Patents

Literature

128results about How to "Smooth conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Voice conversion apparatus and speech synthesis apparatus

Owner:TOSHIBA DIGITAL SOLUTIONS CORP

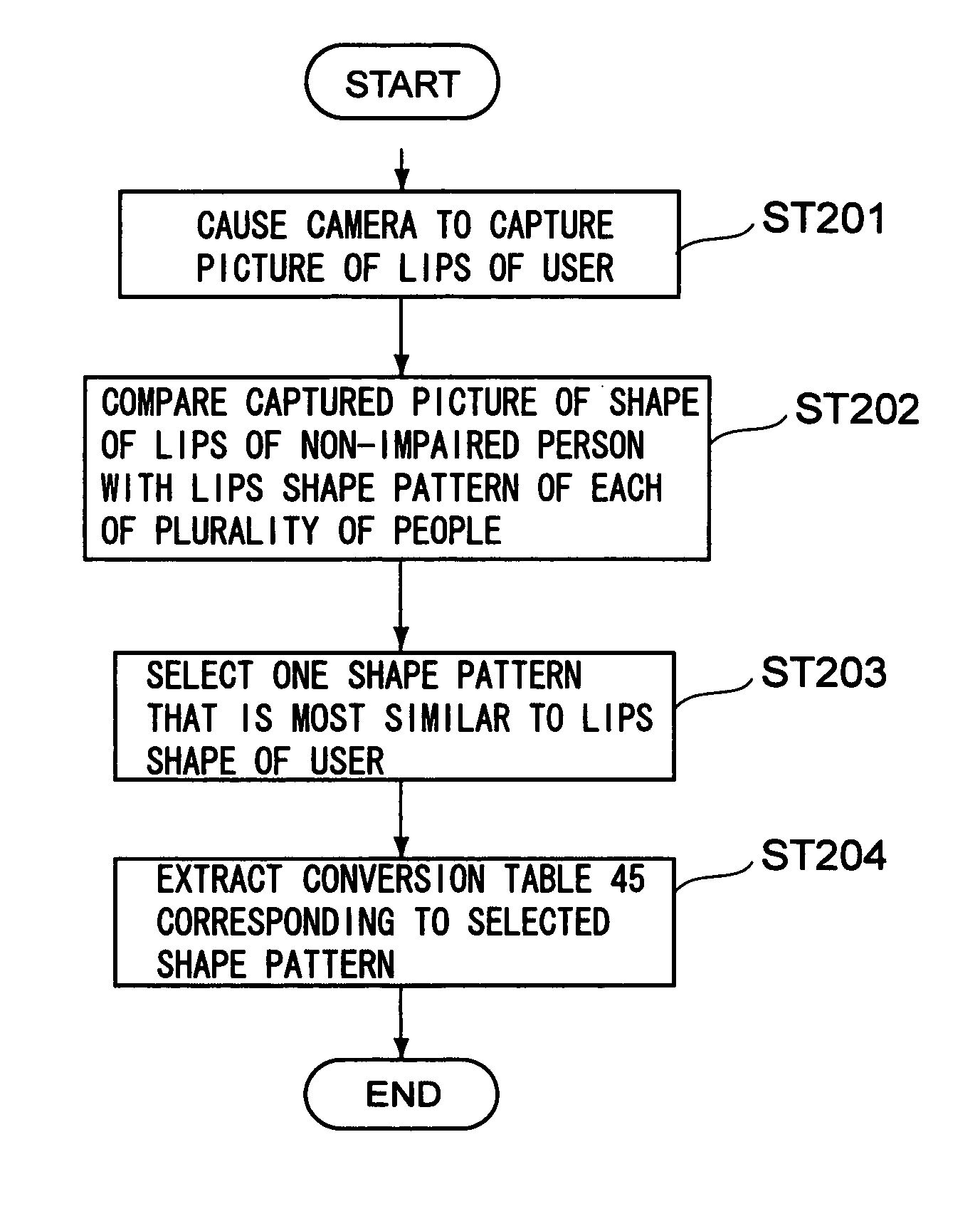

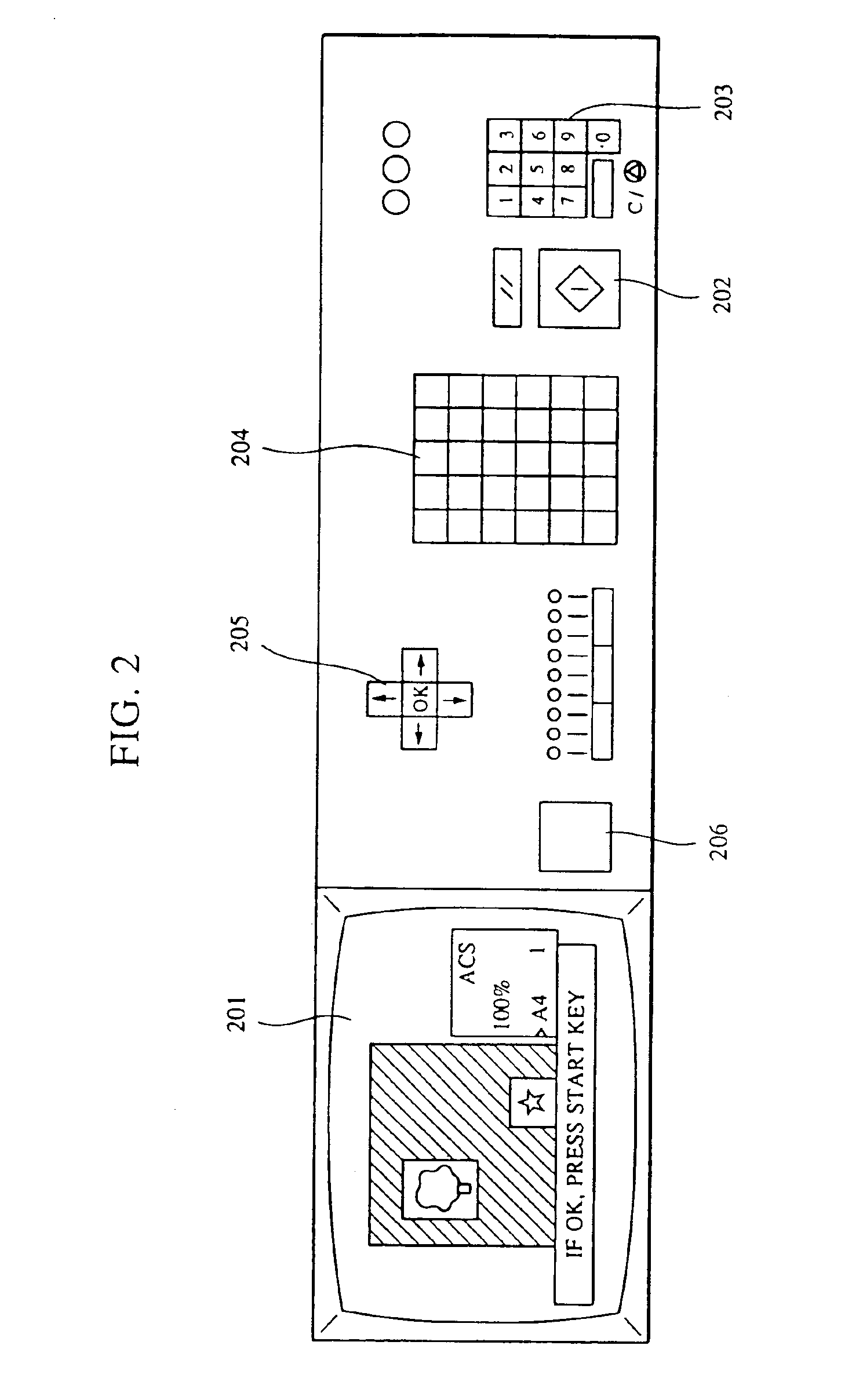

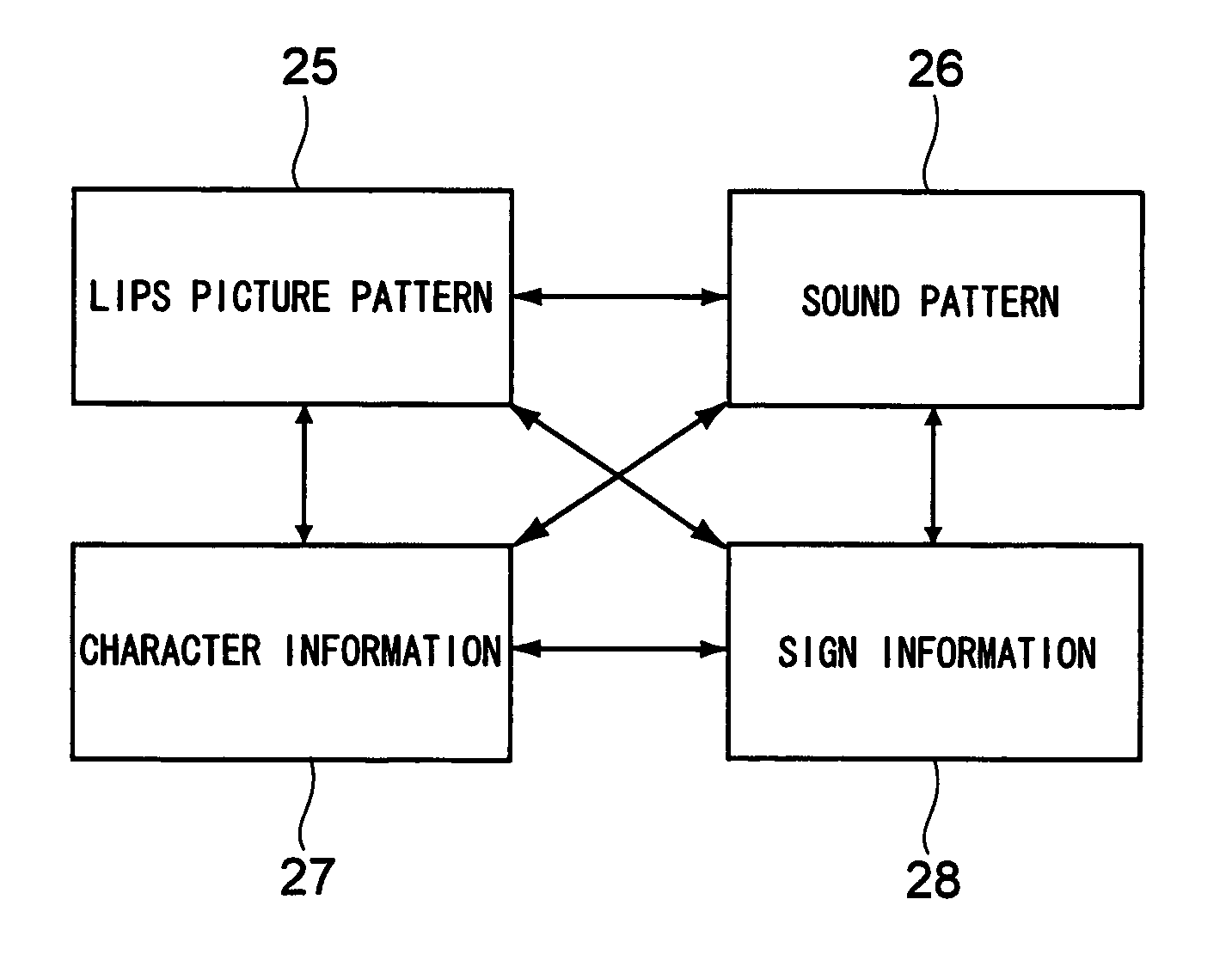

Conversation assisting device and conversation assisting method

InactiveUS20060204033A1Smooth conversionCharacter and pattern recognitionColor television detailsHuman–computer interaction

Owner:YOSHIMINE TAKASHI

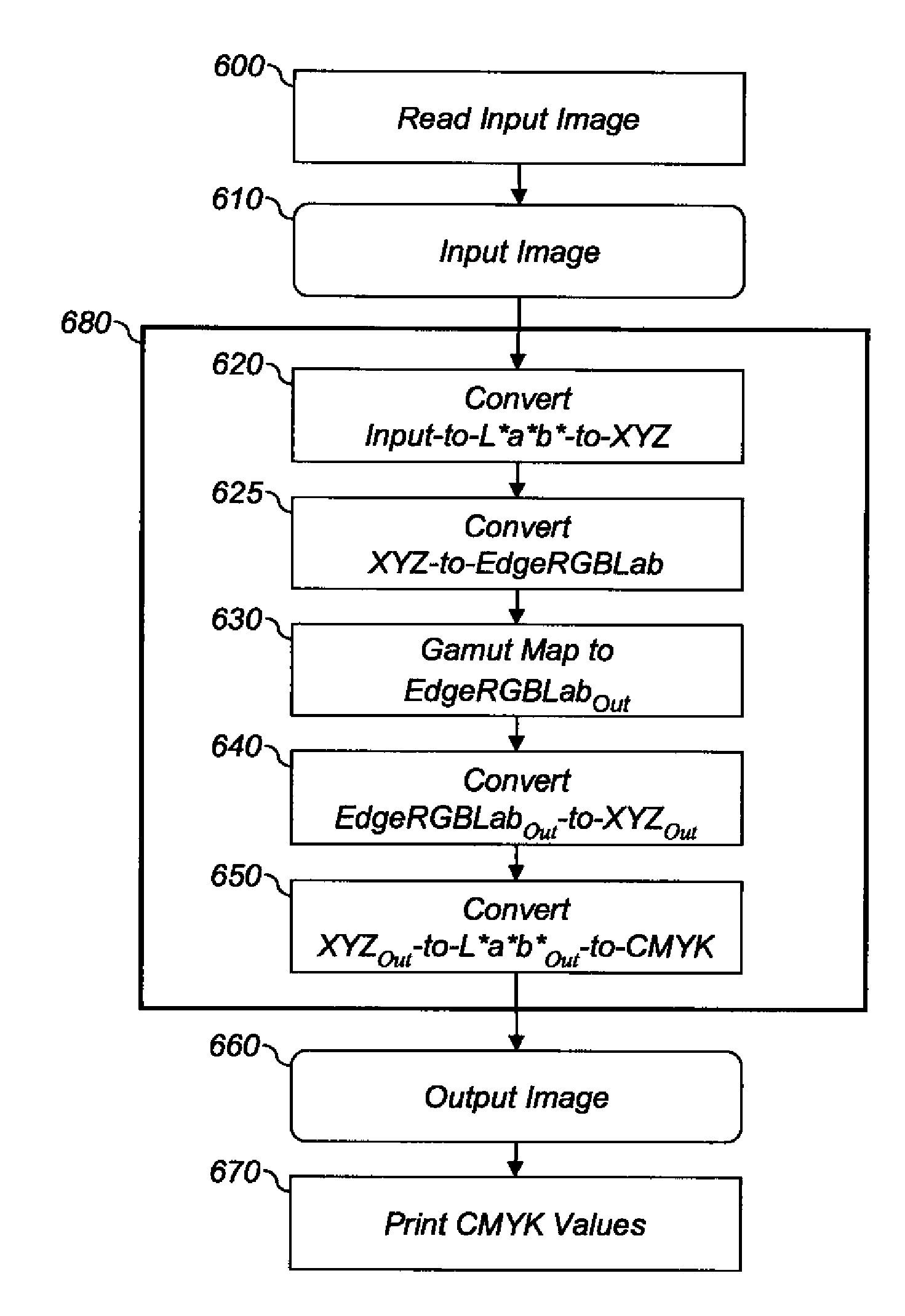

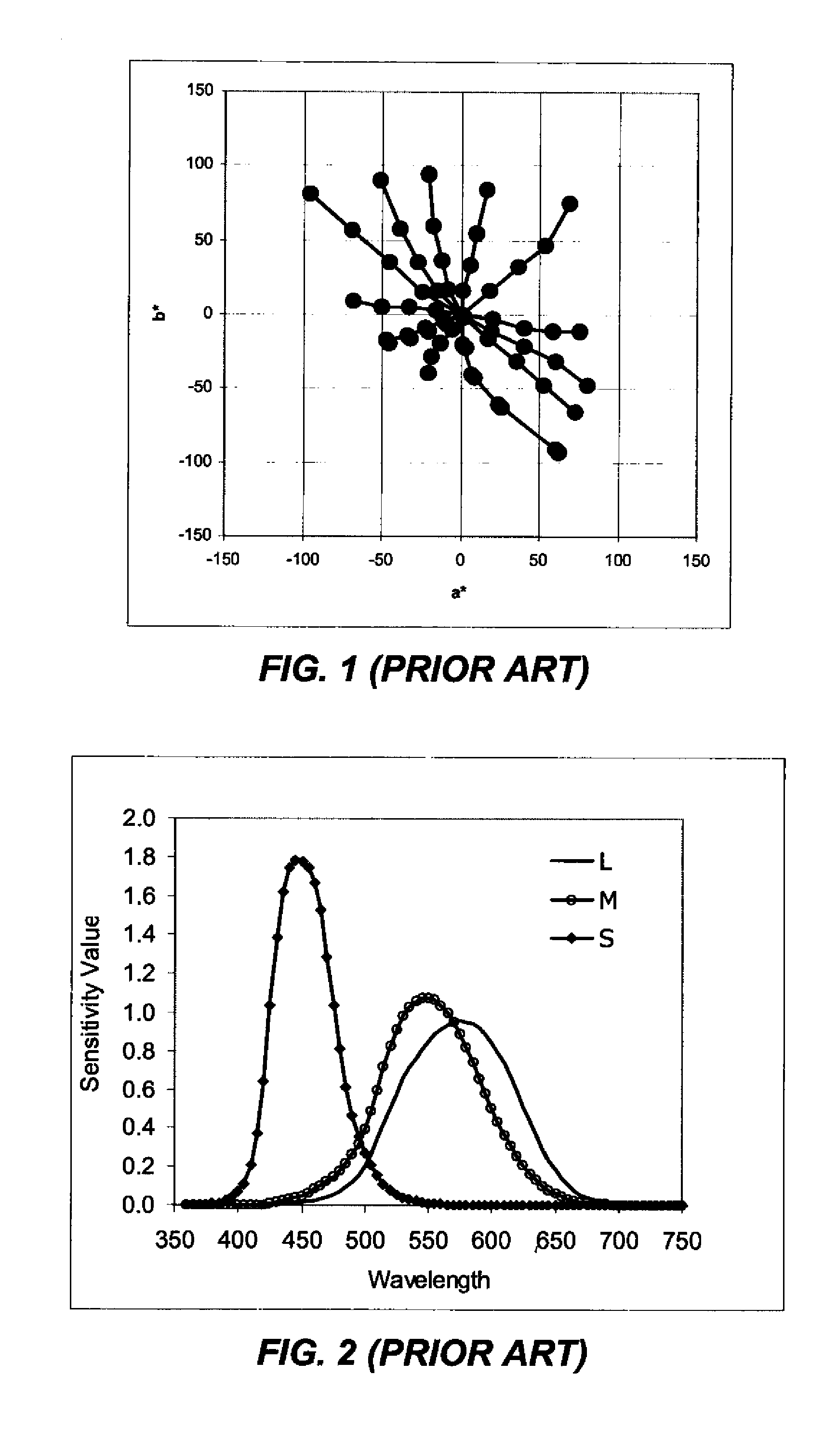

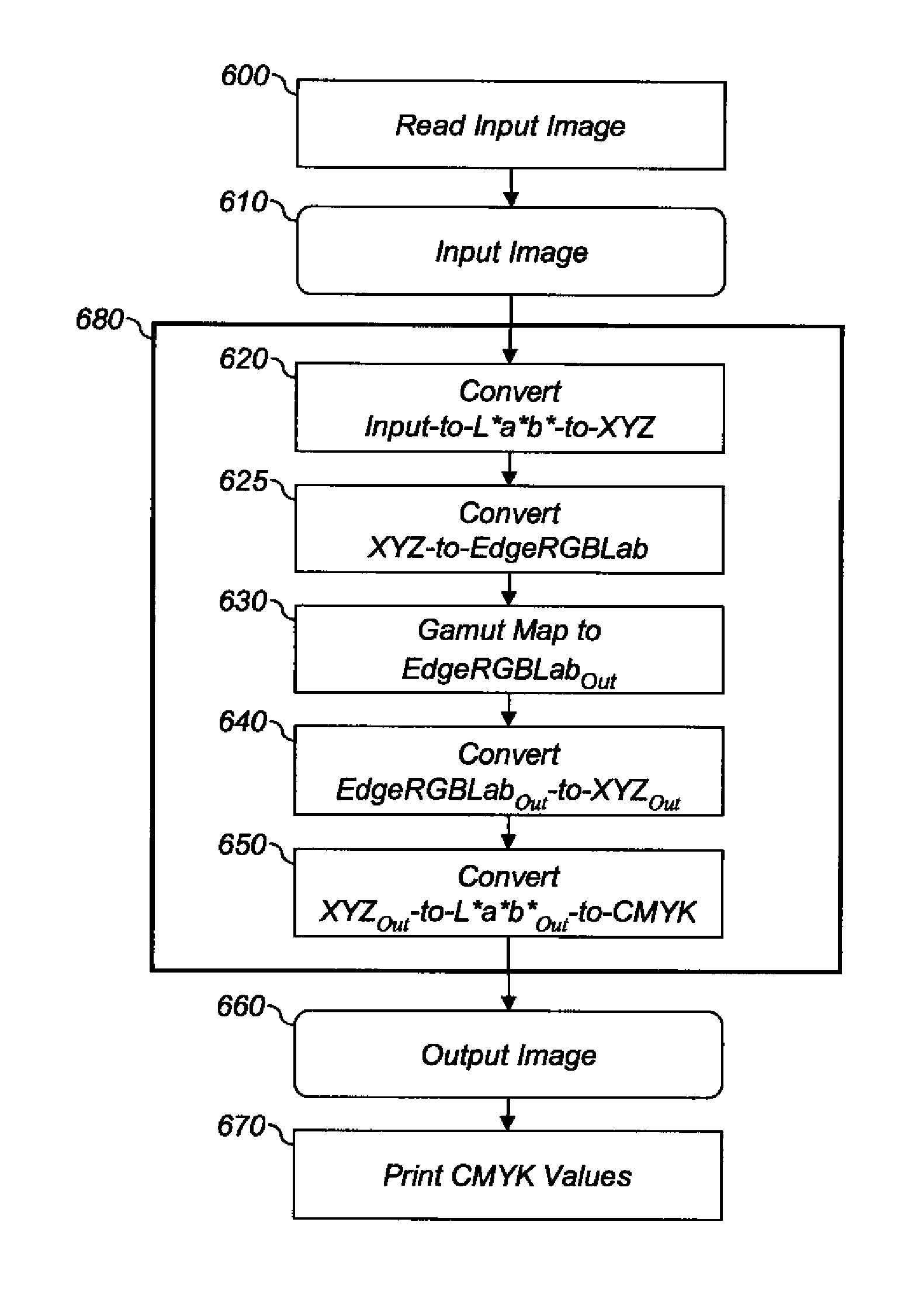

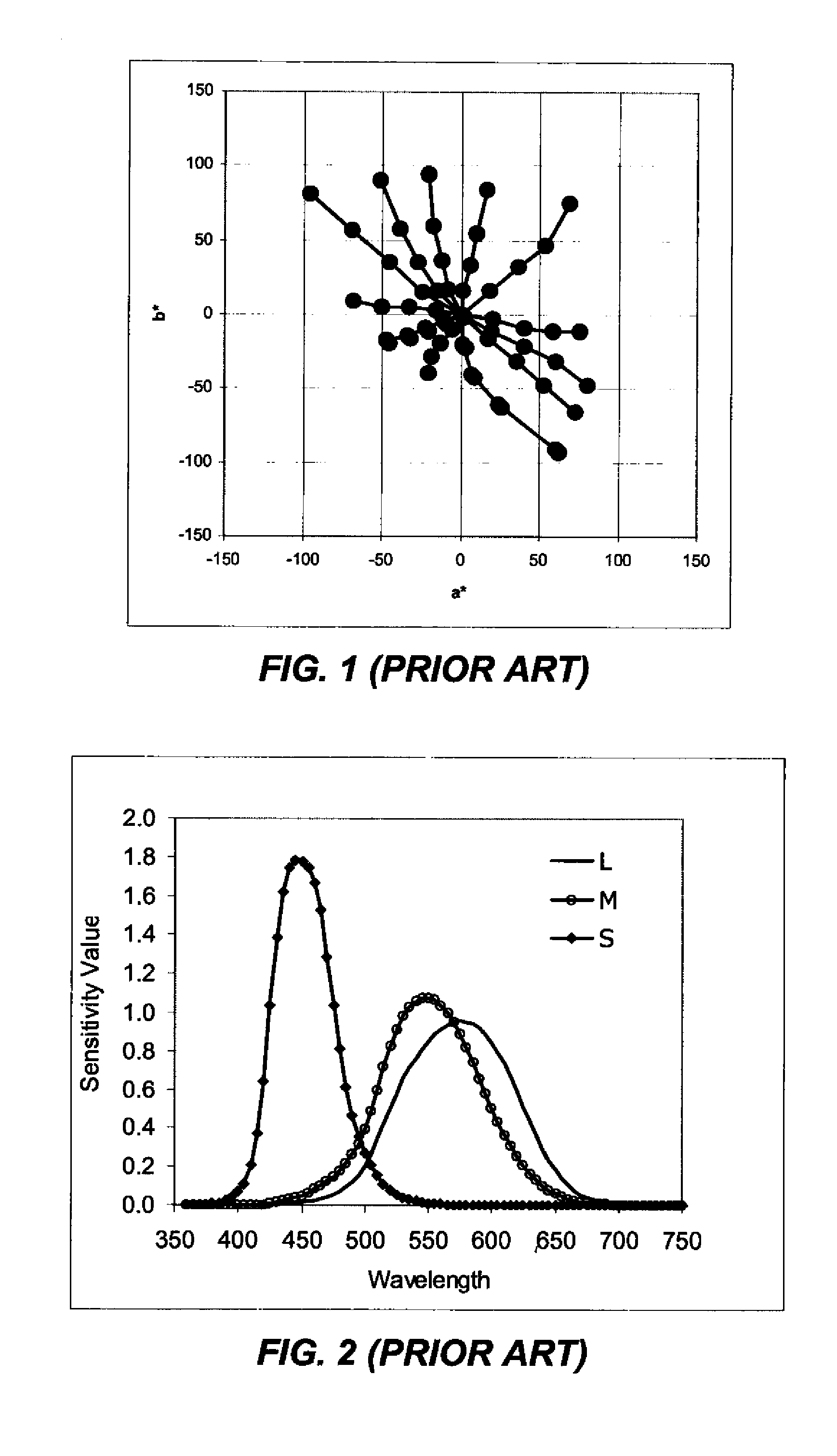

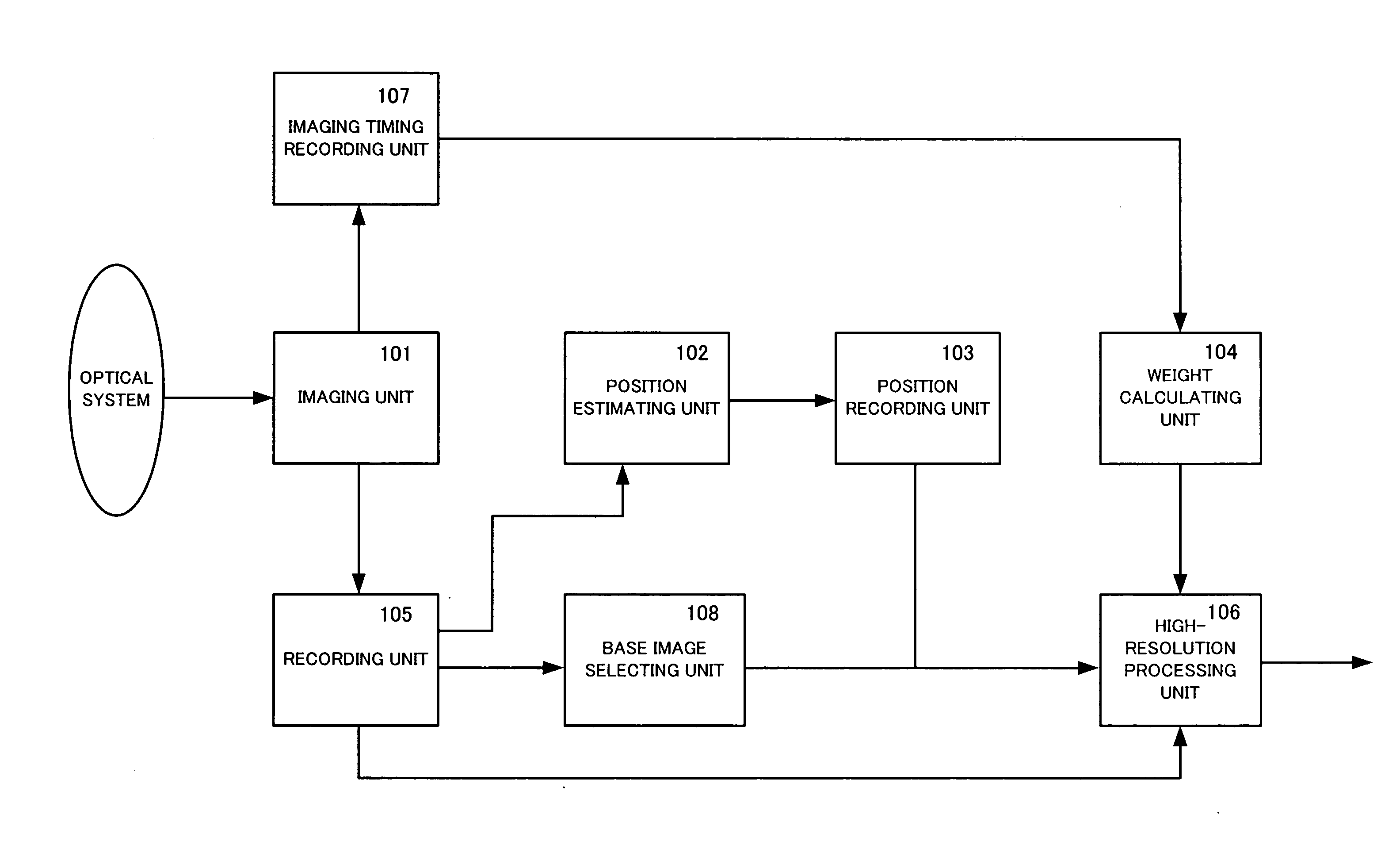

Gamut mapping using hue-preserving color space

InactiveUS20110255101A1Reduced color saturationPreserving saturated appearance of colorDigitally marking record carriersDigital computer detailsGamutHue

A method for applying gamut mapping to an input digital image having an associated input color gamut, to produce an output digital image having an associated output color gamut, which includes: defining a gamut mapping color transform which embodies the operations of transforming input color values from the input color space to linear RGB color values for a linear RGB color space, wherein the linear RGB color space has desirable hue preserving characteristics; transforming the linear RGB color values to determine nonlinear RGB color values; applying a 3×3 matrix transformation to the nonlinear RGB values to an opponent color space; applying a gamut mapping function to map opponent color values within the input color gamut to produce modified opponent color values within the output color gamut; and transforming the modified opponent color values to produce the output color values in the output color space.

Owner:EASTMAN KODAK CO

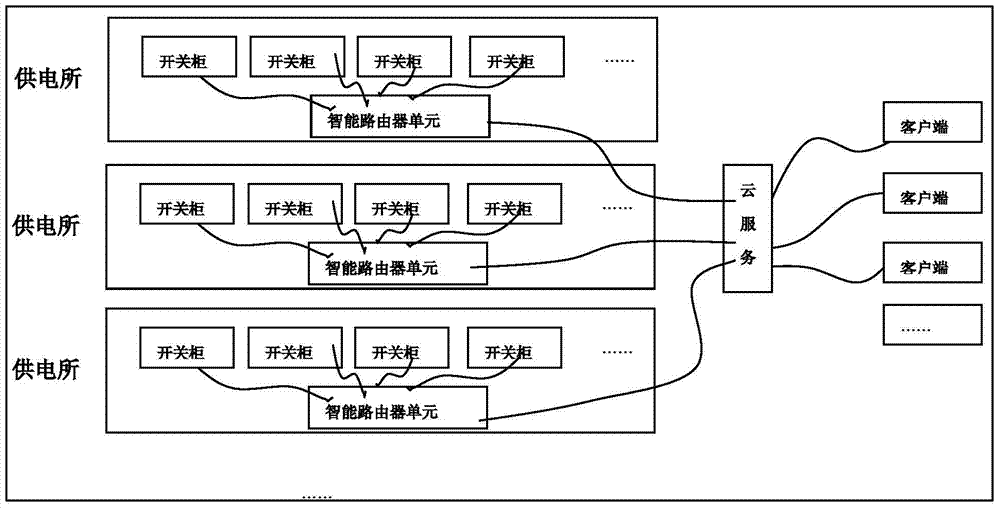

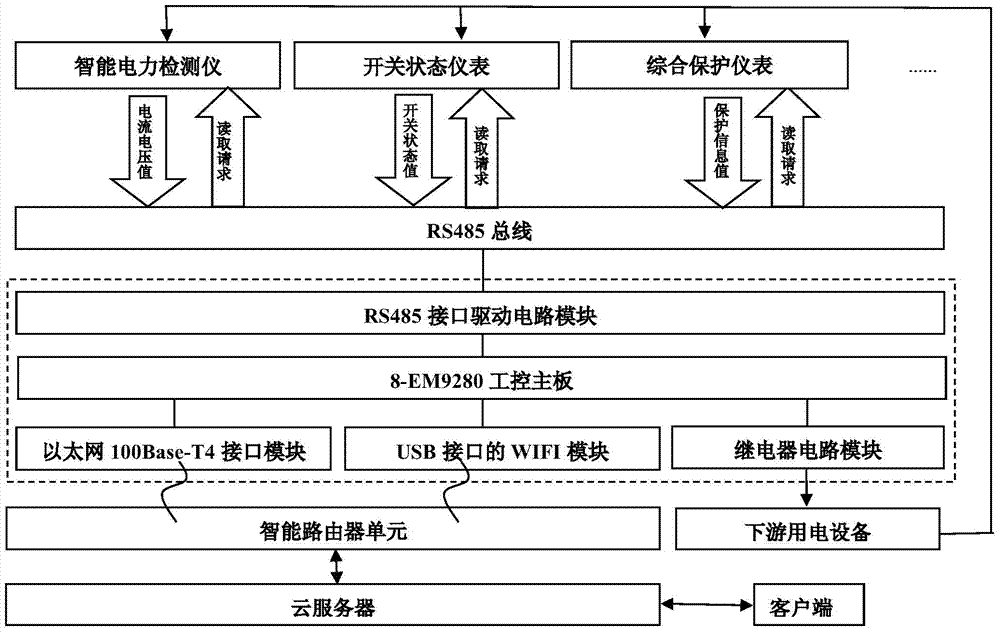

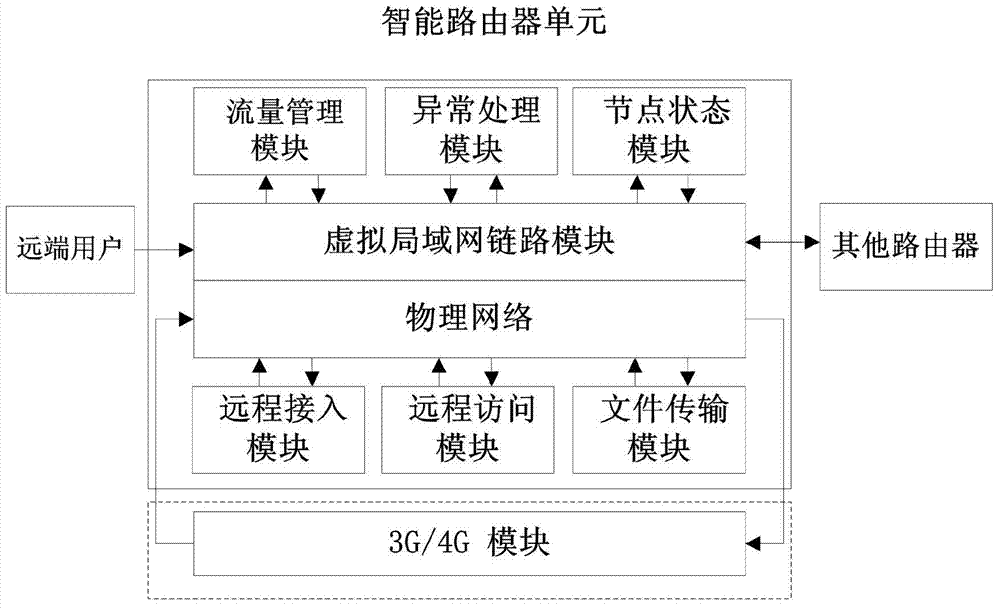

Internet of things based high- and low-voltage switchgear system

ActiveCN104734363AProtection securityImprove intelligenceCircuit arrangementsInformation technology support systemLow voltageTransmitted power

The invention discloses an internet of things based high- and low-voltage switchgear system. The system is characterized by comprising a switchgear master control unit and an intelligent router unit. The intelligent router unit is used for establishing connections of all switchgear master control units of a power supply station and a client and for establishing a virtual local area network; the switchgear master control unit converts power signals periodically received, into power information; the power information is subjected to comprehensive judgement of operation load. The system is available for remote updating and debugging of system files of switchgear and for autonomous trip control; the system is capable of remotely monitoring and controlling the switchgear according to the transmitted power information, thus electrical equipment is more intelligent and equipment monitoring capacity and controllability is enhanced.

