Charging needle water-resistant mounting structure, charging needle water resistance detection method and wrist-mounted equipment

A technology of mounting structure and charging pin, applied in the testing of machine/structural components, circuits, coupling devices, etc., can solve problems such as inability to subjectively adjust, inability to confirm waterproof condition, poor reliability, etc., to improve waterproof stability and reliability , Improve the effect of waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] First, a brief description of the orientation words involved in this specific implementation is given: in this embodiment, the front-back direction and left-right direction are defined along the normal wearing state of the head-mounted virtual reality device.

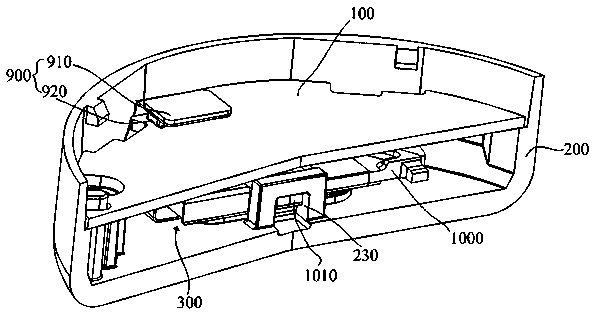

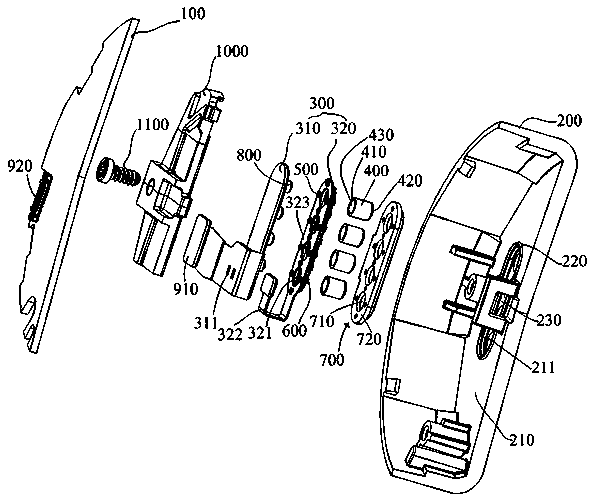

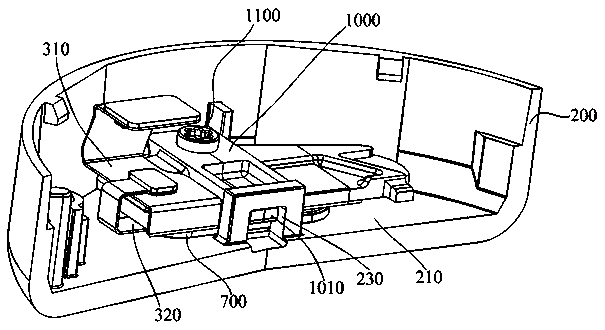

[0032] Such as Figure 1 to Figure 3 As shown, the present embodiment is a charging needle waterproof installation structure, including the installation case 200 and the main control board 100 arranged in the installation case 200, the FPC adapter board 300 and the charging needle 400, the FPC adapter board 300 is connected through the connector 900 Connect with the main control board 100 to realize signal transmission. For the connector 900, a male connector 910 can be set on the FPC adapter board 300, and a female connector 920 can be set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com