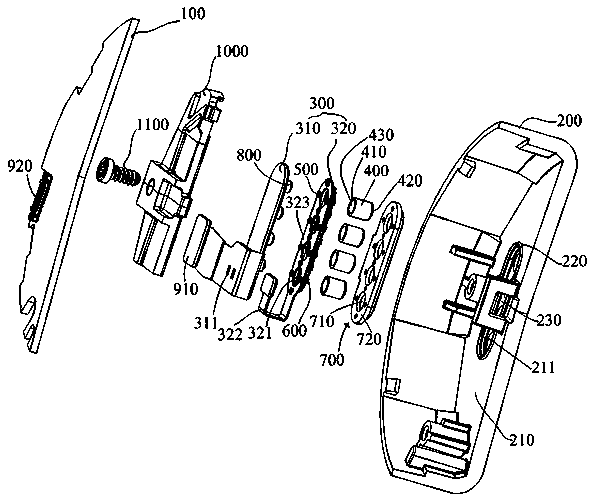

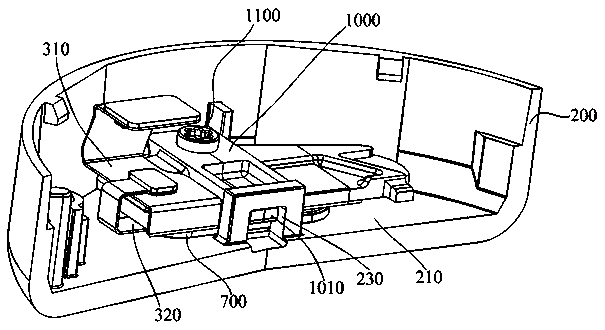

Charging needle water-resistant mounting structure, charging needle water resistance detection method and wrist-mounted equipment

PendingCN109238566AImproved waterproof stability and reliabilityImprove waterproof effectCouplings bases/casesFluid-tightness measurementWristElectricity

The invention provides a charging needle water-resistant mounting structure, a charging needle water resistance test method and wrist-mounted equipment, and aims at realizing real-time detection for water resistance at charging needle positions and improving the water resistance stability and reliability at charging needle positions of products. According to the charging needle water-resistant mounting structure, a first end of a charging needle is fixed on one side surface of an FPC adapter plate and a second end of the charging needle extends into a charging needle hole; a humidity sensor and the temperature sensor are located around the charging needle and electrically connected with a main control panel; a heating device is arranged to correspond to the charging needle and is electrically connected with the main control panel; a sealing member is arranged to correspond to the charging needle, extends into the charging needle and is sleeved on the charging needle; and the sealing member is in clearance fit with both the charging needle hole and the charging needle. The temperature sensor and the humidity sensor are used for detecting the temperature and humidity at the chargingneedle in real time, so that real-time detection and control of water resistance are realized, and the water resistance stability and reliability are improved; and through a thermal expansion effect,the interference amounts and extrusion force between the sealing member and the charging needle hole and the charging needle are strengthened, so that the water resistance effect is improved.

