Patents

Literature

108results about How to "High displacement resolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

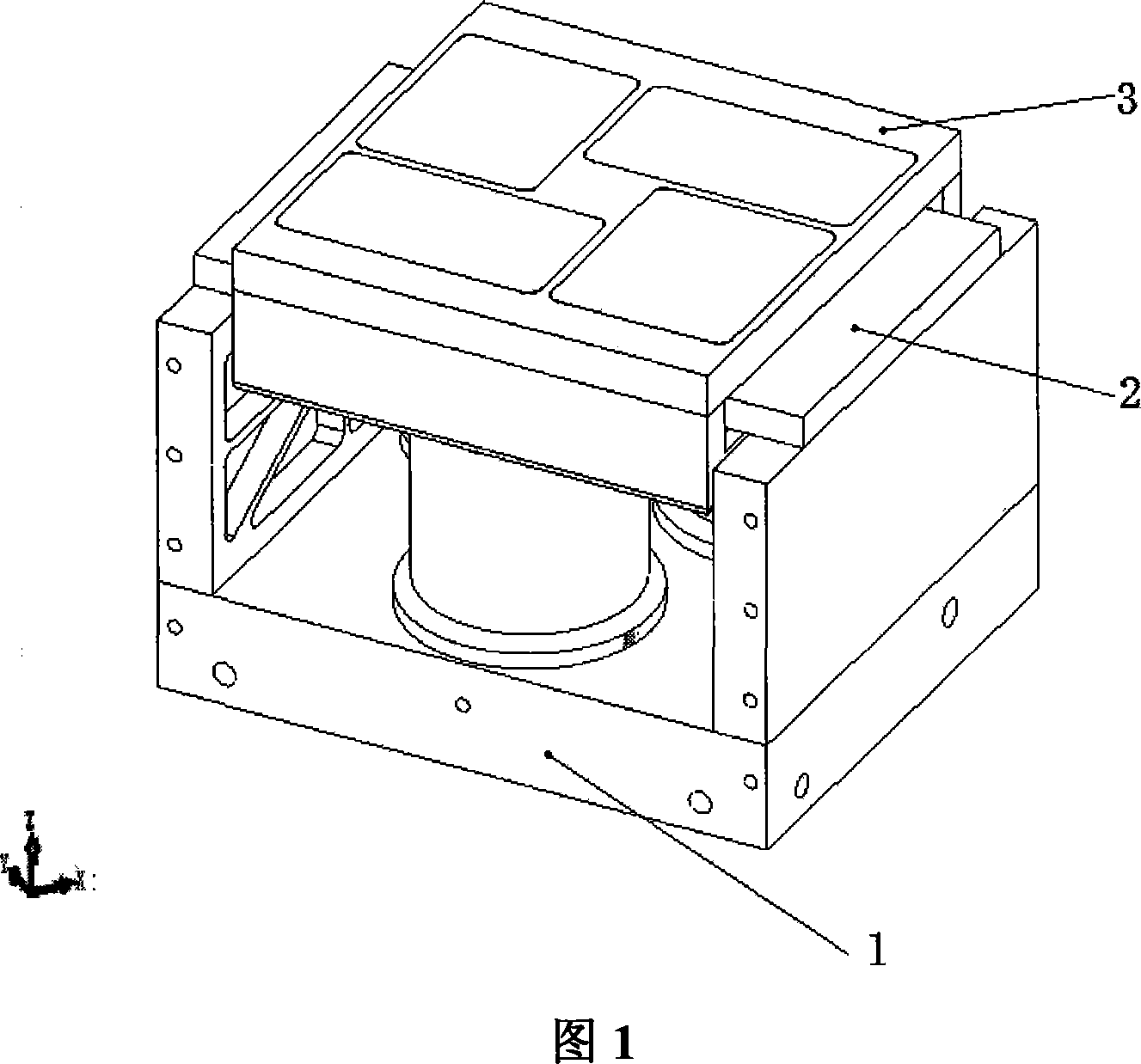

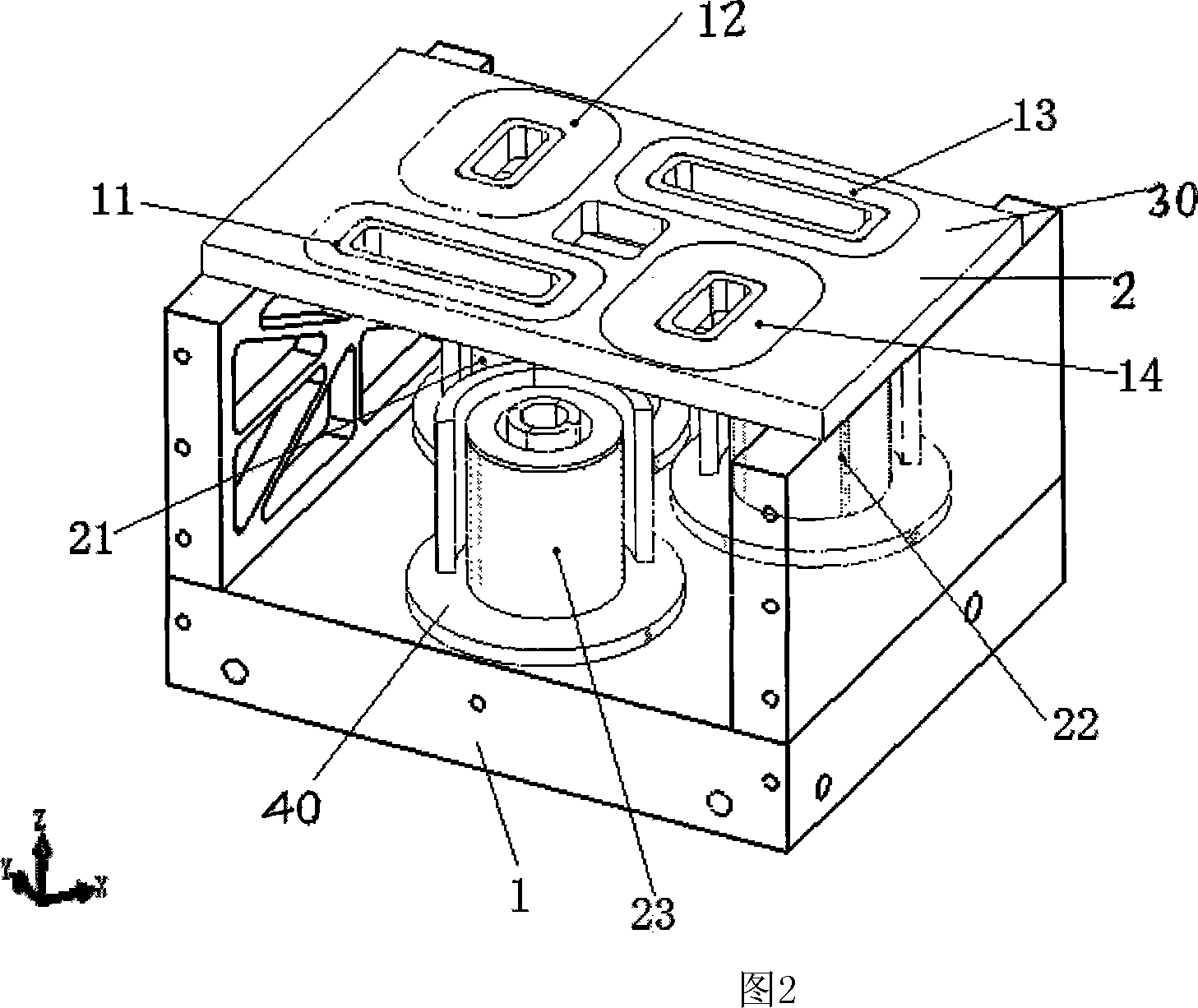

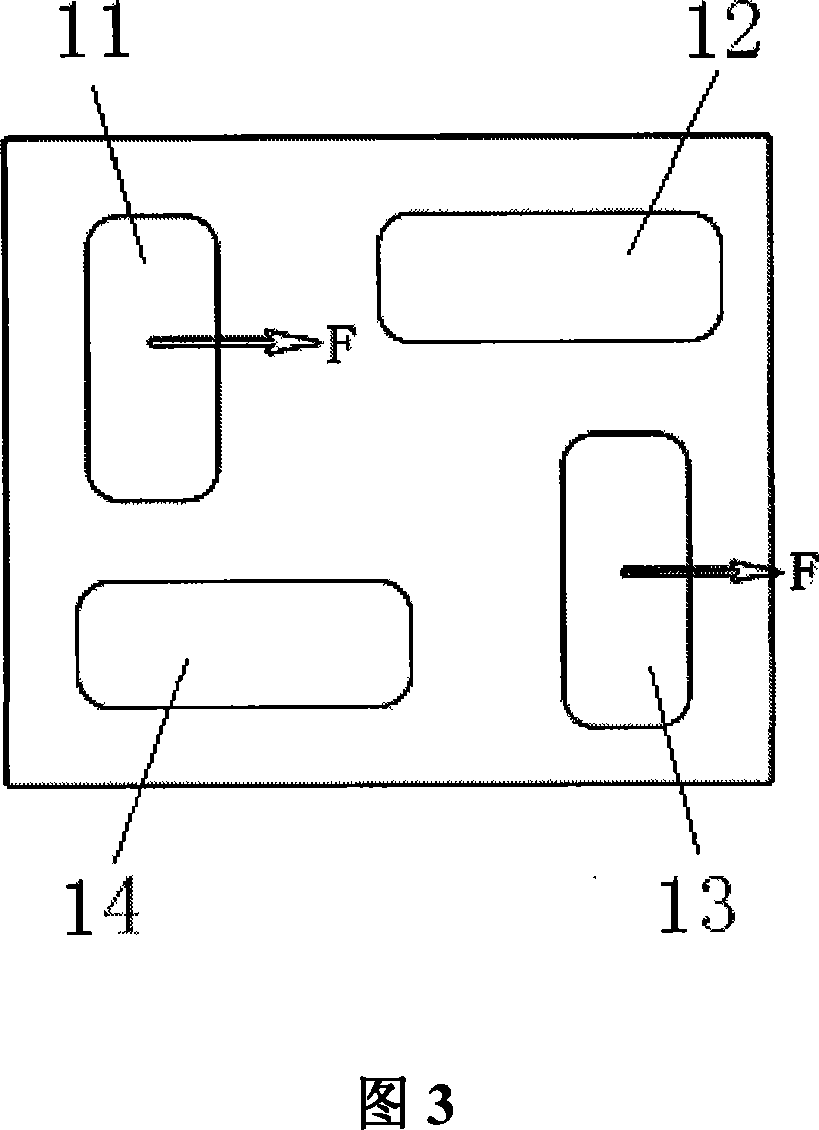

6 freedom degree micromotion operating platform

ActiveCN101078889ASimple structureCompact structurePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringDegrees of freedom

The invention discloses a 6 freedom degree micromotion bench in ultra precise processing and testing device technical domain, which is characterized by the following: possessing three groups of electromagnetic driving units; arranging in horizontal plane; driving the micromotion bench to X, Y, theta z3 freedom degree move in horizontal plane; arranging three electromagnetic driving units along vertical direction; driving the micromotion bench to Z, theta x and theta y3 freedom degree move. This invention possesses simple structure and higher displacement distinguishability, which can be used to realize 6 freedom degree motions for ultra precise process and check.

