Cylindrical driven clamping type piezoelectric wriggle linear motor

A linear motor, clamping technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of low concentricity, large axial size, and control accuracy Low-level problems, to achieve the effect of high concentricity, small axial size, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

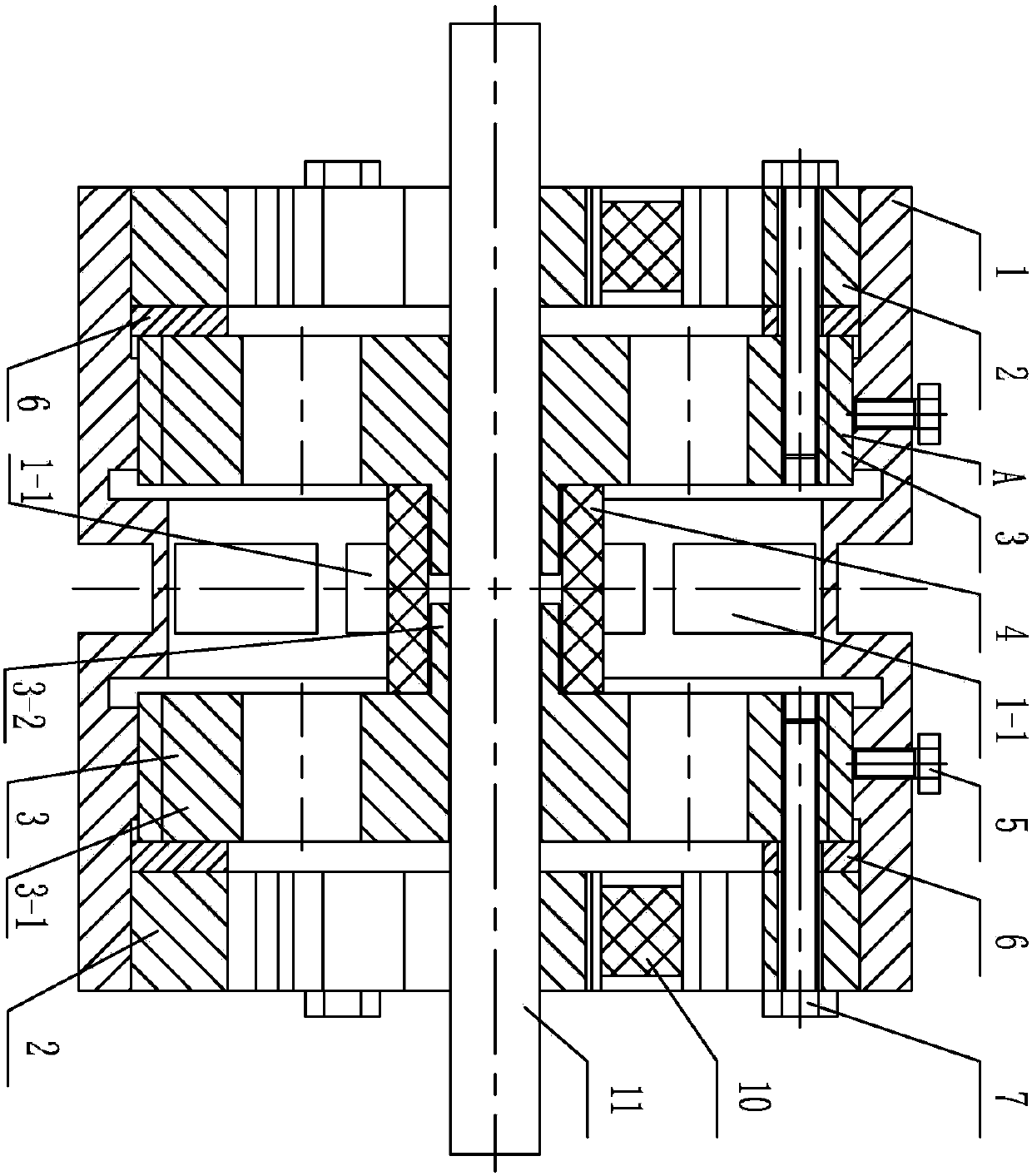

[0016] Specific implementation mode one: combine Figure 1-Figure 5 Illustrate, a kind of cylindrical passive clamp type piezoelectric peristaltic linear motor of this embodiment comprises guide rail 11, driving mechanism A, two annular washers 6 and two sets of clamping mechanisms B, each of said washers 6 is a circle Ring, the guide rail 11 is cylindrical;