Owner:GEER TECH CO LTD

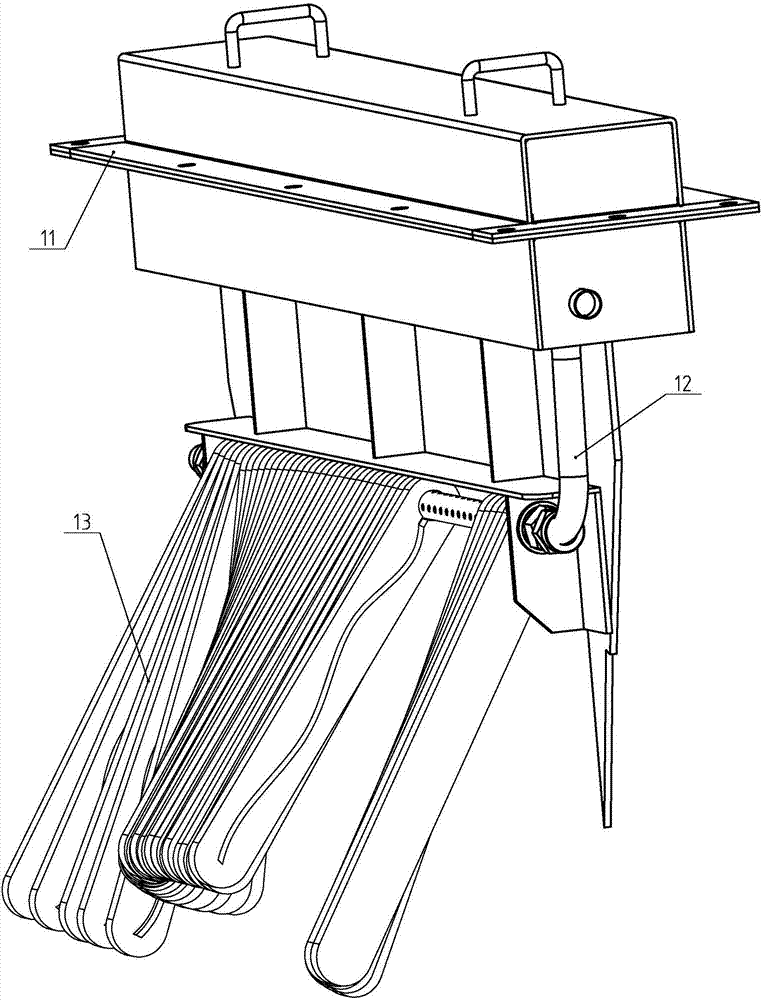

Three-phase foam sealing, pressure relief and dust suppression equipment and material transfer equipment including equipment

ActiveCN107499972AGuaranteed sealing performanceReduce positive pressureConveyorsLoading/unloadingPositive pressureEngineering

The invention relates to material transfer equipment, in particular to three-phase foam sealing, pressure relief and dust suppression equipment. The three-phase foam sealing, pressure relief and dust suppression equipment comprises a first foam dynamic raft type check curtain, a second foam dynamic raft type check curtain, a foam sealing skirtboard, a foam spring pressure relief device and a foam liquid preparation unit. Each foam dynamic raft type check curtain comprises multiple raft pieces rotationally connected with a pipe body. Each raft piece is provided with a first through hole and grooves. Multiple second through holes are formed in each pipe body along the peripheral face of the pipe body, and the second through holes of each pipe body communicate with the corresponding first through holes. The foam sealing skirtboard is provided with a first columnar portion and a second columnar portion, the first columnar portion is provided with ceramic pipes, and multiple cavities used for containing foam liquid are formed between the second columnar portion and the first columnar portion. A foam liquid spray opening, a fixed set, a spring set, a foam disc, a first fixed pulley, a drive motor, a second fixed pulley and a water outlet used for pipeline washing re arranged at the position, close to a first end opening, of the foam spring pressure relief device. According to the three-phase foam sealing, pressure relief and dust suppression equipment, sealing of a guide chute can be dynamically guaranteed for a long time, dust overflow can be dynamically suppressed for a long time, and the positive pressure of the guide chute can be greatly reduced.

Owner:厦门三烨清洁科技股份有限公司

Waterwheel-type aerator

ActiveCN102687686BSimple structureEasy to assembleClimate change adaptationWater aerationImpellerDrive shaft

The invention belongs to an aquaculture machine and relates to a waterwheel-type aerator. The waterwheel-type aerator comprises an impeller, a floating body, a main machine, a transmission shaft and a bearing seat, wherein the floating body is connected by virtue of a thin-wall stainless steel square tube; the square tube is provided with holes through which bolts cab pass; more than two floatingboats are combined by passing the bolts through square tube holes so as to form the floating body; a reinforcing plate is arranged above the square tube holes; two sides of the floating boats are provided with grooves and the bolts are fixed in the grooves; the impeller is composed of a blade and an impeller disc; the impeller disc is provided with a retaining mechanism which is molded by injection; one end of an elastic retaining strip and the straight edge of the impeller disc are molded into a whole body by virtue of injection and the other end of the elastic retaining strip is suspended; and after the blade is assembled in place, the retraining strip is reset and the blade is prevented from being moved out.