Owner:HEFEI UNIV OF TECH +1

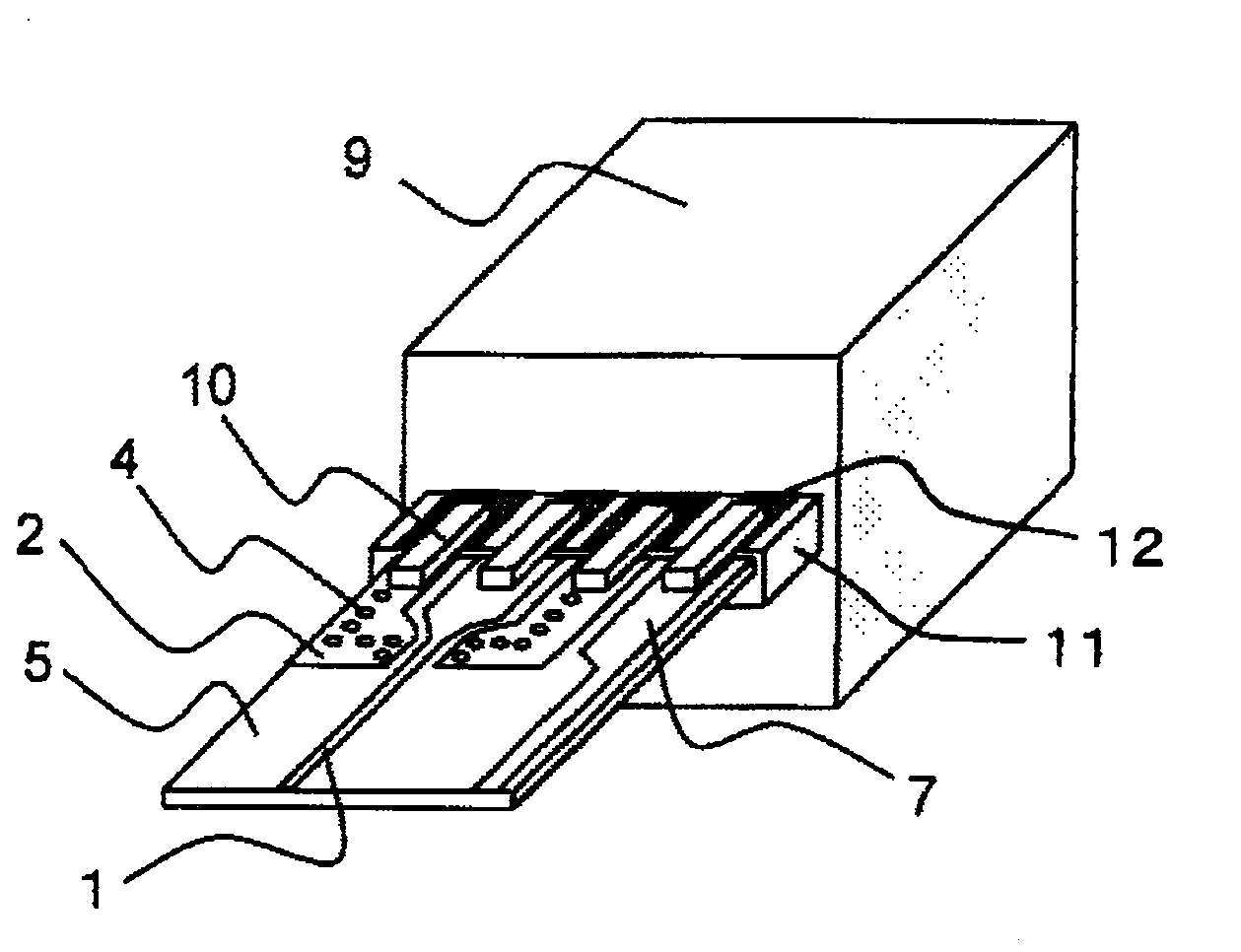

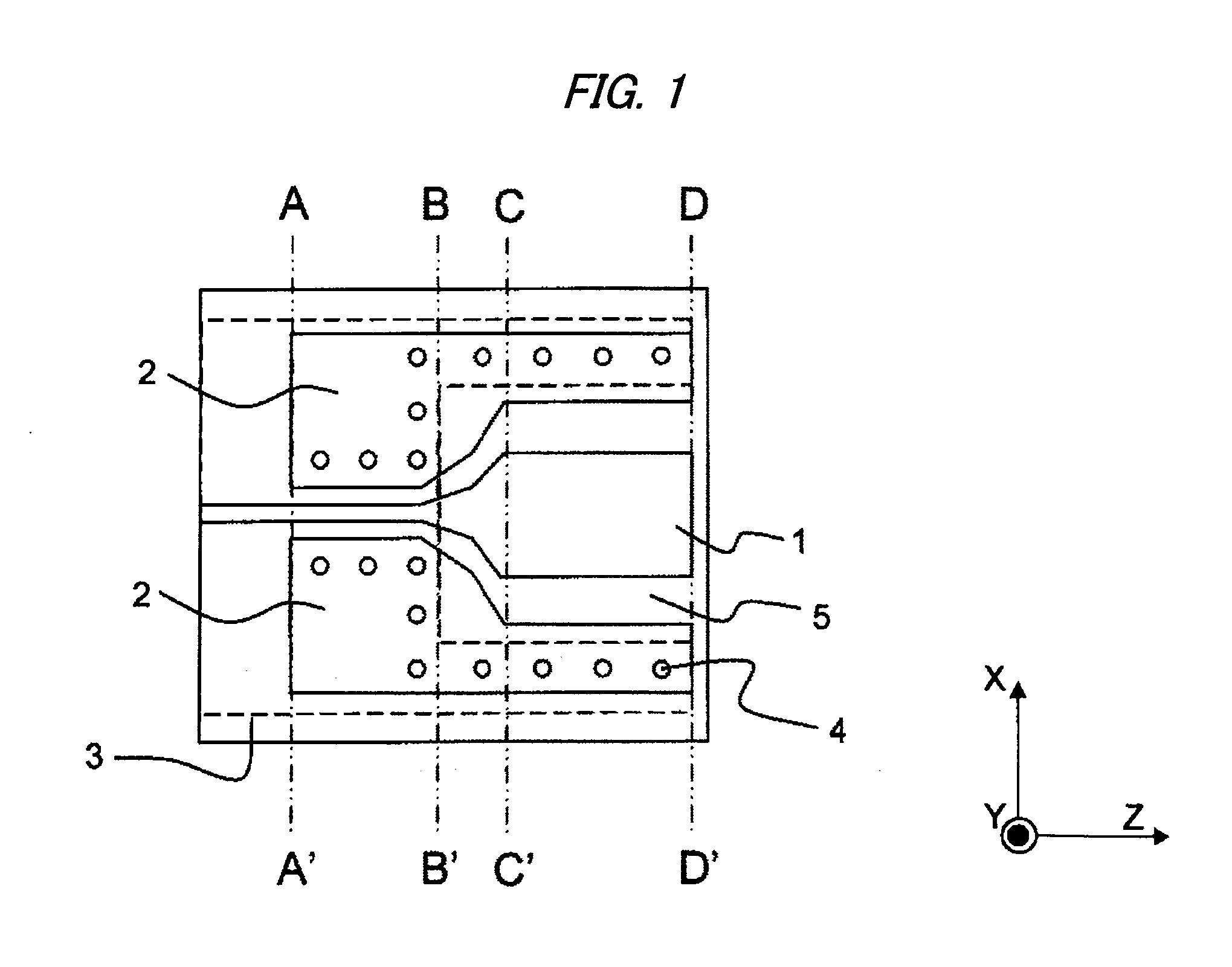

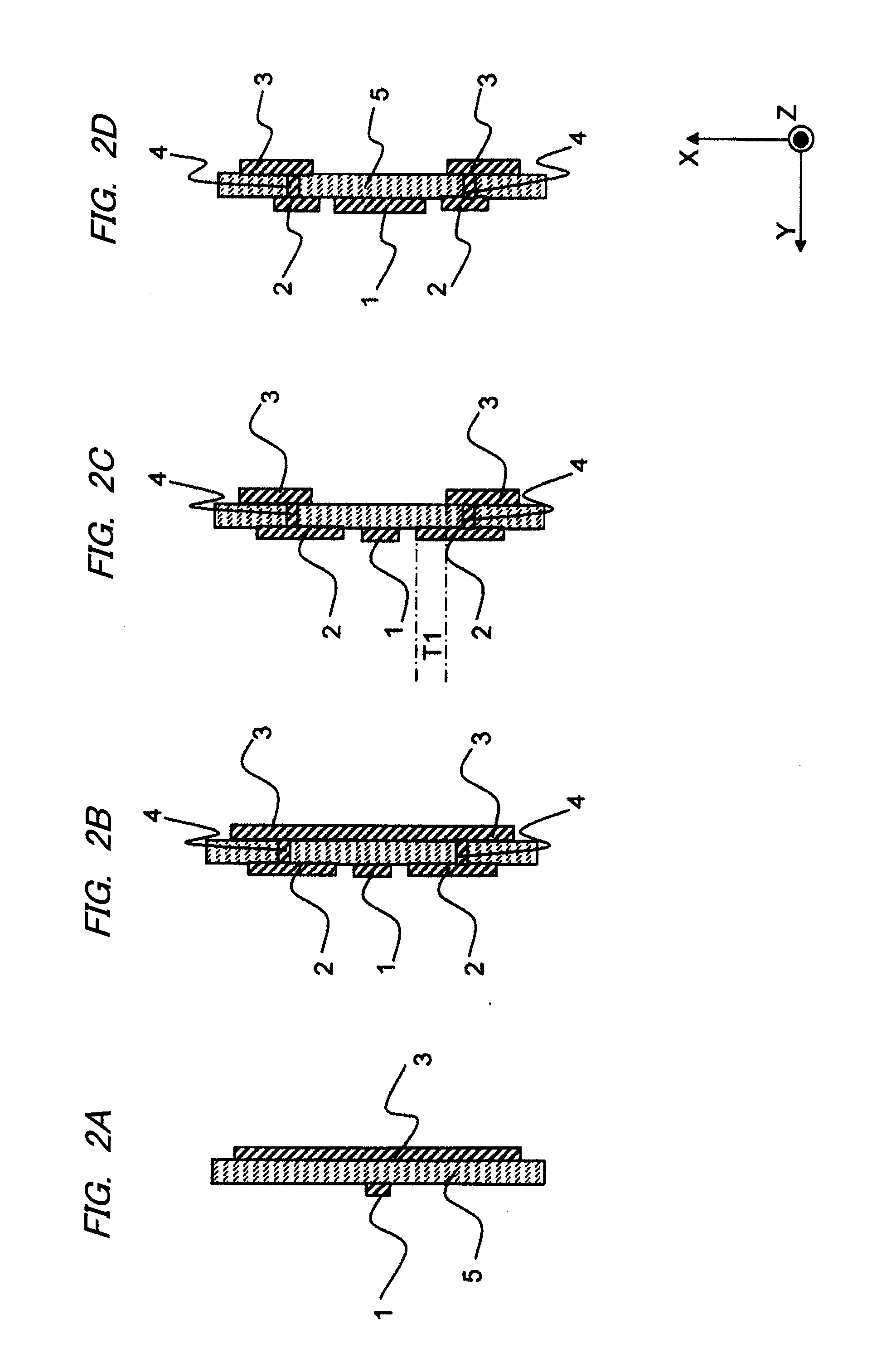

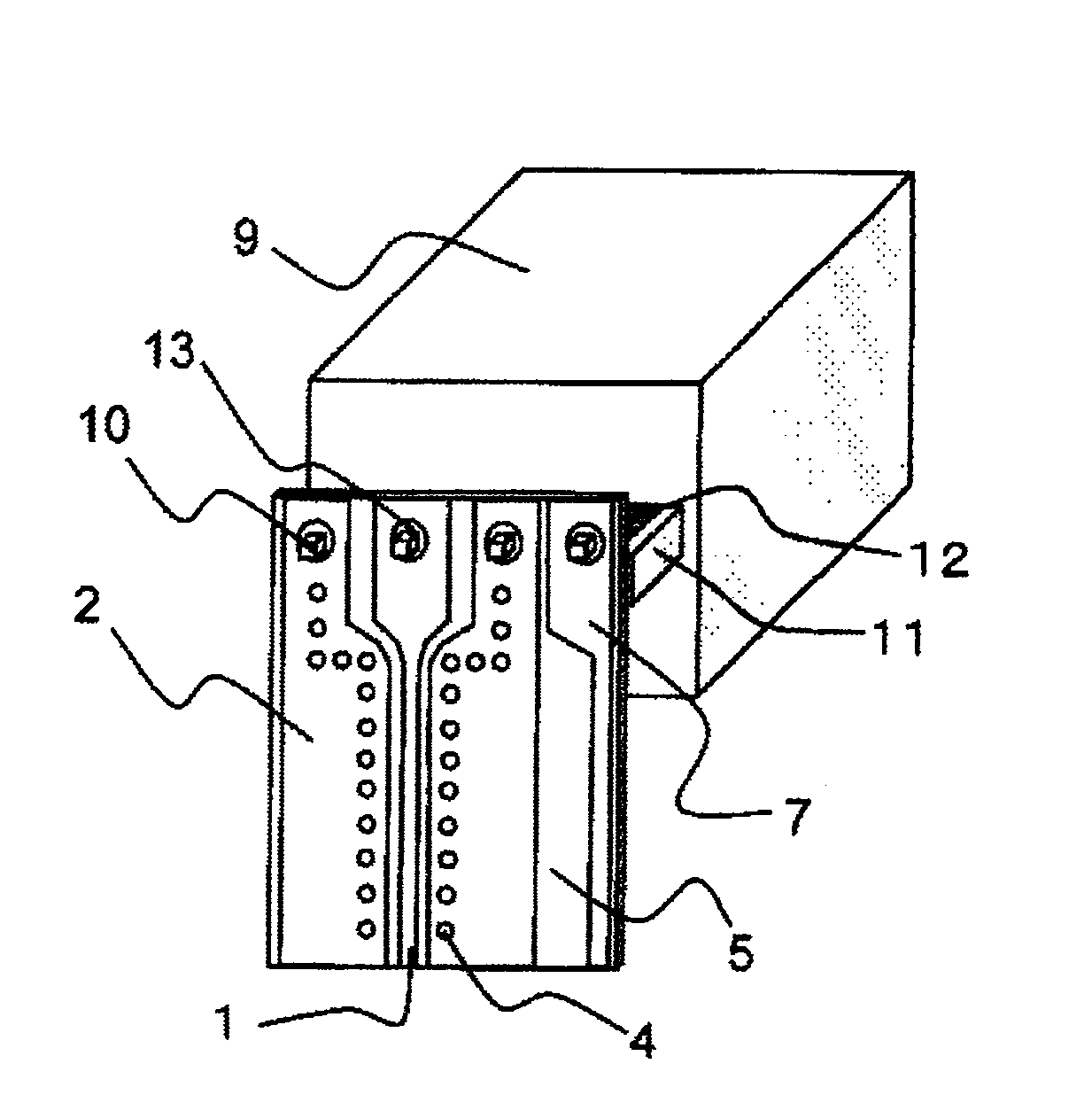

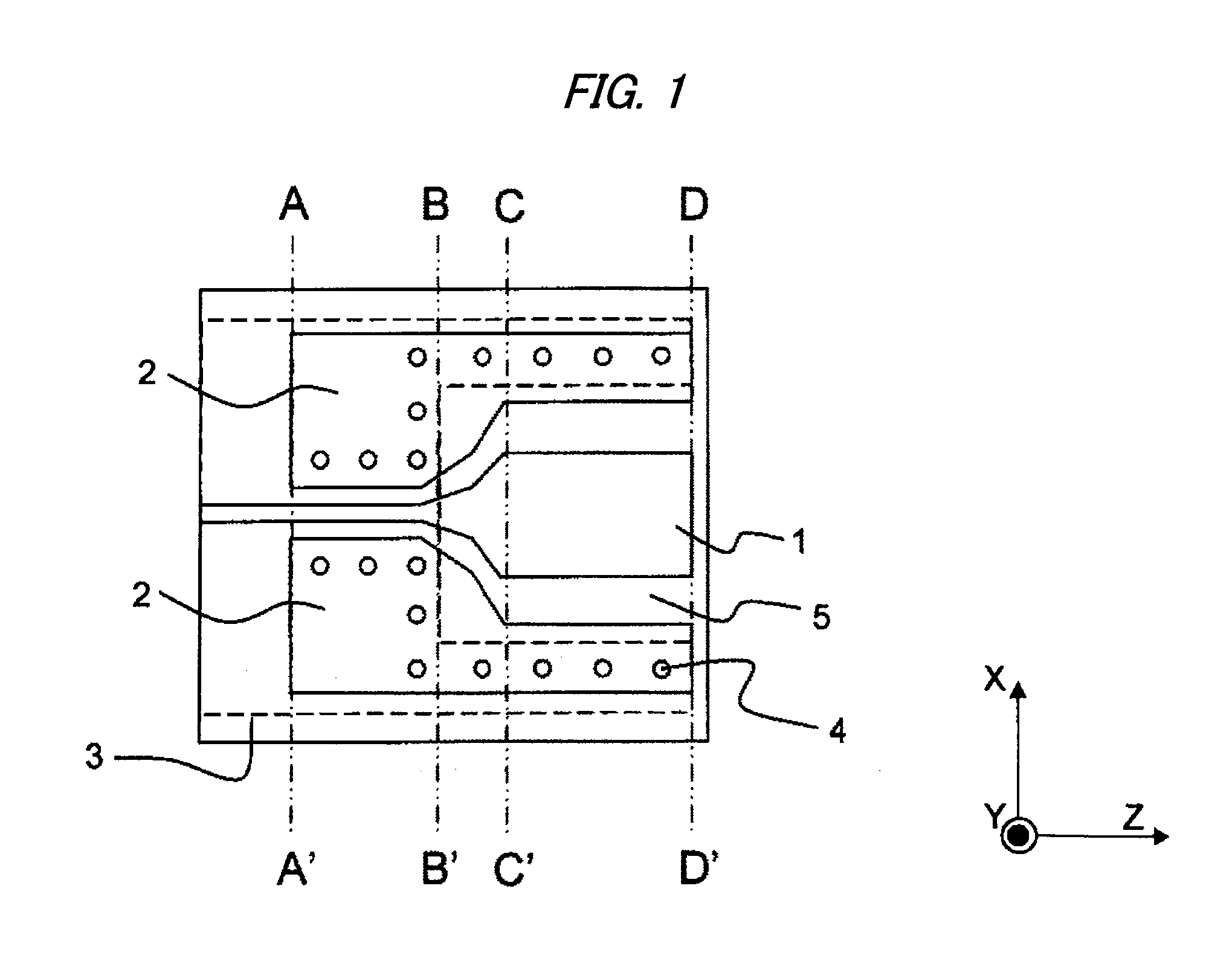

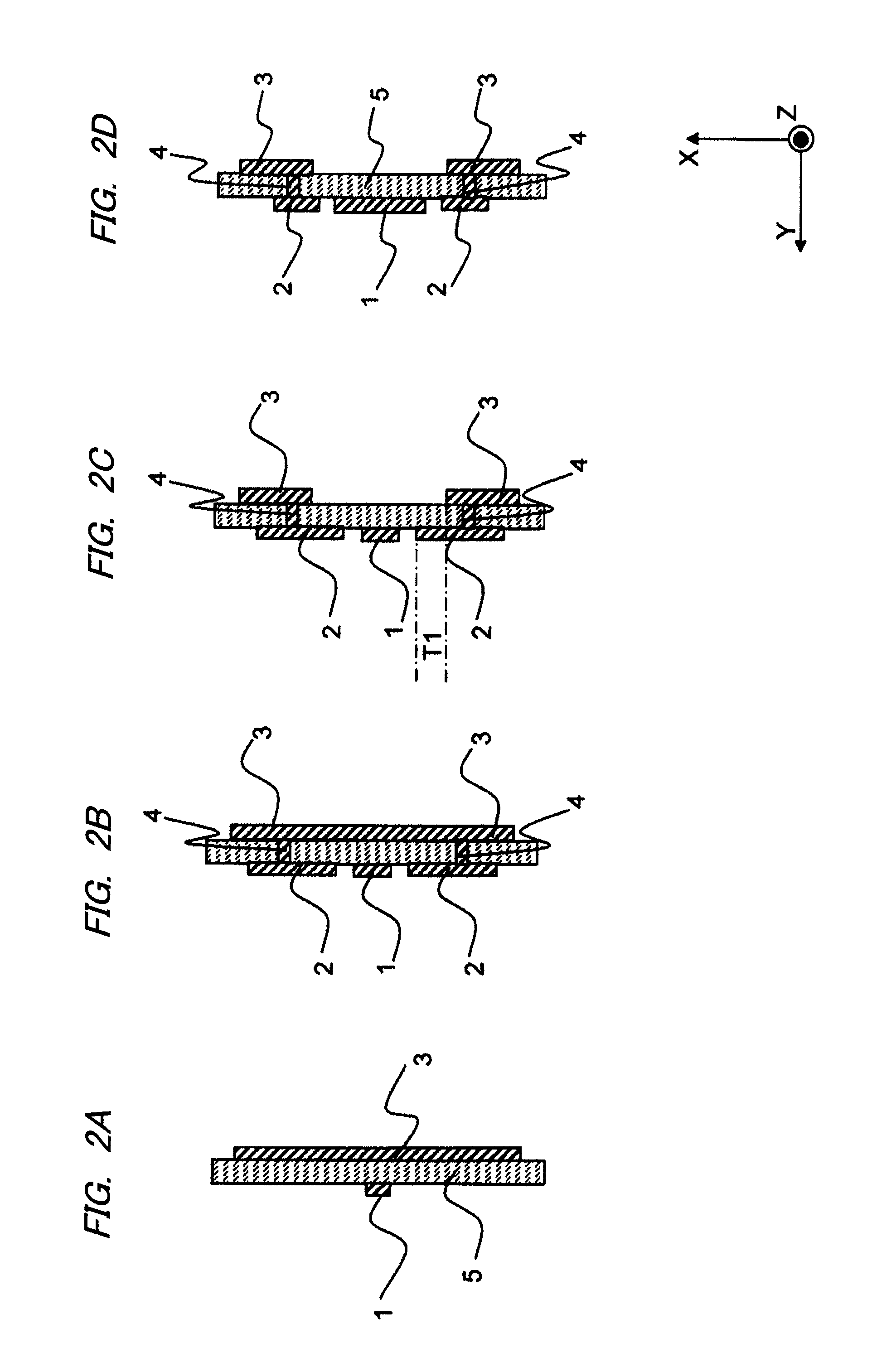

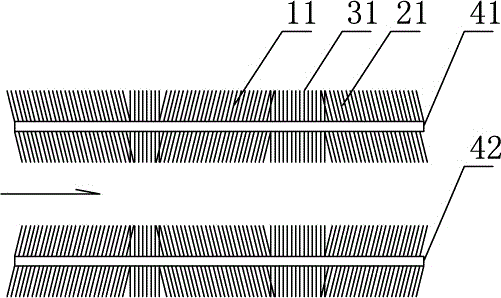

Optical module

ActiveUS20100215324A1Deterioration of characteristicEasy to getCross-talk/noise/interference reductionPrinted circuit aspectsEngineeringElectromagnetic radiation

An optical module having a flexible substrate having, even after actual manufacturing steps, excellent transmission characteristics of high-frequency signals and an advantage that electromagnetic field radiation is reduced even when it is connected with a package. The flexible substrate used in external connection of the package of the optical module uses a flexible substrate having a coplanar line to which a lead pin is fixedly attached, a grounded coplanar line which is in contact with the coplanar region, and a microstrip line which is in contact with the grounded coplanar line. The flexible substrate has an electrode layout in which an electromagnetic field component of a surface ground line and a signal line is more dominant than an electromagnetic field component of a back-surface ground line and the signal line in a region of the coplanar line adjacent to the grounded coplanar line.

Owner:LUMENTUM JAPAN INC

Optical module

ActiveUS8437583B2Decrease productivityDeterioration of characteristicCross-talk/noise/interference reductionHigh frequency circuit adaptationsEngineeringElectromagnetic field

Owner:LUMENTUM JAPAN INC

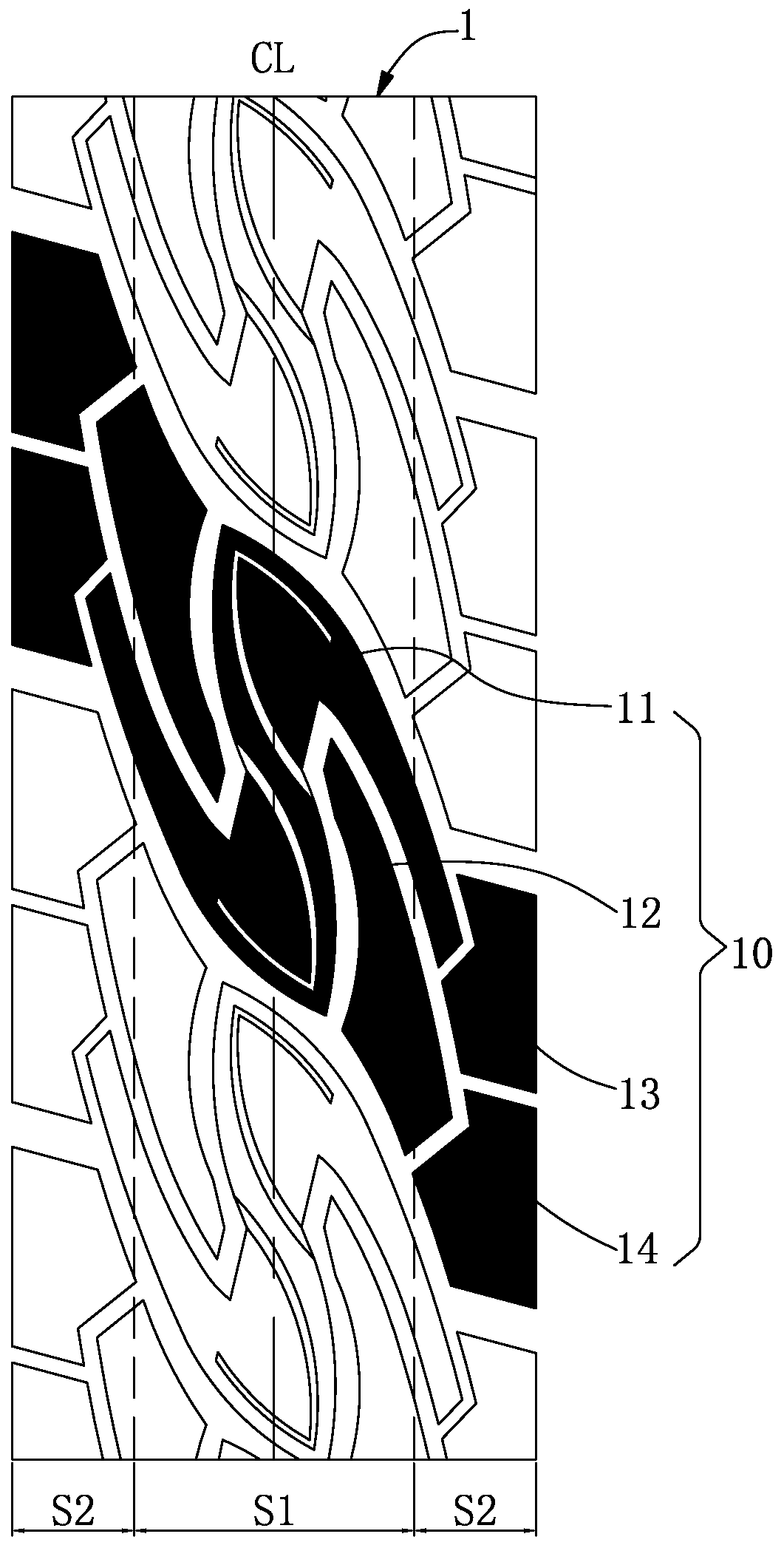

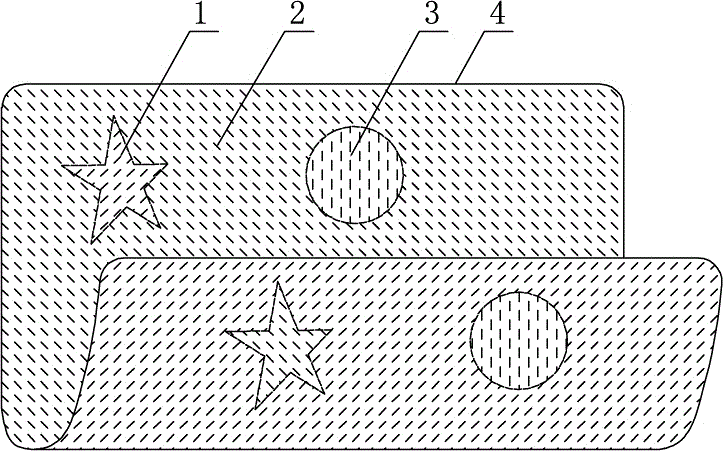

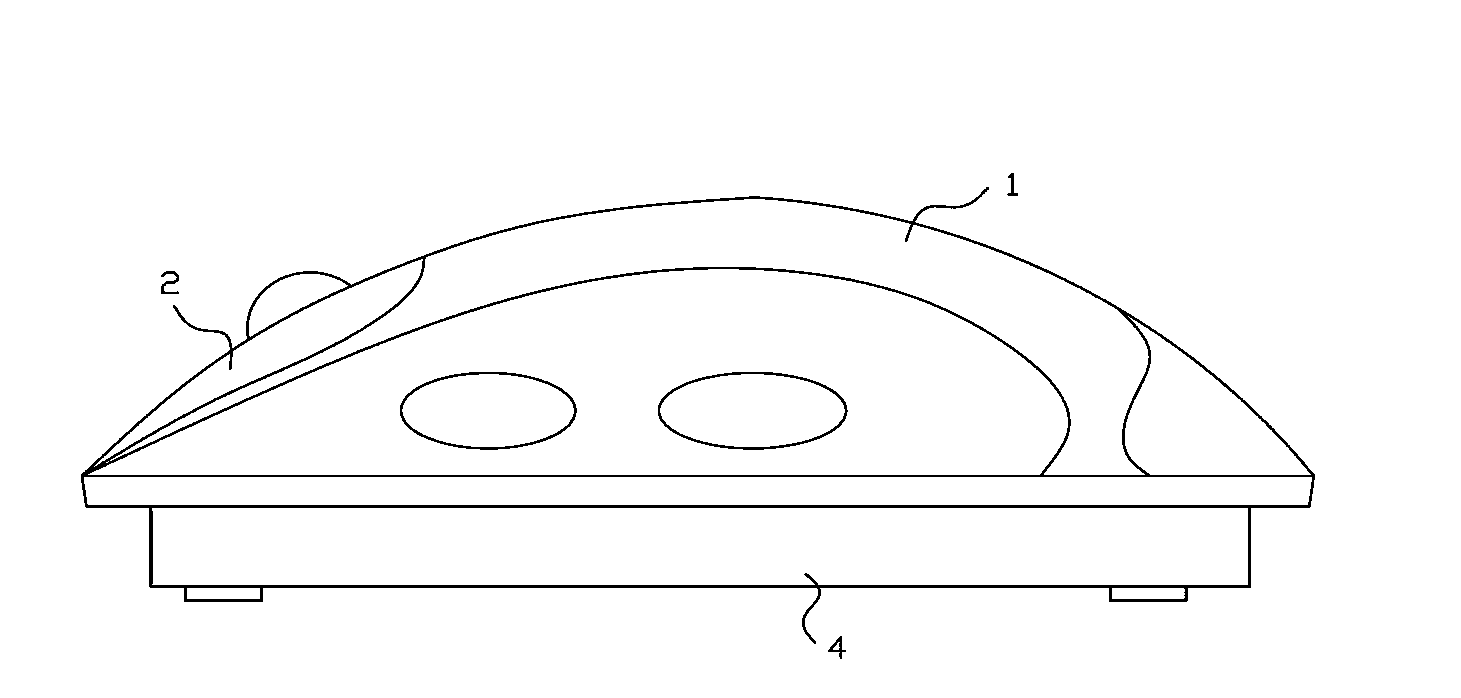

Tire structure for wheelchair

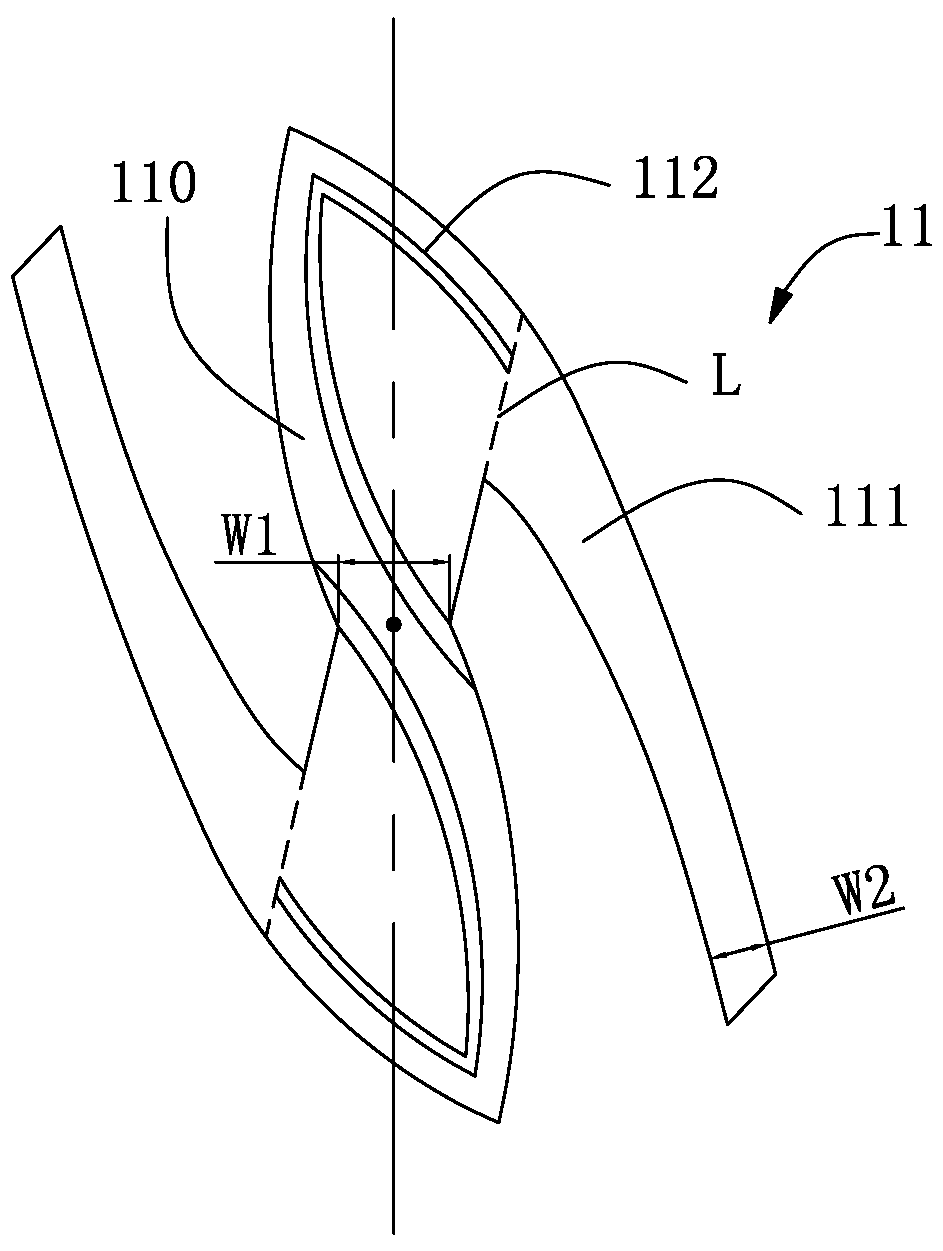

PendingCN109334353ASmooth conversionPromote labor savingTyre tread bands/patternsWheelchairEngineering

The invention discloses a tire structure for a wheelchair. A plurality of pattern groups are uniformly distributed at intervals on a tread of a tire in the circumferential direction, each pattern group contains an inverted S-shaped pattern block on the center line of the tread, and each inverted S-shaped pattern block comprises a central axle part and two flank parts, wherein the two correspondingflank parts are at 180 degrees from each other along the center of the tread. The central axle parts are located on the center line of the tread and are in a concave-convex shape with a wide upper end, a narrow middle end and a wide lower end in the circumferential direction of the tire. The two flank parts of the inverted S-shaped pattern blocks are arranged on one sides of the upper and lower ends of the central axle parts in an opposite mode. According to the tire structure for the wheelchair, through the structural design of the inverted S-pattern blocks on the center line of the tread, so that the inverted S-pattern blocks located at the center of the tread has double directionality, the tire can be switched smoothly between forward, backward, rotation and any other movement, the wheelchair is enabled to be labor-saving in pushing, agile and durable, a good catching performance is played, and safety hazards are reduced.