Owner:TSINGHUA UNIV +1

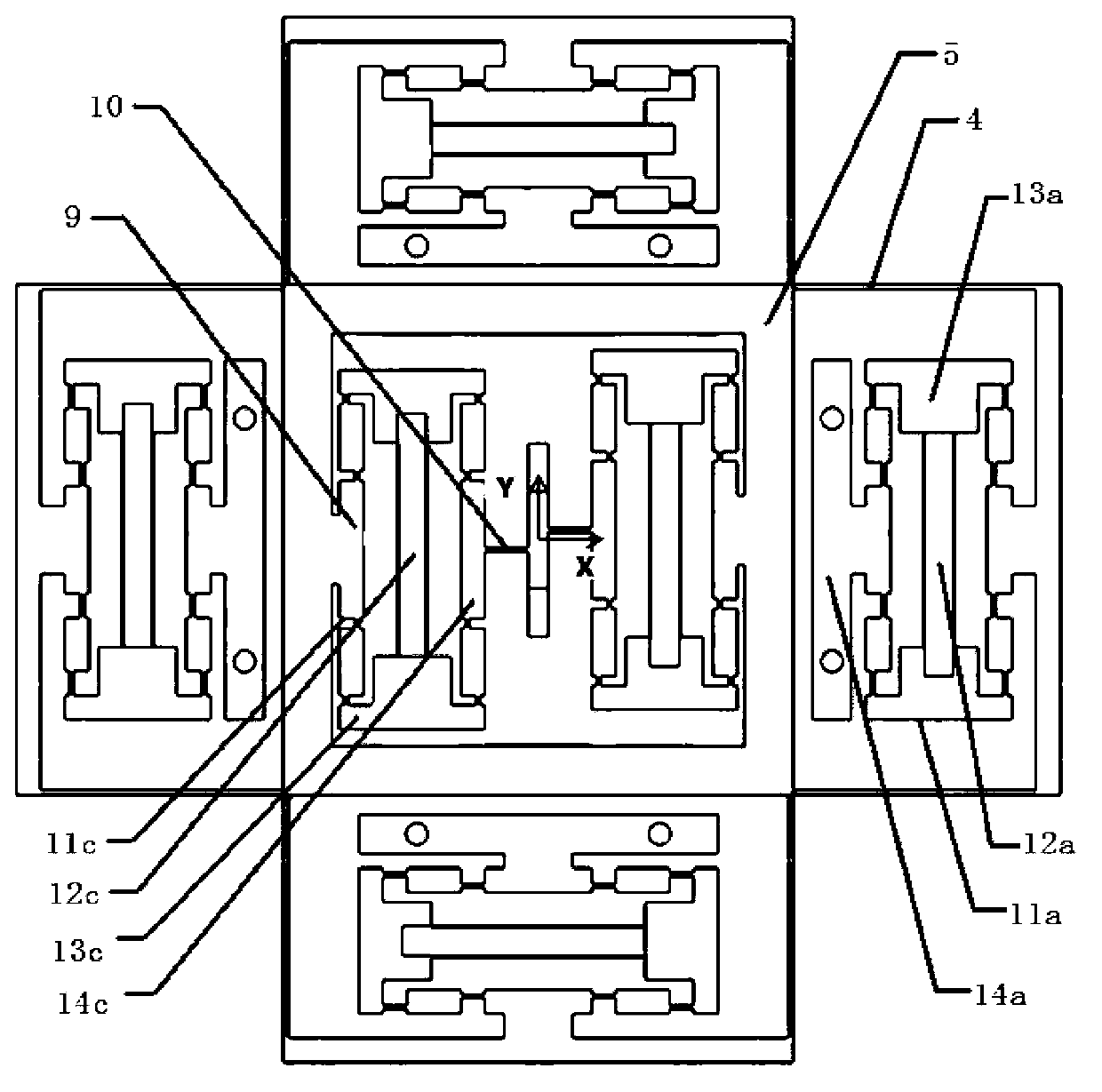

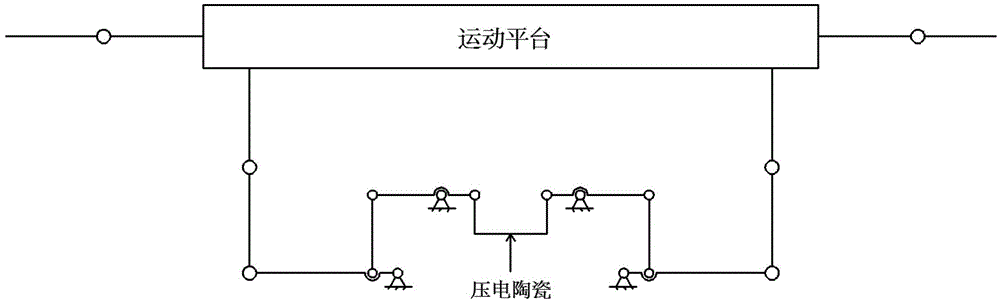

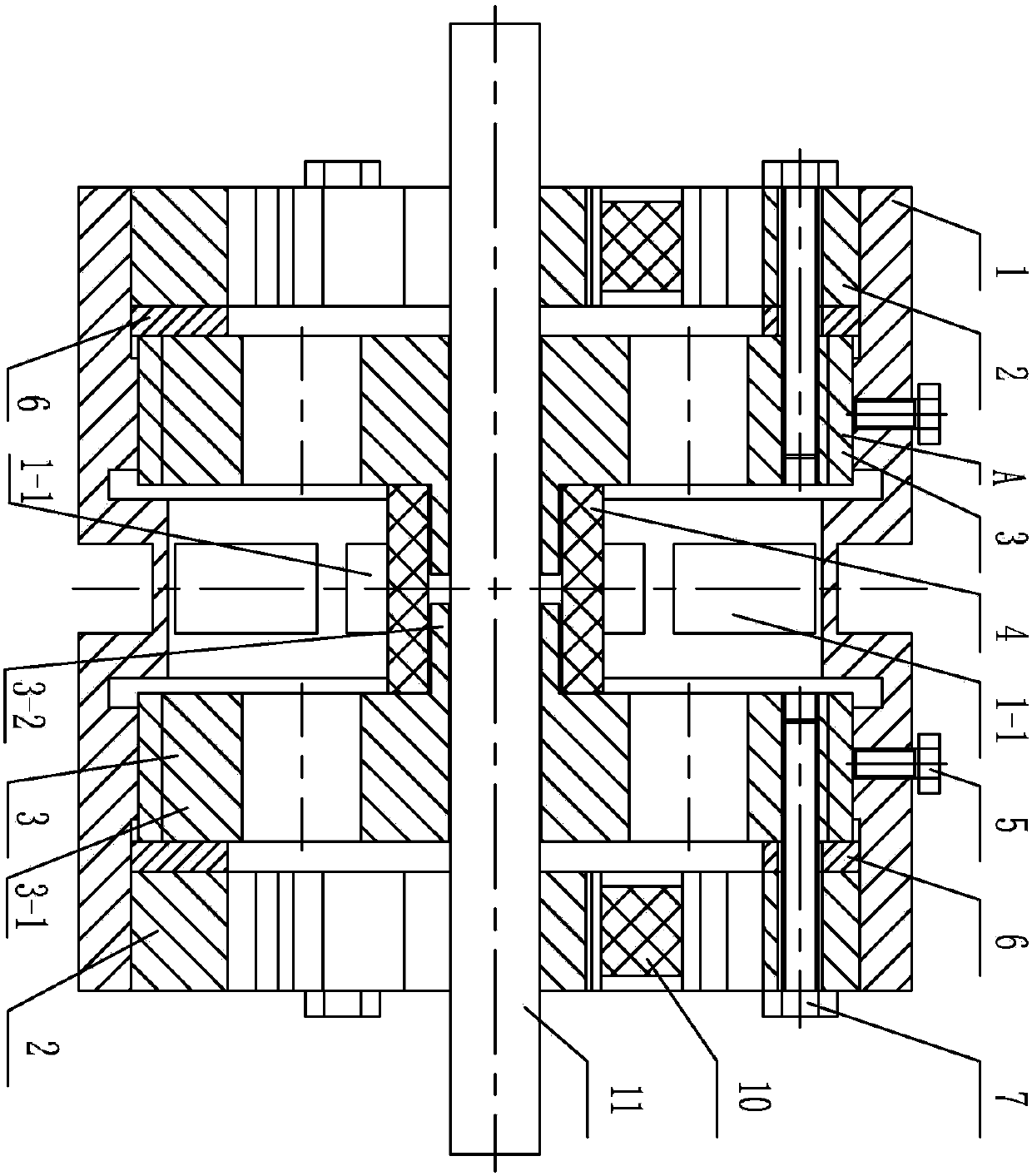

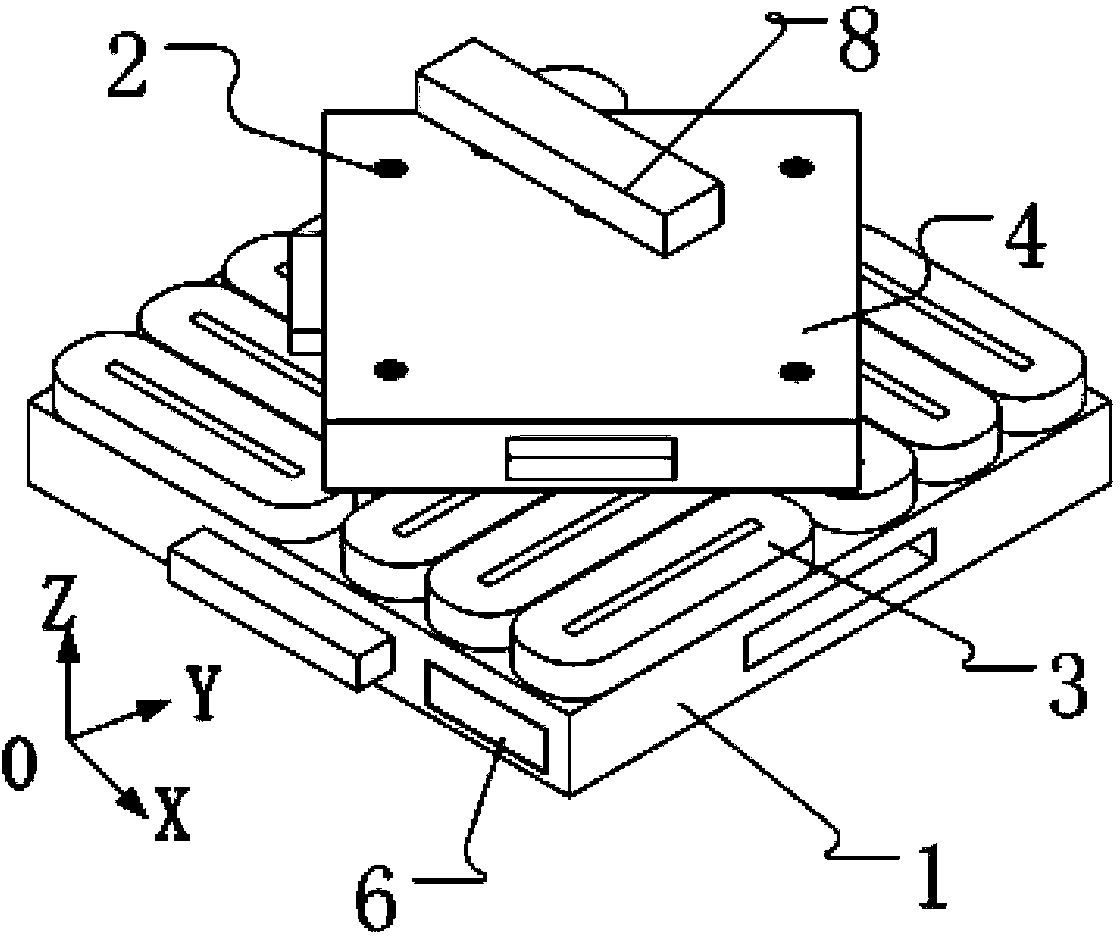

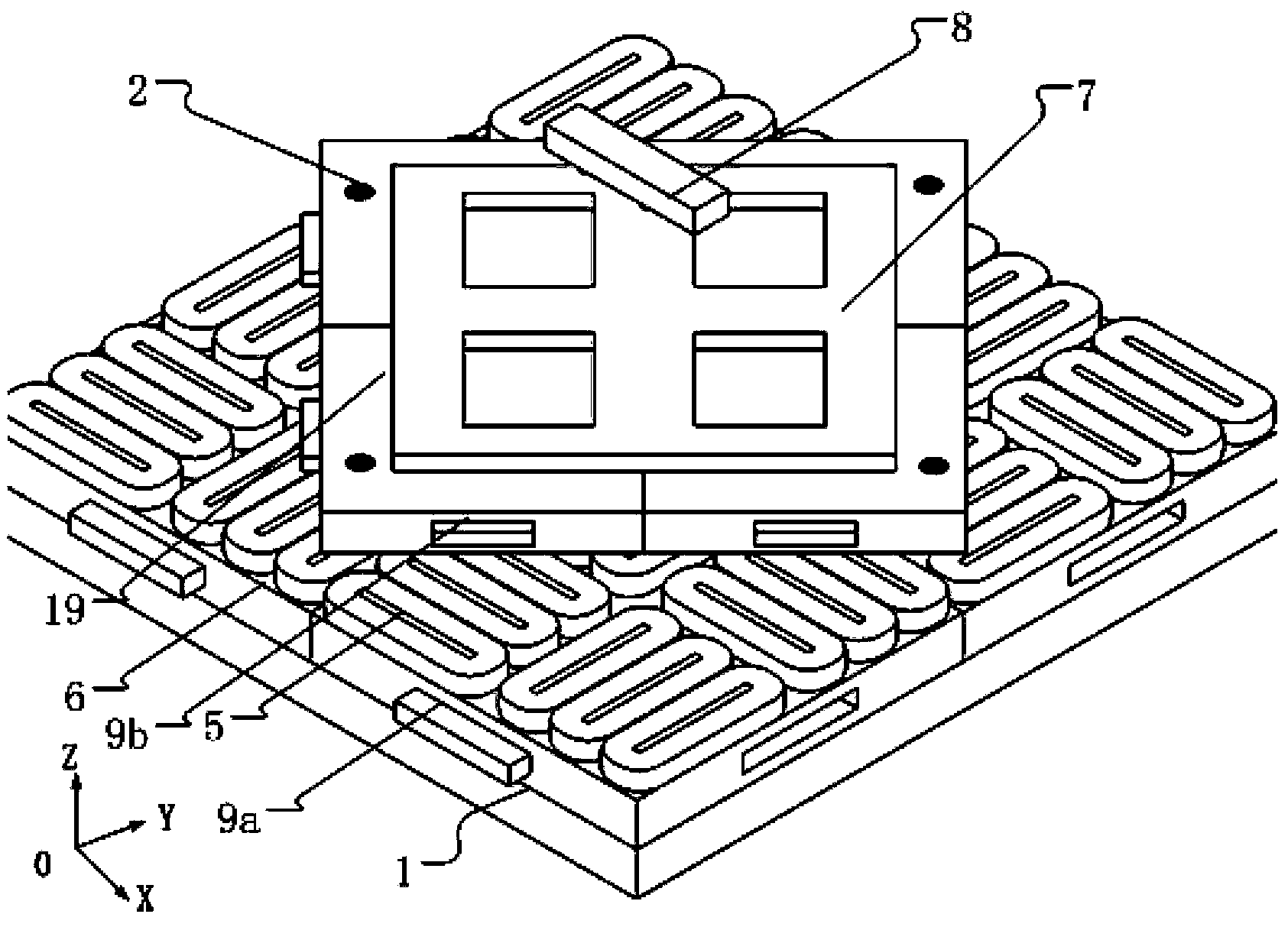

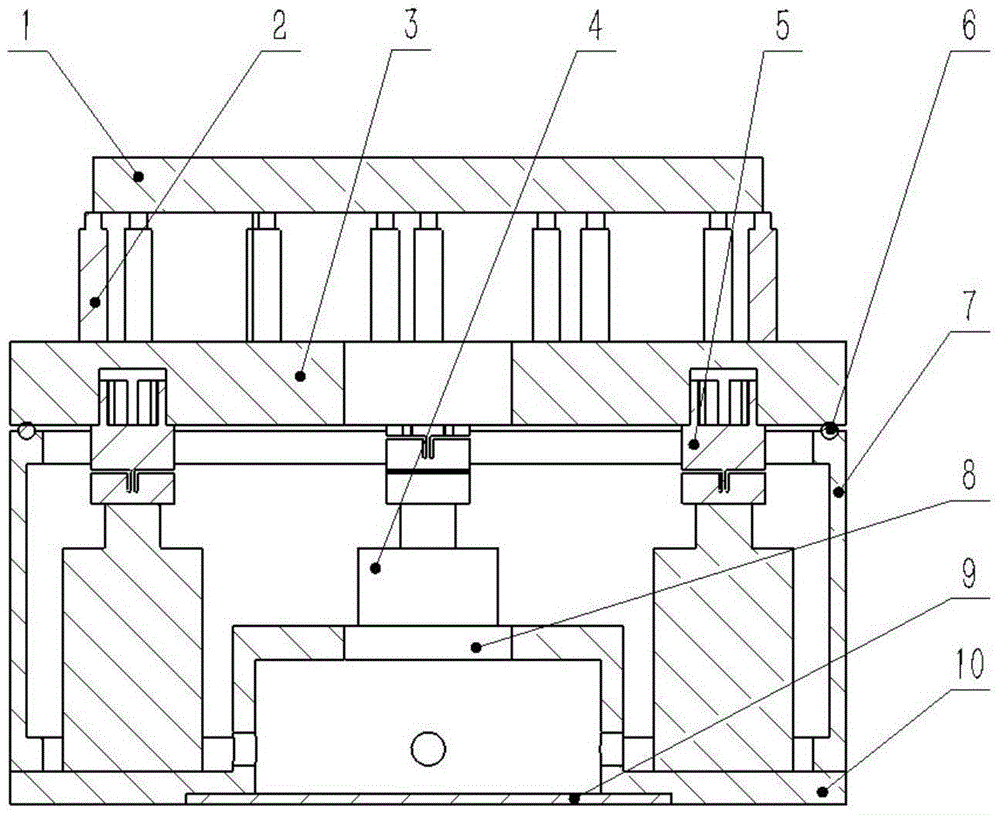

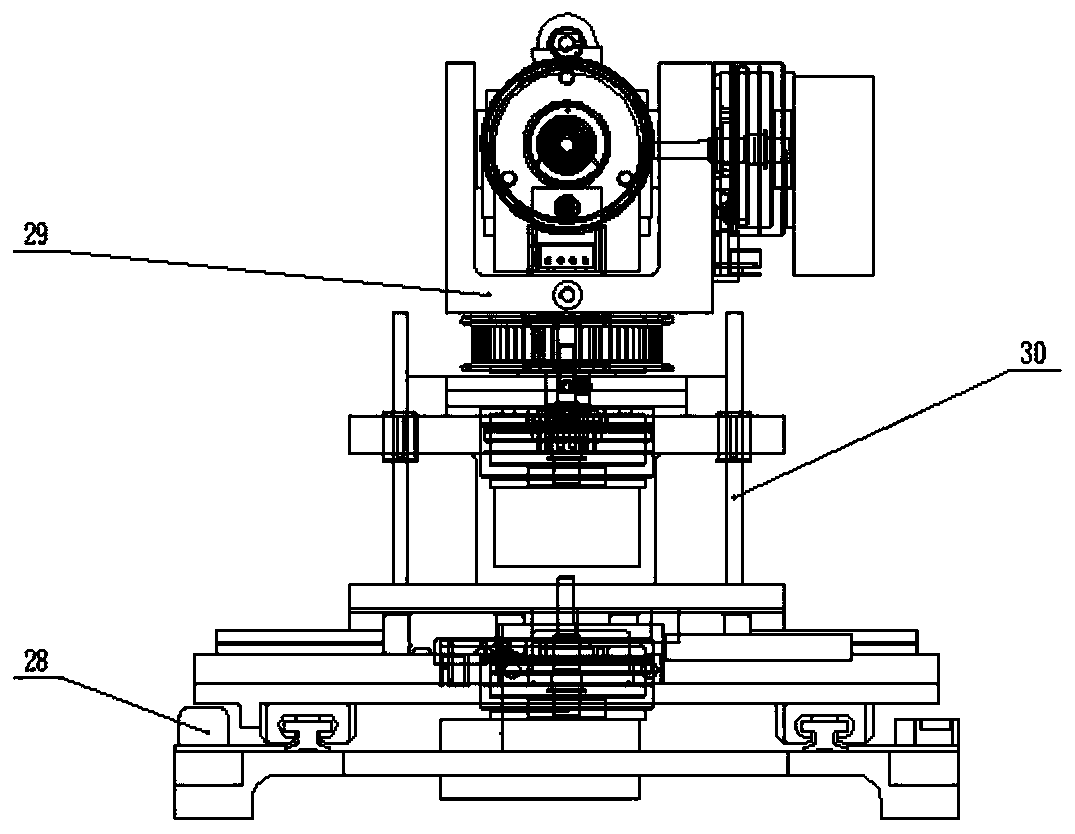

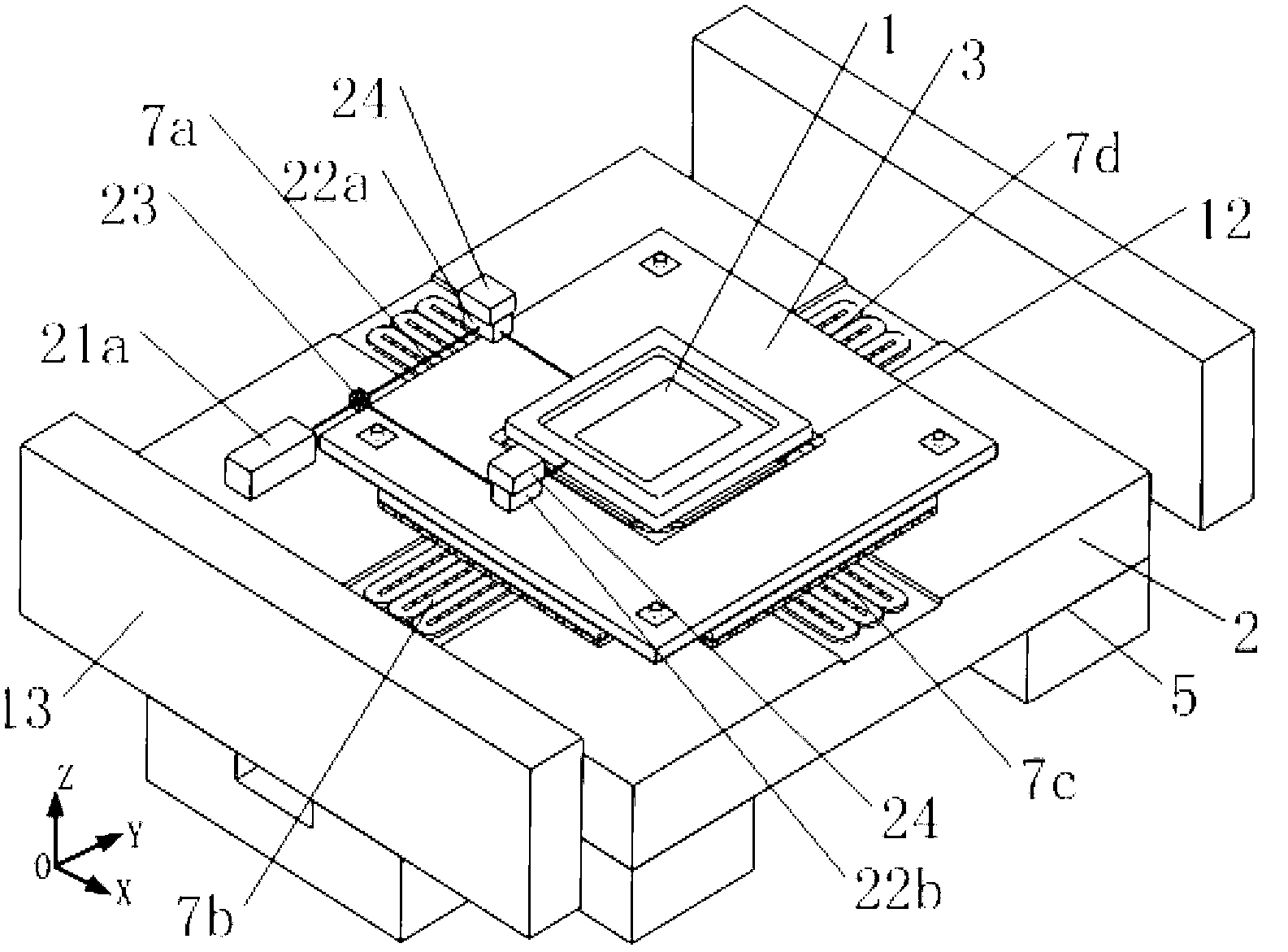

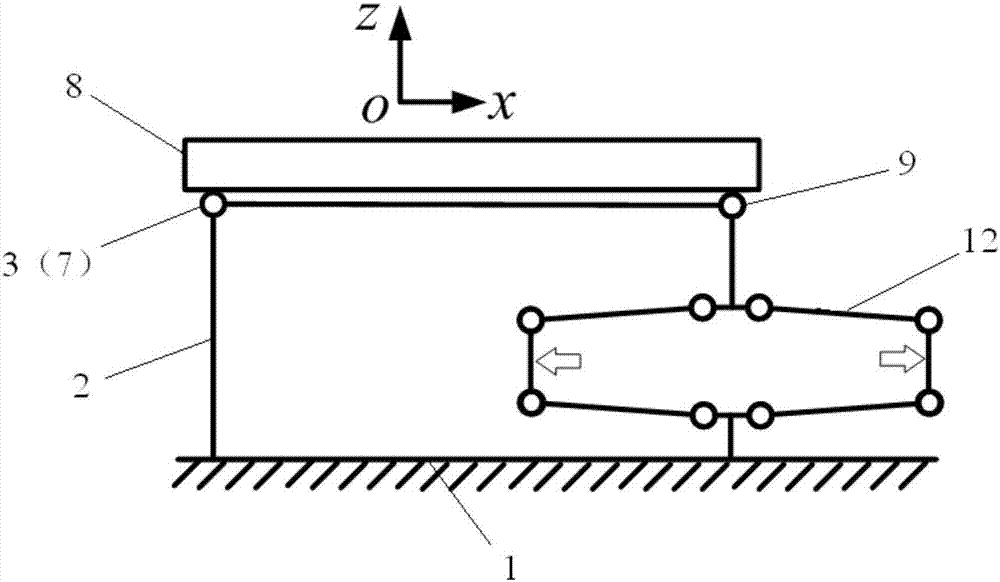

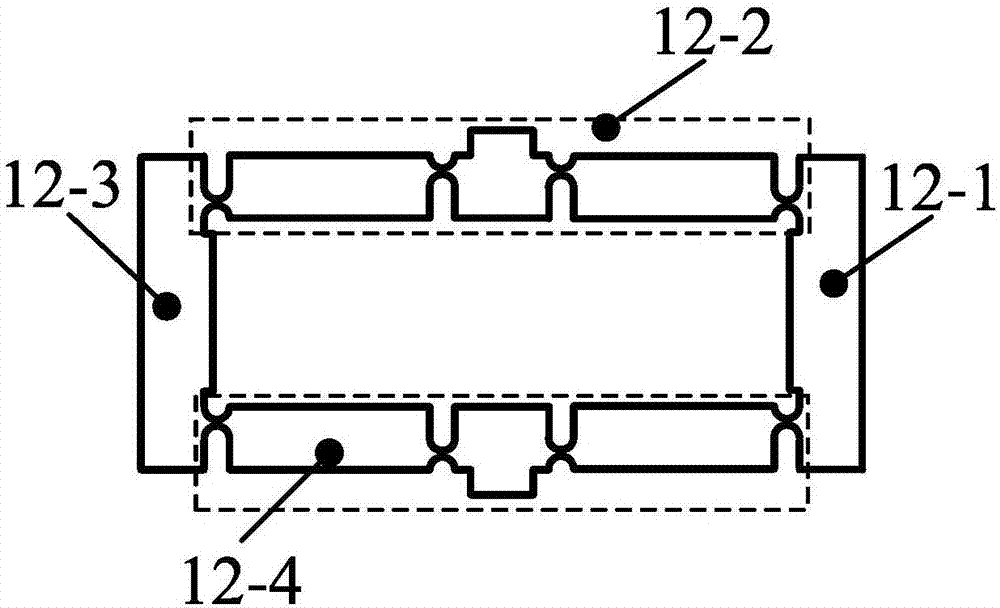

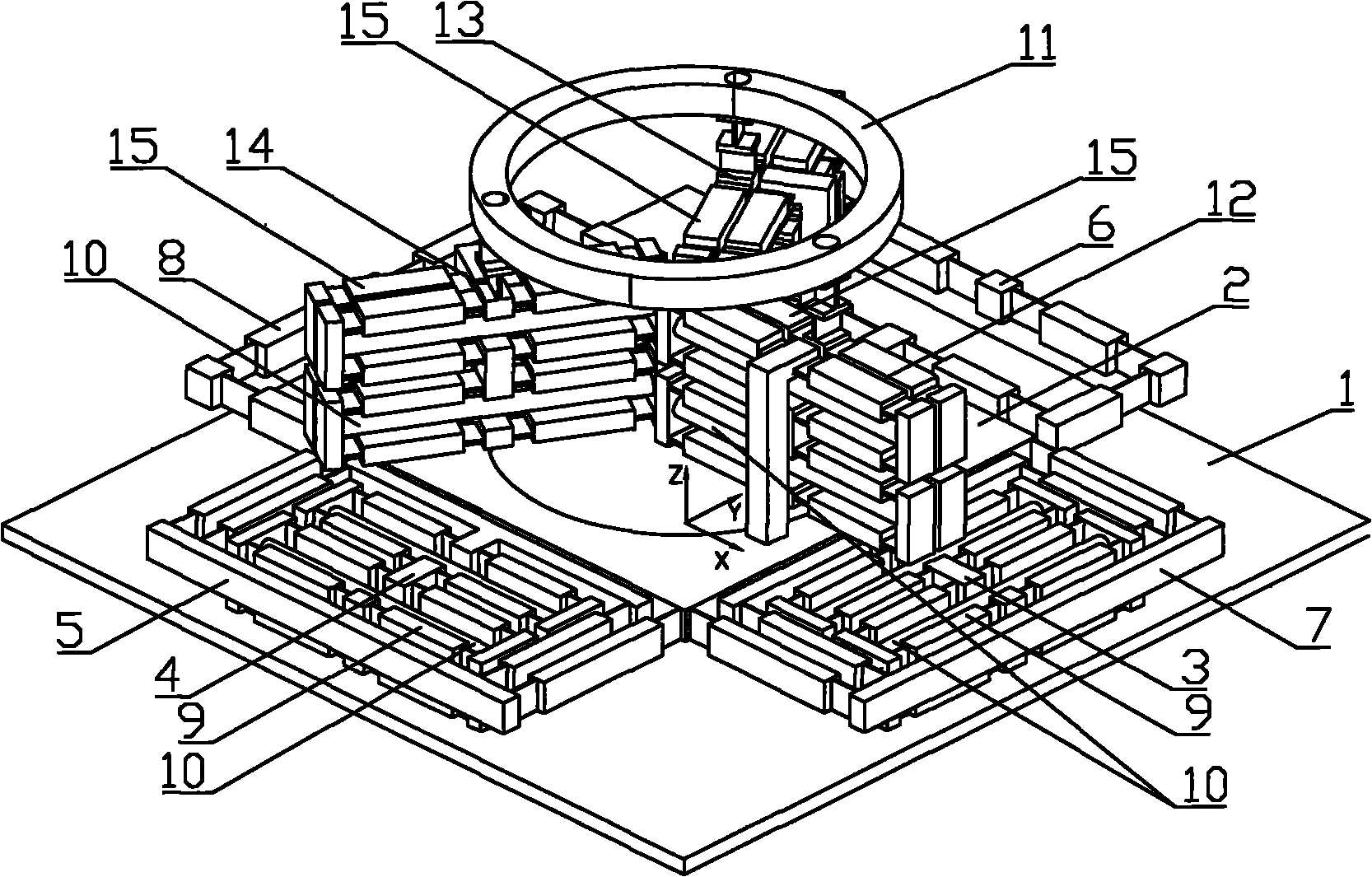

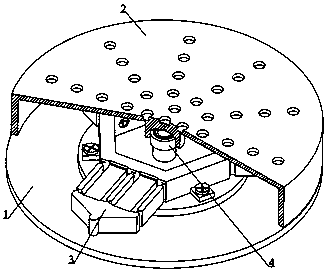

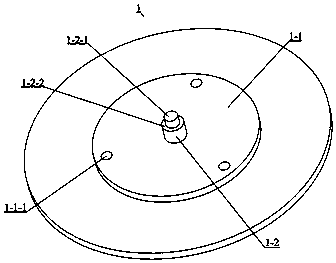

Integrated type six degrees of freedom precision positioning platform

The invention discloses an integrated type six degrees of freedom precision positioning platform. The integrated type six degrees of freedom precision positioning platform comprises a base, a lower platform component, a middle platform component and an upper platform component. The integrated type six degrees of freedom precision positioning platform utilizes a piezoelectric ceramics brake to enable the lower platform component to achieve rectilinear motion along an X direction and a Y direction of a coordinate system, enable the middle platform component to achieve a rectilinear motion along an Z direction of the coordinate system and a rotary oscillation around an axis which is parallel to the X axis and an axis which is parallel to the Y axis, and enables the upper platform component to rotate around the Z axis. The integrated type six degrees of freedom precision positioning platform can achieve precise control position on the six degrees of freedom and effectively avoids displacement coupling among axes due to the fact that the middle platform component and the lower platform component are designed into a symmetric structure. Meanwhile, the transmission platform can achieve integral manufacture, is driven by the piezoelectric ceramics brake, has the advantages of being free from friction and coupling, being high in precision, long in journey and high in resolution rate and can meet complex manufacturing and operation requirements of nanometer science and technology studies.

Owner:CHONGQING UNIV

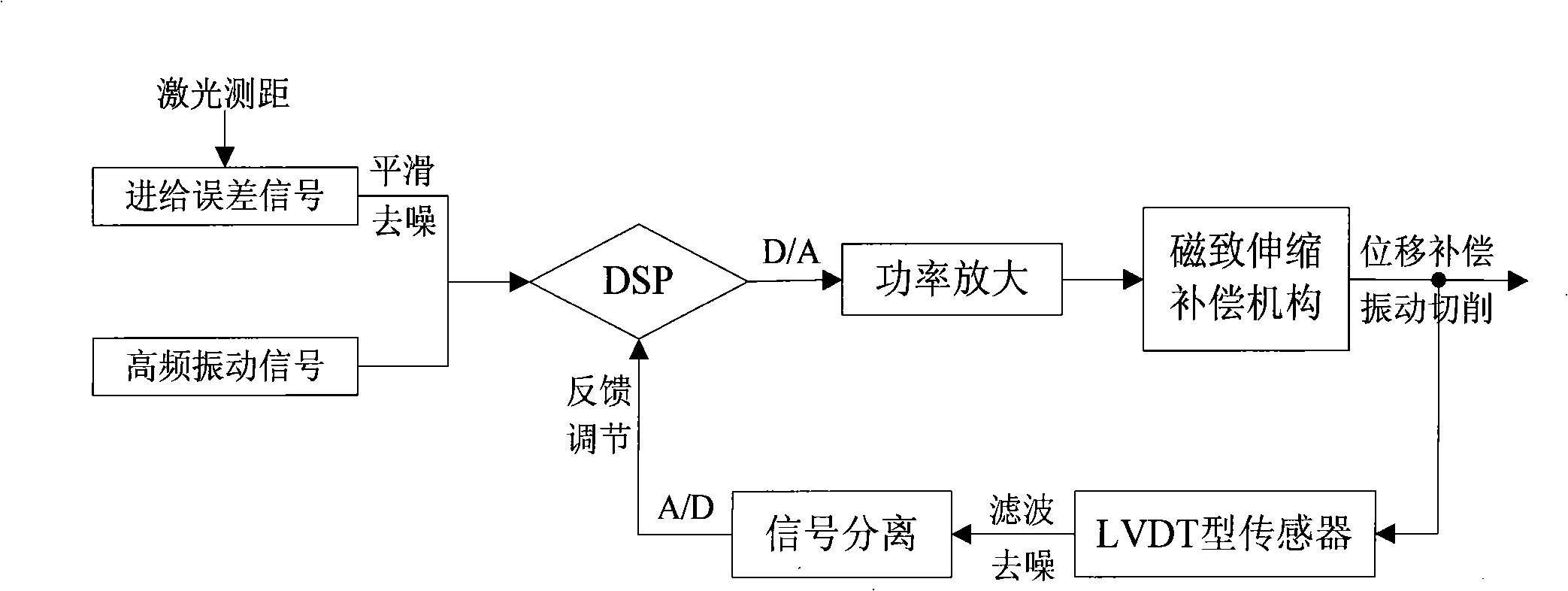

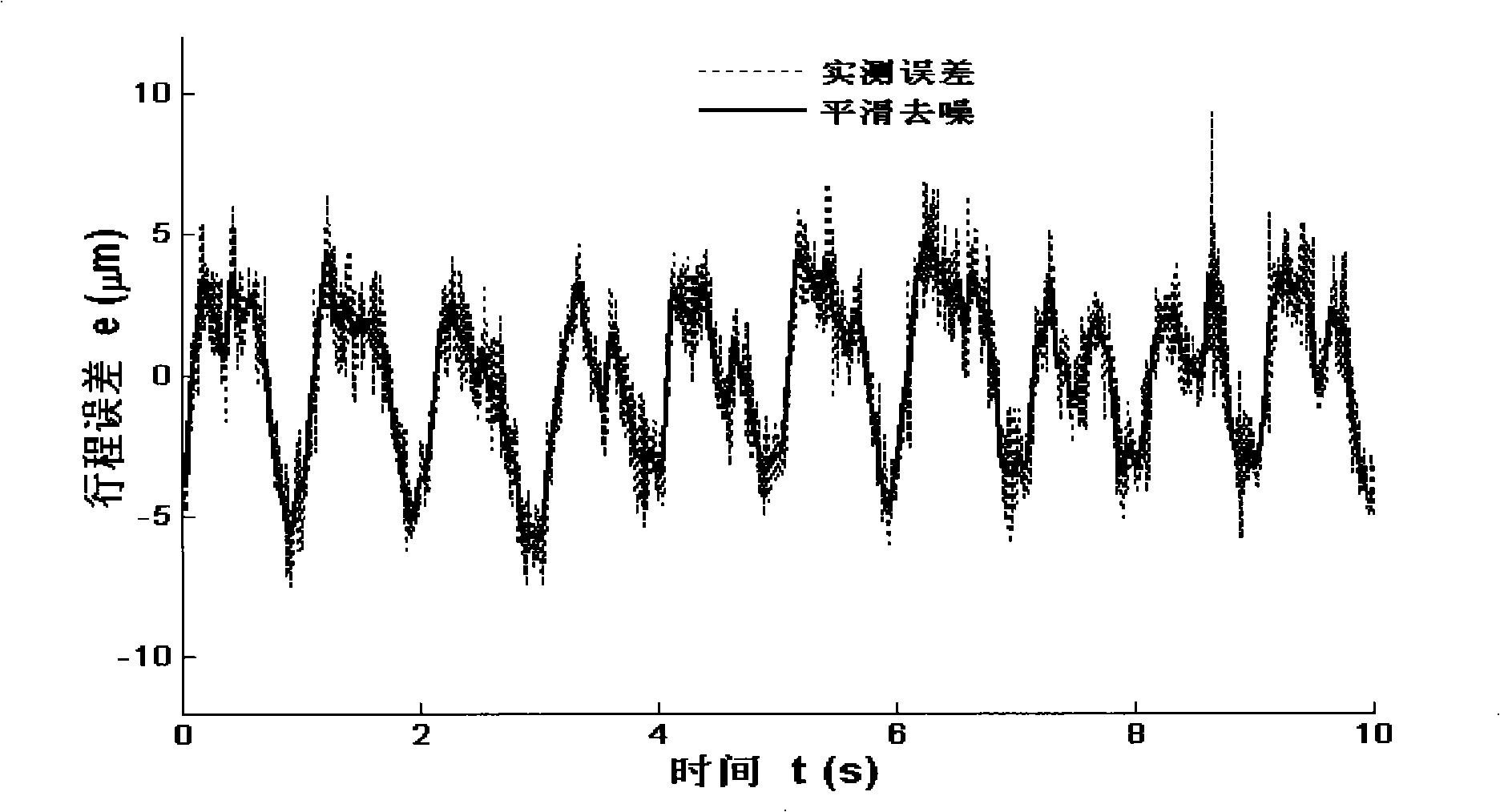

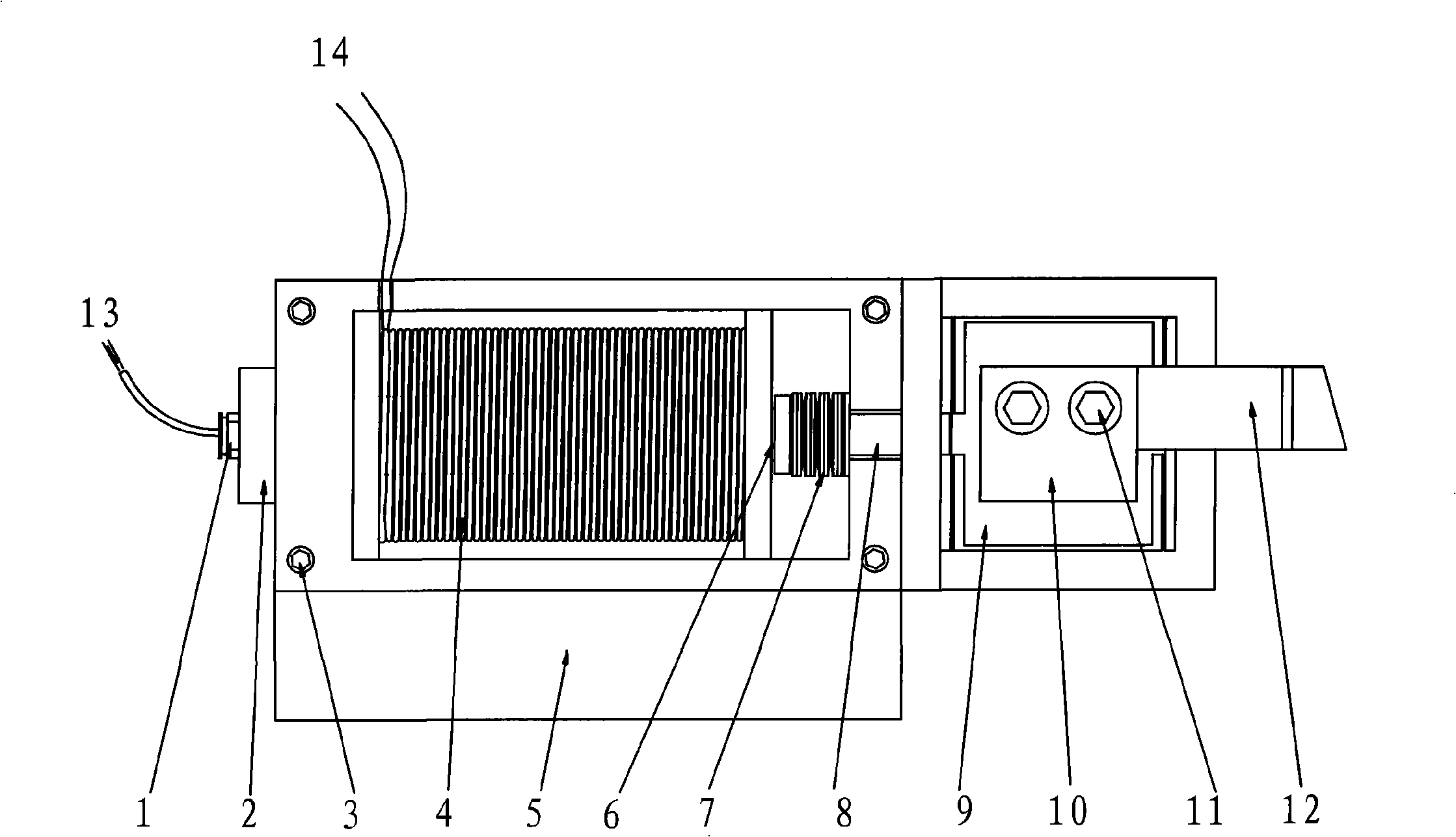

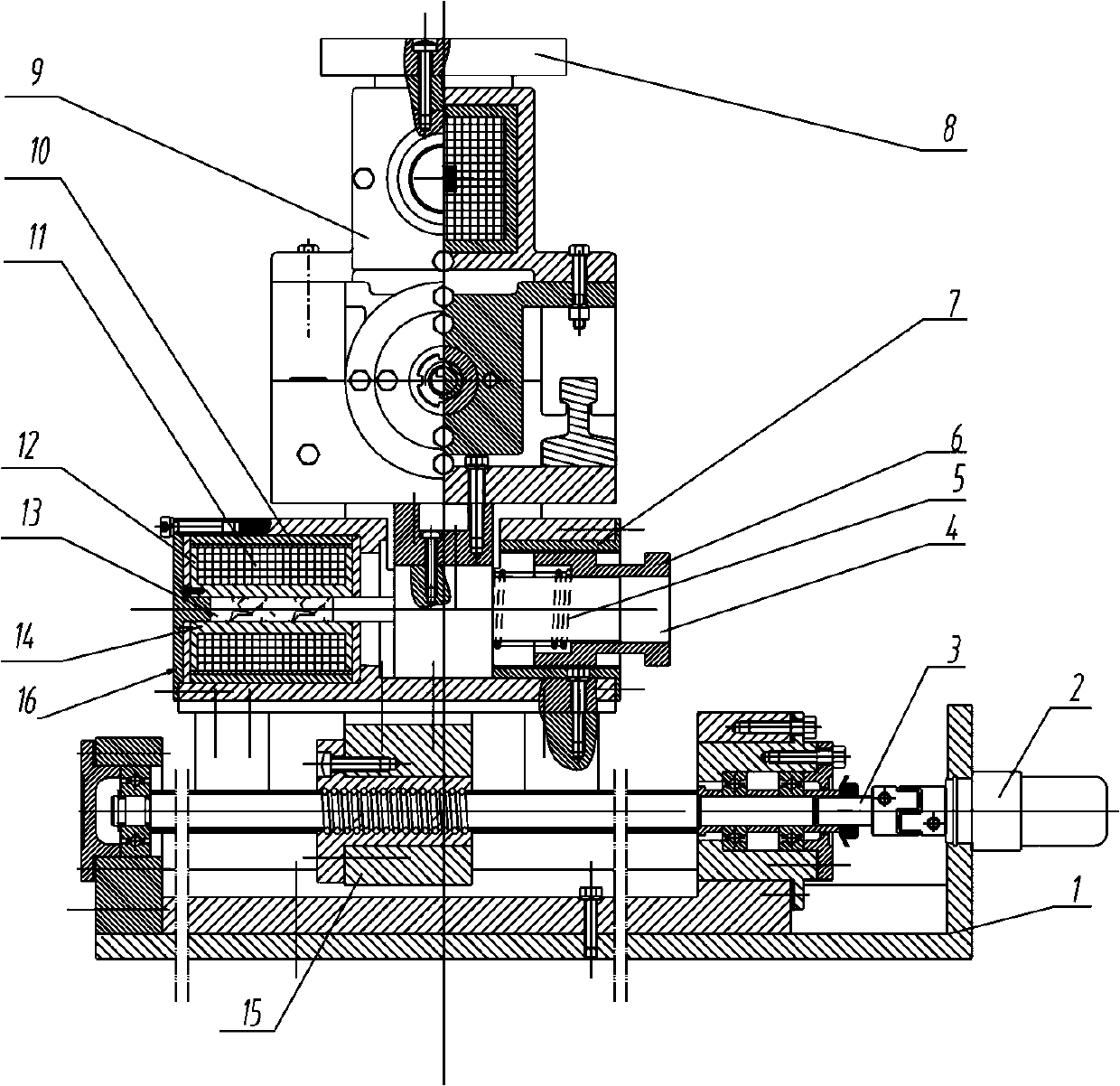

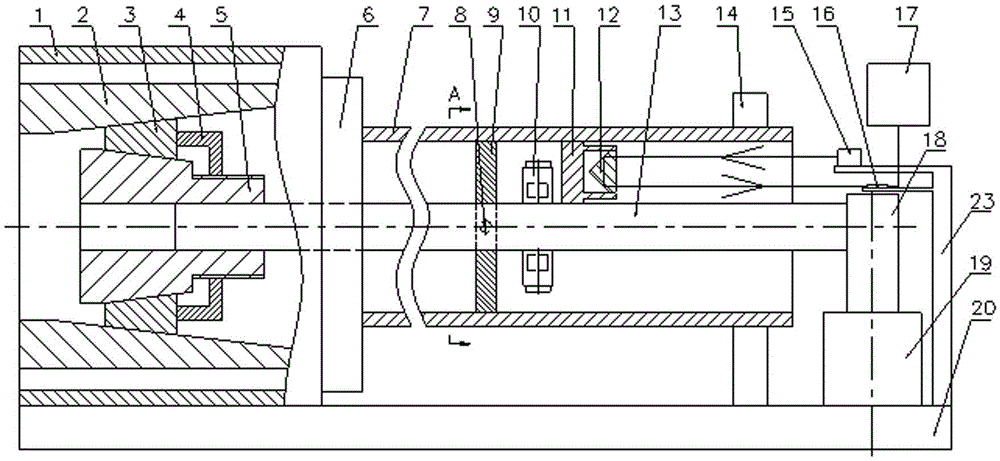

Compensation process capable of increasing machine precision of numerical-controlled lathe and magnetic striction compensation mechanism

ActiveCN101337330AHigh compensation accuracyAvoid breakingAutomatic control devicesMeasurement/indication equipmentsNumerical controlClosed loop

The invention discloses a compensation method for enhancing the machining accuracy of a numerical control machine tool and a magnetostrictive compensation mechanism, in particular to a method for compensating the accuracy of the numerical control machine tool through combined feed and a modularized accuracy compensation mechanism. The method comprises the following steps: aiming to the machine tool, because of a geometrical error formed by a plurality of factors such as manufacture, abrasion, etc., feed errors in a full-stroke range are measured by a dual-frequency laser interferometer; the modularized compensation mechanism is driven to produce the corresponding displacement compensation quantity through power amplification after an error signal is pretreated; the micro-displacement feed is performed in cooperation with the macro displacement feed, so as to correct the accuracy of the machine tool. High-frequency vibration signals are superposed as a drive compensation mechanism for driving the voltage to perform vibration cutting, thereby effectively inhibiting a flutter phenomenon caused by friction during cutting, and enhancing the machining accuracy. An LVDT inductive displacement transducer is mounted at the tail end of an elastic micro-displacement mechanism for position feedback regulation; furthermore, the closed-loop control is formed through real-time control operation in a DSP chip to realize precise positioning.