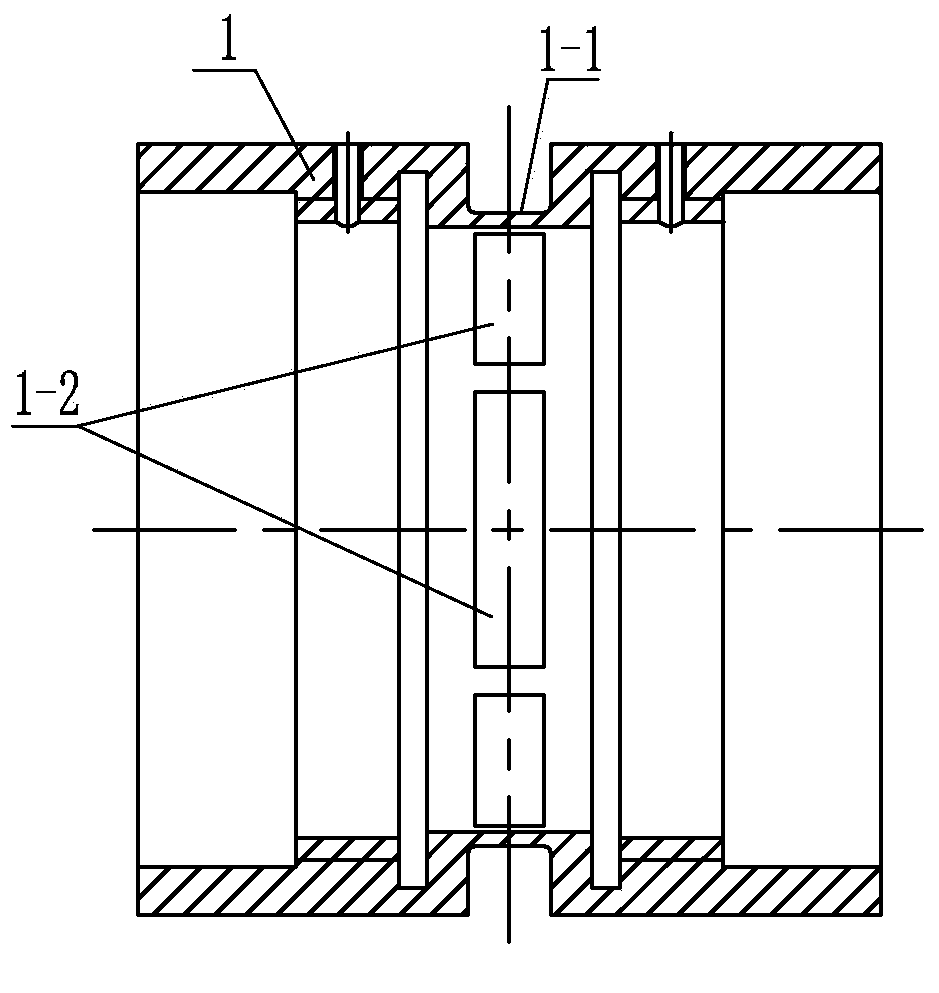

[0017] The drive mechanism A includes a drive sleeve 1, a first piezoelectric stack 4 and two clamping bodies 3; the drive sleeve 1 is cylindrical, and the first piezoelectric stack 4 is a hollow cylinder, each The clamping body 3 is a hollow cylinder;