Owner:CHENG SHIN RUBBER (XIAMEN) IND LTD

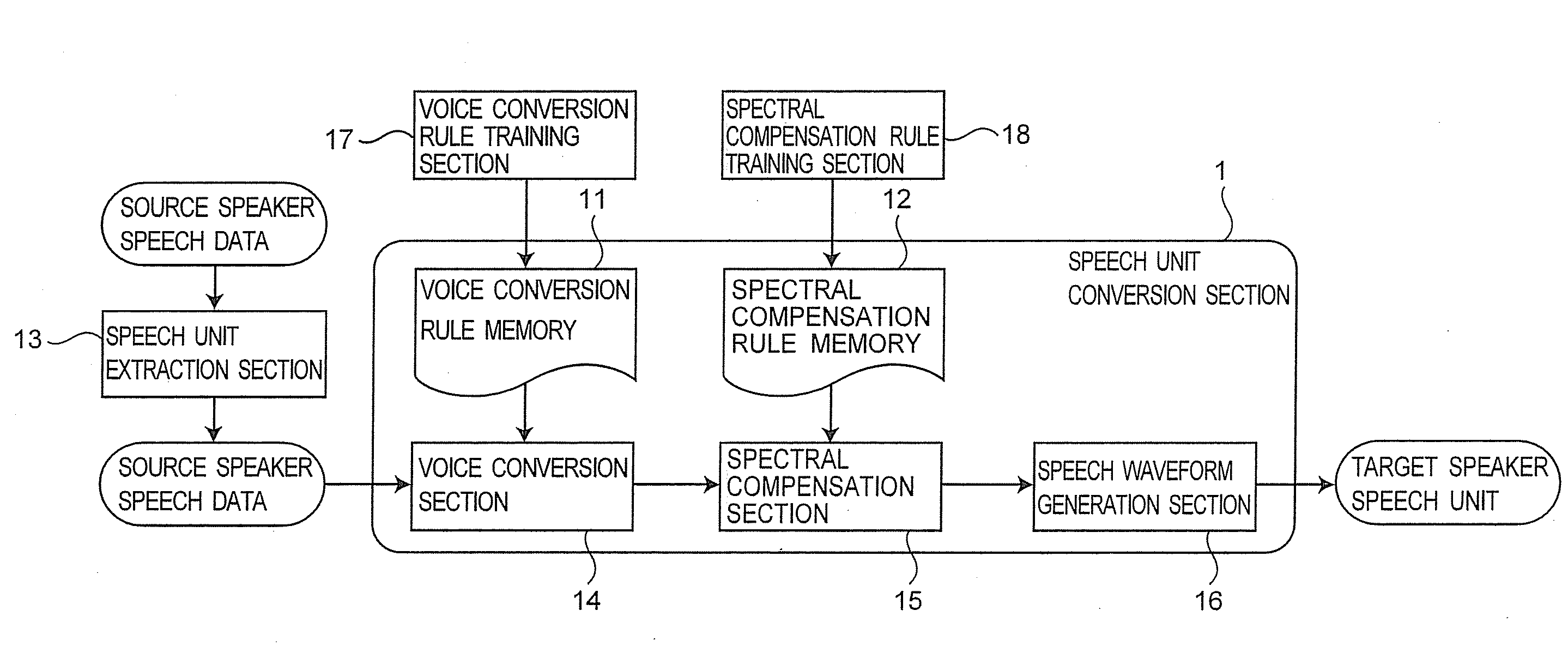

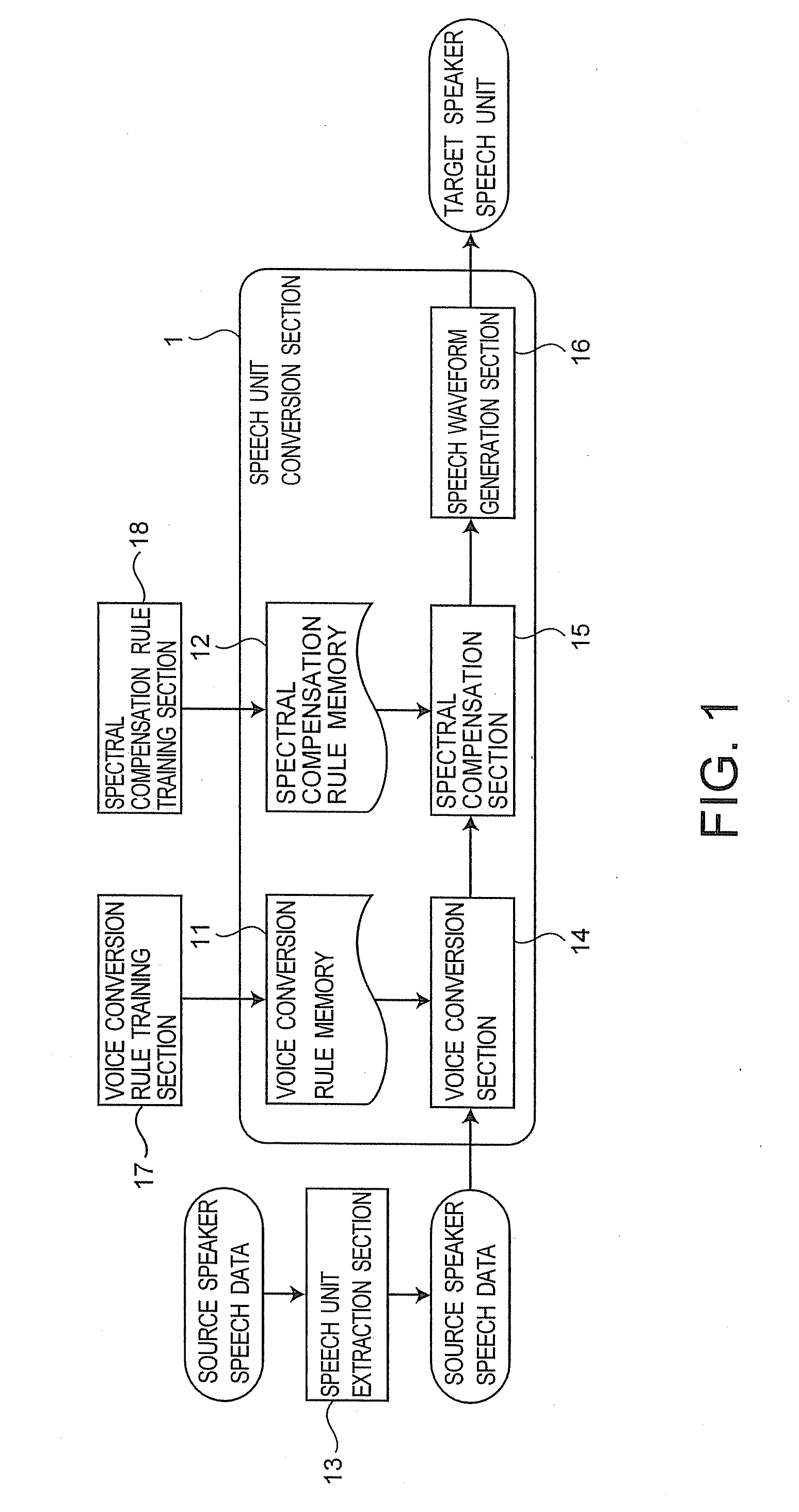

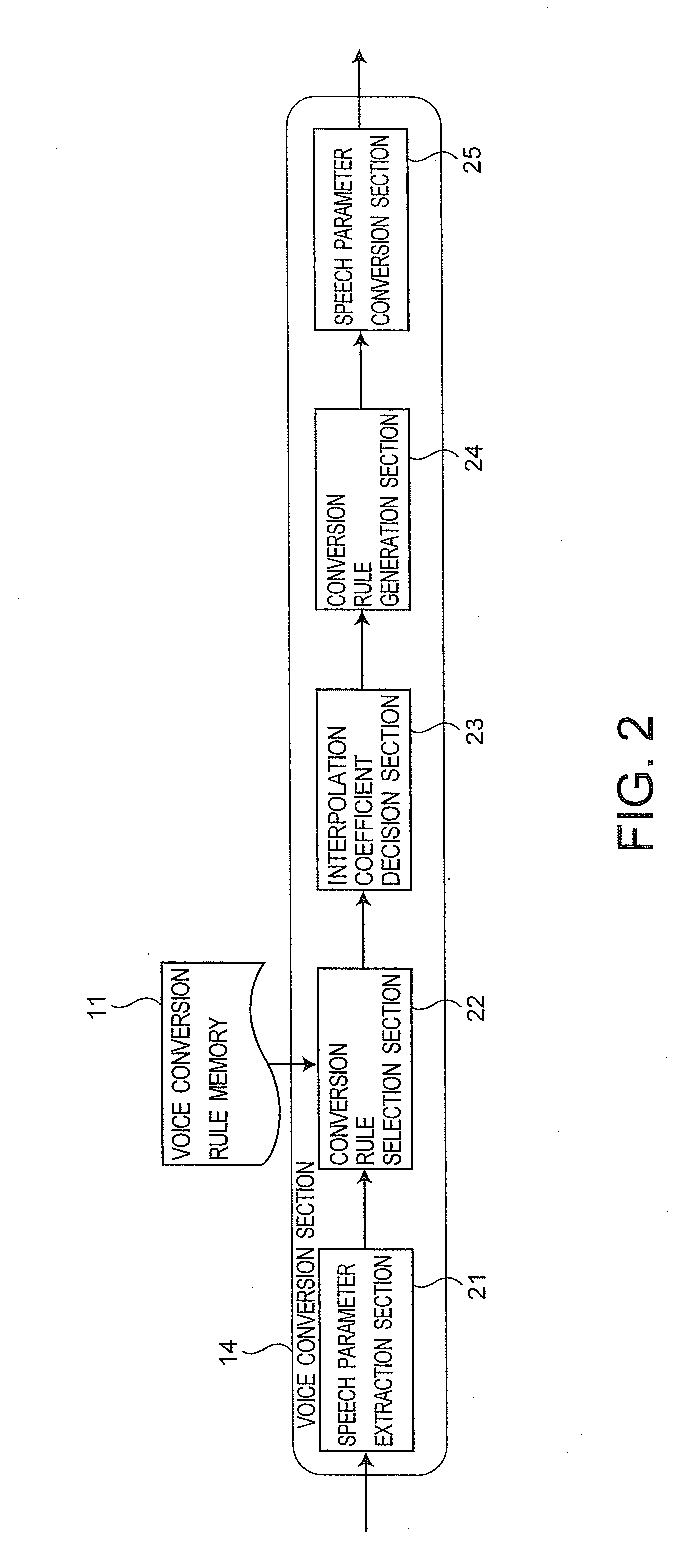

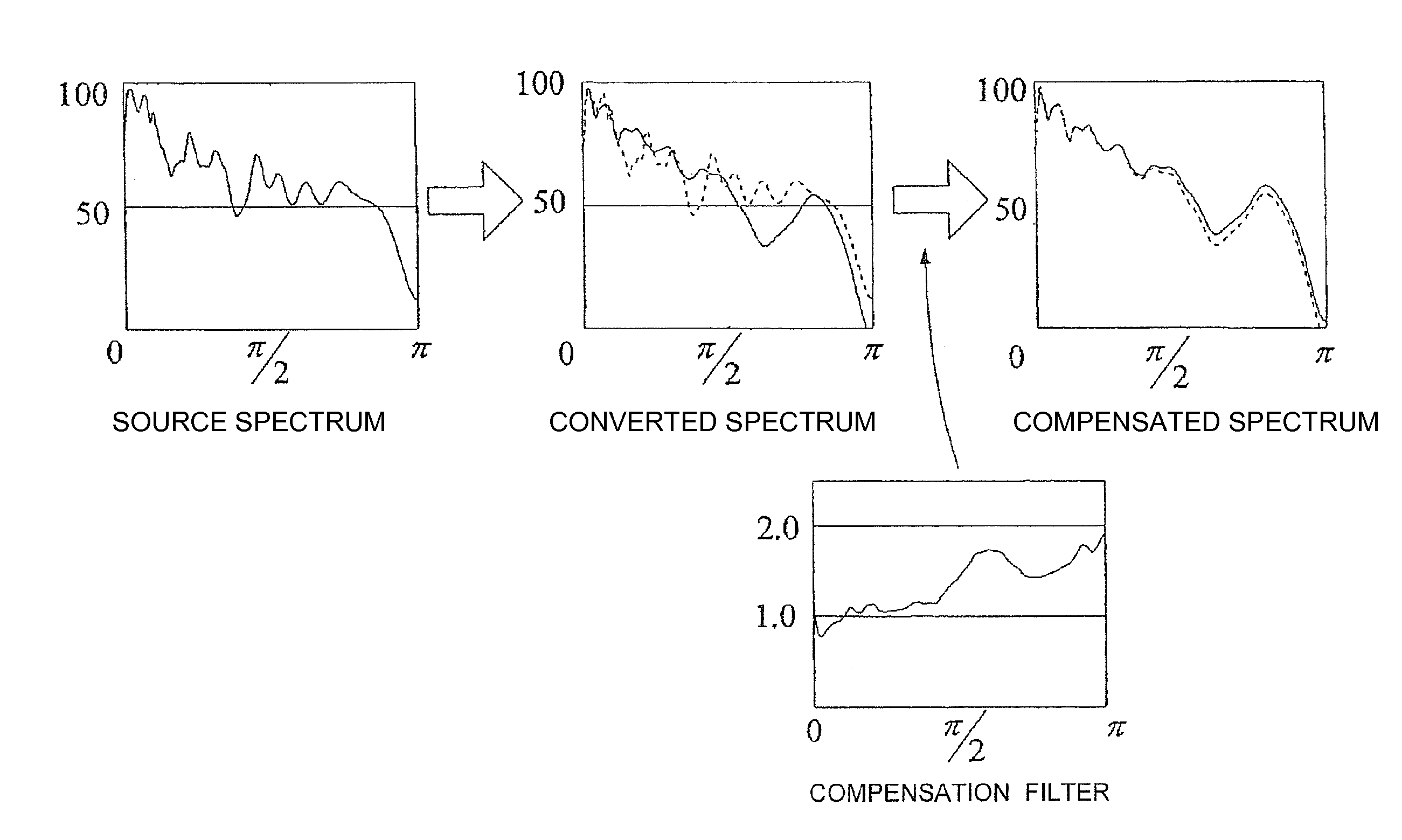

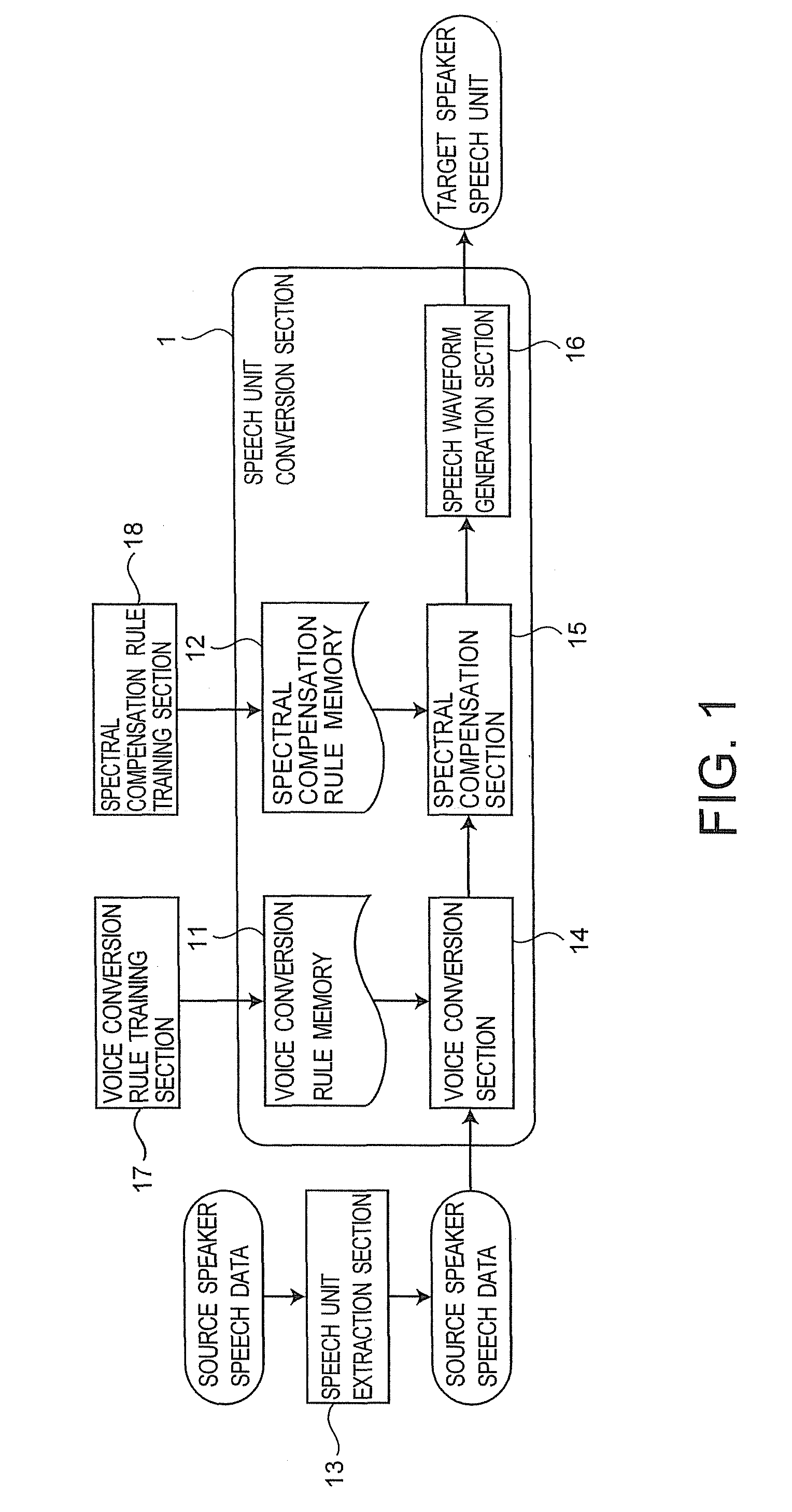

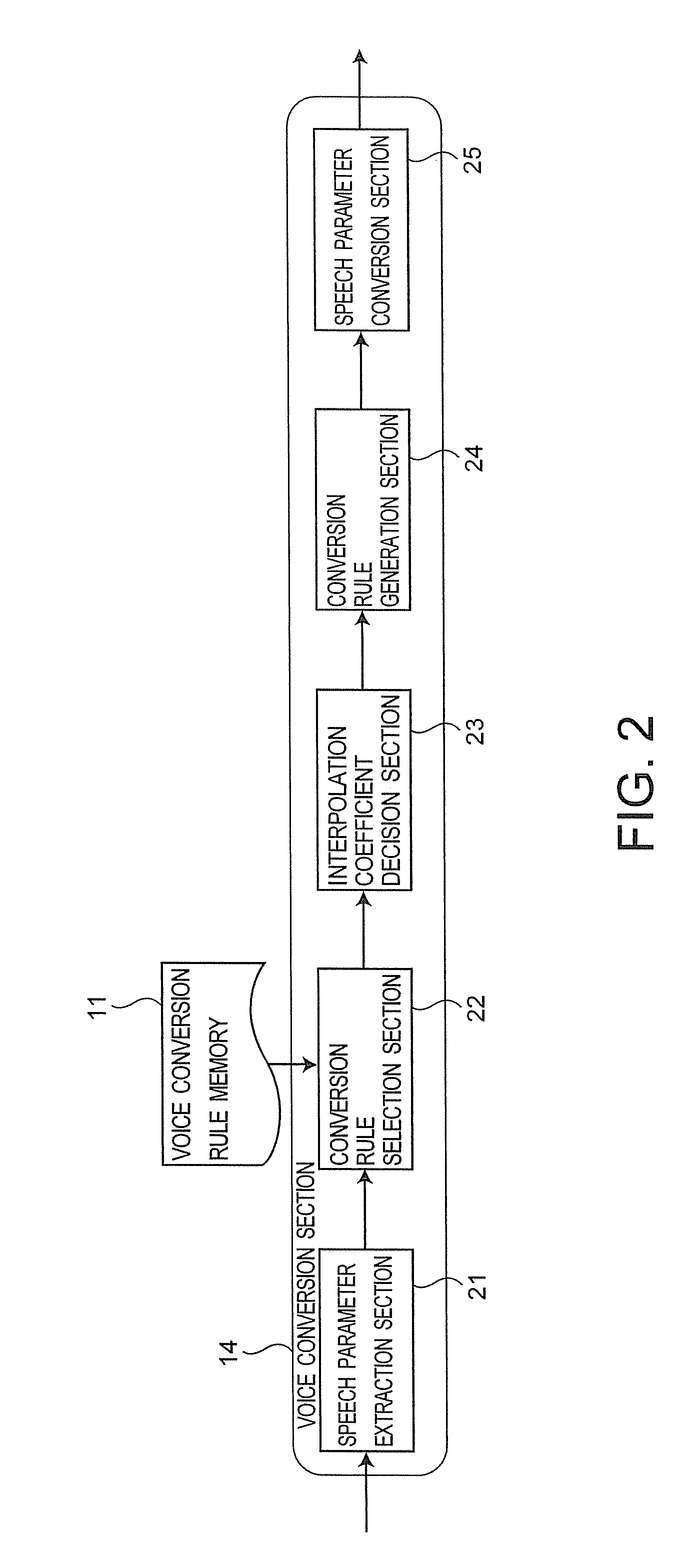

Voice conversion using interpolated speech unit start and end-time conversion rule matrices and spectral compensation on its spectral parameter vector

A voice conversion rule and a rule selection parameter are stored. The voice conversion rule converts a spectral parameter vector of a source speaker to a spectral parameter vector of a target speaker. The rule selection parameter represents the spectral parameter vector of the source speaker. A first voice conversion rule of start time and a second voice conversion rule of end time in a speech unit of the source speaker are selected by the spectral parameter vector of the start time and the end time. An interpolation coefficient corresponding to the spectral parameter vector of each time in the speech unit is calculated by the first voice conversion rule and the second voice conversion rule. A third voice conversion rule corresponding to the spectral parameter vector of each time in the speech unit is calculated by interpolating the first voice conversion rule and the second voice conversion rule with the interpolation coefficient. The spectral parameter vector of each time is converted to a spectral parameter vector of the target speaker by the third voice conversion rule. A spectrum acquired from the spectral parameter vector of the target speaker is compensated by a spectral compensation filter or power ratio. A speech waveform is generated from the compensated spectrum.

Owner:TOSHIBA DIGITAL SOLUTIONS CORP

Gamut mapping using hue-preserving color space

InactiveUS8437053B2Preserving saturated appearance of colorConstant perceived hueDigitally marking record carriersDigital computer detailsGamutHue

Owner:EASTMAN KODAK CO

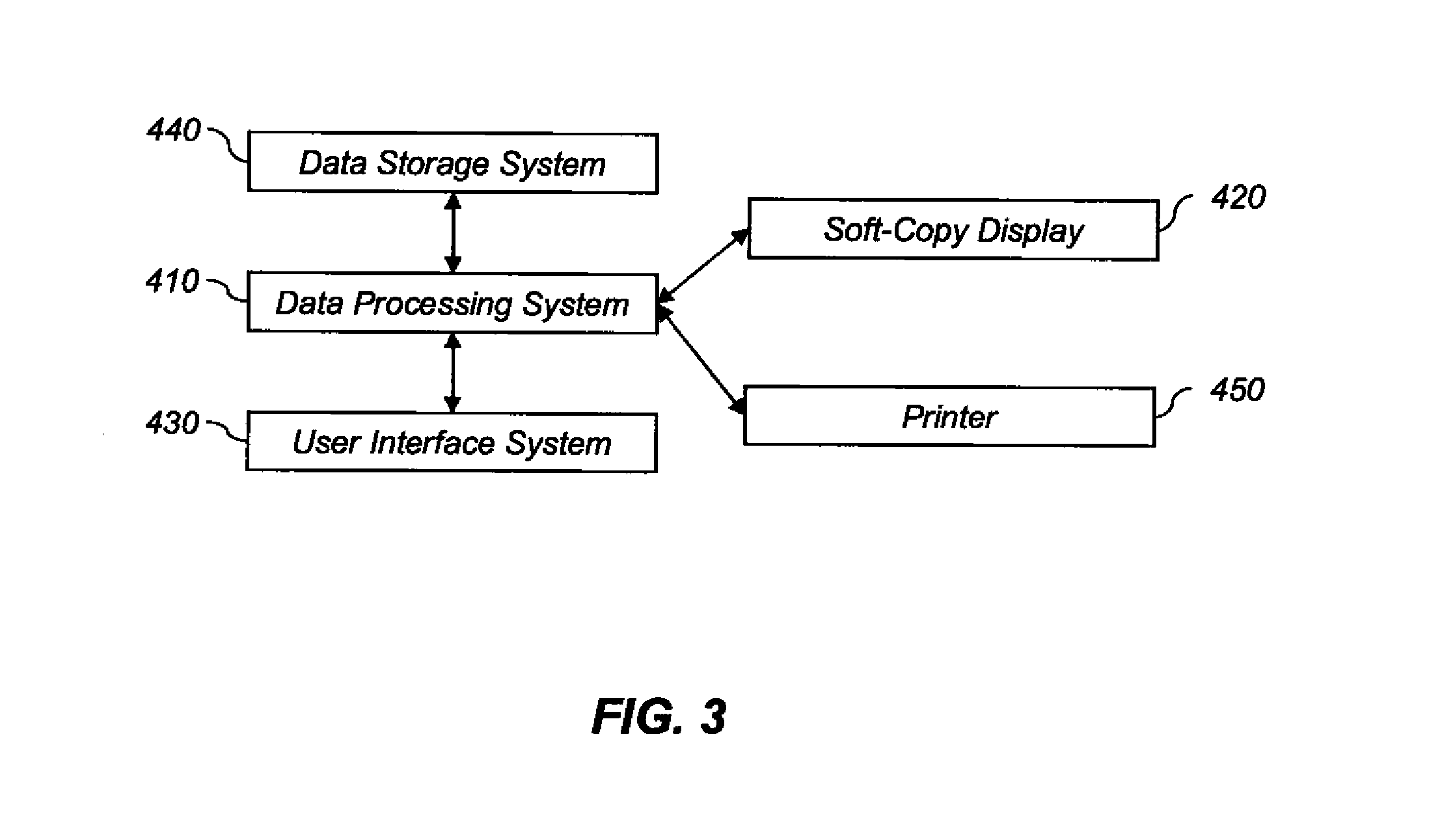

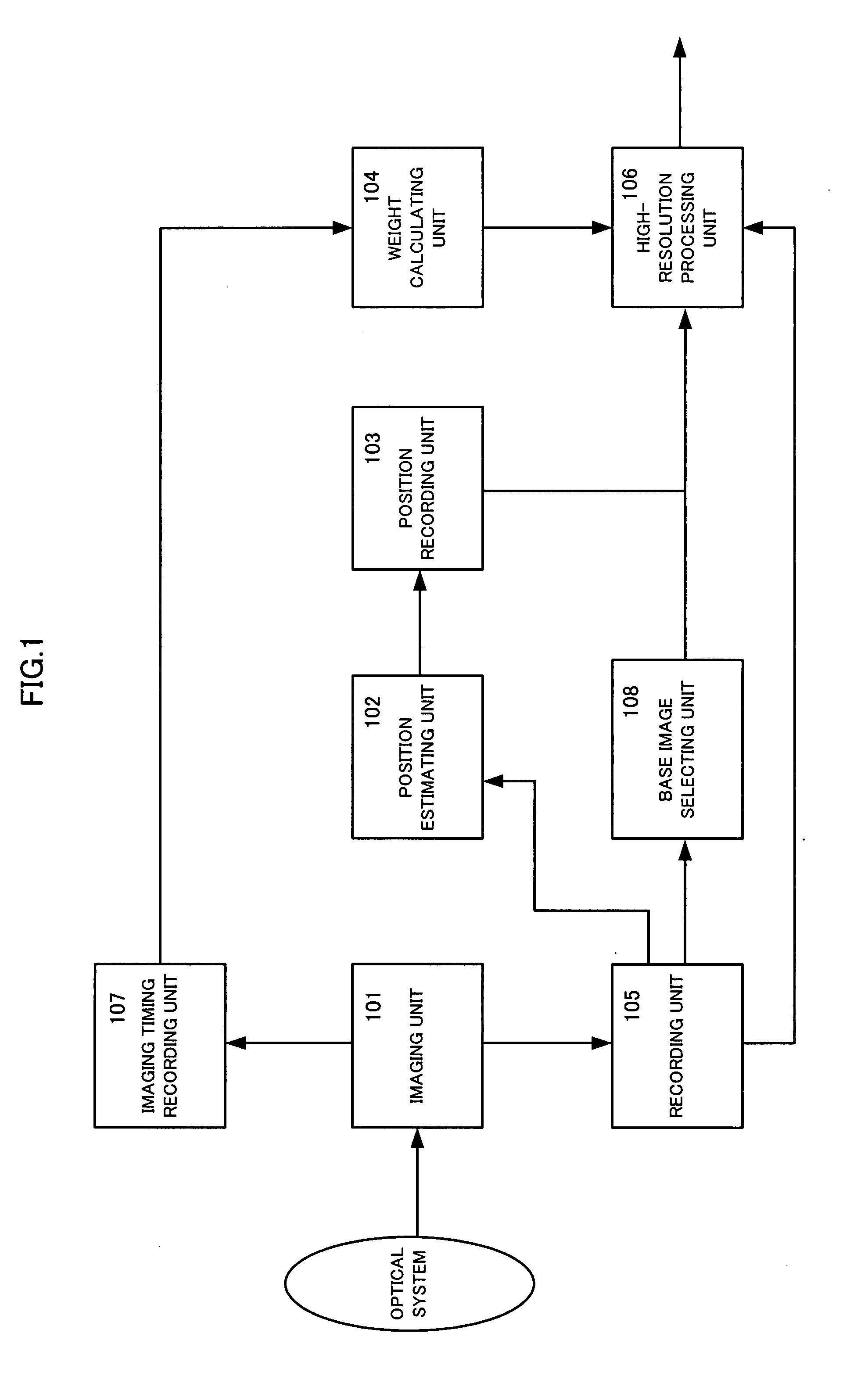

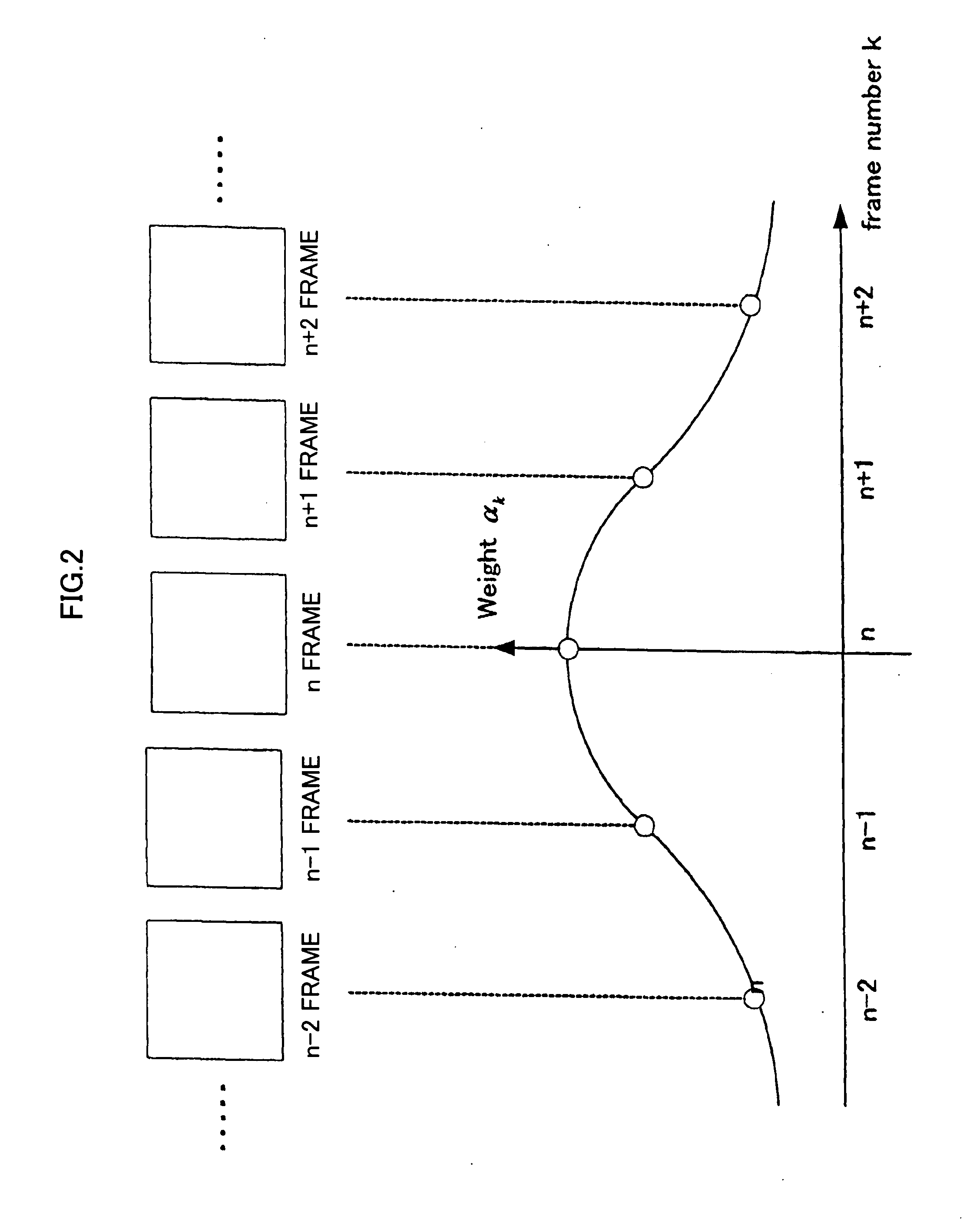

Imaging Device And High-Resolution Processing Method Of Image

InactiveUS20100253796A1Reduce impactAccurate imagingTelevision system detailsCharacter and pattern recognitionWeight coefficientImage resolution

The invention provides imaging device and high-resolution processing method of image which precisely generate high-resolution image by using image data with a little number of the pixels.An optical system images an optical image in an imaging unit (101), the imaged image is spatially discretized so as to sampled and converted into an image signal, thereby being recorded in a recording unit (105). Further, a timing at which the image is imaged by the imaging unit (101) is recorded in an imaging timing recording unit (107). A weight coefficient for imaged image is calculated by a weight calculating unit (104) by utilizing the timing information obtained by the imaging timing recording unit (107). A high-resolution processing unit (106) generates a high-resolution image by using the weighted information of the image generated by the weight calculating unit (104).