Owner:JIANGSU HAIJIAN +1

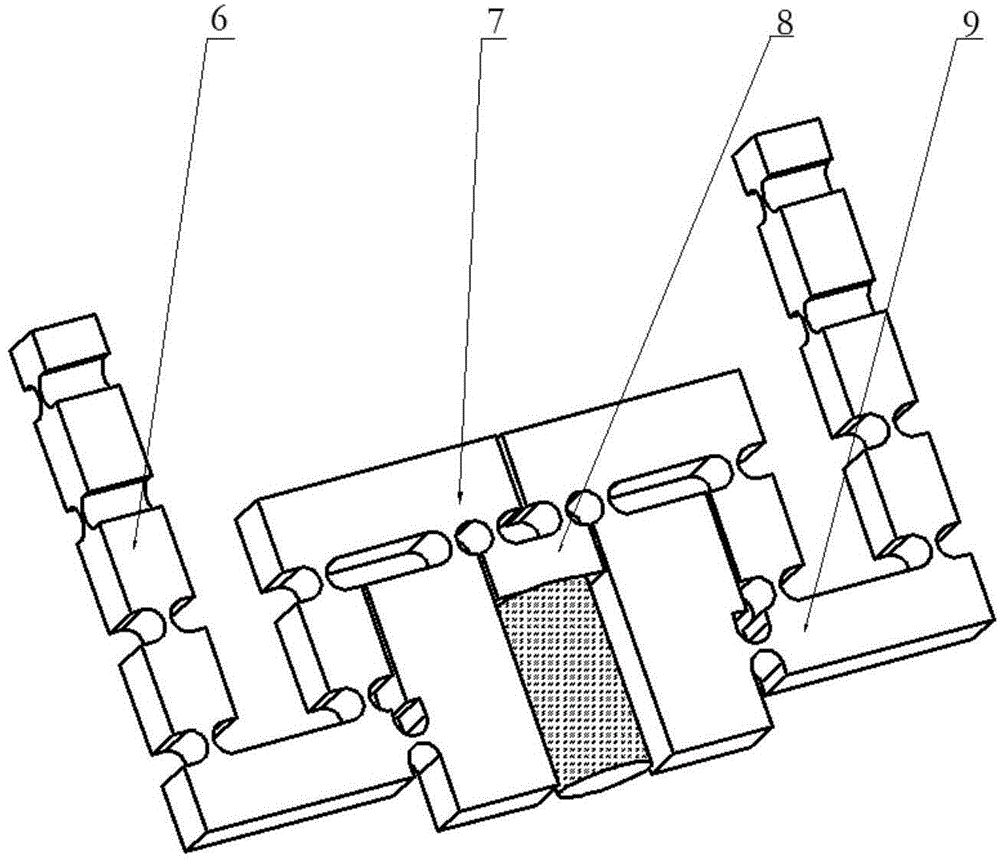

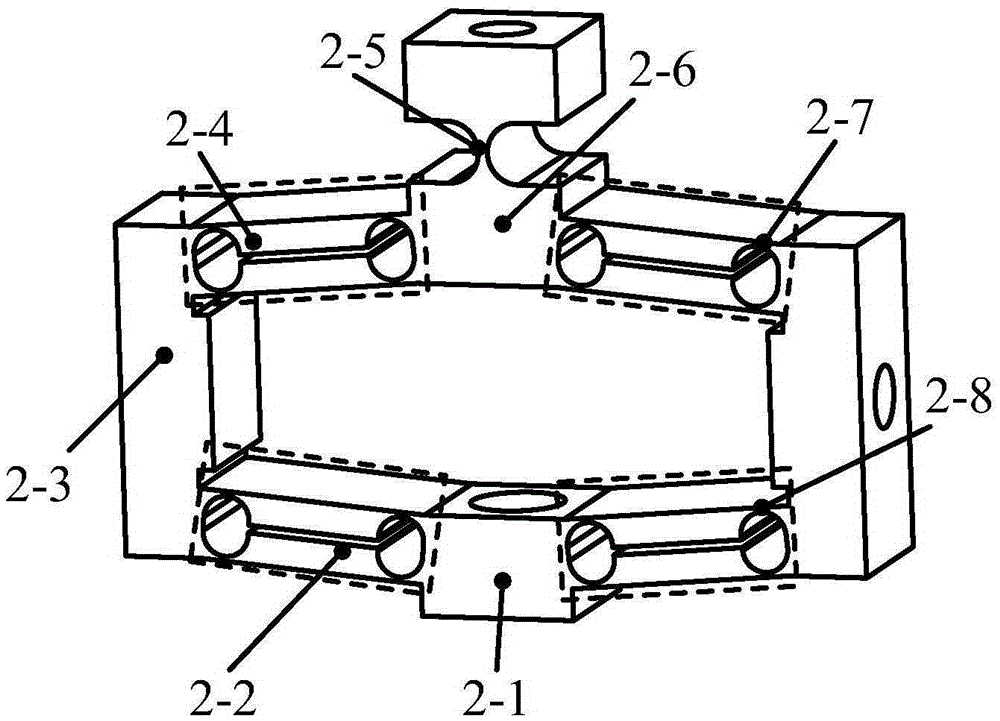

Spatial three-dimensional micro-displacement precise positioning device

ActiveCN104440817AIncrease the range of motionRealize self-decouplingNanostructure manufacturePiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

The invention discloses a spatial three-dimensional micro-displacement precise positioning device which comprises a fixed base and a moving table, wherein the moving table is connected with the fixed base through three connecting mechanisms having a displacement amplifying function and other two connecting mechanisms arranged oppositely respectively; the other two connecting mechanisms play the effect of displacement decoupling and enhance the rigidity of a platform; the connecting mechanisms having the displacement amplifying function amplify piezoelectric ceramic output displacement by a piezoelectric ceramic driver and a secondary cascaded lever amplification mechanism which is arranged symmetrically, so that the working stroke of the positioning device is enlarged and the displacement decoupling function can be realized.

Owner:SHANDONG UNIV

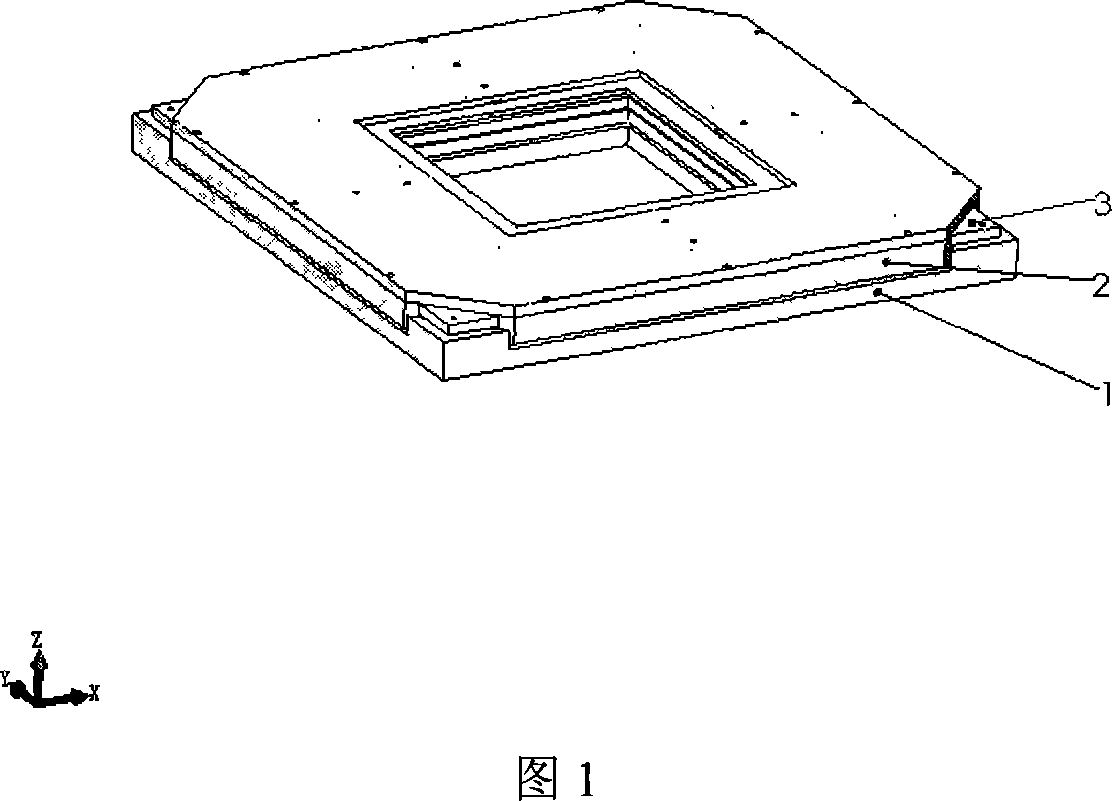

Ultrathin triple-freedom inching work table

ActiveCN101075098ASimple structureCompact structurePhotomechanical exposure apparatusWork benchesEngineeringMovement control

A super-thin operation table of 3-freedow micro-motion type consists of base of micro-motion table, rotator of micro-motion table and stator of micro-motion table. It is featured as forming said stator of micro-motion table by inserting 3-sets of driving unit coils into one coil framework, forming said rotator of micro-motion table by top slide cover and bottom slide cover, firm-jointing two said covers and suspending two said covers on base of micro-motion table through air-floating or magnetic-floating bearing.

Owner:TSINGHUA UNIV +1

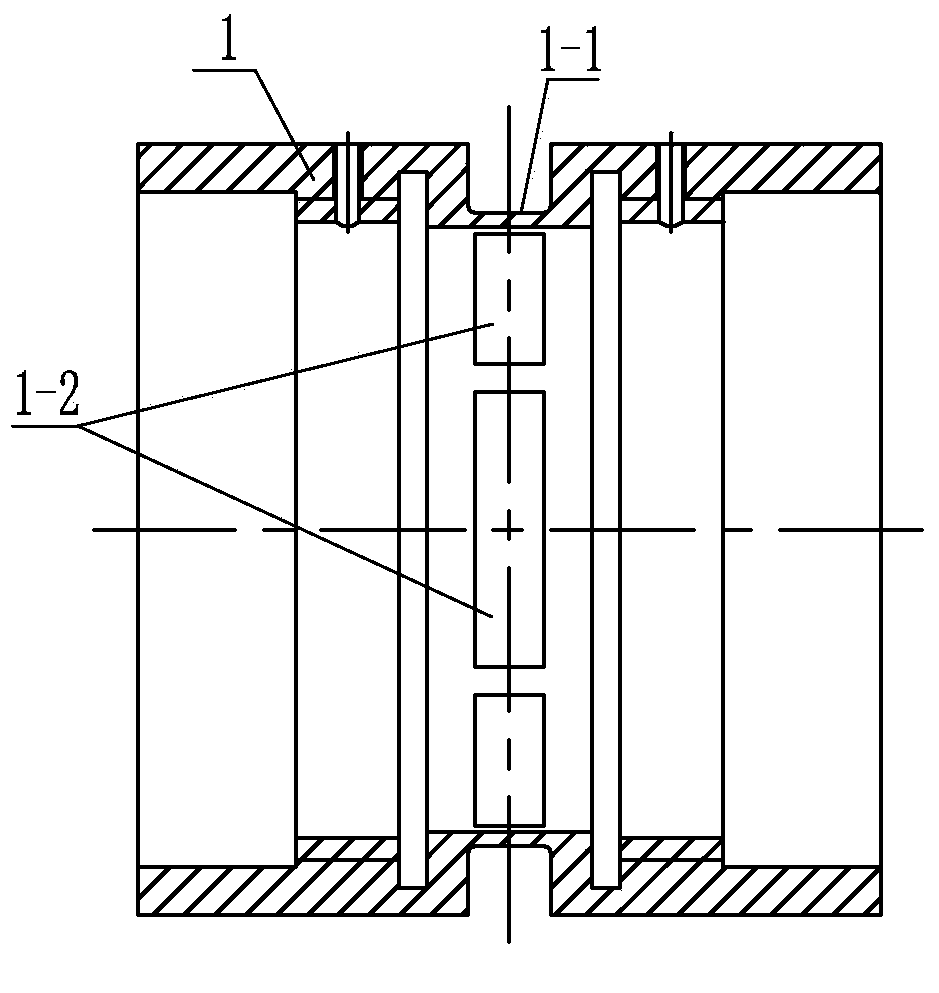

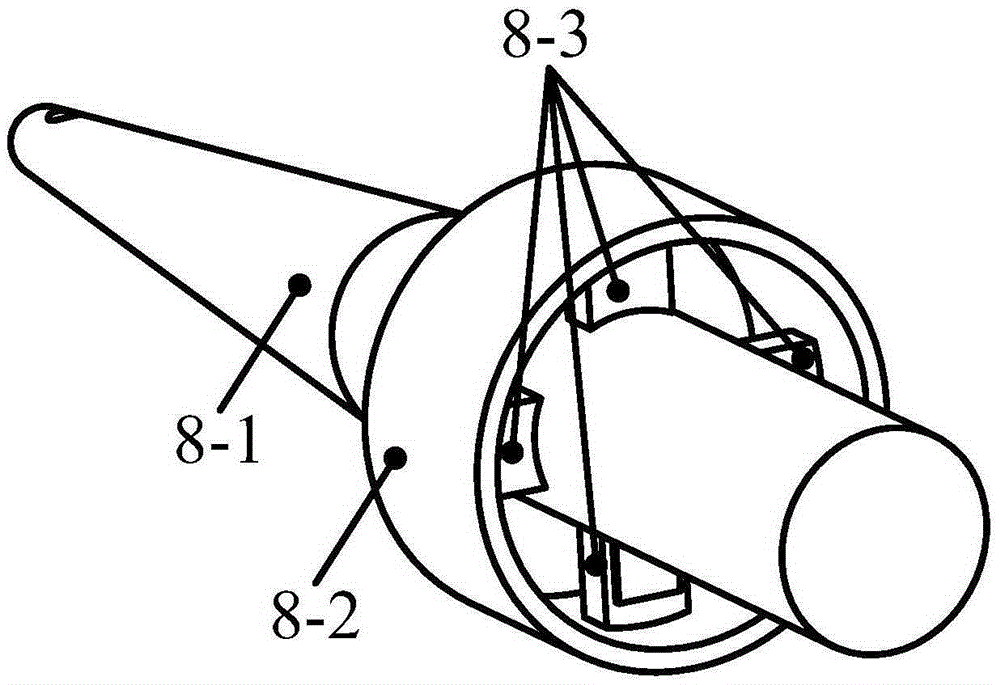

Cylindrical driven clamping type piezoelectric wriggle linear motor

ActiveCN103762887AReduce volumeReduce axial sizePiezoelectric/electrostriction/magnetostriction machinesEngineeringLinear motor

The invention relates to a piezoelectric drive device, in particular to a cylindrical driven clamping type piezoelectric wriggle linear motor to solve the problems that an existing drive clamping type wriggle motor cannot be powered off or self-locked and is not suitable for a compact, thin and long motion mechanism, and a driven clamping type wriggle motor is large in axial size and low in concentricity and control precision and needs an independent guide mechanism. The cylindrical driven clamping type piezoelectric wriggle linear motor comprises a guide rail, a drive mechanism, two annular gaskets and two sets of clamping mechanisms. The drive mechanism comprises a drive sleeve, a first piezoelectric stack and two clipping bodies. Each set of clamping mechanism comprises a clamping body, three second piezoelectric stacks and three flexible bodies. The middle of the drive sleeve is provided with the first piezoelectric stack, the clipping bodies, the gaskets and the clamping bodies are installed inside the drive sleeve from interior to exterior in a left-and-right symmetrical mode, the clipping bodies are in threaded connection with the drive sleeve, and the three flexible bodies are respectively and evenly distributed on the inner surfaces of the clamping bodies in the circumferential direction of the clamping bodies. The piezoelectric drive device is applied to the precise positioning and driving field.

