Patents

Literature

104results about How to "Won't come off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

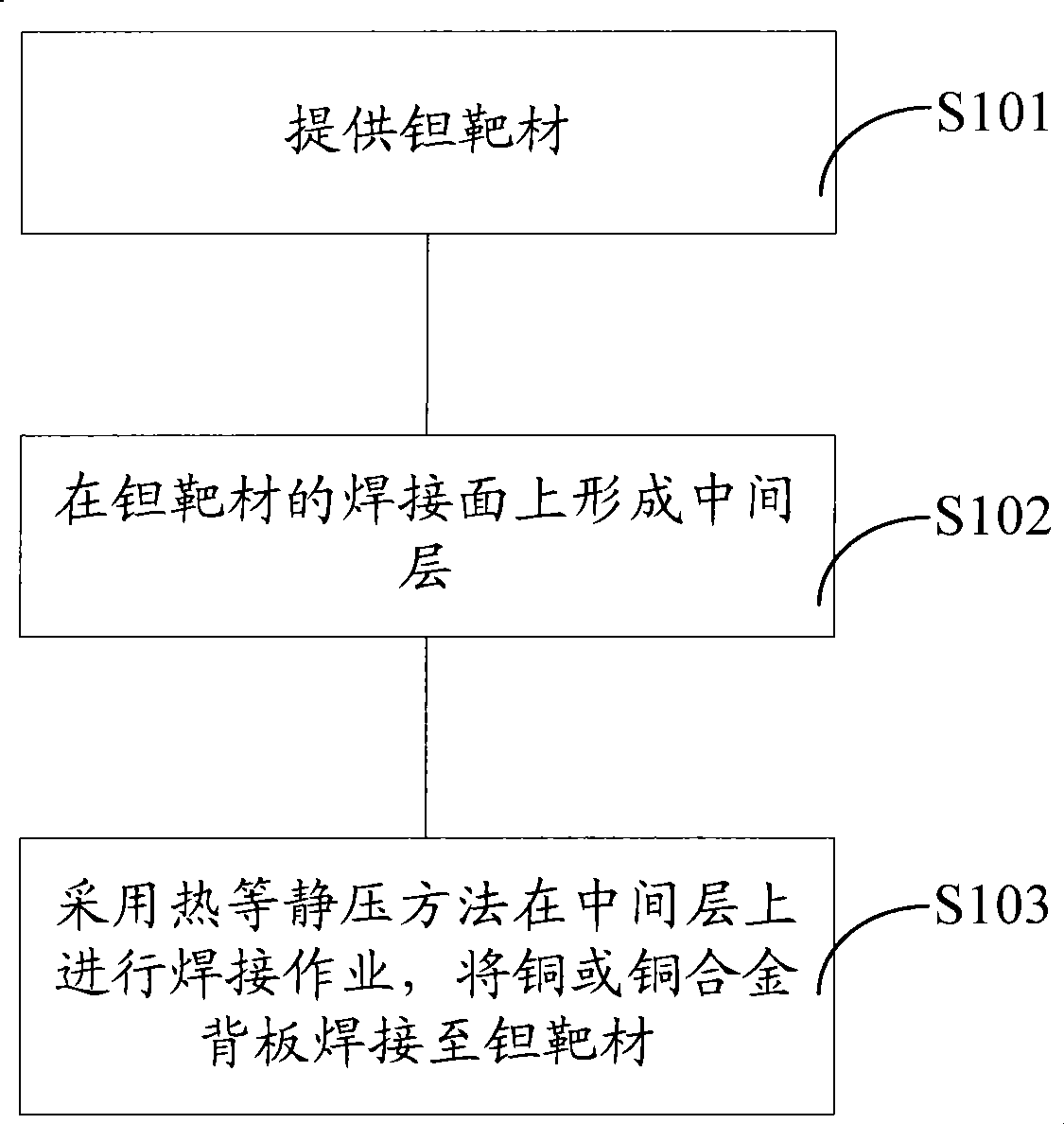

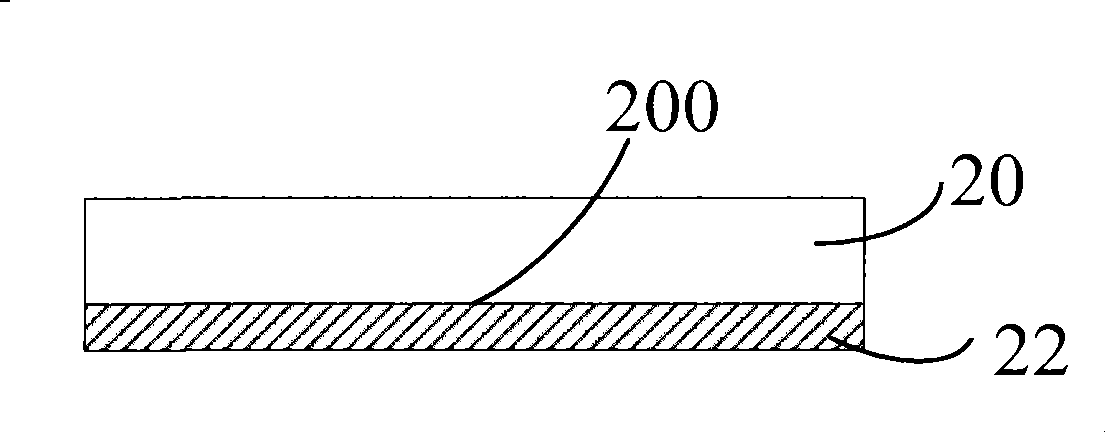

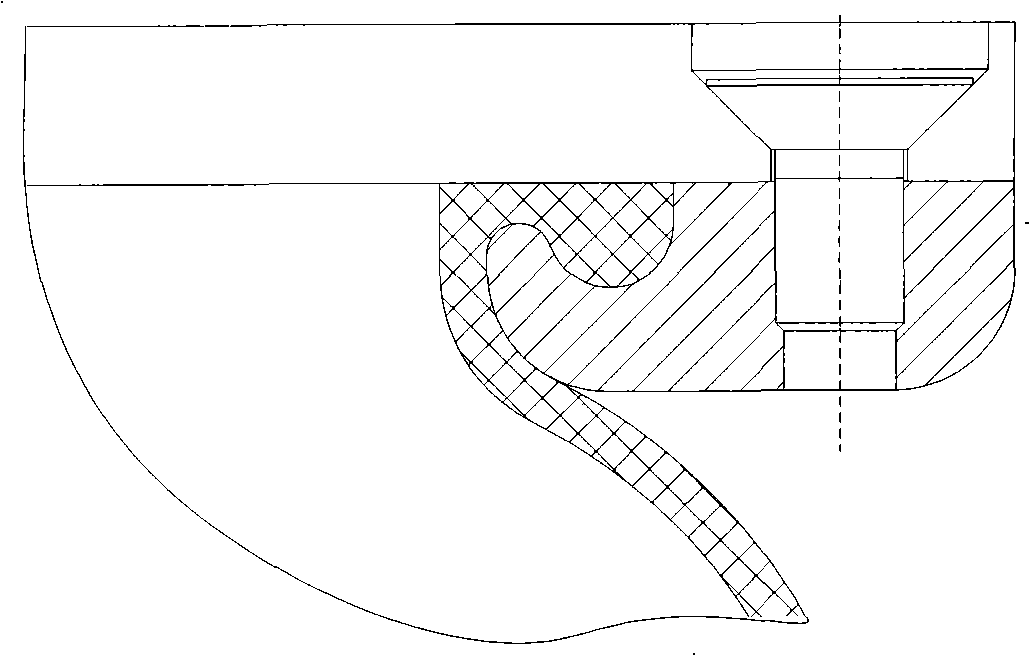

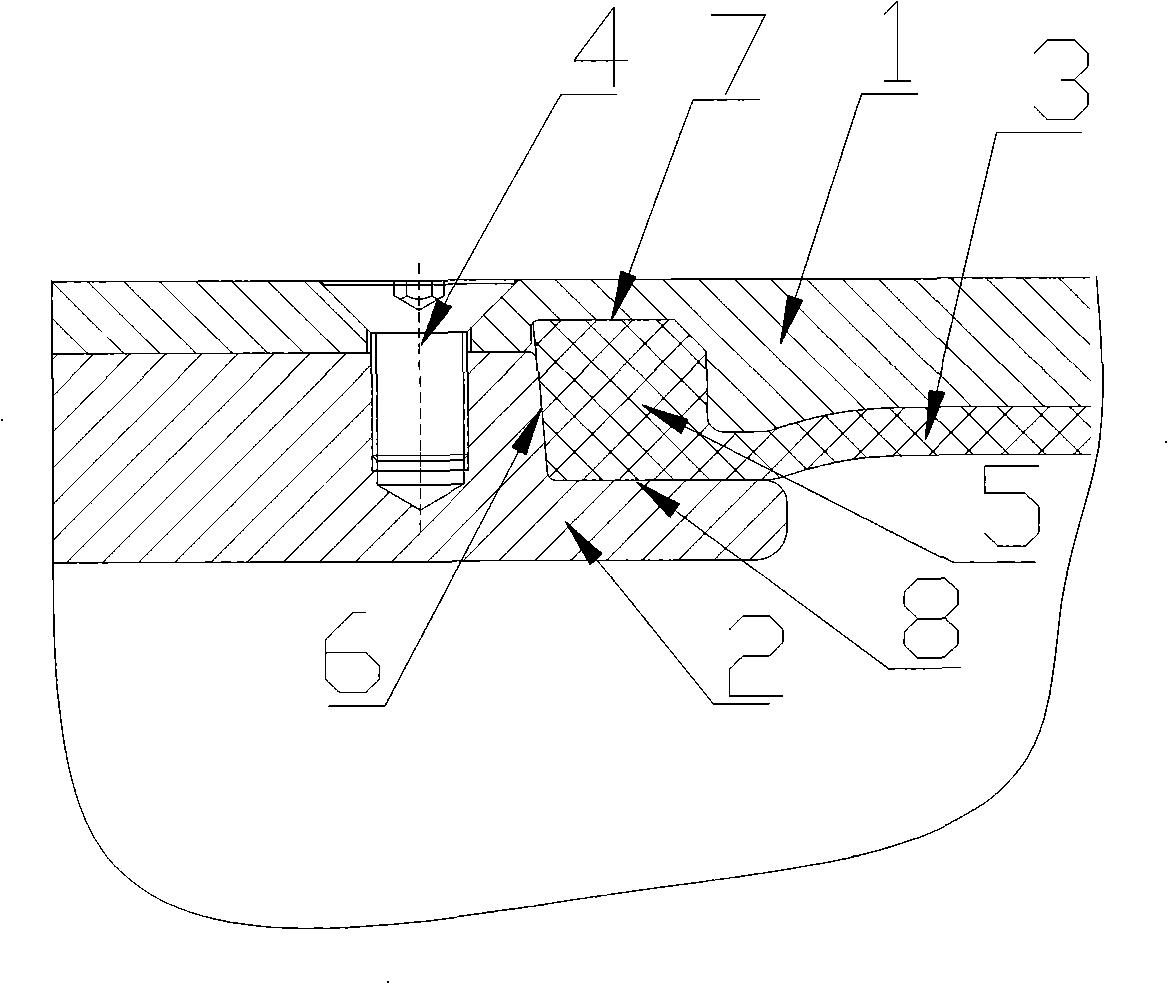

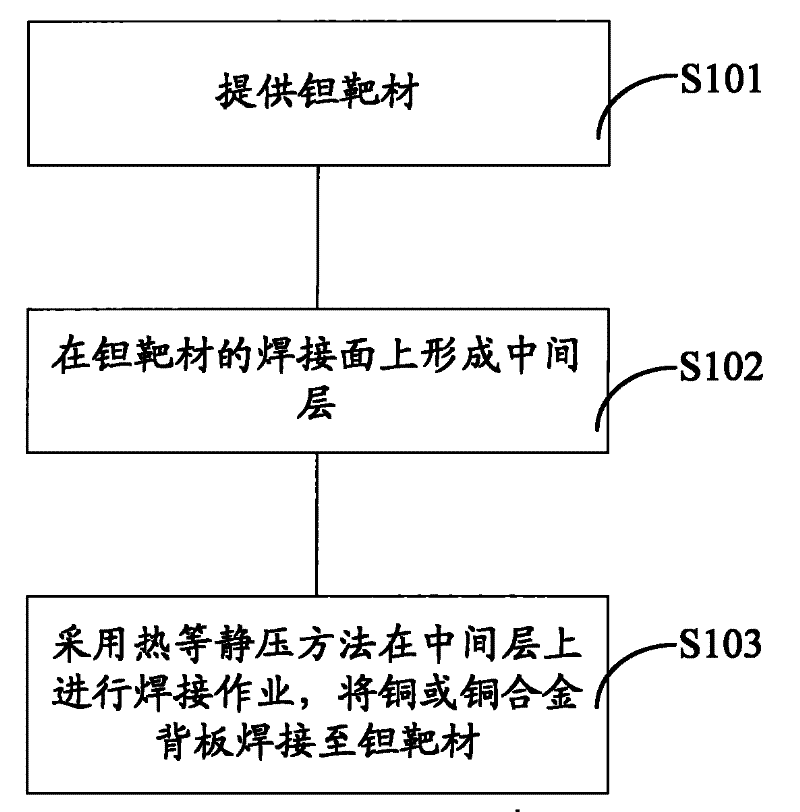

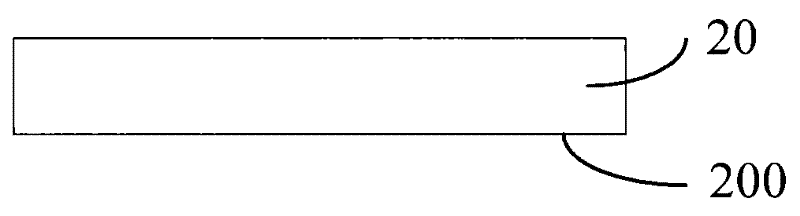

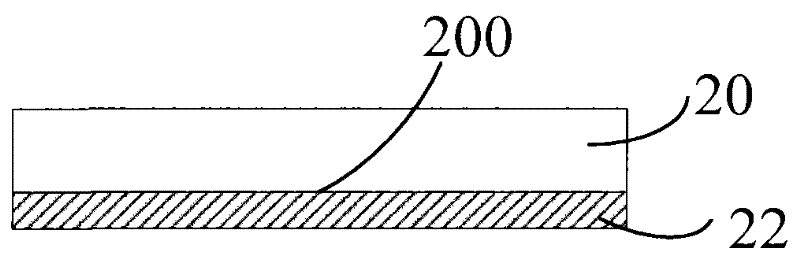

Structure and method for welding target material and backboard

ActiveCN101518851APrevent metals from being oxidizedHigh bonding strengthVacuum evaporation coatingSputtering coatingHot isostatic pressingBackplane

The invention relates to a structure and a method for welding a target material and a backboard, wherein the method for welding the target material and the backboard comprises the following steps: providing a tantalum target material; forming an intermediate layer on the welding surface of the tantalum target material; and performing welding operations on the intermediate layer through a hot isostatic pressing method so as to weld a copper or copper alloy backboard to the tantalum target material. The method can perform extensive welding to effectively prevent metals form being oxidized and improve the bonding strength between the tantalum target material and the copper or the copper alloy backboard, thus the tantalum target material cannot break away in the sputtering process so as to perform sputter coating normally.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

