Connection structure of armature portion and pedestal of magnetic latching relay

A magnetic latching relay and connection structure technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems affecting the stability of relay parameters, easy to generate assembly dross, product failure, etc., to improve product reliability, Small interference fit and less plastic lint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

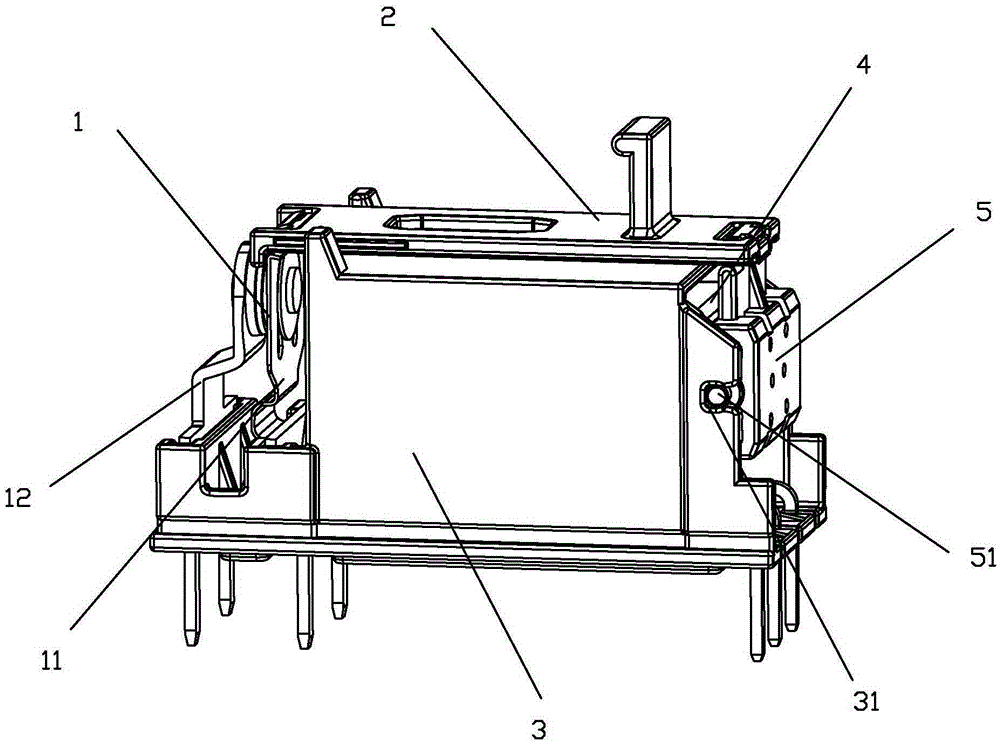

[0027] see Figure 1 to Figure 10 As shown, a magnetic latching relay of the present invention includes a magnetic circuit system, a contact system 1, a push part 2 and a base 3, wherein the magnetic circuit system is composed of a magnetic circuit part 4 and an armature part 5, and the contact system 1 includes a moving spring 11 and static spring 12; the pushing part 2 is a pushing block; the magnetic circuit part 4 usually includes a yoke, an iron core and a coil.