Owner:OLYMPUS CORP

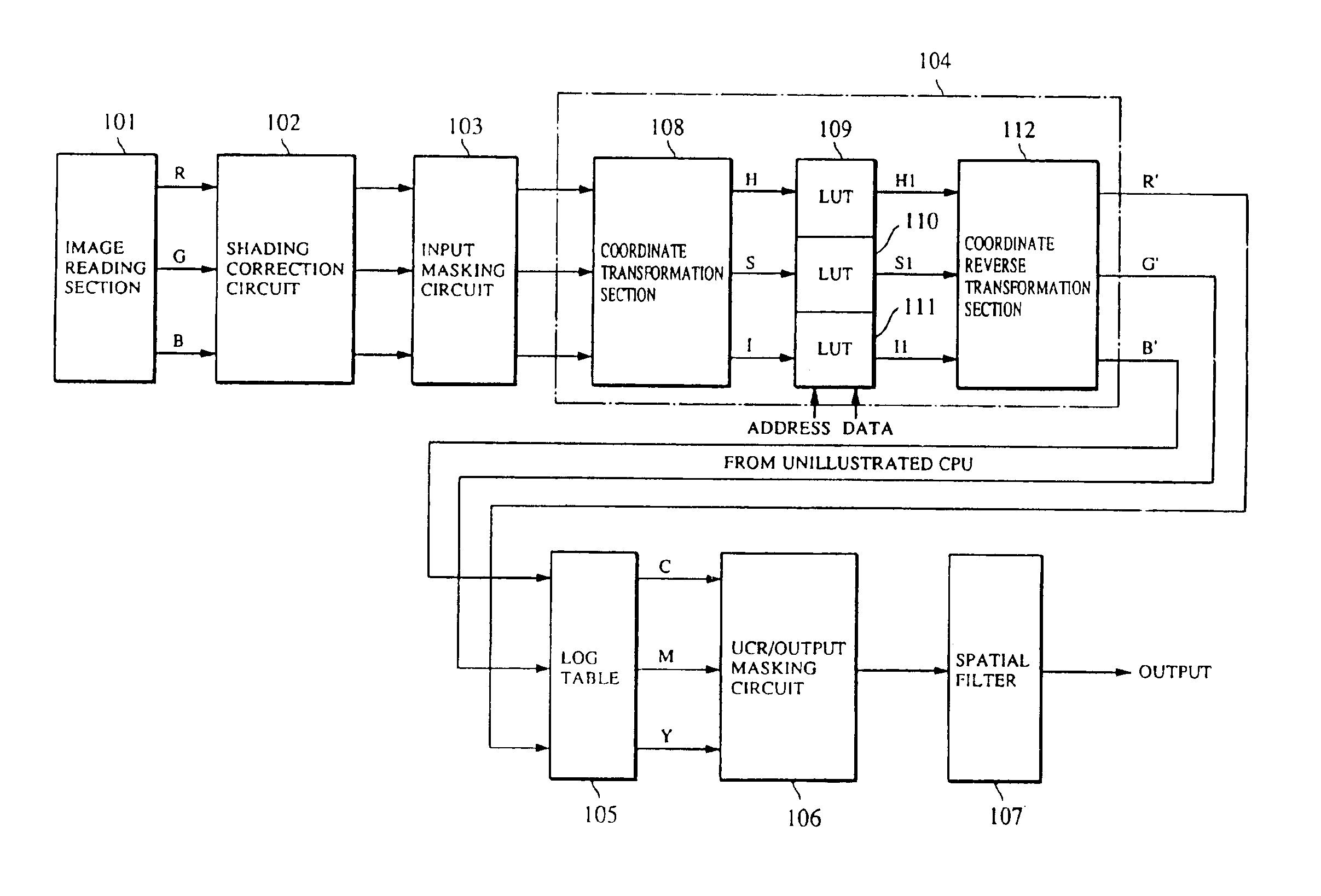

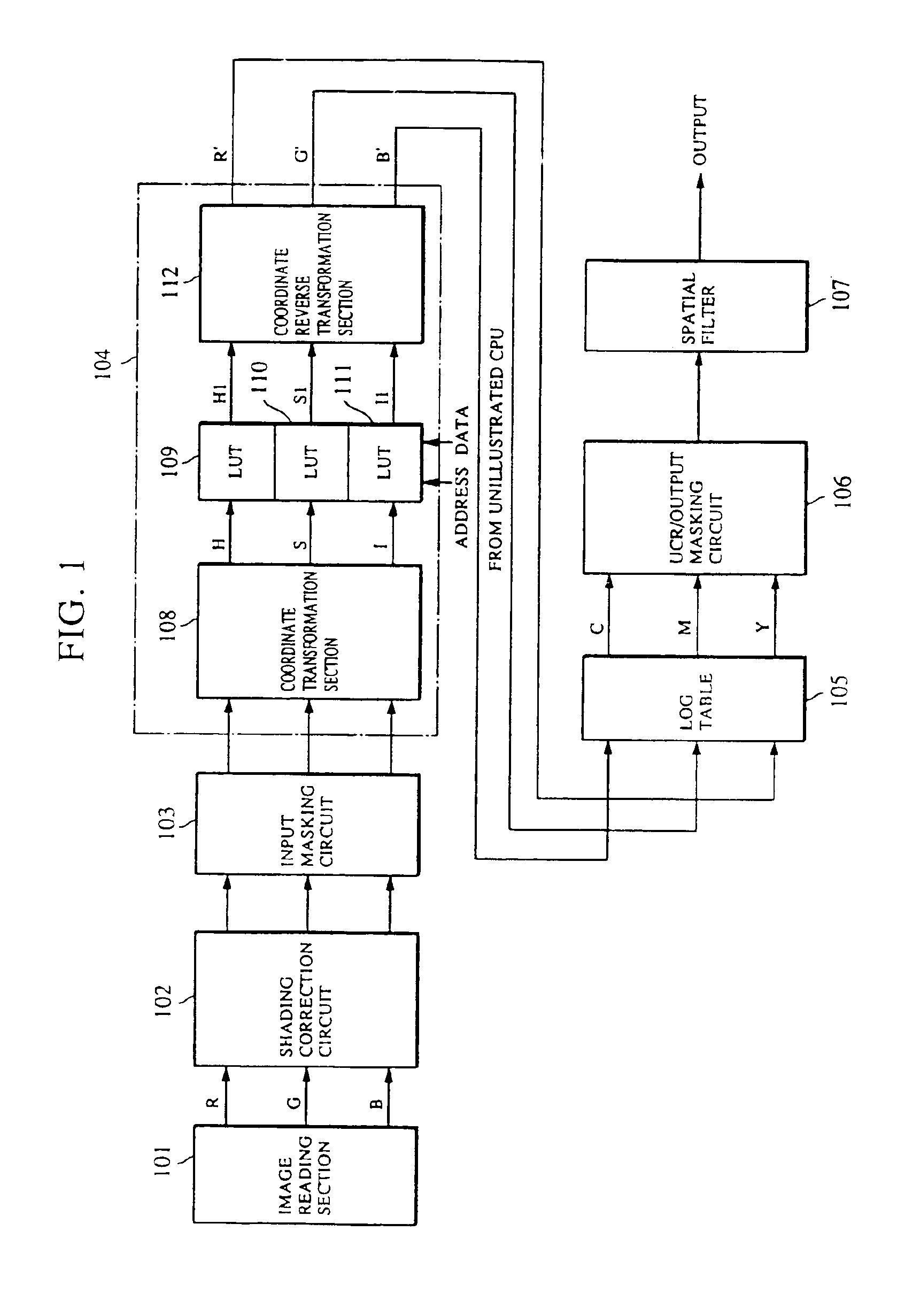

Image processing method and apparatus for converting colors in a color image

InactiveUS6927877B2Reduce circuit sizeEasy to operateDigitally marking record carriersDigital computer detailsColor imagePattern recognition

A color image signal is generated and an arbitrary color in the color image signal is set as a color to be converted. A color after conversion is designated. The color to be converted or a color similar to the color to be converted is converted into the color after conversion or a color similar to the color after conversion. By this processing, a color-converted image, in which a conversion boundary is unnoticeable, can be produced.

Owner:CANON KK

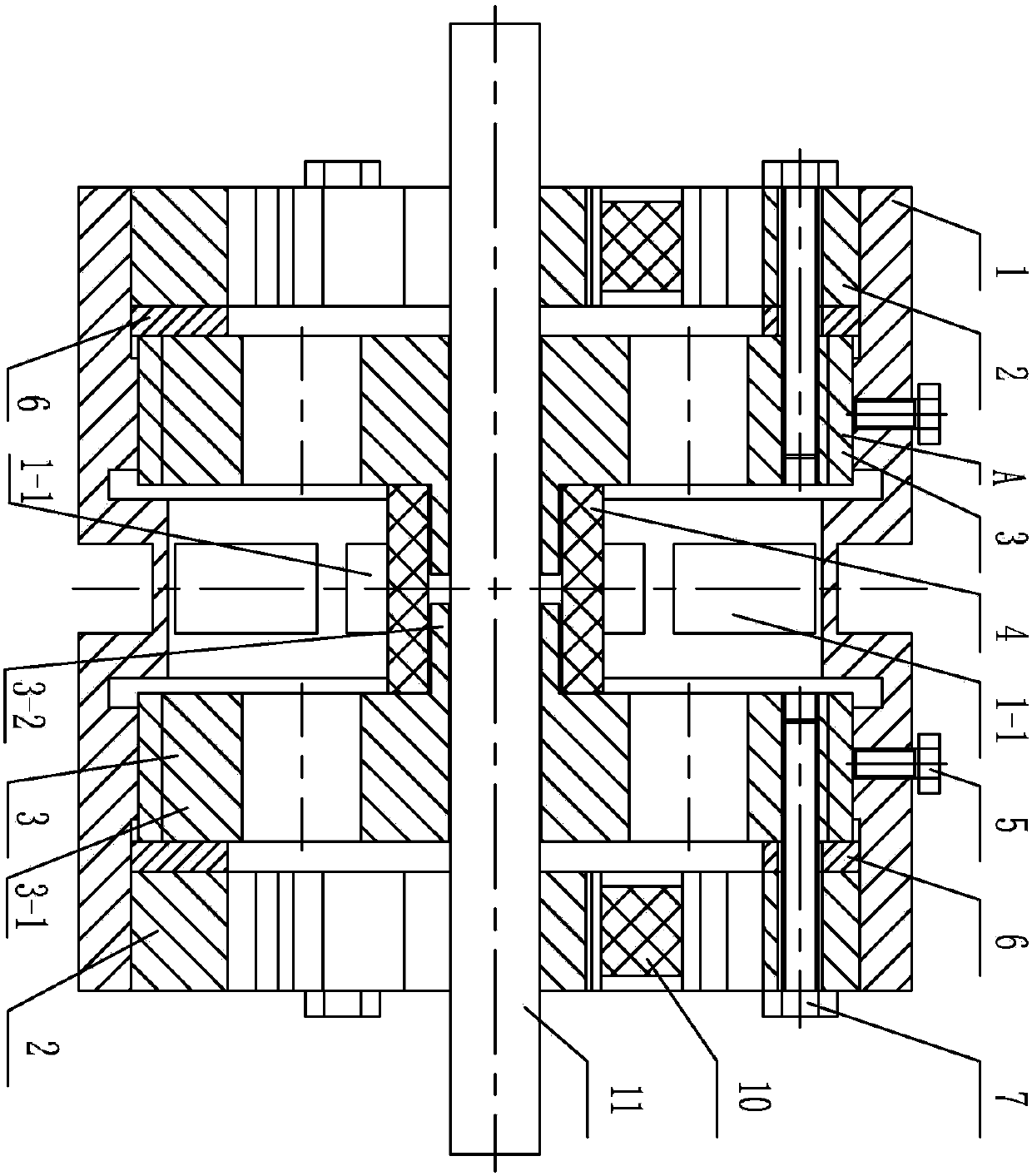

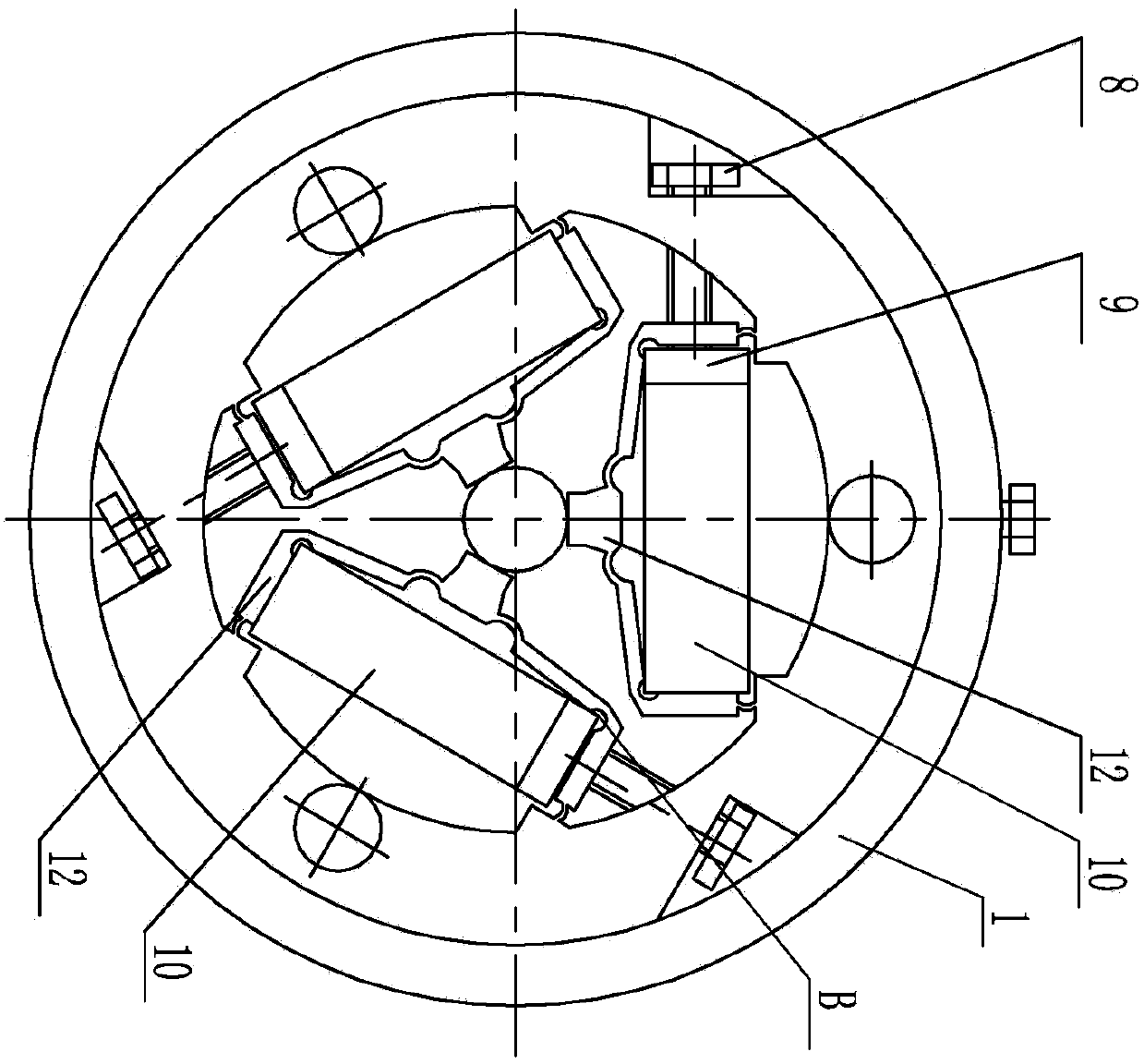

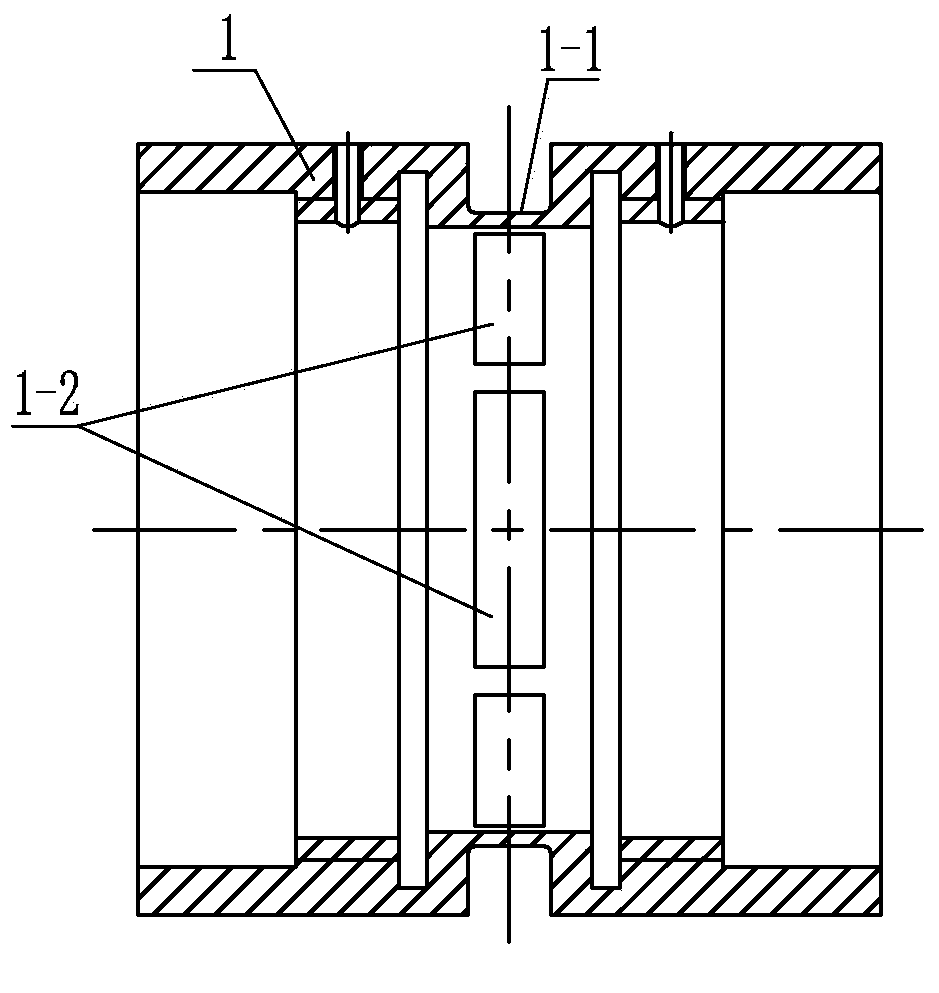

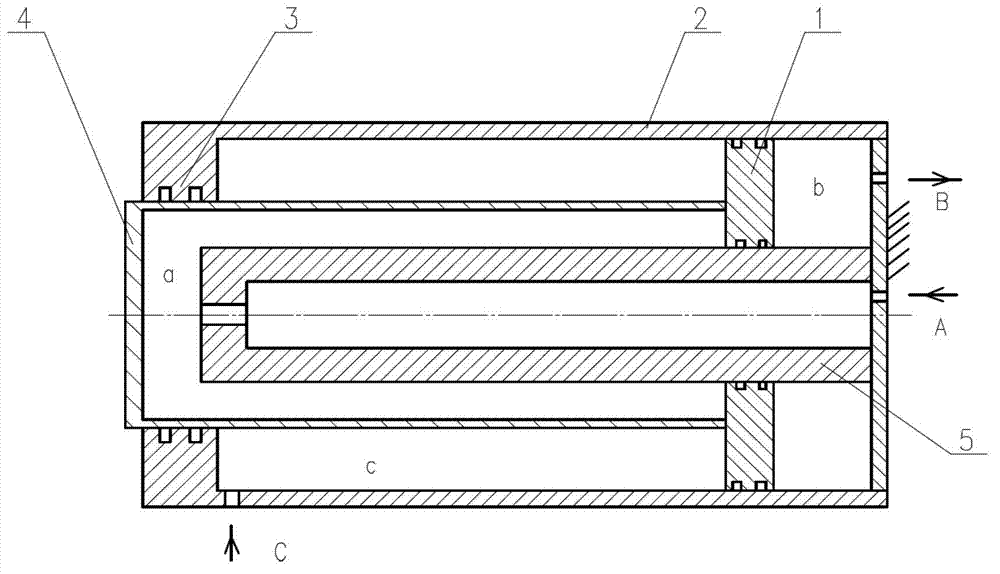

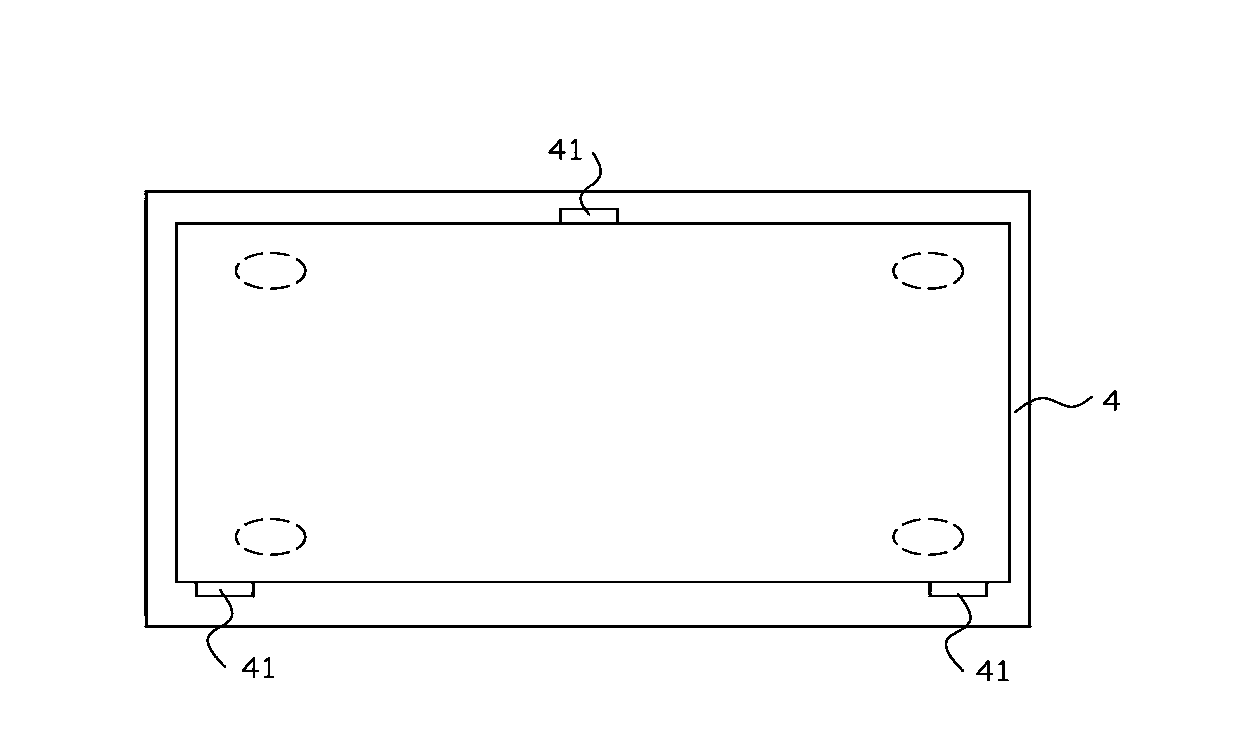

Cylindrical driven clamping type piezoelectric wriggle linear motor

ActiveCN103762887AReduce volumeReduce axial sizePiezoelectric/electrostriction/magnetostriction machinesEngineeringLinear motor

The invention relates to a piezoelectric drive device, in particular to a cylindrical driven clamping type piezoelectric wriggle linear motor to solve the problems that an existing drive clamping type wriggle motor cannot be powered off or self-locked and is not suitable for a compact, thin and long motion mechanism, and a driven clamping type wriggle motor is large in axial size and low in concentricity and control precision and needs an independent guide mechanism. The cylindrical driven clamping type piezoelectric wriggle linear motor comprises a guide rail, a drive mechanism, two annular gaskets and two sets of clamping mechanisms. The drive mechanism comprises a drive sleeve, a first piezoelectric stack and two clipping bodies. Each set of clamping mechanism comprises a clamping body, three second piezoelectric stacks and three flexible bodies. The middle of the drive sleeve is provided with the first piezoelectric stack, the clipping bodies, the gaskets and the clamping bodies are installed inside the drive sleeve from interior to exterior in a left-and-right symmetrical mode, the clipping bodies are in threaded connection with the drive sleeve, and the three flexible bodies are respectively and evenly distributed on the inner surfaces of the clamping bodies in the circumferential direction of the clamping bodies. The piezoelectric drive device is applied to the precise positioning and driving field.

Owner:HARBIN INST OF TECH

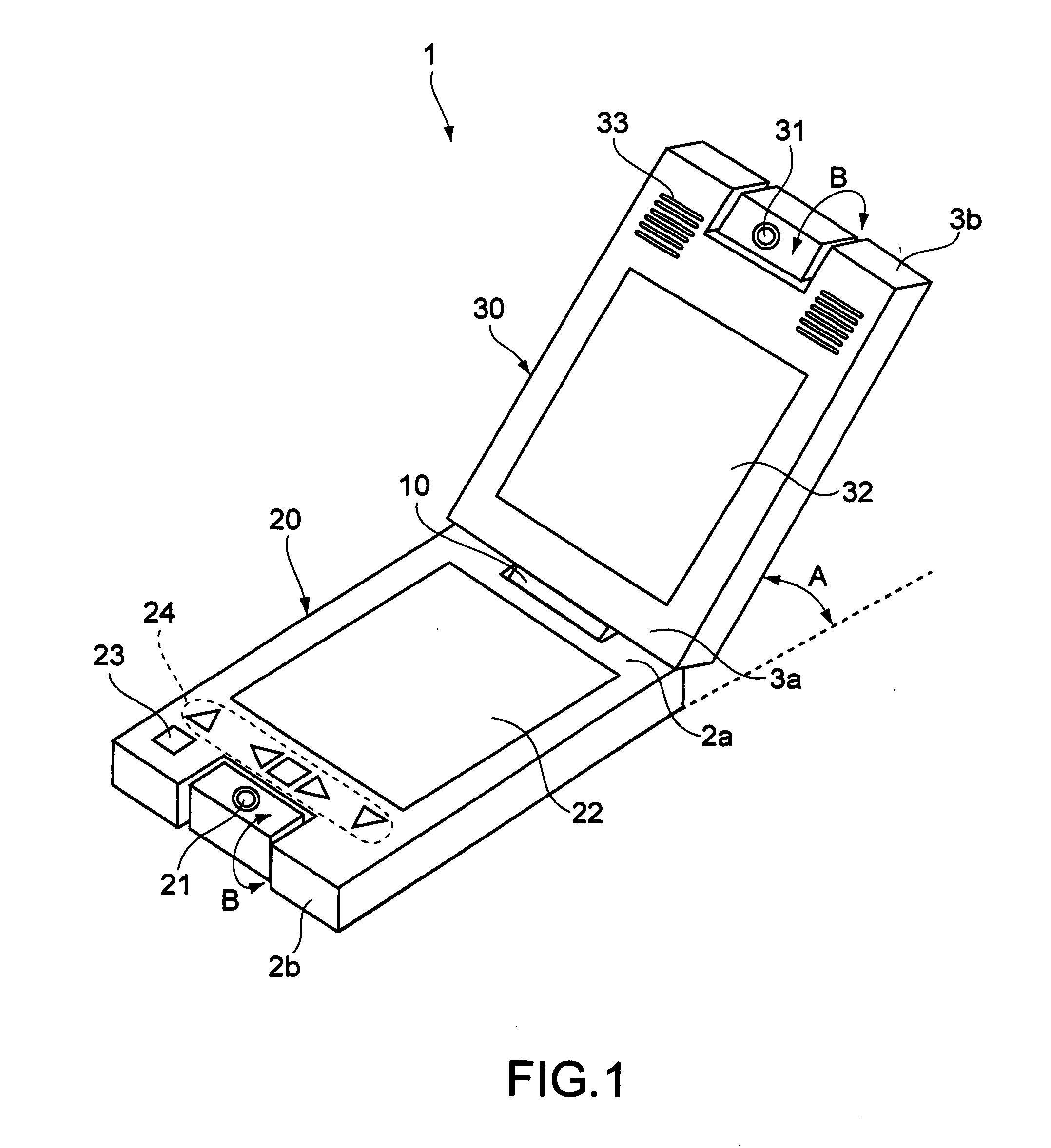

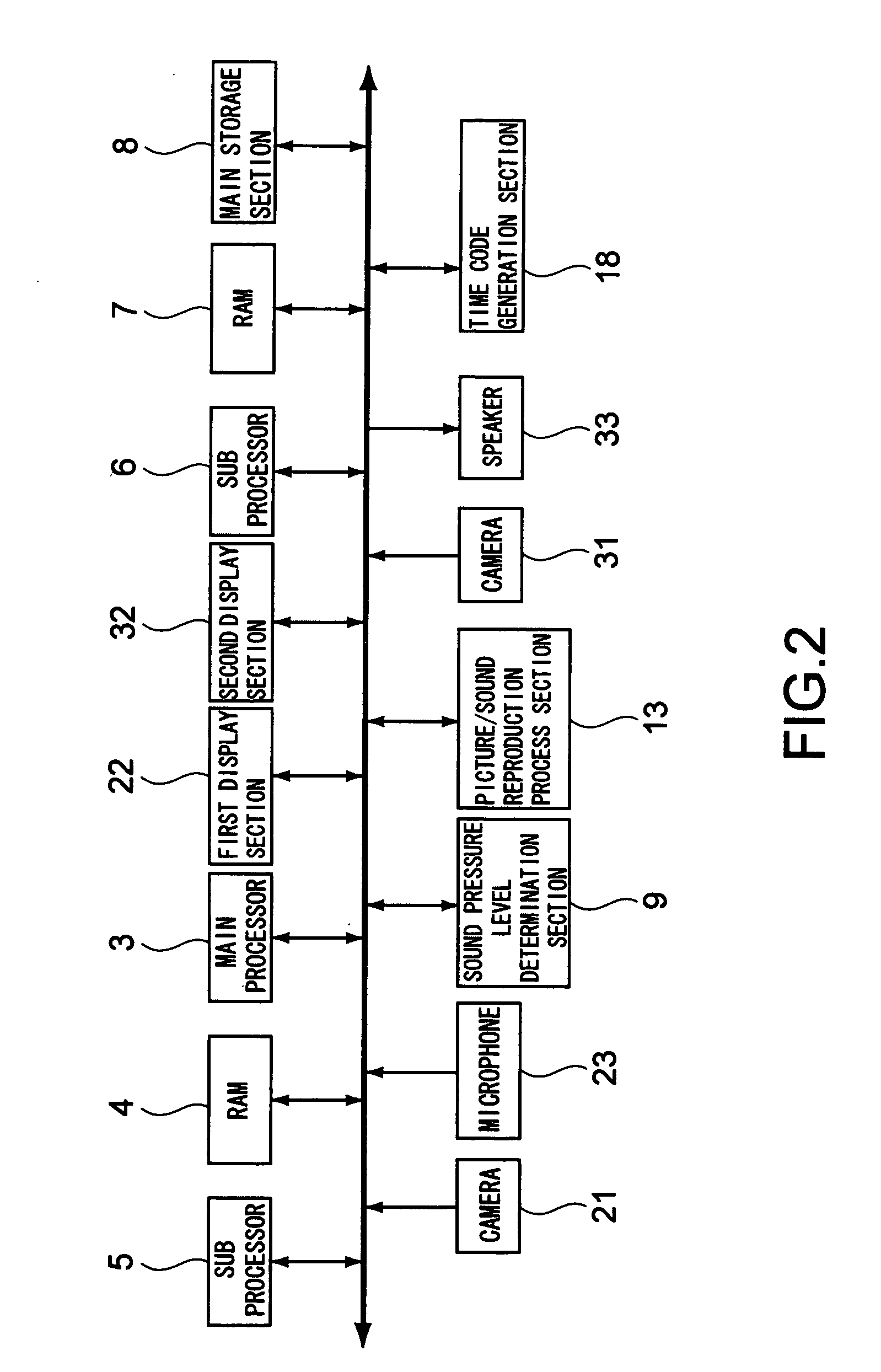

Conversation assisting device and conversation assisting method

InactiveUS7702506B2Smooth conversionSubstation equipmentSpeech recognitionHuman–computer interactionAssistive device