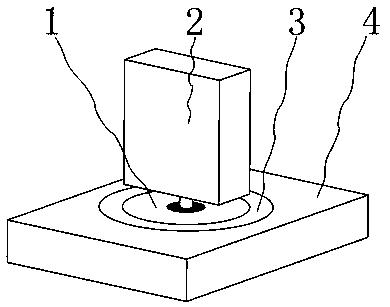

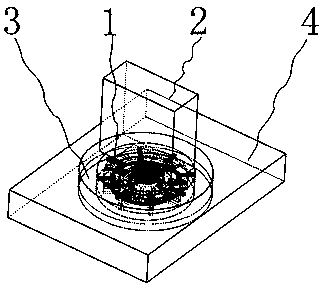

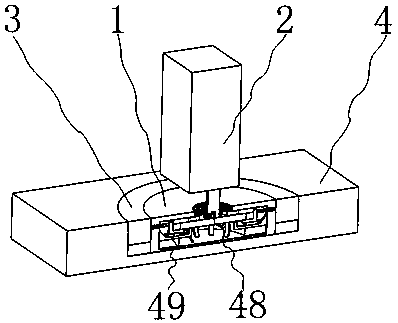

Self-locking rail clamping device

Owner:HUZHOU YANGXI ELEVATORING EQUIP

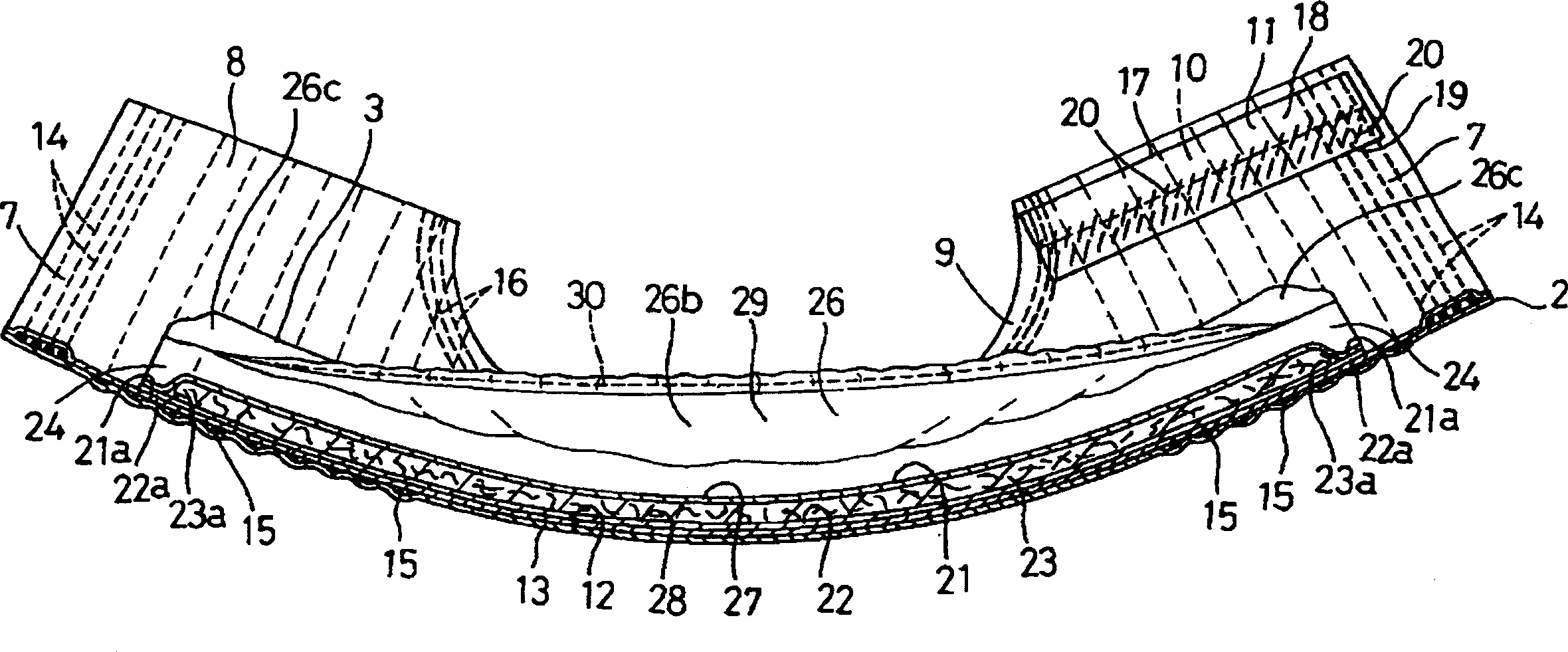

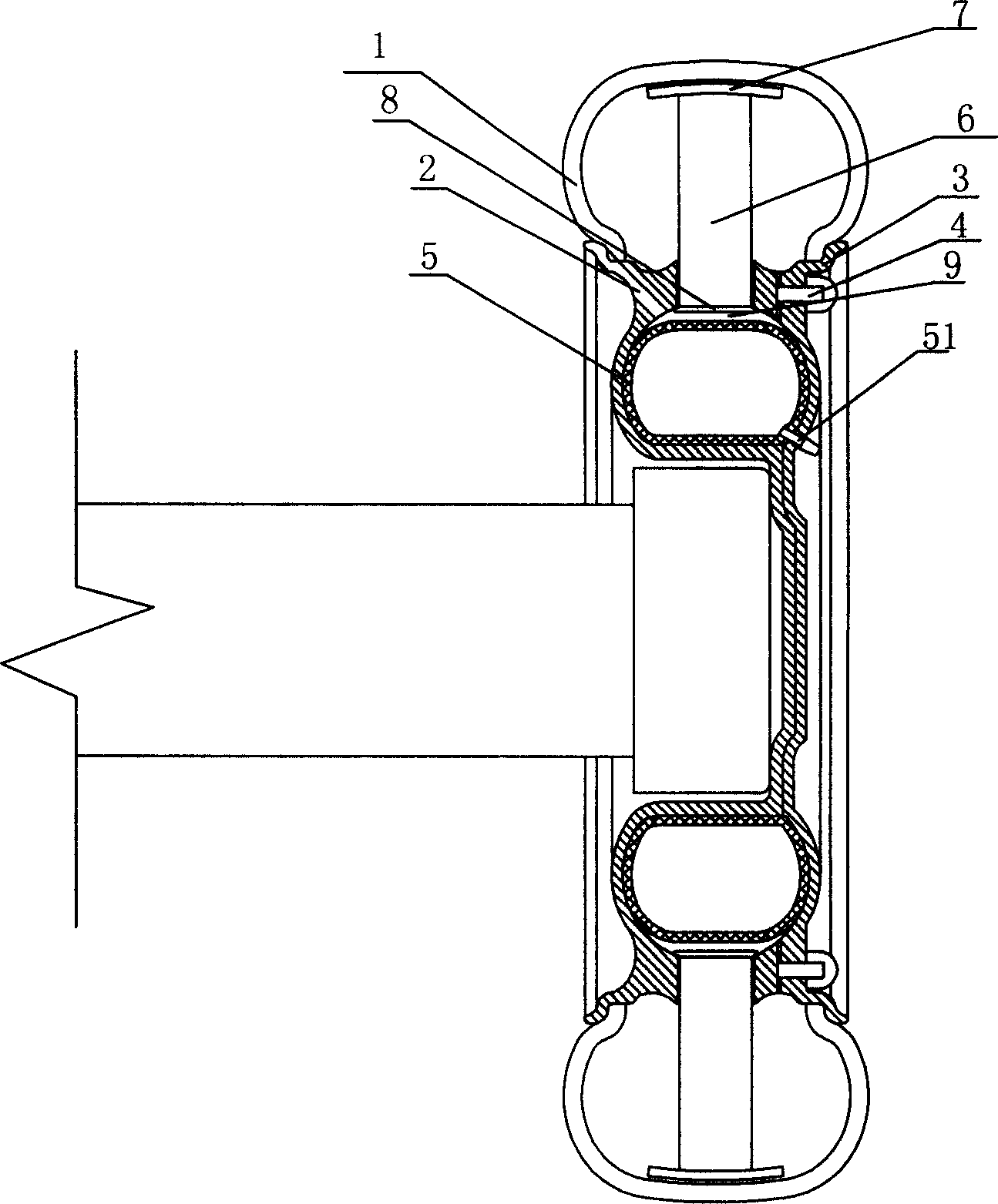

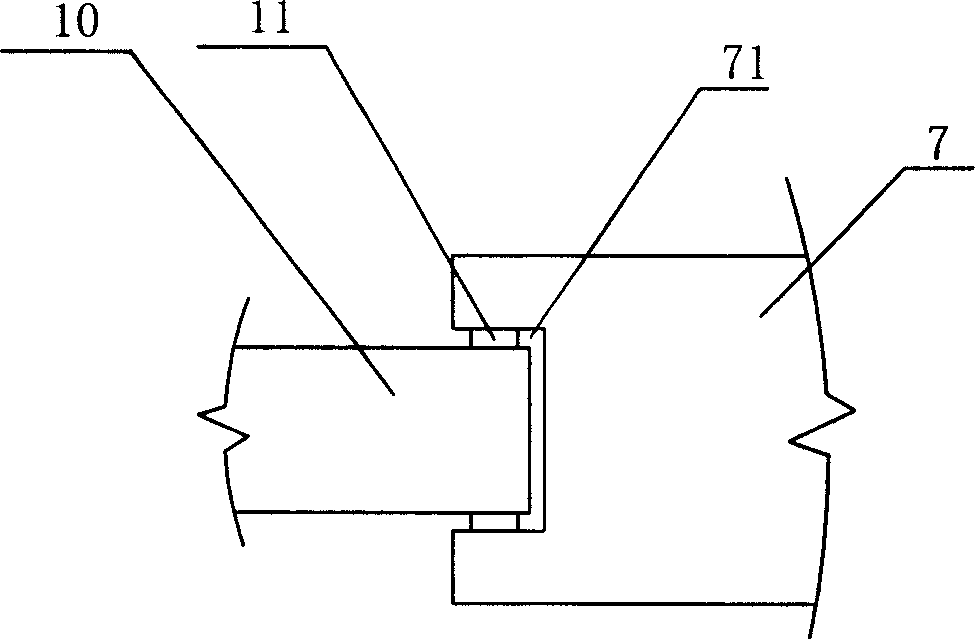

Sub-mouth sealing mode and device of air spring

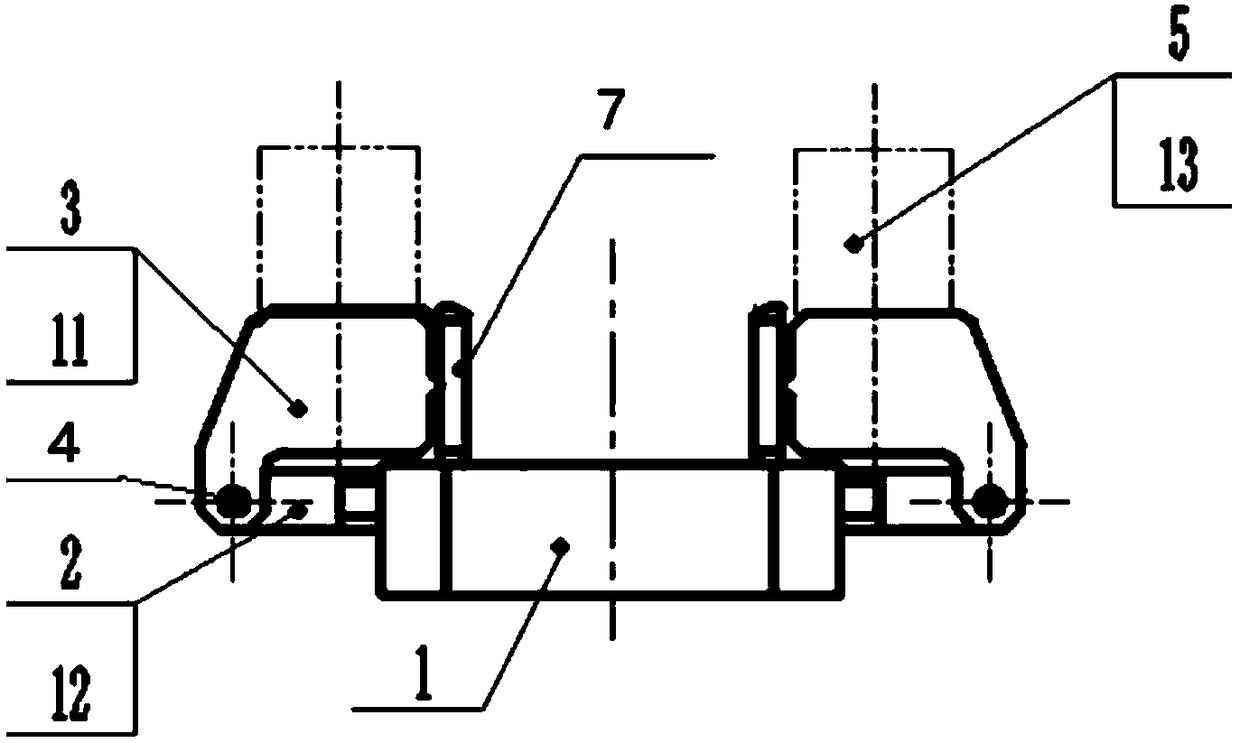

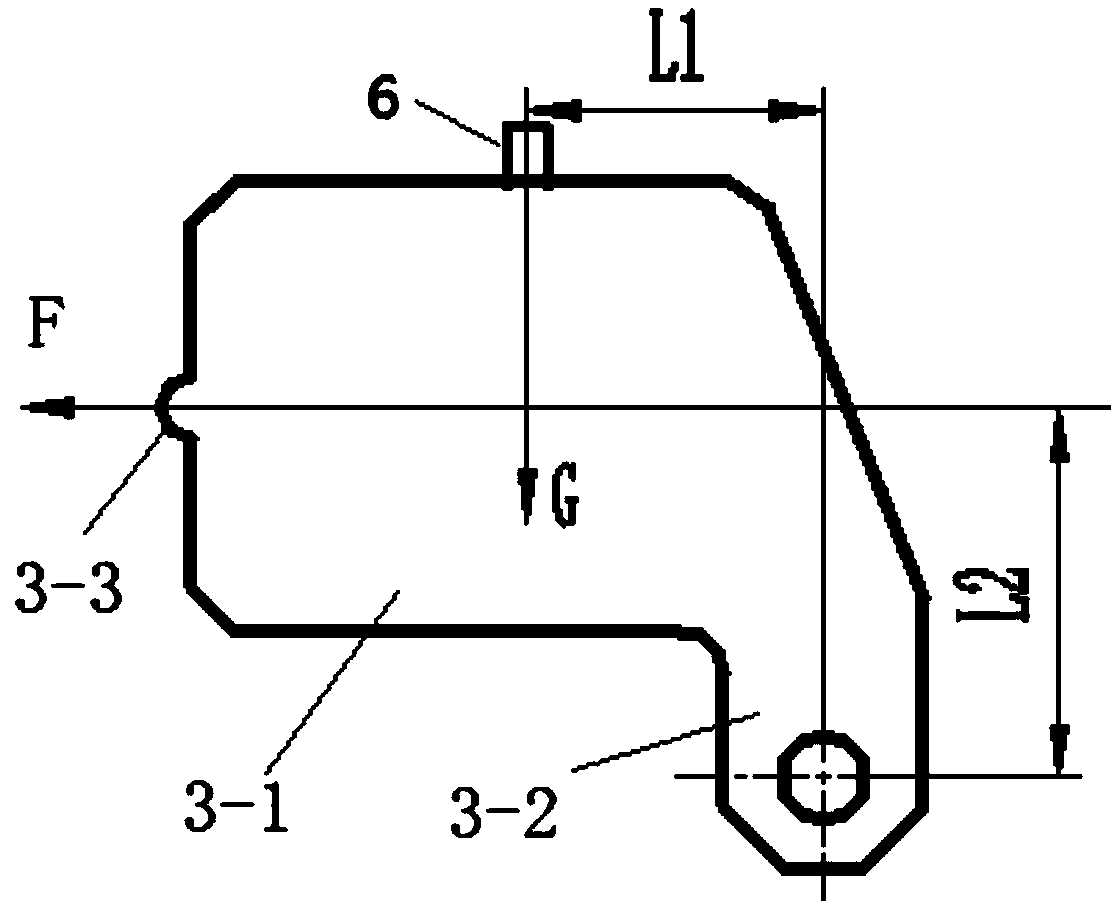

The invention relates to a sealing way of the tire bead on an air spring and a device thereof; the tire bead of a rubber balloon is placed in a tire bead groove which is formed by the combination of an upper cover plate and a friction plate; the tire bead of the rubber balloon is placed in the tire bead groove which is formed by the upper cover plate and the friction plate; and then sealing for the tire bead of the rubber balloon is formed by the joint compression of the upper cover plate and the friction plate. The sealing structure for the tire bead of the rubber balloon is as follows: a groove-shaped gap is arranged on the upper cover plate; a cone-shaped gap is also arranged on the friction plate; the groove-shaped gap on the upper cover plate is combined with the gap on the friction plate to form a cone-shaped cavity with an opening at one edge; the upper cover plate and the friction plate are connected together by a fastener. The tire bead of the rubber balloon is placed in the cone-shaped cavity; the side edge of the rubber balloon is lead out from the side edge opening of the cone-shaped cavity; and the rubber balloon extends outwards from the center by the opening.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

