Modularization moving-iron type six-freedom-degree maglev motion platform

A motion platform, moving iron technology, applied in the field of ultra-precision machining and testing equipment, can solve the problems that the motion platform cannot be integrated and cannot be assembled and used, and achieves installation and maintenance to achieve large-scale production, simple structure, and mature motion control technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

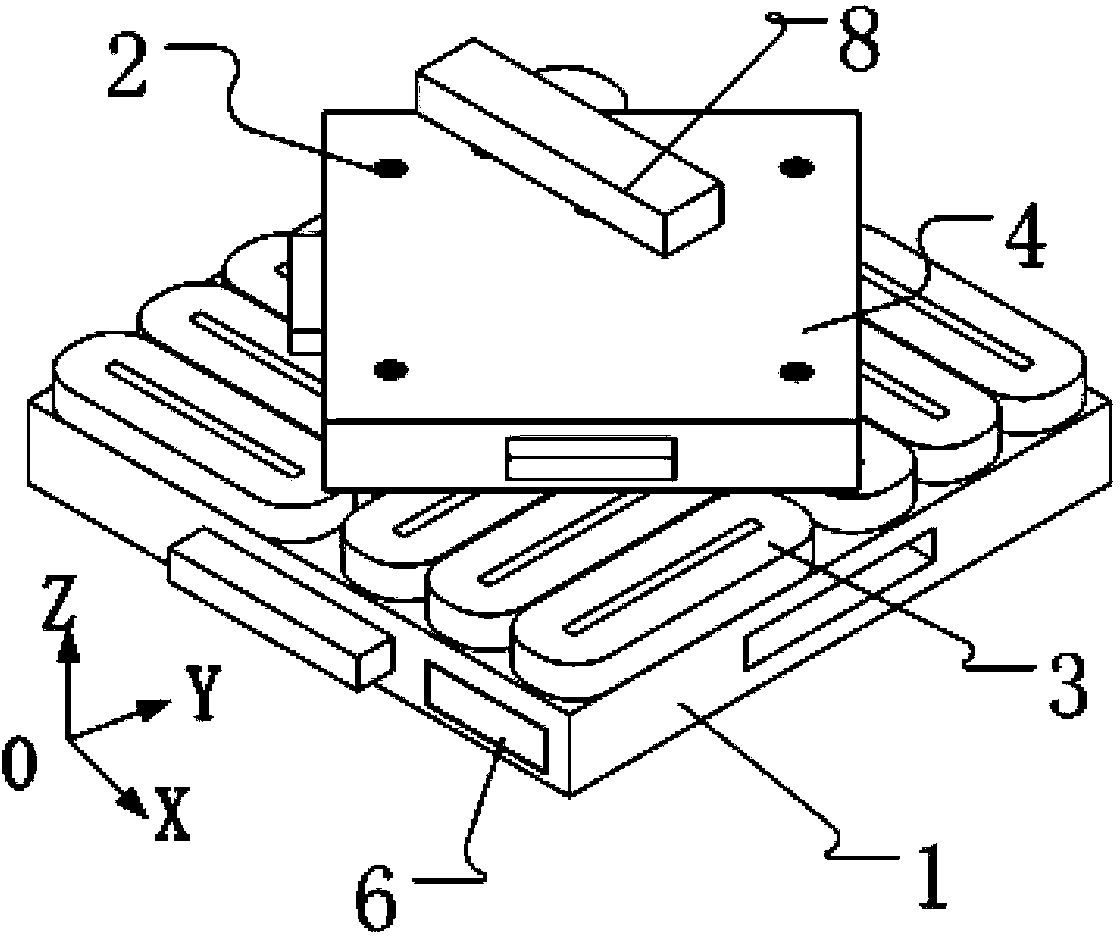

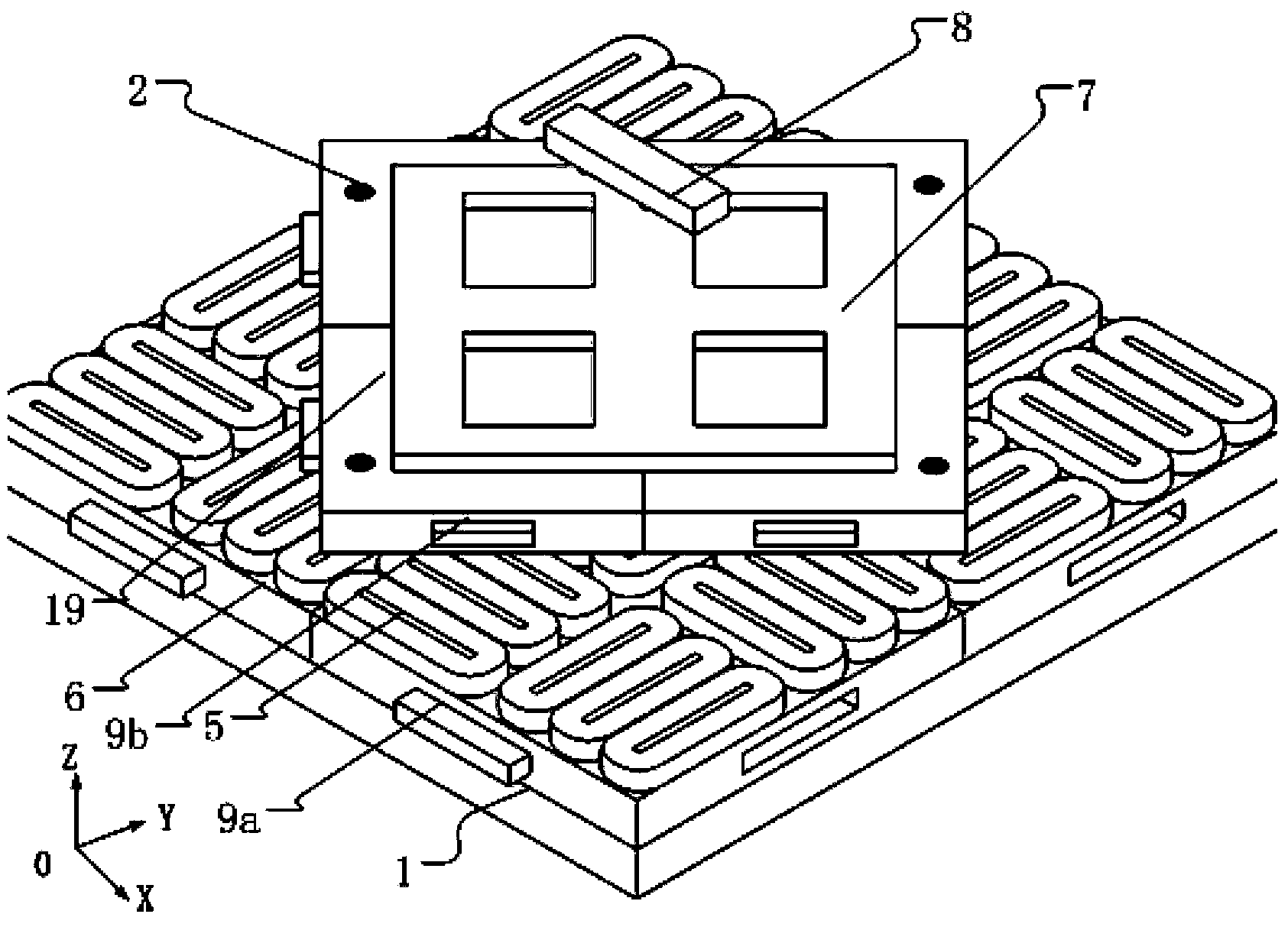

