Method for smelting high-phosphorus steel through converter

A converter smelting and high-phosphorus steel technology, which is applied in the manufacture of converters and the improvement of process efficiency, can solve the problems of slag splashing in the separate furnace, unfavorable maintenance of converter furnace conditions, great influence on the production rhythm and production organization of subsequent processes, and achieve The effect of shortening the oxygen blowing time, reducing the production cost and reducing the consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The 130t converter produces 1215CW steel, and its finished product composition control requirements are: C: 0.04~0.08%, Si≤0.08%, Mn: 0.80~1.05%, P: 0.04~0.08%, S: 0.26~0.35%. According to the composition and temperature of molten iron, the proportion of scrap steel is reasonably matched, and the smelting method is smelted by leaving slag and less slag, increasing the smelting oxygen pressure, and appropriately reducing the position of the oxygen lance, so as to achieve the purpose of rapid decarburization and phosphorus conservation.

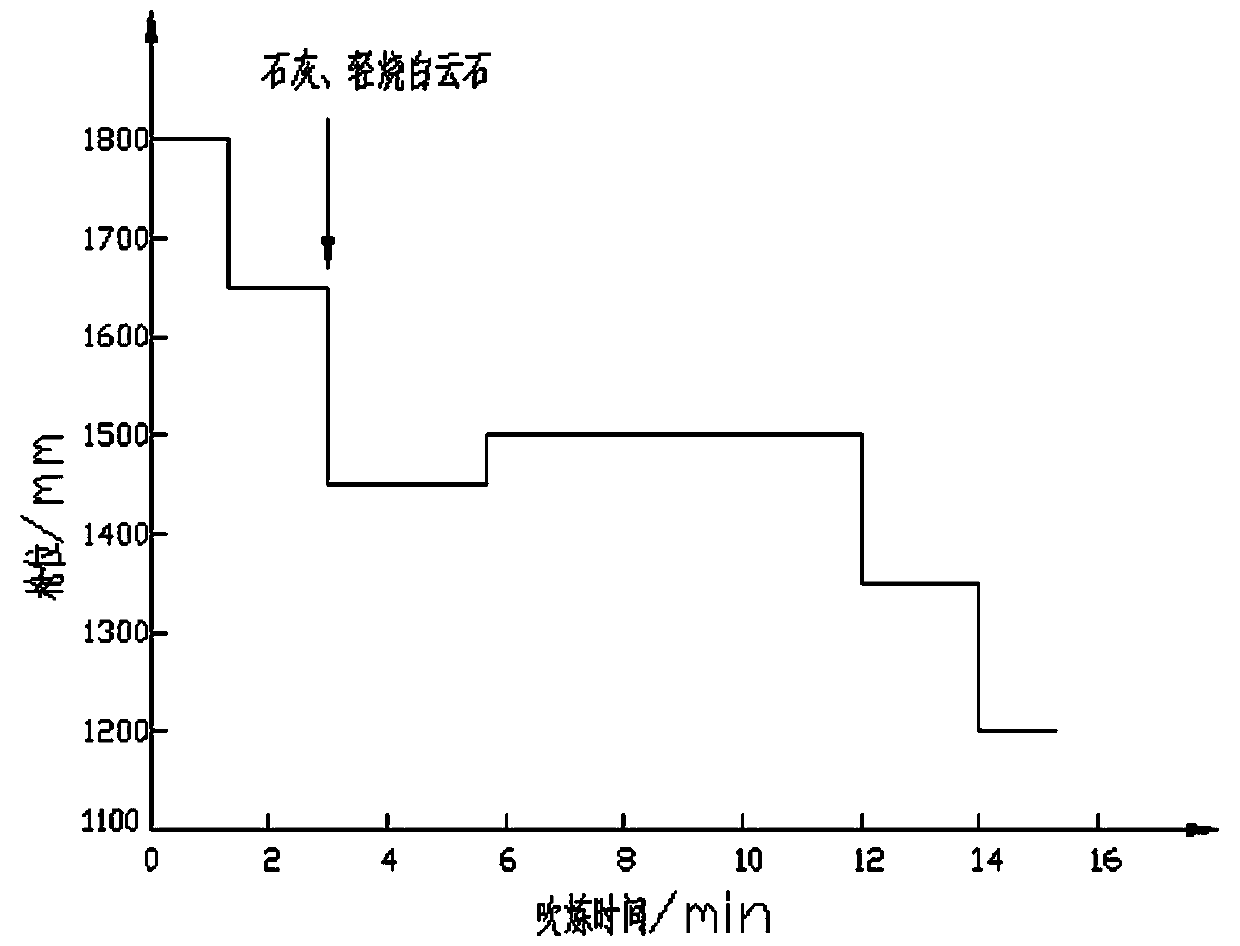

[0020] The specific steps are: the silicon content of the molten iron is 0.250%, the phosphorus content is 0.100%, the temperature of the molten iron is 1275°C, the steel scrap ratio is 16.2%, the amount of slag remaining after tapping the slag from the upper furnace is about 4 tons; within 4 minutes of starting the blowing, 280kg of active lime is added at one time ( 2.15kg / t steel), lightly burned dolomite 1200kg (9.23kg / t steel); the o...