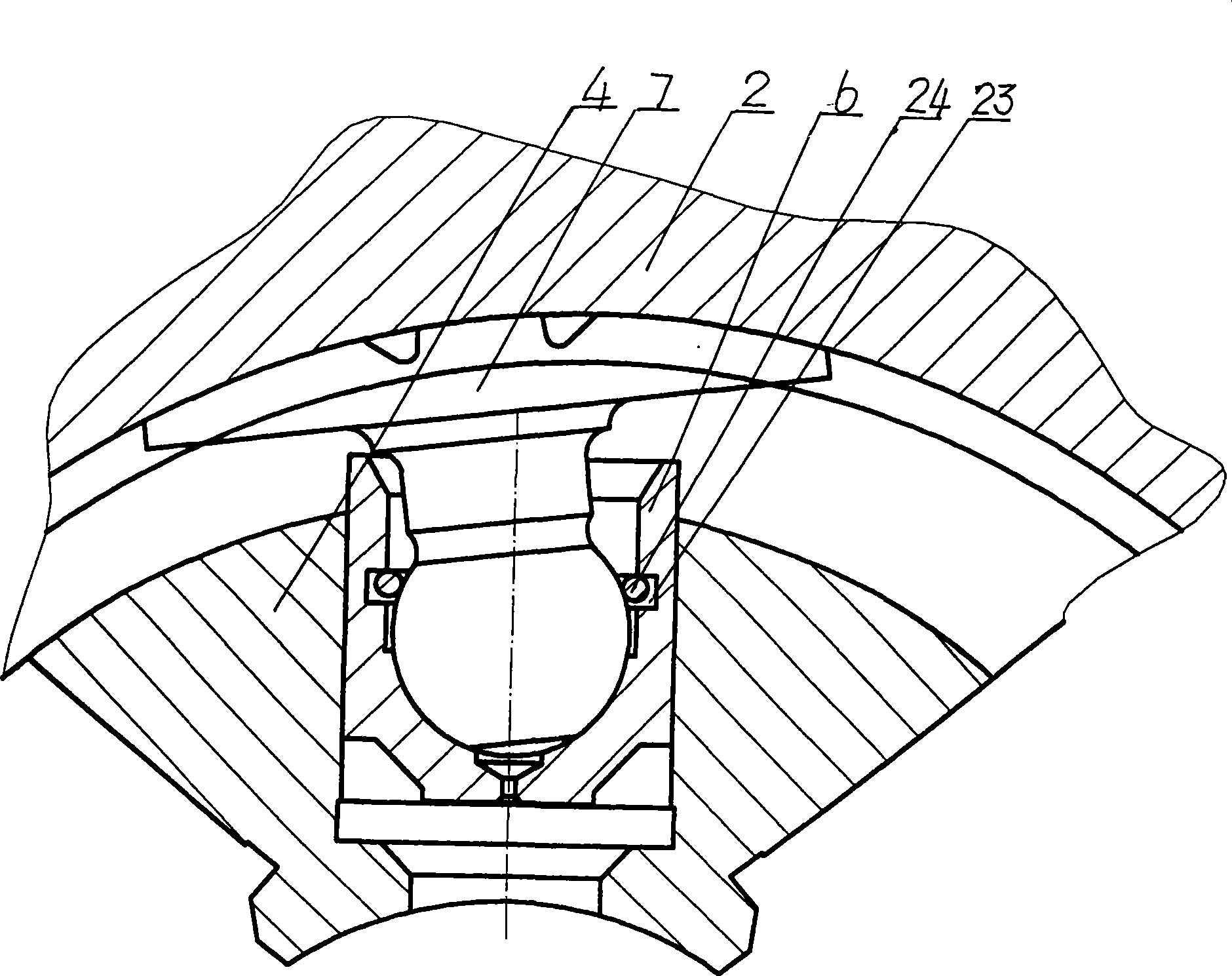

A shifting system

InactiveCN101644319ACombined with lightWon't come offGearingPortable liftingTransfer caseEngineering

The invention relates to a power conversion device of a mechanical transmission system, more particularly to a shifting system of an automobile transfer case. In the shifting system, drive pinion external splines, input shaft shifting external splines, shifting engagement sleeve internal splines and drive gearwheel external splines all employ the splines with the same modulus and teeth number, tooth crests of the engagement sleeve internal splines, the drive pinion external splines and the drive gearwheel external splines shrink inwards, the end face line, from the tooth crest to tooth root, of each spline positioned on the end face is processed from a shape of minus sign into a shape of reversed V, and the shifting engagement sleeve internal splines, the drive pinion shifting external splines, the input shaft shifting external splines and the drive gearwheel shifting external splines are regulated in the thickness of tooth thereof in the direction of axis. The head of the spline is designed with particular angle and shape, which can ensure fast positioning during the bonding of the splines, without the phenomenon of 'gear sliding' and 'out of gear'.

Owner:中国航天三江集团公司特种车辆技术中心

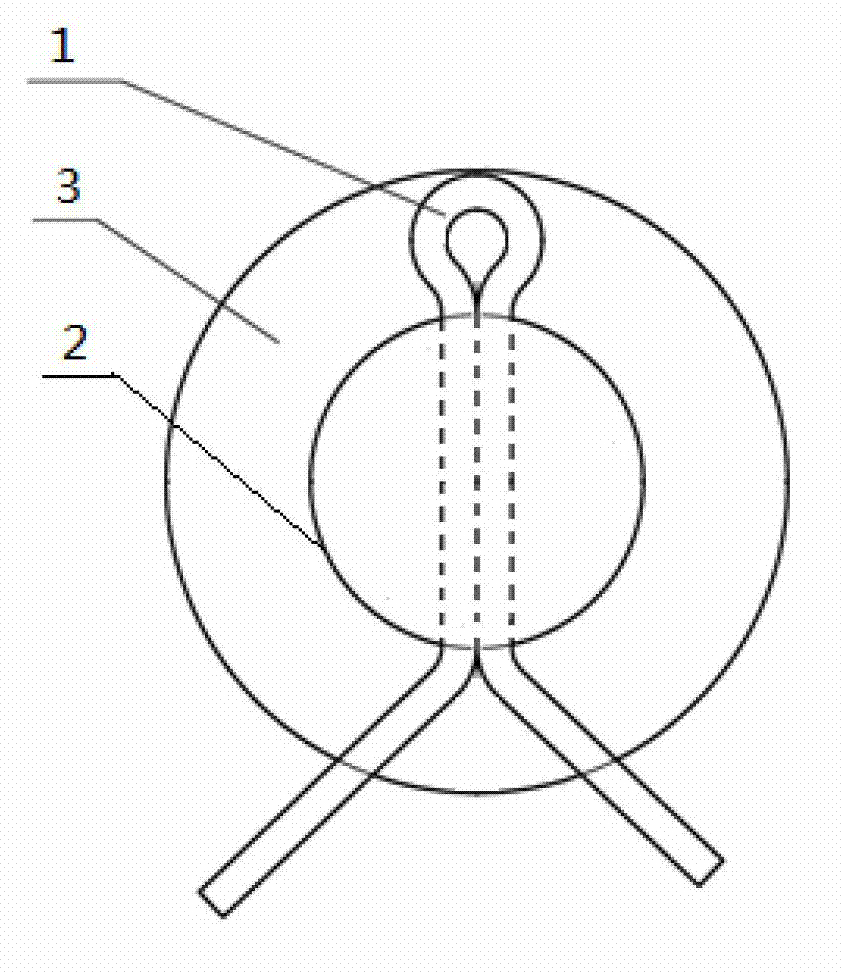

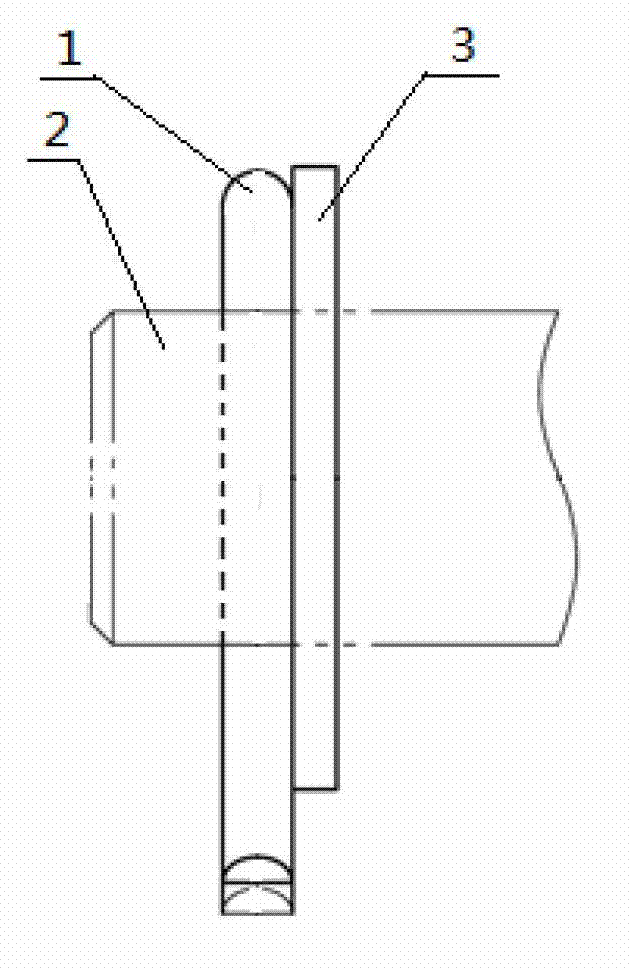

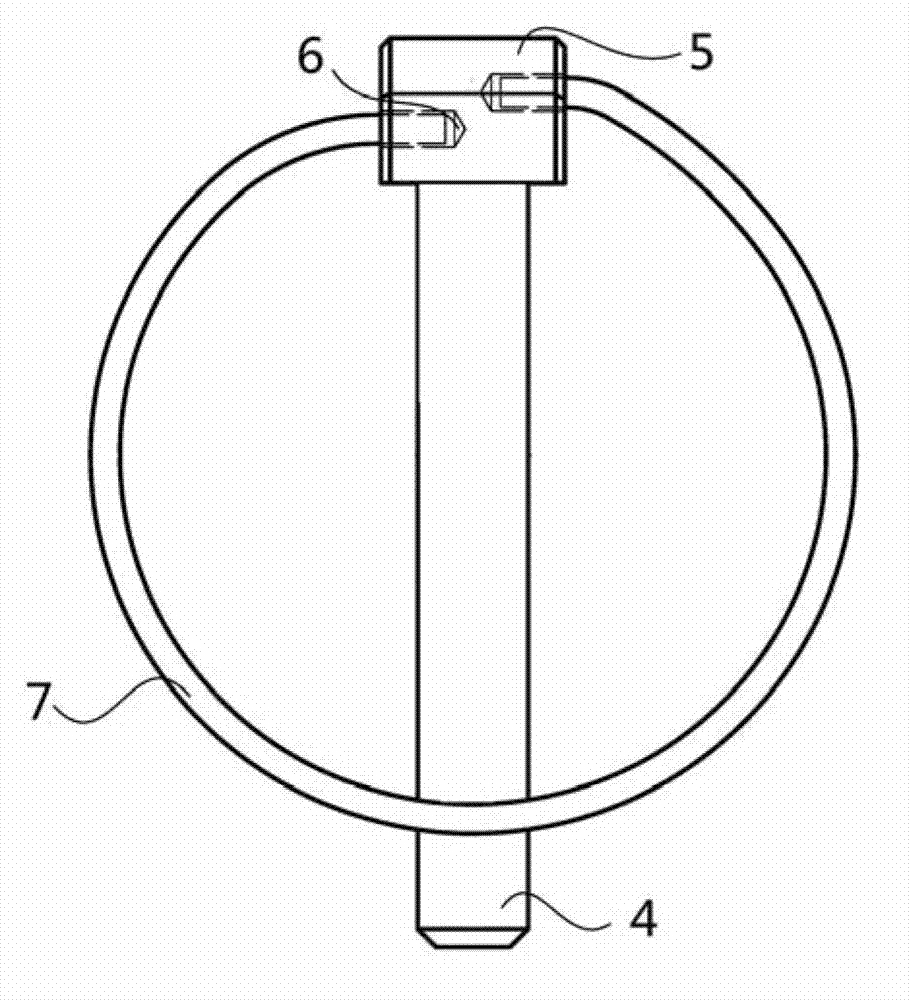

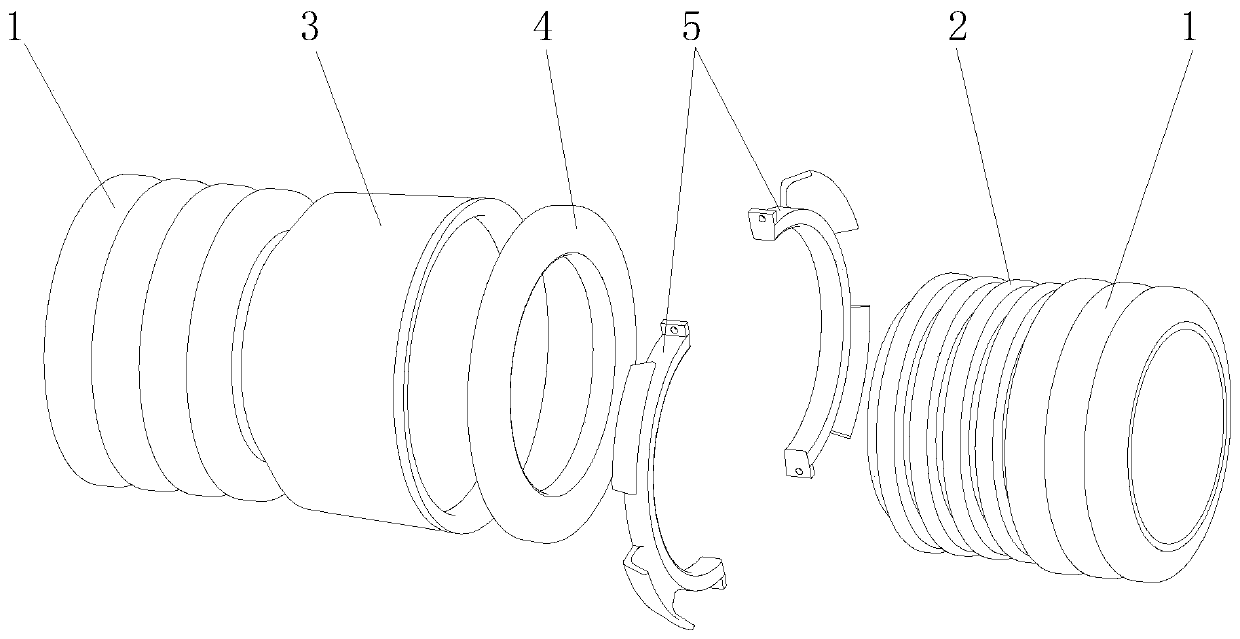

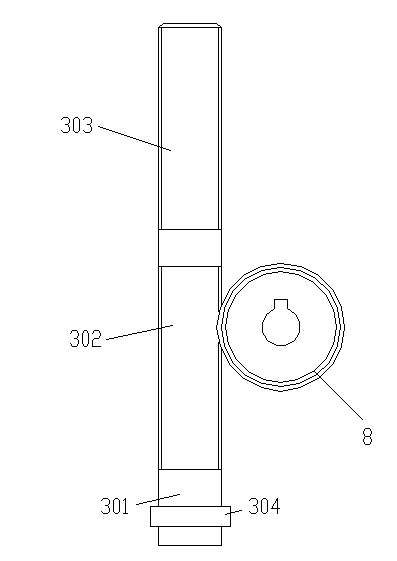

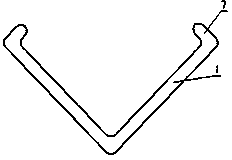

Movable combination pin

The invention provides a movable combination pin which comprises a columnar pin shaft. One end of the pin shaft is provided with a boss, the boss is provided with two holes, the holes are located at opposite two sides of the boss respectively, and axes of the two holes are not on one identical straight line; the movable combination pin further comprises an elastic ring which is in the shape of a loop with an opening, and two ends of the elastic ring are inserted into the two holes respectively. According to the movable combination pin provided by the invention, the columnar pin shaft of which one end is provided with the boss, the opposite two sides of the boss are provided with the two holes of which the axes are not on one identical straight line and the elastic ring is inserted into the two holes; as two hinge points of the elastic ring are not on one identical straight line, an elastic force is generated after the elastic ring is buckled on the pin shaft to lock, so as to realize self locking of the movable combination pin, and guarantee that the movable combination pin does not fall off when vibrating and rotating along with a locking shaft.

