Deep hole processing online detection and correction device

A deviation correction device and deep hole technology, applied in feeding devices, metal processing, automatic control devices, etc., to achieve the effects of large output force, fast response, and high displacement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be further described in conjunction with the accompanying drawings. This embodiment is used to illustrate the present invention, but not to limit the present invention in any way.

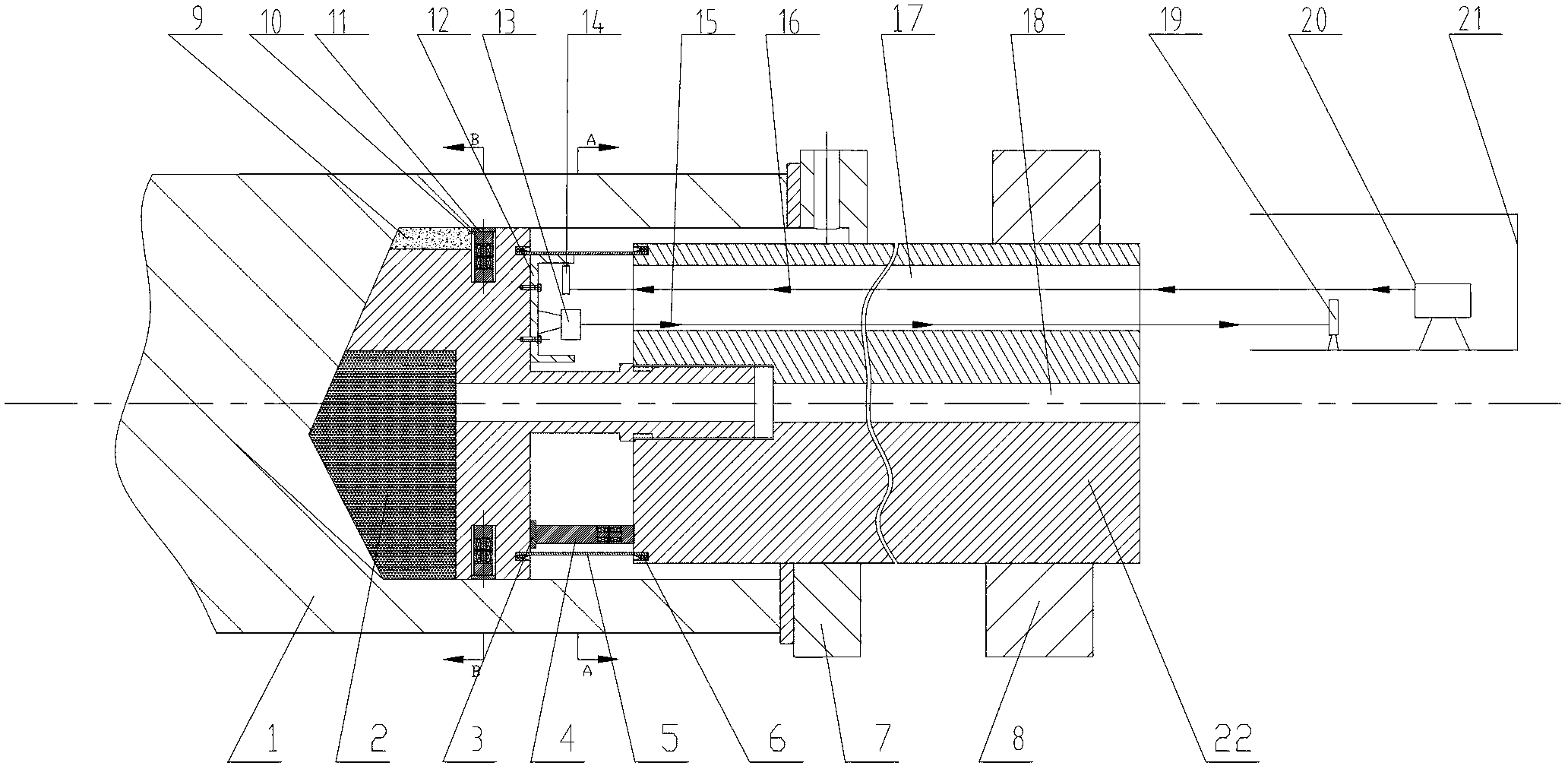

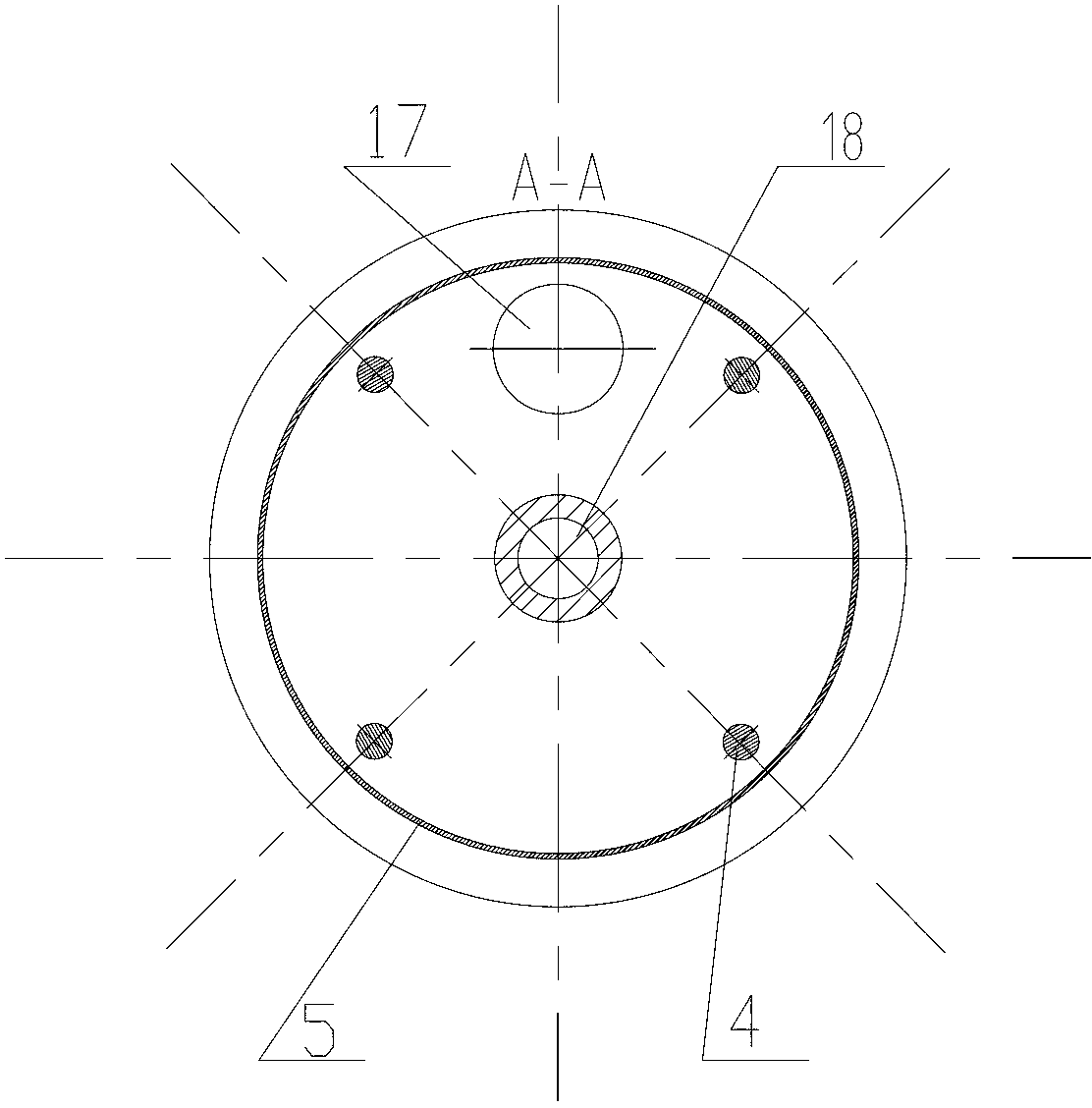

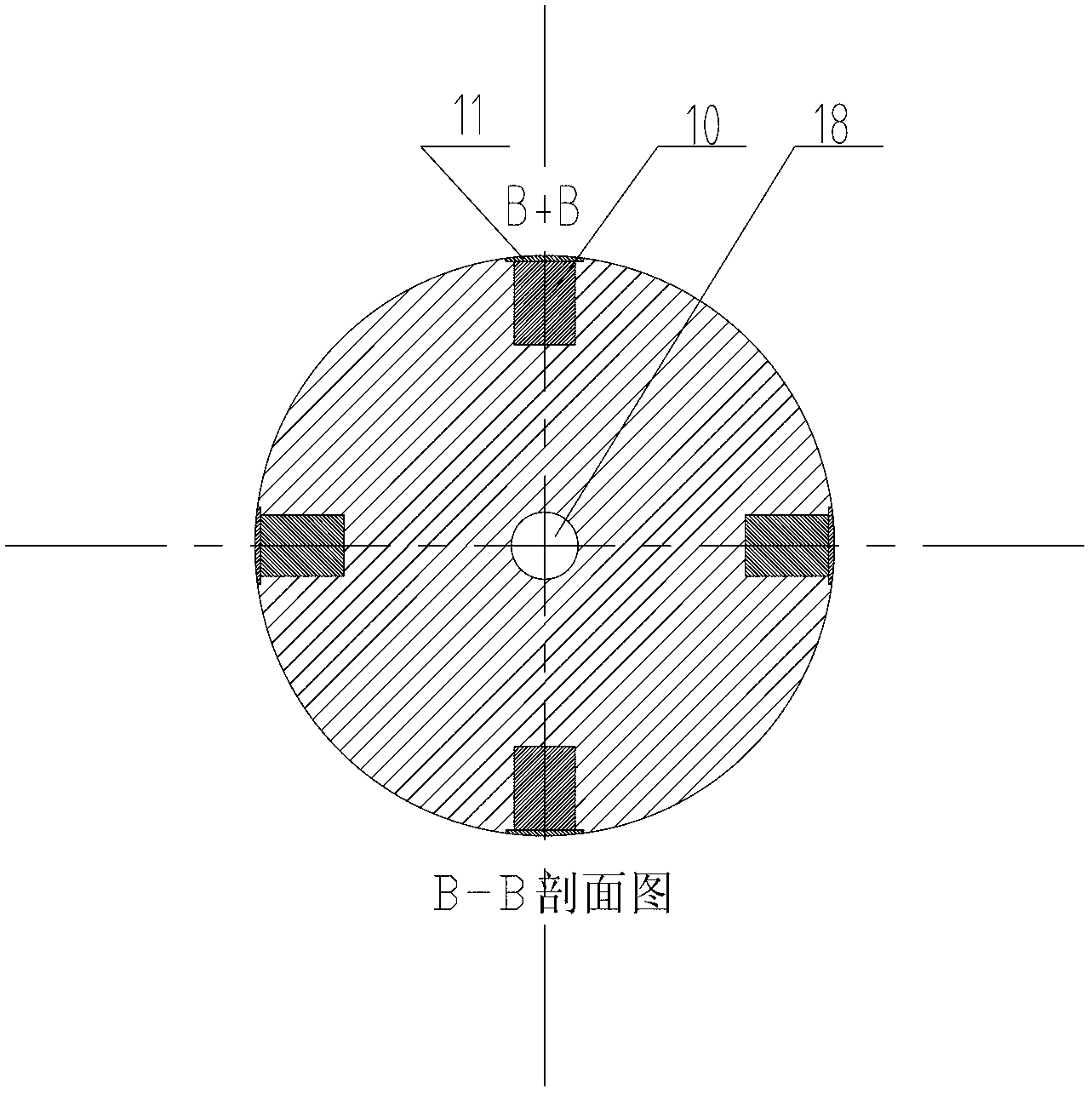

[0025] Such as figure 1 As shown, the present invention includes a drill bit 2, a drill pipe 22, a fixed seat 3, an axial expander 4, an oil deflector ring 5, a sealing ring 6, an oil feeder 7, a feed box 8, a radial expander 10, a wear-resistant Elastic sealing block 11, inner fixing frame 12, inner laser source 13, outer laser source 20, position sensitive detector 14, angle sensitive detector 19, etc.

[0026] The drill bit 2 is fixed on the drill rod 22 by its threaded section, and the drill rod 22 is fixed on the feed box 8 for only feeding motion. The oil feeder 7 provides high-pressure oil for deep hole machining. The oil flows in from the hole of the oil feeder 7, passes through the gap between the drill pipe 22 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com