Owner:ZHEJIANG FORDY MACHINERY

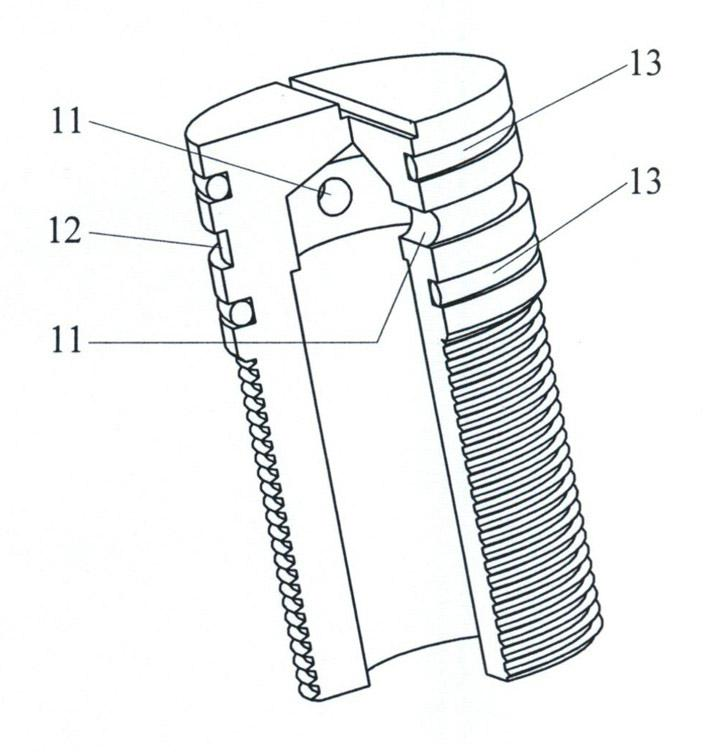

Rear retainer ring of wagon rolling bearing

InactiveCN105128883AEasy to pressReduce axial movementAxle-boxesInterference fitRolling-element bearing

The invention belongs to the technical field of bearing manufacturing, and provides a rear retainer ring of a wagon rolling bearing. The rear retainer ring (1) is provided with a rear retainer body (1-1). The inner surface of the rear retainer body (1-1) is an arc surface matched with the outer wall surface of a shaft shoulder. One side end face of the rear retainer body (1-1) is provided with an annular notch. One end of a sealing ring (1-2) is located in the annular notch in the rear retainer body (1-1), and the other end of the sealing ring (1-2) is arranged on a dust guard seat (4) in a sleeving mode. The inner diameter surface I (12) of the sealing ring is in interference fit with the outer diameter surface (14) of the dust guard seat. The inner diameter surface I (12) of the sealing ring is provided with a conical surface, and the conical surface is of a structure gradually drawing down inwards from the end, away from the rear retainer body, of the sealing ring. According to the rear retainer ring, axial movement, caused by deflection of a main shaft and a shaft neck, of the rear retainer ring is reduced, reutilization of the rear retainer ring is achieved, and the overhaul cost is lowered.

Owner:LUOYANG LYC BEARING

Sealing device and ultrasonic wheel detector

PendingCN111706717AGuaranteed sealing performanceGuaranteed tightnessPipesRailway auxillary equipmentInterference fitFluid Leak

The invention relates to a sealing device and an ultrasonic wheel detector. The sealing device comprises a sealing block and a plate shaft. The plate shaft is provided with a plate shaft through holewhich penetrates through the two ends of the plate shaft. The sealing block is provided with multiple sealing block wire passage holes. At least one end of the plate shaft through hole is provided with an inner conical surface. The diameter of the inner conical surface gradually increases from the middle of the plate shaft to the end of the plate shaft. At least one sealing block is arranged. Thesealing block is provided with an outer conical surface matched with the inner conical surface. The sealing block is in interference fit with the corresponding end of the plate shaft through hole. Wire cables are in interference fit with the sealing block wire passage holes. The sealing device and the ultrasonic wheel detector have the beneficial effects that the problems in sealing of coupling fluid of the ultrasonic wheel detector are solved, the wheel detector can be conveniently and quickly detached or installed, the sealing performance is improved, operation is convenient and quick to carry out, the time for filling glue to dry is shortened, and the assembly efficiency of the wheel detector is improved; and the service life of the wheel detector can be effectively prolonged, the problems of gas intake and interior pressure reduction of a wheel detector caused by fluid leakage happen less, and the detection quality of the wheel detector is improved.