Embodiment 2

[0022] The 130t converter produces 1214Bi steel, and the composition control requirements of the finished product are: C: 0.06~0.09%, Si≤0.08%, Mn: 1.22~1.30%, P: 0.04~0.08%, S: 0.26~0.34%. According to the composition and temperature of molten iron, the proportion of scrap steel is reasonably matched, and the smelting method is smelted by leaving slag and less slag, increasing the smelting oxygen pressure, and appropriately reducing the position of the oxygen lance, so as to achieve the purpose of rapid decarburization and phosphorus conservation.

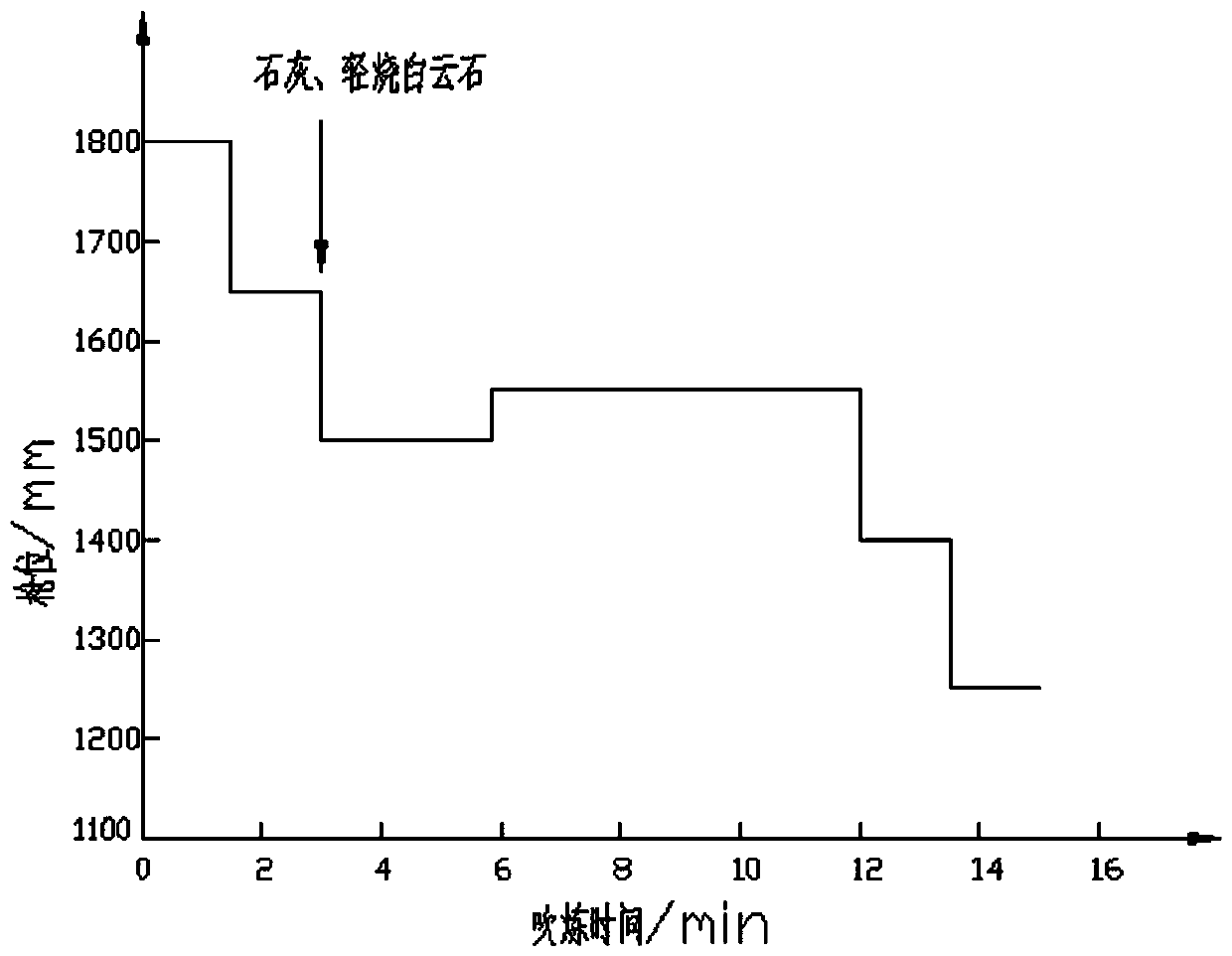

[0023] The specific steps are: the silicon content of the molten iron is 0.319%, the phosphorus content is 0.094%, the temperature of the molten iron is 1310°C, the steel scrap ratio is 19.8%, and the amount of slag remaining after tapping the slag from the upper furnace is about 3 tons; within 4 minutes of starting the blowing, 400kg of active lime is added at a time ( 3.10kg / t steel), lightly burned dolomite 1500kg (11.54kg / t ste...

