Three-phase foam sealing, pressure relief and dust suppression equipment and material transfer equipment including equipment

A foam and equipment technology, applied in the field of material transfer equipment, can solve the problems that the curtain cannot suppress dust, cannot be dynamic, and induces strong wind, etc., to save equipment costs and labor costs, improve foaming efficiency, and improve the effect of dust suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

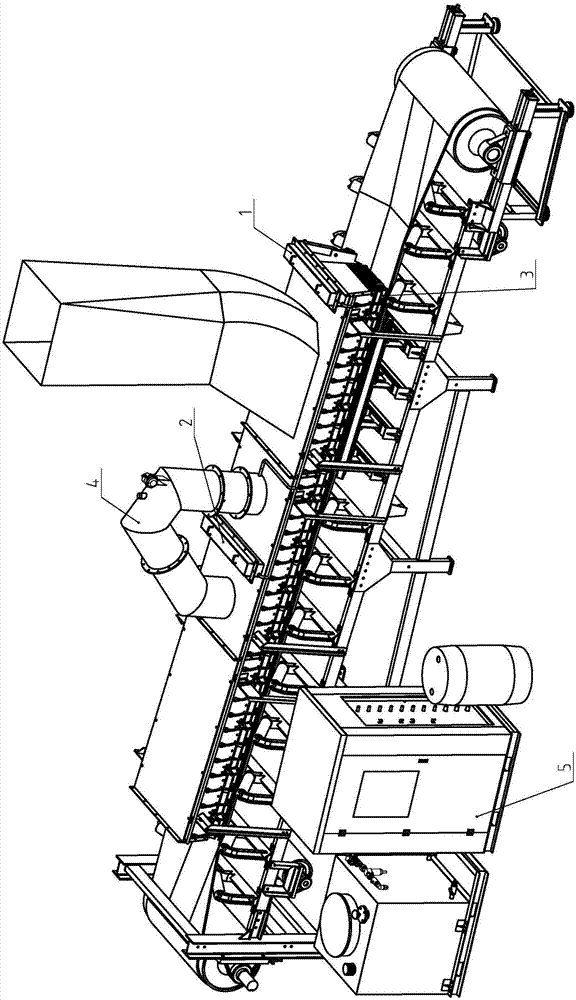

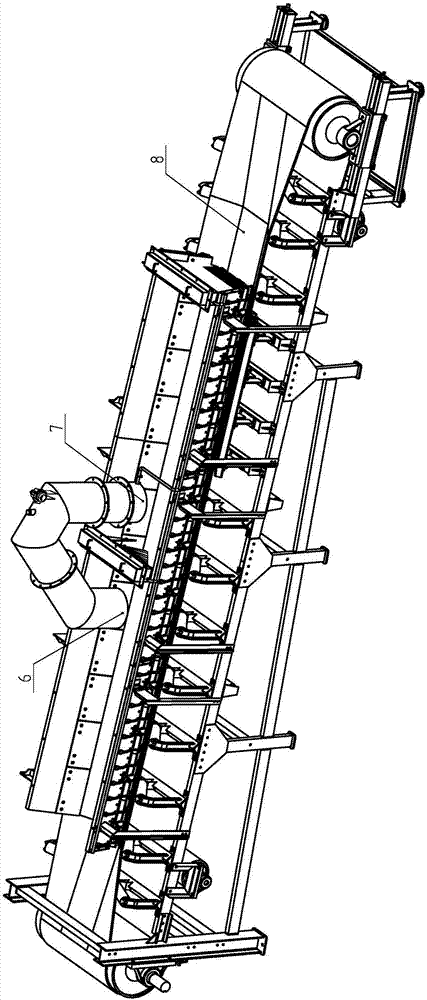

[0054] like figure 1 The material transfer equipment shown includes a belt 8, a motor, a material guide groove, a drop pipe, a first foam dynamic raft curtain 1, a second foam dynamic raft curtain 2, a foam sealing skirt 3, Foam spring pressure relief device 4 and foam liquid preparation unit 5, the first foam dynamic raft curtain 1 is arranged at the tail of the guide trough, the second foam dynamic raft curtain 2 is arranged at the outlet of the guide trough, and the foam sealing skirt The plate 3 is arranged at the edge of the guide groove and the belt 8, the foam spring pressure relief device 4 is arranged on the top of the material guide groove, and the second foam dynamic raft curtain 2 is located at the first port 6 and the second port of the foam spring pressure relief device 4. Between the two ports 7, the foam liquid preparation unit 5 is arranged near the material guide groove according to the site conditions, the first foam dynamic raft curtain 1, the second foam d...