Owner:CRRC QIQIHAR ROLLING CO LTD

Metal non-woven fabric composite board and processing method thereof

InactiveCN102744933ALight in massWon't come offLaminationLamination apparatusWoven fabric compositeSurface layer

The invention provides a metal non-woven fabric composite board and a processing method thereof. The metal non-woven fabric composite board comprises a metal material layer on the surface layer, a non-woven fabric layer at the bottom layer and a binding material layer in the middle, wherein the metal material layer and the non-woven fabric layer are bonded together in a high temperature compounding or cold compounding manner by virtue of the binding material layer. The binding material layer comprises a macromolecule coating and an adhesive, wherein the metal material layer and the non-woven fabric layer are bonded together through high temperature rolling by virtue of the macromolecule coating, and the metal material layer and the non-woven fabric layer are bonded together through rolling by virtue of the adhesive. The metal non-woven fabric composite board has the advantages of light weight, heat resistance and low manufacturing cost, and construction is simple and bonding is firm when the metal non-woven fabric composite board is applied to the external wall of a building.

Owner:徐建永

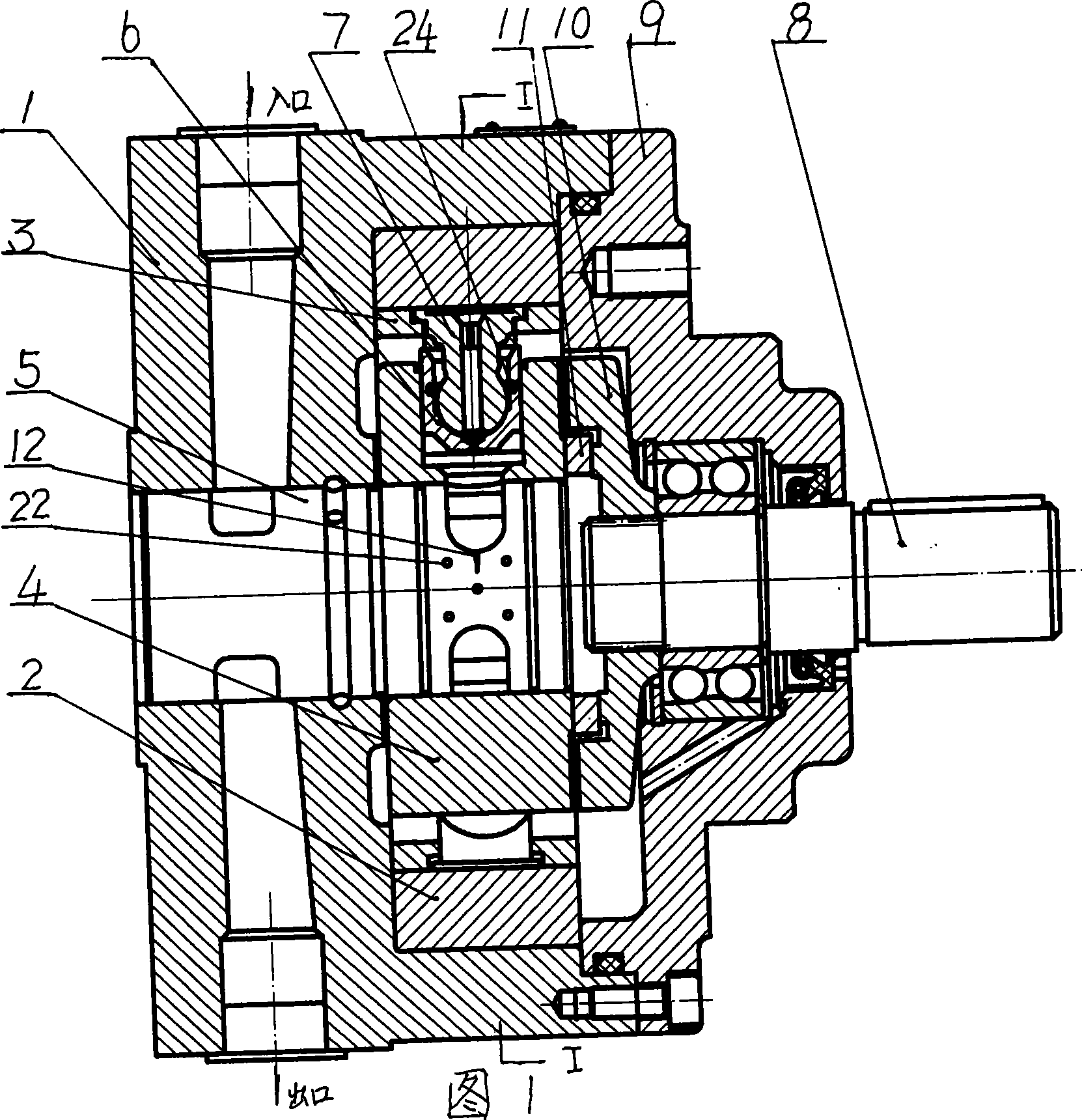

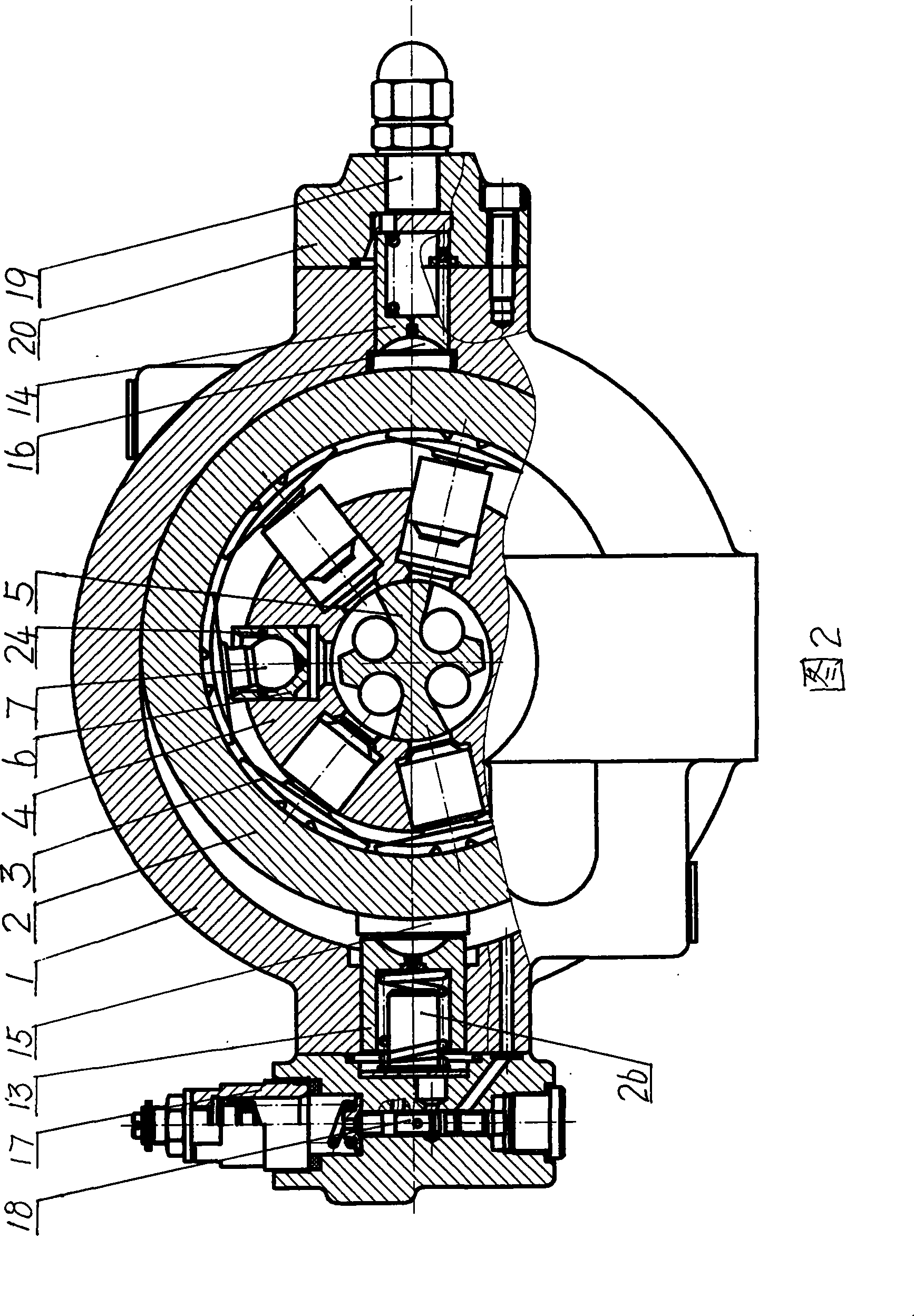

Constant pressure variable radial piston pump

InactiveCN101413493ALow wear resistanceWon't come offPositive displacement pump componentsPositive-displacement liquid enginesLow noiseRadial piston pump

The invention relates to a constant-pressure variable radial plunger pump. The inner bore of a pump case is a long circle; an annular stator is in sliding fit with the pump case, two sides of the inner circle of the stator are in movable fit with a return stroke ring respectively, and the return stroke ring adopts ZQA19-4 albronze; a rotor is freely sleeved on a pintle valve, plungers are evenly distributed in the radial direction of the rotor, inner bores of the plungers are provided with wide annular grooves with the width of 2.2 mm, and clamp springs with the diameter of 2.1 mm are arranged in the grooves, so as to increase locking force to a connecting rod ball; a cambered disc surface of a connecting rod is additionally provided with an annular groove B for storing oil, and oil film is generated when the annular groove B rotates at a high speed, so as to improve the lubricating performance and have good wearing resistance; the pintle valve is provided with a sealed annular groove A in the axial direction and provided with five oil storage holes respectively on the side of a V-shaped groove, and oil film is generated when the annular groove A rotates, so as to improve the lubricating performance. The constant-pressure variable radial plunger pump has the advantages of simple structure, small volume, low noise, large locking force of the clamp springs, no disengagement of the plungers and the connecting rod, and high lubricating performance and wearing resistance of parts; and the return stroke ring adopts the ZQA19-4 albronze and has strong wearing resistance, so the whole service life is long.

