Designing and manufacturing method and sealing method of sealing structure of oil well pipe joint

A sealing structure and manufacturing method technology, applied in drilling equipment, design optimization/simulation, casing, etc., can solve problems such as disappearance, oil well pipe joint leakage, thread loosening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

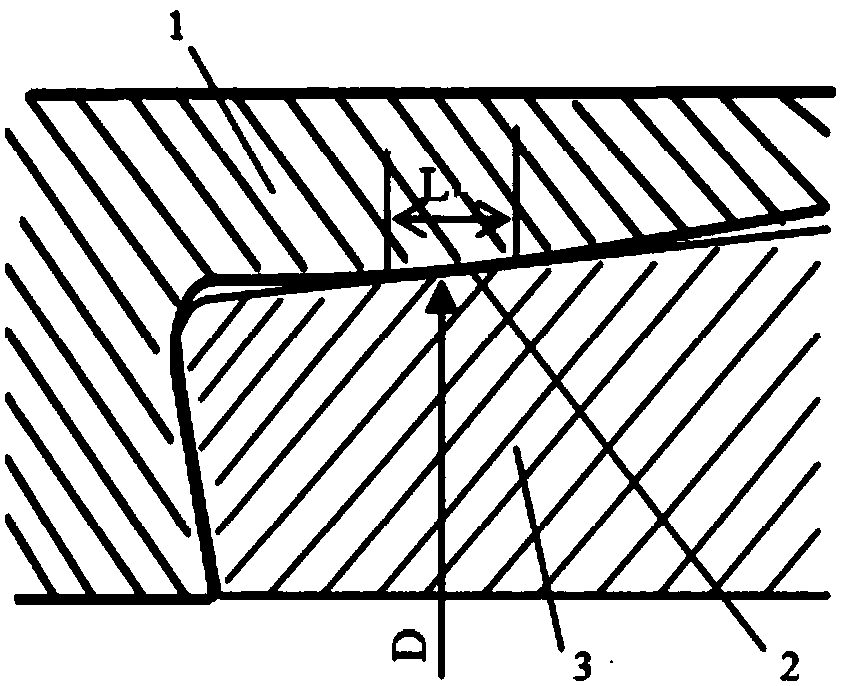

[0197] Example 1. Using additive manufacturing technologies such as surfacing or 3D printing, the superelastic shape memory alloy is used to manufacture a sealing cladding layer, and the sealing cladding layer is laminated on the surface of the sealing structure of the oil well pipe joint to form the sealing structure shown in Figure 4.

[0198] According to the design results of step 1 and step 2, the width of the sealing cladding layer of the superelastic shape memory alloy is L≥2.2mm, which can take a value of L=3~10mm, and the strain of the superelastic shape memory alloy is ε e = 4%; ε s is the elastic deformation of the steel material of the oil well pipe joint body, which can be taken as ε s = 0.2%; the average value of the outer diameter and inner diameter of the oil well pipe joint is approximately equal to the outer diameter of the oil pipe or the diameter of the sealing circular surface D = 80mm. If the thickness of the sealing cladding layer of the superelastic sh...

example 2

[0199] Example 2: Apply the superelastic shape memory alloy sealing ring design and manufacturing technology to form the sealing structure shown in Figure 5 to realize the sealing of the oil well pipe joint.

[0200] According to the design results of step 1 and step 2, the width of the superelastic shape memory alloy sealing ring should be L≥2.2mm, which can be taken as L=3~8mm, and the elastic strain of the superelastic shape memory alloy is ε e = 4%; ε s is the elastic deformation of the steel material of the oil well pipe joint body, which can be taken as ε s = 0.2%; the average value of the outer diameter and inner diameter of the oil well pipe joint is approximately D = 80mm. If the thickness of the superelastic shape memory alloy sealing ring is t=3.0mm, then the radial interference of the sealing surface is θ=θ e +θ s =ε e t+ε s D=0.30mm. Outer diameter of sealing surface of male thread joint D ps It is basically the same as the existing TGRC special thread, nam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com