Tool capable of controlling heat treatment distortion of high pressure turbine static case

A heat treatment deformation, high-pressure turbine technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of gaps in constraints, not easy to take out, and no constraints, etc., to control deformation, reduce processing costs, repeat The effect of high usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

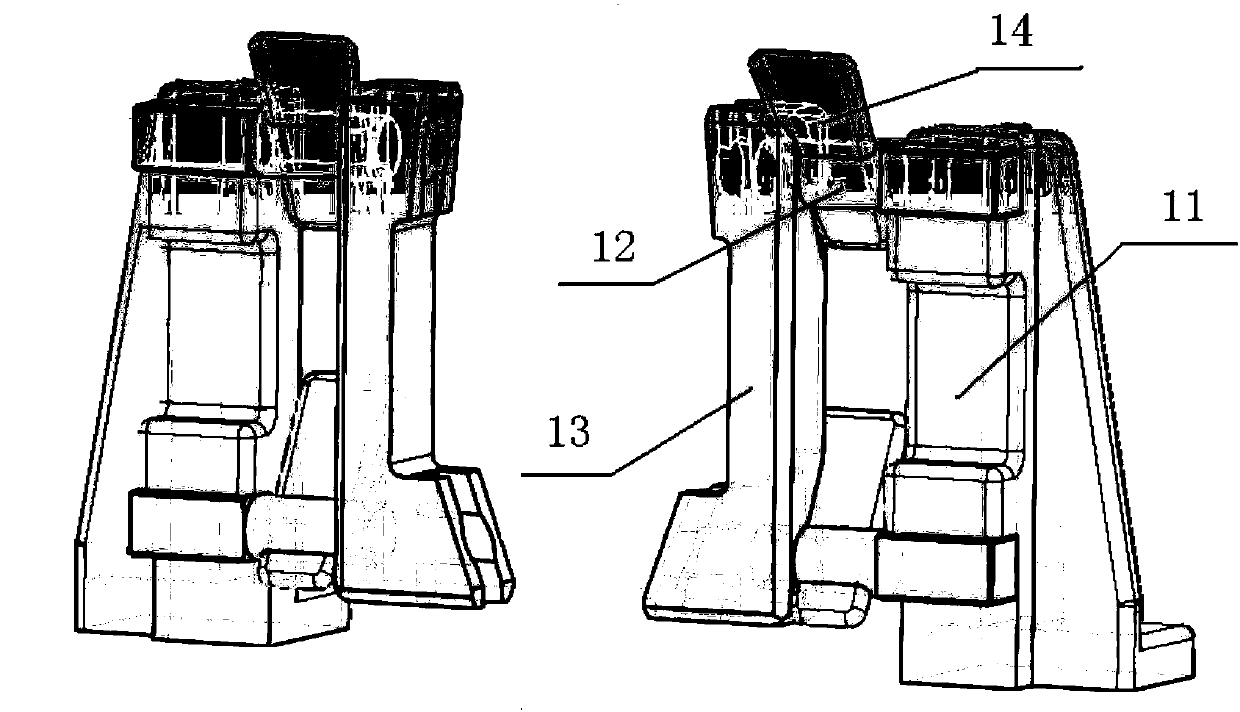

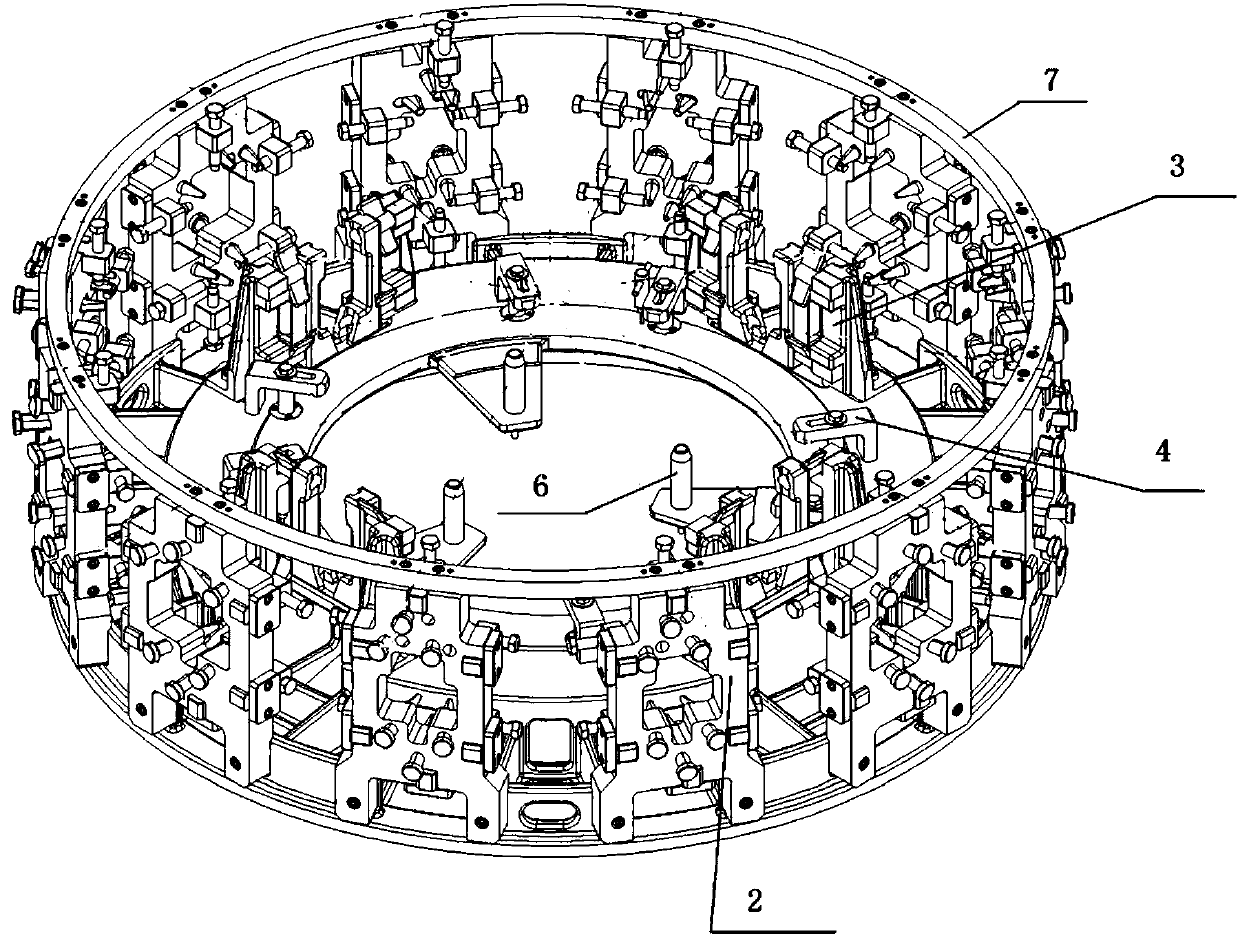

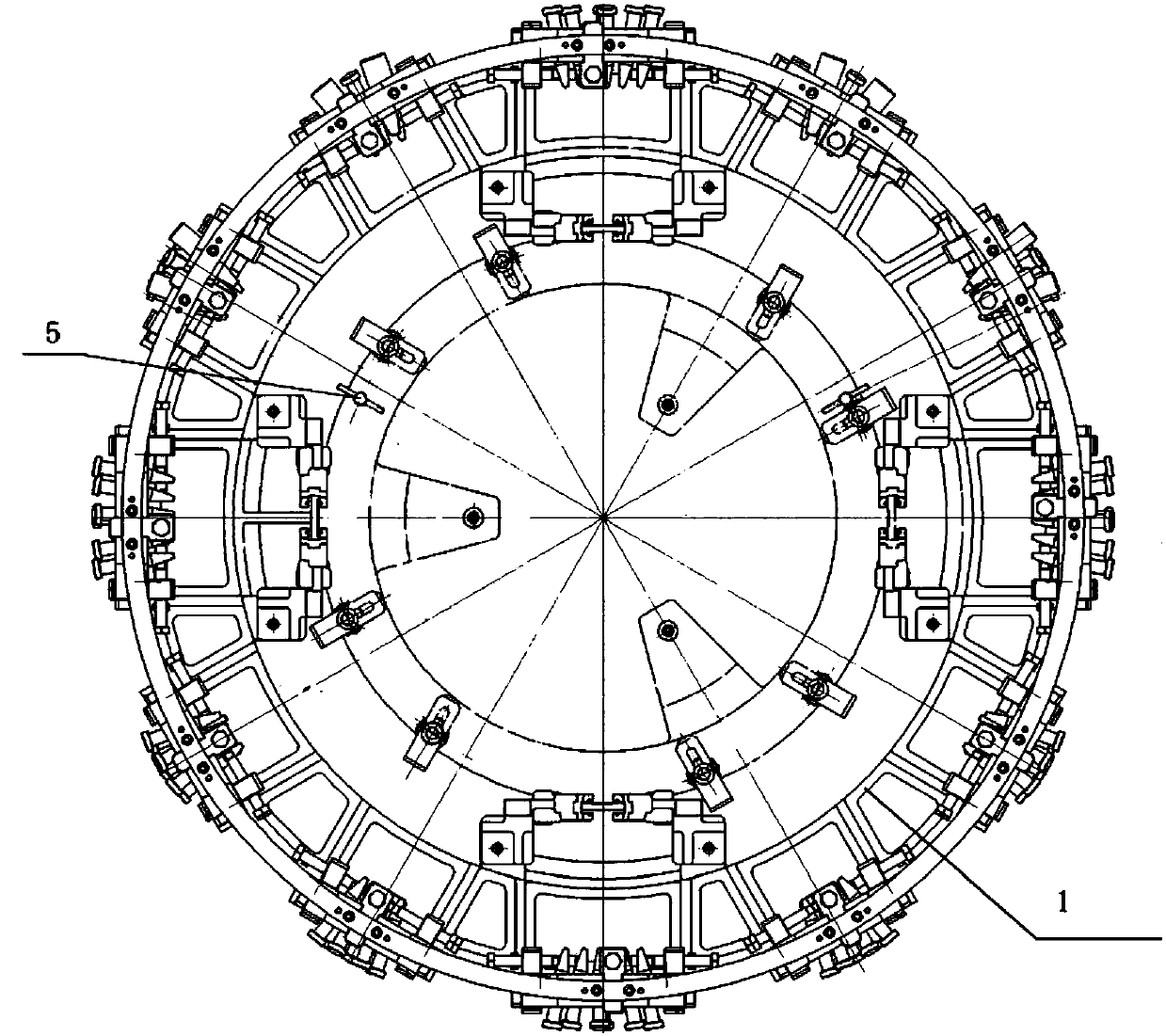

[0026] The tool for controlling the heat treatment deformation of the high-pressure turbine stationary casing described in this embodiment, the control target high-pressure turbine stationary casing is as attached Figure 5 As shown, the structure of the tooling is as attached figure 1 , 2 , 3 and 4, its composition mainly includes a chassis 1 with a hollow center, two first-type positioning pins 5 located on the chassis for positioning the receiver in mirror symmetry, and for positioning the shaft center of the receiver 3 evenly distributed cylindrical table shaft seats 6, 8 pressing plate assemblies for pressing and fixing the casing evenly distributed, connecting plate fixing device for fixing the blade connecting plate 16, and fixing support plate blade 15 The blade body fixing device of the blade body, and the top ring 7 used to connect all the connecting plate fixing devices into one body. The pressure plate assembly is composed of a pressure plate 4 with a cantilever stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com