Owner:HARBIN INST OF TECH

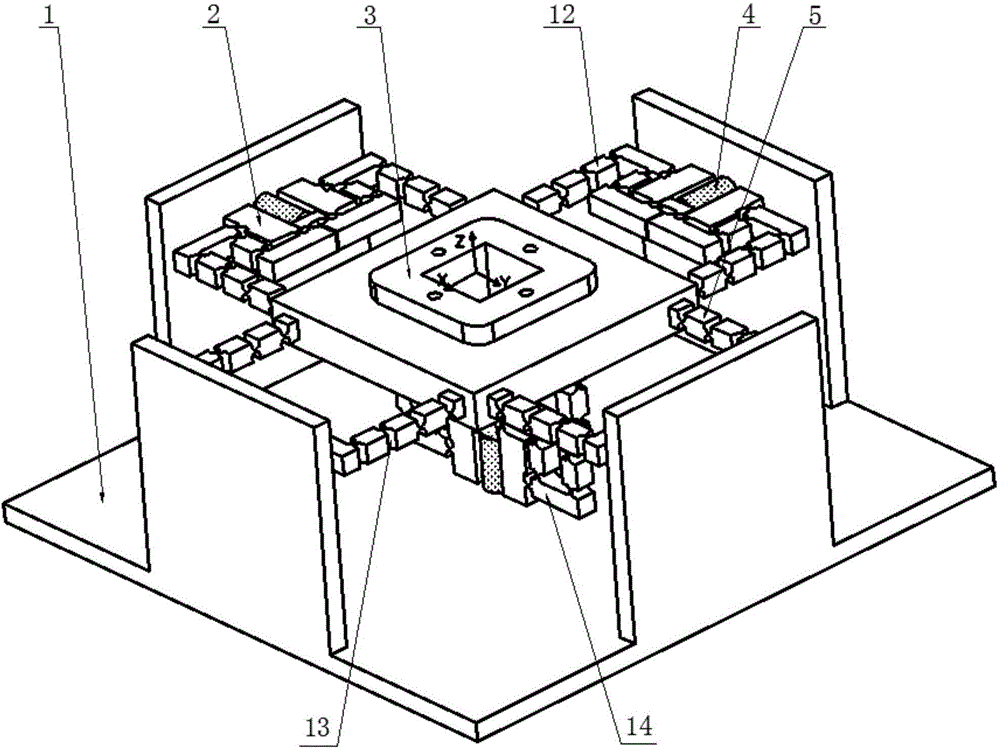

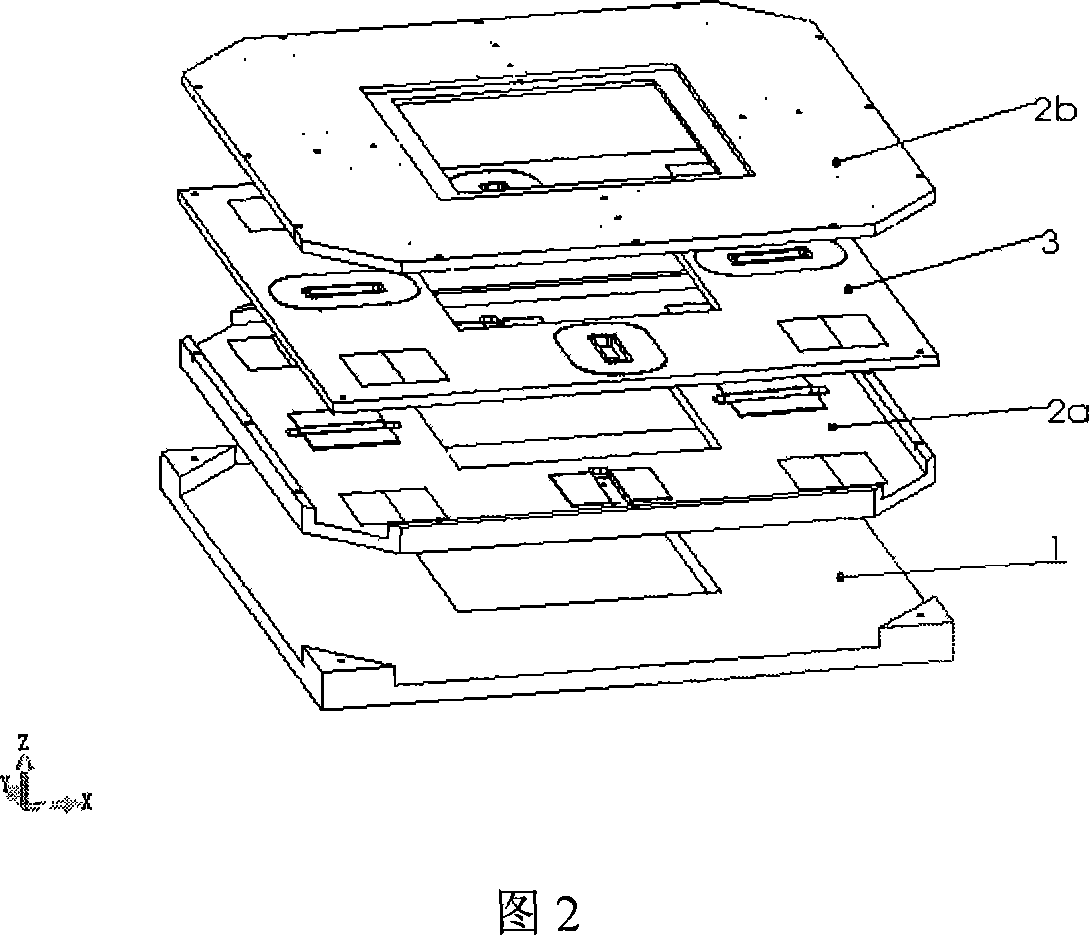

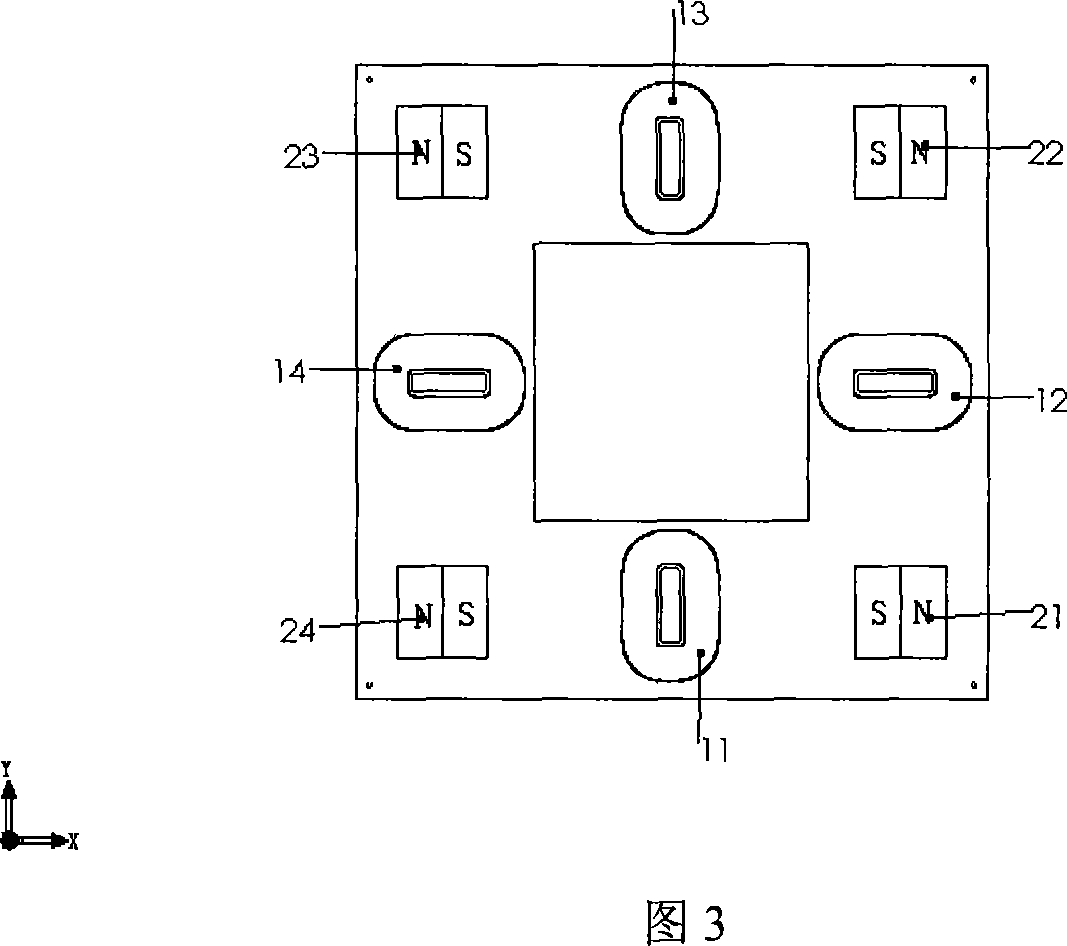

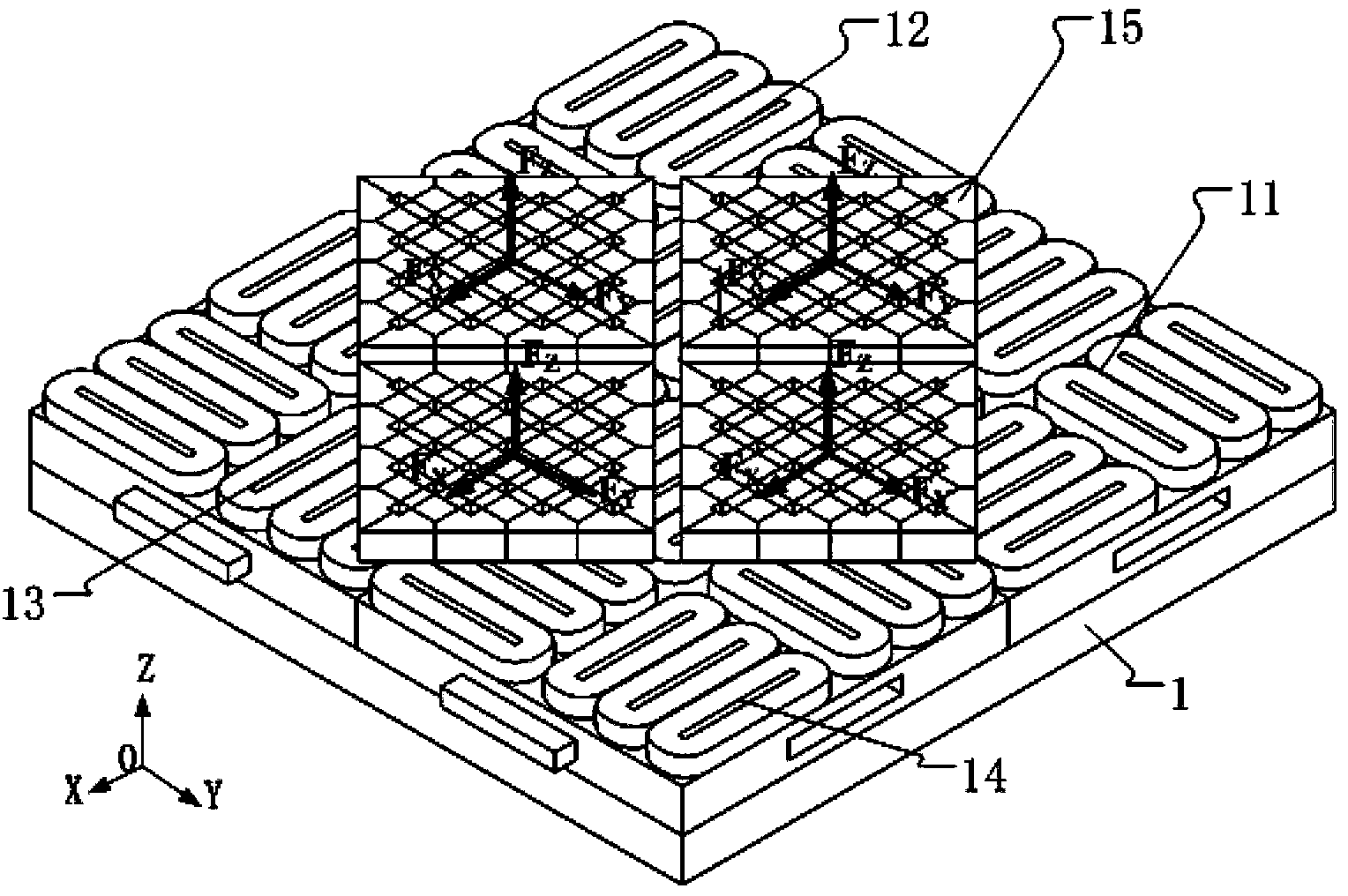

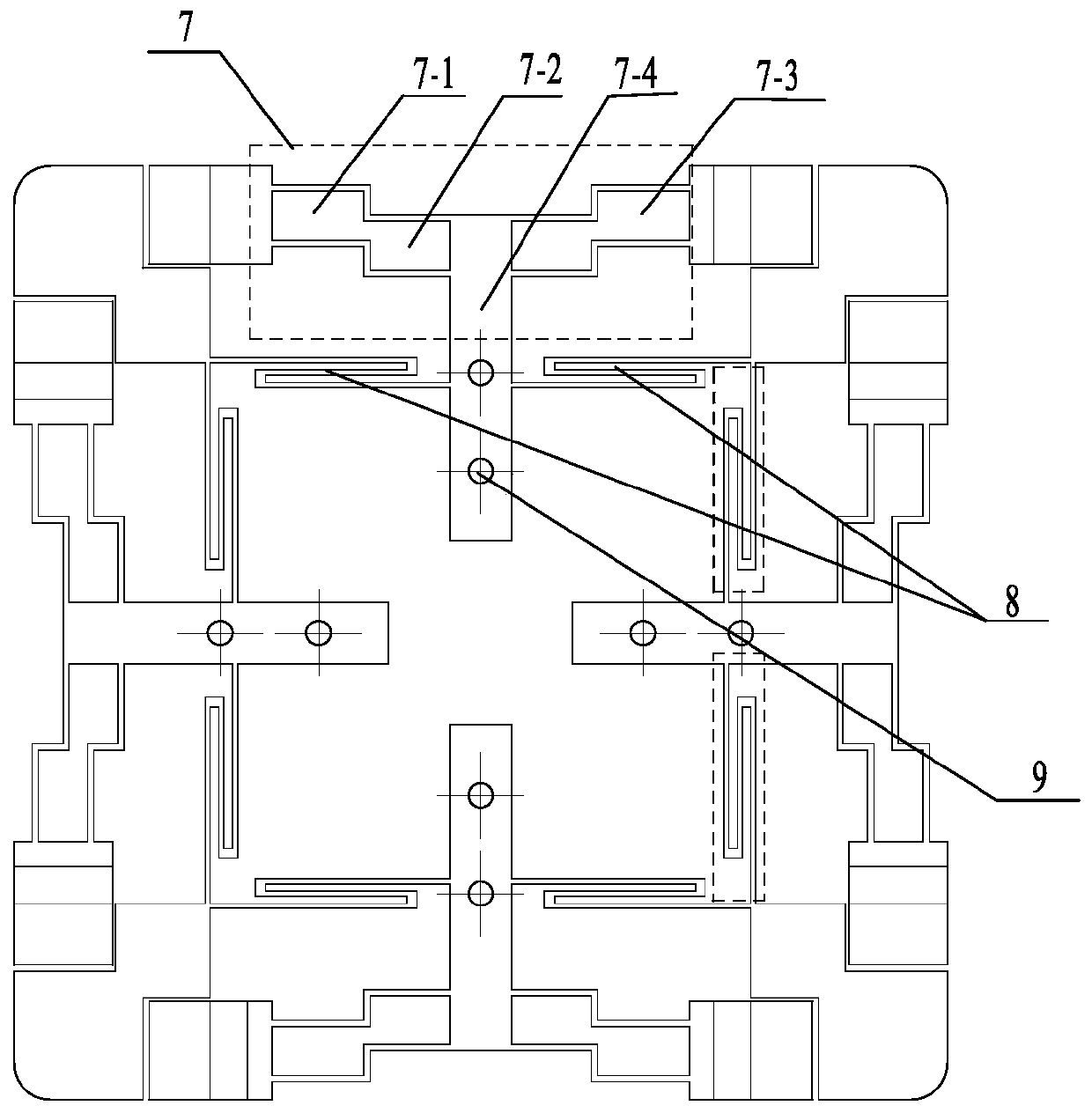

Modularization moving-iron type six-freedom-degree maglev motion platform

ActiveCN103441708AReduce in quantityReduce complexityPhotomechanical exposure apparatusMicrolithography exposure apparatusCarrying capacityComputer module

The invention discloses a modularization moving-iron type six-freedom-degree maglev motion platform and is mainly applied to semiconductor lithography equipment. The motion platform comprises a pedestal, at least one maglev planar motor module and a somatosensory controller. Each maglev planar motor module is composed of a maglev planar motor rotor and a maglev planar motor stator so that a micro moving workbench can rotate in an X direction, in a Y direction and around a Z axis. Compared to the prior art, the motion platform provided by the invention has the following advantages: coils are optimized and the coils with different specifications can be adaptive to a certain thrust range so that combination can be carried out according to different carrying capacity requirements; and the provided motion platform also has the advantages of simple structure, high-efficient integration, saved production cost and the like.

Owner:TSINGHUA UNIV +1

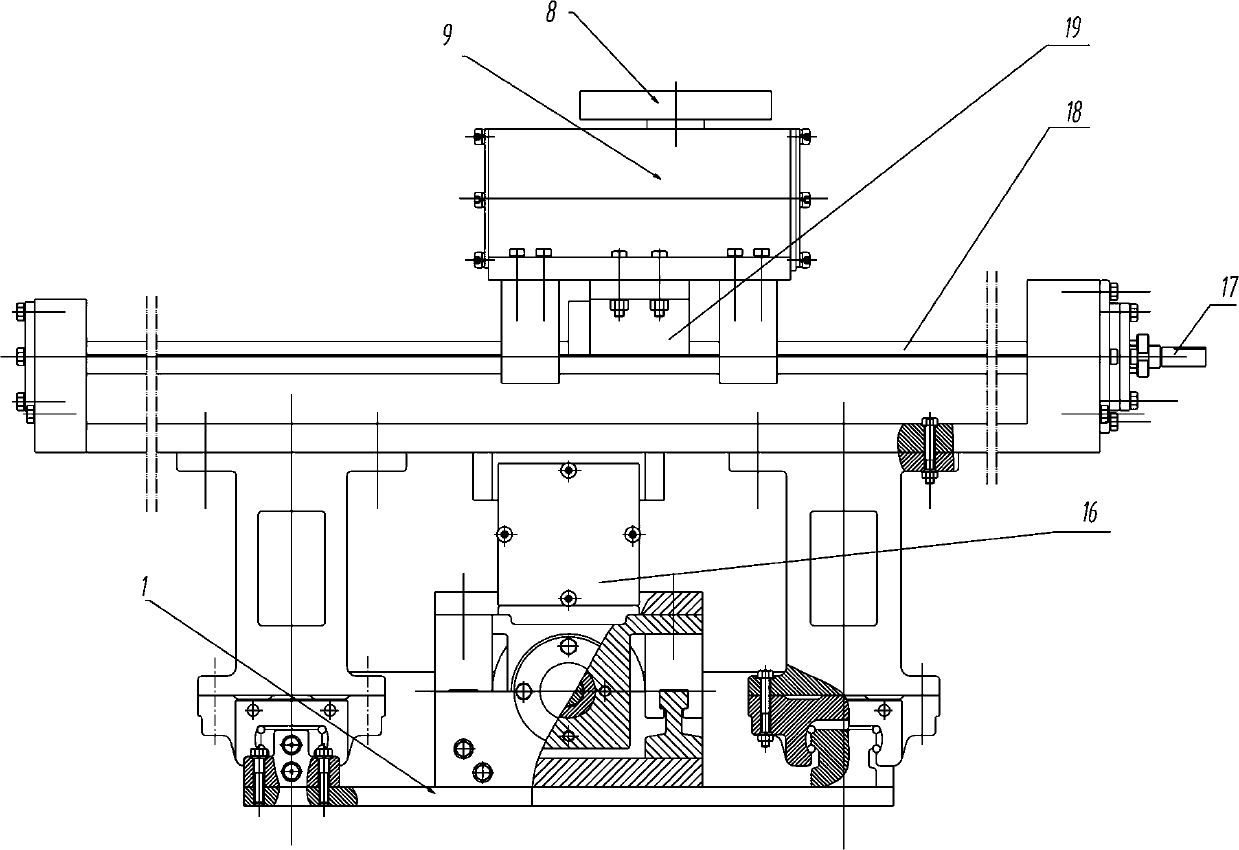

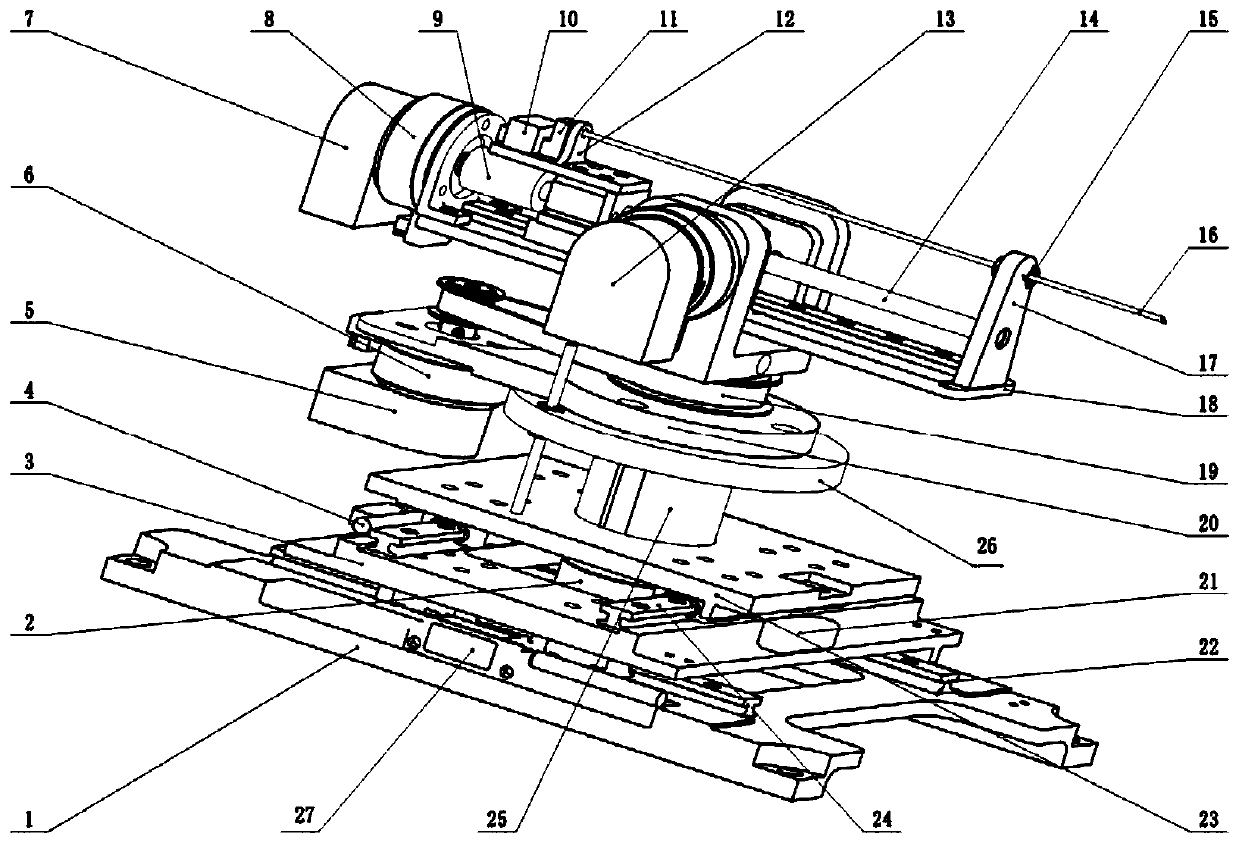

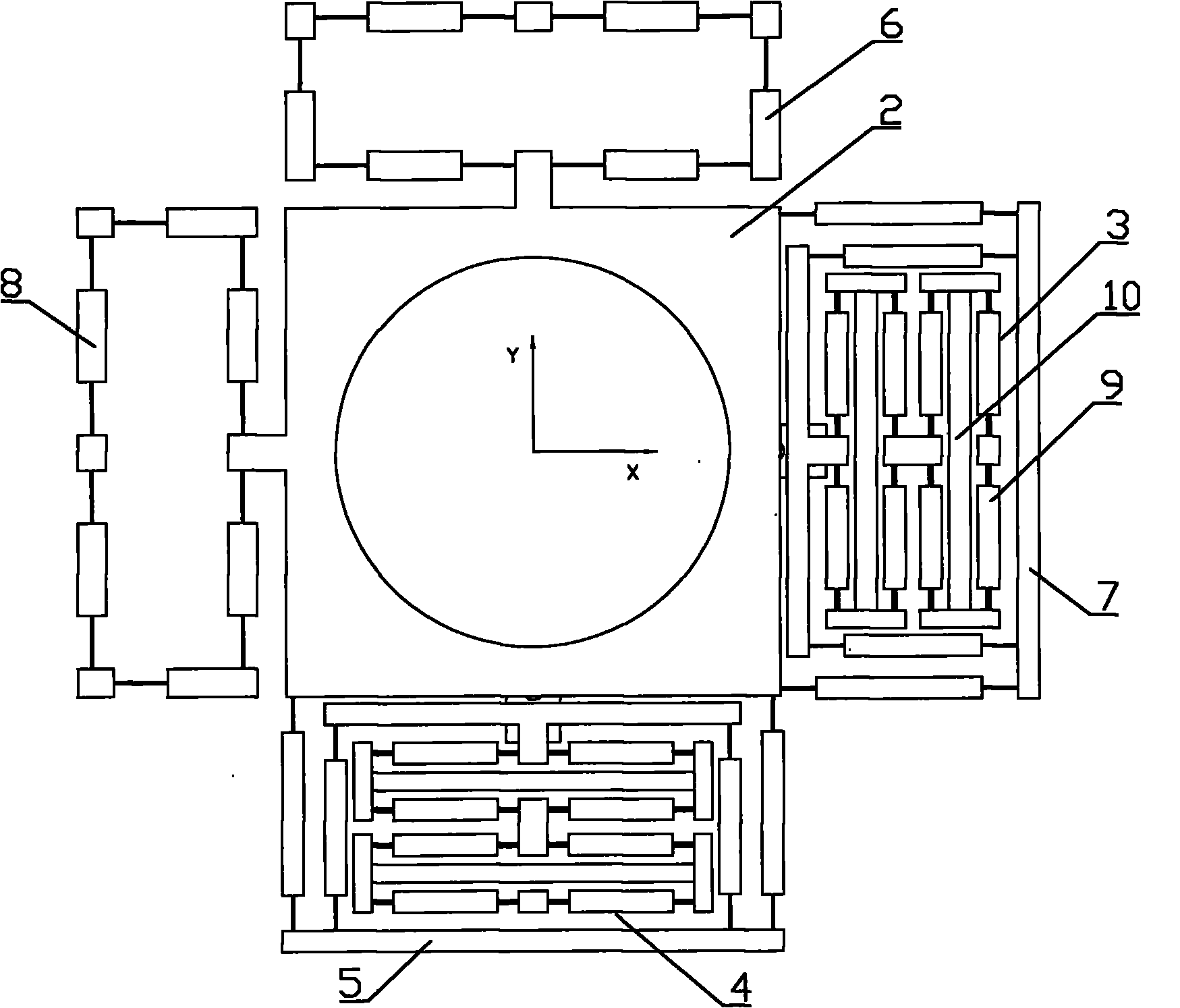

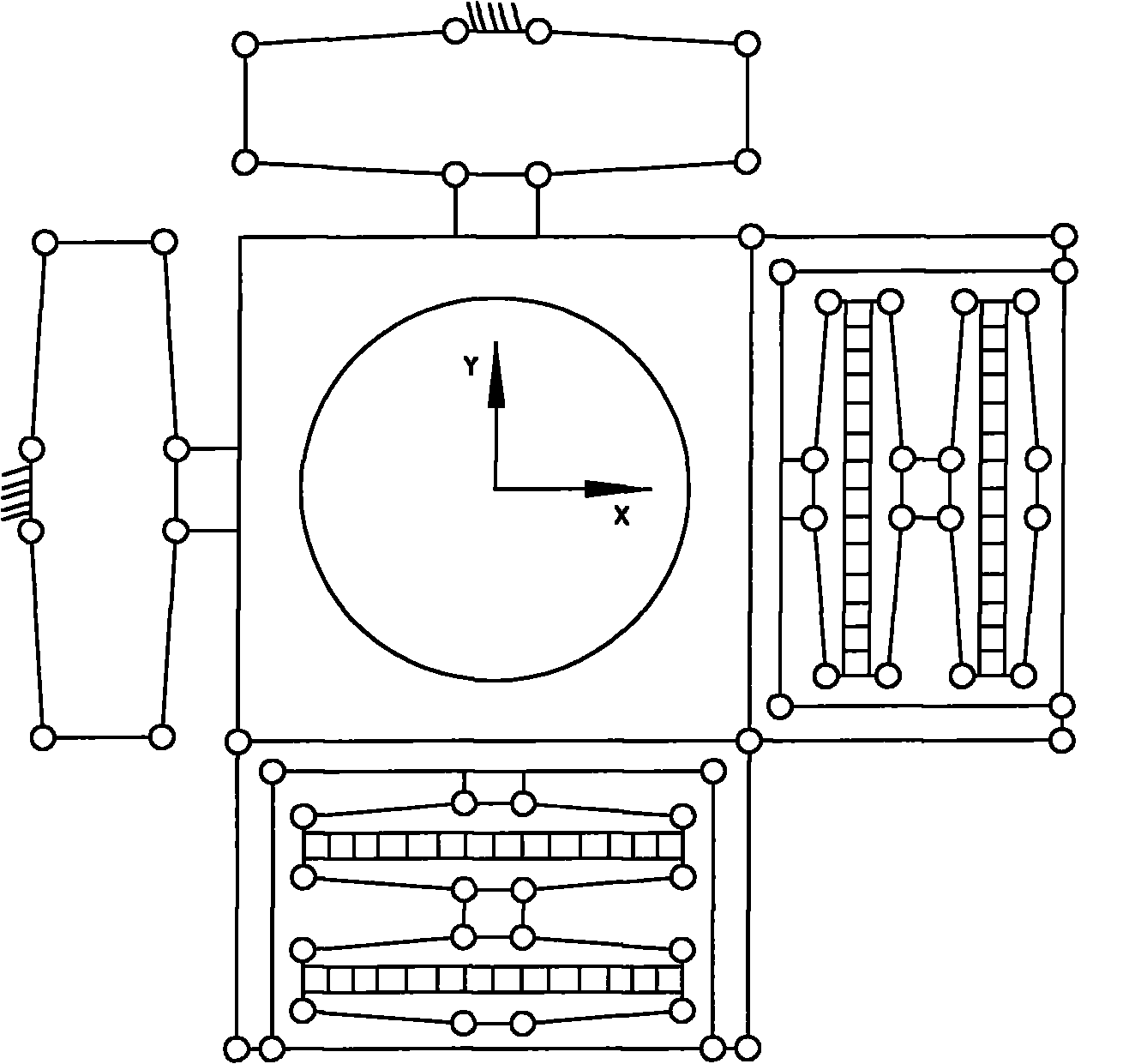

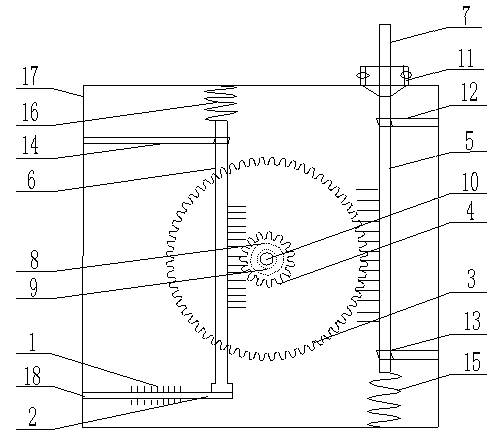

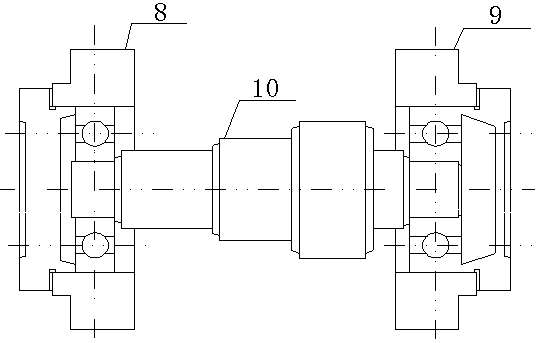

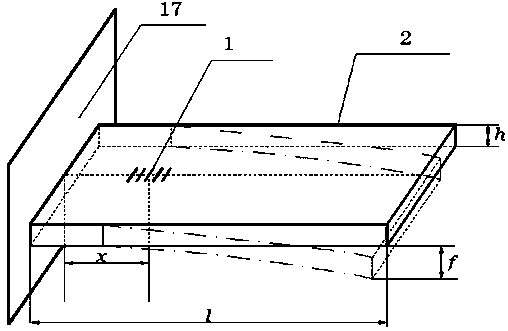

Large-stroke micro-drive precise two-dimensional worktable

InactiveCN103273328AMeasures to overcome leakageAvoiding Impact Processing DilemmasFeeding apparatusLarge fixed membersImage resolutionMachine tool

The invention discloses a large-stroke micro-drive precise two-dimensional worktable which is mainly composed of a base, an X-direction feeding device, a Y-direction feeding device and a feeding device top worktable surface, wherein the X-direction feeding device and the Y-direction feeding device are mutually perpendicular in a two-dimensional plane, the Y-direction feeding device is arranged above the X-direction feeding device, the X-direction feeding device comprises an X-direction large-stroke feeding device and an X-direction micro-feeding device, the Y-direction feeding device comprises a Y-direction large-stroke feeding device and a Y-direction micro-feeding device, and the Y-direction large-stroke feeding device is arranged above the X-direction micro-feeding device and can move along with feeding motion of the X-direction micro-feeding device. A transition connecting plate of the base is connected with a machine tool. Due to the fact that fine precision drive of the worktable is matched with large-stroke displacement output, output force is large, the resolution ratio of displacement is high, the range of the displacement is large, and the large-stroke micro-drive precision two-dimensional worktable has a wide application prospect. Due to cooperation of a cooling system, the large-stroke micro-drive precision two-dimensional worktable avoids the machining difficulty that the feeding precision is influenced by heat generated by long-time precise machining and heating.

Owner:WUHAN UNIV OF SCI & TECH +1

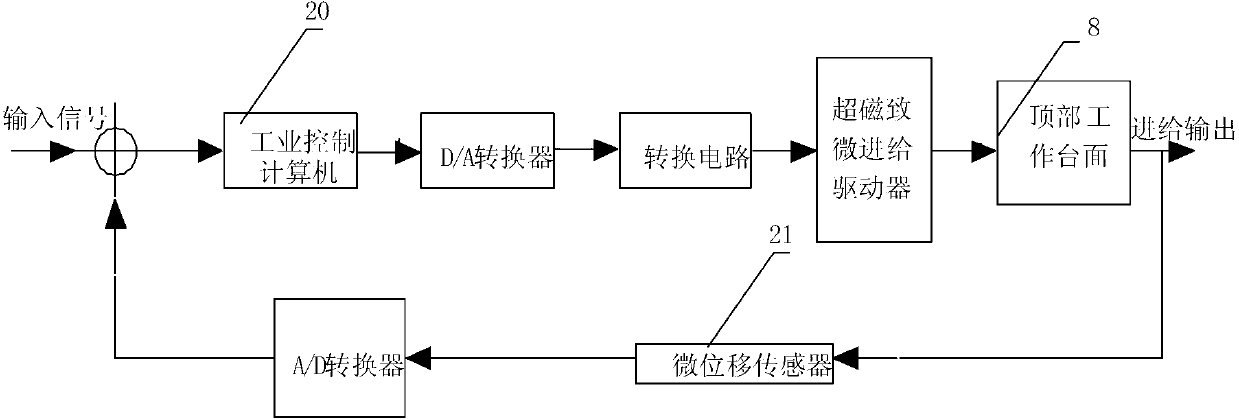

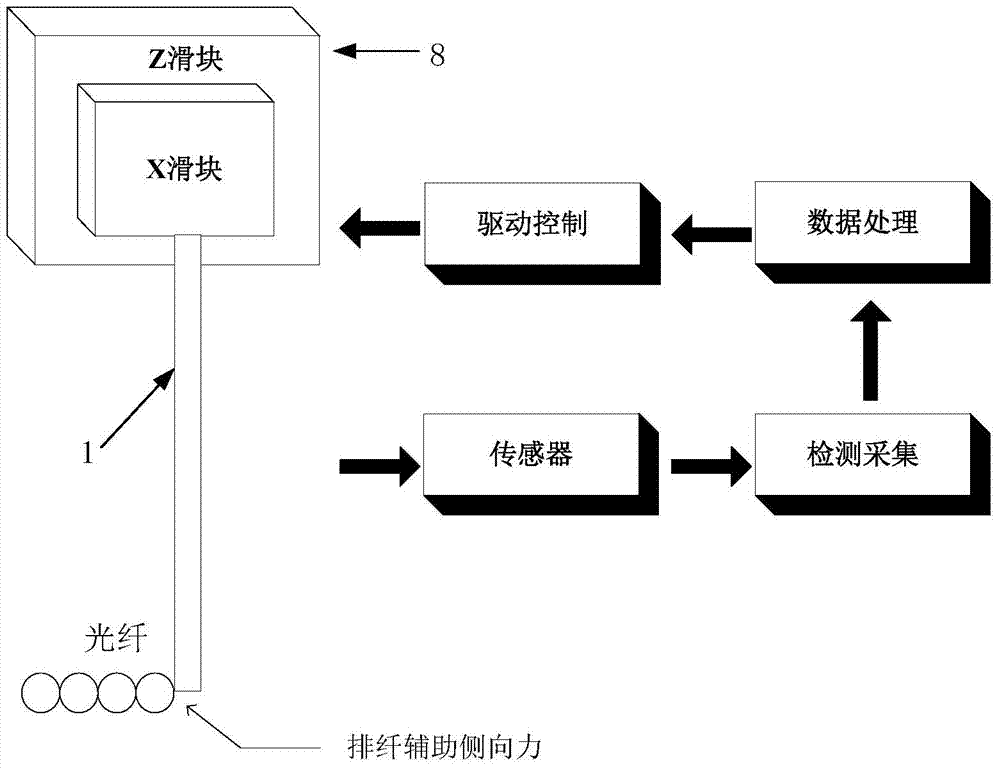

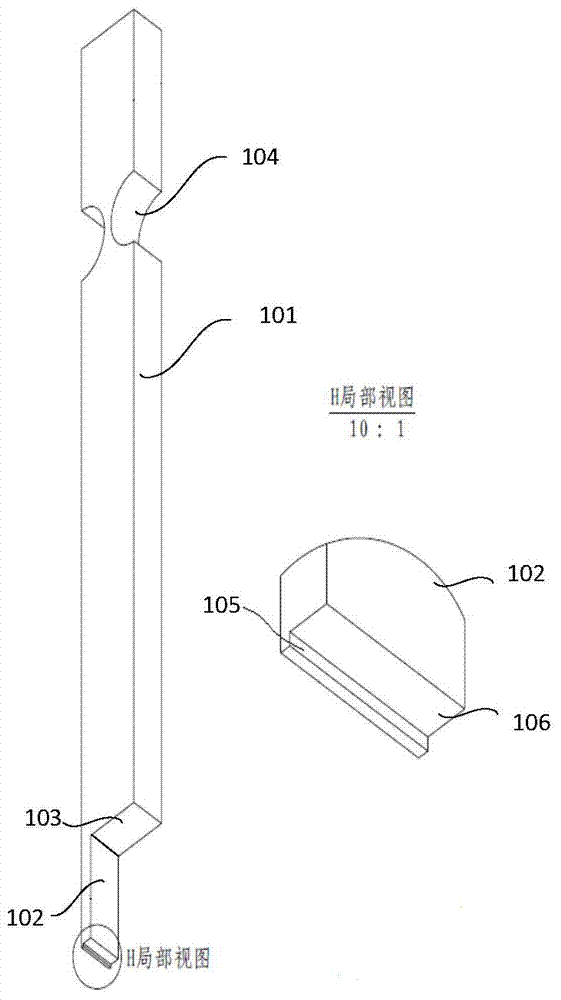

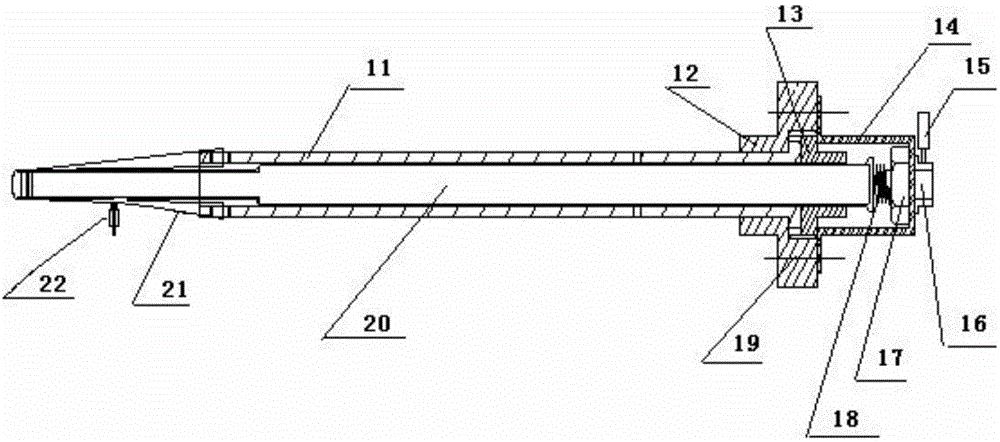

Optical fiber automatic guiding control device suitable for optical fiber ring winding machine

InactiveCN104724544AHigh displacement resolutionHigh precisionFilament handlingSagnac effect gyrometersWinding machineLoop control

The invention discloses an optical fiber automatic guiding control device suitable for an optical fiber ring winding machine. According to the optical fiber automatic guiding control device suitable for the optical fiber ring winding machine, an elastic guiding rod is adopted to serve as a front end sensitive device, a fiber arranging auxiliary lateral force is provided for an optical fiber in a winding process, and an optimal lateral force value obtained through related experiments serves as a reference value. The optical fiber automatic guiding control device enables the auxiliary lateral force to keep the constant optimal value all the time by highly dynamically detecting the auxiliary lateral force and performing closed-loop compensation control, thereby guaranteeing that the optical fiber can be precisely wound on a reserved optical fiber ring. The optical fiber automatic guiding control device suitable for the optical fiber ring winding machine eliminates a rollback idle stroke and mechanical friction in a transmission process, can obtain a high displacement resolution ratio, achieves intelligent optical fiber precise winding by adopting automatic guiding and real-time compensation closed-loop control, and improves the ring winding quality of the optical fiber ring winding machine.

