Tire structure for wheelchair

A technology for tires and wheelchairs, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of labor-intensive promotion, single performance, and weak grip, so as to save labor and reduce potential safety hazards , the effect of good grip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

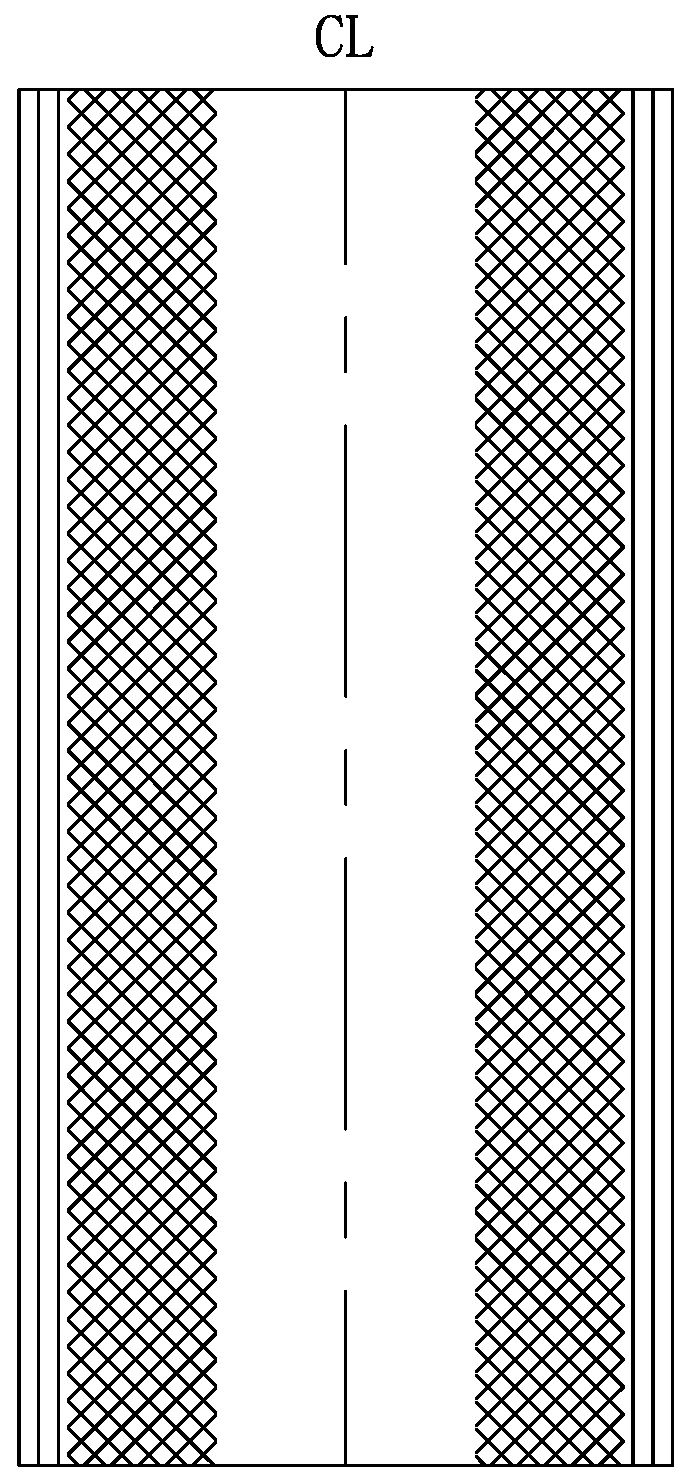

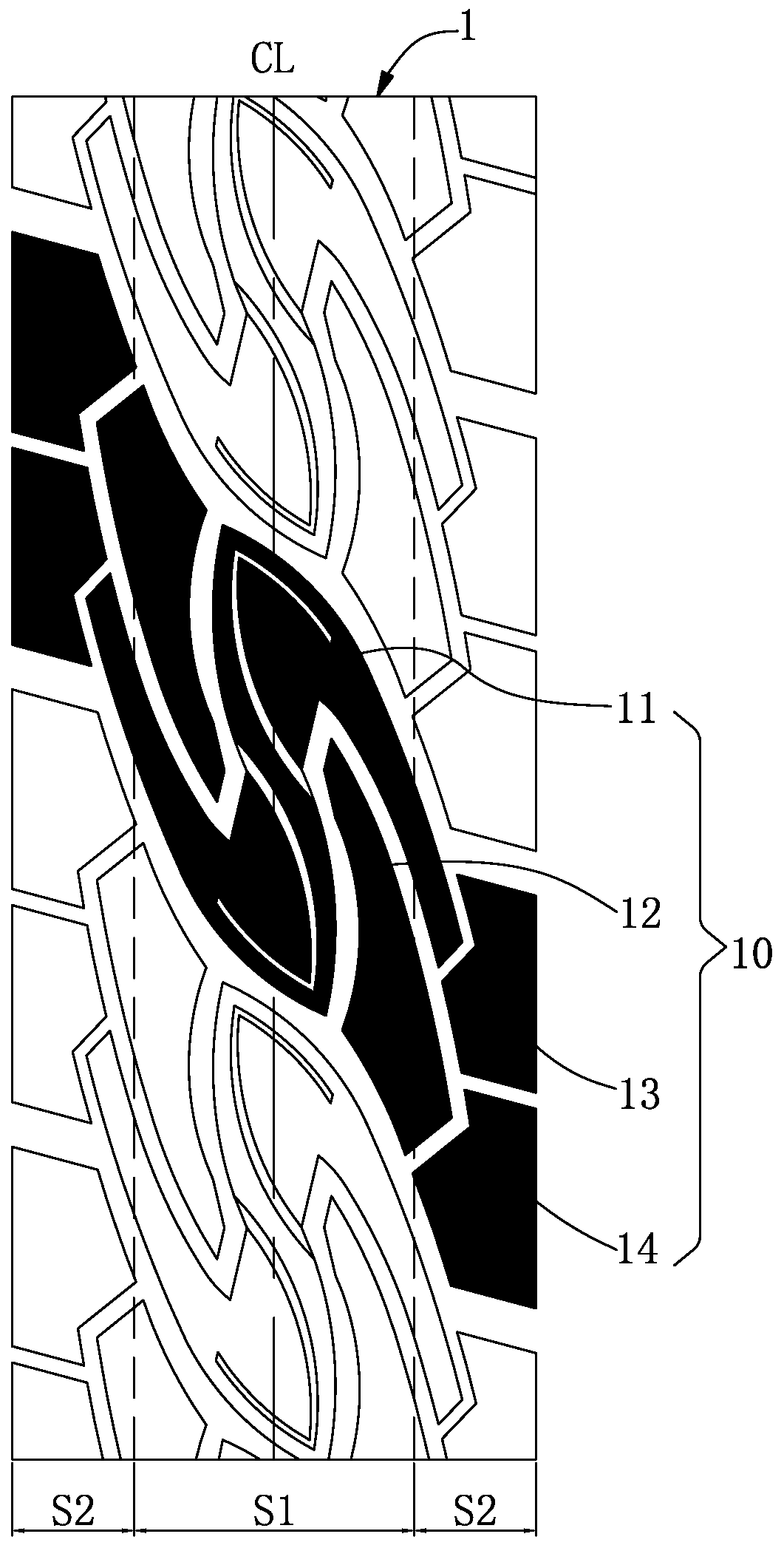

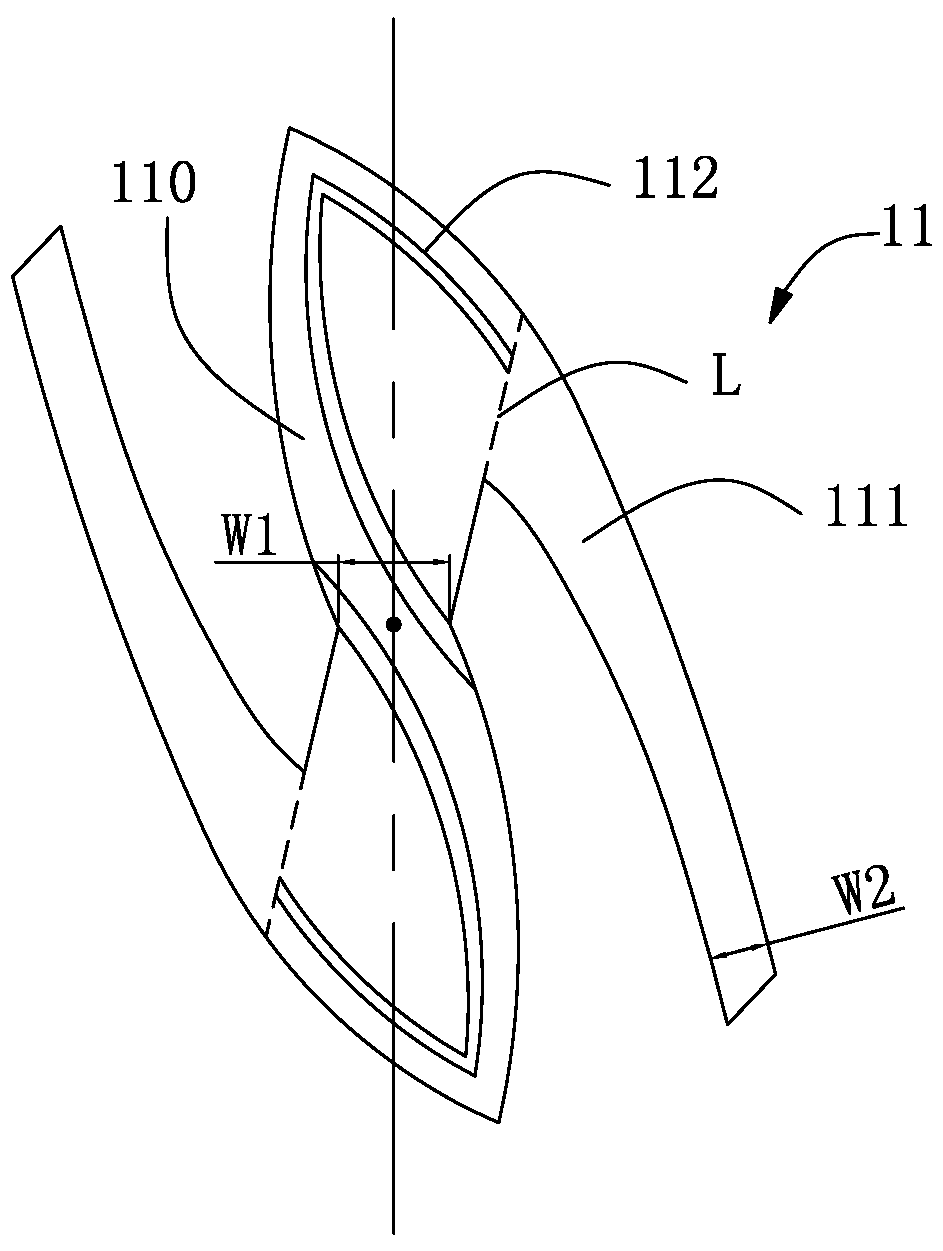

[0037] Such as Figure 2 to Figure 6 As shown, the present invention discloses a wheelchair tire structure. exist Figure 2 to Figure 5 The vertical direction is the tire circumferential direction, the transverse direction is the tire axial direction, and the single dotted line represents the tread centerline CL. exist Image 6 In the middle, the vertical direction is set as the tire radial direction, the transverse direction is the tire axial direction, and the single dotted line indicates the equatorial plane.

[0038] Such as figure 2 Shown is a tread pattern of the tire tread of the present invention, in view of the actual use of wheelchair tires, such as Image 6 As shown, the tread 1 is divided into the contact area S1 and two transition areas S2, where the contact area S1 is figure 2 The area defined between the two das...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com