Networked intelligent warehouse status detection control system

A detection control system, intelligent storage technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of many network structure levels, low energy utilization, energy waste, etc., to improve data transmission efficiency , the effect of reducing the number of charging and discharging, and the flattening of the network architecture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

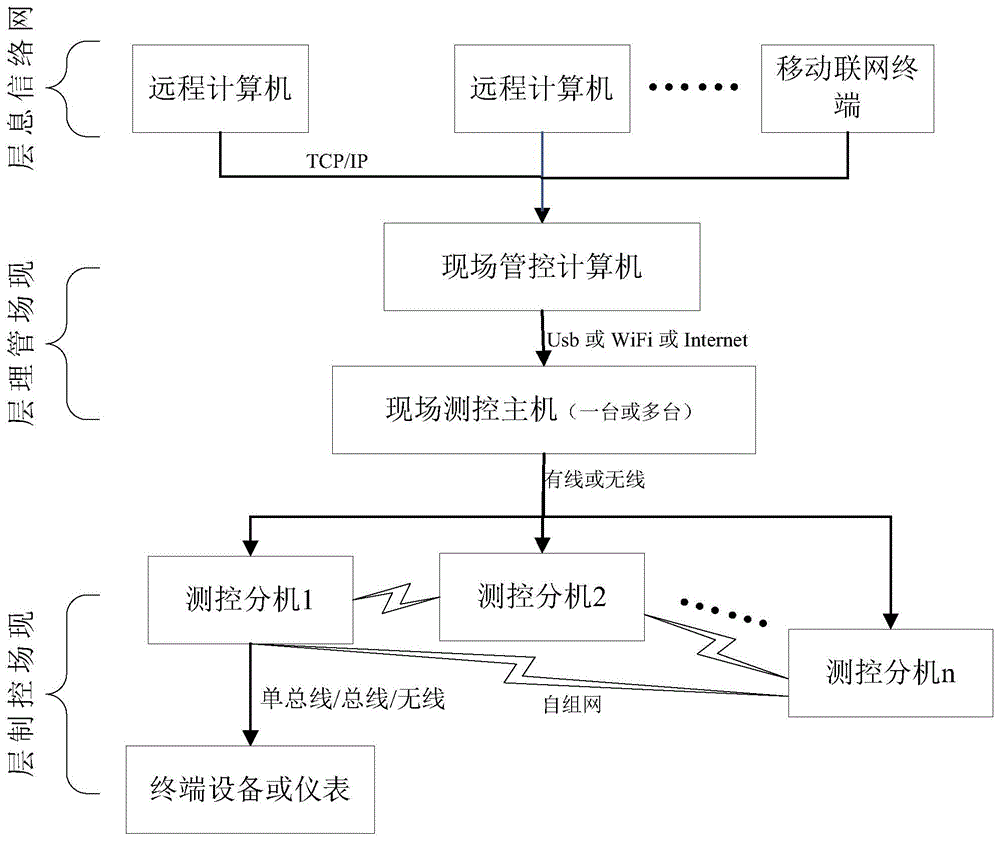

[0064] The present invention provides a networked intelligent storage status detection and control system, which is applied in the field of grain storage as an example, such as figure 1 As shown, it includes the network information layer, on-site management layer, and on-site control layer, which are divided into three layers of standard industrial networks from top to bottom;

[0065] the information layer includes at least one remote computer;

[0066] On-site management includes at least one on-site control computer and at least one on-site measurement and control host;

[0067] The on-site control layer includes at least one measurement and control extension and terminal equipment or instruments communicatively connected to the measurement and control extension;

[0068] The remote computer communicates with the on-site control computer through a network based on the TCP / IP network protocol;

[0069] The on-site management and control computer communicates with the on-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com