Owner:BEIHANG UNIV

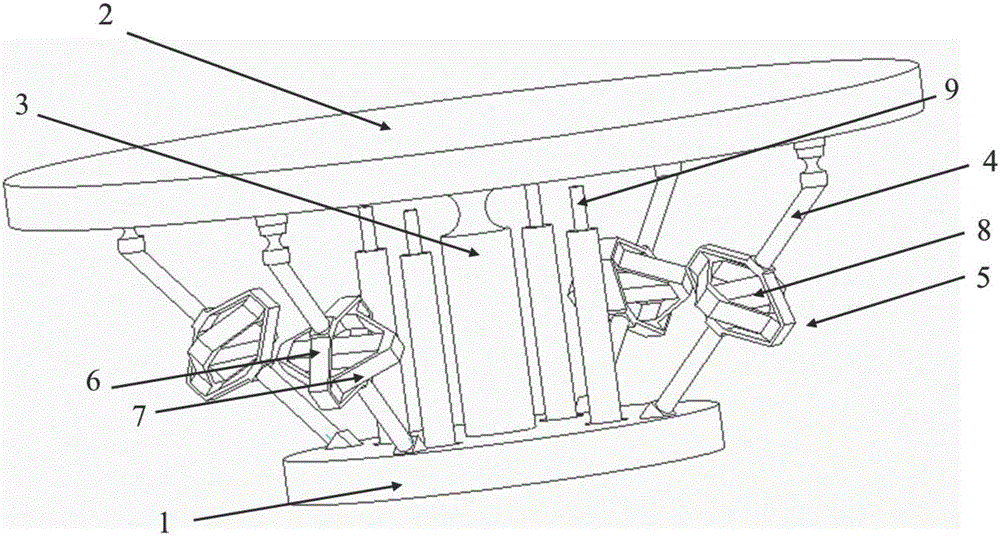

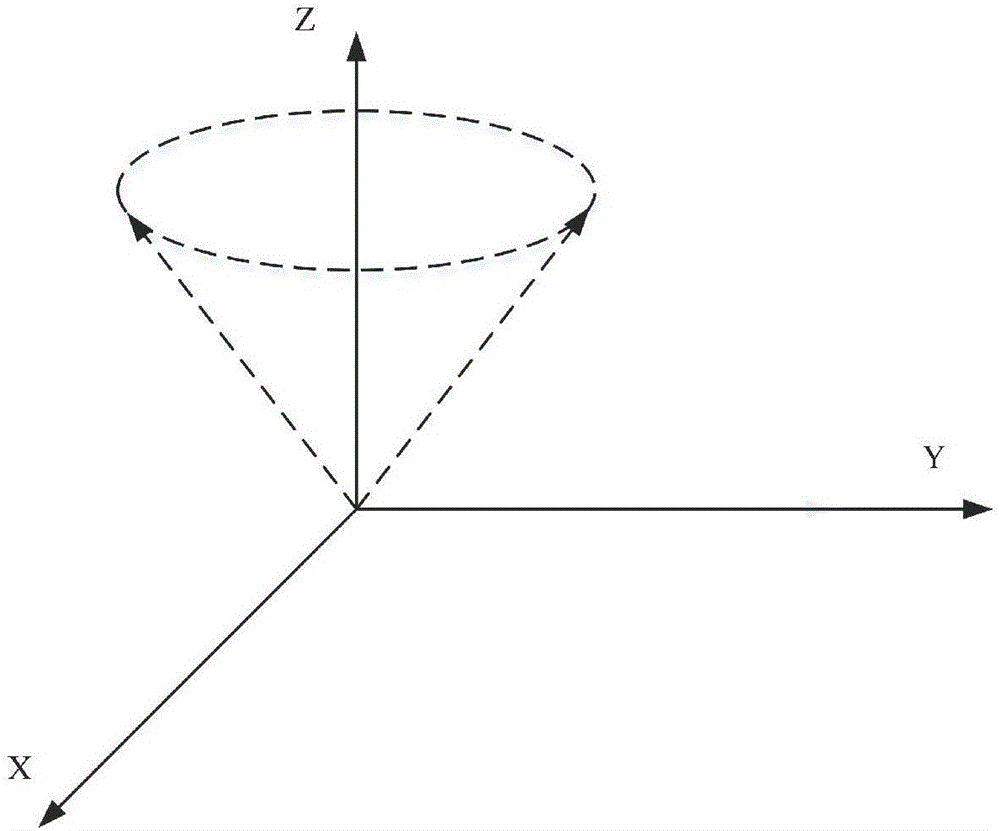

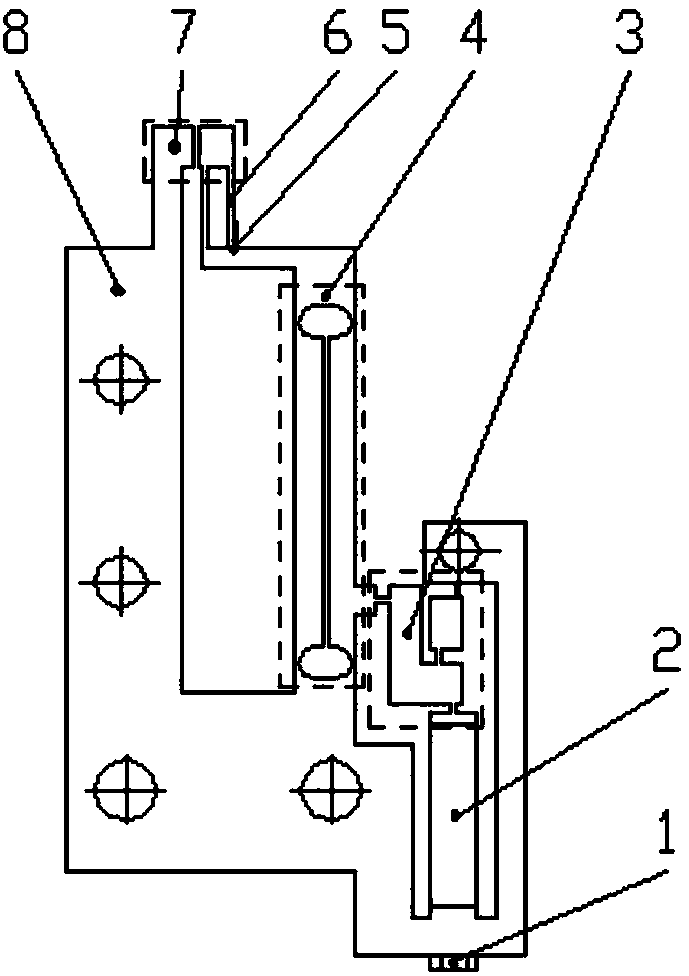

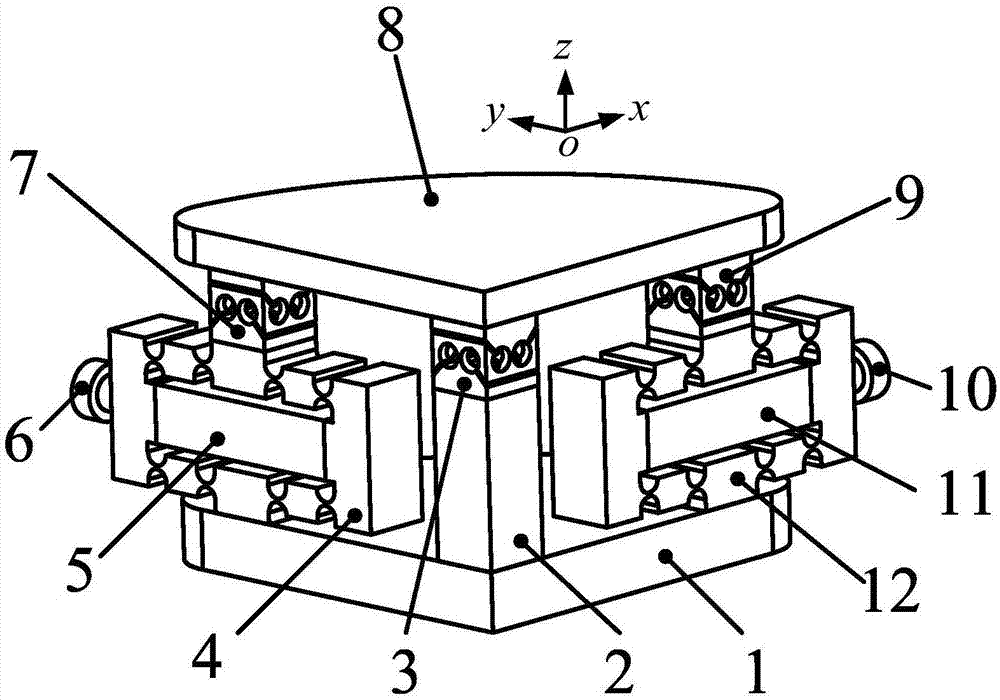

Actuating platform with functions of slight swing prevention and pointing regulation and actuating method

ActiveCN105680719AReduce weightReduce volumePiezoelectric/electrostriction/magnetostriction machinesDiagonalEddy current

The invention relates to an actuating platform with functions of slight swing prevention and pointing regulation and an actuating method. The platform comprises actuating rods, a lower base, an upper platform, a flexible hinge support, second-stage diamond-shaped displacement amplification mechanisms, piezoelectric piles and eddy current displacement sensors, wherein lower base is connected with the upper platform by the flexible hinge support, the lower ends of the actuating rods are fixed on the lower base, the actuating rods are arranged at diagonal lines in a paired way, the upper ends of the actuating rods are connected with the upper platform by a flexible hinge, piezoelectric drivers comprising the piezoelectric piles and the second-stage diamond-shaped displacement amplification mechanisms are connected in series onto the actuating rods, and the eddy current displacement sensors are arranged aside the actuating rods. A displacement signal of the upper platform is acquired by the eddy current displacement sensors, the actuating rods are driven to output the displacement along an axial direction by the piezoelectric drivers comprising the piezoelectric piles and the second-stage diamond-shaped displacement amplification mechanisms, the piezoelectric piles arranged at the diagonal lines in a paired way actuate coordinatively, the upper platform is driven to rotate along a diagonal direction, and high-accuracy regulation of a two-dimensional pointing angle and active control on slight swing of the pointing angle can be achieved.

Owner:XI AN JIAOTONG UNIV

Deformable rapid control integrated reflector device

InactiveCN105572861AHigh displacement resolutionEliminate mechanical frictionMountingsEngineeringProtection ring

The invention discloses a deformable rapid control integrated reflector device, relating to the precision ray machine structure design technology field and solving the problems that the rapid control reflector technology cannot finish the correction of the lower order aberration and the resonant frequency can be affected. The deformable rapid control integrated reflector device comprises a deformable reflector, first actuators, a support platform, a second actuator, an elastic sleeve, a protection ring, a housing, an electric control base plate and a pedestal; the usage quantity of the first actuators is the same as the way of its layout; the deformable reflector is fixedly bonded with the first actuators to form a deformable mirror; the lower part of the first actuators is adhered on the upper surface of the support platform; the second actuator, the elastic sleeve, and the protection ring are fixed under the support platform and fixed on the pedestal; wiring holes are formed in the pedestal; the electric wires of the first actuators which passes through the center hole of the support platform, the electric wire of the second actuator and the related circuit boards are collected in the pedestal; and then the pedestal is sealed through the electric control base plate. The invention can perform wave-front medium-high-order error correction through face shape control.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

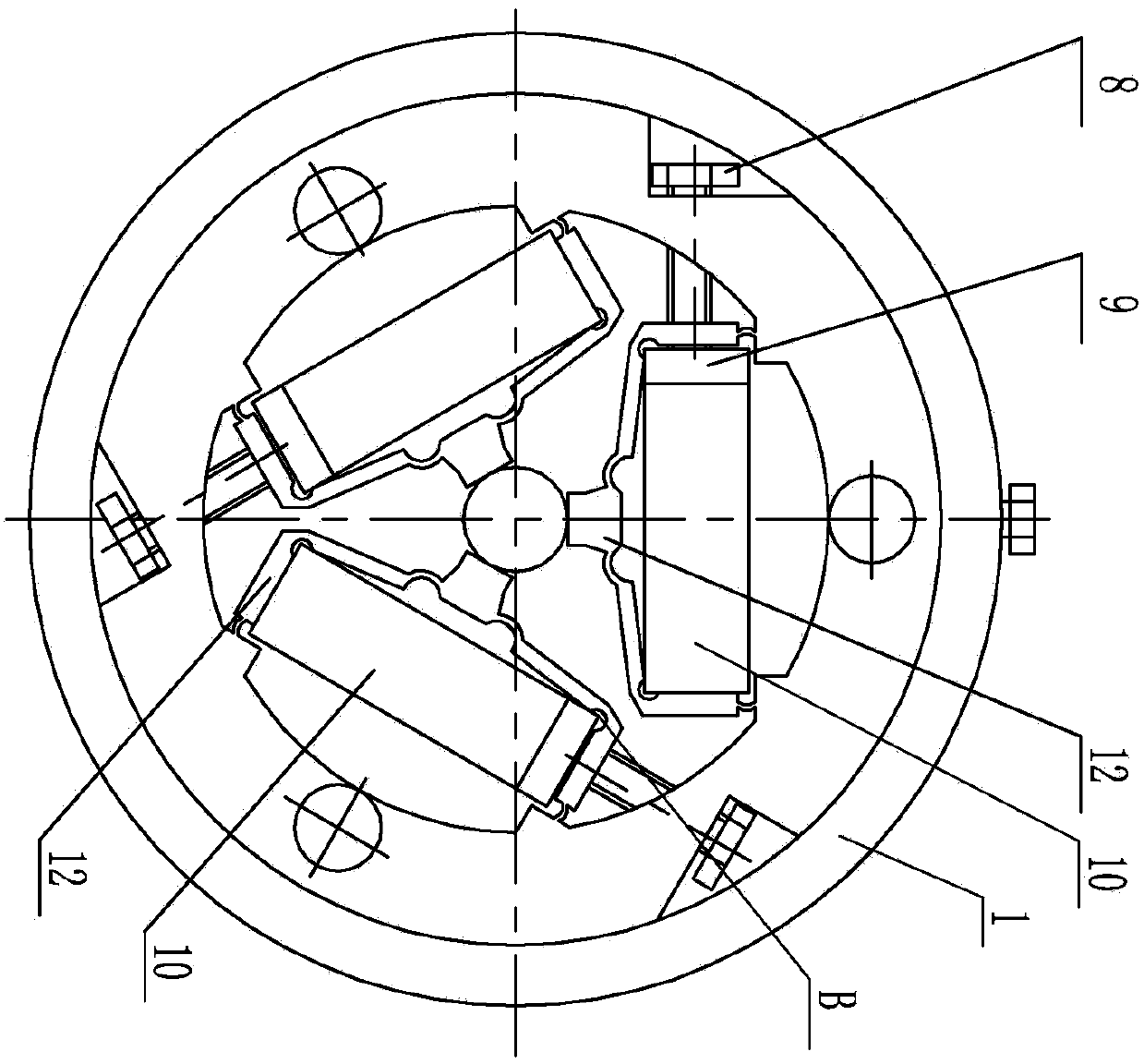

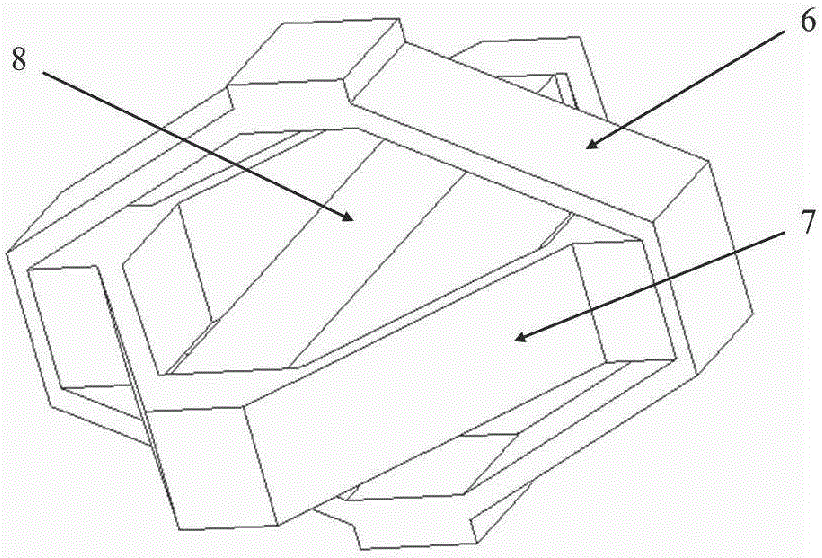

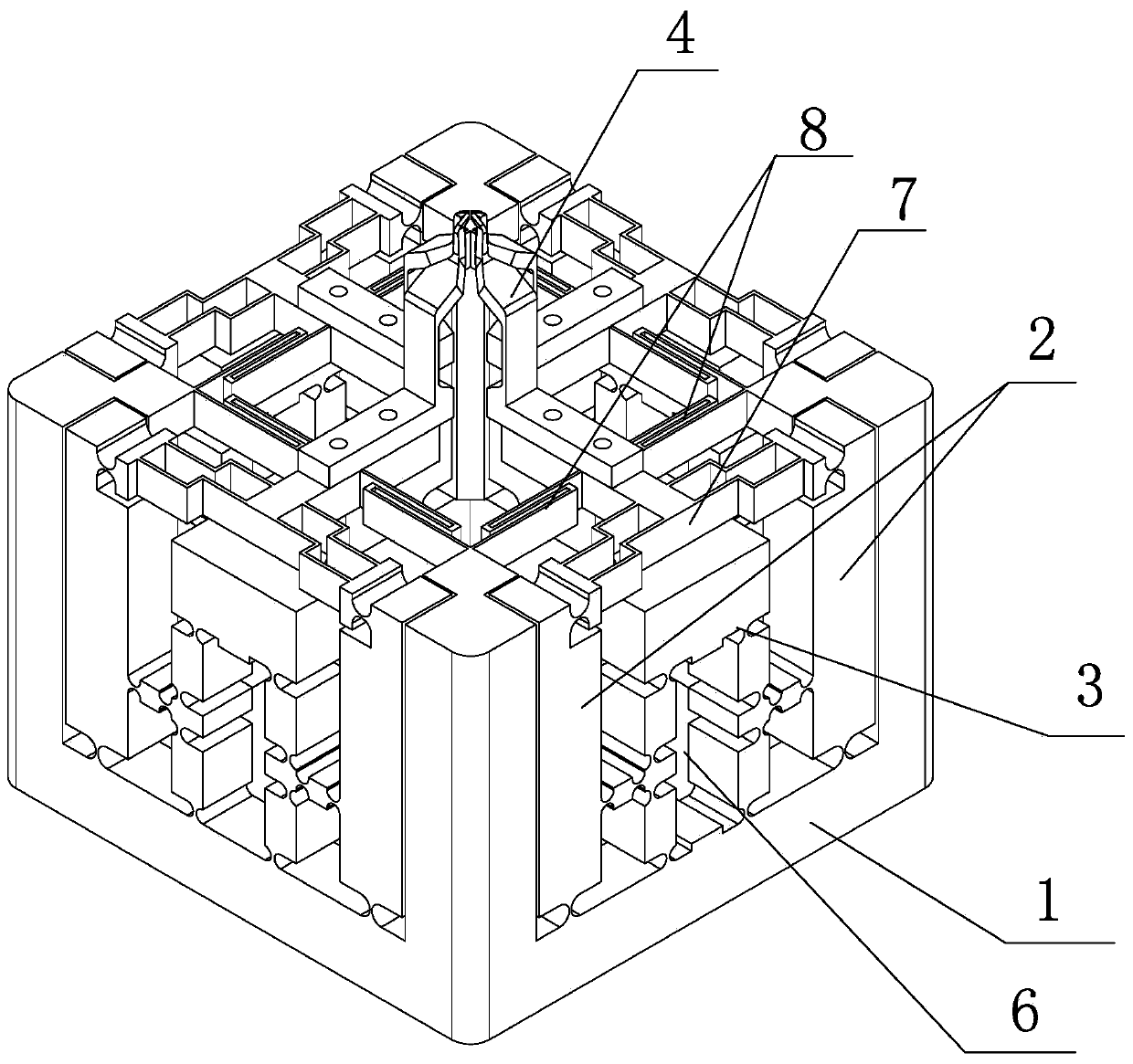

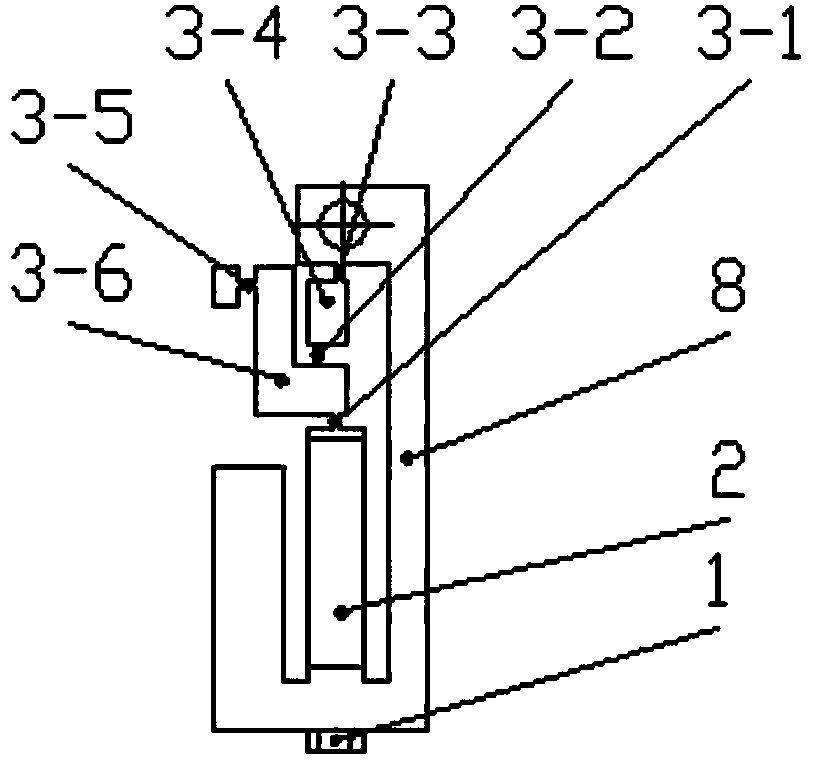

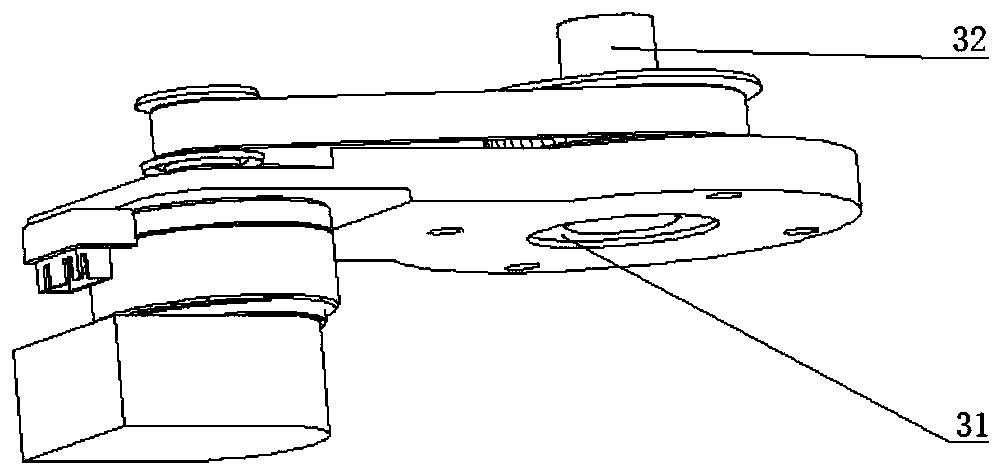

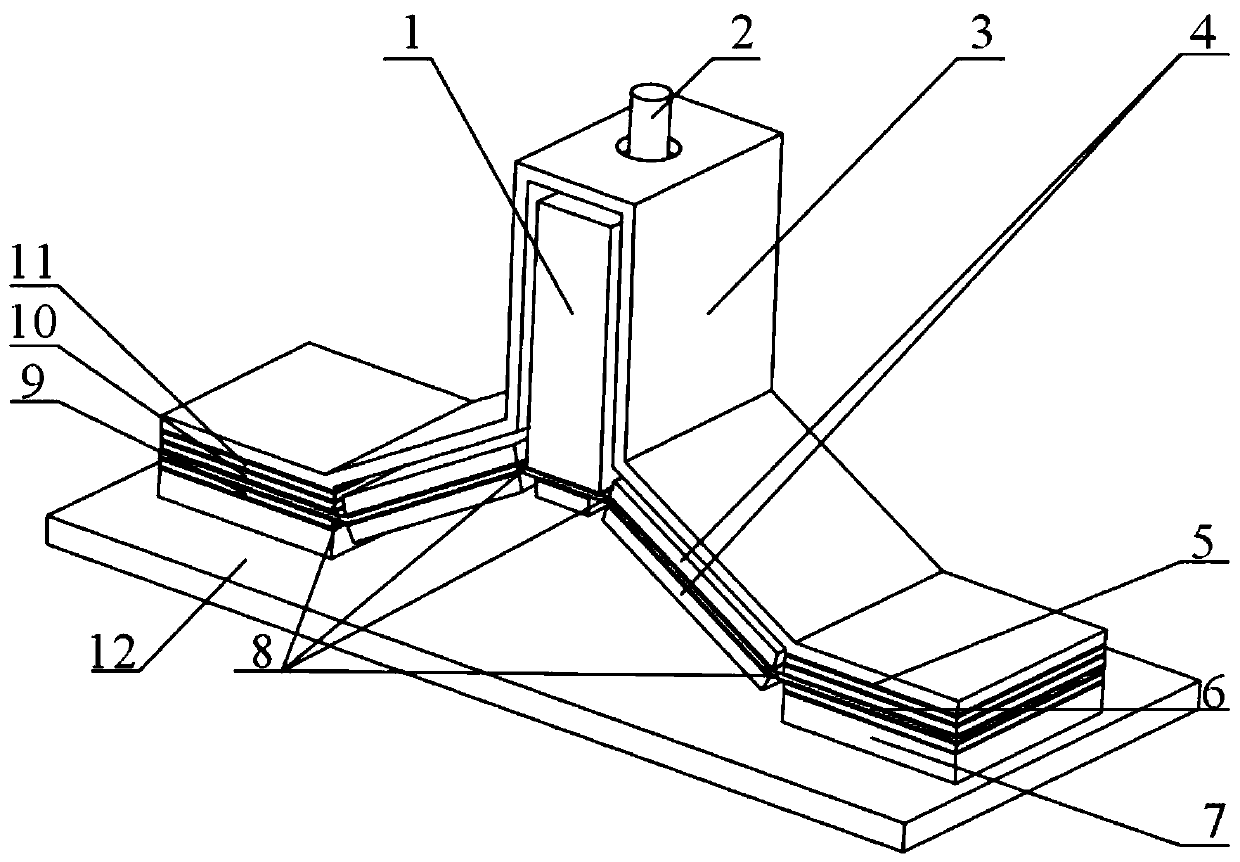

Symmetric spatial three-dimensional micro manipulator with three-stage motion amplifying mechanism

ActiveCN109909976AFirmly connectedActive releaseProgramme-controlled manipulatorGripping headsShaped beamThree stage

The invention discloses a symmetric spatial three-dimensional micro manipulator with a three-stage motion amplifying mechanism. The micro manipulator is small in size, compact in structure, stable andreliable in clamping force and high in movement precision. The micro manipulator is composed of a base and a plurality of amplification clamping modules, wherein each amplification clamping module comprises a piezoelectric ceramic driver, a bridge type displacement amplification mechanism, two lever displacement amplification mechanisms, a Z-shaped beam displacement amplification mechanism, two flexible guide mechanisms and a clamping jaw; the piezoelectric ceramic driver is arranged between the base and the movable end of the bridge type displacement amplification mechanism; and the piezoelectric ceramic driver drives the movable end of the bridge type displacement amplification mechanism, the output end of the bridge type displacement amplification mechanism drives the input ends of thelever displacement amplification mechanisms, the output end of each lever displacement amplification mechanism drives the input end of the Z-shaped beam displacement amplification mechanism, and theoutput end of the Z-shaped beam displacement amplification mechanism is fixedly connected with the clamping jaw. The micro manipulator is compact in structure, stable and reliable in clamping force, low in cost and high in movement precision.

