Method and installation for the production of synthesis gas

A technology for synthesis gas and equipment, which is applied in hydrogen/syngas production, chemical instruments and methods, and joint combustion mitigation, etc., to achieve the effect of reducing costs and investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

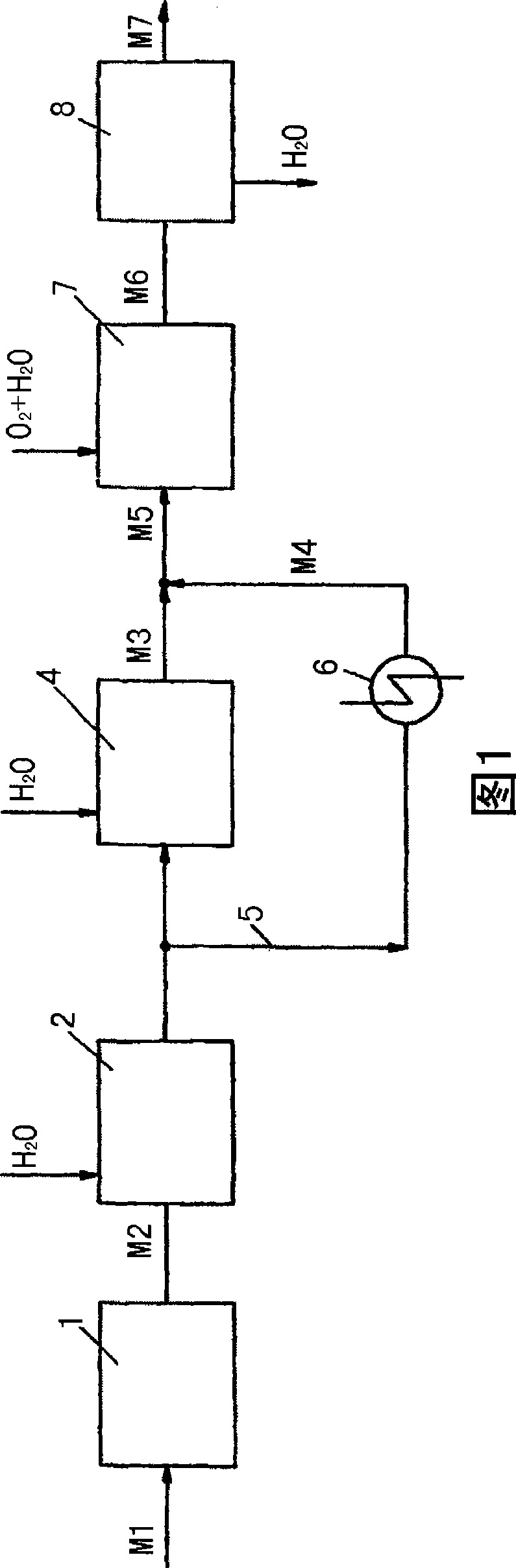

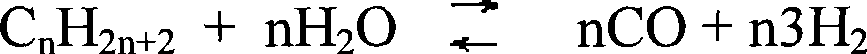

[0026] In the flow diagram of the method according to the invention for producing synthesis gas shown schematically in FIG. 1 , the raw material, in particular natural gas, is firstly freed of interfering by-products, especially sulfur, in a desulfurization plant 1 . Subsequently, natural gas (for example with a content of higher hydrocarbons greater than 12 vol.-%, ie hydrocarbons with two or more carbon and hydrogen atoms) is mixed with water or steam and introduced into the pre-reforming unit 2 middle. Here, for example, use is made of a steam reformer operated adiabatically with a nickel-based or copper-based catalyst, in which steam reforming reaction converts the carbon Hydrogen compounds are converted to C 1 compound. The selected temperature makes the reaction equilibrium largely shift to the methane side. Higher hydrocarbons will crack into CO and H 2 , followed by the main reaction to form methane. Then we get methane-rich and H-containing 2 and CO 2 gas. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com