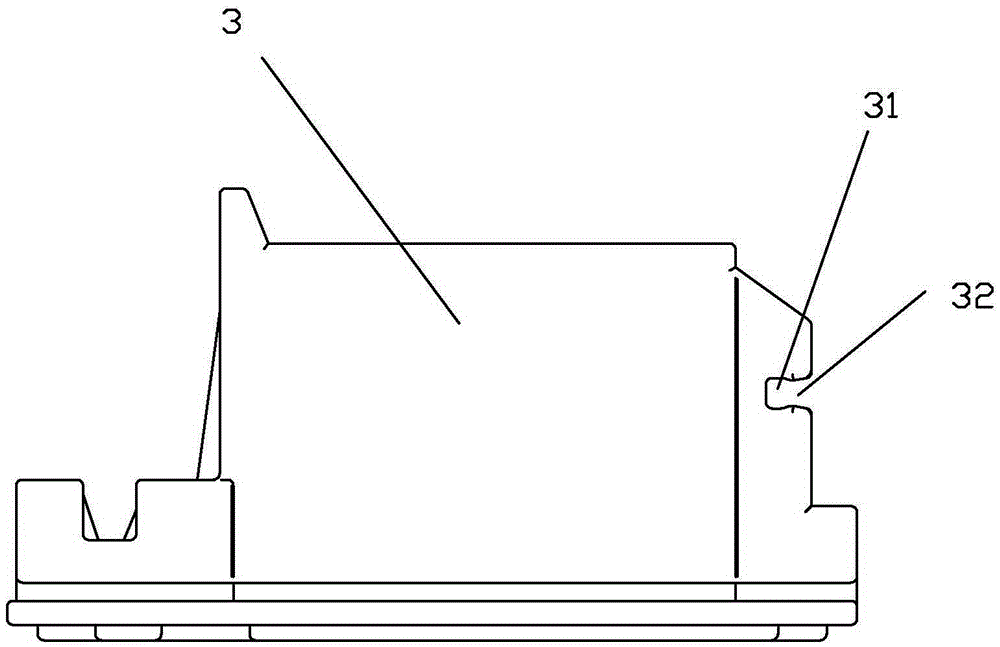

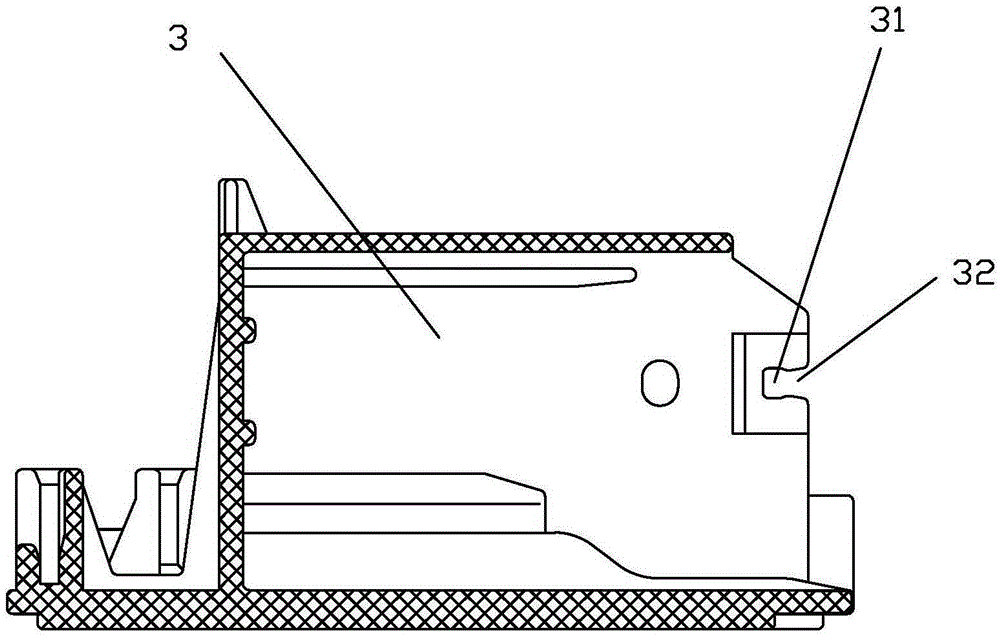

[0028] A connection structure between the armature part and the base of a magnetic latching relay in the present invention, the armature part 5 is provided with a circular rotating shaft 51, and the base 3 is provided with a shaft hole 31 for supporting the rotating shaft of the armature part. The rotating shaft 51 of the armature part 5 is fitted to rotate in the shaft hole 31 of the base. When the magnetic latching relay is reset or set, the rotating shaft 51 will rotate in the shaft hole in the forward or rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com