Sub-mouth sealing mode and device of air spring

An air spring and sealing device technology, which is applied to the sealing of rubber air springs, the sealing method of rubber capsules on the upper openings of air springs and the field of their devices, to achieve the effects of easy production and processing, excellent sealing performance, and air tightness assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

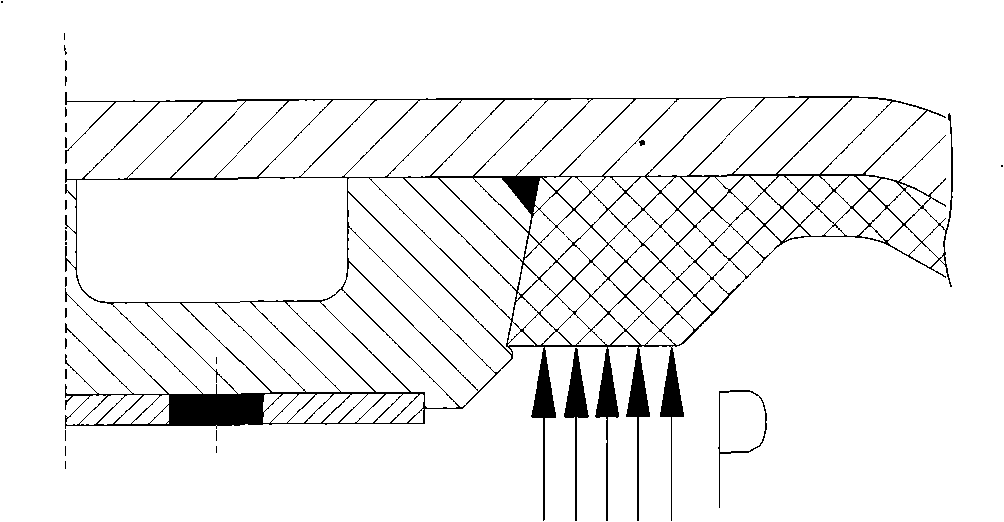

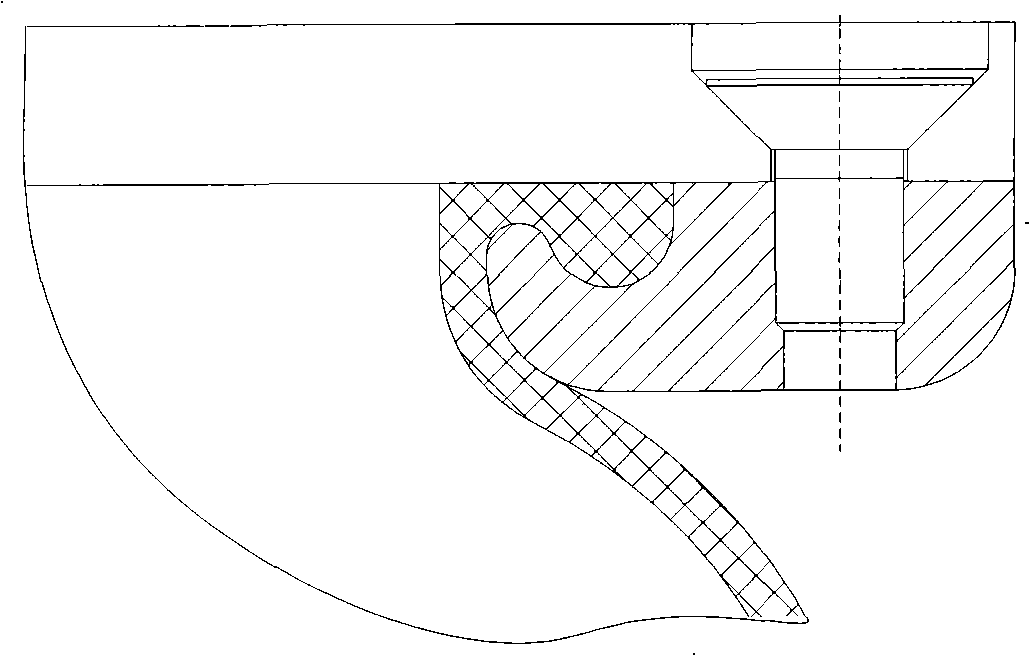

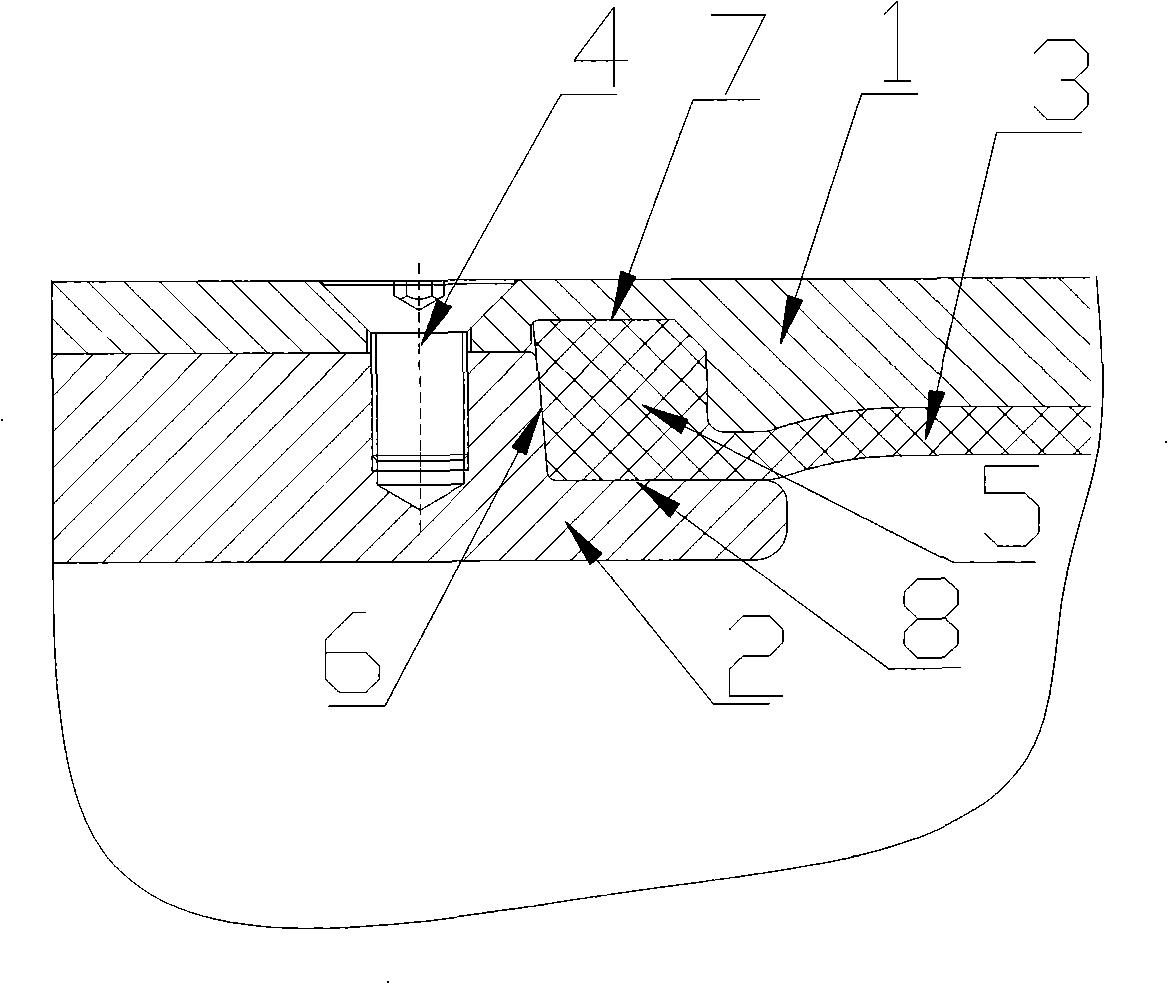

[0019] A sealing device for the upper mouth of a rubber air spring rubber airbag, comprising an upper cover plate 9, a friction plate 15, and a rubber airbag 10. The upper mouth 11 of the rubber airbag 10 is sandwiched between the upper cover plate 9 and the friction plate 10 In the middle, the upper sub-mouth 11 of the rubber airbag 10 is in the shape of a unilateral cone; on the upper cover plate 1, there is a groove-shaped notch 12 for installing the upper sub-mouth 11 of the rubber airbag 10, and the fastener is passed in the groove-shaped notch 12 13 is equipped with a boss 14, and a gap in the shape of a "7" is formed by the groove-shaped notch 12 and the boss 14; on the friction plate 15, there is also a gap 16 for installing the upper sub-mouth 11 of the rubber air bag 10, and the friction plate The notch 16 on 15 is a unilateral conical notch close to the outer circle; the "7" notch formed by the groove-shaped notch 12 of the upper cover plate 9 and the boss 14 is comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com