Owner:YOSHIMINE TAKASHI

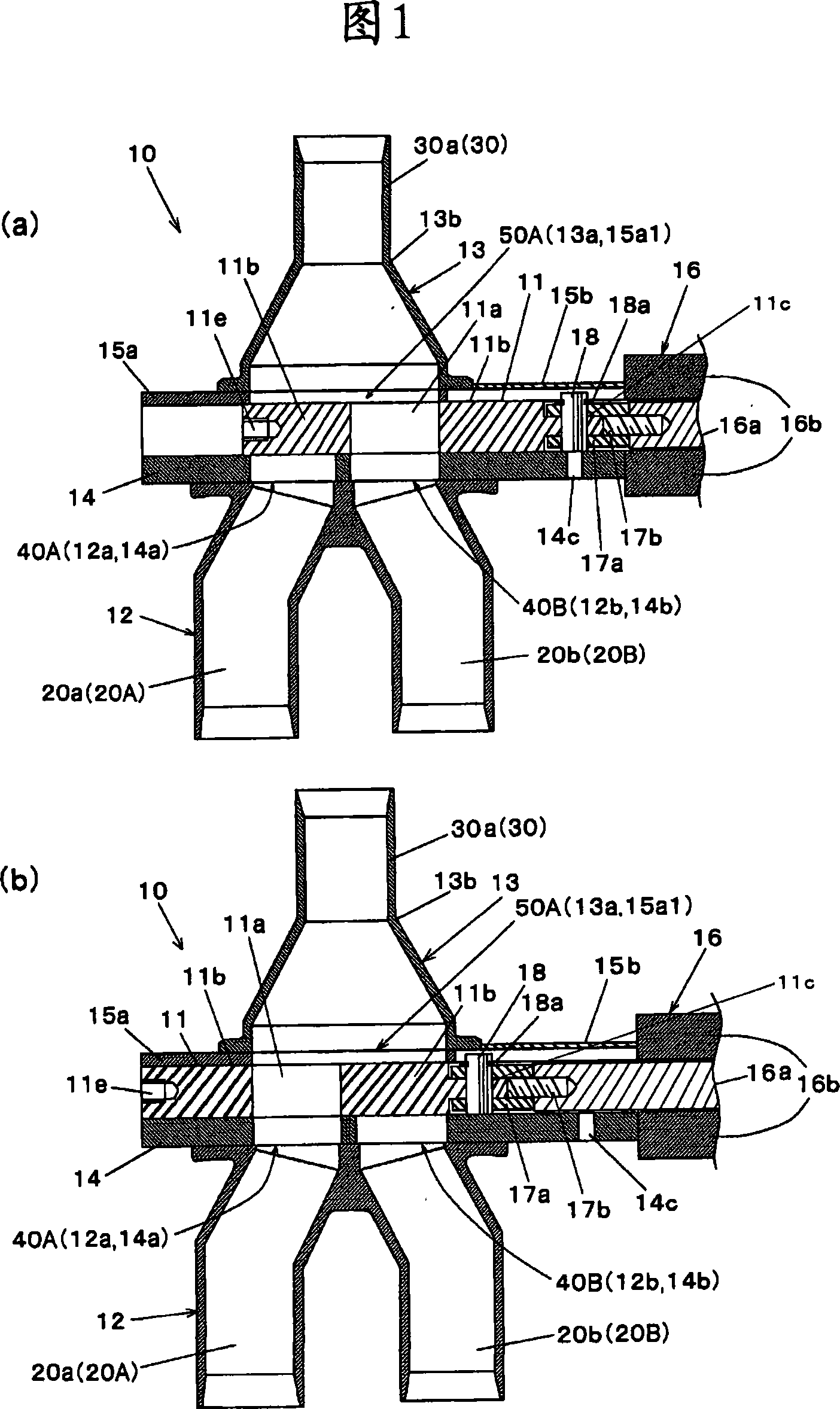

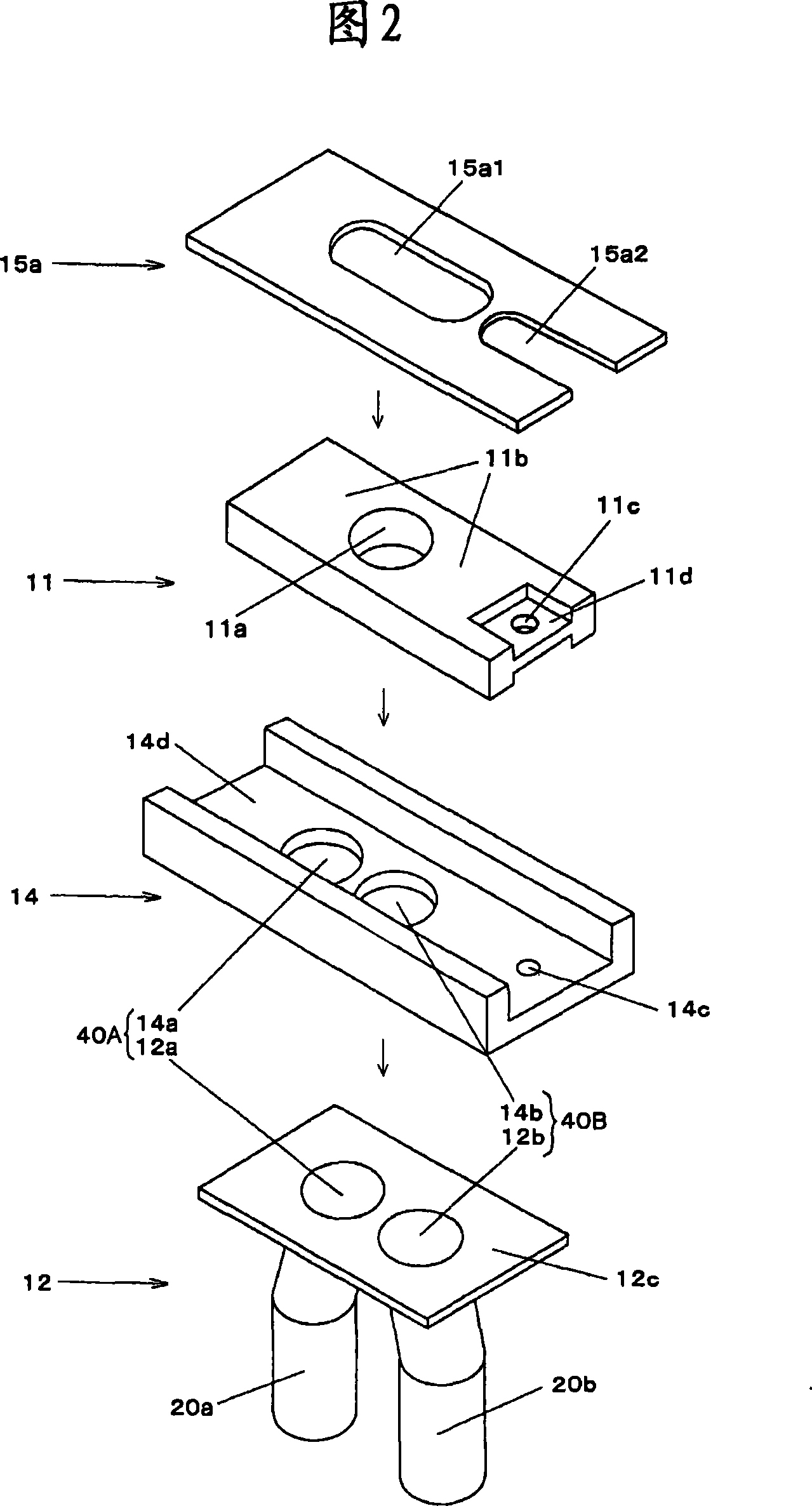

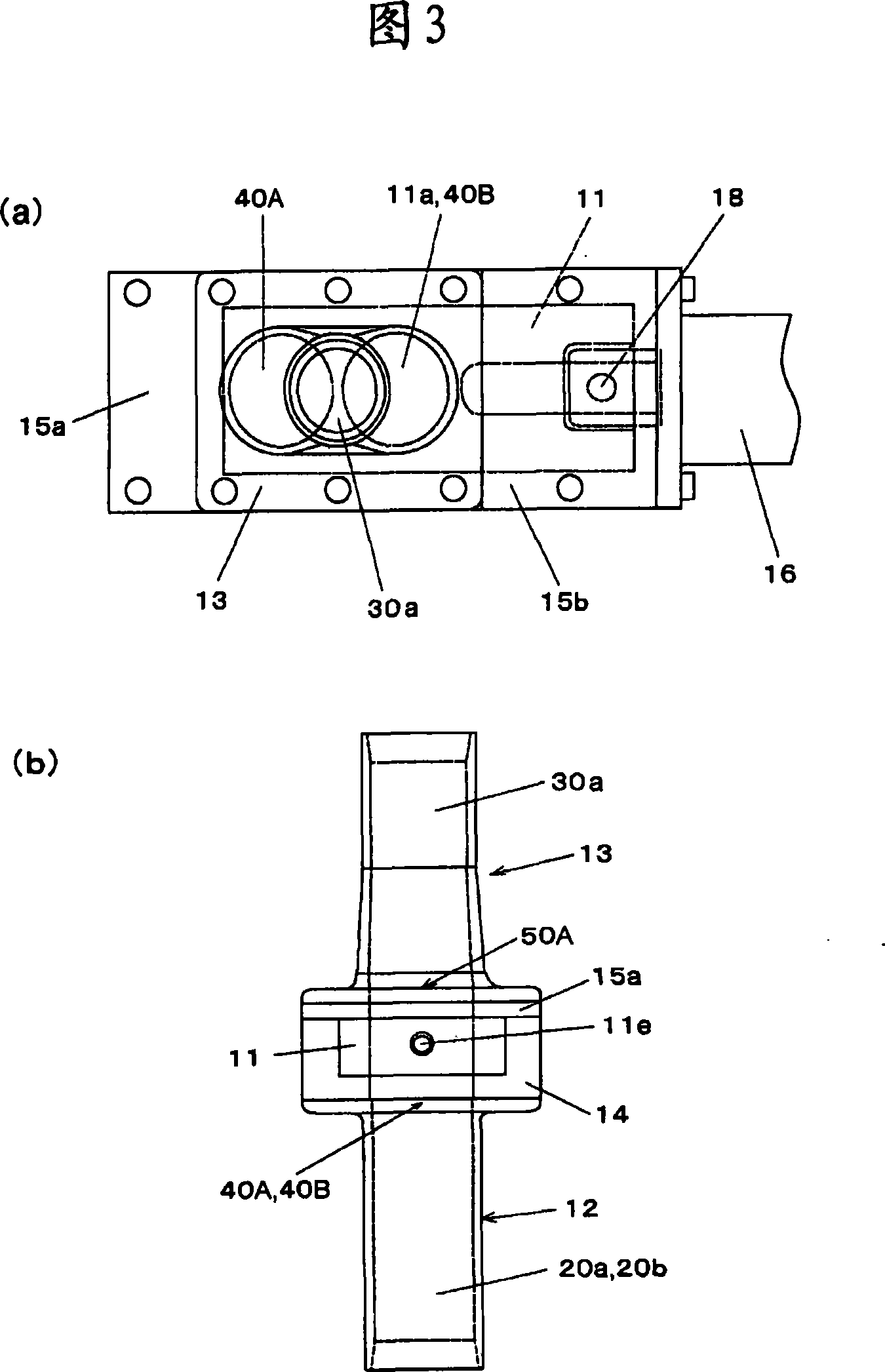

Switching device

InactiveCN101081663ASmooth conversionIncrease costMultiple way valvesBulk conveyorsAir transportBody size

The invention provides a switching device for reducing the air break resulted from powder particle entering into body box and change-over valve without maximizing the device and increasing the price. The invention comprises: body box (14.15a), two upstream side peristomes (40A.40B), downstream side peristome (50A), shift-type tabular change-over valve (11) for switching the two upstream side peristomes and driving mechanism (16) for driving the shift-type tabular change-over valve. The shift-type tabular change-over valve is equipped with two occlusive parts (11b.11b) and body size hole (11a) in the middle along the shifting direction and shifts along the direction approximately perpendicular with air transport channel(20A.20B.30) using the driving mechanism. When one side of the upstream side peristome is obturated using any occlusive part, the body size hole will integrate with the other side of the upstream side peristome to make the air transport channel connected with the peristome connect with the air transport channel of the downstream side.

Owner:MATSUI MFG +1

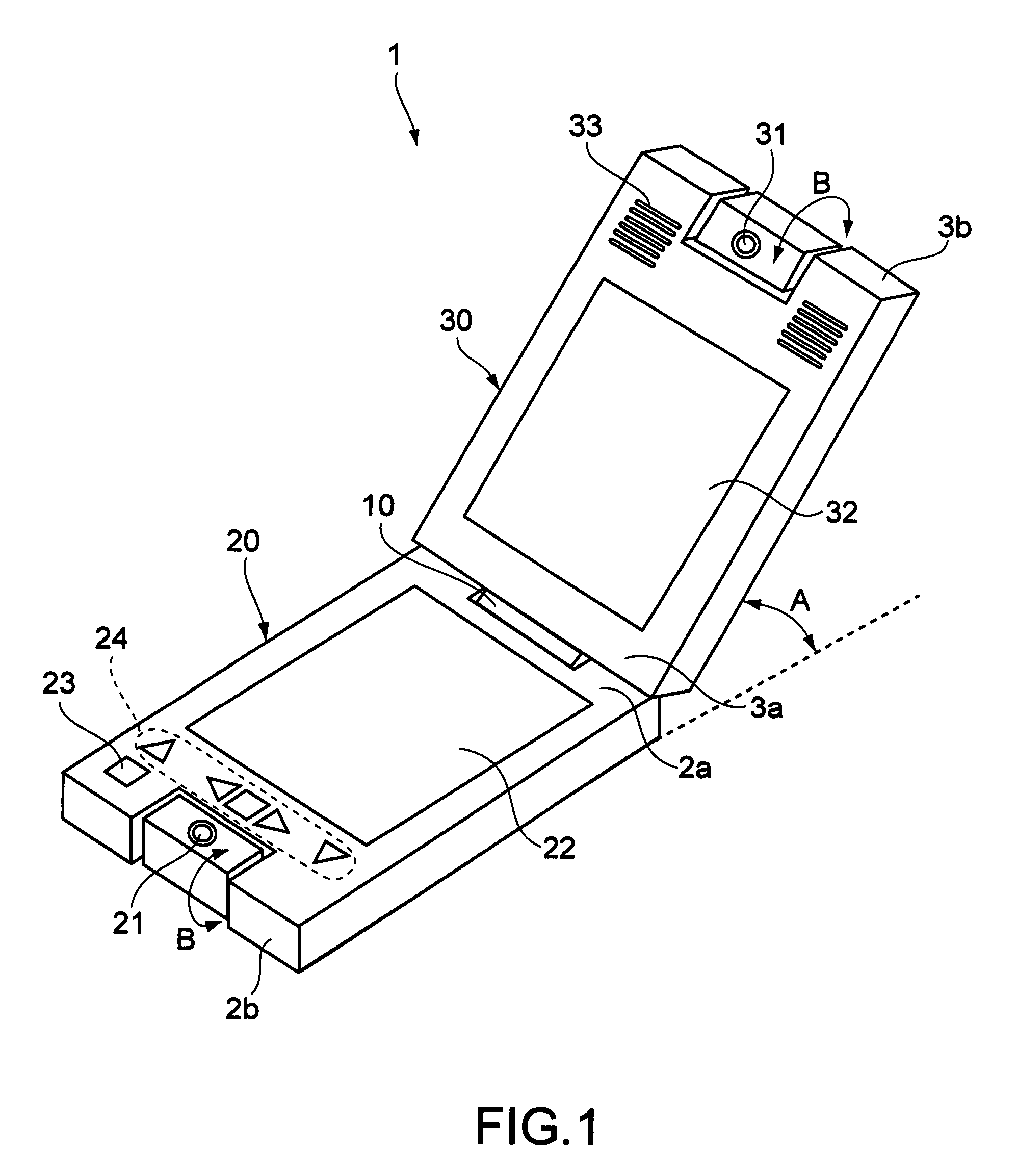

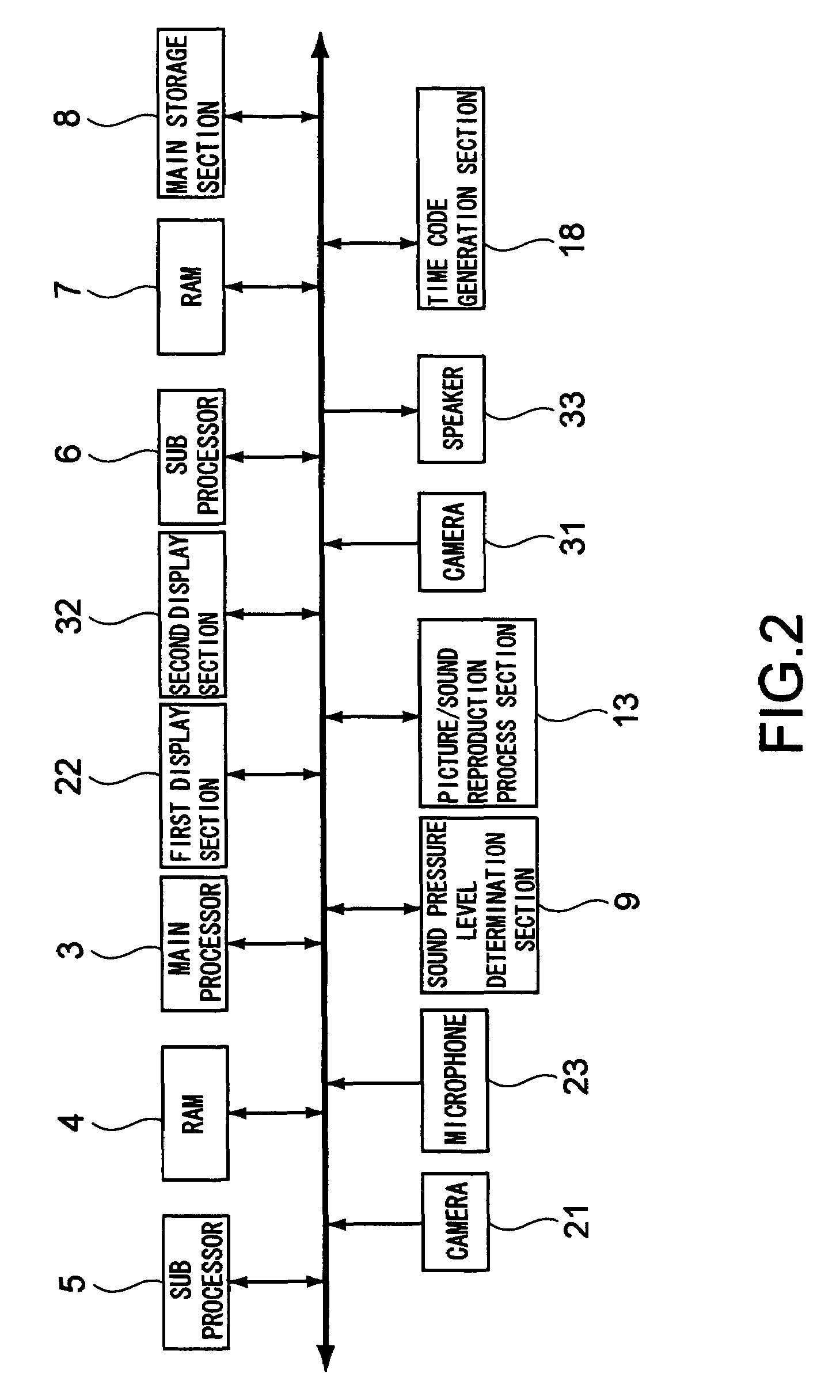

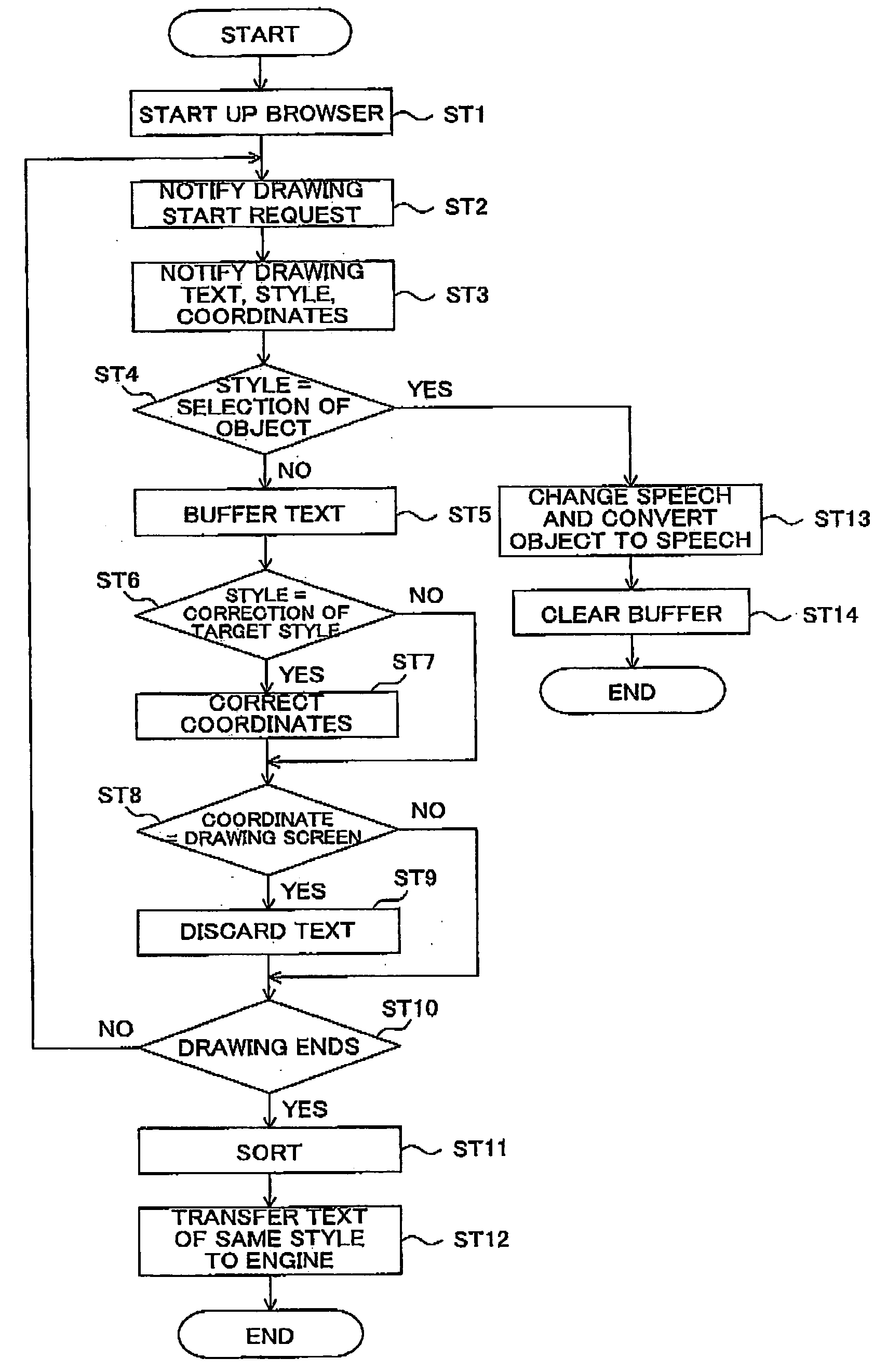

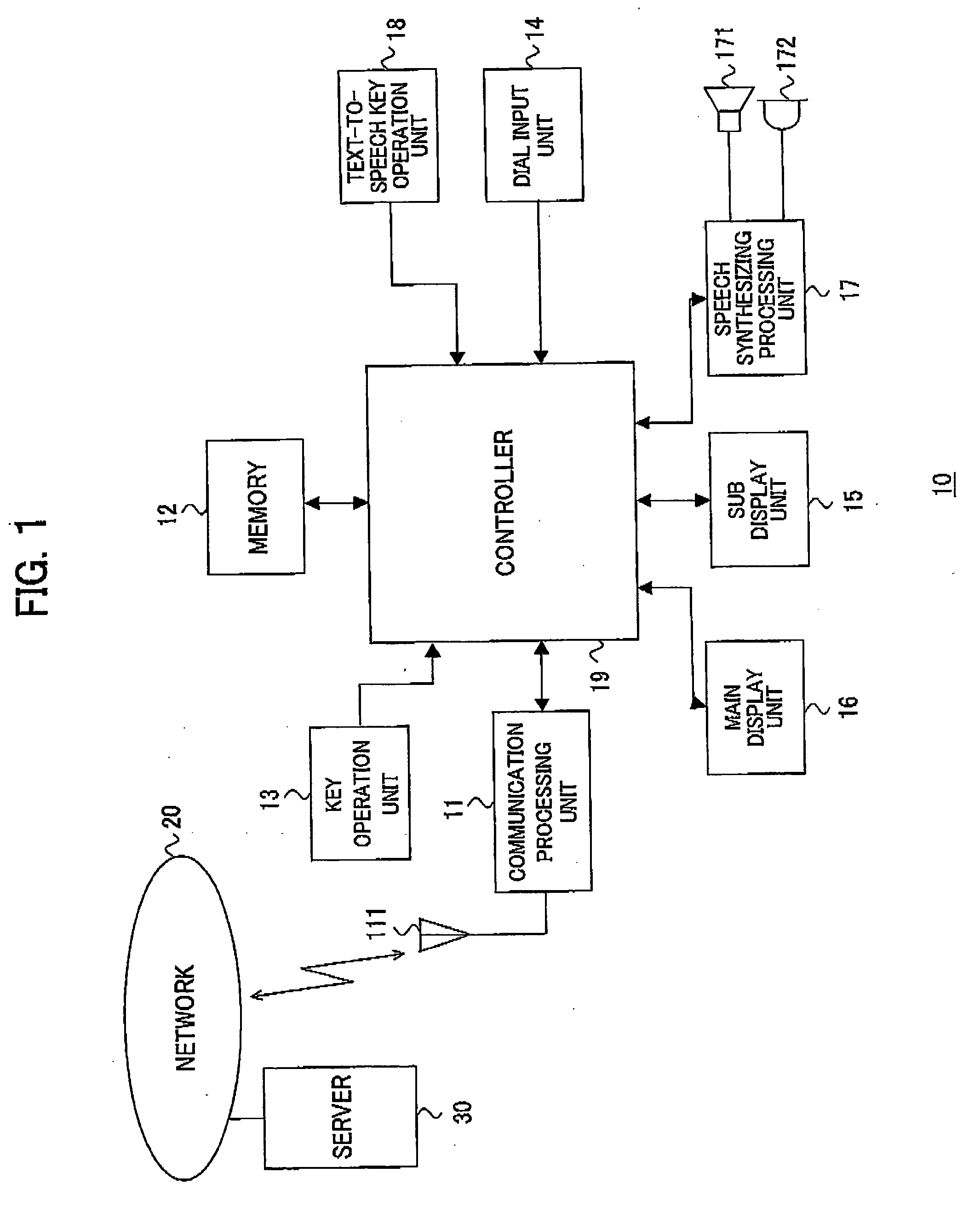

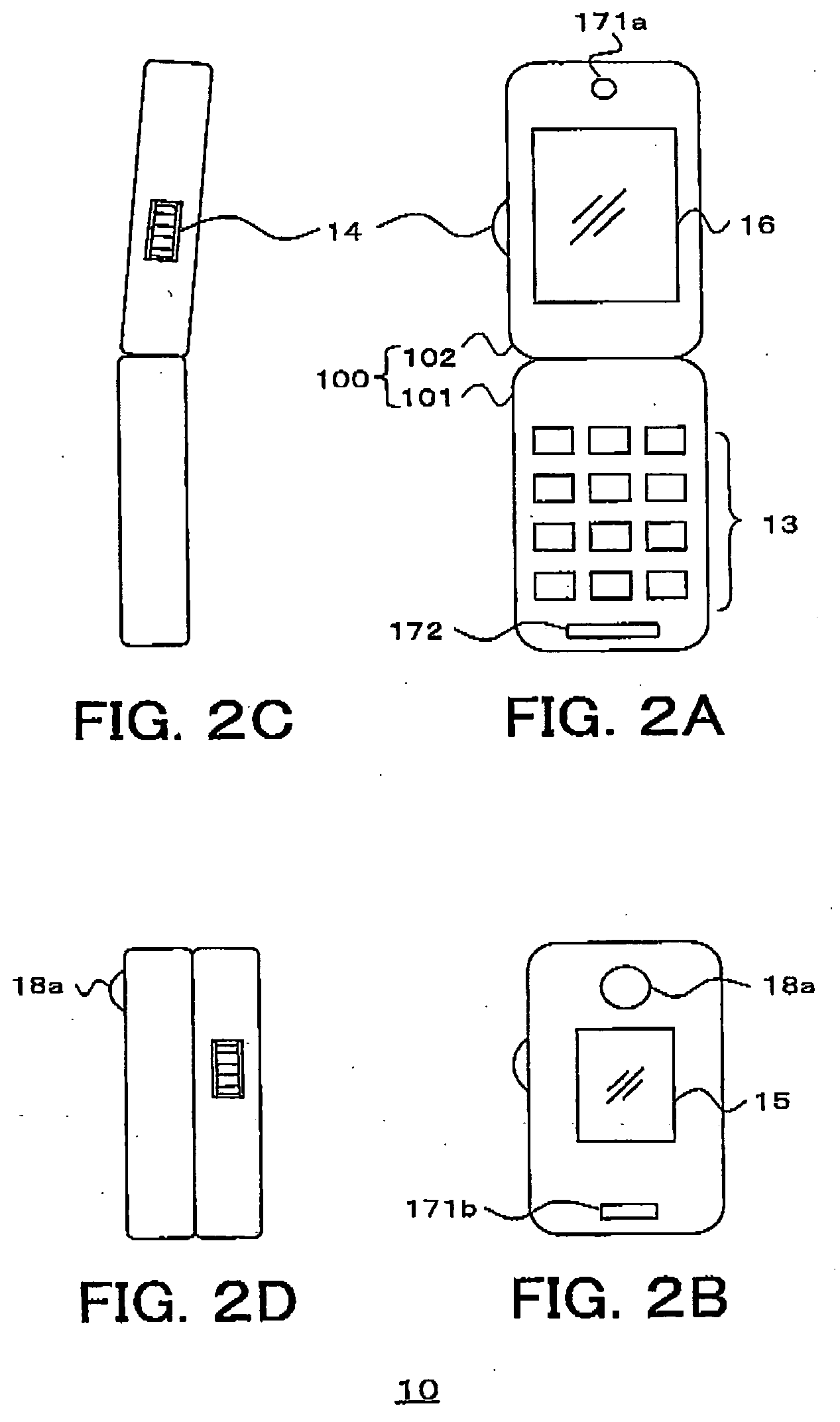

Mobile terminal and text-to-speech method of same

InactiveUS20060161426A1Smooth conversionSmooth text-to-speech conversionDevices with multiple display unitsSubstation equipmentComputer hardwareCommunication unit

A mobile terminal able to achieve smooth text-to-speech conversion, that is, a mobile terminal able to display on a display unit information acquired from a server connected to a network by a communication unit, comprising a storage unit; a speech synthesizer for converting text to speech; and a controller for extracting from the acquired information display objects and display rules defined by the server providing the display objects, storing the display objects and the display rules in the storage unit linked with each other, and displaying the same on the display unit according to the display rules, wherein when start-up of the speech synthesizer is requested in the state displaying the acquired information, the controller controls so that the speech synthesizer converts the text extracted from the display objects to speech with reference to the display rules stored in the storage unit; and a text-to-speech method of the same.

Owner:KYOCERA CORP

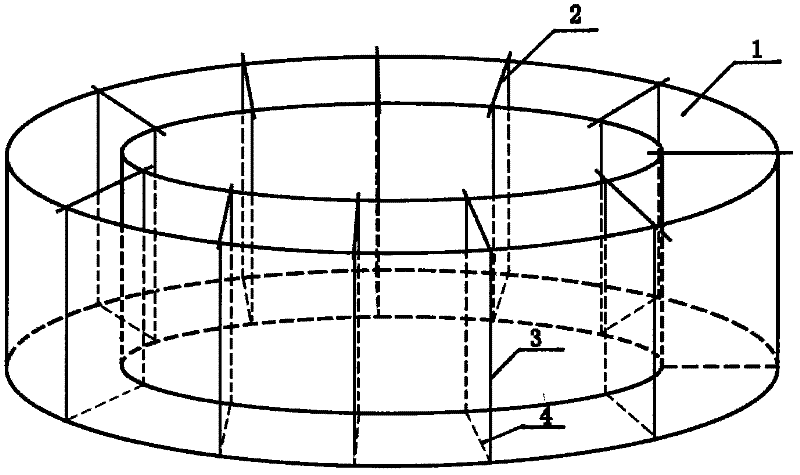

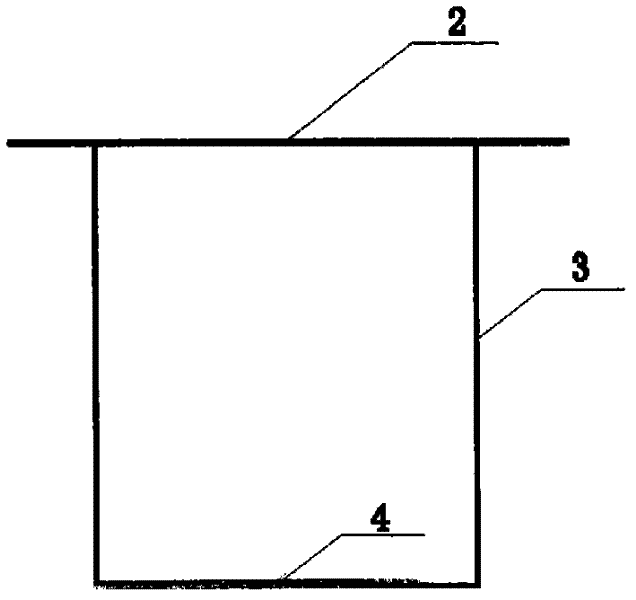

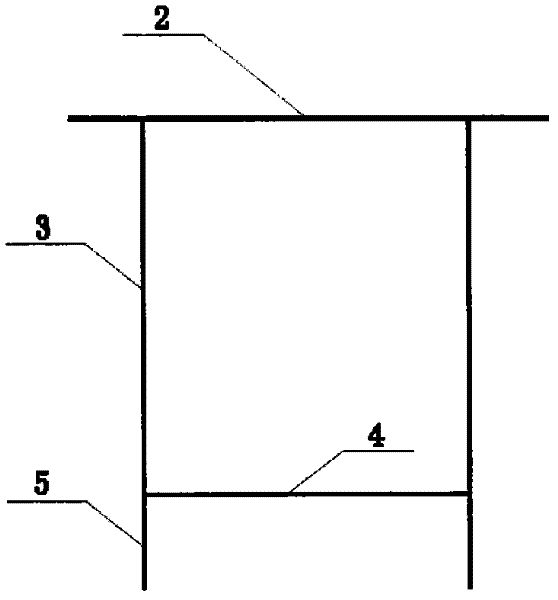

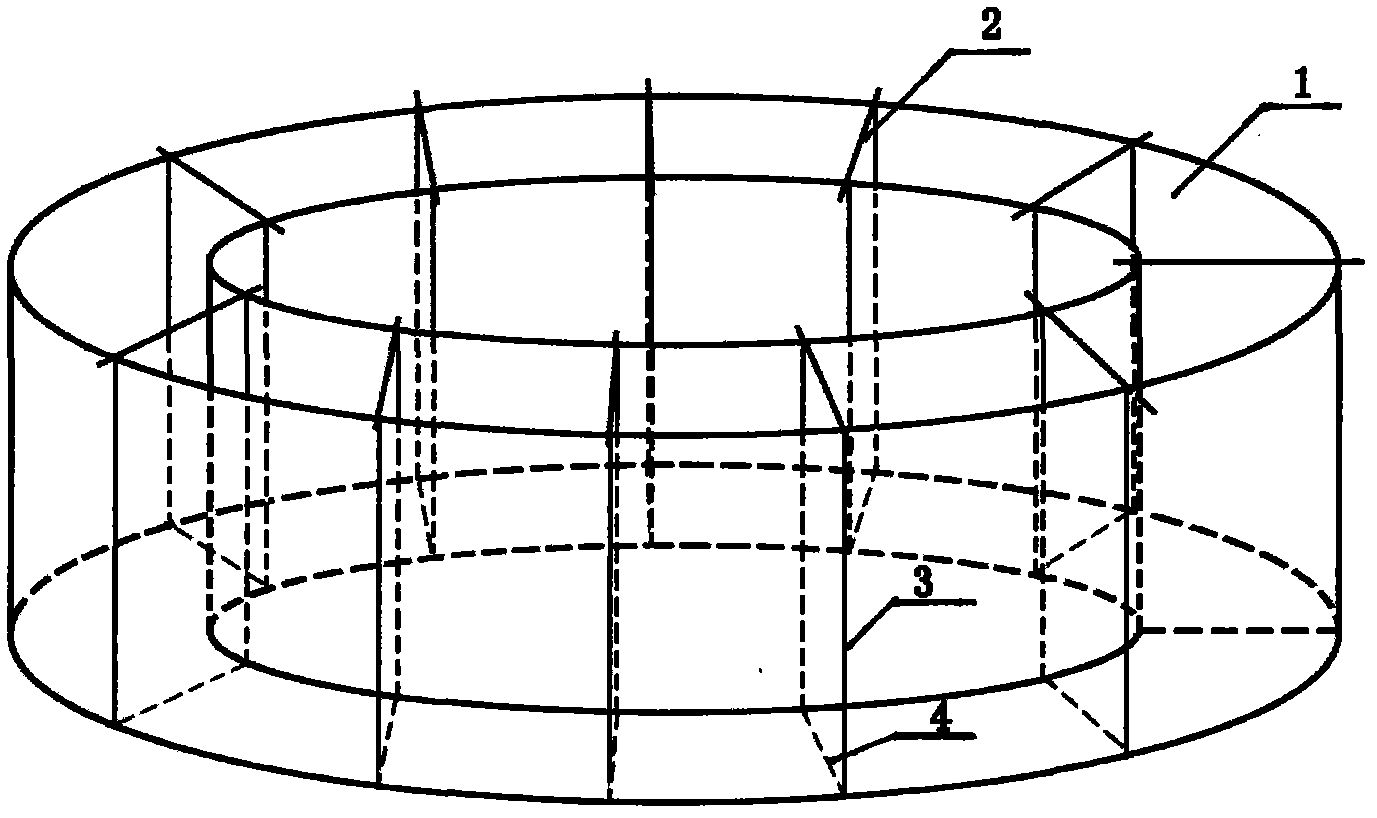

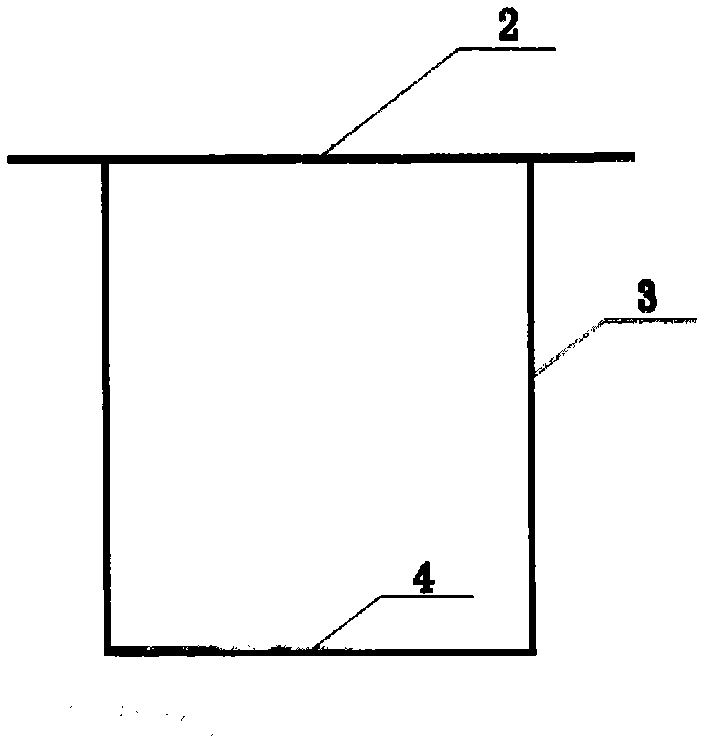

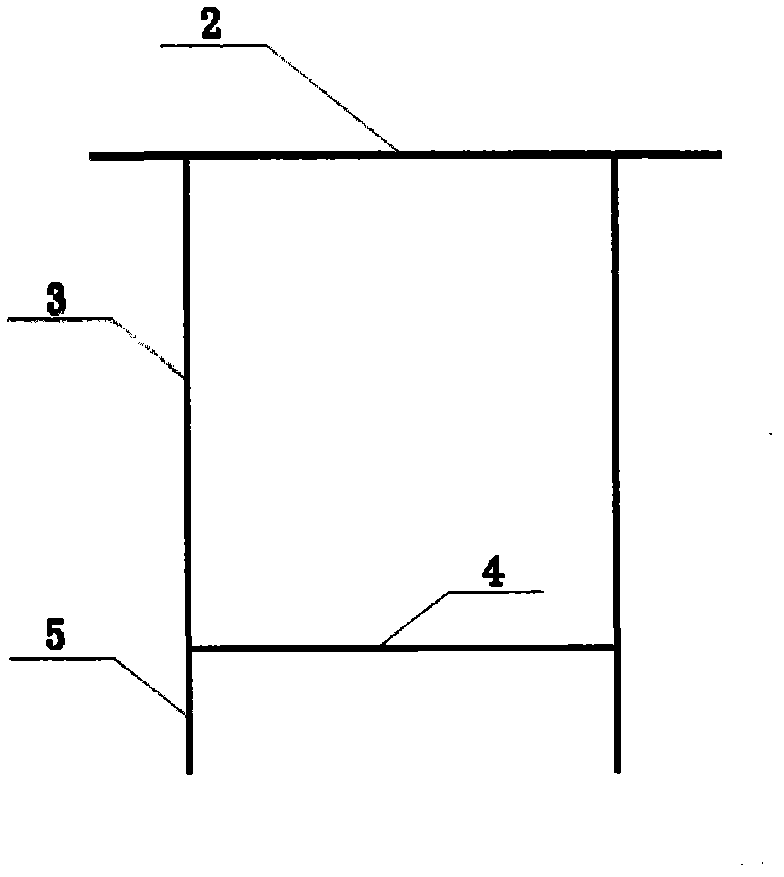

Ring-duct net cage for breeding of oriental weatherfish

InactiveCN102379256AEvenly distributedGuaranteed oxygen supplyClimate change adaptationPisciculture and aquariaWeatherfishAphrodisiac