Embodiment 3

[0025] The 130t converter produces 1215YG steel grade, and the composition control requirements of the finished product are: C: 0.04~0.08%, Si≤0.08%, Mn: 1.25~1.38%, P: 0.04~0.08%, S: 0.30~0.38%. According to the composition and temperature of molten iron, the proportion of scrap steel is reasonably matched, and the smelting method is smelted by leaving slag and less slag, increasing the smelting oxygen pressure, and appropriately reducing the position of the oxygen lance, so as to achieve the purpose of rapid decarburization and phosphorus conservation.

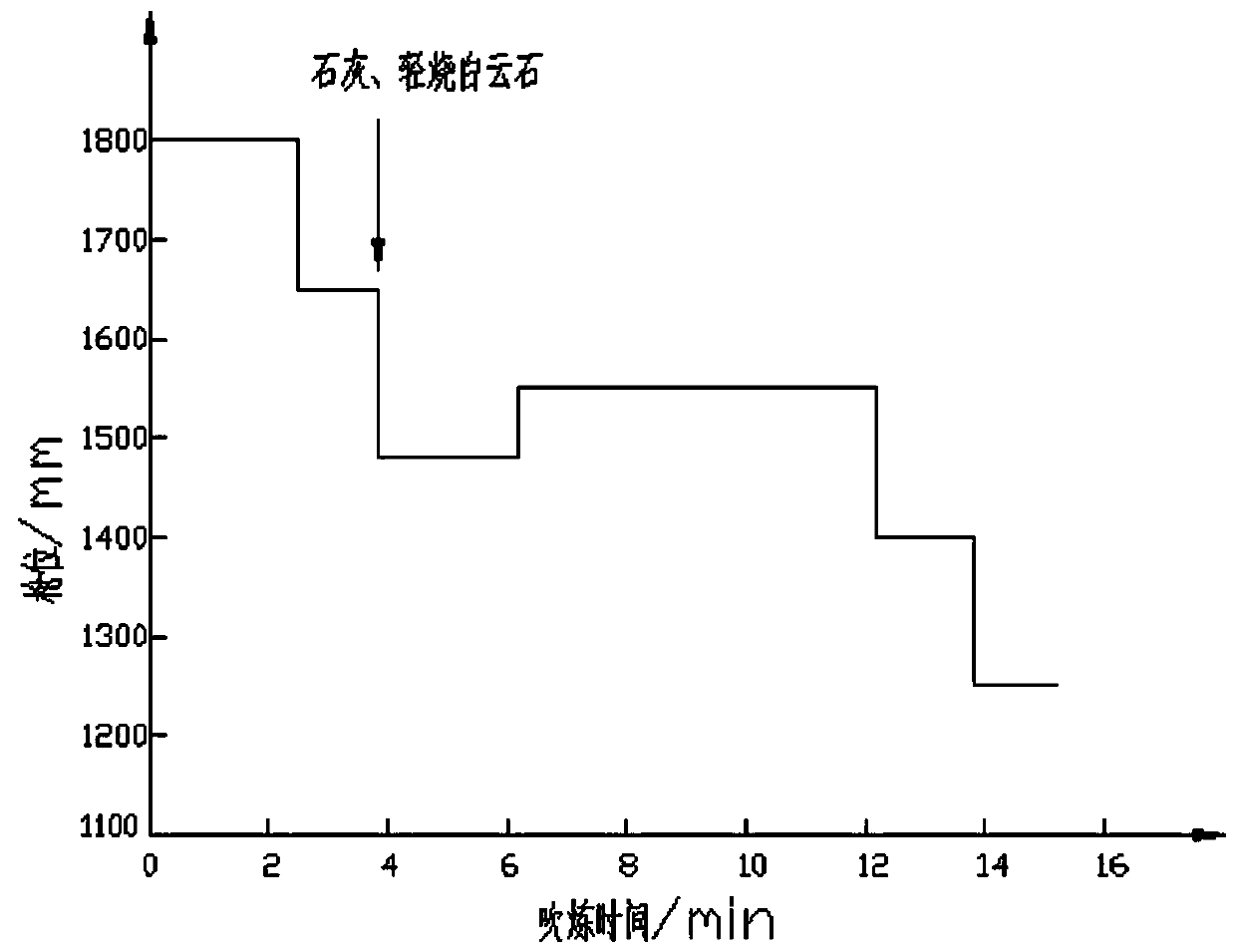

[0026] The specific steps are as follows: the silicon content of the molten iron is 0.512%, the phosphorus content is 0.110%, the temperature of the molten iron is 1344°C, the steel scrap ratio is 22.9%, the amount of slag remaining after tapping the slag from the upper furnace is about 5 tons; within 4 minutes of starting the blowing, 477kg of active lime is added at one time ( 3.67kg / t steel), lightly burned dolomite 1400kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com