Owner:北京地平线轨道技术有限公司

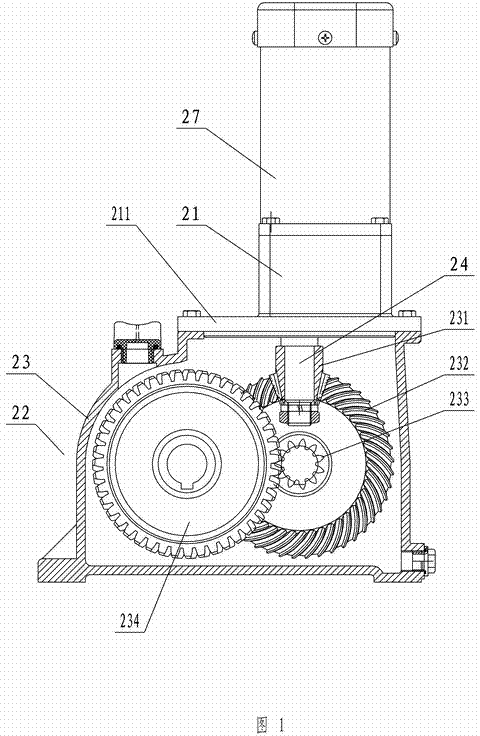

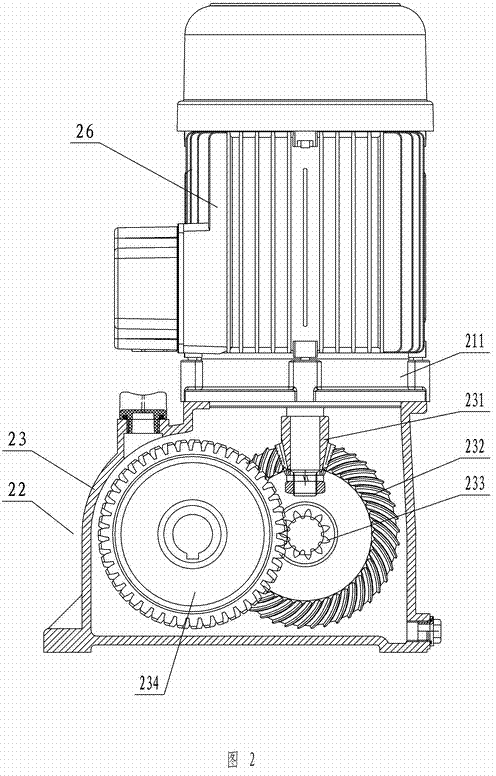

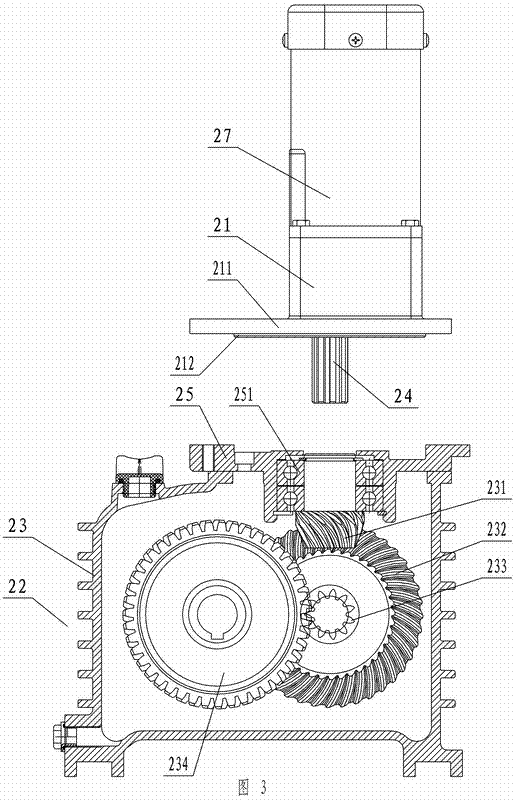

Horizontal water tilling machine

InactiveCN103081849AOutstanding FeaturesHighlight significant progressPisciculture and aquariaImpellerGear wheel

The invention belongs to aquaculture machinery, and relates to a horizontal water tilling machine which mainly comprises a motor, reduction gearboxes, an impeller and a floating body. The reduction gearboxes include a primary reduction gearbox and a secondary reduction gearbox, the primary reduction gearbox is integrated with the motor, an output shaft of the primary reduction gearbox drives a bevel pinion, the bevel pinion drives a bevel gear wheel, the bevel gear wheel and a cylindrical pinion are coaxial, the cylindrical pinion drives a cylindrical gear wheel, the output shaft penetrates through a seal, then extends out of one side or two sides of a gearbox body and drives the impeller to rotate, and the integral horizontal water tilling machine floats on a water surface owing to the floating body. The primary reduction gearbox is connected with the secondary reduction gearbox by a flange, and the positioning dimension of a joint surface of the flange is identical to that of a joint surface of a flange of a motor of an aerator. The horizontal water tilling machine has the advantages that the horizontal water tilling machine is applied to aquaculture, when fish and shrimp are young, oxygen consumption is low, the water tilling machine can be started to enable water to flow, the quality of the water of a pond is improved, and the water tilling machine is low in power consumption; and when the fish and shrimp grow to a certain degree, the oxygen consumption is increased, the pond can be aerated as needed by means of disassembling the primary reduction gearbox and using the horizontal water tilling machine with the motor of the aerator, and other structural change is omitted.

Owner:ZHEJIANG FORDY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com