The invention belongs to the technical field of aquaculture, in particular to the technique enabling weatherfish to reproduce and lay eggs in a net cage disposed in a hatching ring duct and leads fertilized eggs to fall into the hatching ring duct from the net cage to be hatched directly in the hatching ring duct. A large net cage or a plurality of independent large net cages are disposed in the hatching ring duct to serve as a place for aphrodisiac injected parent weatherfish to mate and lay eggs, the net cages are removed while the parent weatherfish having laid eggs are removed after eggs are laid, and the eggs fall into the ring duct from meshes prior to directly being hatched. The large net cages of the hatching ring duct can effectively prevent the parent weatherfish from eating the eggs, the parent weatherfish is not easy to be hurt, loss of the eggs is low, and breeding effect is better. The method omits the egg transferring process, so that labor intensity is reduced greatly, and work efficiency is improved.

Owner:ANHUI SCI & TECH UNIV

Low-flow fast movable cylinder

InactiveCN102788061ASolve matching problemsSolve the problem of mutual conversionFluid-pressure actuatorsPiston rodPlunger

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI +1

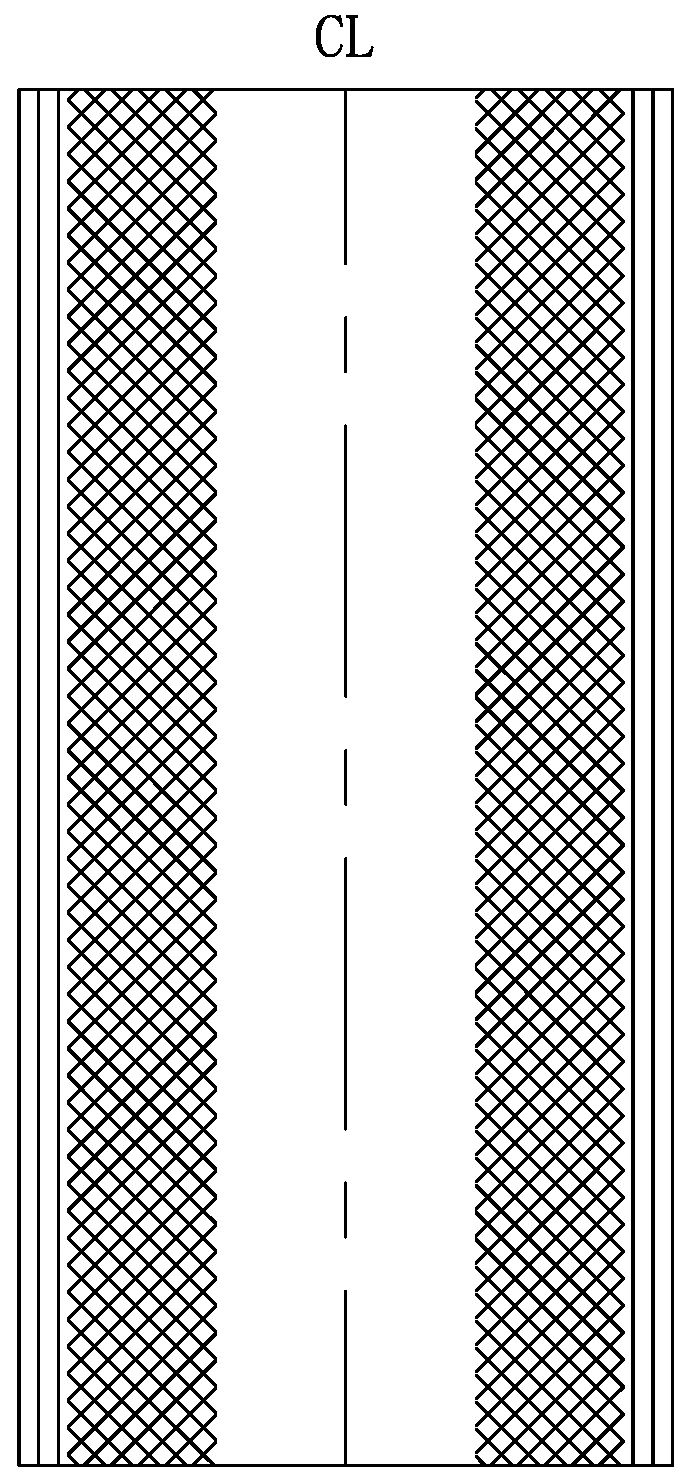

Double-side jacquard velvet with plain color shadows and weaving method of double-side jacquard velvet

InactiveCN105755649AMaintain the original ecological characteristicsCreate pollutionWoven fabricsPulp and paper industryWeft yarn

The invention discloses a double-side jacquard velvet with plain color shadows. The double-side jacquard velvet comprises a piece of base cloth, wherein a front leaning pile region, a rear leaning pile region and an erecting pile region form a velvet fabric with plain color shade patterns on two sides of the base cloth, the base cloth is formed by weaving of stretched warp yarns, loose warp yarns and base cloth weft yarns, and the stretched warp yarns and the loose warp yarns are woven in a matching manner, so that every three base cloth weft yarns form a group in a warp yarn direction, and each group of the base cloth weft yarns and the plane of the base cloth are arrayed in the shape of an arrow towards the bottom right, top right or right, the velvet warp yarns are fixedly connected to three base cloth weft yarns in each group in a W shape, and through velvet cutting, weft pulling and rear finishing, front leaning piles, or rear leaning piles or erecting piles are formed. The double-side jacquard velvet with the plain color shadow does not need dyeing treatment or thermoplastic treatment, shadow patterns can be formed on the two sides of the velvet, environment pollution cannot be generated in the production process, and besides, the velvet without chemical dyeing treatment maintains the original ecology characteristics of the velvet to the maximum extent. The invention further discloses a weaving method of the double-side jacquard velvet with the plain color shadow.

Owner:LIAONING CAIYI WILD SILK PROD

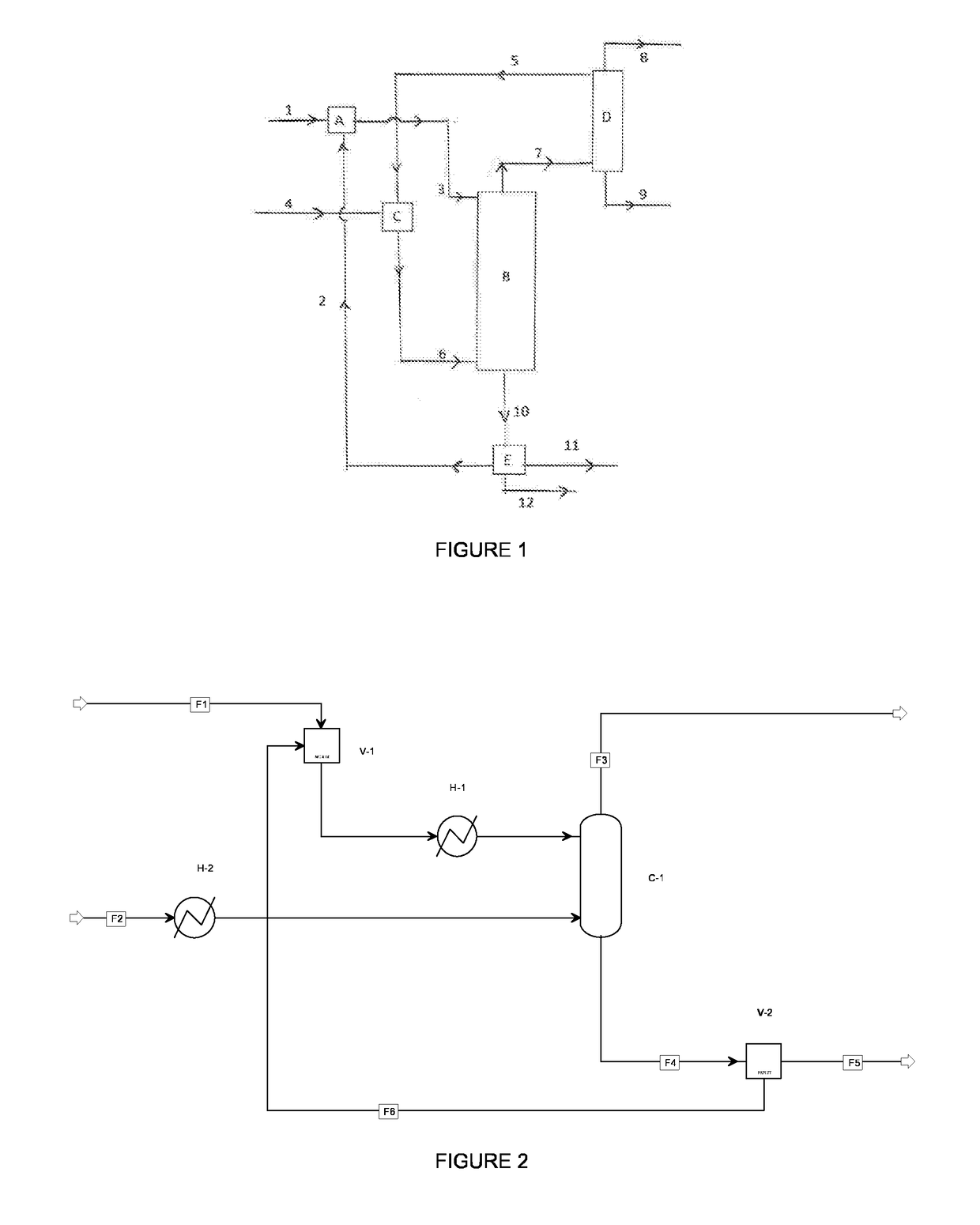

Preparation of dialkyl esters of 2,5-furandicarboxylic acid

ActiveUS20170313670A1Easy to separateKeep energy smallOrganic chemistryReaction zoneEsterification reaction

Dialkyl esters of 2,5-furandicarboxylic acid are prepared from a 2,5-furandicarboxylic acid-containing starting material in a process, which includes: contacting a vaporous stream of an alkanol countercurrently with the at least partially liquid starting material having the 2,5-furandicarboxylic acid, in a reaction zone to conduct an esterification reaction to yield the dialkyl ester of 2,5-furandicarboxylic acid and water; withdrawing a reaction vapor comprising the alkanol and water from the reaction zone; and discharging a liquid phase having at least the dialkyl ester of 2,5-furandicarboxylic acid, from the bottom part of the reaction zone, to obtain the dialkyl ester of 2,5-furandicarboxylic acid.

Owner:FURANIX TECH BV

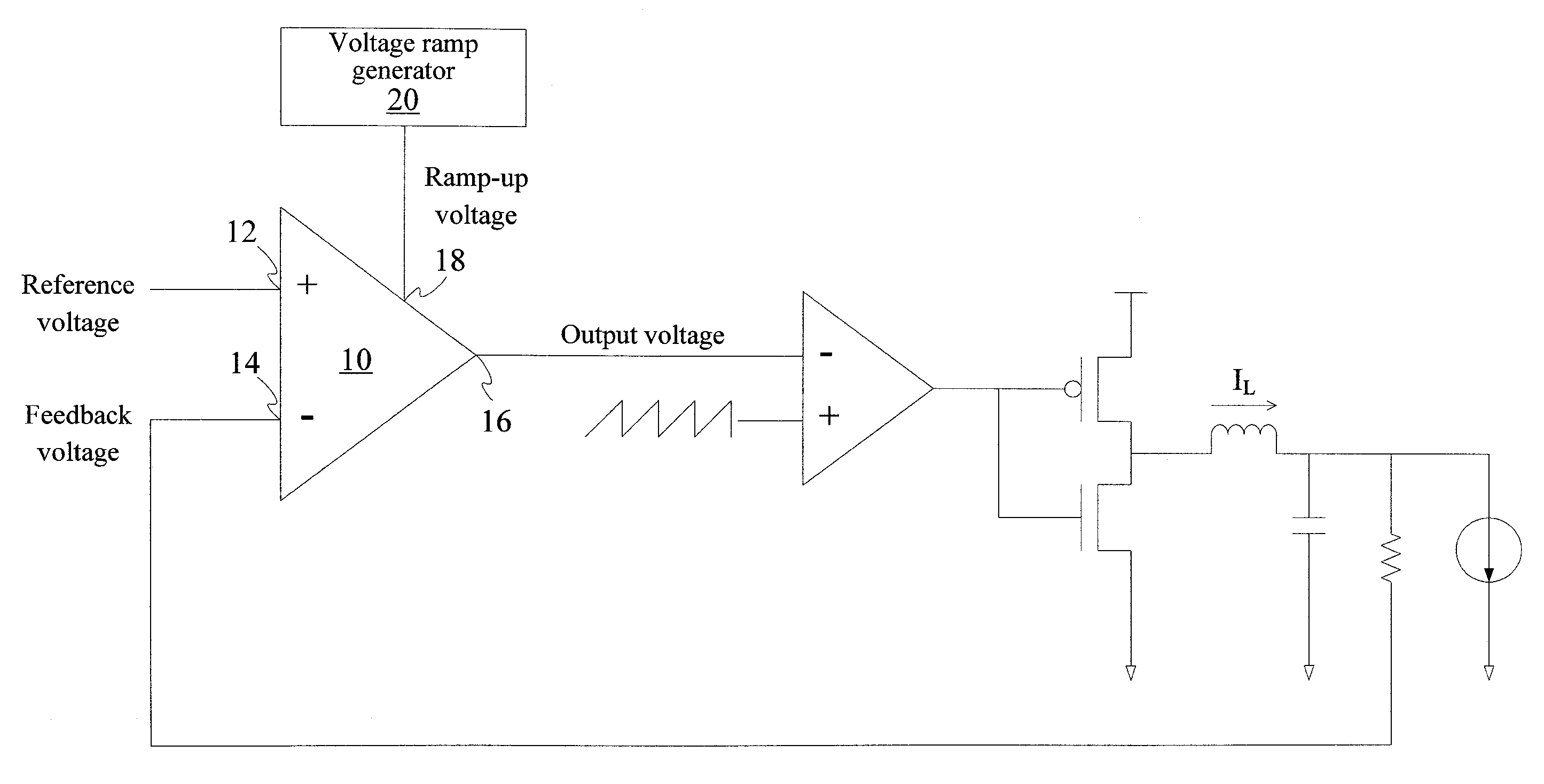

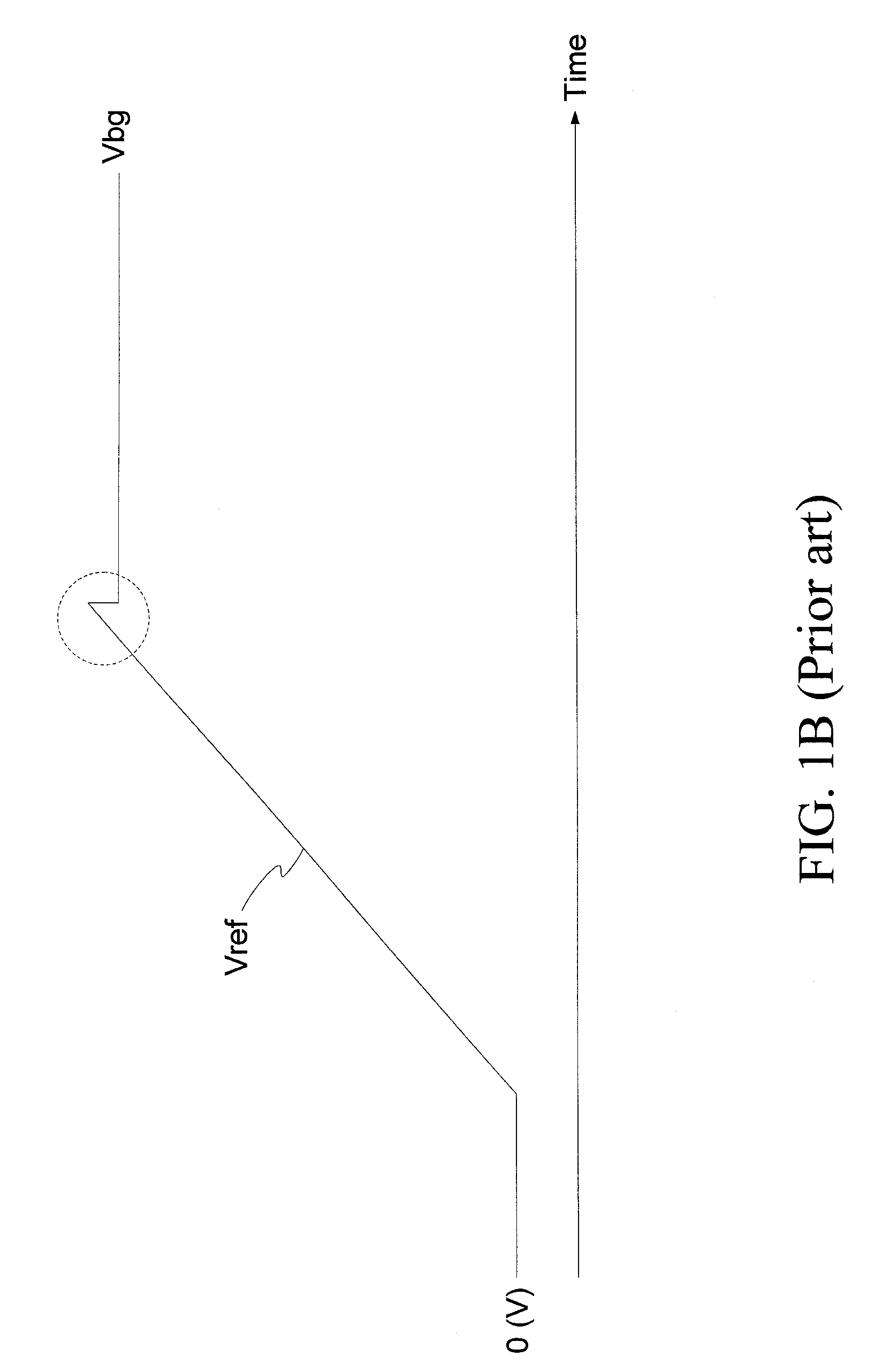

Soft-Start Circuit and Method Thereof

ActiveUS20090167276A1Smooth functionReduce stepsDc-dc conversionElectric variable regulationVoltage referenceEngineering

A soft-start circuit and a method thereof are described. The circuit includes an amplifier and a voltage ramp generator. The amplifier has a first input end, a second input end, an output end, and a power source control end. The first input end is coupled to a reference voltage. The second input end is coupled to a feedback voltage. The output end outputs an output voltage, and the feedback voltage corresponds to the output voltage. The voltage ramp generator is coupled to the power source control end, and generates a ramp-up voltage. When the ramp-up voltage is lower than a threshold value, the output voltage rises with the ramp-up voltage. When the ramp-up voltage is not lower than the threshold voltage, the output voltage remains at a stable value. A surge current occurring during smooth soft-start or even in operation is thus prevented.

Owner:REALTEK SEMICON CORP

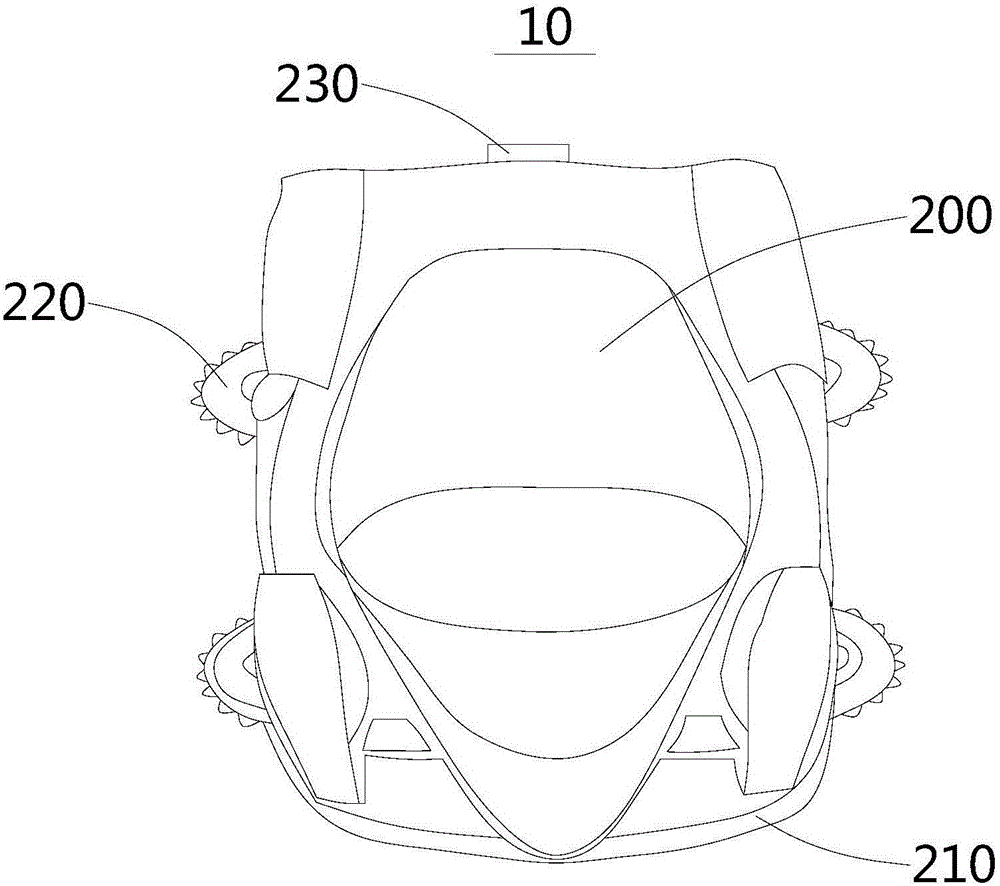

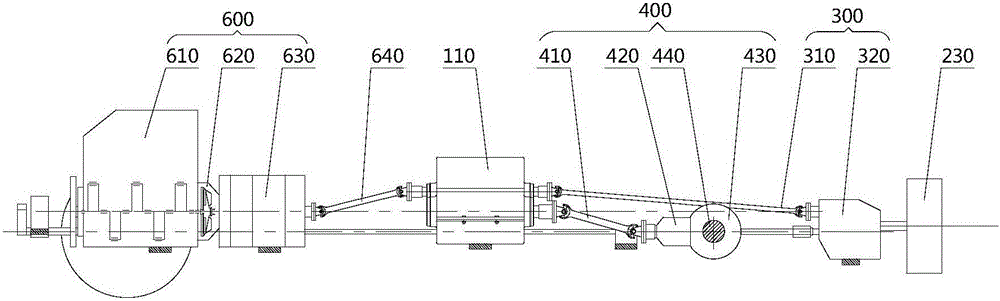

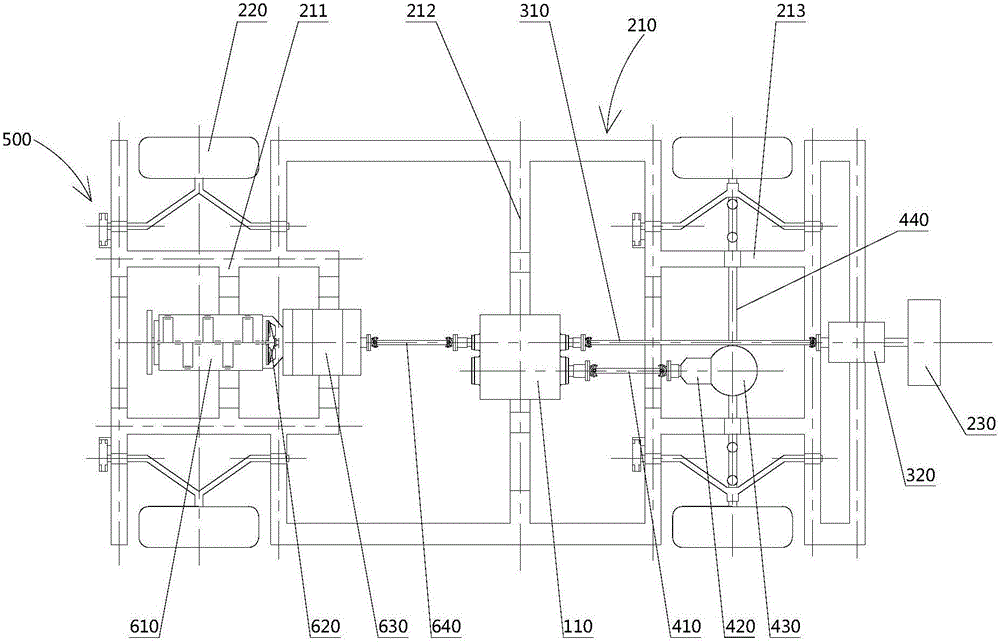

Amphicar structure

ActiveCN106080069AReduce resistanceSmooth transmissionAmphibious vehiclesTransmission with mechanical gearingTransfer casePropeller

The invention provides an amphicar structure, which comprises an amphicar body, a chassis, a plurality of wheels, a propeller, a power system and a drive system, wherein the amphicar body is connected with the chassis; the power system and the drive system are installed on the chassis; the drive system comprises a power conversion device and a wheel collecting and releasing device; the power conversion device comprises a first drive mechanism, a second drive mechanism and a transfer case; the power system and the transfer case are connected; the transfer case can be independently connected with the first drive mechanism or the second drive mechanism; the first drive mechanism is connected with the propeller; the second drive mechanism is connected with the wheels; the wheel collecting and releasing device is connected with the wheels. The amphicar structure can realize stable drive and smooth conversion, power can be stably transmitted, driving is more stable, and the power conversion of an amphicar in water and on land can be perfectly realized. In addition, the collection and the release of the wheels can be realized, the wheels are collected when the amphicar is driven on water, resistance between the amphicar body and the water surface can be reduced, and the amphicar can be more stably and quickly driven on the water.