Owner:TIANJIN UNIV

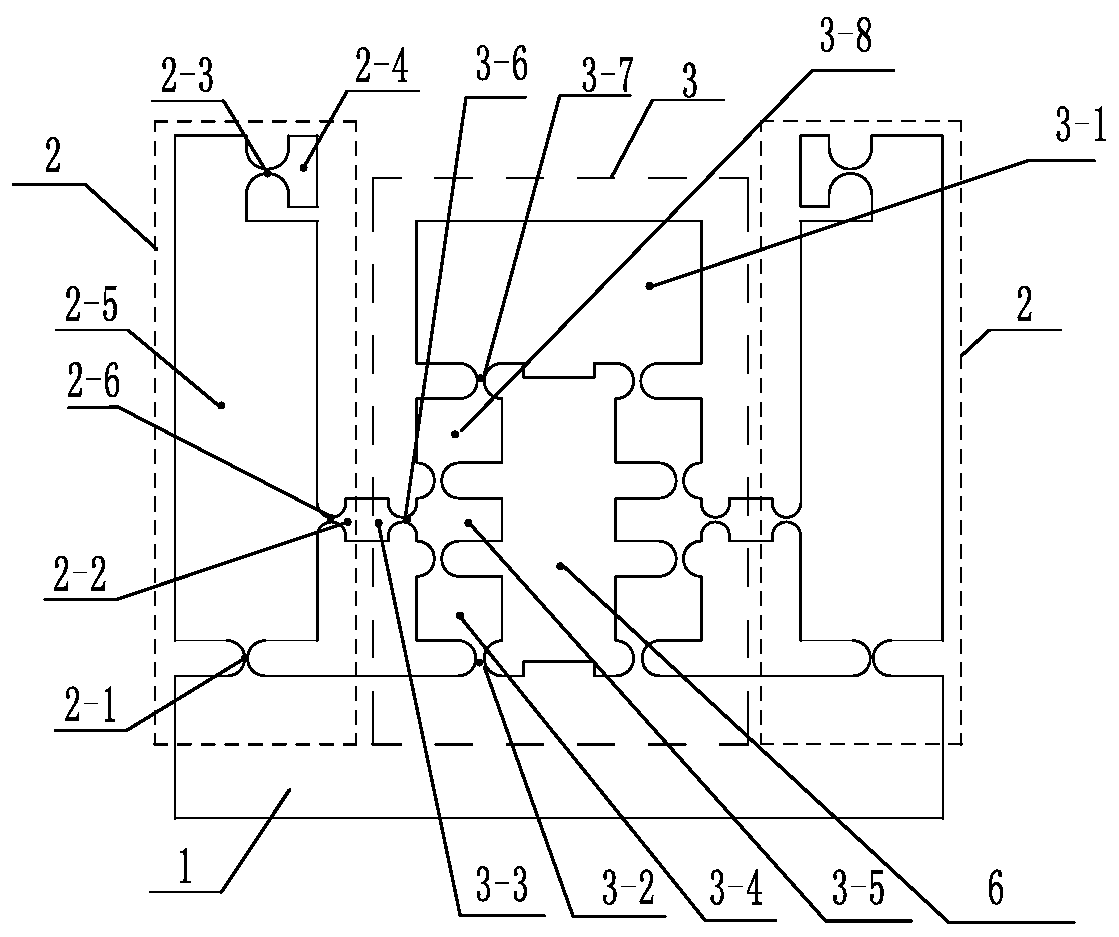

Asymmetric two-stage displacement amplification flexible micro-operation mechanism

ActiveCN108297086ACompact structureStable clampingProgramme-controlled manipulatorMicro-operationNon symmetric

The invention relates to an asymmetric two-stage displacement amplification flexible micro-operation mechanism. The mechanism comprises a base body, a piezoelectric ceramic driver, an SR displacementamplification mechanism, a parallelogram lever amplification mechanism and a pre-tightening bolt, wherein the piezoelectric ceramic driver is installed on the base body through the pre-tightening bolt. The micro-operation mechanism only controls movement of one jaw, and the other jaw is connected with the base body and is fixed to be unmoved; the output end of the piezoelectric ceramic driver is connected with the input end of the SR displacement amplification mechanism through a flexible hinge IV, the SR displacement amplification mechanism is connected with the base body through a flexible hinge I, the output end of the SR displacement amplification mechanism is connected with the input end of the parallelogram lever amplification mechanism through a flexible hinge II, and the output endof the parallelogram lever amplification mechanism is connected with the jaws through a flexible parallel double-plate mechanism; and a metal strain gauge is adhered to the flexible parallel double-plate mechanism. According to the asymmetric two-stage displacement amplification flexible micro-operation mechanism, the asymmetric structure design is adopted, so that the structure of the micro-operation mechanism is compact, stable clamping is realized, and the defects of de-synchronic clamping and instability existing in symmetrical clamping are overcome.

Owner:TIANJIN UNIV

Six-degree-of-freedom acupuncture robot for internal use of magnetic resonance imager

PendingCN109965949AReal-time navigationThe puncture process is stable and reliableSurgical needlesComputer-aided planning/modellingAcupunctureResonance

The invention discloses a six-degree-of-freedom acupuncture robot for internal use of a magnetic resonance imager. The six-degree-of-freedom acupuncture robot comprises a Cartesian module, a swing module and an acupuncture module; the swing module is fixed onto the Cartesian module, the acupuncture module is fixed onto the swing module, the Cartesian module is used for controlling the motion of the swing module in X direction, Y direction and Z direction, and the X direction, the Y direction and the Z direction are perpendicular to one another; the swing module is used for controlling the acupuncture module to swing horizontally; the acupuncture module is used for controlling the pitching motion and the needle movement of the acupuncture module. Various forms of non-magnetic ultrasonic motor drive is adopted, prostate puncture with the desired position and posture can be realized, and based on the characteristics of power off and self-locking of an ultrasonic motor, adding of an extralocking device to keep the position is not needed; the overall system of the six-degree-of-freedom acupuncture robot is simple and compact and easy to miniaturize.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

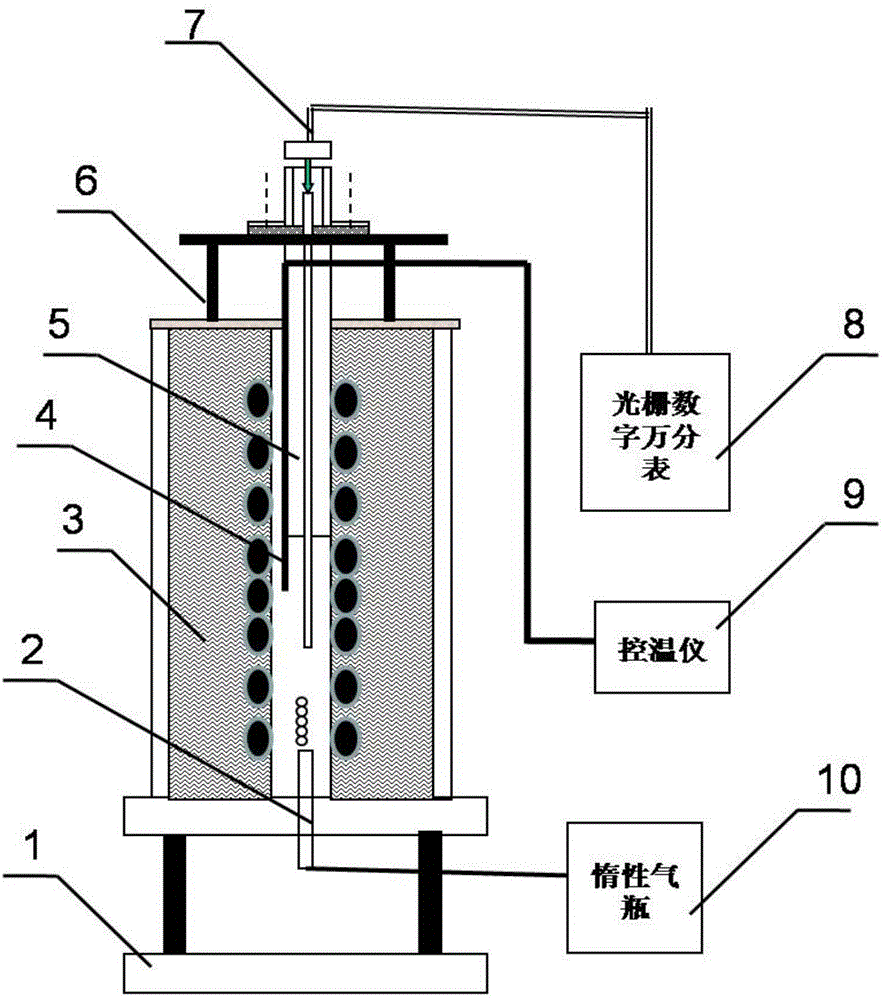

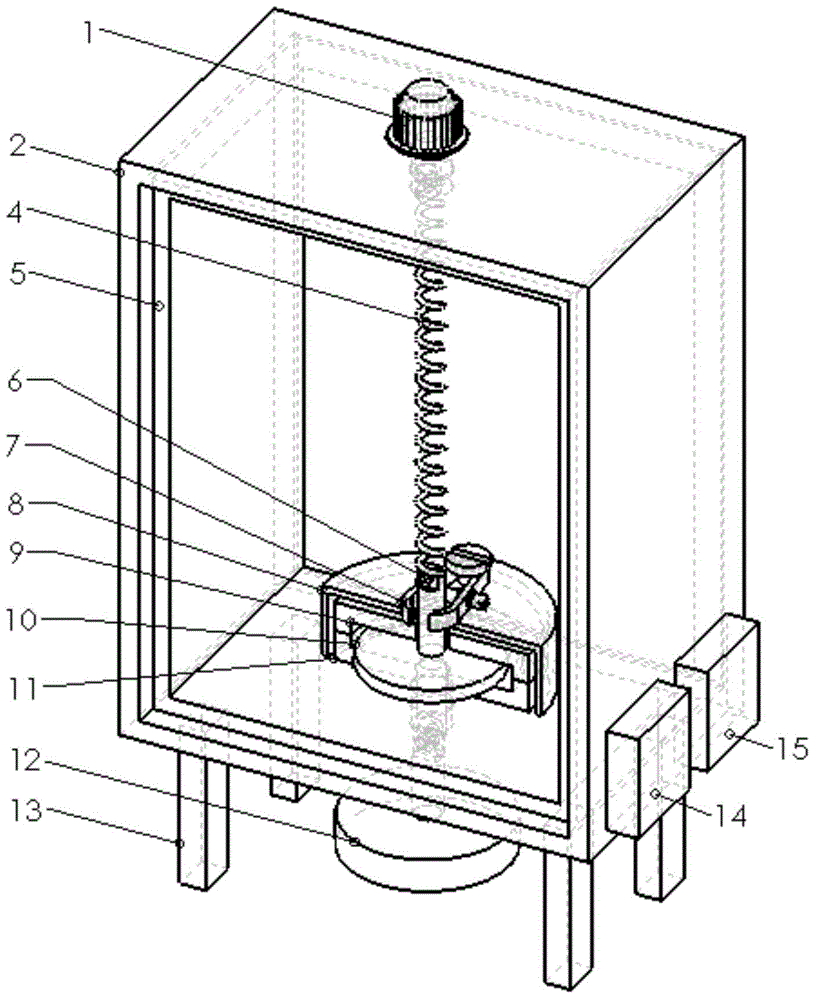

Fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device

ActiveCN103983658ASimple structureStable structureMaterial thermal coefficient of expansionTemperature controlFiber

The invention discloses a fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device, the temperature range of which is from a room temperature to 800 DEG C. The fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device comprises a grate, a gas tube, an electric heating furnace, a thermocouple, a quartz differential sensor unit, a quartz differential sensor unit bracket, a raster digital displacement sensor probe, a raster digital universal meter, a temperature-controlled instrument, and an inert gas cylinder. The fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device has a technical core of the design of the quartz differential sensor unit and a connecting method of a fiber sample to be tested. The fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device is capable of effectively solving all main technical problems and difficulties of the prior art, and remarkably improving the longitudinal coefficient-of-linear-expansion testing precision of fiber materials with low coefficient-of-linear-expansion characteristic.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

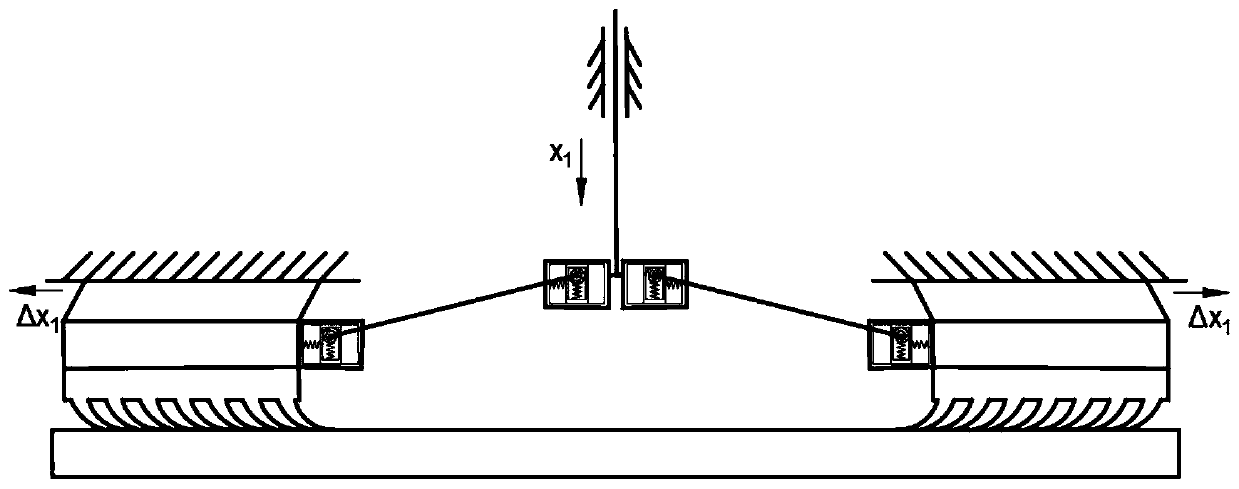

Variable-scale driving bionic dry adhesion mechanism

ActiveCN110125941AFull tangential loadingLimit parasitic movementProgramme-controlled manipulatorBrush bodiesFlexible circuitsSurface loading

The invention discloses a variable-scale driving bionic dry adhesion mechanism. The mechanism comprises a wedge-shaped seta beam unit, a tangential loading unit, a variable-scale driving transmissionunit, a normal driving unit and a supporting outer frame, the wedge-shaped seta beam unit is used for contacting and adhering a target object, the tangential loading unit is used for carrying out tangential loading / unloading on the wedge-shaped seta beam, the variable-scale driving transmission unit transmits the driving displacement and the driving force to the tangential loading unit, the normaldriving unit serves as an active driving source of the mechanism and is used for loading / unloading the variable-scale driving transmission unit, and the supporting outer frame is used for supportingthe whole mechanism and keeping the relative positions of all parts of the whole mechanism. According to the variable-scale driving bionic dry adhesion mechanism, a traditional point loading mode is converted into a surface loading mode, stable tangential loading / unloading of the wedge-shaped seta beam under micro-displacement is realized through a variable-scale driving principle, so that the application requirements of space fragment cleaning and flexible circuit board nondestructive operation are met.

Owner:BEIHANG UNIV

Piezoelectric driving type wire bonding device

ActiveCN105355571AReduce quality problemsQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingBridge typeEngineering

The invention discloses a piezoelectric driving type wire bonding device. The piezoelectric driving type wire bonding device comprises a substrate and a swinging platform arranged above the substrate, wherein a left upright post, a right upright post and a bridge-type amplifying mechanism are arranged between the swinging platform and the substrate; a piezoelectric ceramic driver is arranged in the bridge-type amplifying mechanism; the piezoelectric ceramic driver is provided with a pre-tightening bolt; the pre-tightening bolt is connected to the bridge-type amplifying mechanism; a fixed seat is mounted in the middle of the front part of the upper surface of the swinging platform; the fixed seat is fixedly connected with an energy converter; the energy converter comprises an amplitude-change pole arranged vertical to a swinging shaft of the swinging platform; an ultrasonic piezoelectric vibrator is arranged at the input end of the amplitude-change pole; and the output end of the amplitude-change pole is connected with a chopper vertical to the amplitude-change pole. The device adopts the piezoelectric ceramic driver for driving, and is compact in structure, low in weight and little in movement inertia, so that the operation stability of a bonding head in the packaging process can be improved.

