Fast repair spare part of shaft end of cooling table roller way and use method thereof

A technology for spare parts and roller table, which is applied in the field of quick repairing spare parts for the shaft head of the roller table of the cooling bed, which can solve the wear of the shaft diameter at the bearing assembly of the shaft head of the roller table, the long time for the replacement and maintenance of the roller table, and the inner ring of the shaft head of the roller table. and other problems, to achieve the effect of saving maintenance time, simple and practical effect, and improving the amount of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

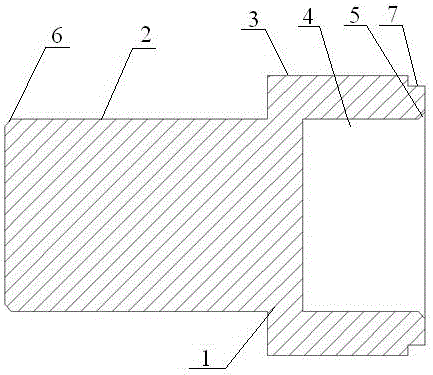

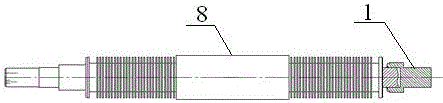

[0024] Such as figure 1 As shown, a quick repair spare part for the shaft head of a cooling bed roller table includes a shaft head body 1, and the shaft head body 1 includes a shaft rod 2 and a shaft head seat 3, and the shaft rod 2 and the shaft head seat 3 adopt 45# Round steel is integrally processed and formed. The outer diameter of the shaft head seat 3 is larger than the outer diameter of the shaft rod 2, and a cylindrical shaft head inner hole 4 is provided in the middle of one end of the shaft head seat 3, and the opening end of the shaft head inner hole 4 is provided with an inner chamfer 5. The end of the shaft 2 is provided with an outer chamfer 6 .

[0025] Specifically, in order to facilitate welding and assembly with the old cooling bed roller table, and to mee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com