Owner:YANCHENG INST OF TECH

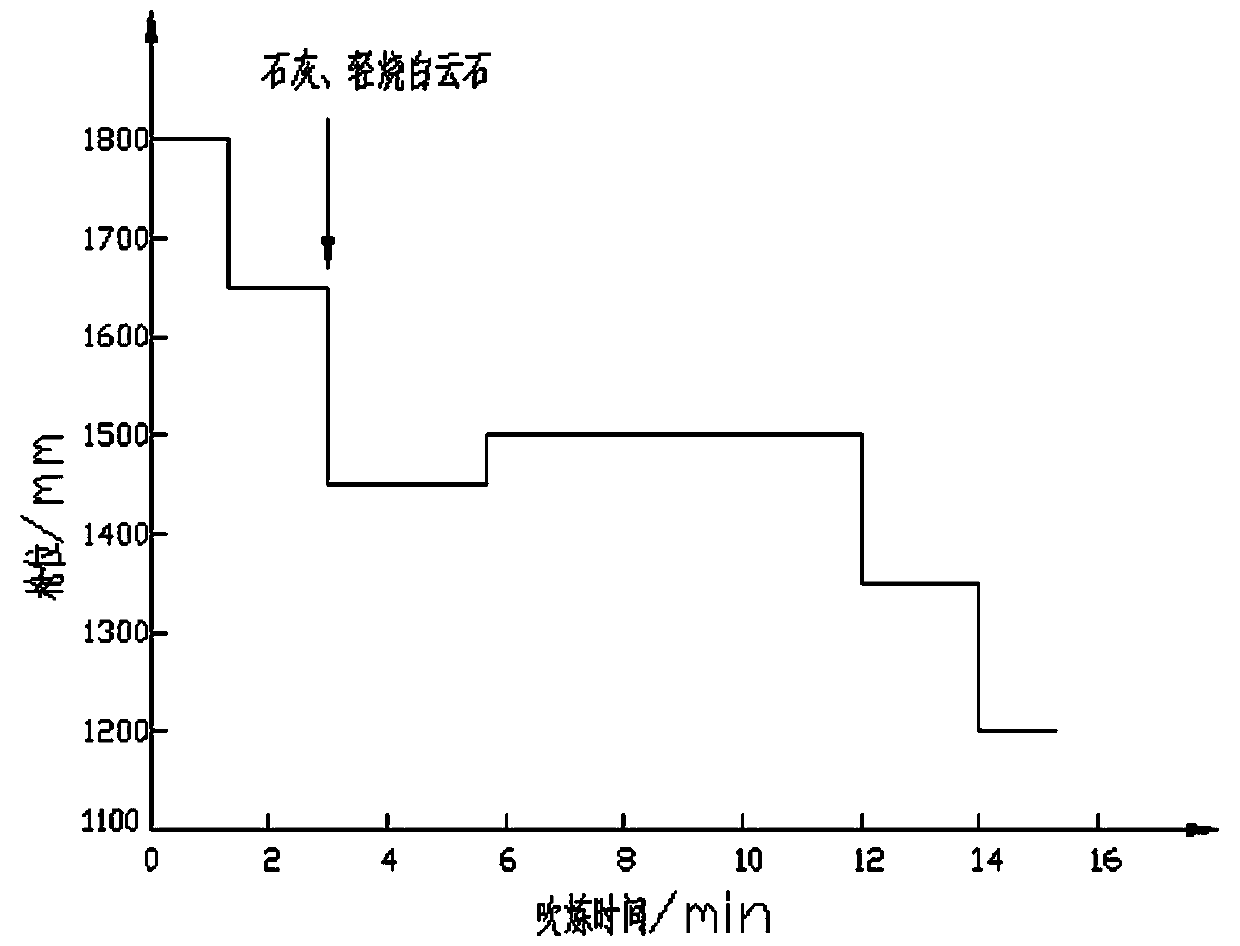

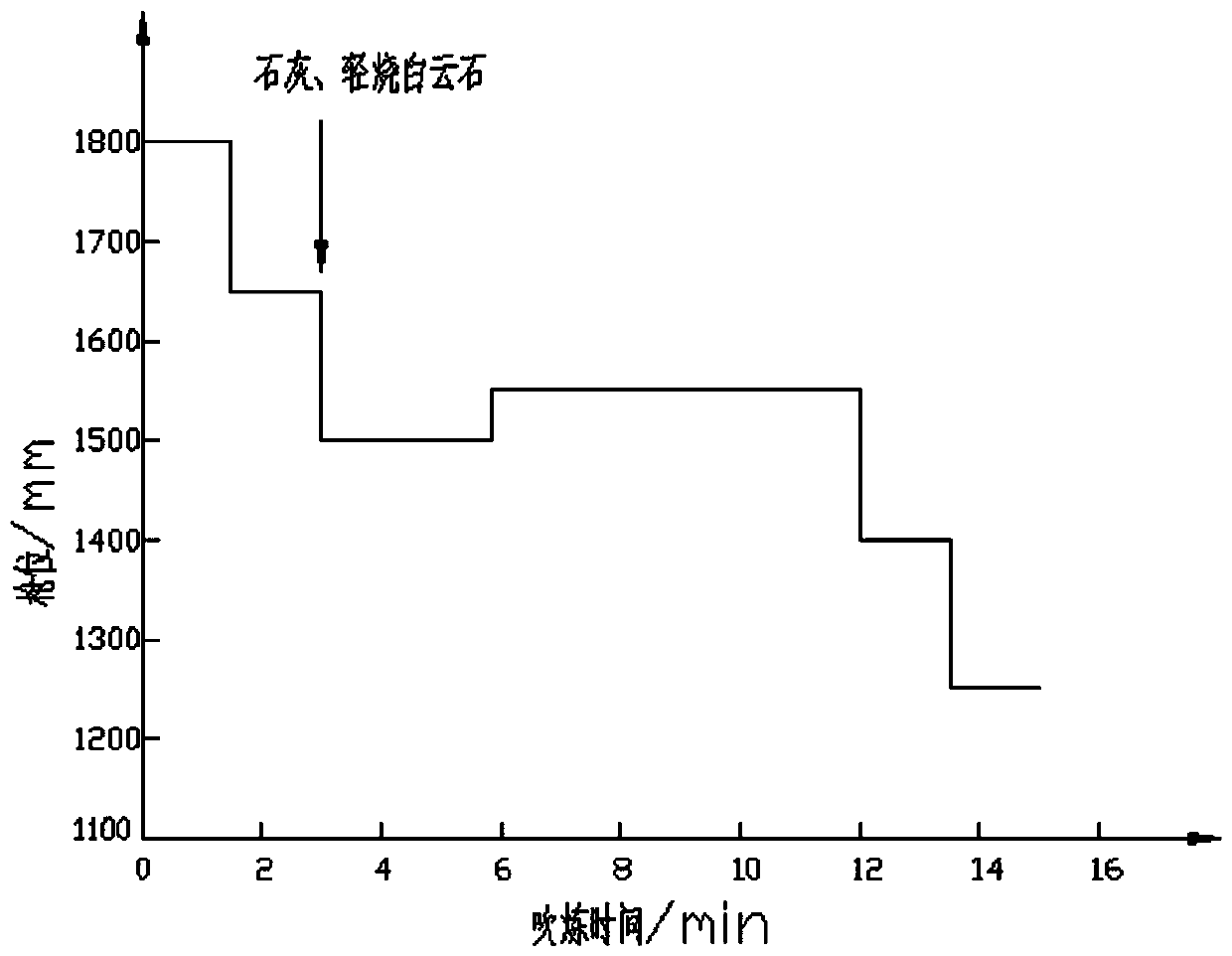

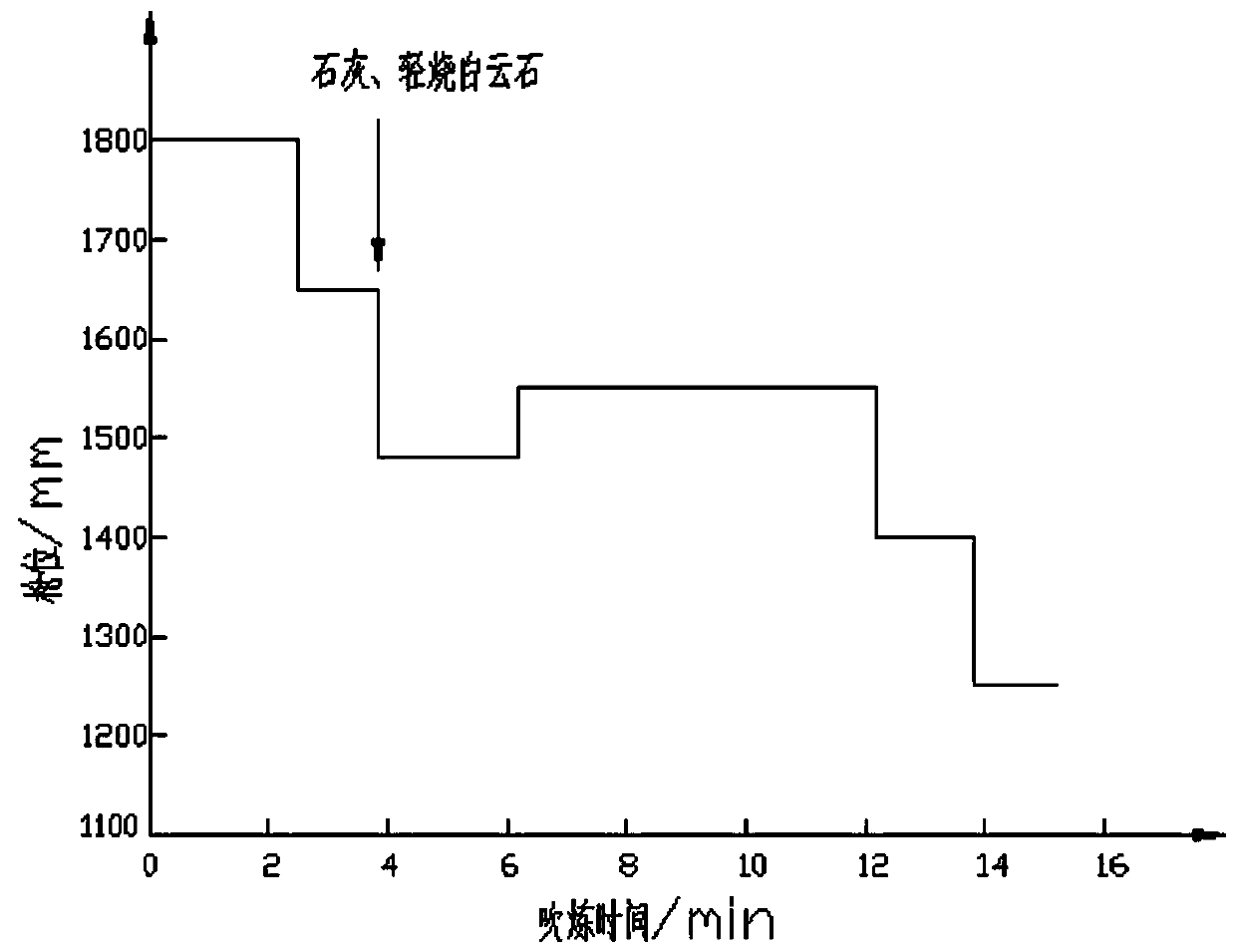

Method for smelting high-phosphorus steel through converter

ActiveCN110643778AReduce consumptionReduce iron lossManufacturing convertersProcess efficiency improvementTemperature controlSmelting process

The invention relates to a method for smelting high-phosphorus steel through a converter. The method includes the following steps of firstly, adding all active lime and light-burned dolomite at a timewithin 5 minutes of open blowing of the converter, controlling the alkalinity of final slag to be 2.0-2.5 and the oxygen pressure in the smelting process to be 0.85-1.00 Mpa, controlling the positionof a blowing lance to be 100-200 mm lower than that in normal dephosphorization melt, applying the high-low-low lance position to an oxygen lance in the blowing process, controlling the end point carbon temperature to hit the target, controlling the temperature, measured by a sublance, of a molten pool of a TSC to be 1610-1640 DEG C when oxygen blowing is completed by 80-85%, and forbidding to add a cold material within 100 seconds before oxygen blowing ends; secondly, controlling the end point carbon C in the converter to be 0.04-0.09%, controlling the tapping temperature to be 1645-1685 DEGC, and controlling the end point phosphorus P to be 0.040-0.070%; and thirdly, pouring part of slag after tapping is completed, adding light-burned dolomite for slag-splashing for protection of the converter, determining whether slag needs to be poured or not according to the after-slag-splashing slag amount condition, and controlling the residual slag amount to be 3-5 t for a next round of high-phosphorus steel smelting in the converter. By means of the method, the consumption of slag and alloy can be reduced, and the continuous and stable smelting of the converter can be ensured.

Owner:SGIS SONGSHAN CO LTD

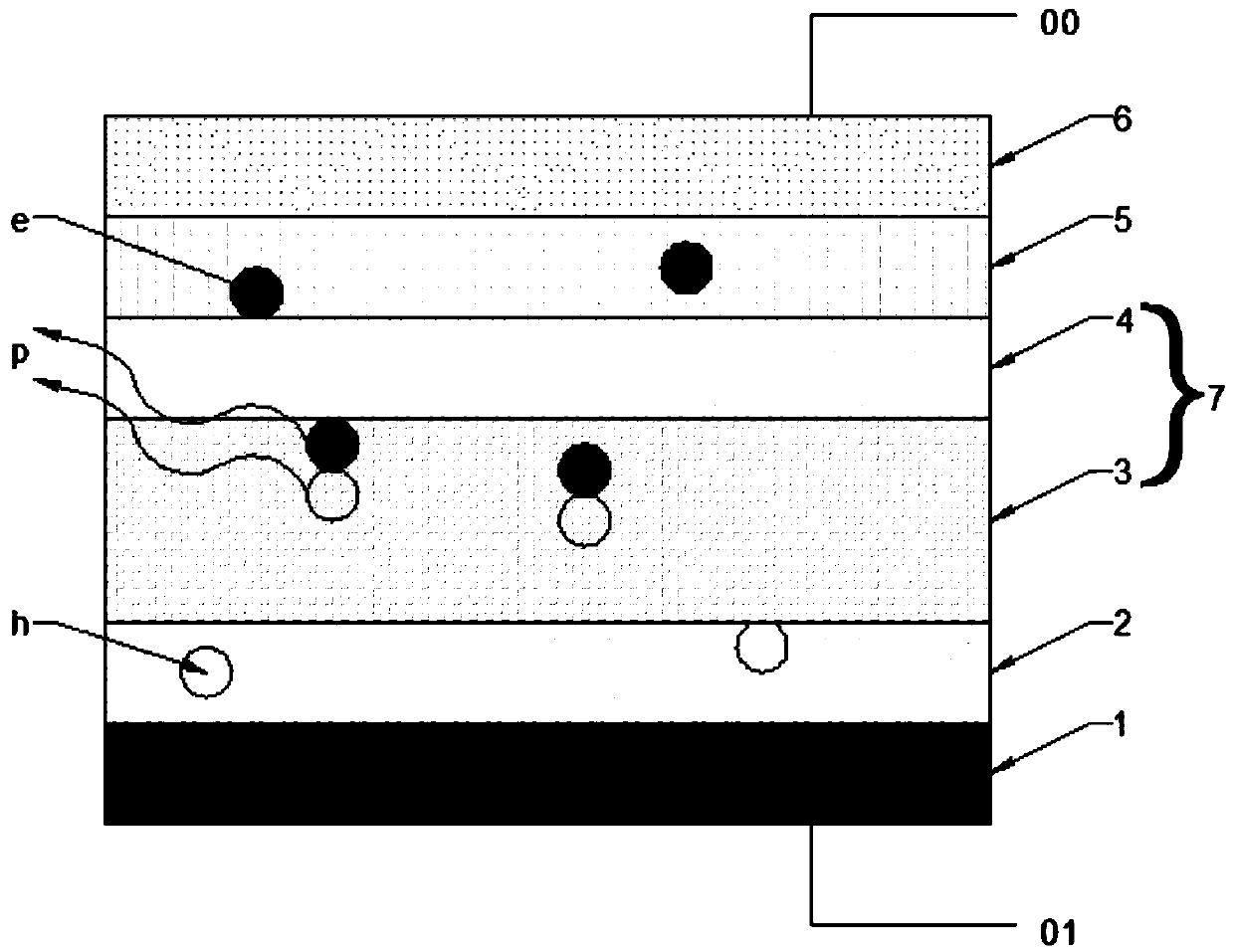

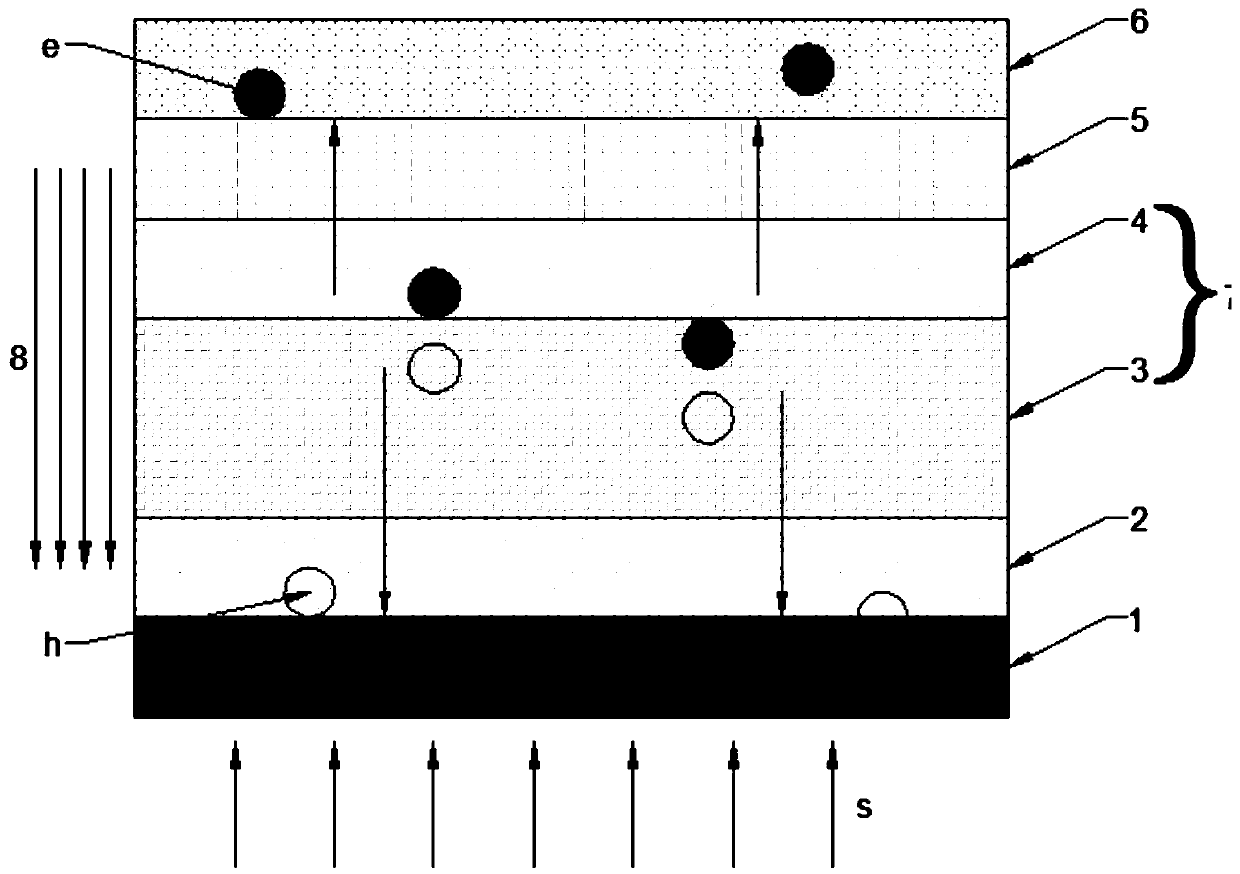

Multifunctional optoelectronic device

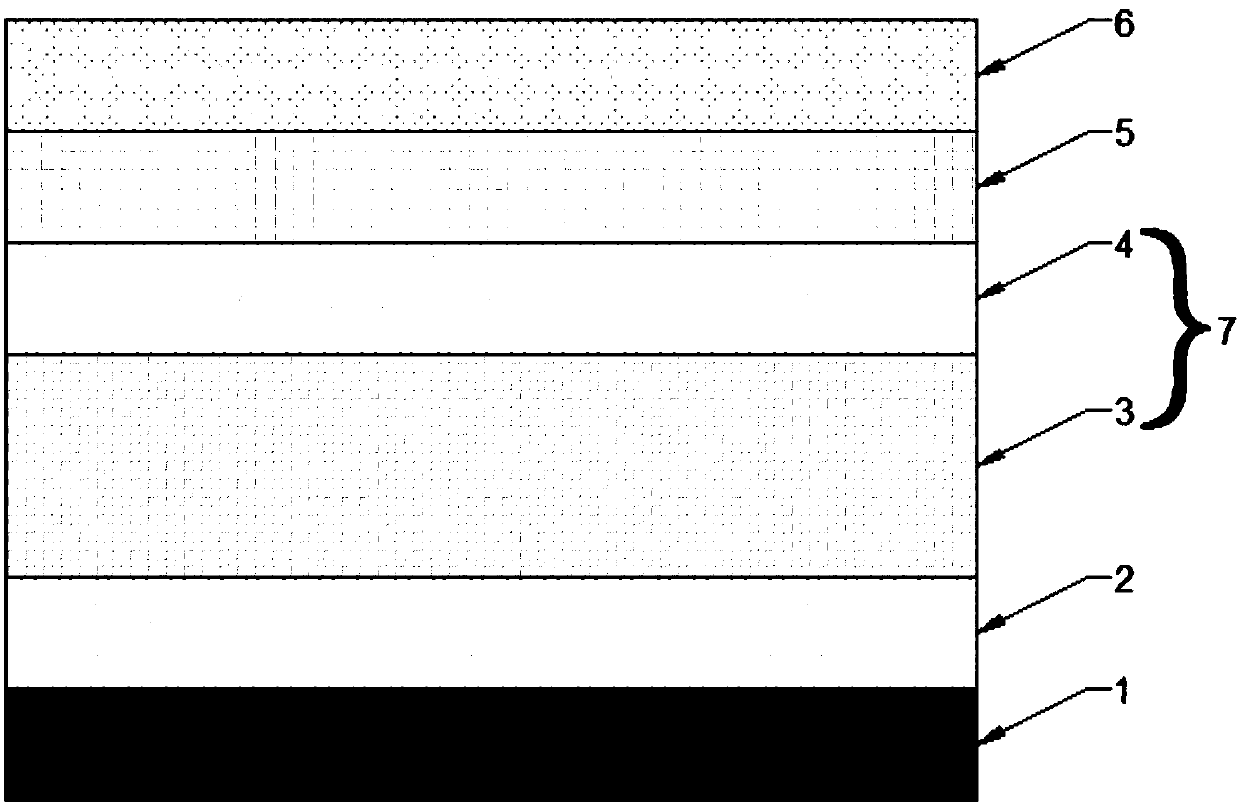

ActiveCN109638165ARealize the collectionRealize photodetectionSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionHole transport layer

A multifunctional optoelectronic device comprises ITO glass, a hole transport layer, a heterojunction, an electron transport layer and a metal electrode, wherein the ITO glass is a substrate of the entire optoelectronic device; the hole transport layer, the heterojunction, and the electron transport layer are successively disposed on the ITO glass from bottom to top, or the electron transport layer, the heterojunction, and the hole transport layer are successively disposed on the ITO glass from bottom to top; the surface of the electron transport layer or the hole transport layer at the uppermost layer is plated with the metal electrode; the heterojunction is formed by stacking a perovskite layer and a quantum dot layer; the hole transport layer forms a P-type semiconductor; the heterojunction forms an intrinsic semiconductor; and the electron transport layer forms an N-type semiconductor such that the optoelectronic device has a PIN structure and a built-in electric field from the electron transport layer to the hole transport layer is generated in the optoelectronic device. The multifunctional optoelectronic device of the invention can realize energy collection, energy injectionand energy detection functions on a single device structure.

Owner:SHENZHEN UNIV

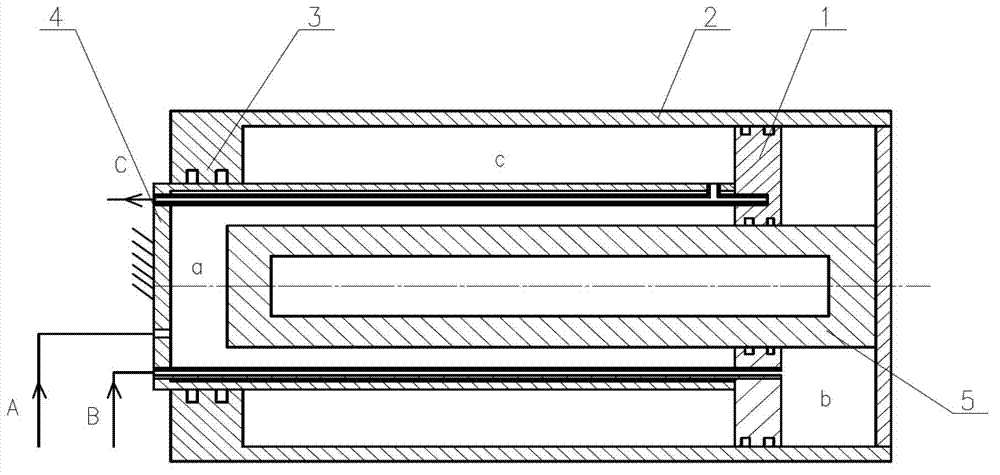

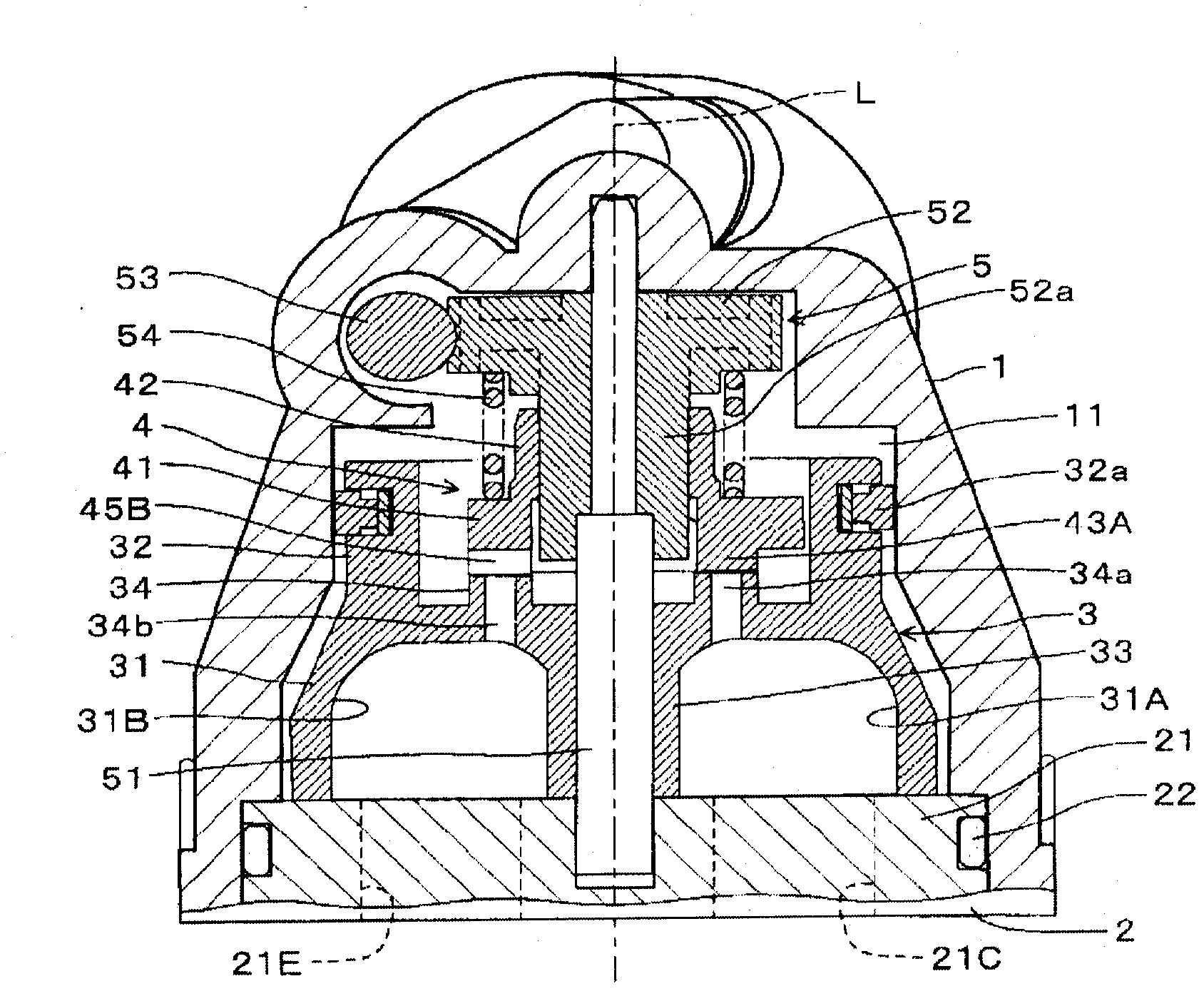

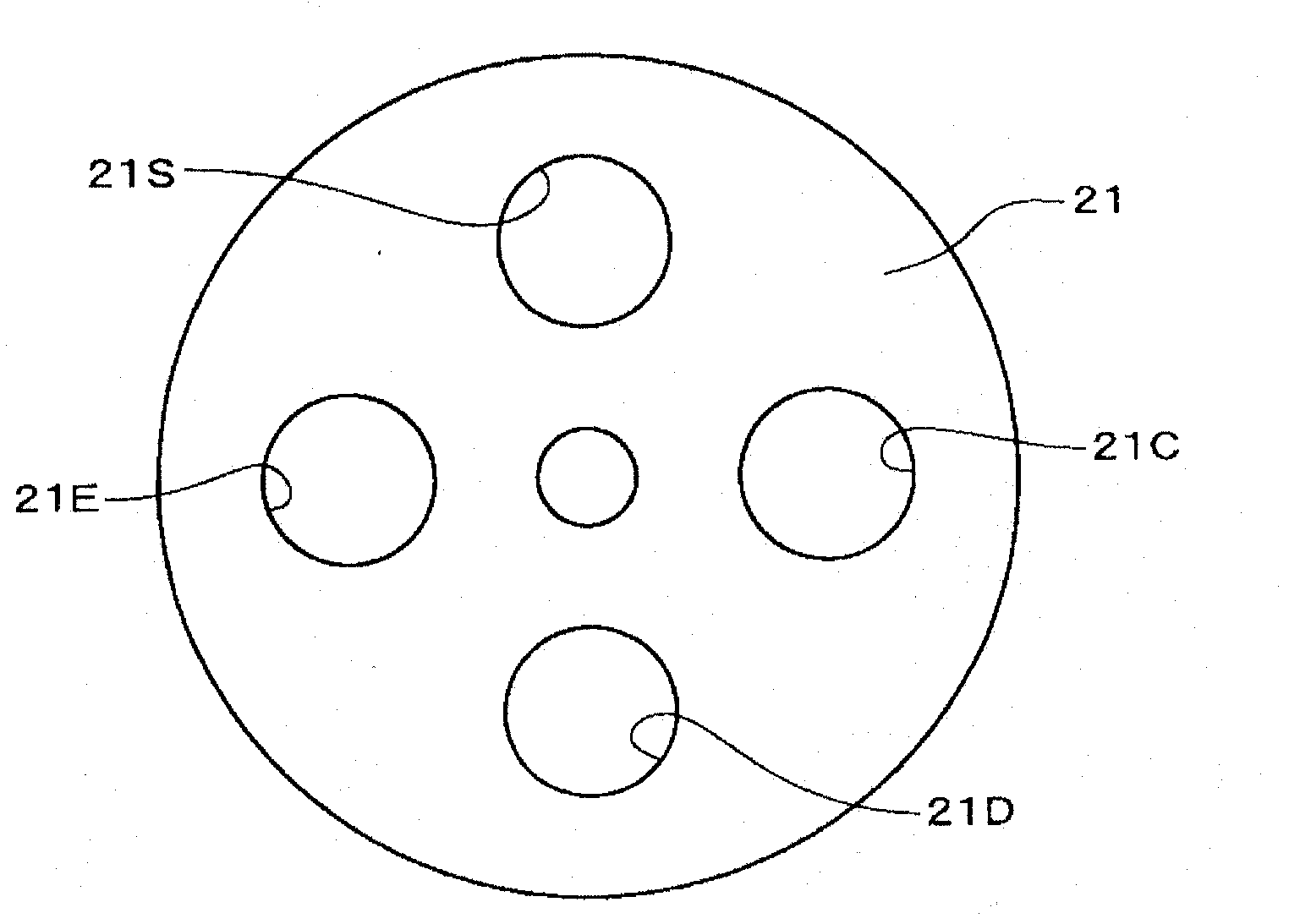

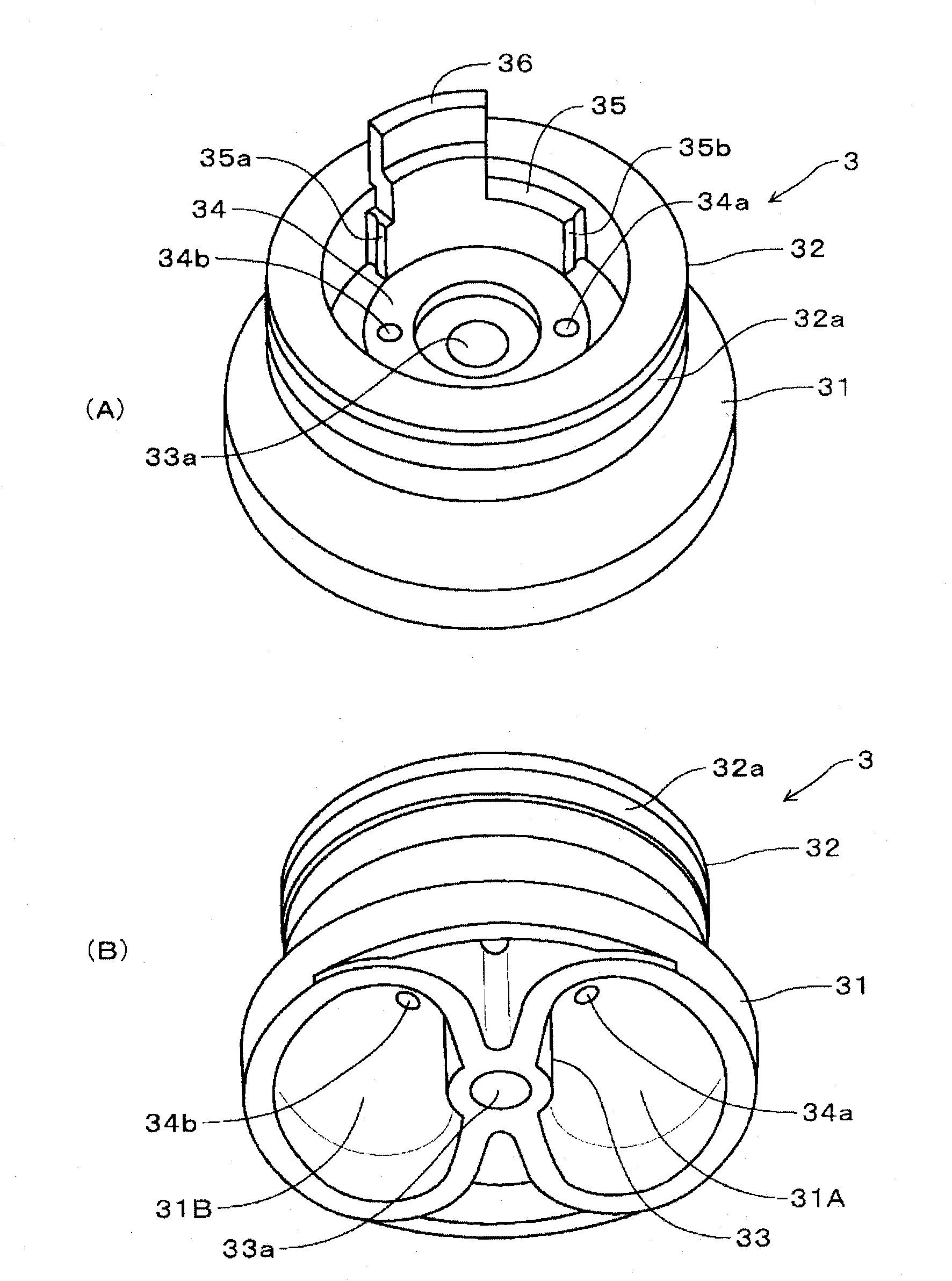

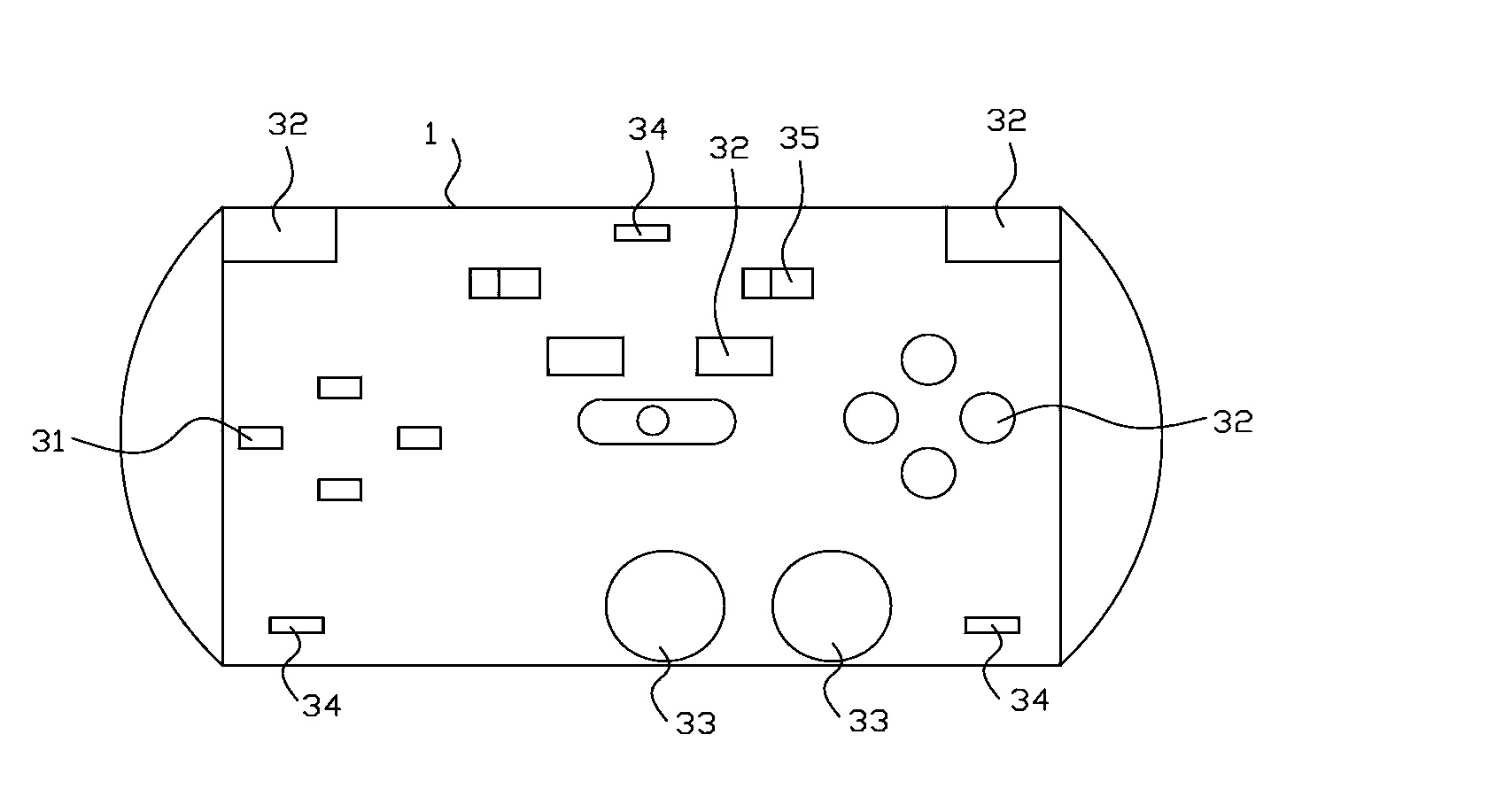

Flow path selector valve

InactiveCN102047014AReliable conversionPromote conversionOperating means/releasing devices for valvesMultiple way valvesEngineeringSwitching time

A flow path selector valve for switching between a cooling state and a heating state by rotation of a main valve (3) together with a auxiliary valve (4), wherein rotational operation of the main valve (3) and the auxiliary valve (4) are simplified to make operation of the main valve (3) reliable and to reduce a switching time. An outdoor heat exchanger-side communication passage (31A) and an indoor heat exchanger-side communication passage (31B) are formed in the main valve (3). An outdoor heat exchanger-side equalizing hole (34a) for connecting the outdoor heat exchanger-side communication passage (31A) to a valve chamber (11) is formed in the main valve. An indoor heat exchanger-side equalizing hole (34b) for connecting the indoor heat exchanger-side communication passage (31B) to the valve chamber (11) is formed in the main valve (3). A closing section (43A) for closing the outdoor heat exchanger-side equalizing hole (34a) and an equalizing hole opening section (45B) for opening the indoor heat exchanger-side communication passage (34b) are also formed in the auxiliary valve (4). A closing section for closing the indoor heat exchanger-side equalizing hole (34b) and an equalizing hole opening section for opening the outdoor heat exchanger-side communication passage (34a) are also formed in the auxiliary valve. A support section sliding on an auxiliary valve seat (34) is formed on the auxiliary valve (4). The main valve (3) is rotated 90 DEG by merely operating the auxiliary valve (4) in either forward or reverse directions, and this switches between the cooling state and the heating state.

