Device and method to study relationship between interference and thermal contact resistance

A technology of contact thermal resistance and interference, which is applied in the field of devices to explore the relationship between the interference and the contact thermal resistance of the joint surface of the cylindrical sleeve, can solve the problems that the spindle affects the machining accuracy of the machine tool, bearing burns, temperature distribution deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

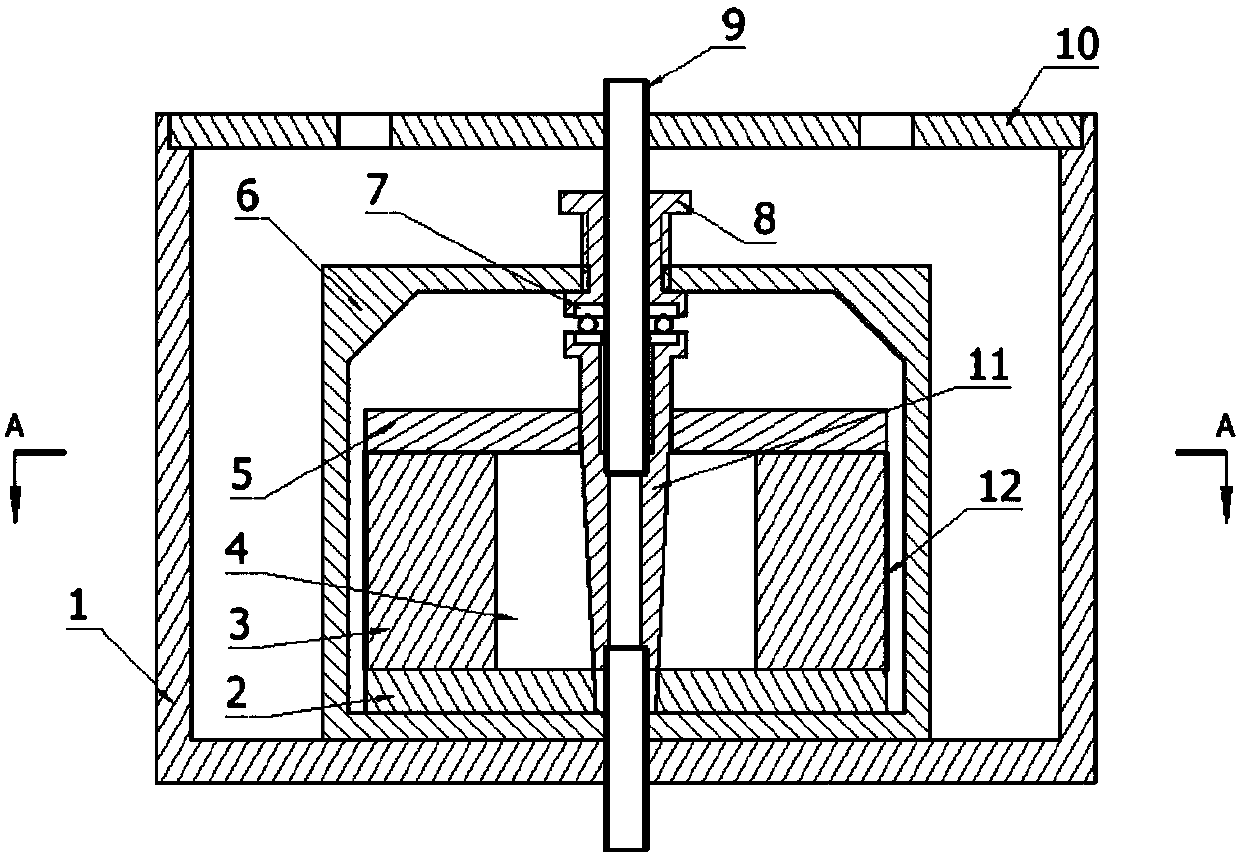

[0039] A device for exploring the relationship between the interference amount and the contact thermal resistance of the joint surface of a cylindrical sleeve, including a cooling conical mandrel 11, a ring 4, a sleeve 3, a host computer and a support 6,

[0040] The outer surface of the sleeve 3 is provided with a heating film 12 for maintaining the constant temperature of the outer surface of the sleeve 3; wherein, the heating film 12 is a common thermal insulation heating device, which has a heater, a temperature detector and a feedback controller, The temperature detector detects the temperature of itself or the outer surface of the sleeve 3, and transmits the detection result to the feedback controller; the feedback controller determines the heating power of the heater according to the set target.

[0041] The ring 4 is at the same height as the sleeve 3, the outer surface of the ring 4 is in contact with the inner surface of the sleeve 3, and the inner cavity of the ring ...

Embodiment 2

[0069] The present invention designs a device for exploring the relationship between the interference amount and the contact thermal resistance of the joint surface of the cylindrical sleeve. The technical scheme of the device is as follows:

[0070] The detection device includes a cooling conical mandrel 11, a four-lobed ring 4, a sleeve 3, a heating film 12, a screw loader 8, a thrust bearing 7, a heat insulation cover, a support 6, a vacuum cover, and the like. All other components except the vacuum hood are placed inside the vacuum hood. The inner hole of the cooling conical mandrel 11 is used for circulating cooling water, and the upper and lower parts are connected with water pipes with pipe threads, and the direction of circulating cooling water is from bottom to top; , the four-petal ring 4 is to divide the ring 4 into four equal parts to realize external expansion; the four-petal ring 4 is radially externally connected to the sleeve 3, and the outer wall of the sleeve...

