Rear retainer ring of wagon rolling bearing

A technology for rolling bearings and railway wagons, which is applied in the field of bearing manufacturing, and can solve the problems of increasing wear speed, wear of the back ring, and reducing the sealing effect of the back ring, so as to compensate for fretting wear, reduce axial movement, and realize reuse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in conjunction with accompanying drawing and specific embodiment:

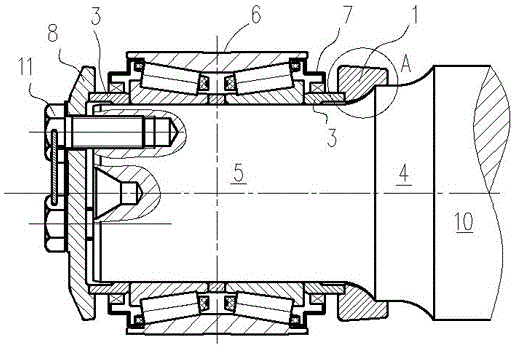

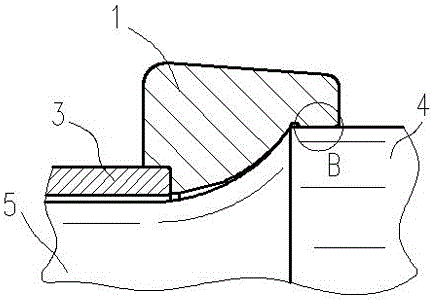

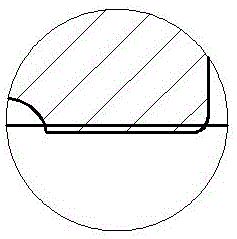

[0017] like Figure 4 , Figure 5 , Figure 6 Shown is a backstop ring for rolling bearings of railway wagons. The backstop ring 1 is sleeved at the junction of the journal 5 and the dustproof plate seat 4; the backstop ring 1 has a backstop main body 1-1; The backstop main body 1-1 is ring-shaped, sleeved on the shaft shoulder at the end of the journal, and cooperates with the bearing seal seat 3 on the journal; the inner surface of the backstop main body 1-1 is in contact with the shaft The outer wall of the shoulder matches the arc surface; one side end surface of the backstop main body 1-1 has an annular slot for installing the sealing ring 1-2; one end of the sealing ring 1-2 is located at the backstop main body 1-1, the other end is sleeved on the above-mentioned dust-proof plate base 4; the middle part of the inner diameter surface of the sealing ring has an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com