Owner:SAGINOMIYA SEISAKUSHO INC

Saccharomyces cerevisiae and application thereof in preparing (R)-(+)-beta-hydroxy-benzenepropanoic acid ethylester by microbial transformation

InactiveCN101709271ALow costMild reaction conditionsFungiMicroorganism based processesMicroorganismMicrobial transformation

The invention provides a new strain-Saccharomyces cerevisiae CGMCC NO.3361 and application thereof in preparing (R)-(+)-beta-hydroxy-benzenepropanoic acid ethylester by microbial transformation. The Saccharomyces cerevisiae was collected in China General Microbiological Culture Collection Center (CGMCC), the address of which is Institute of Microbiology, Chinese Academy of Sciences, Datun Road, Chaoyang District, Beijing 100101. The collection date is October 23, 2009 and the collection number is CGMCC NO.3361. The beneficial effects of preparing (R)-(+)-beta-hydroxy-benzenepropanoic acid ethylester by the microbial transformation method in the invention are mainly as follows: (1) the biocatalyst is a microbial thallus, thus is lower in cost than the chemical catalysts; (2) the environment is friendly, the reaction conditions are mild and the transformation can be carried out smoothly under normal temperature and normal pressure; (3) the strain used in the production is safe and nontoxic; (4) the method is not influenced by seasons and is easy to realize large-scale industrial production; (5) the production operation is simple and convenient and the biotransformation rate is higher; and (6) coenzyme is unnecessary to be added in the whole reaction process.

Owner:ZHEJIANG UNIV OF TECH

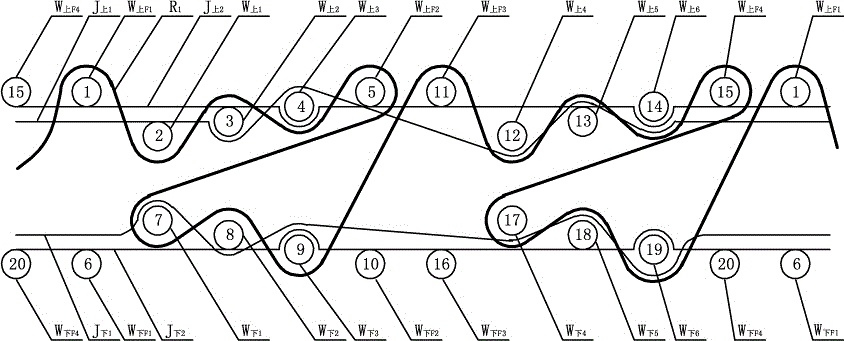

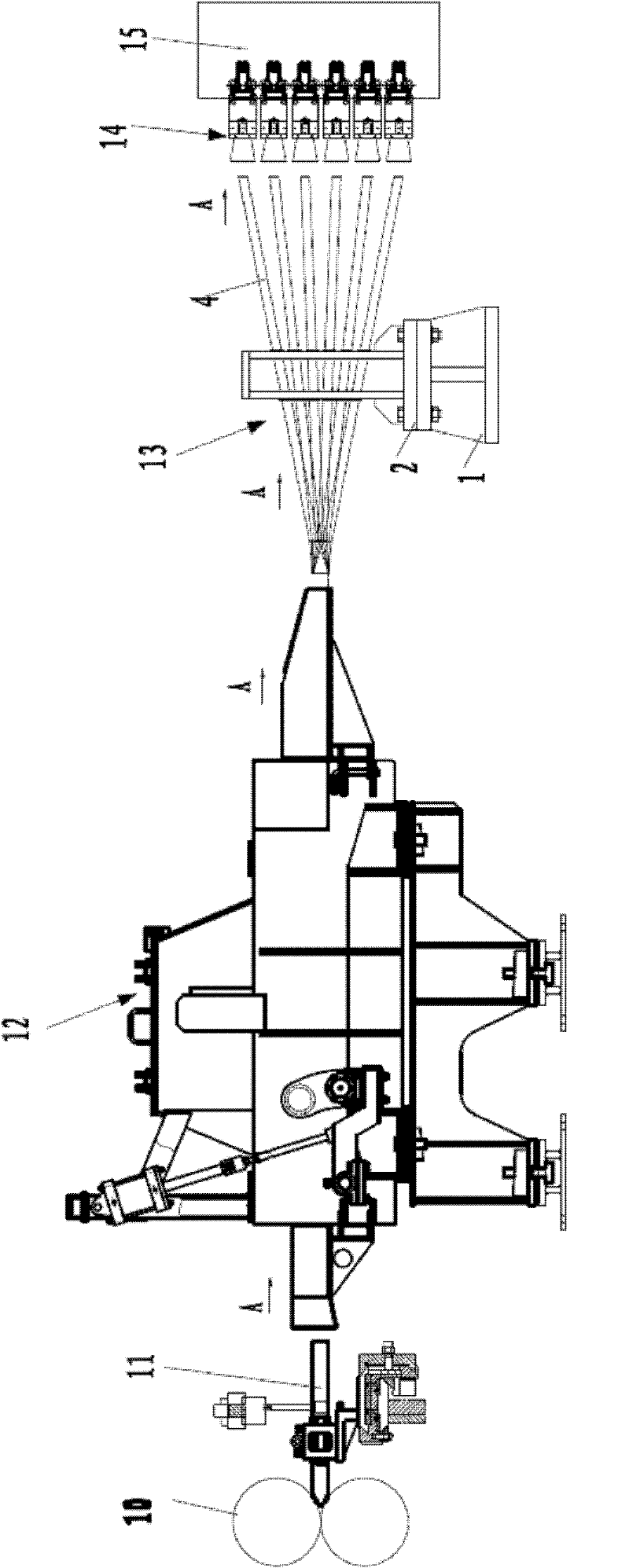

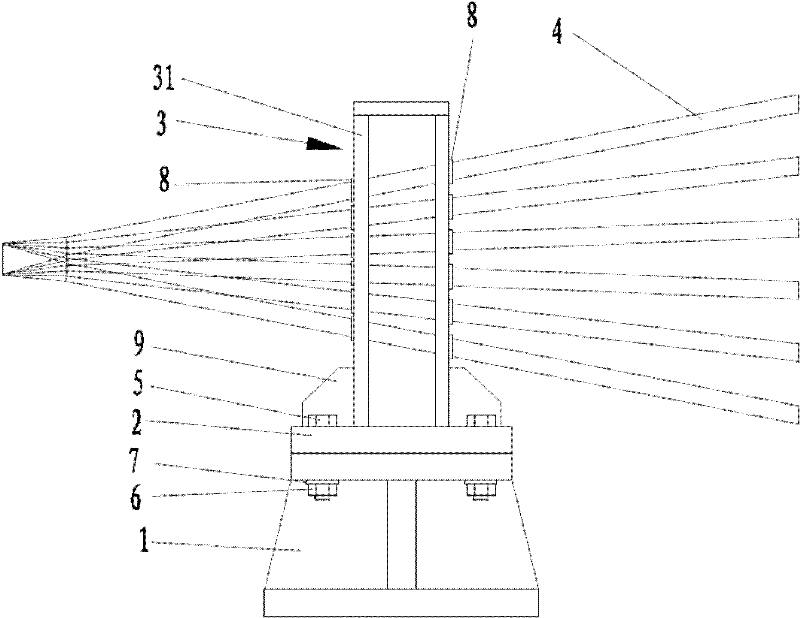

Steel rolling system provided with no-twist interchange type rolling piece guiding device

ActiveCN102225431ALow costEliminate a point of failureGuiding/positioning/aligning arrangementsFlexible work arrangmentsEngineeringSingle line

The invention discloses a steel rolling system provided with a no-twist interchange type rolling piece guiding device, and is characterized in that a second rolling mil counting backwards in a finish rolling region is a horizontal rolling mill, a sliding type outlet guiding device is arranged on the last but one rolling mill, a movable looping device is arranged at a rolling piece outlet end of the sliding type outlet guiding device, a no-twist interchange type rolling piece guiding device used for changing a row of horizontally-arranged rolling pieces into a vertically-arranged row is arranged at the rolling piece outlet end of the movable looping device, and a last rolling mill provided with an inlet guiding device is arranged at the rolling piece outlet end of the no-twist interchange type rolling piece guiding device, and is of a vertical rolling mill. The invention is applicable to rolling a steel production line, and has the advantages of being capable of omitting a twist guiding device, removing one fault point of the steel rolling process, smoothly realizing changing of the single-line rolling mode of a rolling system into a segmentation rolling mode, reducing the cost of the steel rolling system, being applicable to 4-slitting-segmentation, 5-slitting-segmentation and 6-slitting-segmentation steel rolling systems, and the like.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

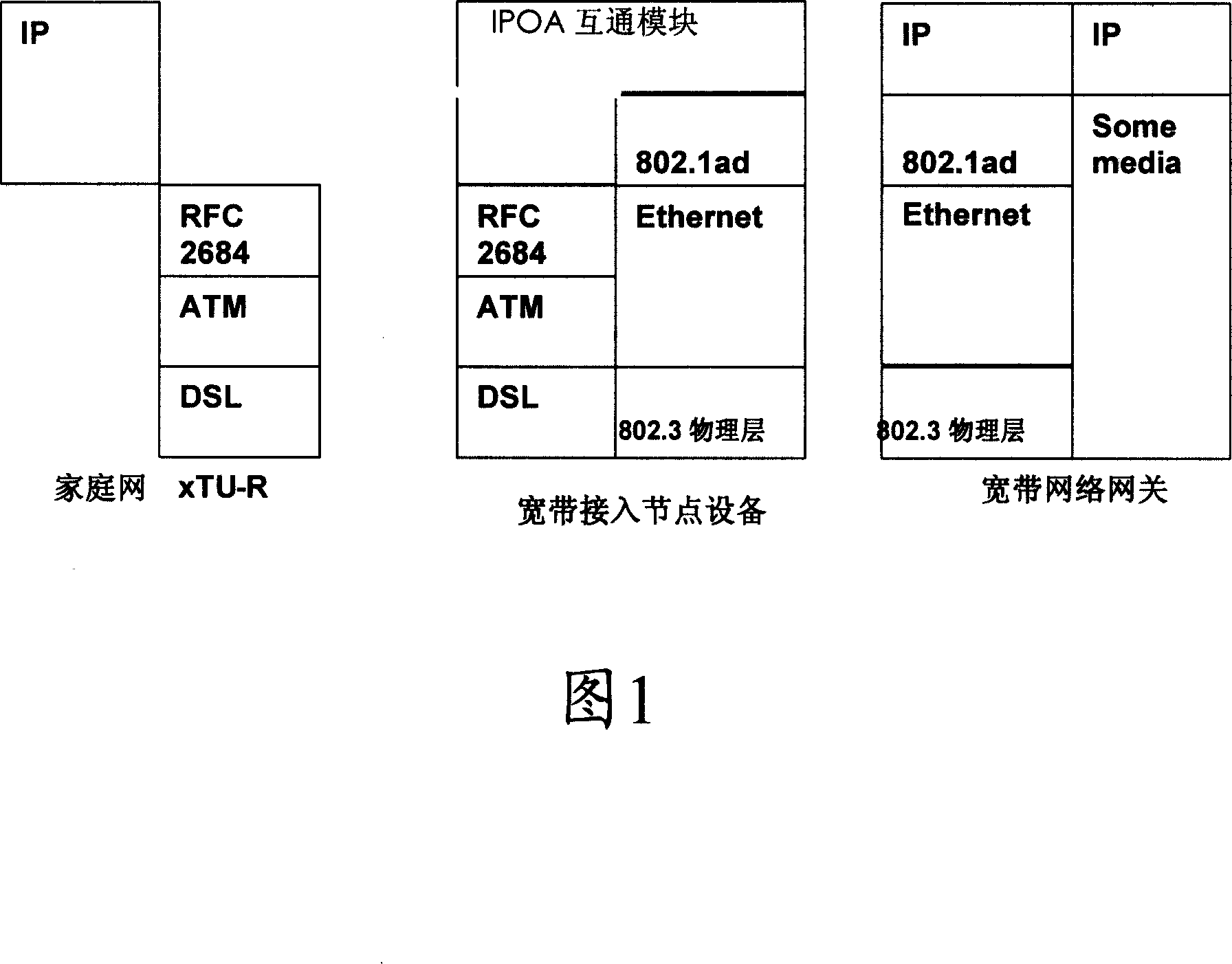

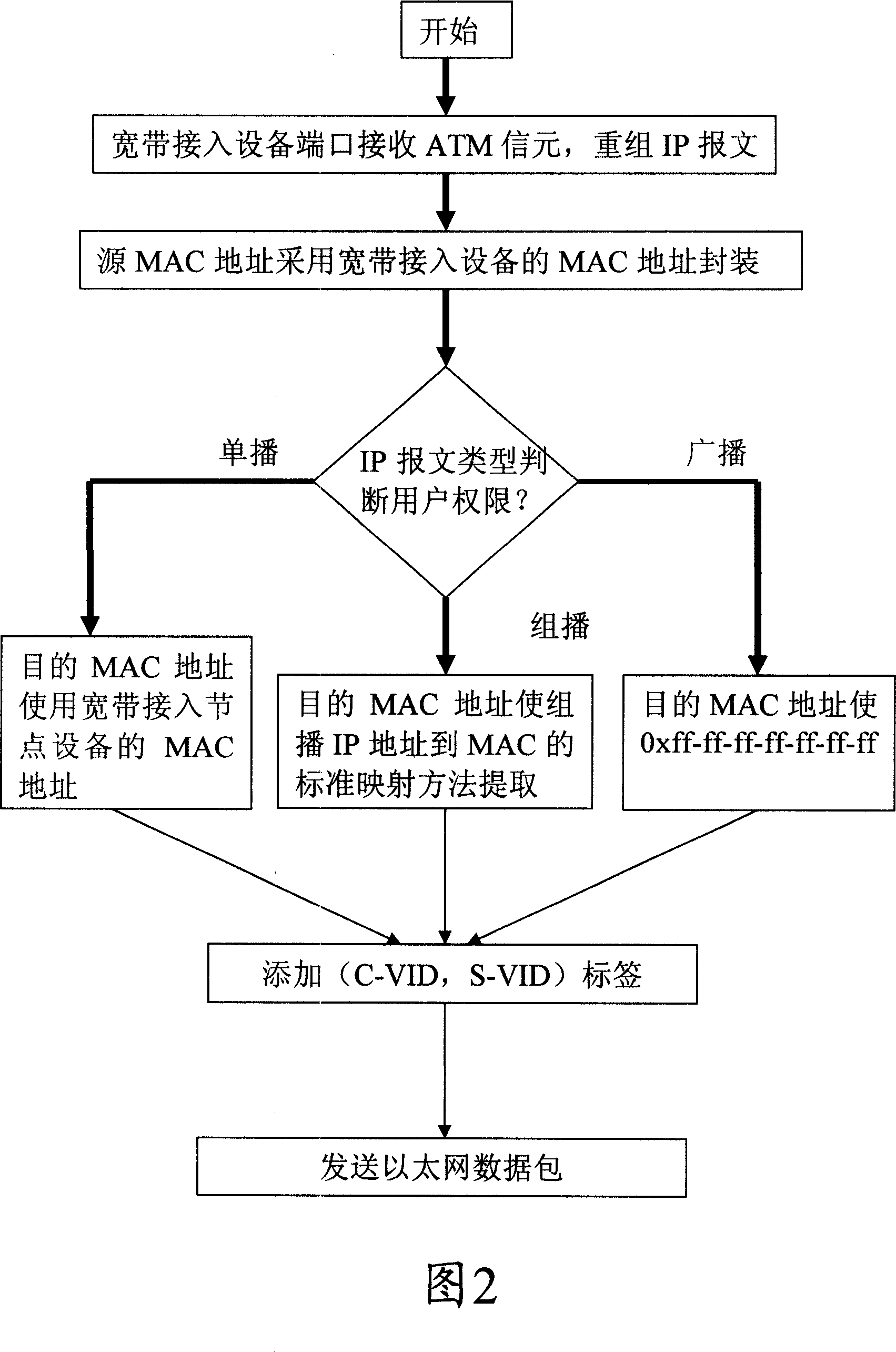

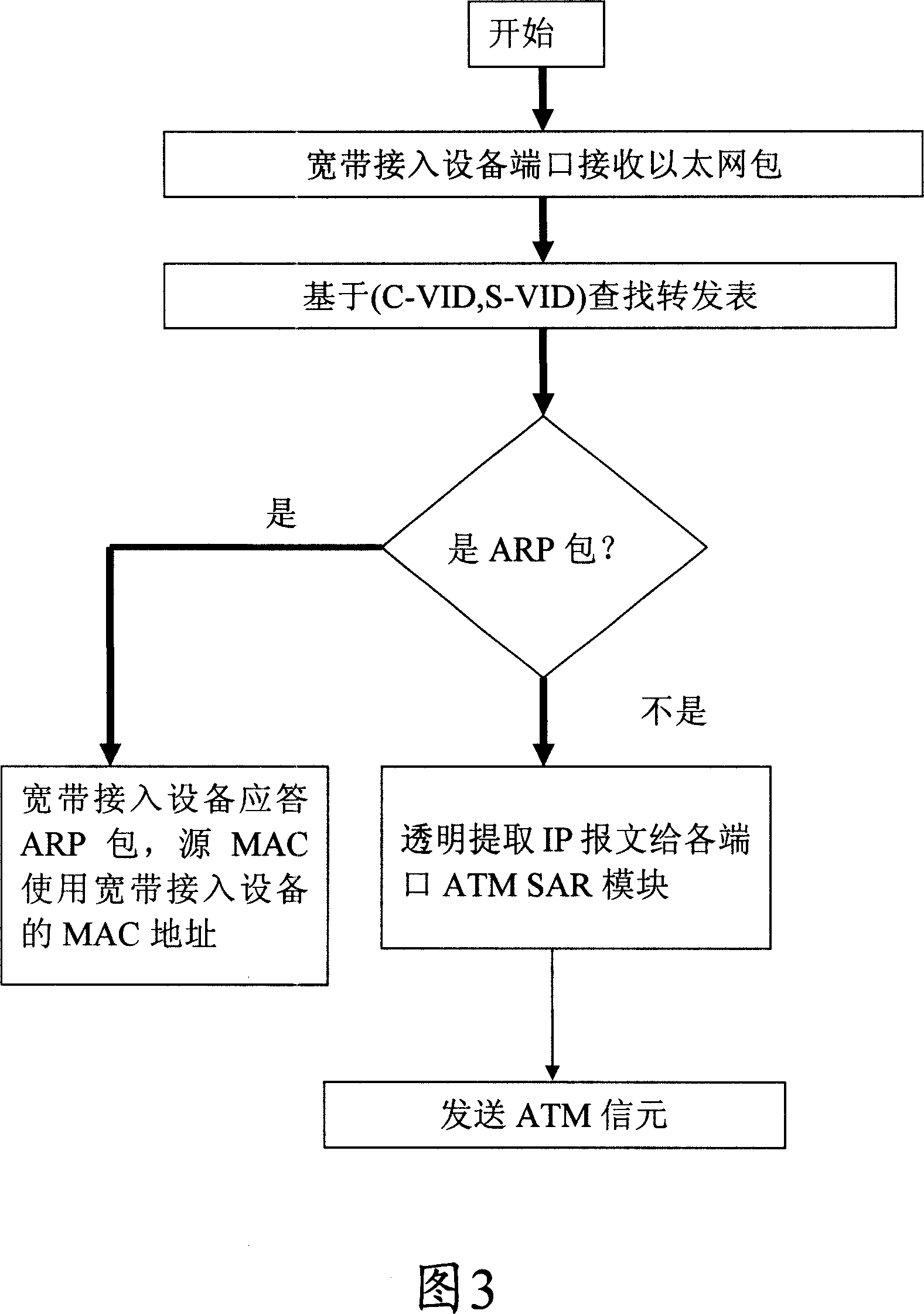

Interconnection implementing method of IPoA and IPoE

ActiveCN101098280ASmooth conversionSolve interconnection problemsNetworks interconnectionVirtual LANIPoE

The invention discloses an interconnection method of IPoA and IPoE, wherein at the ascending direction of IPoA-IPoE conversion, a wideband access device recombines an ATM signal unit received from user interface into an IP report, processes MAC package on the IP report, adds a virtual local network mark, and sends an Ethernet data pack to network interface, and at the descending direction of IPoE-IPoA conversion, the wideband access device receives an Ethernet data pack from network interface, based on a virtual local network mark searches a transfer list, judges that the Ethernet data pack is not ARP pack, extracts an IP pack transparently, uses an ATM SAR module to process the IP pack segmented into ATM signal units, and sends the ATM signal units to user interface, and answers the ARP pack. The invention realizes the intercommunication between IPoA interface and IPoE interface, which can resolve the interconnection problem between prior ATM network and Ethernet.

Owner:ZTE CORP

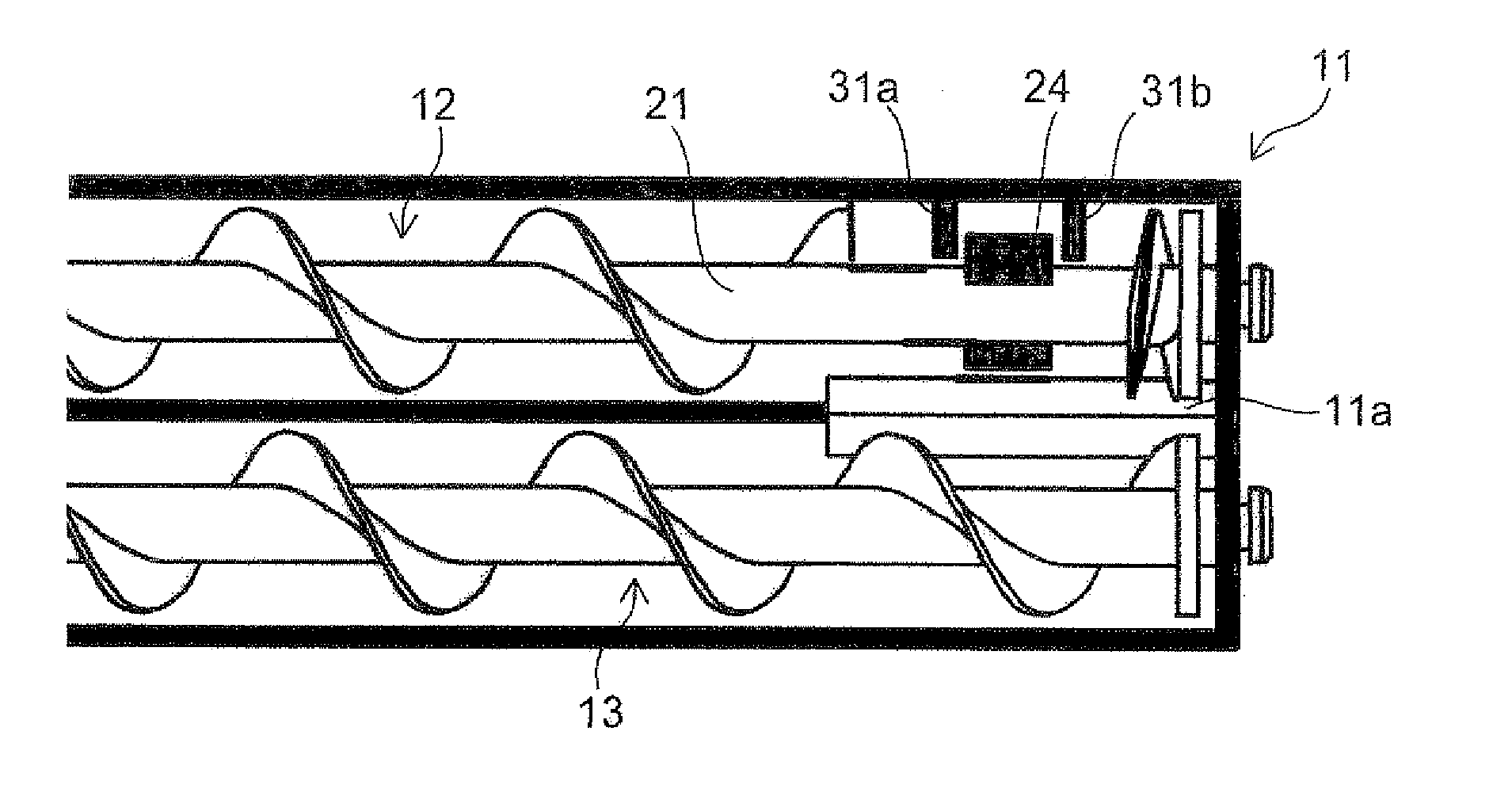

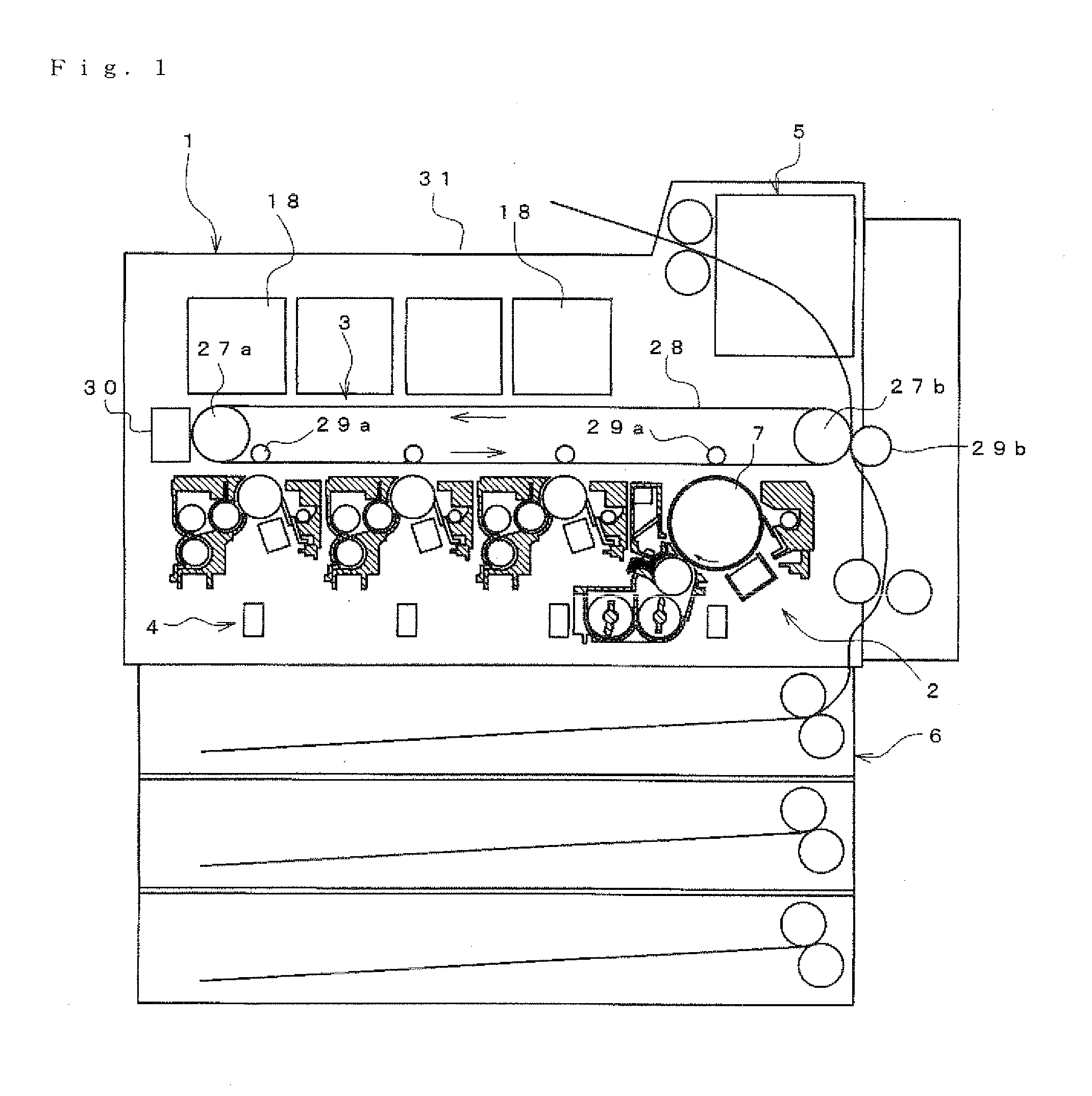

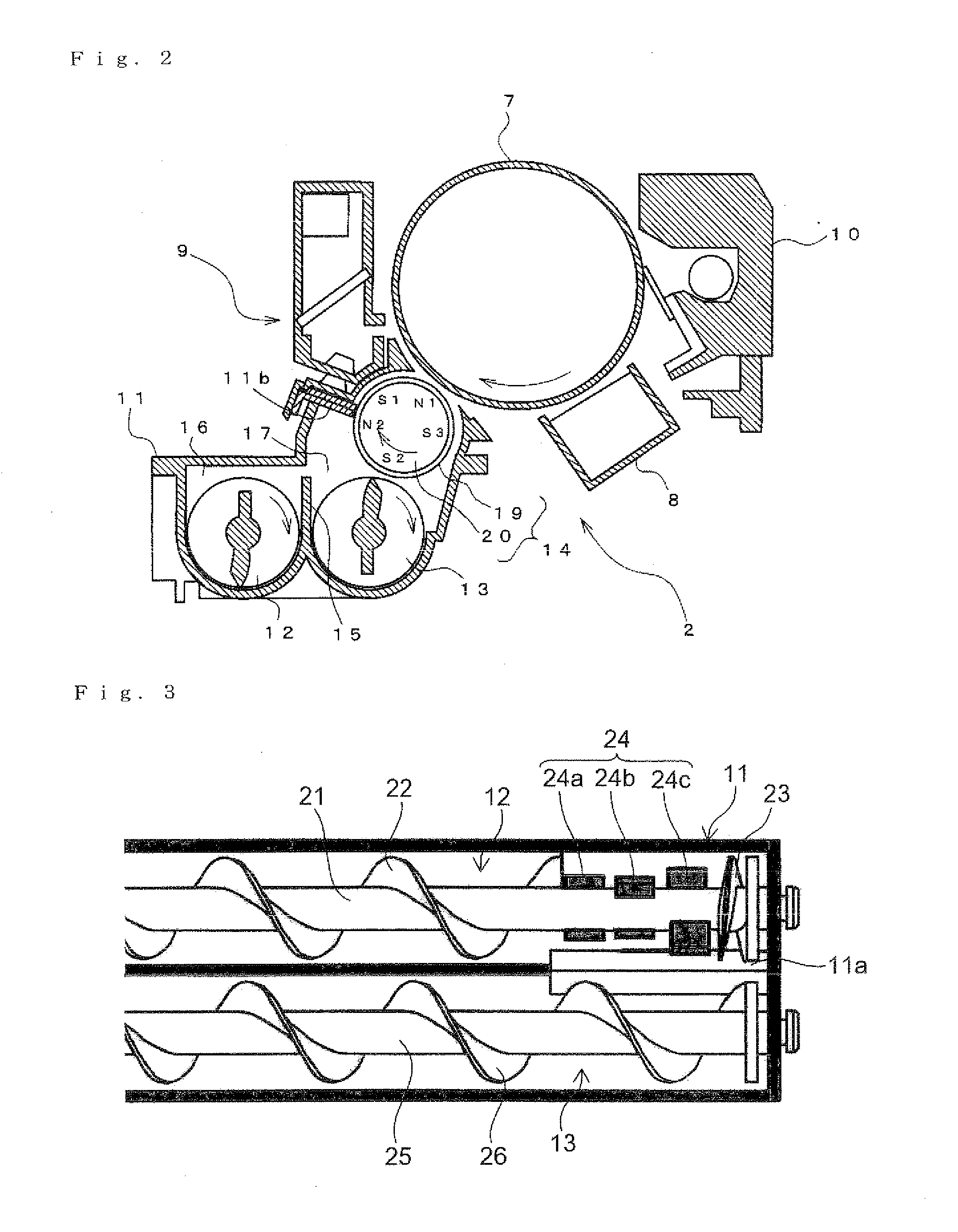

Developer conveyance device, developing device, and image forming device

ActiveUS20110170911A1Improve abilitiesEfficiently convertedElectrographic process apparatusEngineeringMechanical engineering

There is provided a developer conveyance member that conveys a contained developer from one end side of a delivery region to other end of the delivery region while agitating the contained developer in a developer container, in which the developer is contained. Around a rotation shaft of the developer conveyance member, a spiral wing toward from one end side to other end side is formed. A plurality of paddle parts for conveying the developer in a direction that is perpendicular to a shaft core are formed around the rotation shaft in a delivery region. The paddle parts are arranged with their positions deviated in a circumferential direction.

Owner:KONICA MINOLTA BUSINESS TECH INC

Wireless mouse with gamepad function

InactiveCN103389809AConditions that affect the effect of useAvoid adverse consequencesInput/output processes for data processingMode changeLight-emitting diode

The invention discloses a wireless mouse with a gamepad function. The wireless mouse comprises a shell, mouse buttons which are arranged on the shell, and a gamepad which is arranged on the bottom surface of the shell, wherein a direction button, a mouse / gamepad mode changing switch and a plurality of custom keys are arranged on the gamepad. A gamepad protection cover is arranged on the bottom surface of the shell; the gamepad protection cover is fixed on the bottom surface of the shell in a mouse mode; and the keys on the gamepad are all contained in the gamepad protection cover. When the gamepad protection cover is fixed on the bottom surface of the shell, a completely-closed protection space is provided for the gamepad, so that a condition that a part accidentally enters the bottom of a mouse along with the moving mouse cannot be caused, accordingly, a phenomenon that bad consequences are generated by accidental contact of the keys on the gamepad and other elements which are arranged on the bottom of the shell is avoided, and a condition that a using effect of the mouse is influenced when the light of a light-emitting diode (LED) on the bottom of the mouse is shielded by the accidentally entered part is prevented.

Owner:XUDA COMP KUSN

Misgurnus anguillcaudatus loop net cage propagation method

InactiveCN102415344AImprove reproductive efficiencyEasy to operateClimate change adaptationPisciculture and aquariaWeatherfishAquatic product

The invention belongs to the technical field of aquaculture, and in particular relates to a technology for allowing misgurnus anguillcaudatus to propagate and lay eggs in a net cage arranged in a hatching loop and allowing fertilized eggs to fall into the hatching loop from the cage to directly hatch in the hatching loop. An integrated large net cage or a plurality of independent large net cages are placed in the hatching loop and used as a site for mating and egg laying of parent misgurnus anguillcaudatus injected with a sexual maturity promoting agent, the net cages are moved out after egg laying is finished, and meanwhile, the parent misgurnus anguillcaudatus which has laid eggs is moved out. The misgurnus anguillcaudatus eggs fall into the loop from the meshes and directly enter the hatching process. By the method, the parent misgurnus anguillcaudatus can be effectively prevented from swallowing spawns and is difficultly hurt, and the misgurnus anguillcaudatus eggs have low loss and good propagation effect. By the method, the transfer process of the eggs is saved, the labor intensity is greatly reduced, and the work efficiency is improved.

Owner:ANHUI SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com