Embodiment approach 2

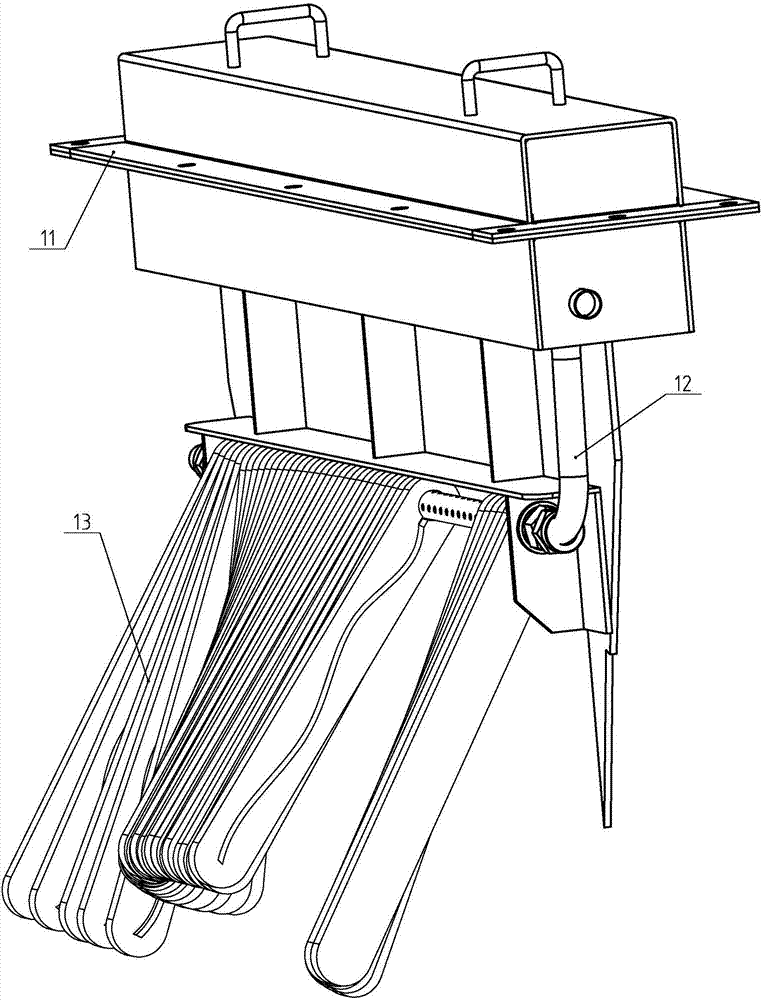

[0066] like Figure 12-14 As shown, the foam liquid nozzle 41, the spring group 43 and the first fixed pulley 46 in the first embodiment are removed, the foam plate 44 is fixedly connected to the fixed net 42, and the turntable 411 is coaxially arranged on the foam plate 44. The turntable 411 The base is fixedly connected with the foam plate 44, the blade 412 of the turntable 411 is rotated under the action of the driving rod 413, and the blade 412 is provided with a scraper 414 and a liquid outlet 415 on the bottom surface of the blade 412 close to the foam generating plate 45. The scraper 414 and the foam generating plate 45 is movably fitted, and a liquid storage cavity 416 for storing foam liquid is provided inside the turntable 411 , and the liquid storage cavity 416 communicates with the liquid outlet 415 . The turntable 411 is connected with the drive motor 48 through the rotating shaft 417 , and a transmission rod 418 is coaxially arranged inside the rotating shaft 417...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com