Owner:TIANJIN UNIV

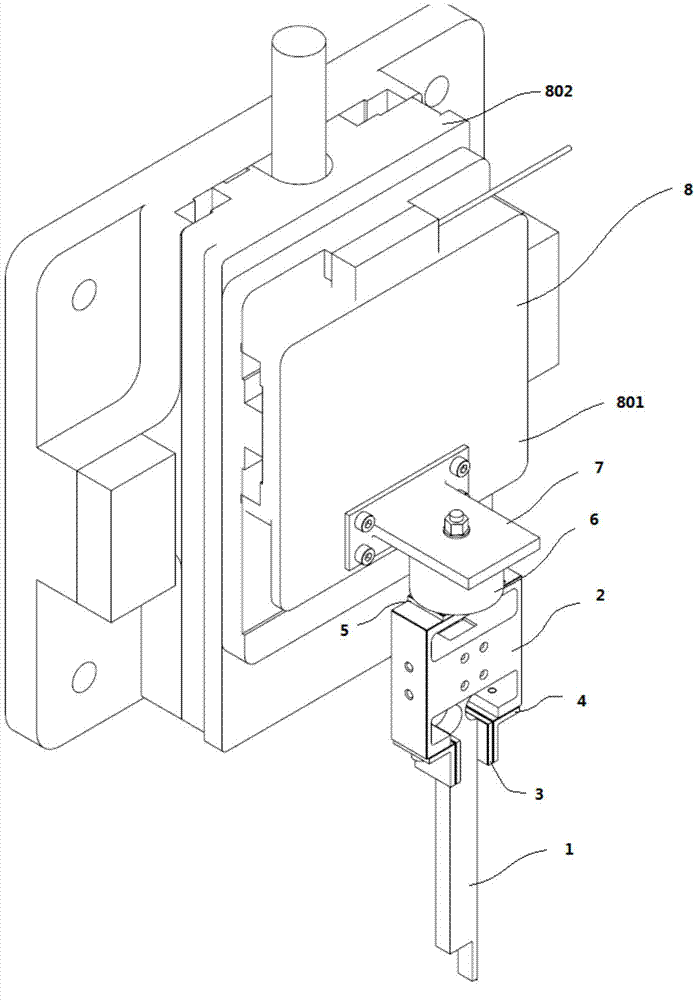

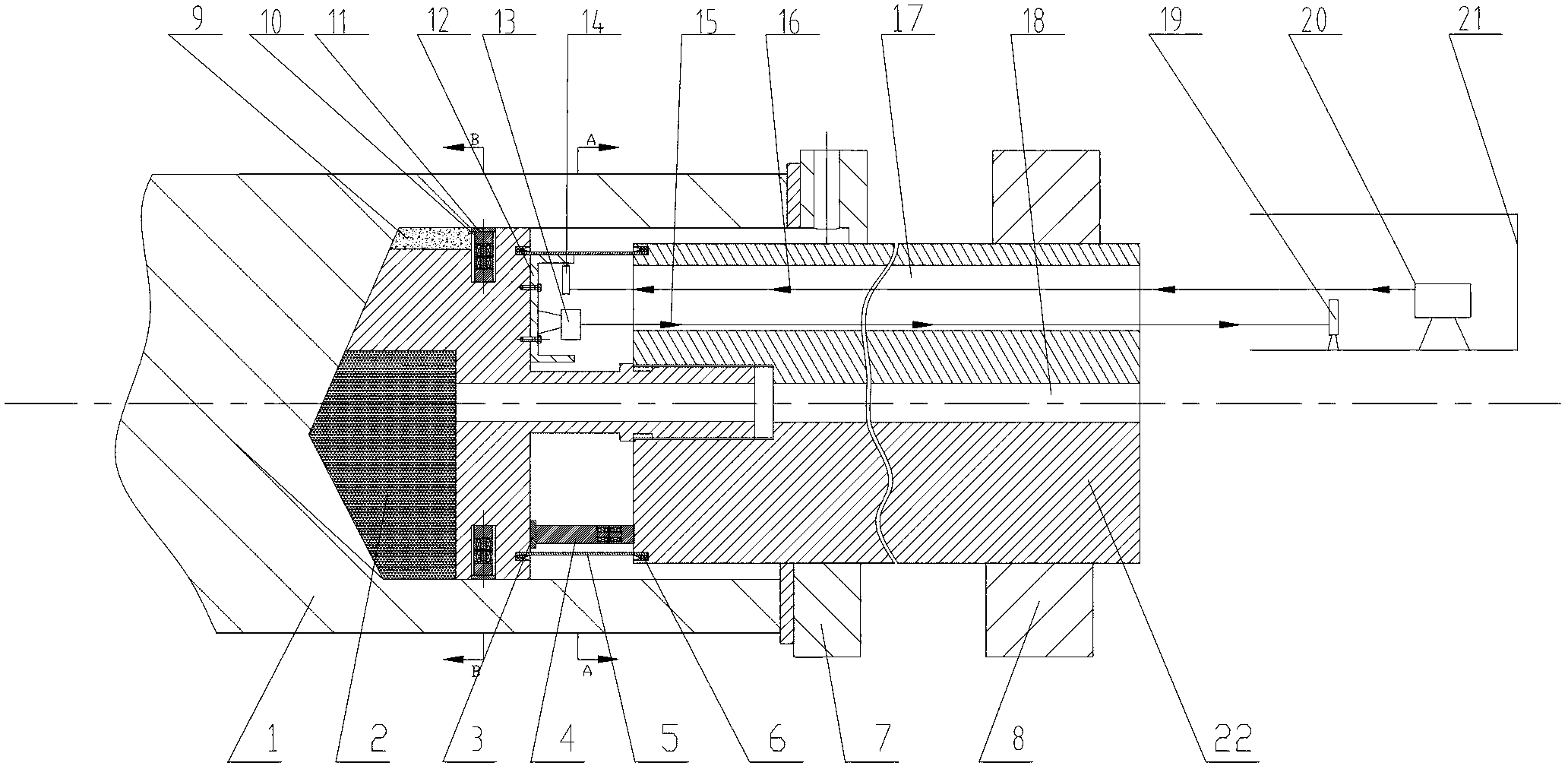

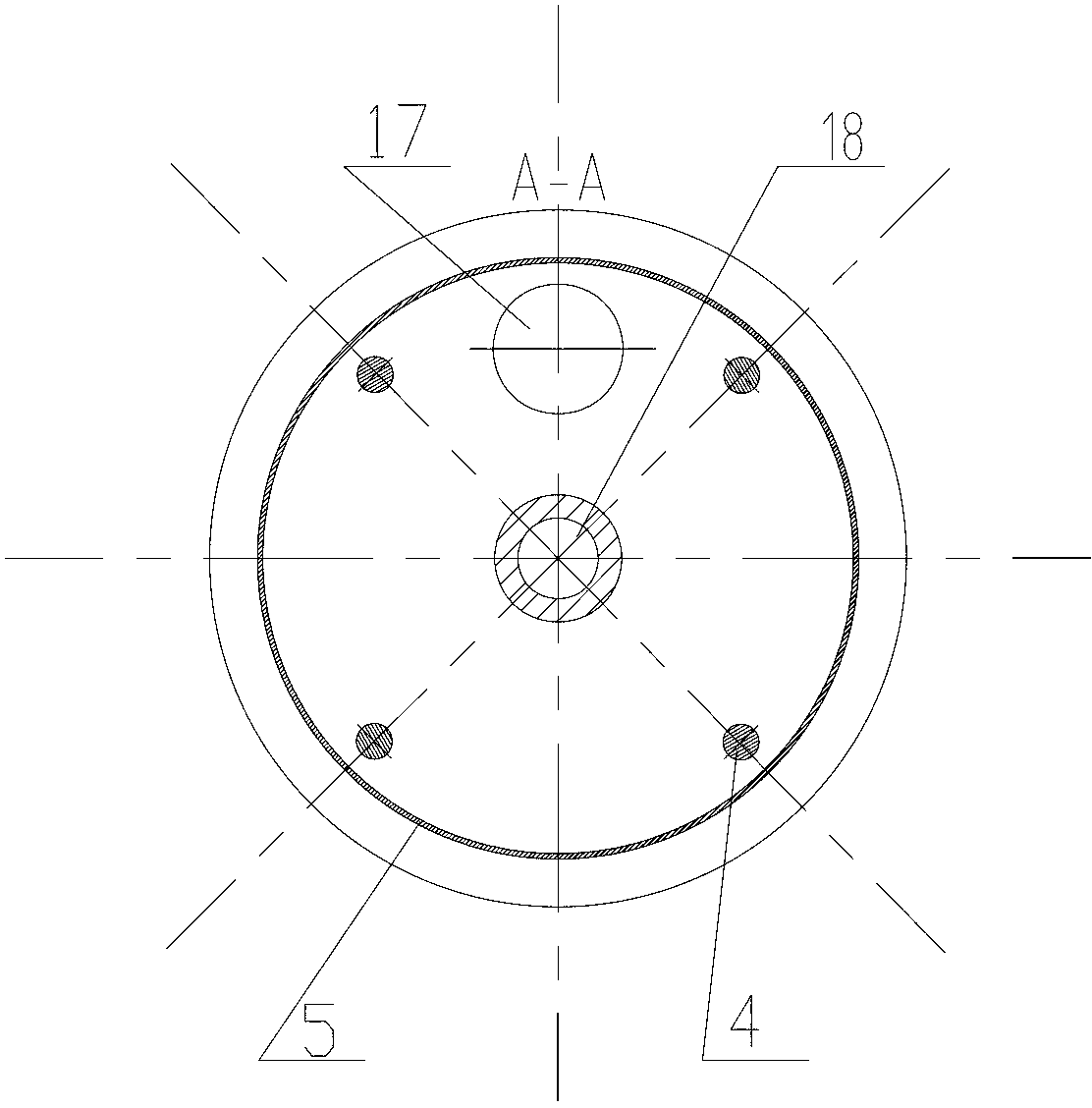

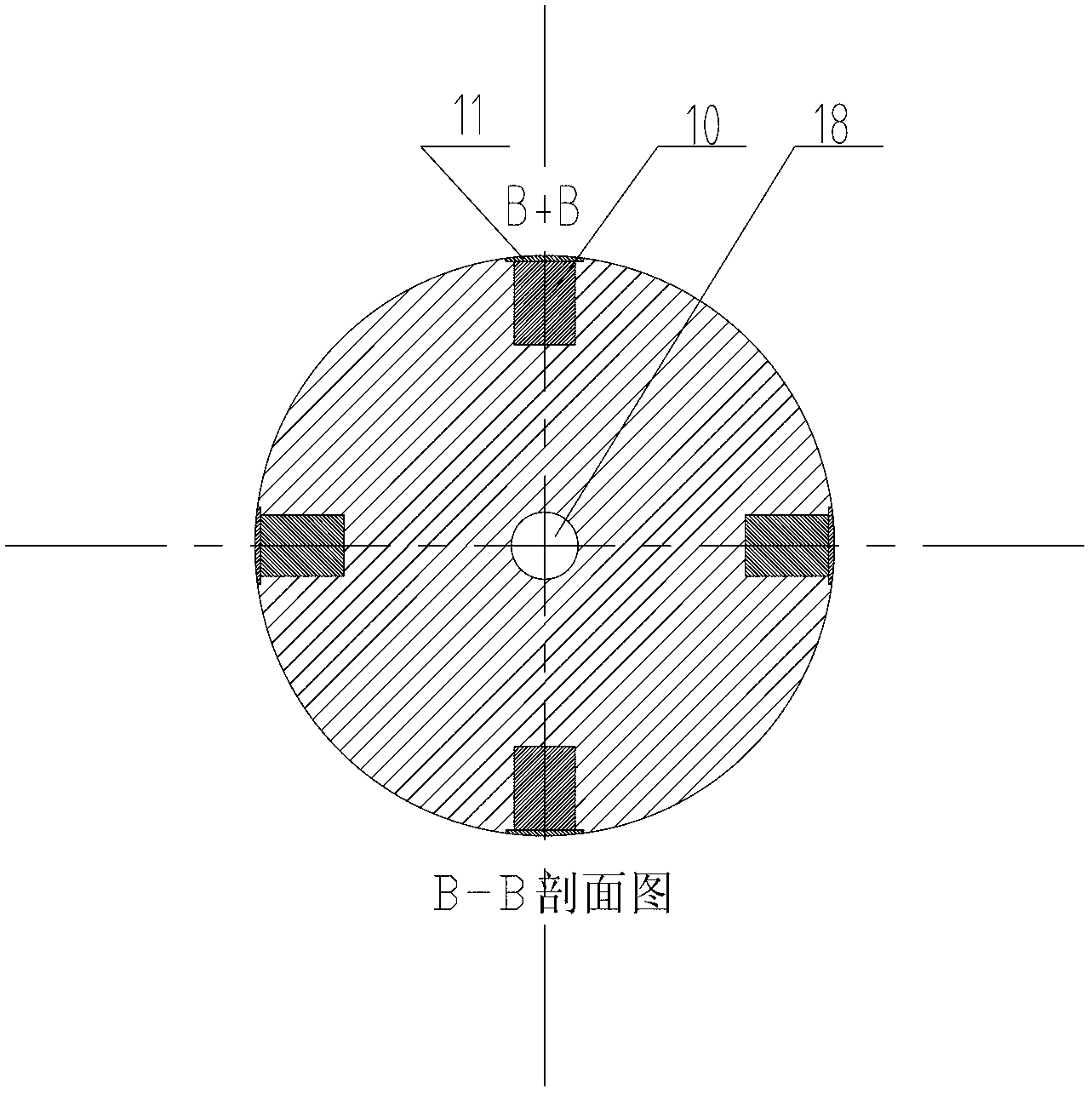

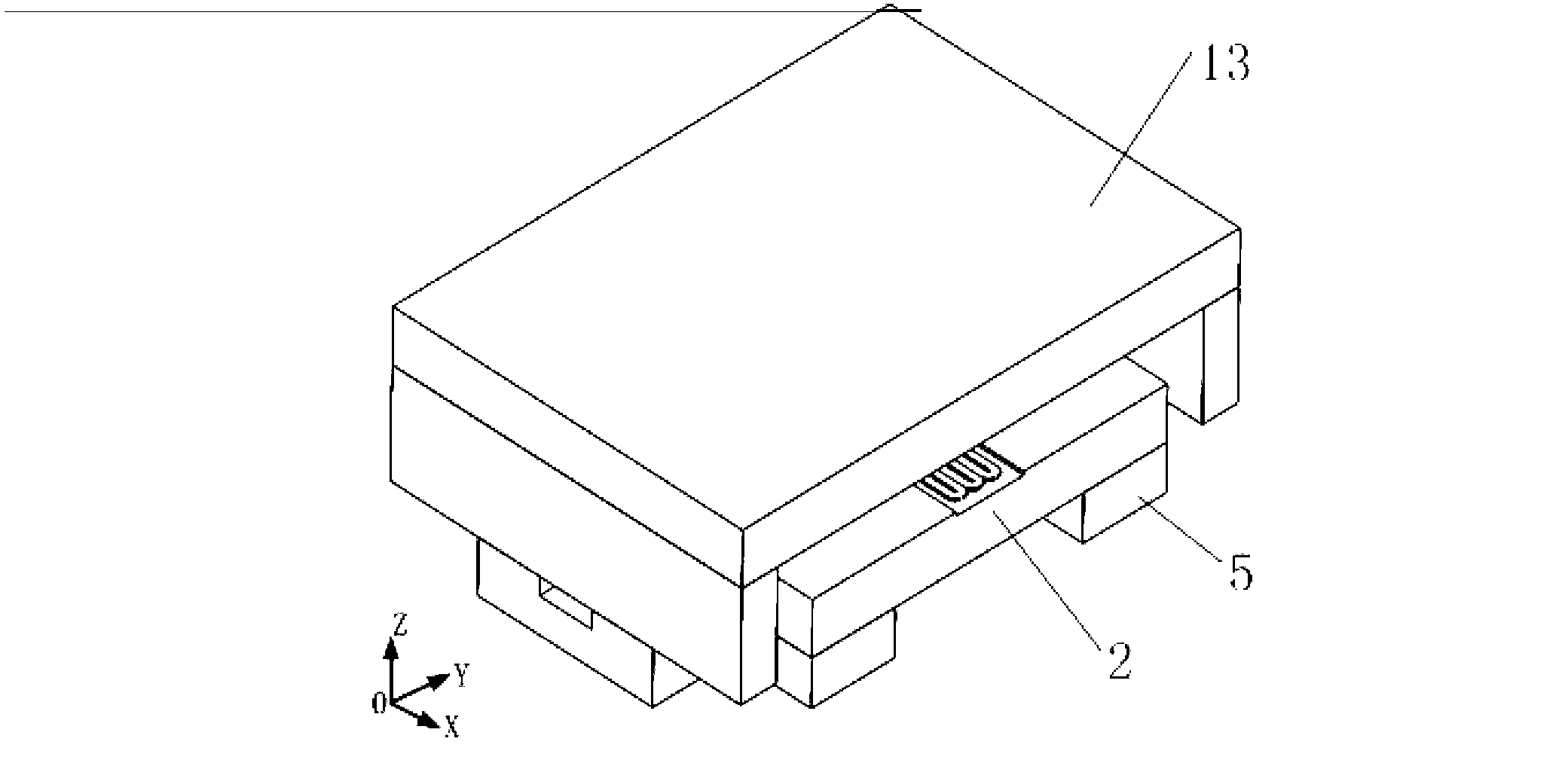

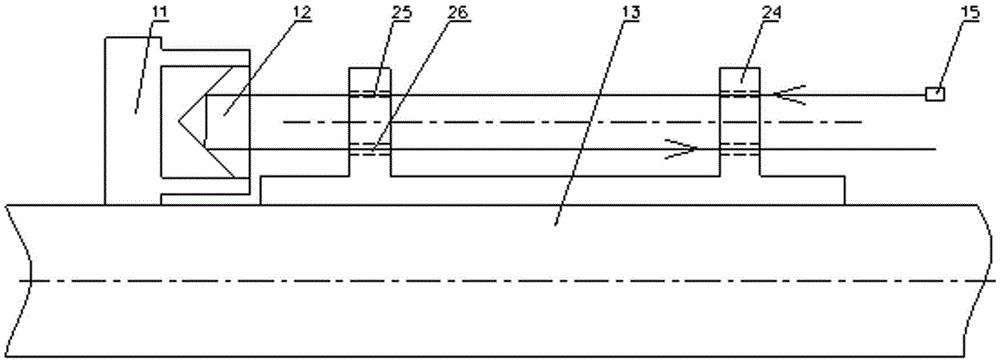

Deep hole processing online detection and correction device

ActiveCN103182552ALarge outputReduce volumeAutomatic control devicesDrilling/boring measurement devicesMachining processLaser source

The invention discloses a deep hole processing online detection and correction device. The deep hole processing online detection and correction device is characterized in that an inspection hole is formed between a chip removal hole of a drill rod and an outer circle, an internal fixation frame provided with an internal laser source and a position-sensitive detector is arranged at corresponding positions on a drill bit and the inner end of the inspection hole, an external fixation frame provided with an external laser source and an angle-sensitive detector is arranged on the outer end of the inspection hole of the drill rod, the angle-sensitive detector corresponds to the internal laser source, and the position-sensitive detector corresponds to the external laser source; and radial expansion pieces are distributed along the circumferential direction of the drill bit, and axial expansion pieces are arranged while avoiding a circular groove space of the internal fixation frame between the drill bit and the drill rod. According to the deep hole processing online detection and correction device, the internal laser source and the external laser source transmit laser, positions and angles of the drill bit in a machining process are detected online, and the positions and angles of the drill bit are adjusted by virtual of a radial expansion piece and an axial expansion piece, so that the problems that drilling deflection can not be observed and correction can not be timely carried out are solved.

Owner:ZHONGBEI UNIV

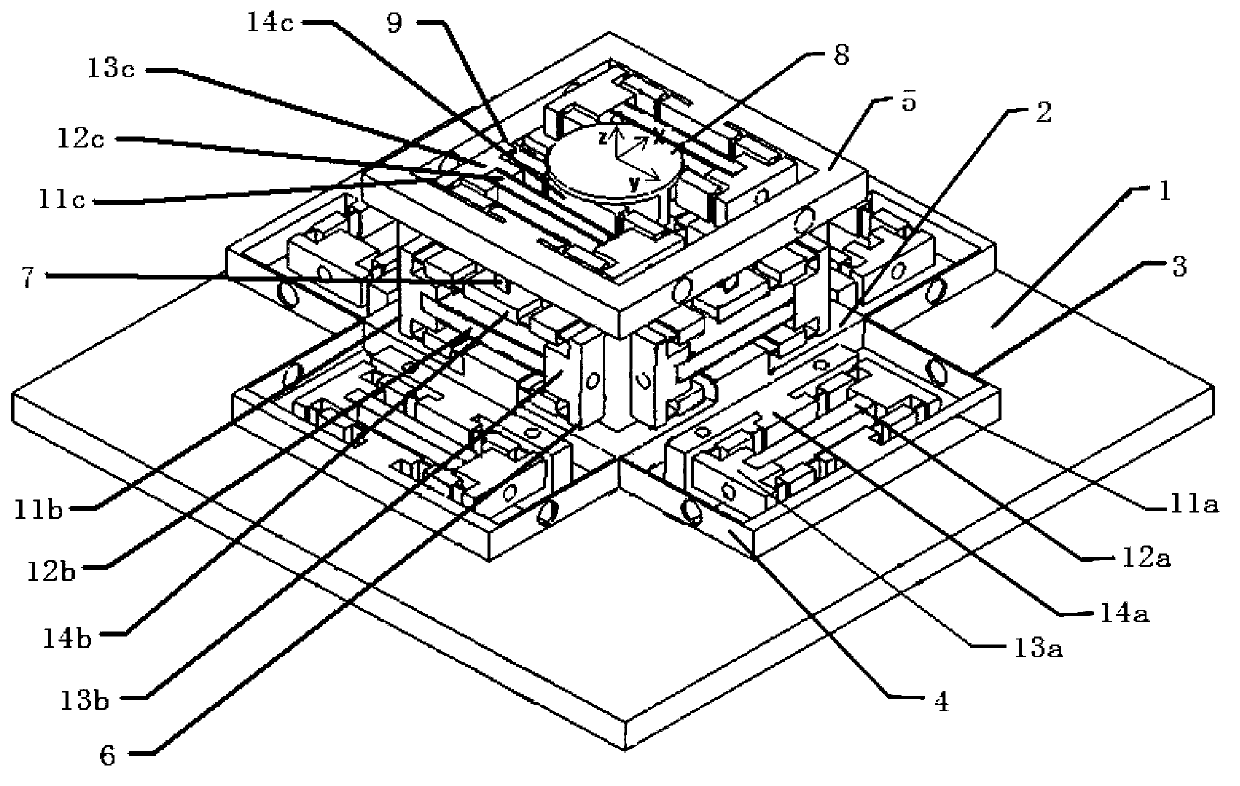

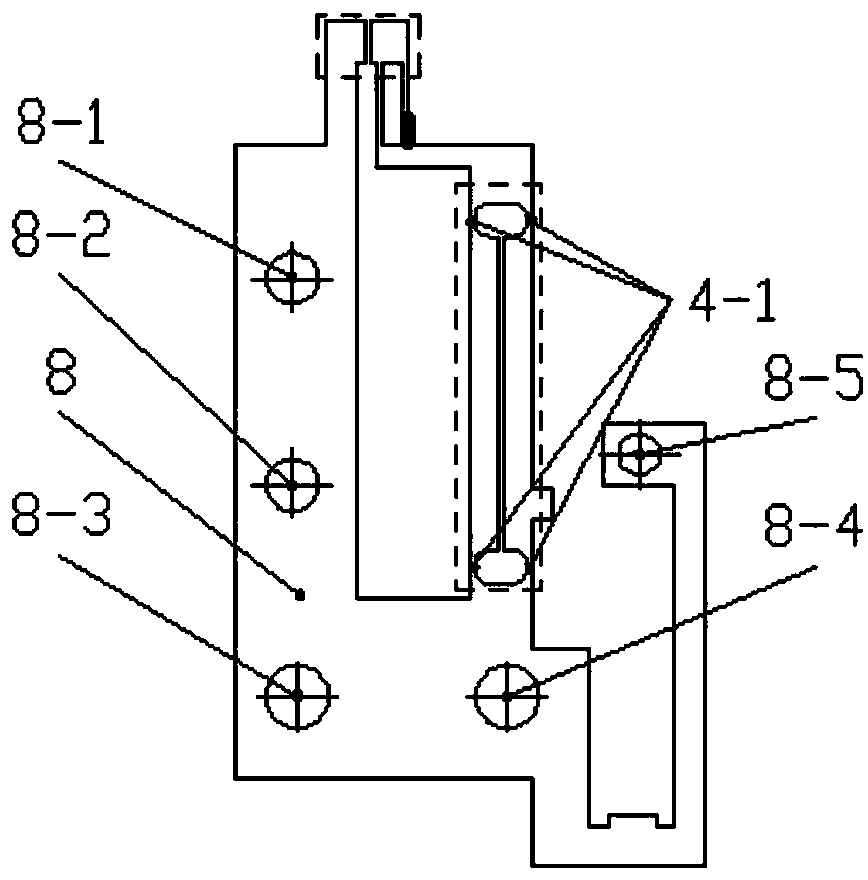

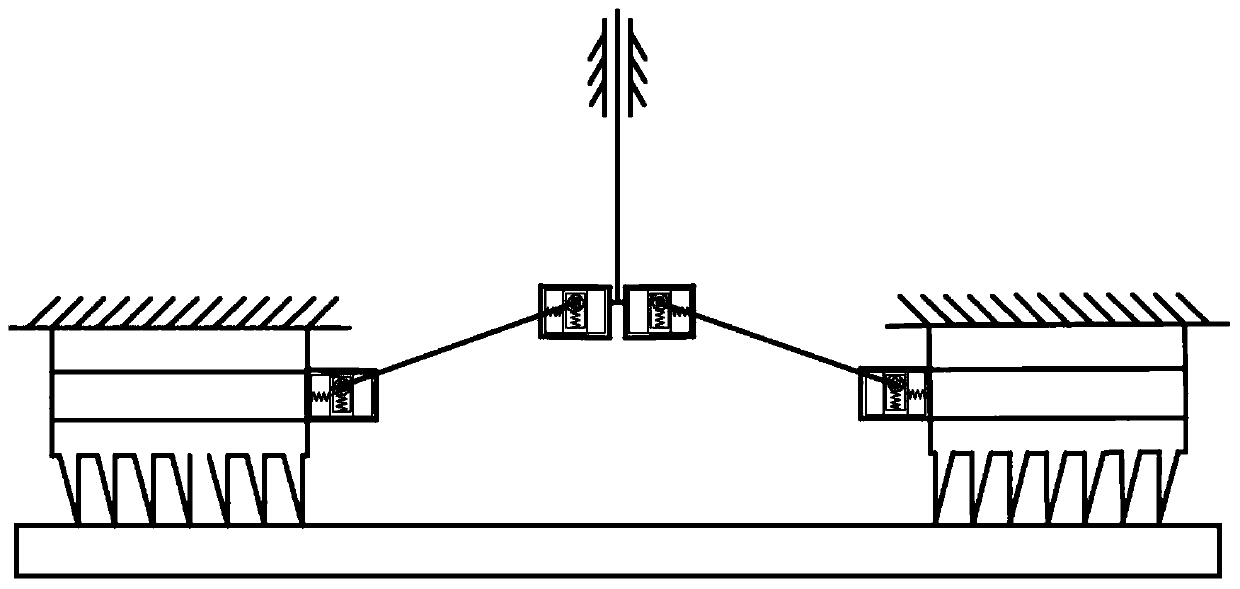

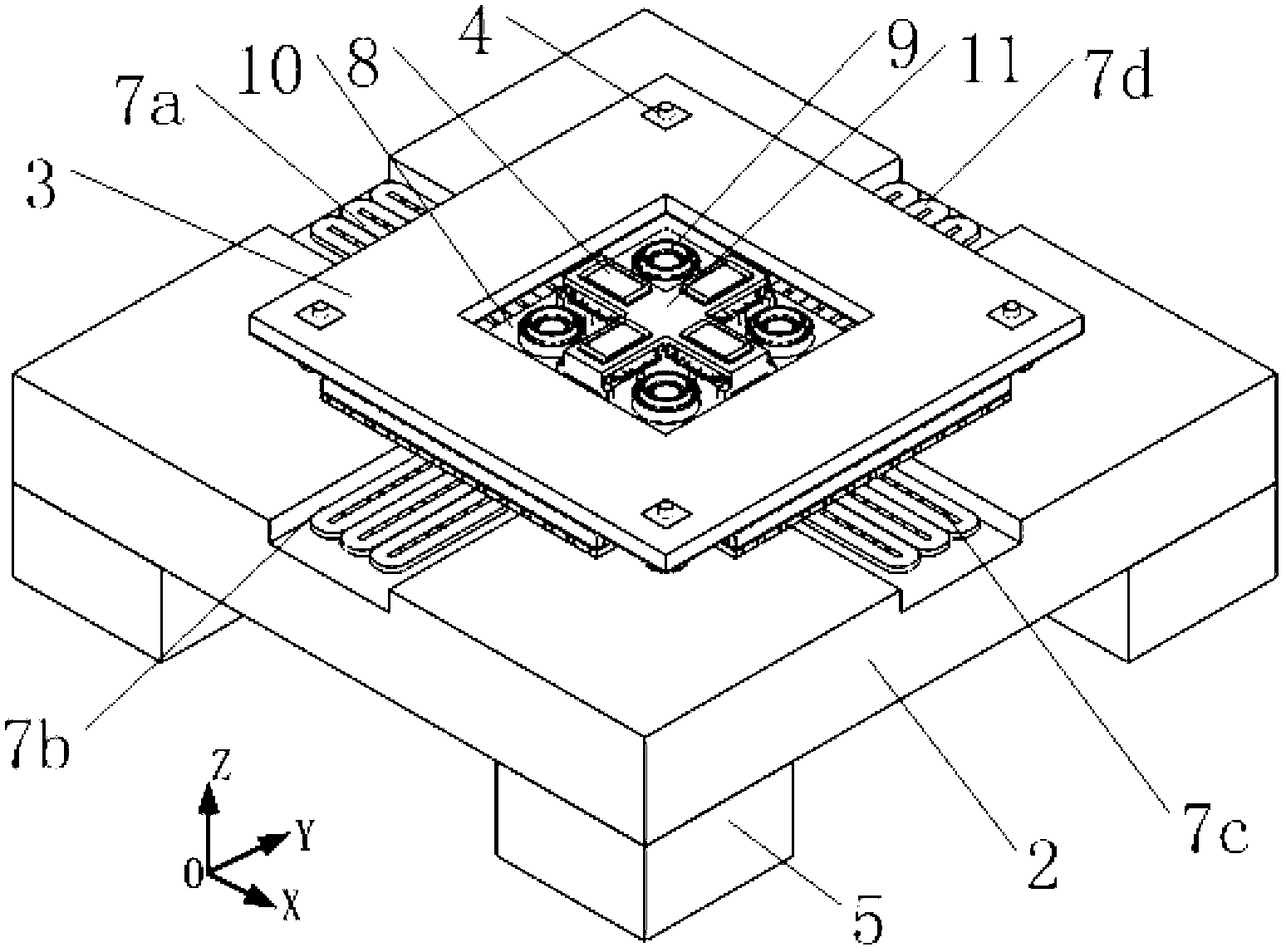

Rough-fine-movement laminated workbench with laser interferometer measurement

ActiveCN103226296AAvoid production difficultiesIncrease the itineraryUsing optical meansPhotomechanical exposure apparatusAir bearingLithographic artist

The invention relates to a rough-fine-movement laminated workbench with laser interferometer measurement. The workbench is mainly used in a lithography system. The laminated workbench comprises a fine movement bench, a rough movement bench, a balancing block, four vibration isolators, and a measuring frame. The rough movement bench comprises a rough movement bench frame, four moving iron electromagnetic driving modules, and four air bearings. The fine movement bench is arranged at the middle of the rough movement bench frame. The system also comprises a laser interferometer measurement assembly used in position feedback between a sheet bearing stage of a six degrees of freedom (DOF) positioning device and a pedestal. The laser interferometer measurement assembly is composed of a laser source, an optical path assembly, and a laser interferometer. With the laser interferometer measurement assembly, real-time six-DOF measurement can be carried out upon the movement part of the device. The workbench provided by the invention has a simple and compact structure. The mass of the movement parts is light. A rough movement bench driving motor adopts a lengthened rectangular coil group. On a basis that movement precision is not influenced, manufacturing difficulty of a large-scale halbach magnetic steel array is avoided, and driving motor stroke is increased, such that movement precision is improved.

Owner:TSINGHUA UNIV +1

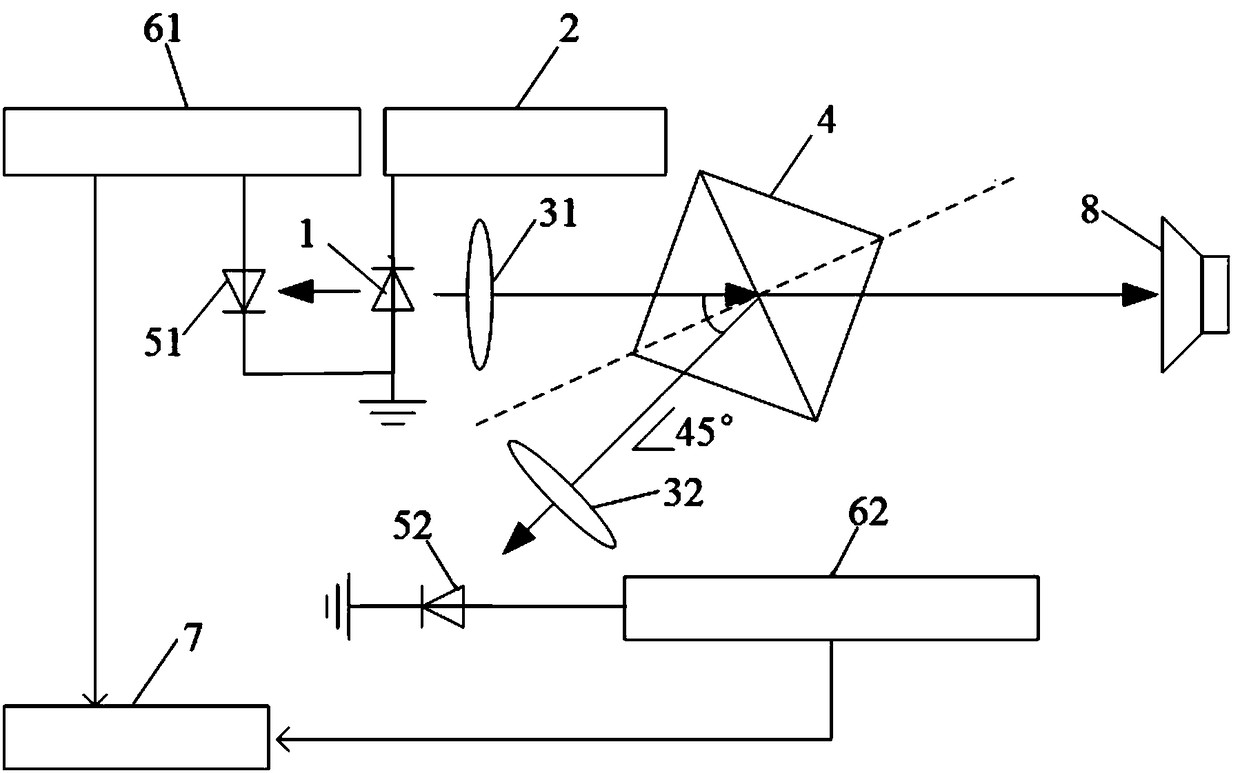

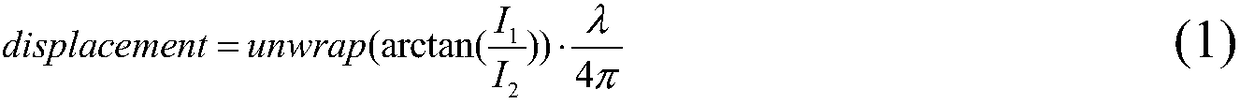

Self-mixing interference orthogonal detection vibration measuring device and method

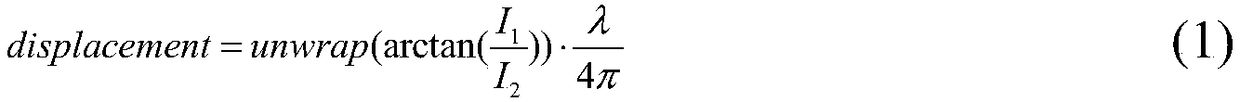

InactiveCN108225543ASimplify demodulation difficultyHigh displacement resolutionSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibration measurementComputer module

The invention discloses a self-mixing interference orthogonal detection vibration measuring device and method. A single-mode semiconductor laser diode adjustable in constant current source control outputs incidence laser, one part of the incidence laser is reflected to a second photoelectric diode, and optical signals are converted into current signals which are detected by a second photoelectricdetection module and fed back to a collecting module; the other part of the incidence laser is irradiated on the surface of a to-be-detected object and is reflected to a first photoelectric diode according to the original path, and the optical signals are converted into the current signals which are detected by a first photoelectric detection module and fed back to the collecting module. Comparedwith a traditional self-mixing measuring device, the self-mixing interference orthogonal detection vibration measuring device has the advantages that the orthogonal self-mixing signals can be acquired, inverse tangent demodulation of the vibration signals is completed, signal demodulation difficulty of the system is reduced, high displacement resolution is achieved, demodulation precision of the vibration signals of the system is improved, and real-time and online measuring can be realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