Owner:董桂敏

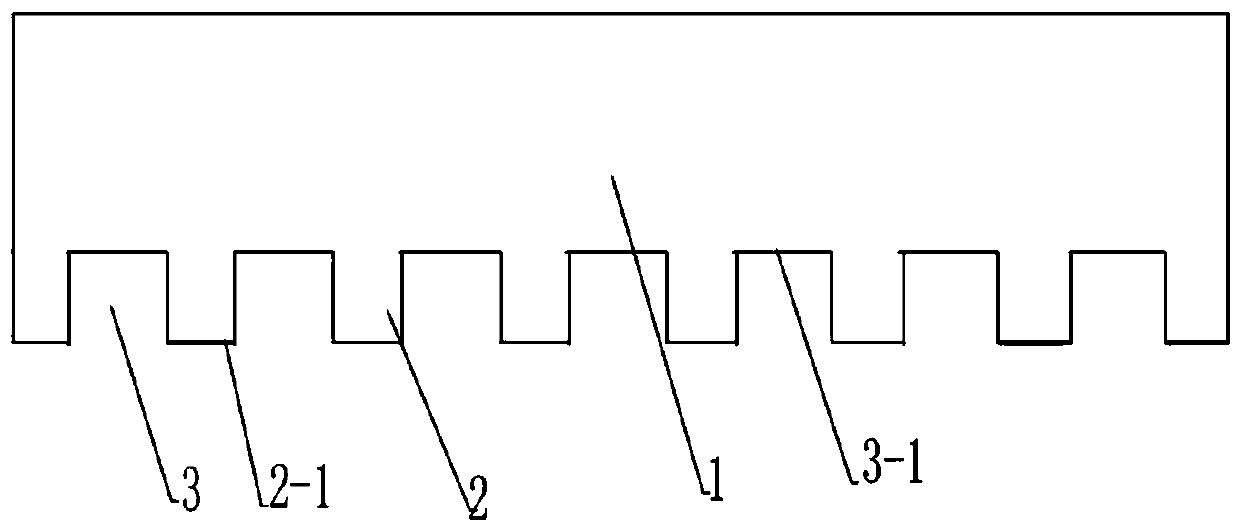

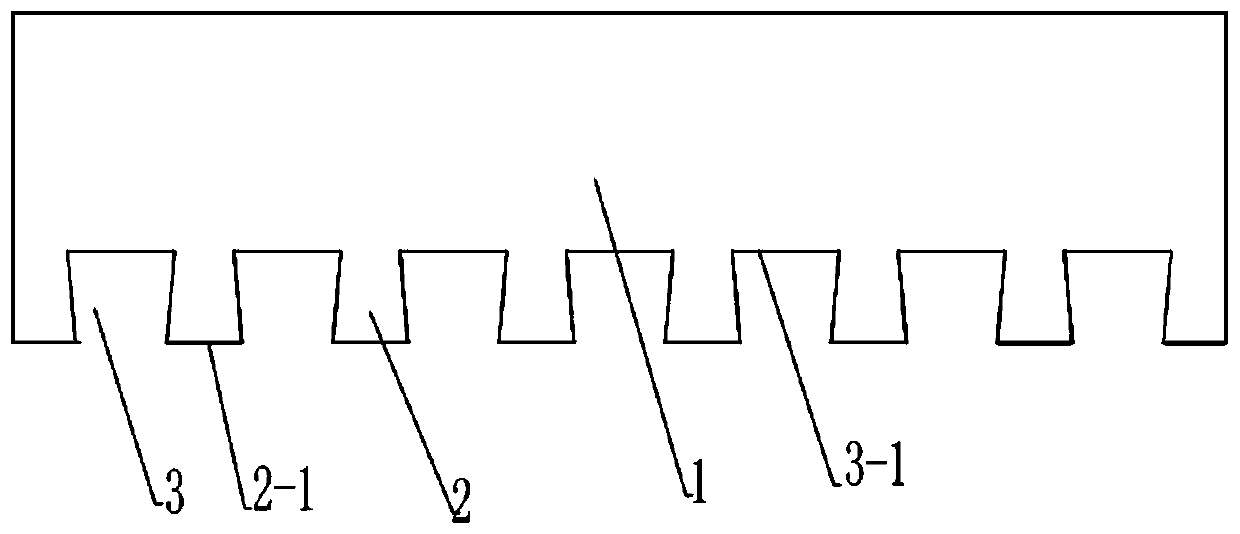

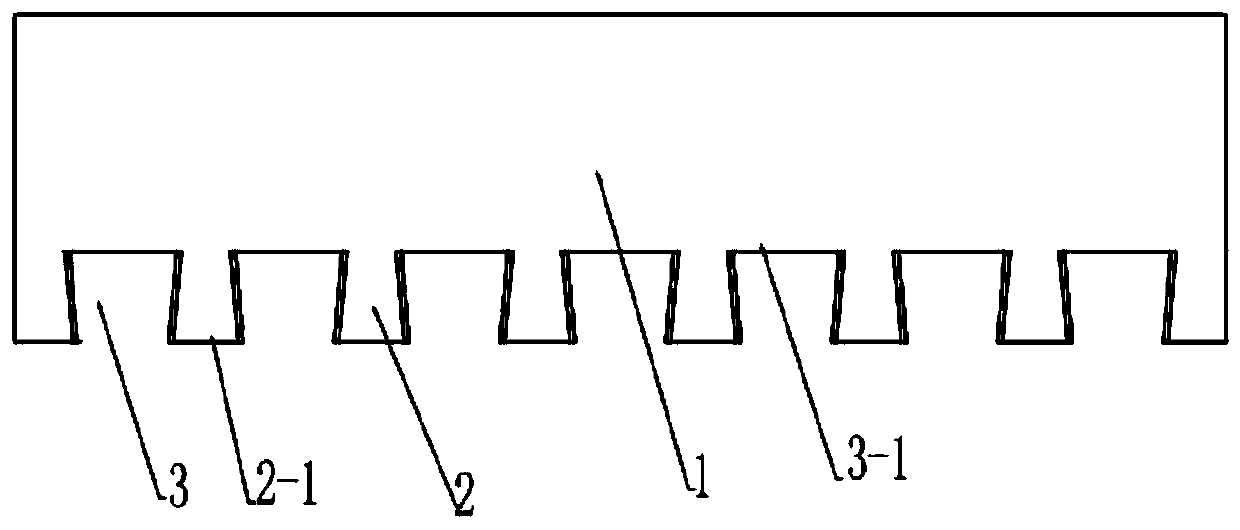

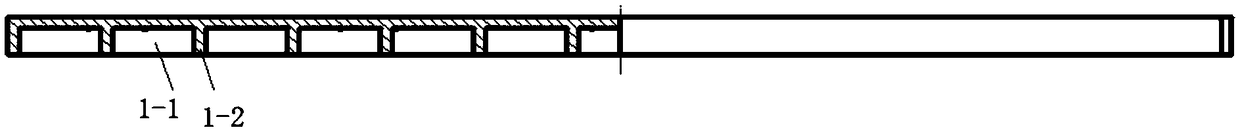

Plate inserting connecting edge structure and inserting connecting assembly and assembly method

PendingCN110056094AWon't come offTightly boundBuilding material handlingEdge structureElectrical and Electronics engineering

The invention relates to a wood plate connecting technology, in particular to a large plate inserting connecting edge structure. The large plate inserting connecting edge structure comprises a plate body and at least one inserting connecting edge, and is characterized in that inserting connecting grooves and inserting connecting raised blocks are arranged in the inserting connecting edges in a mutual spaced mode, and the width of the inserting connecting grooves is larger than the width of the inserting connecting raised blocks; the inserting connecting grooves are dovetail grooves, and the inserting connecting raised blocks are dovetail inserts; the width of the dovetail grooves in the front side is larger than the width of the dovetail grooves in the back side; and the width of the dovetail inserts in the front side is smaller than the width of the dovetail inserts in the back side. The invention further relates to a plate inserting connecting assembly. The plate inserting connectingassembly comprises a first plate and a second plate, and further comprises insert pieces; and inserting connecting grooves or inserting connecting raised blocks of the first plate are mutually connected with inserting connecting raised blocks or inserting connecting grooves of the second plate in an inserting mode, and the insert pieces are arranged at gap positions between the inserting connecting grooves and the inserting connecting raised blocks. The invention further relates to an assembly method. The plate inserting connecting edge structure, the plate inserting connecting assembly and the assembly method have the beneficial effects that hoisting and fixing between the plates are facilitated, and the connection is steady and firm.

Owner:PENGLAI ZHENGTAI WOOD IND CO LTD

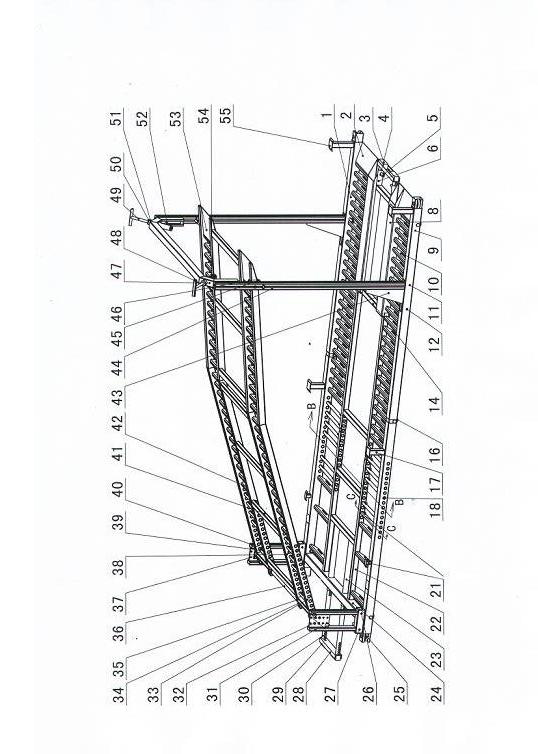

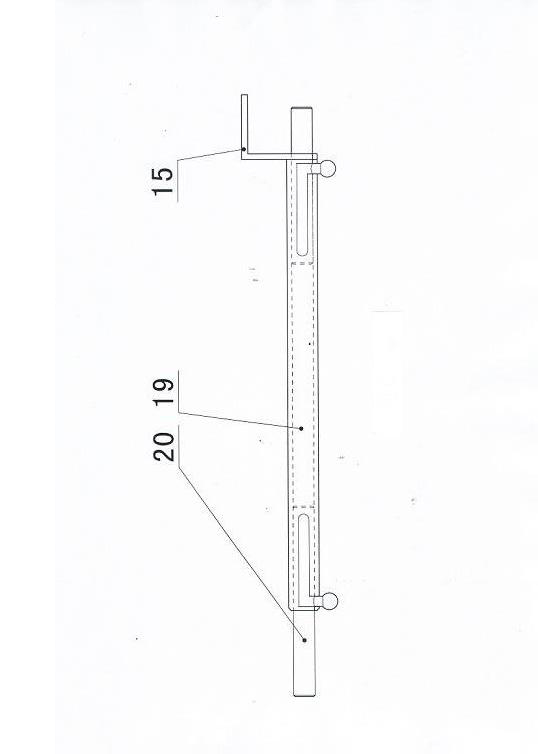

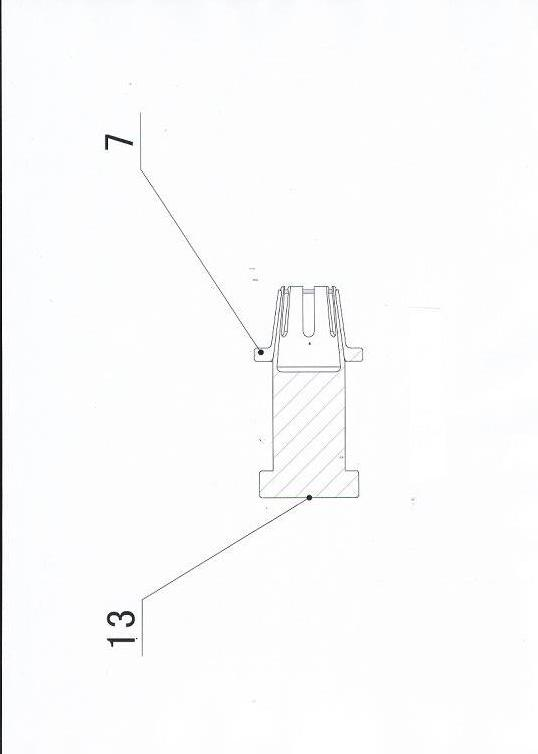

Double-layer car pallet

The invention discloses a double-layer car pallet, which comprises a bottom pallet component, an upper pallet component, a small frame, a big frame component, a front roof box device, a rear roof box device and a roof support device. A side wheel is arranged at the end part of the side surface of a bottom main beam of the bottom pallet component; multiple bearing wheels are arranged on the bottom surface; the bottom main beam and a bottom auxiliary beam of the bottom pallet component are correspondingly provided with bolt pin holes for mounting bottom lane rods; lane boards with equal space are arranged between the bottom main beam of the bottom pallet component as well as the bottom auxiliary beam and a forklift sleeve, and form car carrying lanes in pairs with the lane rods; and oblique guide boards are also fixed on the car carrying lanes at one end close to the big frame component, of the bottom pallet component. The double-layer car pallet disclosed by the invention has the advantages that: the product is lighter, the production organization is convenient, the appearance quality is consistent, the shortcomings of high possibility of loosening and rusting of threads are overcome, the pallet assembly / disassembly operation is quick, the complete functions of the double-layer car pallet can be maintained, and the functions of a conveyor are exerted furthest.

