Sealing connection method of metal and glass of novel medium-high temperature solar energy heat collection pipe

A solar heat collecting tube, medium and high temperature technology, applied in the field of solar energy applications, can solve the problems of reduced air tightness of the device, low output, high price, etc., and achieve the effects of reducing the possibility of bursting, saving production costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

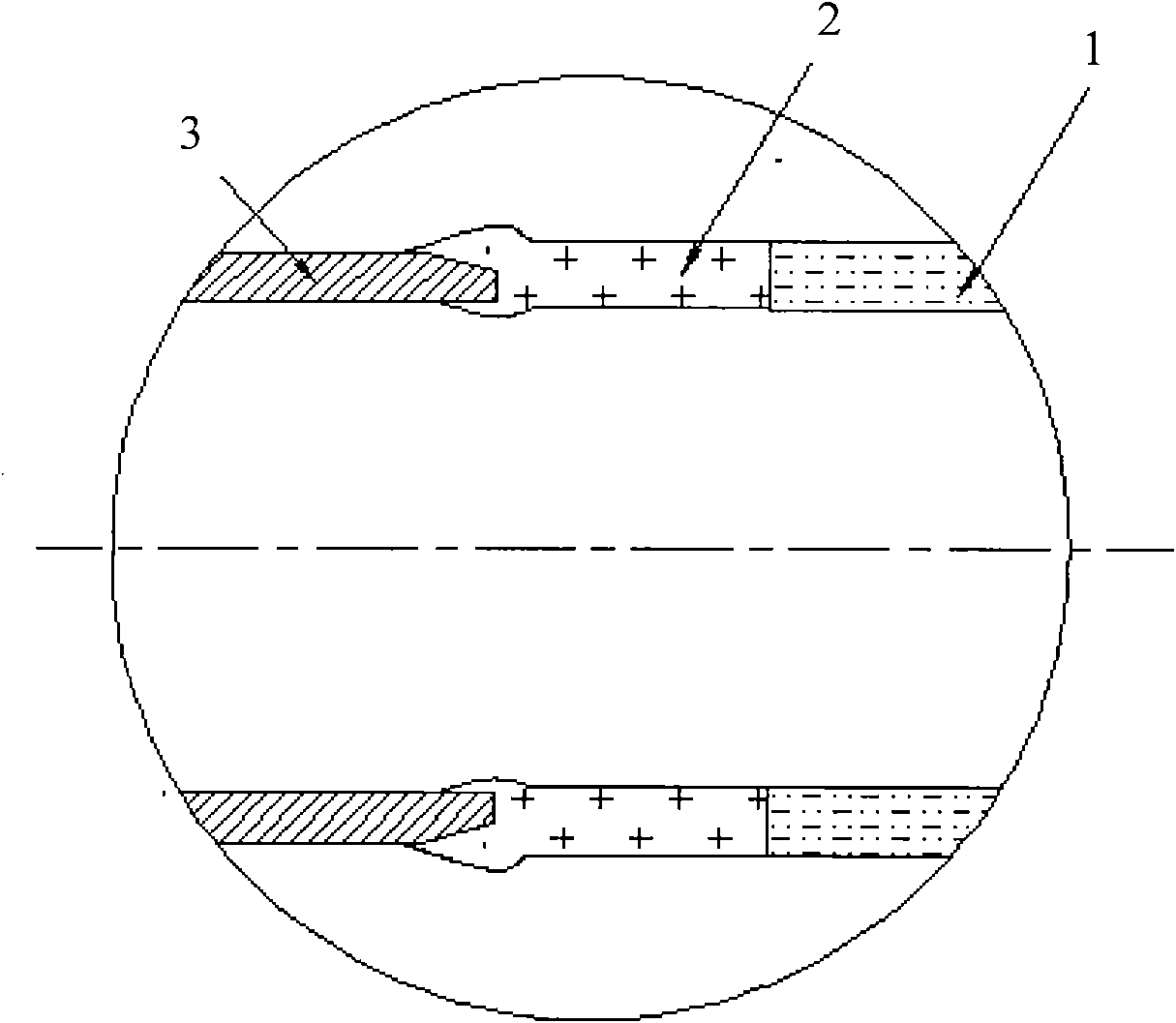

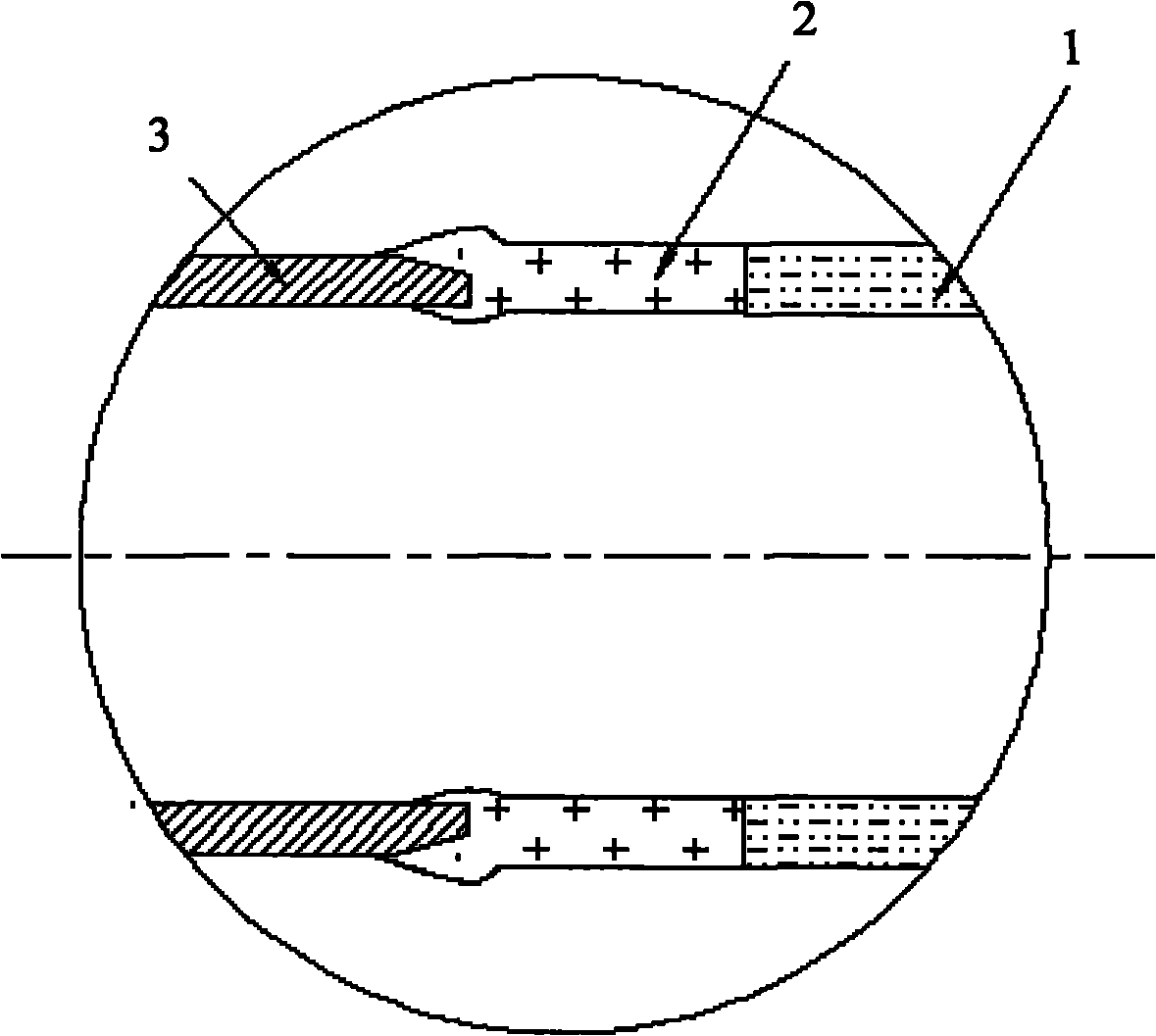

[0012] The present invention is a novel method for sealing metal and glass of medium and high temperature solar collector tubes, such as figure 1 As shown, the neutral borosilicate glass 1 is first sealed with the transition glass 2, and then the transition glass 2 is directly sealed with the Kovar alloy 3. The expansion coefficients of neutral borosilicate glass 1, transition glass 2 and Kovar 3 are 4.8×10 -6 ~5.2×10 -6 / °C, 4.7×10 -6 ~5.2×10 -6 / °C and 4.7×10 -6 ~5.2×10 -6 / °C, transition section glass 2 adopts electronic glass DM308. The neutral borosilicate glass refers to a thermal expansion coefficient of 4.8~5.2×10 -6 / ° C (20 ~ 300 ° C), glass with a light transmittance of 91%, its chemical properties are stable, water resistance level, acid resistance level, alkali resistance level A, and has strong resistance to cold and heat shock a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com