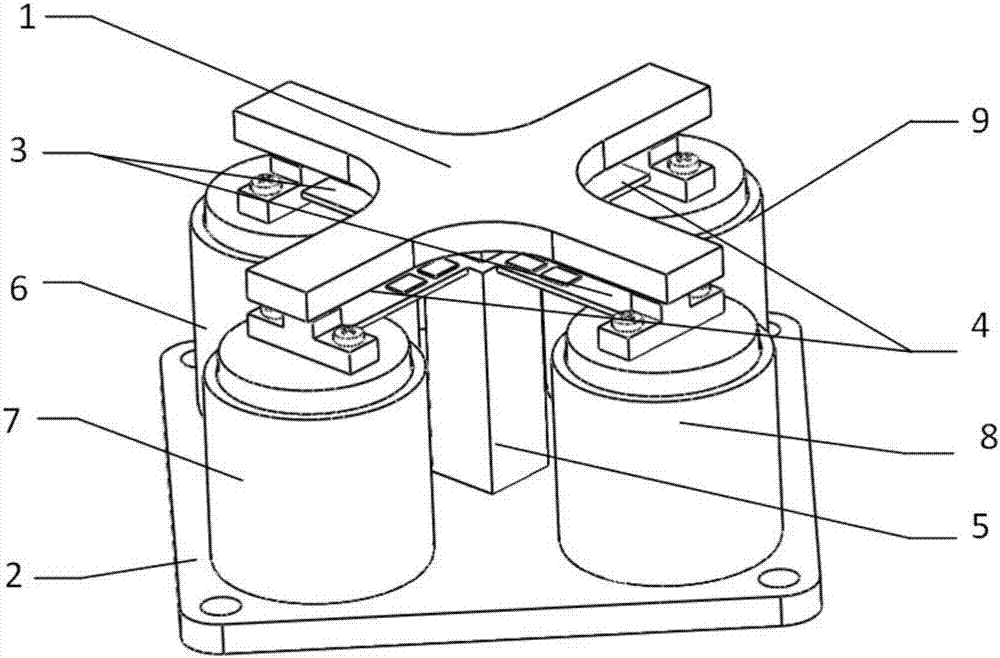

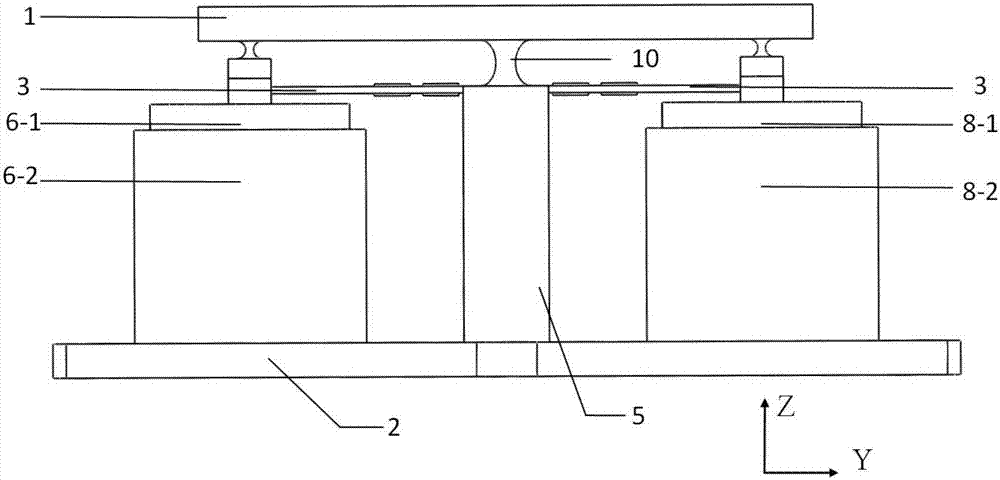

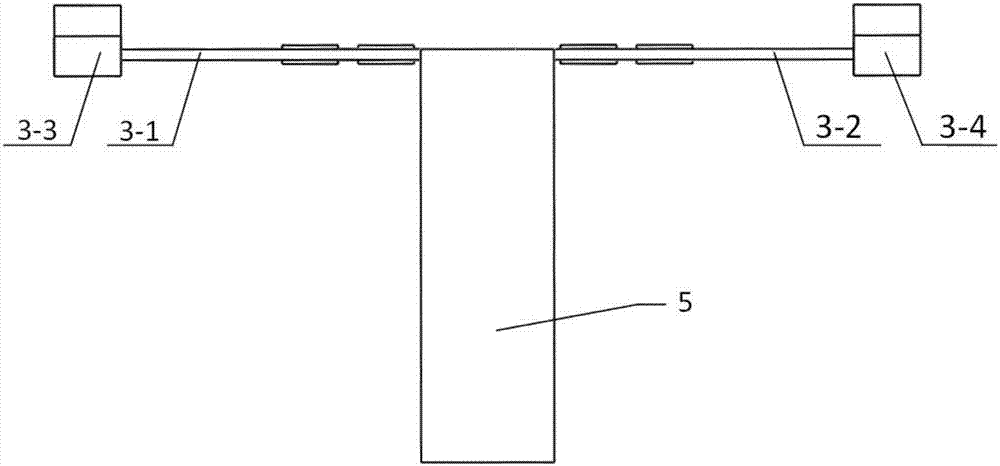

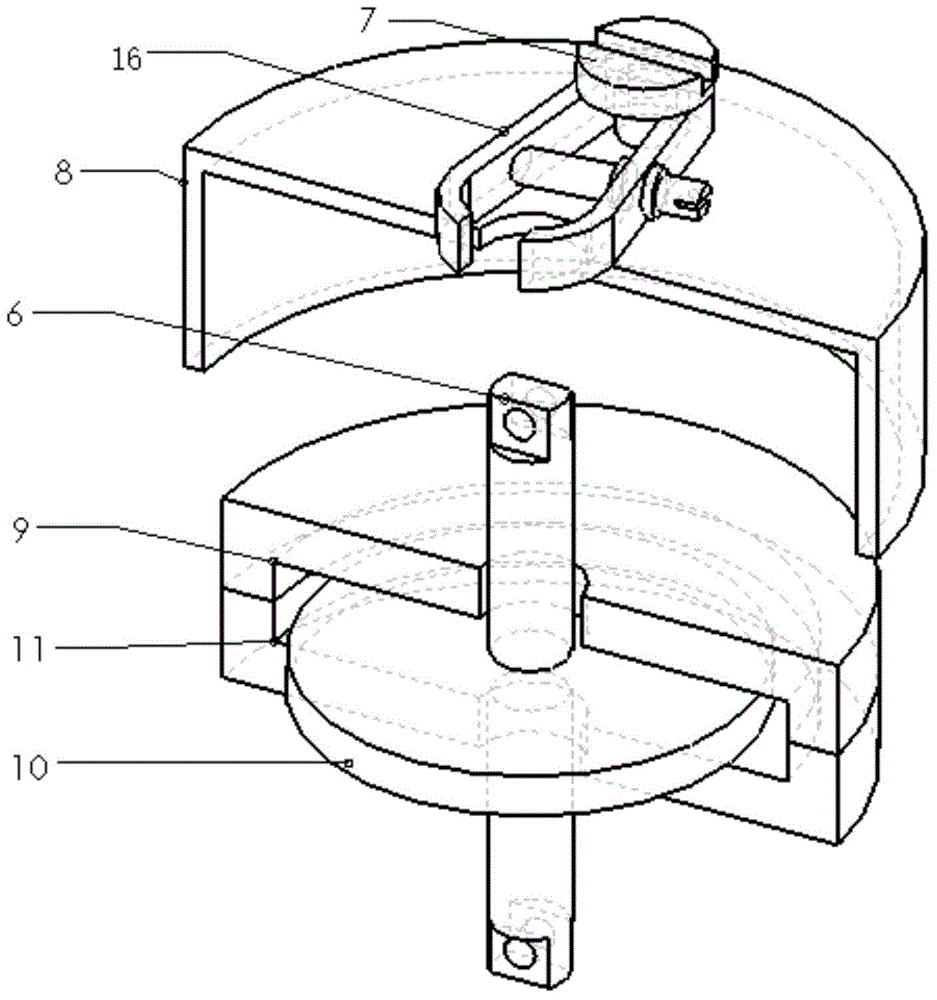

Piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform

The invention discloses a piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform. The piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform comprises a base, a stand column, a decoupling hook hinge, an X-axis bridge type amplification mechanism, an X-axis piezoelectric ceramic driver, an X-axis pre-tightening bolt, an X-axis hook hinge, a Y-axis bridge type amplification mechanism, a Y-axis piezoelectric ceramic driver, a Y-axis pre-tightening bolt, a Y-axis hook hinge and a working platform. The X-axis bridge type amplification mechanism and the Y-axis bridge type amplification mechanism are mounted on the outer sides of the two sides of the base. The vertex distances of the X-axis bridge type amplification mechanism and the Y-axis bridge type amplification mechanism and the base are equal, the X-axis piezoelectric ceramic driver is mounted in the X-axis bridge type amplification mechanism through the X-axis pre-tightening bolt, and the Y-axis piezoelectric ceramic driver is mounted in the Y-axis bridge type amplification mechanism through the Y-axis pre-tightening bolt. Each of the X-axis bridge type amplification mechanism and the Y-axis bridge type amplification mechanism comprises flexible hinge mechanisms symmetrically arranged on the two sides of the X-axis piezoelectric ceramic driver or the Y-axis piezoelectric ceramic driver and a beam for connecting the bridge type flexible hinge mechanisms. The X-axis bridge type amplification mechanism is connected with the working platform through the X-axis hook hinge, and the Y-axis bridge type amplification mechanism is connected with the working platform through the Y-axis hook hinge. By the adoption of the piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform, the two-degrees-of-freedom decoupling precision slight swing can be achieved.

Owner:TIANJIN UNIV

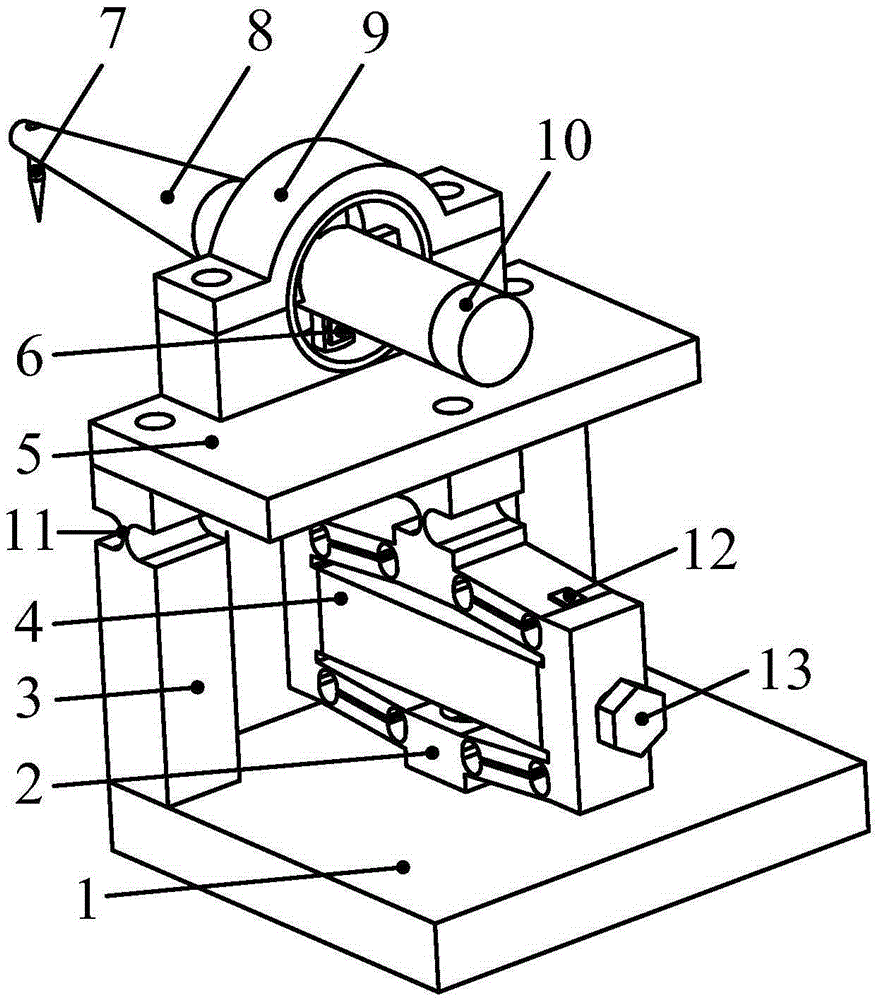

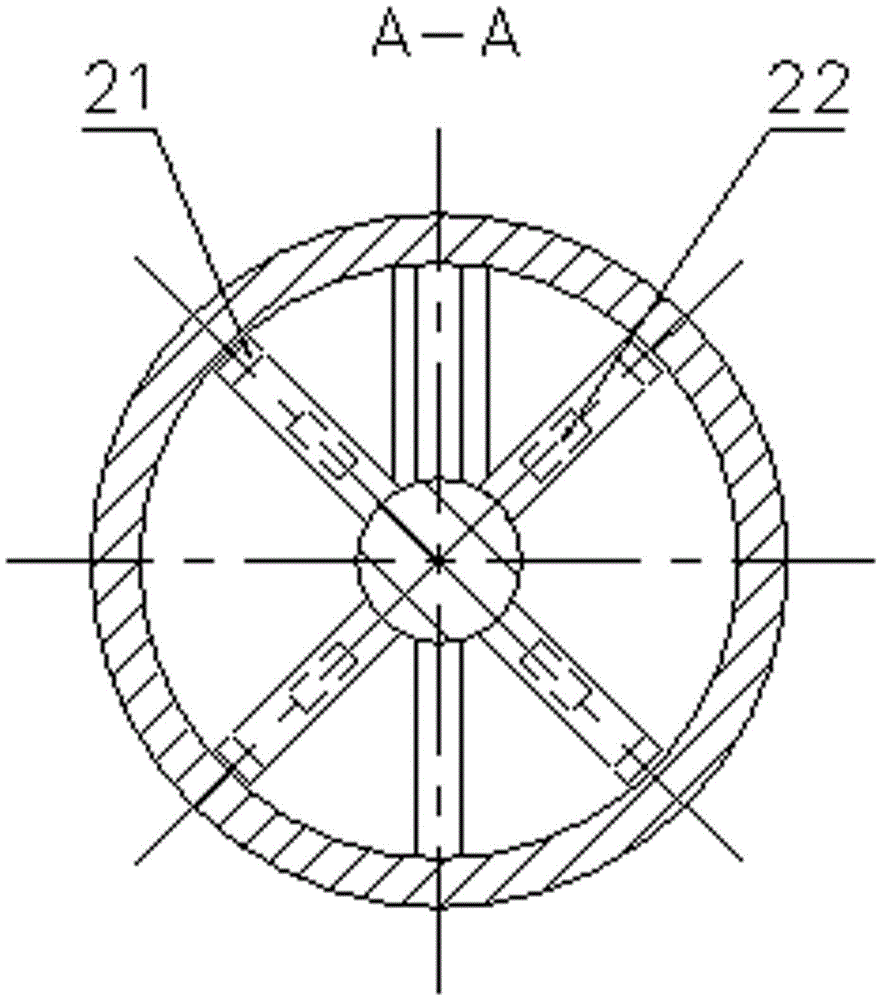

Deep-hole machining online deviation rectifying device based on laser detection principle

ActiveCN105345094AImprove straightnessHigh positioning accuracyAutomatic control devicesDrilling/boring measurement devicesLight beamEngineering

The invention belongs to the technical field of deep-hole machining and particularly relates to a deep-hole machining online deviation rectifying device based on the laser detection principle. The problem that real-time straightness detection and deviation rectification are difficult in an existing deep-hole machining process is solved. The deep-hole machining online deviation rectifying device comprises a deep-hole cutter and a cutter rod. A laser orientation block, a cube-corner prism support, the deep-hole cutter and a metal block internally provided with a heating device are mounted on the cutter rod. Light beams emitted by a laser emitting device enter in parallel with the axis of the cutter rod after being oriented through the laser orientation block, and after passing through a cube-corner prism, the light beams form return light beams arriving at a photosensitive sensor. The deep-hole machining online deviation rectifying device has the beneficial effects that deviation of the deep-hole cutter can be examined in time and rectified according to the thermal expansion and cold shrinkage principle, and the straightness and positional accuracy of a machined deep hole are improved.

Owner:ZHONGBEI UNIV

Micrometer-nanometer transmission platform

The invention discloses a micrometer-nanometer transmission platform. The transmission platform comprises a base, a lower platform component and an upper platform component, wherein by the piezoelectric effect, the lower platform component can perform straight-line movements along the X and Y directions of a coordinate system, the upper platform component can perform straight-line movements along the Z direction of the coordinate system and rotation around the X and Y directions of the coordinate system, and the travels are increased by a displacement magnifying mechanism; an orientating mechanism relatively arranged on the lower platform component can effectively eliminate the displacement coupling between shafts; and simultaneously, the transmission platform is manufactured in one piece, all components are hinged by flexible hinges, the no-gap and no-friction platform transmission is completely realized, the transmission accuracy of the platform is effectively improved; in addition, the piezoelectric ceramic pipe is high in displacement resolution and rapid in response speed; and thus, the micrometer-nanometer transmission platform has the advantages of high accuracy, large travel, big rotation, more degree of freedom, high resolution, high frequency response and the like.

Owner:CHONGQING UNIV

Bi-piezoelectric stack driving type precision rotary driving device

PendingCN107947629AHigh frequency responseReduce volumePiezoelectric/electrostriction/magnetostriction machinesInterference fitRotary stage

The invention relates to a bi-piezoelectric stack driving type precision rotary driving device, and belongs to the technical field of precision engineering. The bi-piezoelectric stack driving type precision rotary driving device comprises a support base, a rotary table, a stator assembly, a bearing and the like; the support base and the rotary table are connected through the bearing in a matched manner; the support base and the stator assembly are connected through a bolt; the rotary table and the stator assembly are contacted and matched through the front end of a driving foot; and the bearing, the support base and the rotary table are in interference fit. When an exciting electric signal acts on a stack type piezoelectric component, the stack type piezoelectric component performs axial elongation based on the inverse piezoelectric effect; therefore, the driving foot performs tangential displacement, so that the rotary table is driven to perform rotational motion; and the direction and the time sequence of driving voltage are changed, so that the rotary table can be controlled to perform forward rotation, inverse rotation and positioning stillness. The bi-piezoelectric stack driving type precision rotary driving device disclosed by the invention has the technical advantages of being simple in structure, high in positioning precision, large in stroke, rapid in response speed and the like, and has wide application prospect in the technical field of precision engineering.

Owner:JILIN UNIV

Two-dimensional rapid deflection table combining sensing unit with constraint element and method

ActiveCN107393599AIncrease constraint stiffnessImprove stabilityUsing electrical meansInstrumental componentsElectrical resistance and conductanceMeasurement device

The invention discloses a two-dimensional rapid deflection table combining a sensing unit with a constraint element and a method. The deflection table comprises an X axis angle displacement sensing measurement device and a Y axis angle displacement sensing measurement device which are located between a micro-angle swinging platform and a base and further comprises four linear voice coil motors, and a double-axis flexible hinge is arranged on the lower surface of the micro-angle swinging platform. The X axis angle displacement sensing measurement device and the Y axis angle displacement sensing measurement device each comprise a rigid support, a pair of flexible metal beams which extend out relative to the two sides of the rigid support and mass blocks which are fixedly connected with the tail ends of the flexible metal beams correspondingly. The positions, nearby the root, of the upper surface and the lower surface of each flexible metal beam are provided with electric resistance strain gauges in an attachment mode. The first voice coil motor and the third voice coil motor are oppositely arranged with the same specification and form a first actuator set. The second voice coil motor and the fourth voice coil motor are oppositely arranged with the same specification and are perpendicular to the first actuator set in a crossing mode. The voice coil motors are adopted for driving to achieve large angular travel, the constraint rigidity of the deflection table is improved through the flexible metal beams, and the mechanism stability is improved; and meanwhile, the deflection table serves as the sensing unit to perform real-time measurement of double-axis deflection angles in a strain feedback mode.

Owner:XI AN JIAOTONG UNIV

A displacement sensor based on a gear rotary-type fiber Bragg raster and an application method thereof

The invention relates to a displacement sensor based on a gear rotary-type fiber Bragg raster and an application method thereof, and belongs to the technical field of photoelectron measurement. The displacement sensor of the invention comprises a fiber Bragg raster, a cantilever beam, a first gear, a second gear, a first tooth bar, a second tooth bar, a measurement contact head, a first rolling bearing, a second rolling bearing, a stepped shaft, a displacement space limiting sleeve pipe, a first tooth bar sleeve pipe, a second tooth bar sleeve pipe, a third tooth bar sleeve pipe, a first spring, a second spring, a metal box, an externally connected fiber, a bottom seat of the first rolling bearing and a bottom seat of the second rolling bearing, wherein the fiber Bragg raster, the cantilever beam, the first gear, the second gear, the first tooth bar, the second tooth bar, the first rolling bearing, the second rolling bearing, the stepped shaft, the first tooth bar sleeve pipe, the second tooth bar sleeve pipe, the third tooth bar sleeve pipe, the first spring, the second spring, the bottom seat of the first rolling bearing and the bottom seat of the second rolling bearing are packaged inside the bottom box. According to the displacement sensor based on the gear rotary-type fiber Bragg raster and the application method thereof of the invention, on-line monitoring of displacement is realized. At the same time, the structure is simple; the usage is convenient; the measuring range is large; the sensitivity is adjustable; and the anti-interference capability is strong.

Owner:KUNMING UNIV OF SCI & TECH

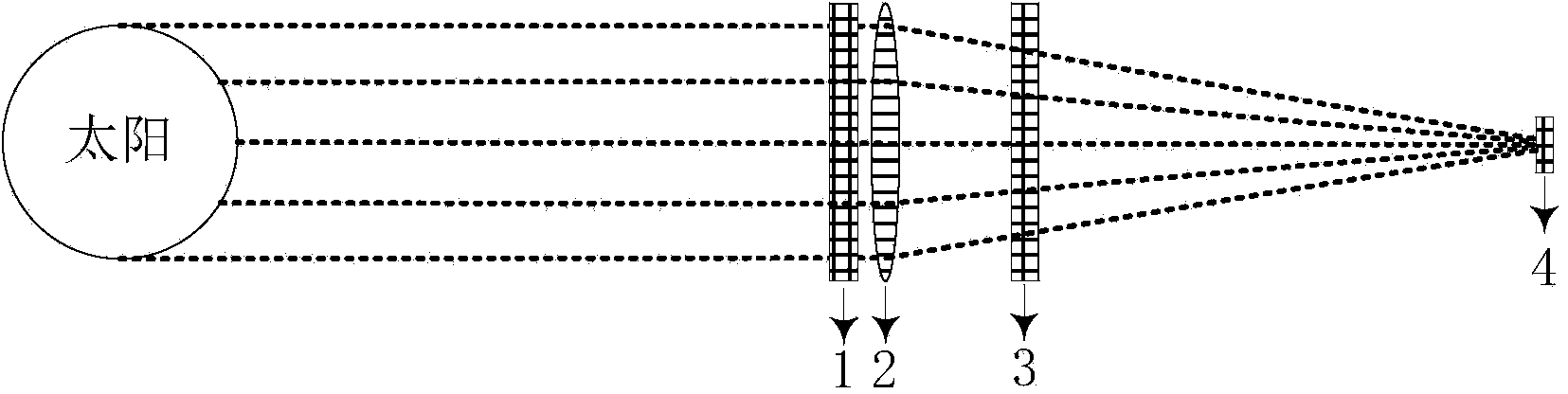

Precision sun sensor applied to image stabilizing system

The invention relates to a precision sun sensor applied to an image stabilizing system. The precision sun sensor comprises a filtering system, a focusing lens and a PSD (Phase-Sensitive Detector), wherein the filtering system at least comprises a primary optical filter and a secondary optical filter, the primary optical filter is arranged at the right front end of the precision sun sensor for reflecting sunlight heat and attenuating energy of incident rays in an observation wave band; the focusing lens is arranged behind the primary optical filter and is used for gathering sunlight after primary filtering onto the focal position of the focusing lens; the secondary optical filter is arranged in right front of the focal plane of the focusing lens and is used for secondarily filtering gathered light rays; the PSD is arranged at the focal position of the focusing lens and is used for converting a solar facula energy signal into an electric signal and recognizing angular offset of the incident rays by an acquired four-quadrant electrical signal.

Owner:NAT SPACE SCI CENT CAS

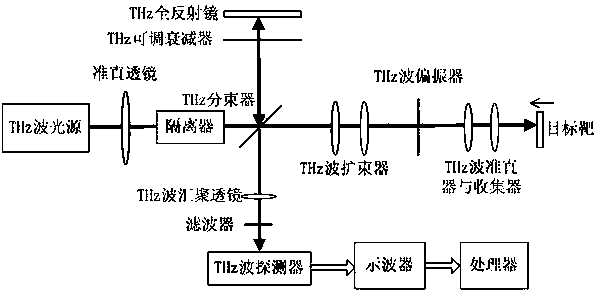

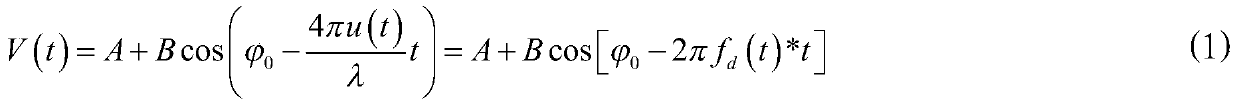

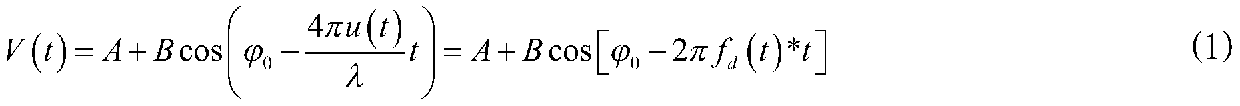

TeraHertz wave Doppler interferometry instrument and method

ActiveCN105509817AEffective penetrationMeet high bandwidth requirementsAcceleration measurement using interia forcesDevices using optical meansBeam splitterMicrowave

The invention relates to the field of testing, in particular to a TeraHertz wave Doppler interferometry instrument and method to solve the problems of the prior art. The instrument comprises a reference light adjusting device, a target detecting device and a data processing device. Interference signals processed by a THz wave beam splitter are filtered through a THz filter, and the filtered interference signals are detected through a THz wave detector; then signals output by the THz wave detector are recorded through an oscilloscope, and finally data acquired by the oscilloscope are analyzed and processed through a processor, so that the movement distance and speed of a target relative to an interferometer are obtained. The wavelength of the TeraHertz wave is larger than dust grains, and therefore dust penetrability is high. The wavelength of the TeraHertz wave is smaller than that of microwaves, so that displacement resolution is high. Furthermore, interference fringe frequency is low, and the bandwidth of a required probe and oscilloscope can be effectively reduced.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Capacitance sensing probe and precise spring shift-measurement instrument

ActiveCN104535625AImprove stabilityHigh displacement resolutionUsing electrical meansMaterial capacitanceCapacitanceParallel plate

The invention discloses a capacitance sensing probe and a precise spring shift-measurement instrument. The capacitance sensing probe is composed of a variable parallel-plate capacitor, a capacitor moving plate locking mechanism, an electromagnetic shielding cover and a moving plate connecting part, wherein the capacitive sensing probe skillfully utilizes the variable parallel-plate capacitor and can realize detection to the micro displacement of a capacitor moving plate by combining a capacitance sensor circuit. The shift-measurement instrument enables a precise spring and the capacitance sensing probe to be combined, the micro change of the length of the precise spring is acquired through the measurement of the changes of the capacitance of the variable parallel-plate capacitor, and further the temperature drift or time drift coefficient of the precise spring to be detected can be calculated. The shift-measurement instrument skillfully utilizes the capacitance sensing probe, the temperature drift and time drift coefficients of the precise spring (similar device samples) to be detected can be rapidly and accurately measured successfully, and the shift-measurement instrument has very high measurement result precision higher than the measurement precision of all existing instruments for measuring the temperature drift and the time drift of the precise spring.

Owner:INST OF GEODESY & GEOPHYSICS CHINESE ACADEMY OF SCI

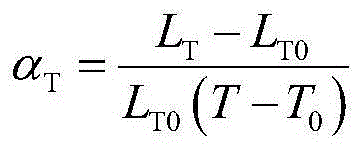

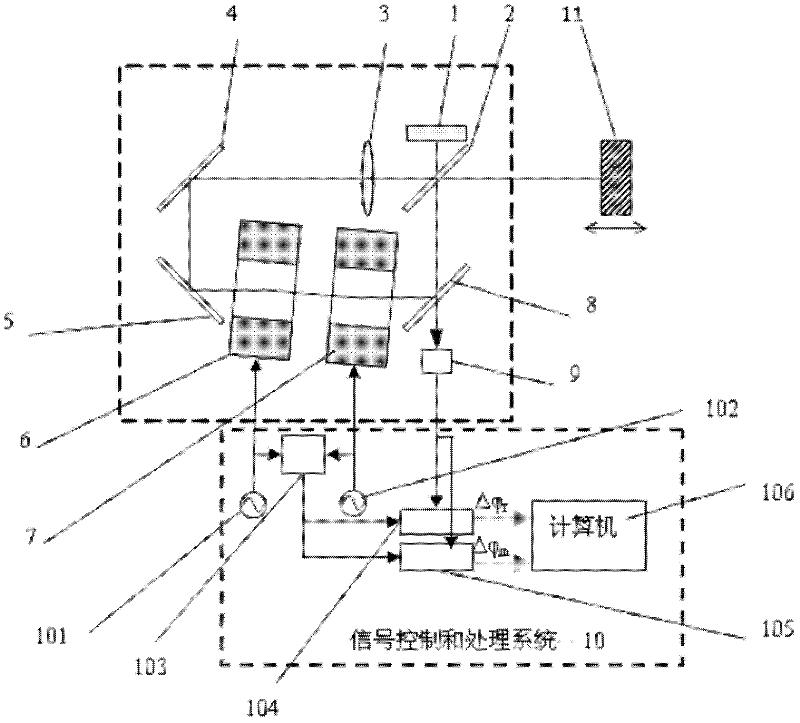

Complete common-path type microchip laser feedback interferometer

ActiveCN102410809AEliminate crosstalkEliminate stabilityUsing optical meansResonant cavityPhotovoltaic detectors

The invention relates to a complete common-path type microchip laser feedback interferometer which comprises a microchip laser, wherein a first spectroscope is arranged on an axis at an emitting end of the microchip laser; a first holophote is arranged on a reflected light path of the first spectroscope; a second holophote is arranged on the reflected light path of the first holophote; a first acousto-optic frequency shifter, a second acousto-optic frequency shifter and a second spectroscope are arranged on the reflected light path of the second holophote in turn; the second spectroscope is arranged on a transmission light path of the first spectroscope; a photoelectric detector is arranged on the transmission light path of the second spectroscope; a circular light path is formed by the first spectroscope, the first holophote, the second holophote, the first acousto-optic frequency shifter, the second acousto-optic frequency shifter and the second spectroscope; the laser emitted by the microchip laser once returns to a resonant cavity of the microchip laser through the circular light path, thereby modulating an output power of the laser and forming the reference feedback light; and the laser once passing by a circular path is reflected by a to-be-detected object and returns to the resonant cavity of the microchip laser through the circular light path again, thereby modulating the output power of the laser and forming the measuring feedback light. The complete common-path type microchip laser feedback interferometer can be widely applied to the unmatched target non-contact type accurate displacement measurement.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com