A displacement sensor based on a gear rotary-type fiber Bragg raster and an application method thereof

A technology of grating displacement and sensor, which is applied in the direction of instruments, optical devices, measuring devices, etc., and can solve the problems that online displacement monitoring is susceptible to electromagnetic interference and has low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

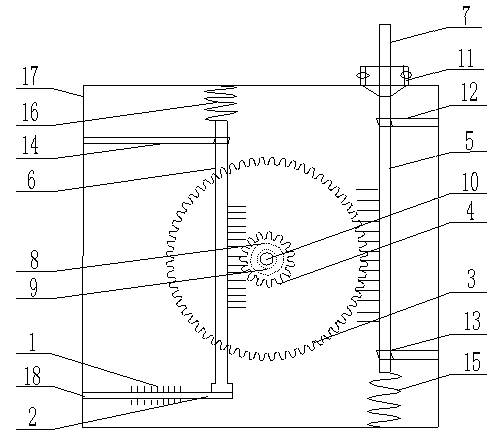

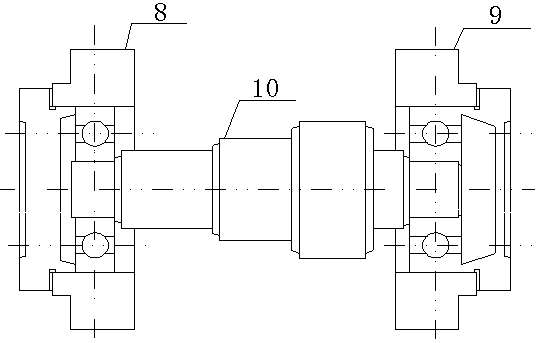

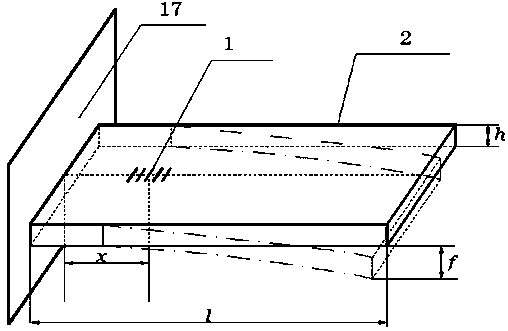

Embodiment 1

[0049] Embodiment 1: as Figure 1-3 As shown, a gear-based rotary optical fiber Bragg grating displacement sensor includes optical fiber Bragg grating 1, cantilever beam 2, gear I3, gear II4, rack I5, rack II6, measuring contact head 7, rolling bearing I8, rolling bearing II9, Step shaft 10, displacement limit sleeve 11, rack sleeve I12, rack sleeve II13, rack sleeve III14, spring I15, spring II16, metal box 17, external optical fiber 18, rolling bearing I base and rolling bearing II base ; Among them, fiber Bragg grating 1, cantilever beam 2, gear Ⅰ 3, gear Ⅱ 4, rack Ⅰ 5, rack Ⅱ 6, rolling bearing Ⅰ 8, rolling bearing Ⅱ 9, stepped shaft 10, rack bushing Ⅰ 12, rack bushing Ⅱ 13, rack sleeve Tube III 14, spring I 15, spring II 16, rolling bearing I base and rolling bearing II base are packaged inside the metal box 17, and the fiber Bragg grating 1 is pasted on the central axis of the upper and lower surfaces of the cantilever beam 2 and leads out of the rectangular metal box 17...

Embodiment 2

[0053] Embodiment 2: as Figure 1-3 As shown, a gear-based rotary optical fiber Bragg grating displacement sensor includes optical fiber Bragg grating 1, cantilever beam 2, gear I3, gear II4, rack I5, rack II6, measuring contact head 7, rolling bearing I8, rolling bearing II9, Step shaft 10, displacement limit sleeve 11, rack sleeve I12, rack sleeve II13, rack sleeve III14, spring I15, spring II16, metal box 17, external optical fiber 18, rolling bearing I base and rolling bearing II base ; Among them, fiber Bragg grating 1, cantilever beam 2, gear Ⅰ 3, gear Ⅱ 4, rack Ⅰ 5, rack Ⅱ 6, rolling bearing Ⅰ 8, rolling bearing Ⅱ 9, stepped shaft 10, rack bushing Ⅰ 12, rack bushing Ⅱ 13, rack sleeve Tube III 14, spring I 15, spring II 16, rolling bearing I base and rolling bearing II base are packaged inside the metal box 17, and the fiber Bragg grating 1 is pasted on the central axis of the upper and lower surfaces of the cantilever beam 2 and leads out of the rectangular metal box 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com