Owner:JIANGXI KEBUKE AUTOMOTIVE TECH

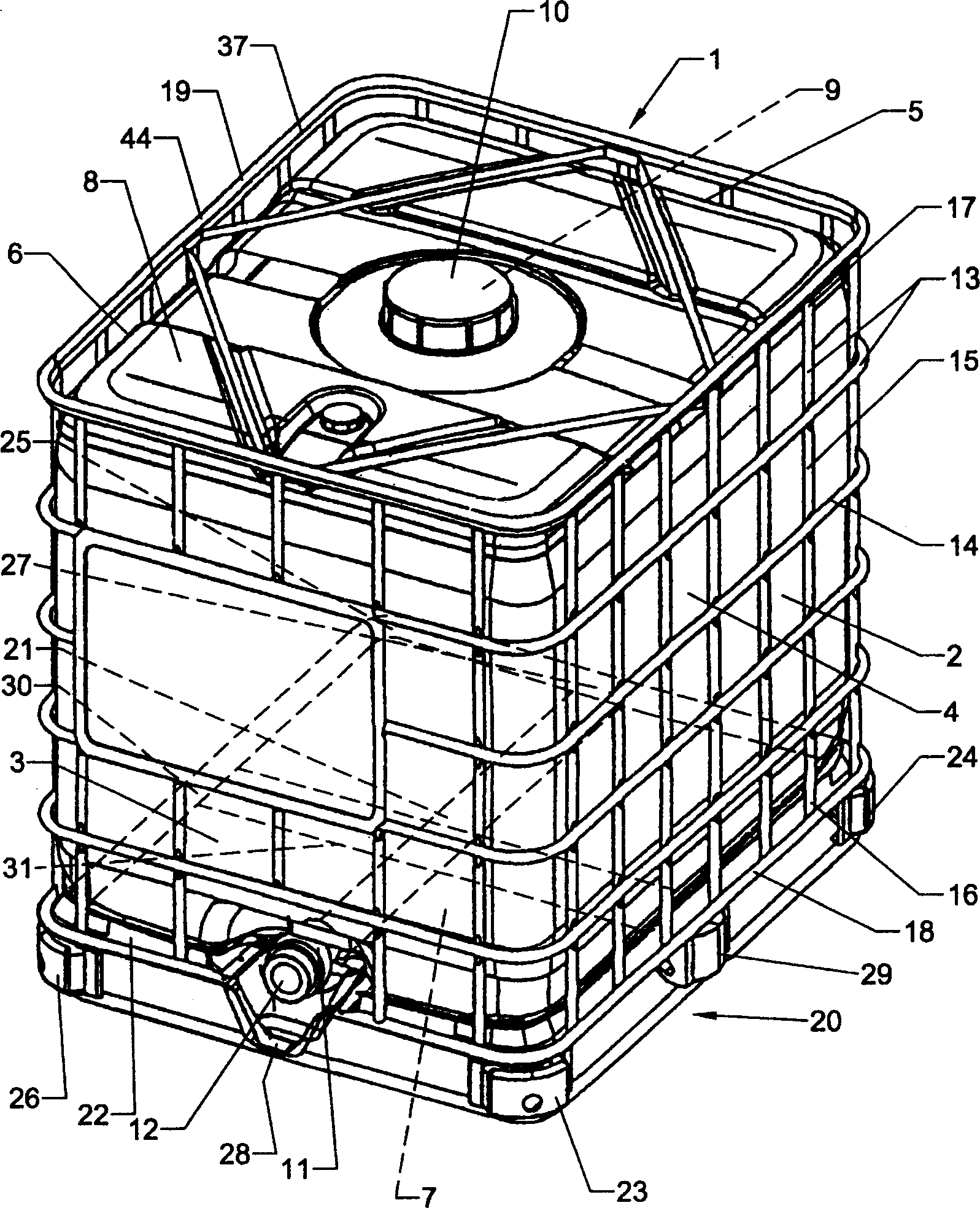

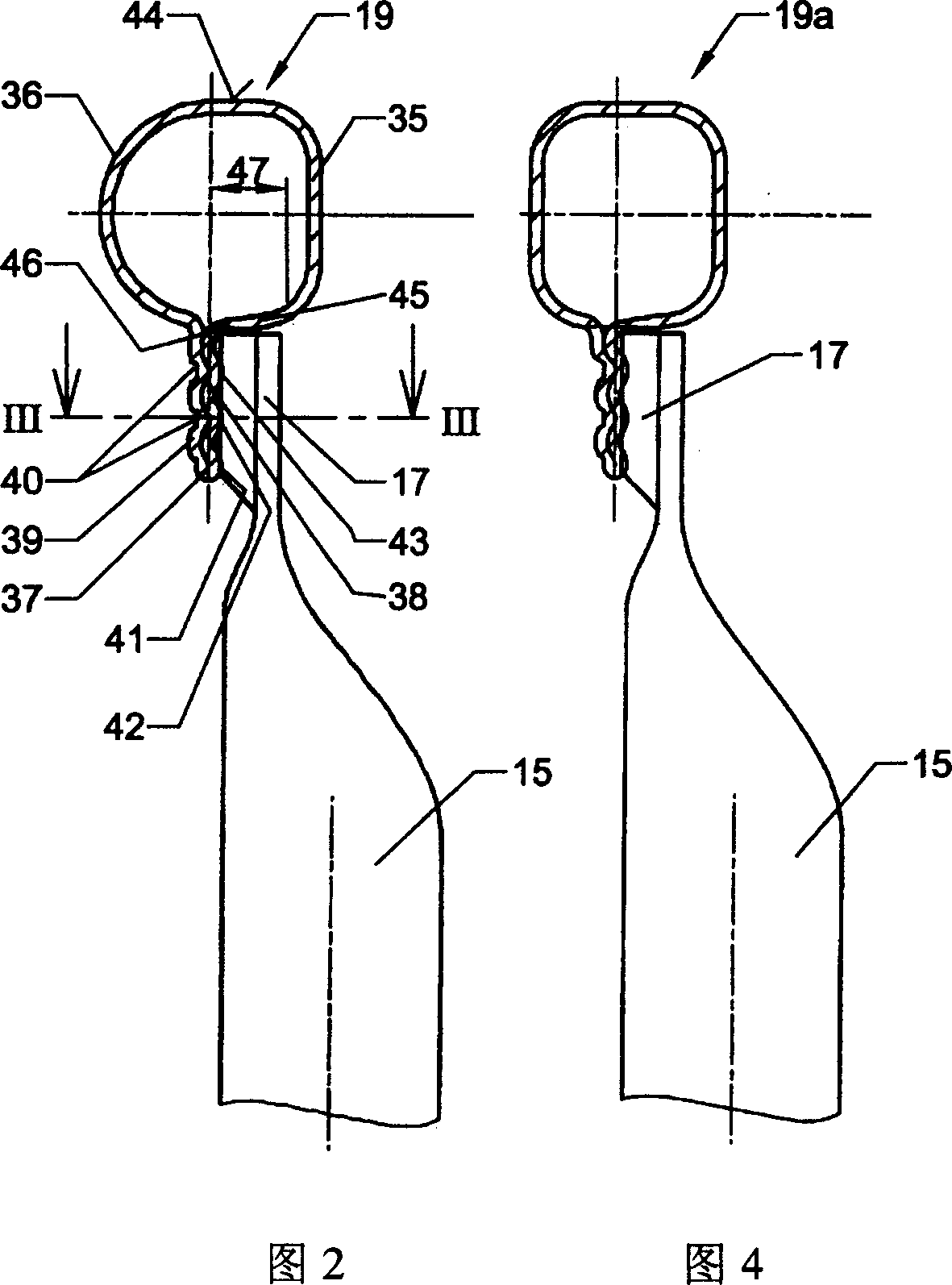

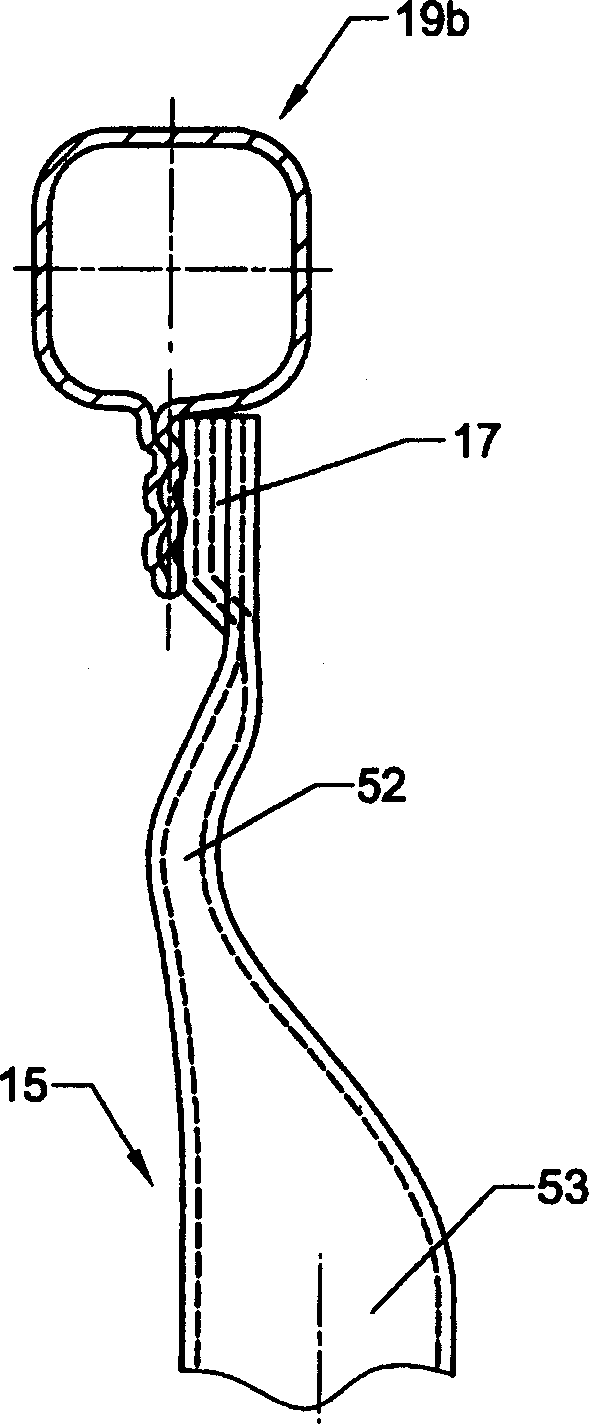

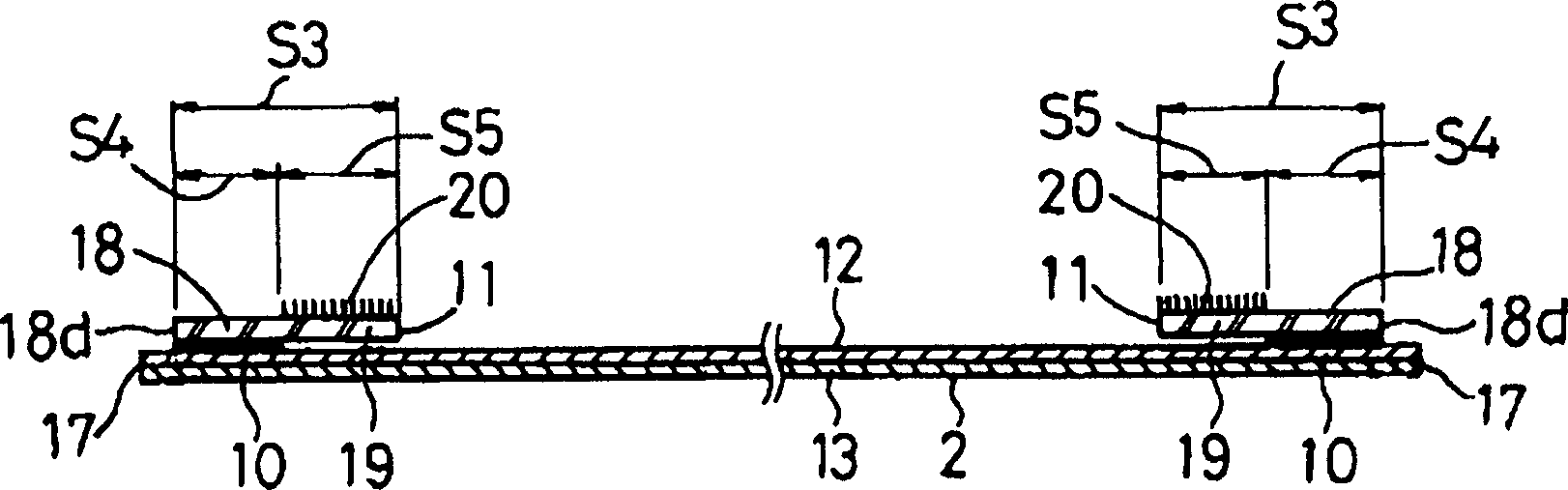

Transport and storage container for liquids

ActiveCN1557686AAvoid damageImproved spring actionLarge containersRigid containersEngineeringHorizontal and vertical

The transportation-cum-storage container (1) mainly consists of a plastic inner container (2), an outer grid shell (13) formed of metallic crosspieces and longitudinal pieces (14, 15) crossing each other, for housing therein the inner container (2), and a pallet base (20) having length / width dimensions conforming to the European Steel Community Standards. An upper edge (17) of each longitudinal piece (15) of the grid shell (13) and a double edge (37) of an upper edge forming shape (19) are projection-welded to each other by crosswise butting against each other at six locations. Then the outer edge forming shape (19) of the grid shell (13) has a flat upper rim (44) arranged along it, for bearing corner legs and intermediate legs (23 to 30) of the pallet base (20) of another pallet container (1) stacked thereon.

