Low-flow fast movable cylinder

A fast-moving, low-flow technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of high configuration cost, complicated pipeline, and complex structure of two-speed cylinder, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

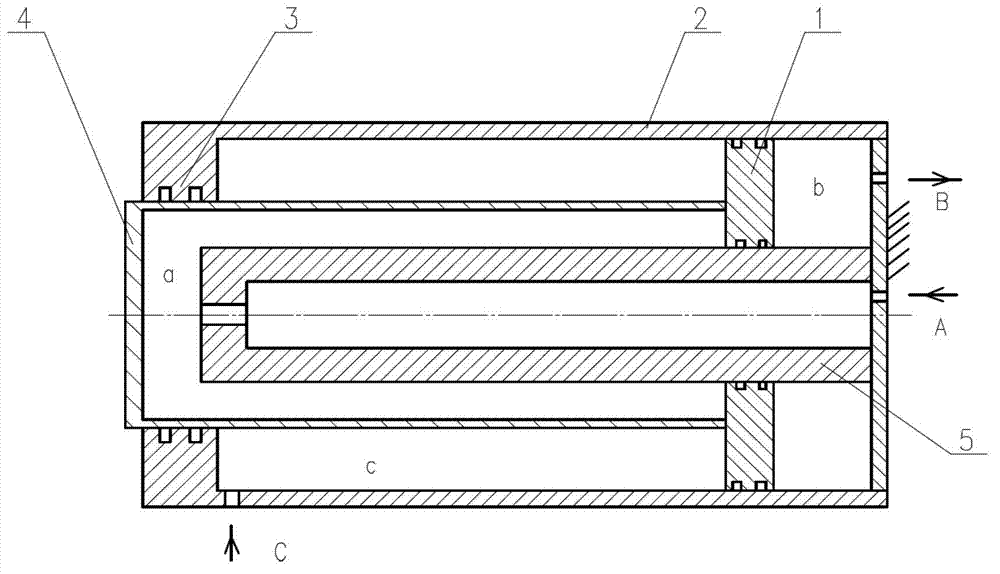

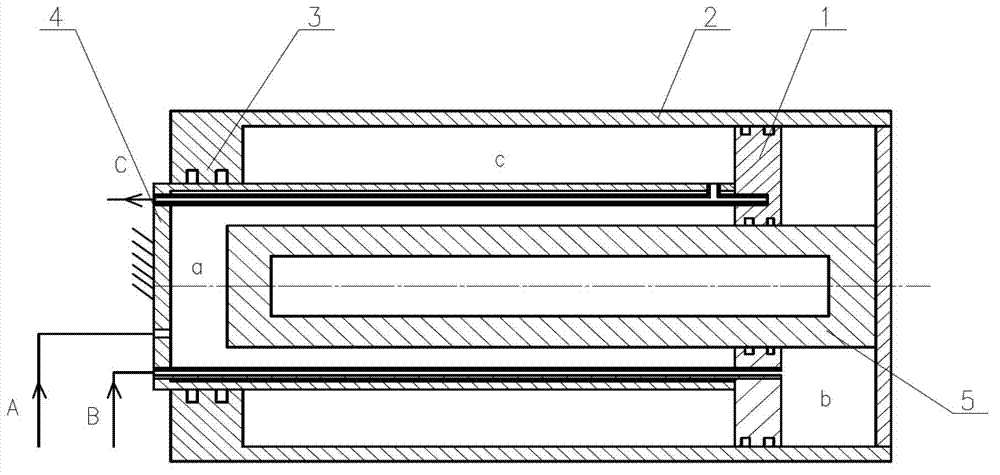

[0017] Such as figure 1 As shown, the small-flow fast-moving oil cylinder of the present invention includes a cylinder barrel 2, a piston 1, a hollow piston rod 4, and a hollow plunger 5; The inner cavity of the cylinder is divided into a first oil storage chamber c and a second oil storage chamber b. Those skilled in the art should know that the volumes of the first and second oil storage chambers will change with the relative movement between the piston and the cylinder One end of the piston rod 4 is fixedly connected to the side of the piston 1 forming the first oil storage chamber c, and the other end is used as an output end to connect with the side wall of the first oil storage chamber c opposite to the piston 1 in a closed sliding fit; the plunger One end of 5 is fixedly connected with the side wall of the second oil storage chamber b opposite to the piston 1, and the other end is connected with the piston in an airtight sliding fit, and extends into the hollow cavity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com