Structure and method for hanging and installing bottom suspension device of high speed motor train unit

A technology for high-speed EMUs and off-board equipment, which is applied in transformer/reactor installation/support/suspension, locomotives, transportation and packaging, etc. It can solve problems such as long reloading time, reduced comfort, and high transformation costs, and achieves installation The structure is simple and convenient, the effect of improving the replacement efficiency and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

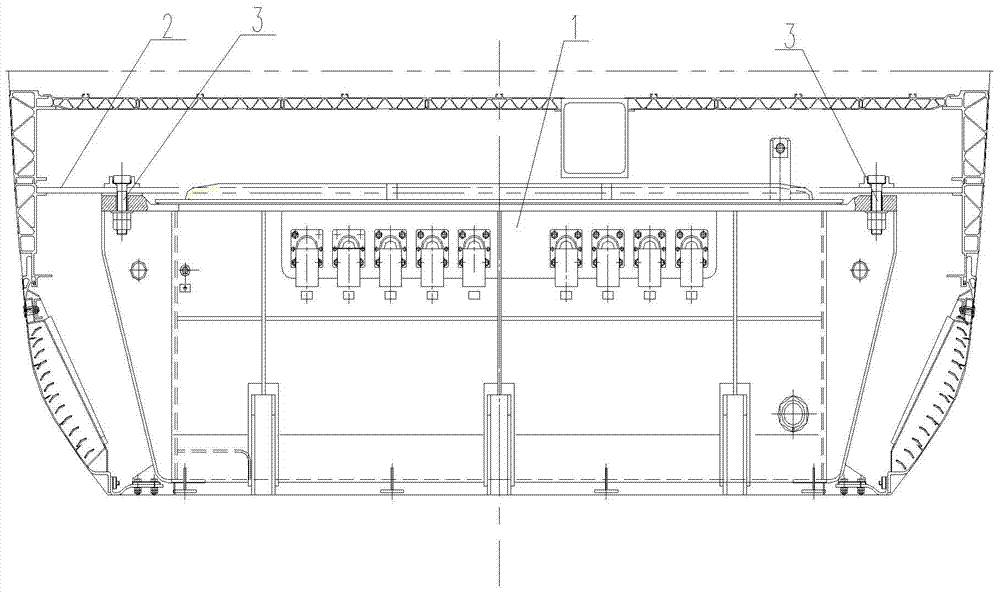

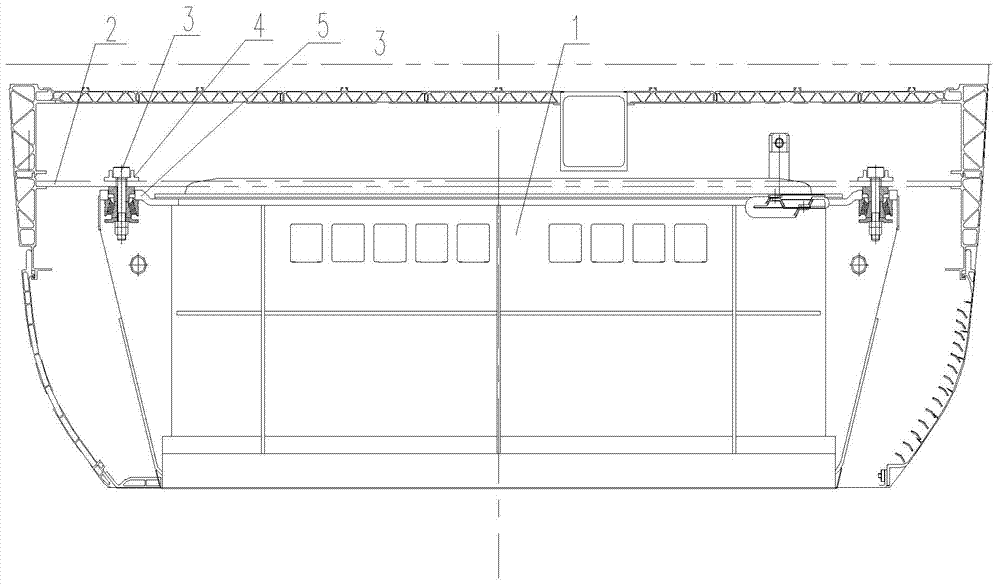

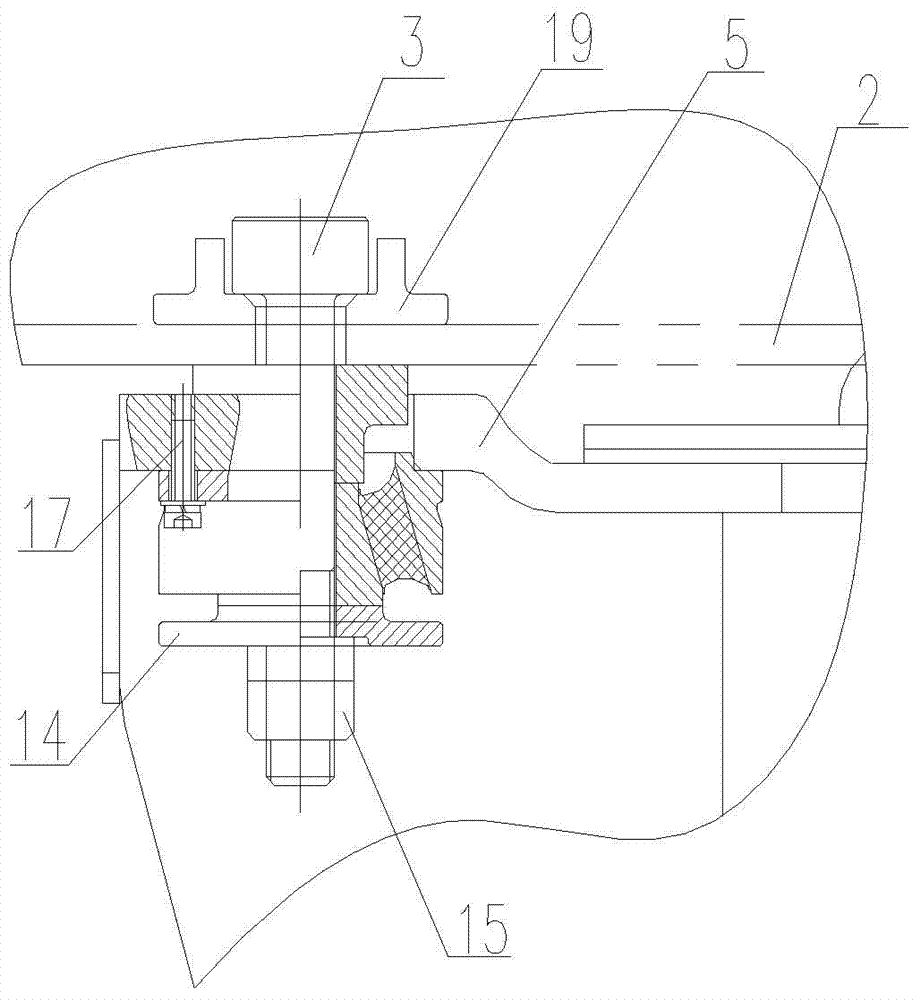

[0035] like Figure 2 to Figure 4 As shown, the present invention provides a hanging installation structure for the undercarriage equipment of a high-speed EMU. In this embodiment, the traction transformer 1 is used as an example for the undercarriage equipment to be described in detail.

[0036] The traction transformer 1 is suspended below the crossbeam 2 of the underframe of the car body, and the mounting part 4 is arranged on the crossbeam 2 of the underframe of the carbody, and the mounting seat 5 is correspondingly arranged on the traction transformer 1. On both sides of the top of the traction transformer 1, There is one mounting seat 5, and eight mounting holes 6 are provided on each mounting seat 5. Correspondingly, two mounting parts 4 for hanging the traction transformer 1 are provided on the vehicle body underframe beam 2, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com