Sealing device and ultrasonic wheel detector

A sealing device, ultrasonic technology, applied in the direction of transportation and packaging, railway car body parts, pipes, etc., can solve the problems of uneven sealing effect of glue, restricting the performance of the probe wheel, disassembly and maintenance of the probe wheel, etc., to save time , good operability, and the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

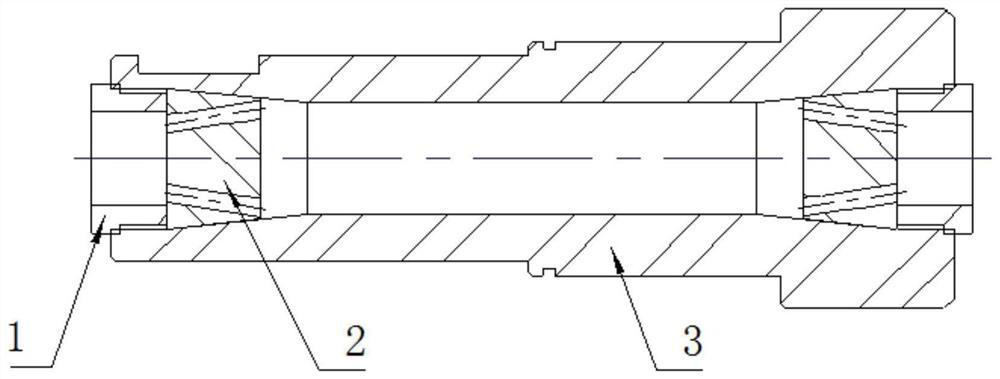

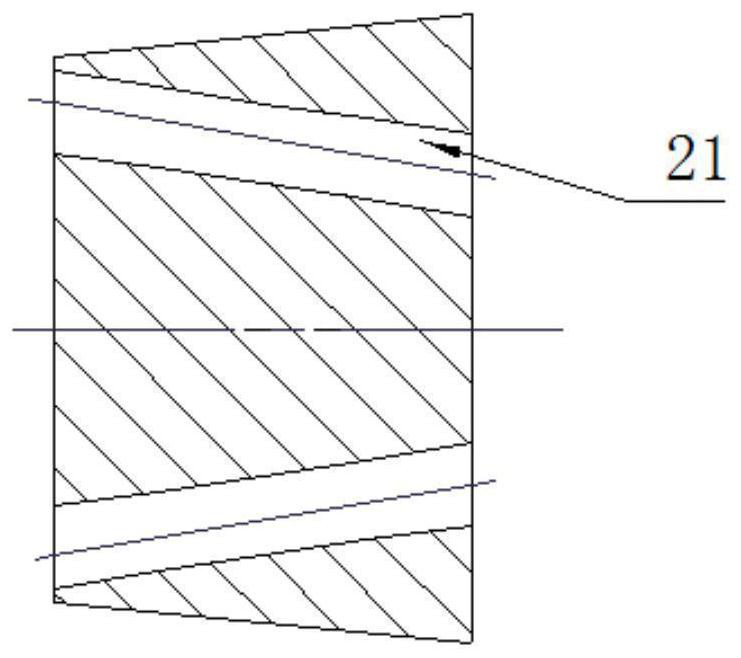

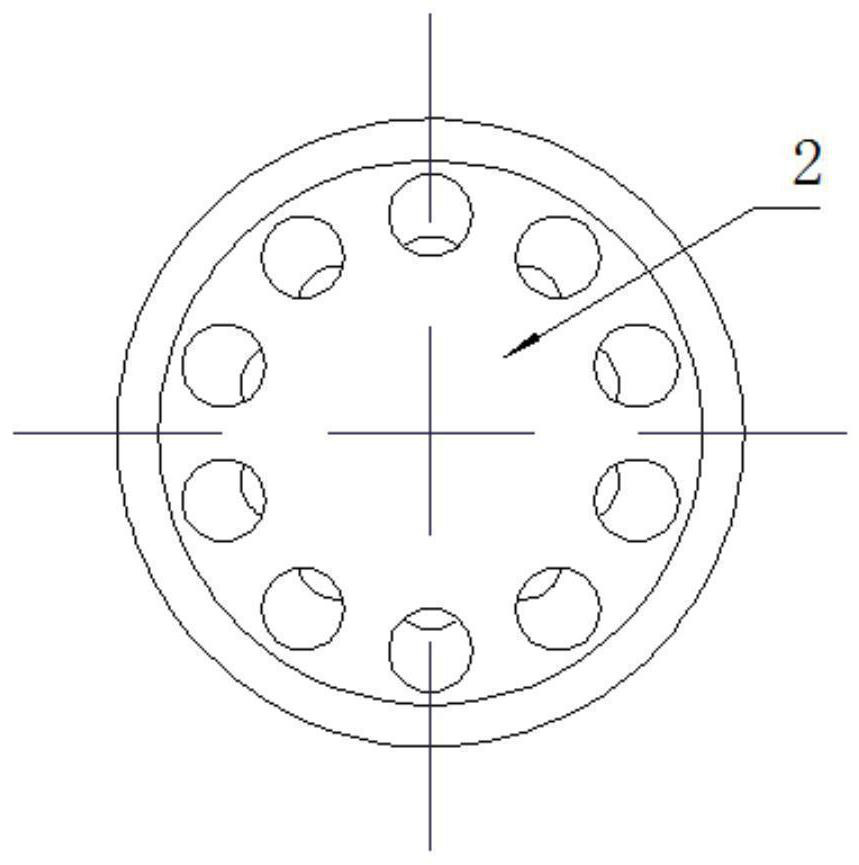

[0034] Such as Figure 1-Figure 5 As shown, this embodiment relates to a sealing device, including a sealing block 2 and a disk shaft 3, the disk shaft 3 has a disk shaft through hole passing through its two ends, and the sealing block 2 has a plurality of holes for passing cables The sealing block passing hole 21, at least one end of the disc shaft through hole has an inner cone surface, the diameter of the inner cone surface gradually increases from the middle of the disc shaft 3 to the end, and the sealing block 2 is provided with at least one , and has an outer tapered surface matching the inner tapered surface, the sealing block 2 is interference fit with the end corresponding to the through hole of the disk shaft, and the cable passes through the cable ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com