Owner:PROTECHNA SA

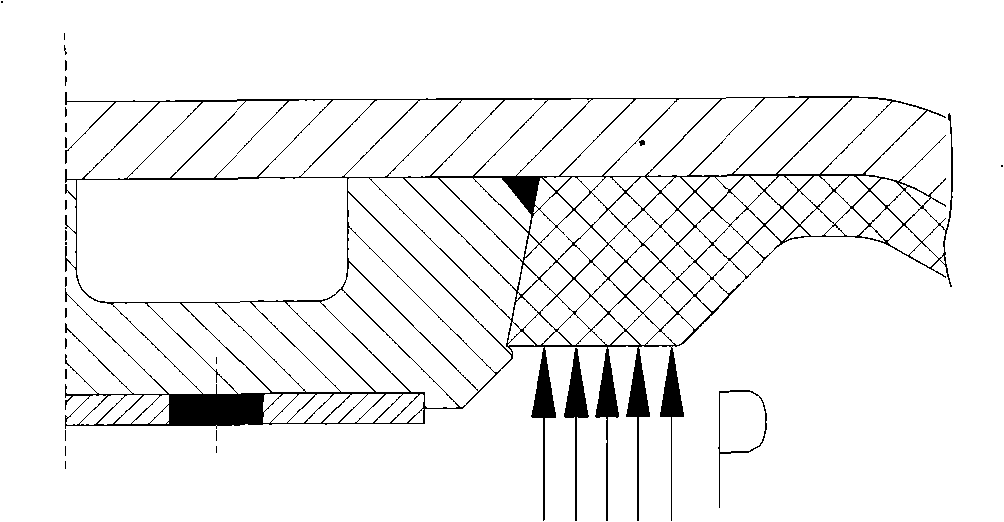

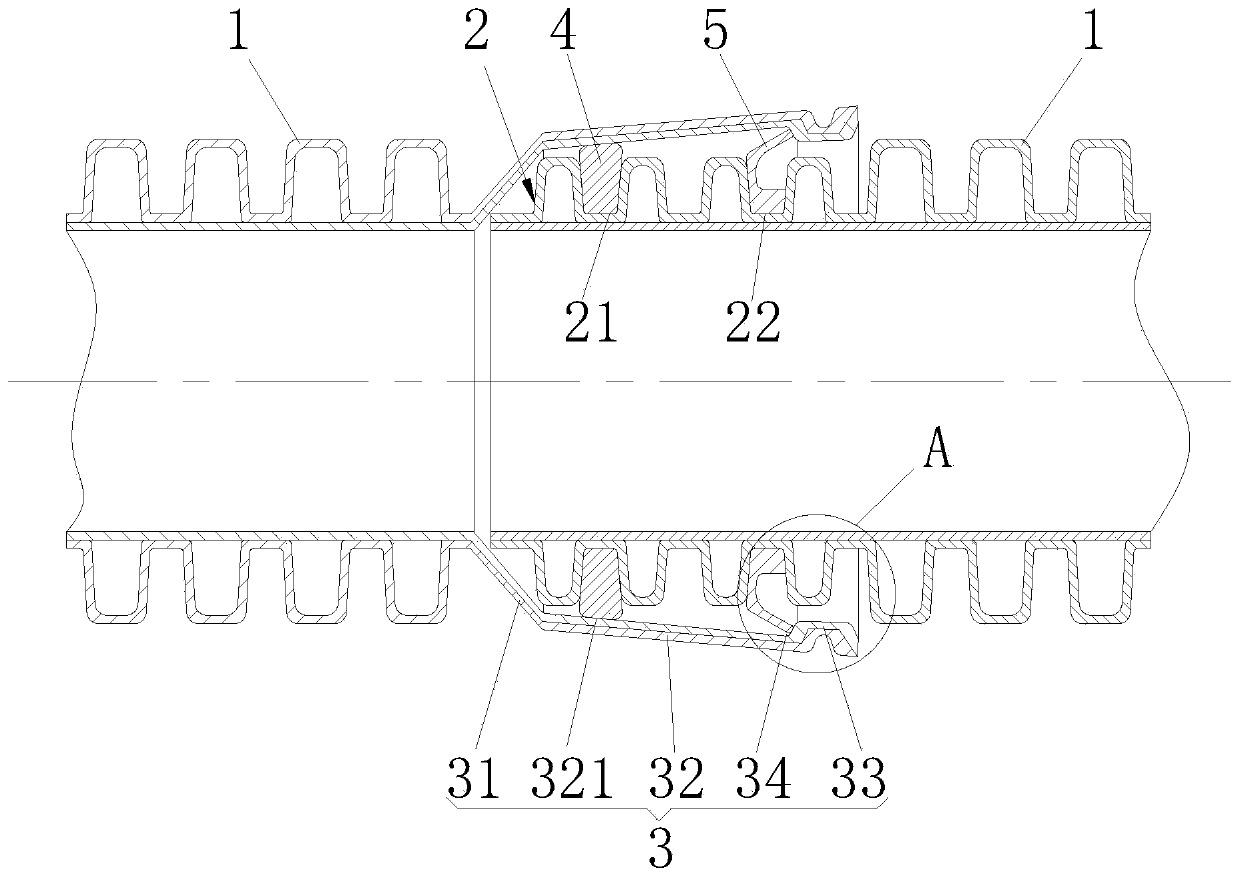

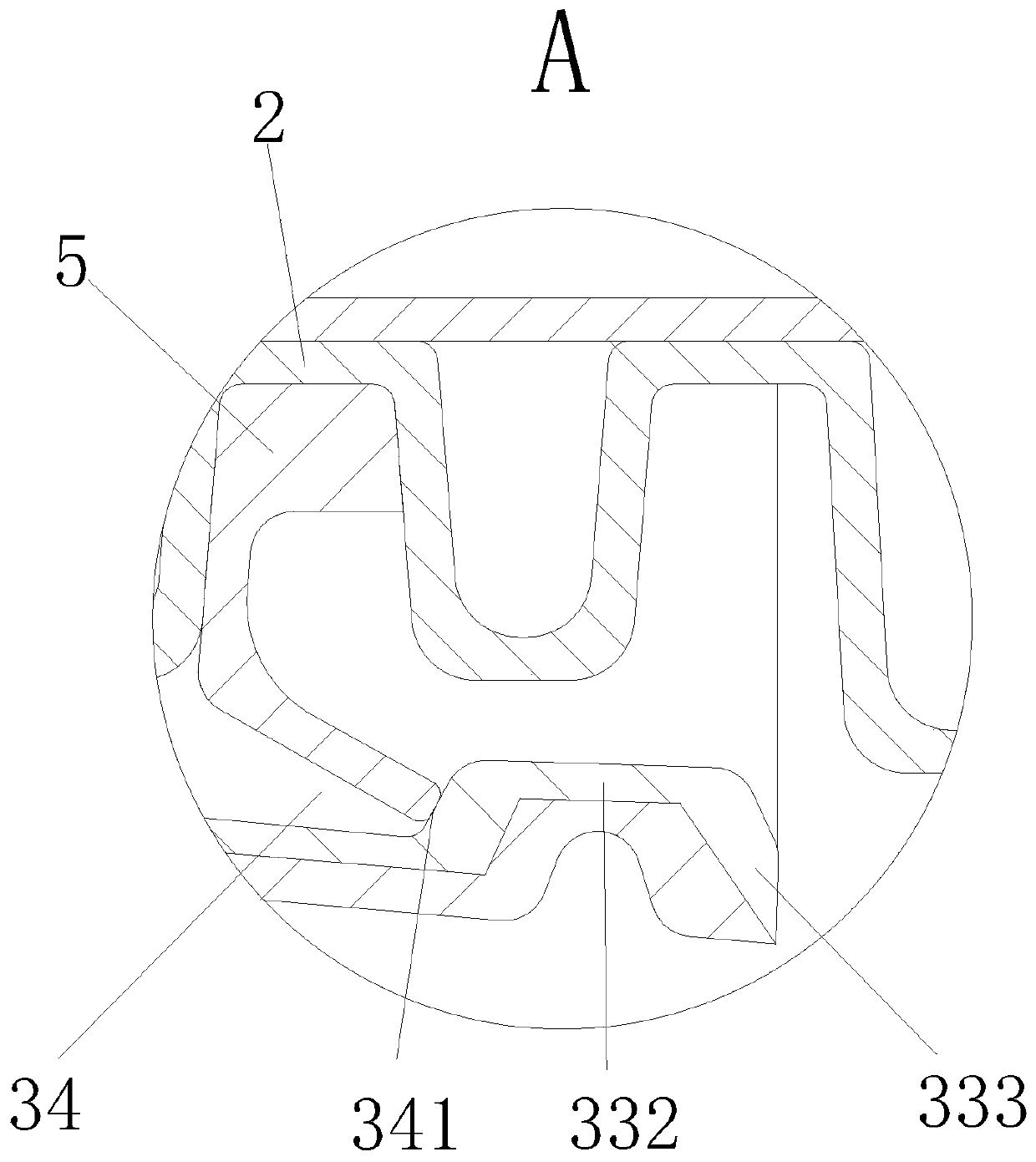

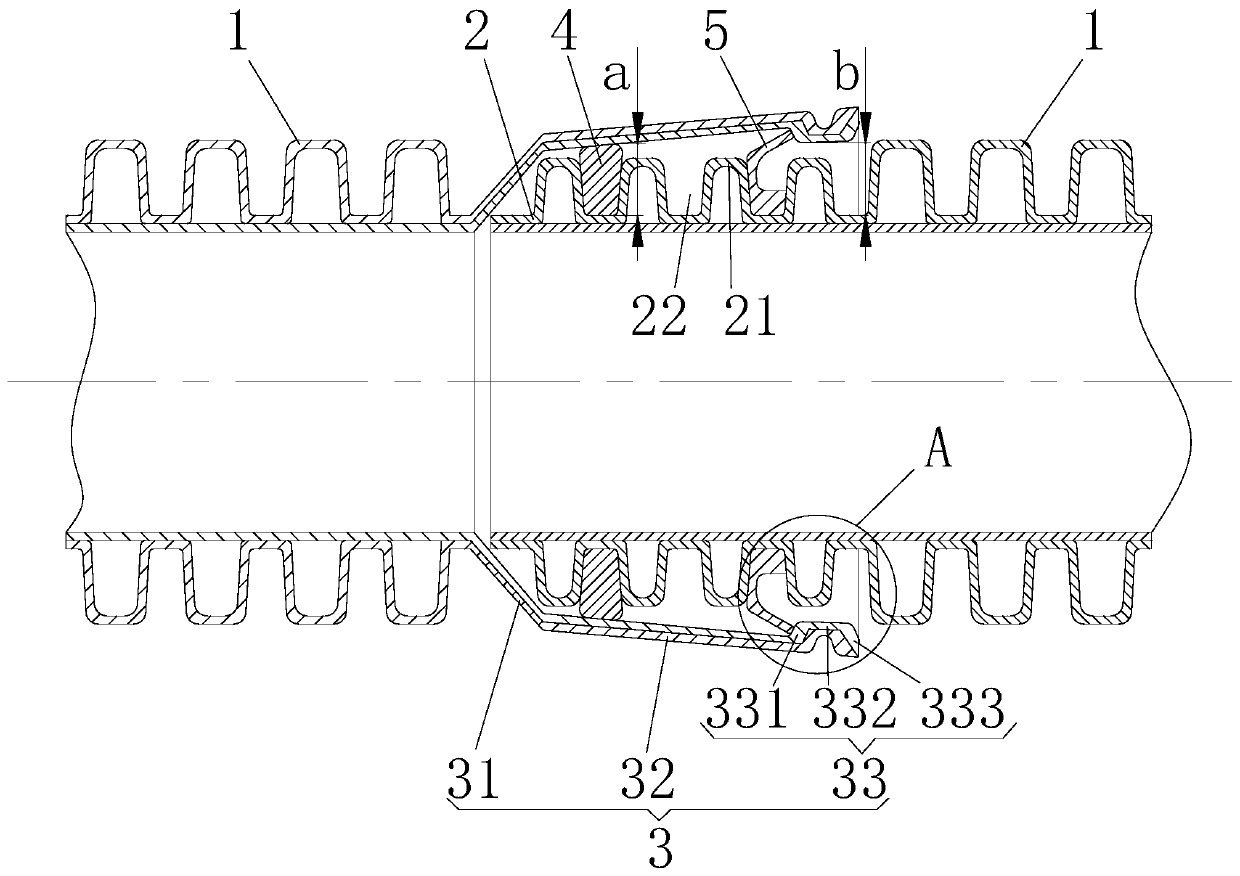

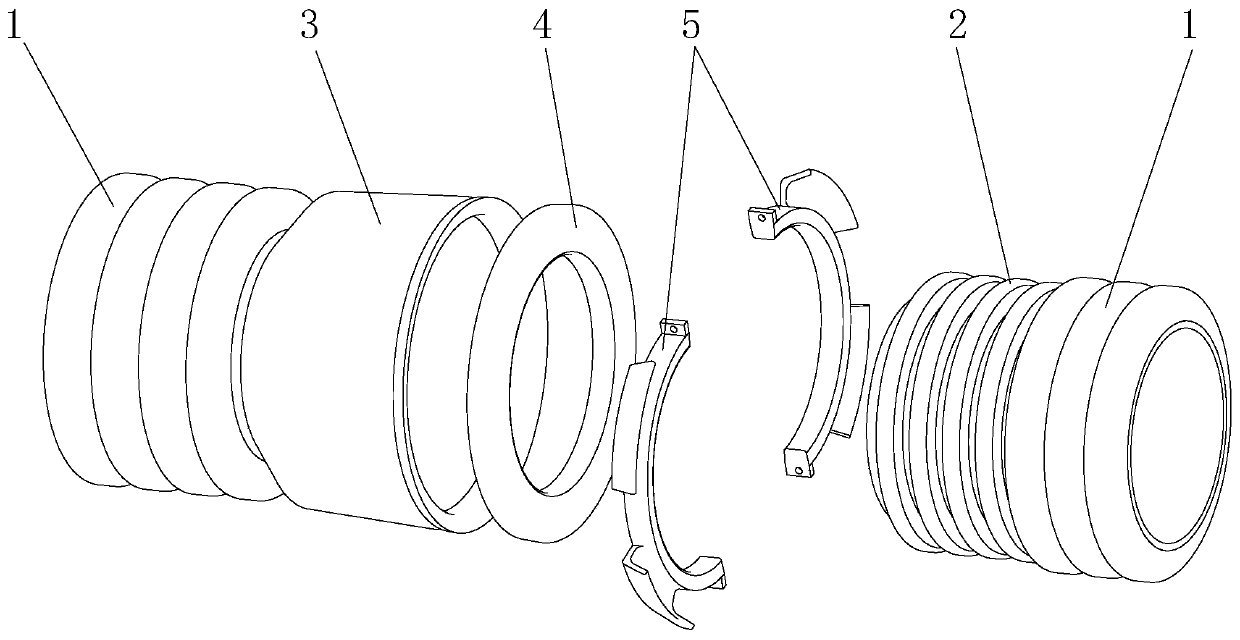

Pipe assembly with anti-disengagement sealing structure

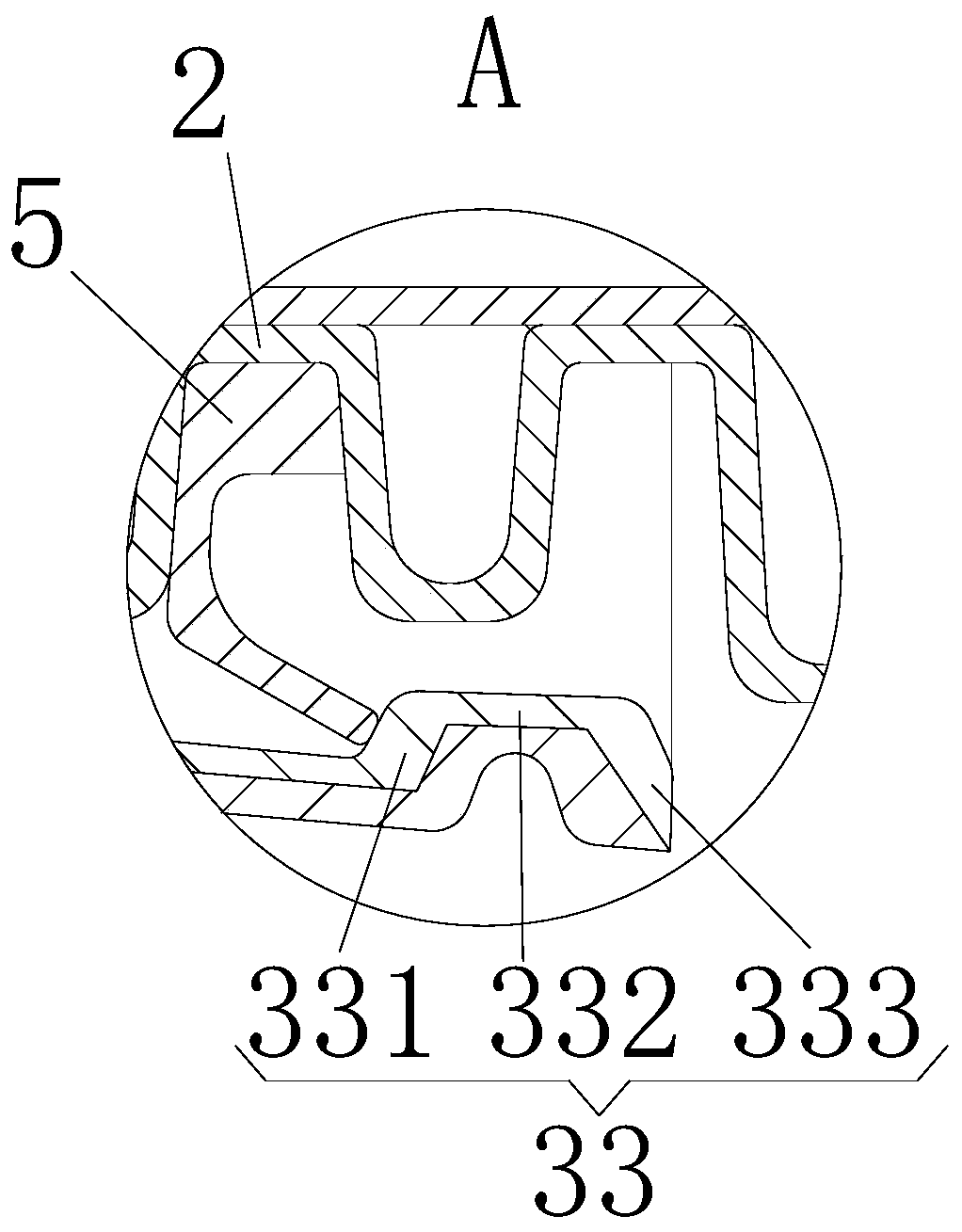

PendingCN110578841APrevent axial springbackEasy to installSleeve/socket jointsEngineeringMechanical engineering

The invention relates to a pipe assembly with an anti-disengagement sealing structure. The pipe assembly comprises at least two pipes. A pipe-shaped insertion opening section is connected to one end of one pipe, a pipe-shaped bearing opening section is connected to one end of the other pipe, and the pipe assembly with the anti-disengagement sealing structure further comprises a sealing ring and ananti-disengagement part. The outer circumferential wall of the insertion opening section is provided with a sealing ring installation groove and an anti-disengagement part installation groove. The bearing opening section comprises a clamping section, a sealing bearing section and a jointing section. A first conical sealing section is arranged on the inner circumferential wall of the sealing bearing section, a limiting clamping groove is formed in the sealing bearing section, and the anti-disengagement part comprises an anti-disengagement body and an elastic anti-disengagement body. By means of the pipe assembly, the sealing bearing section is tightly matched with the sealing ring, the anti-disengagement part is automatically ejected and pressed in the limiting clamping groove between thesealing bearing section and the clamping section through the elastic anti-disengagement body arranged on the outer circumferential part, the sealing ring is effectively prevented from driving the pipes to axially rebound, installation is convenient, in addition, the sealing effect is ensured, disengagement cannot happen even if later-period geological sedimentation happens, and the service life islong.

