Flow path selector valve

A switching valve, flow channel technology, applied in the field of flow channel switching valve, to achieve the effect of shortening the switching time, reliable switching, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

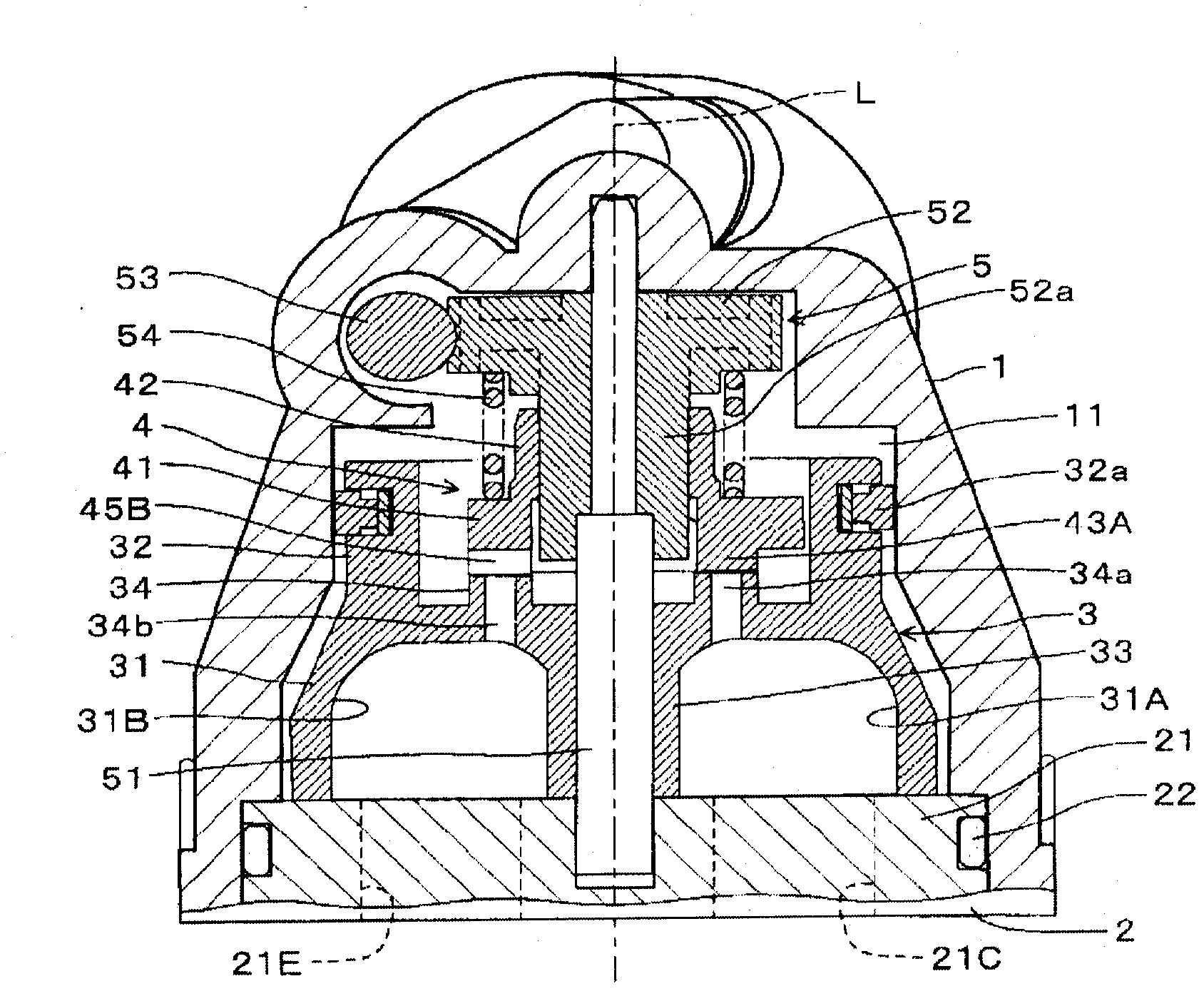

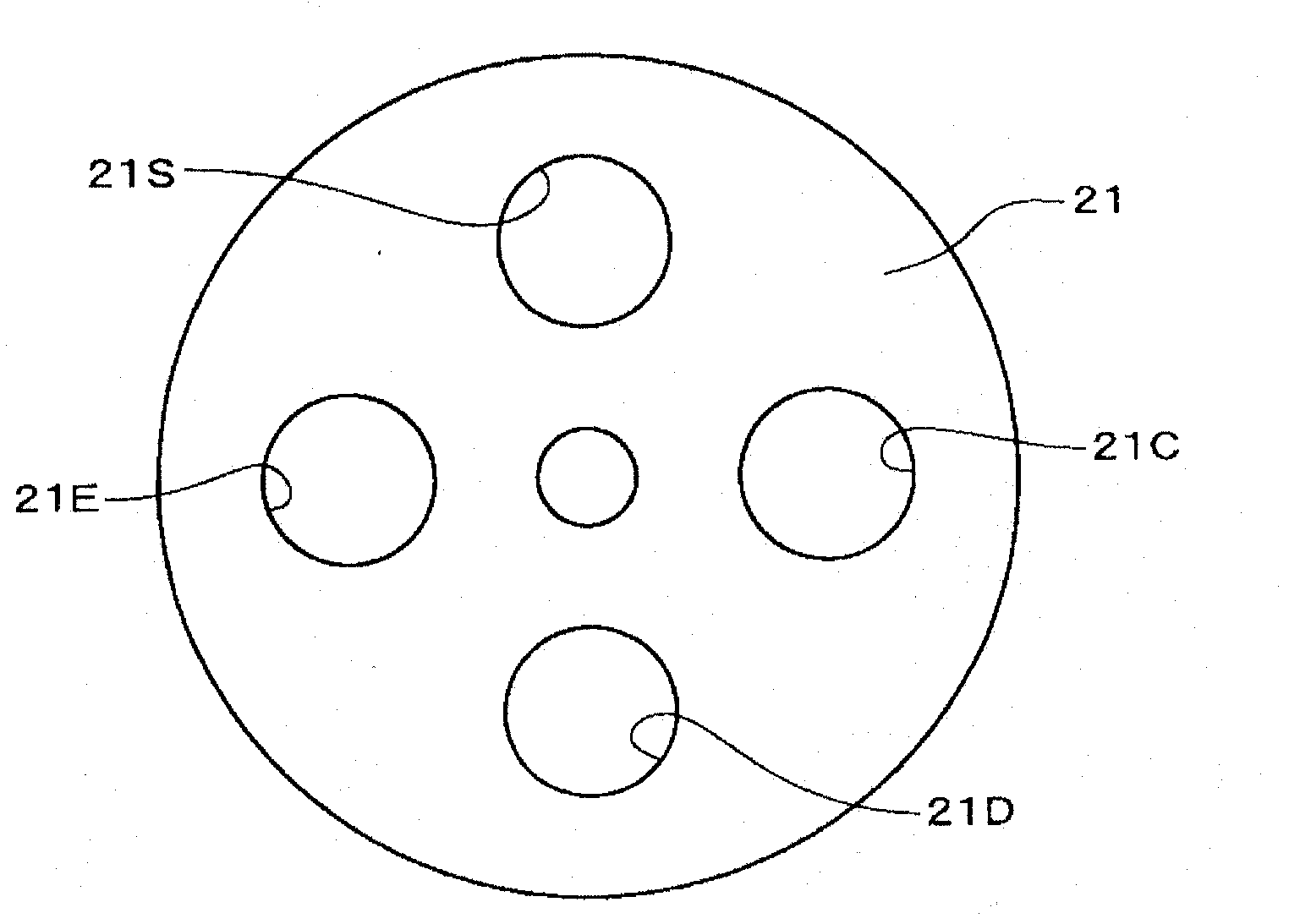

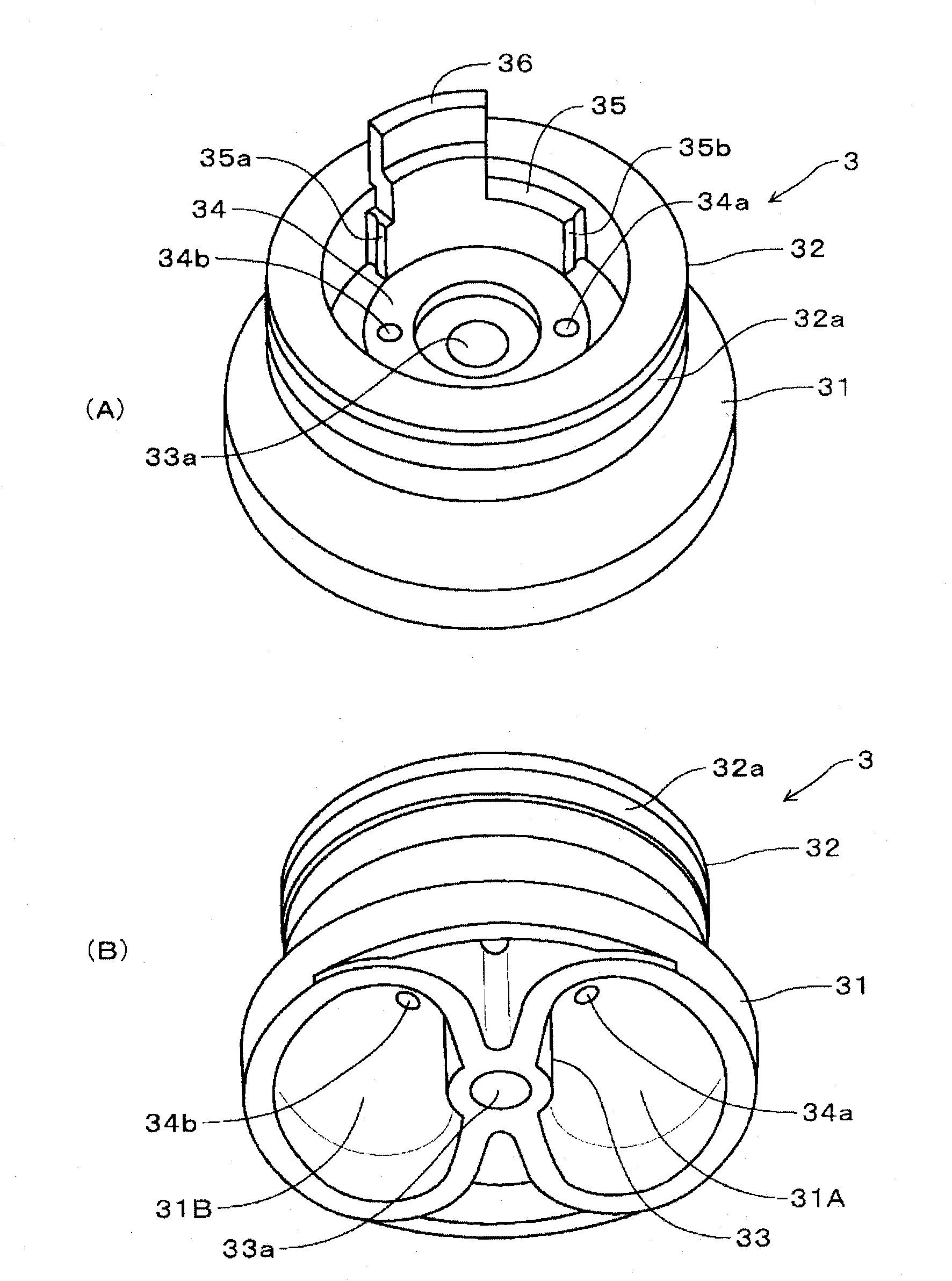

[0035] Next, embodiments of the channel switching valve of the present invention will be described with reference to the drawings. figure 1 It is a longitudinal sectional view of the channel switching valve according to the first embodiment of the present invention, figure 2 is a top view of the valve seat of the channel switching valve, image 3 is a perspective view of the main valve of the channel switching valve, Figure 4 is a perspective view of the auxiliary valve of the channel switching valve, Figure 5 ~ Figure 7 This is an explanatory diagram of the operation of the channel switching valve. and also, figure 1 It is a figure showing the middle of switching of the main valve.

[0036] The channel switching valve of the first embodiment has a case member 1 and a valve seat member 2 . A valve chamber 11 cut into a substantially cylindrical shape is formed in the housing member 1 . In addition, a circular platform-shaped valve seat 21 is formed on the valve seat m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com