Embodiment 3

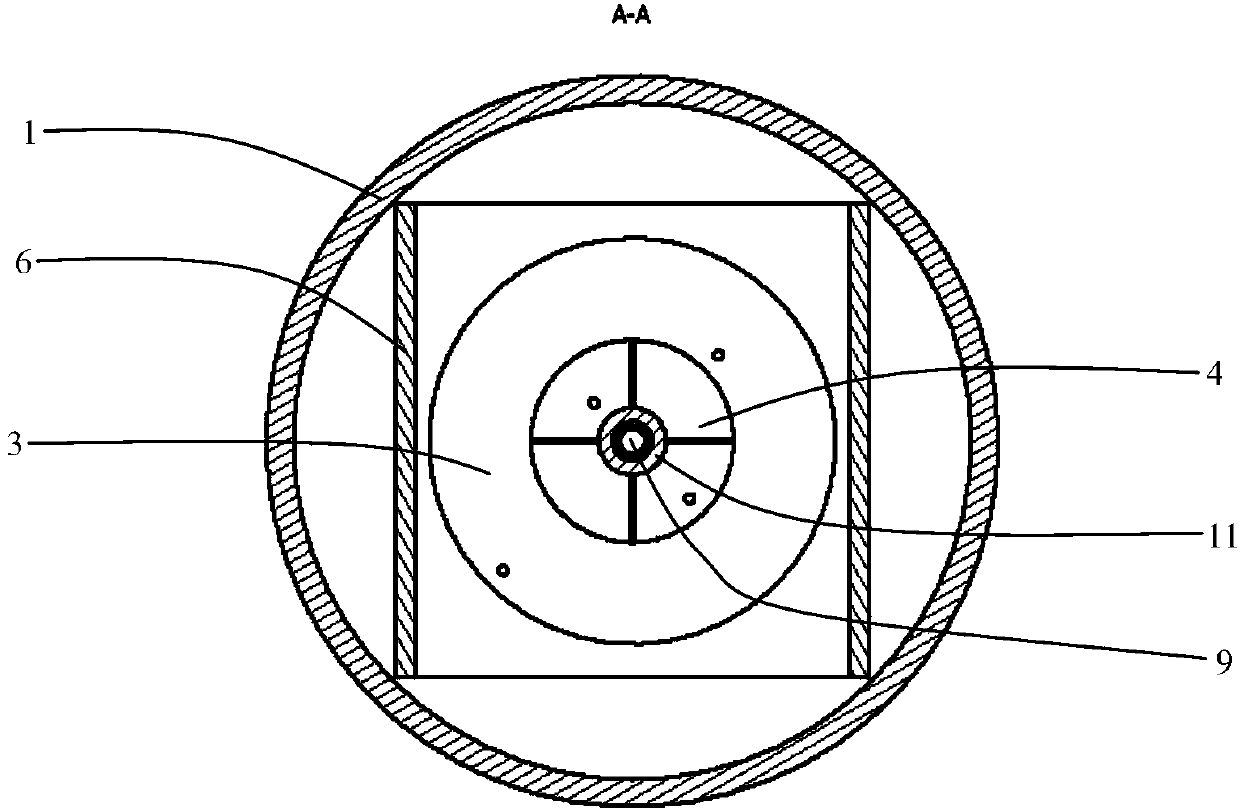

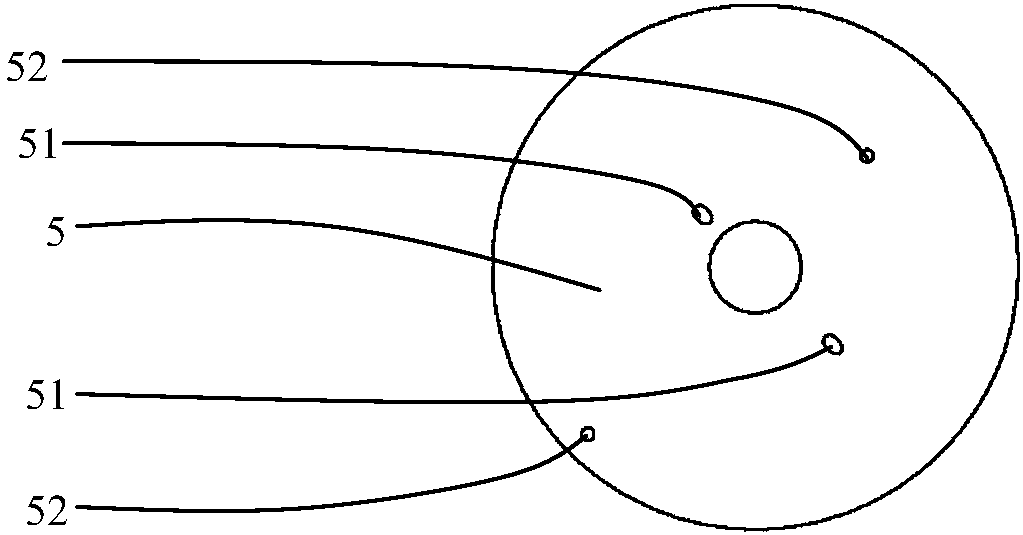

[0085] Such as Figure 1 to Figure 4 As shown, the device designed in the present invention to explore the relationship between the interference amount and the contact thermal resistance of the cylindrical sleeve joint surface includes a cooling conical mandrel 11, a four-lobed ring 4, a sleeve 3, a heating film 12, a spiral loading Device 8, thrust bearing 7, upper heat insulation cover 5, lower heat insulation cover 2, support 6 and vacuum cover 10.

[0086]The temperature of the heating film 12 on the outer surface of the sleeve 3 is kept constant, and the cooling conical mandrel 11 is fed with circulating constant temperature cooling water, and the water pipes are threaded through the upper and lower pipes in the cooling conical mandrel. The four-lobe ring 4 and the upper and lower end faces of the sleeve 3 are insulated with a heat insulating cover. This ensures a large temperature gradient in the radial direction, improves test accuracy, and facilitates later data proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com