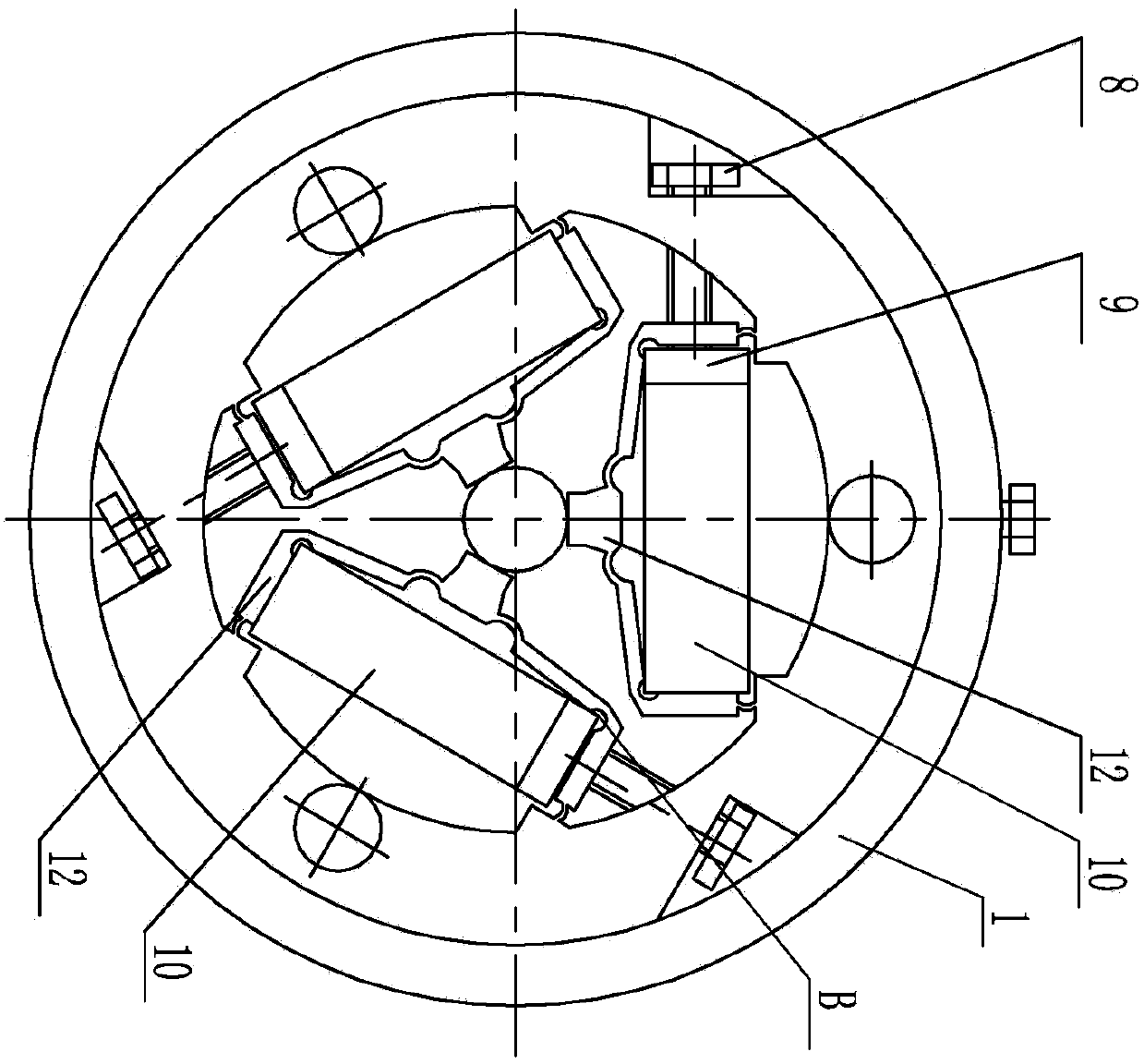

[0018] Each clamping mechanism B includes a clamping body 2, three second piezoelectric stacks 10 and three flexible bodies 12; each clamping body 2 is a hollow cylinder, and each second piezoelectric stack 10 is a cuboid , the section of each flexible body 12 is {-shaped;

[0019] A first piezoelectric stack 4 is installed in the middle of the driving sleeve 1, and a...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 2 To illustrate, the clamping body 2 of this embodiment is in clearance fit with the drive sleeve 1 . Such arrangement ensures the relative movement of the clamping body and the driving sleeve. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 To illustrate, the washer 6 in this embodiment is in clearance fit with the drive sleeve 1 . In this way, the axial compression of the clamping body, the clamping body and the washer will not affect the circumferential deformation of the flexible mechanism on the clamping elastic body, which is beneficial to realize the triangular displacement amplification of the flexible body on the clamping body. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com