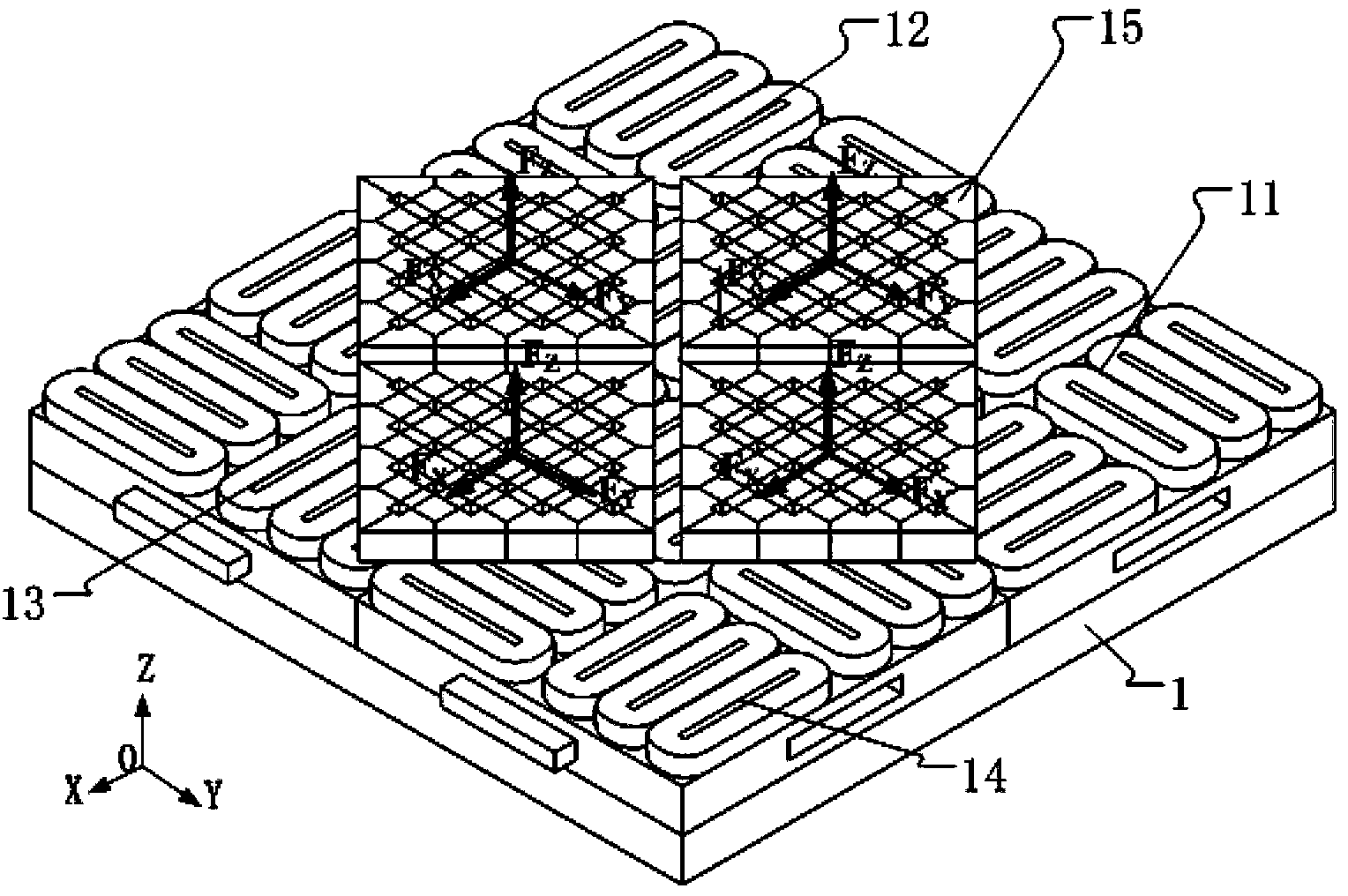

[0016] figure 1 A three-dimensional structure diagram of an embodiment of a modular moving iron six-degree-of-freedom maglev motion platform provided for the invention, the maglev motion platform includes a base 1, at least one maglev plane motor module and a somatosensory controller 8; each maglev The planar motor module is composed of a maglev planar motor mover 4 and a maglev planar motor stator 3, the maglev planar motor stator includes a coil module 5 and an integrated driver module 6, and the coil module 5 and the integrated driver module 6 are fixed On the base 1; the magnetic levitation planar motor mover 4 includes a group of permanent magnet arrays 15 and a permanent magnet module backplane 19, the permanent magnet array 15 and the permanent magnet module backplane 19 are fixed together, and Located above the stator 3 of the maglev planar motor; the somatosensory controller 8 is located directly above the mover 4 of the maglev planar motor, and at least three infrare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com