Owner:KANGMINGYUAN GUIZHOU SCI & TECH DEV CO LTD

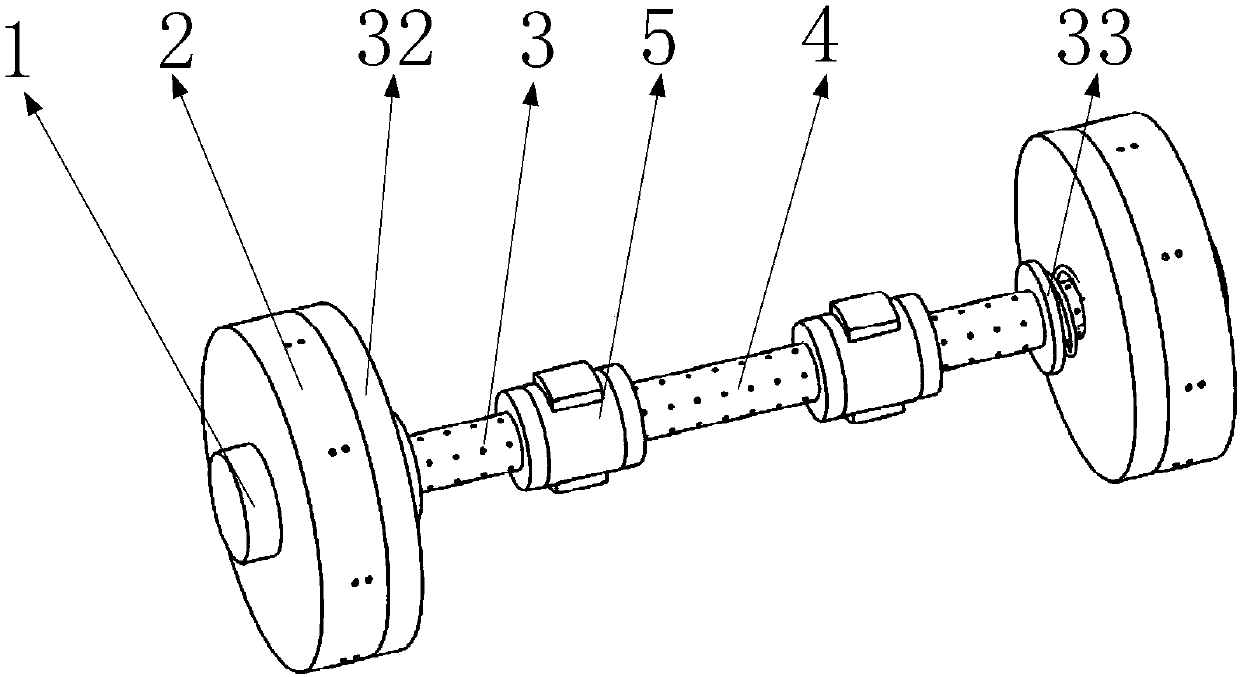

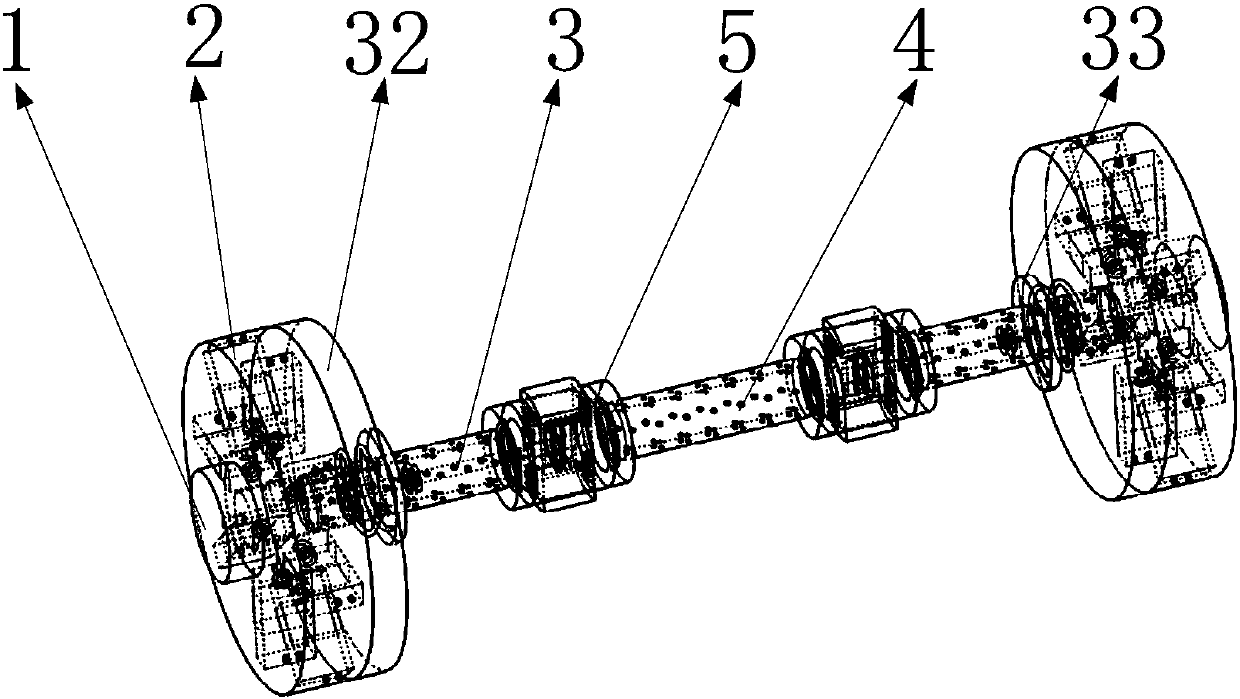

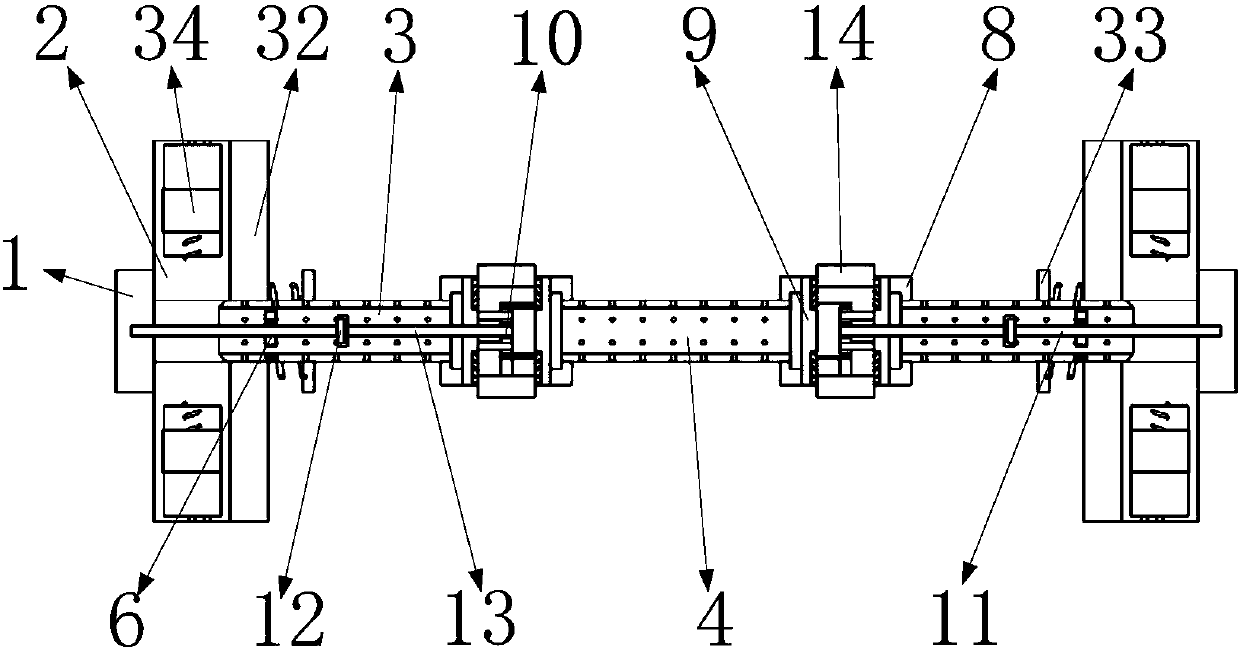

Self-power-generating shared barbell

The invention belongs to the technical field of barbells and particularly relates to a self-power-generating shared barbell. The self-power-generating shared barbell comprises counter weight driving discs, a barbell counter weight, first barbell bars, a second barbell bar, a trigger mechanism and a coil circular ring. When a user uses the designed barbell without code scanning, a two-dimensional code sensor makes a trigger handle in a closed state. Under the effect of self gravity of the barbell, the first barbell bars on two sides break away from corresponding counter weight driving discs ofthe barbell, so that the user cannot perform normal exercise. When the user uses the designed barbell after code scanning, the two-dimensional code sensor makes the trigger handle in an opened state at the moment, the user firstly lifts the barbell upward with double hands and then reversely turns the barbell after lifting the barbell, so that the whole barbell is located on the upper side of thedouble hands, and finally the barbell is lifted upwards.

Owner:陈桂音

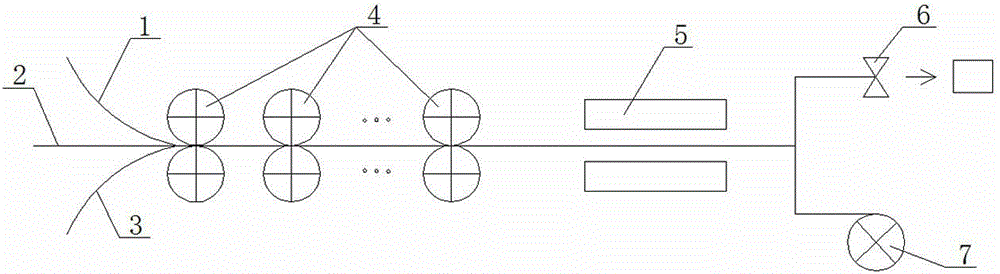

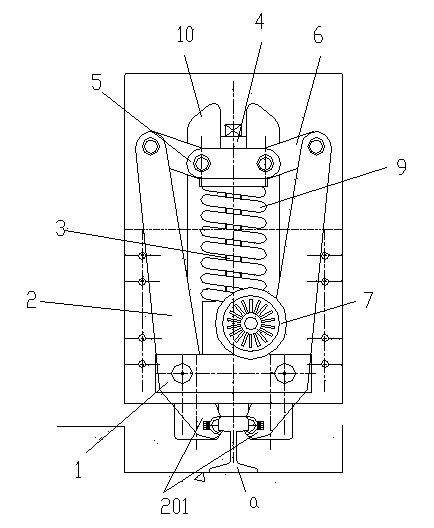

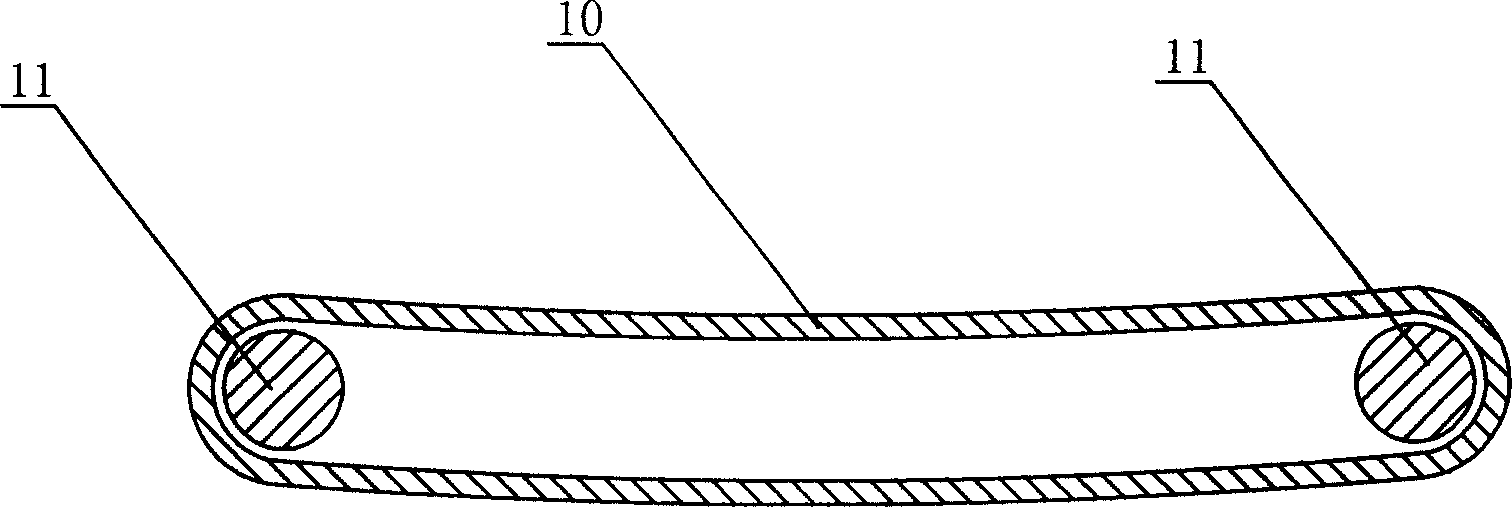

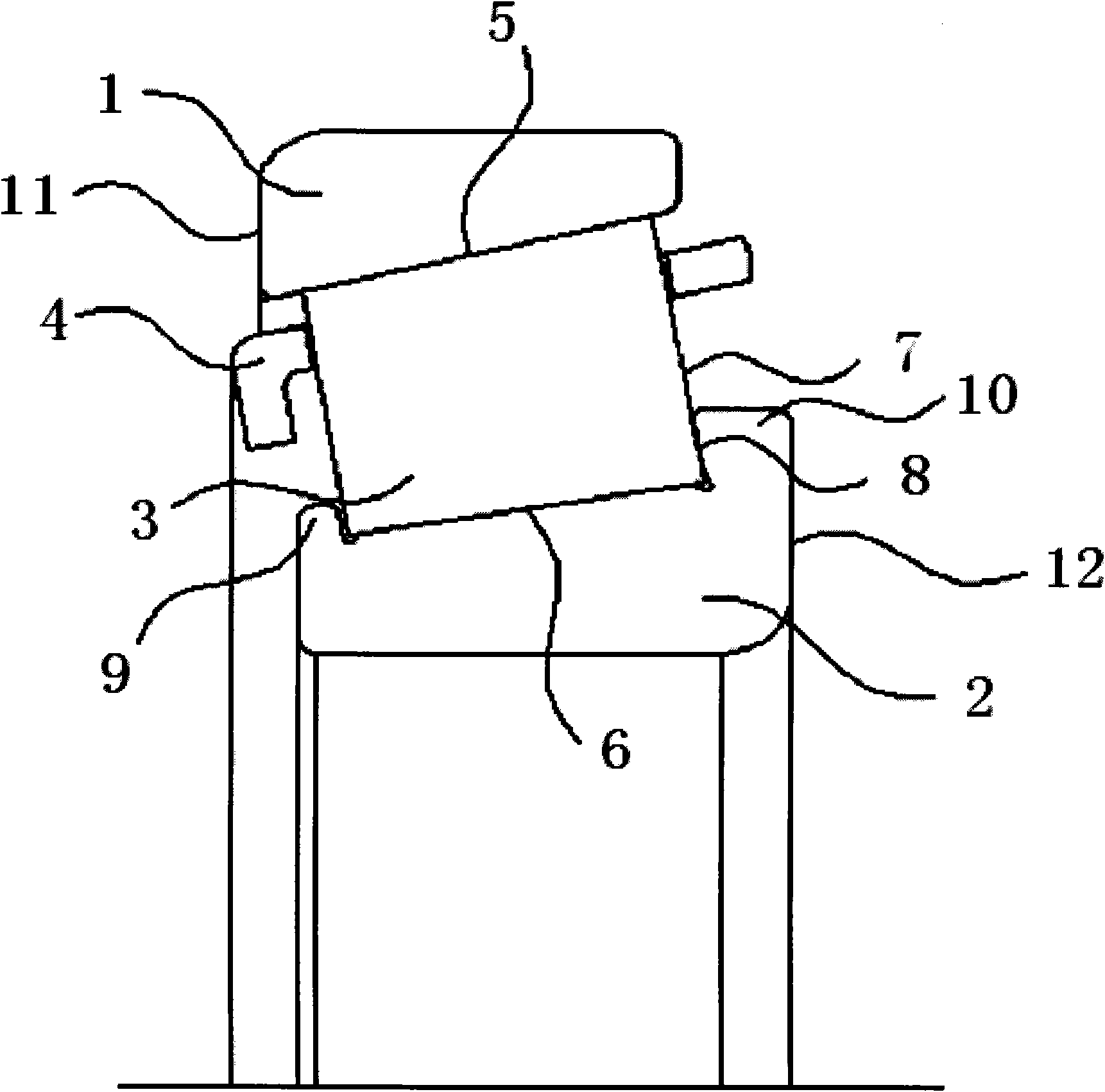

Peristaltic pump structure

InactiveCN102102656AWon't come offImprove the extrusion effectFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

The invention discloses a peristaltic pump structure which comprises a motor, a pump body, an upper cover, a rolling component and a hose, wherein the motor is fixedly connected with one end of the pump body, an extrusion cavity is arranged at the other end of the pump body, the rolling component and the hose are both arranged in the extrusion cavity, the hose surrounds the rolling component, the motor is in transmission connection with the rolling component, the upper cover is fixedly connected with the other end of the pump body, the inlet end and the outlet end of the hose extend out of the pump body, the rolling component comprises a rolling roller and a bracket, radial convex wings are respectively arranged at the upper end and the lower end of the bracket, the upper end of the rolling component is connected to the radial convex wing arranged at the upper end of the bracket, the lower end of the rolling component is connected to the radial convex wing arranged at the lower end of the bracket, and fixing joints are respectively arranged at the inlet end and the outlet end of the hose and are installed in a locking installation groove of the pump body in a locking way. The invention has good extrusion effect and long service life.

Owner:CHANGZHOU PREFLUID TECH

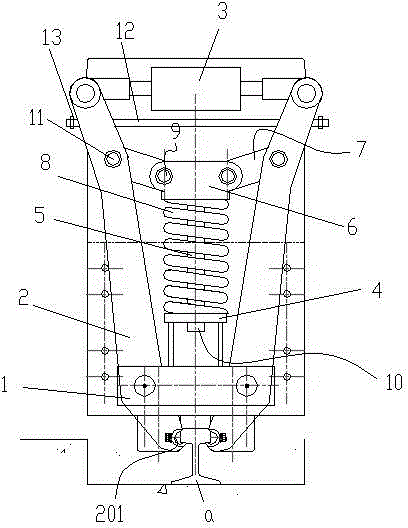

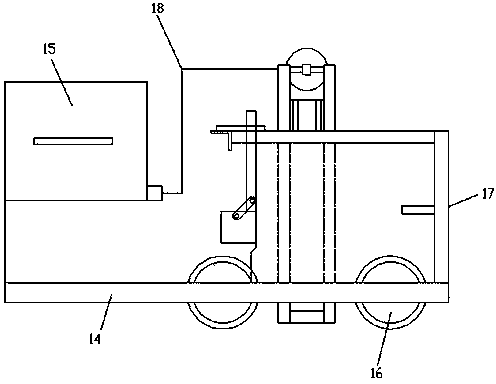

Novel rail clamping device

The invention discloses a novel rail clamping device. The rail clamping device comprises a base, a pair of clamping pliers with chucks, a connecting rod and a hydraulic motor, wherein the pair of clamping pliers is hinged on the base, the connecting rod is installed on the base in a rotatable manner and comprises a lower connecting shaft, a worm and an external thread section, the lower connecting shaft is connected with the base, the worm is arranged at the upper end of the lower connecting shaft, the external thread section is arranged at the upper end of the worm and is screwed with a rotating nut, a lantern ring is sleeved on the rotating nut and is hinged with the upper ends of the pair of clamping pliers by a pair of link rods, and a worm gear meshed with the worm is fixed on an output shaft of the hydraulic motor. The rail clamping device has a simple structure, is easy to manufacture, can clamp rails firmly under the unforeseen circumstances such as power failure and the like, and can not come away.

Owner:枣庄高新建设集团有限公司

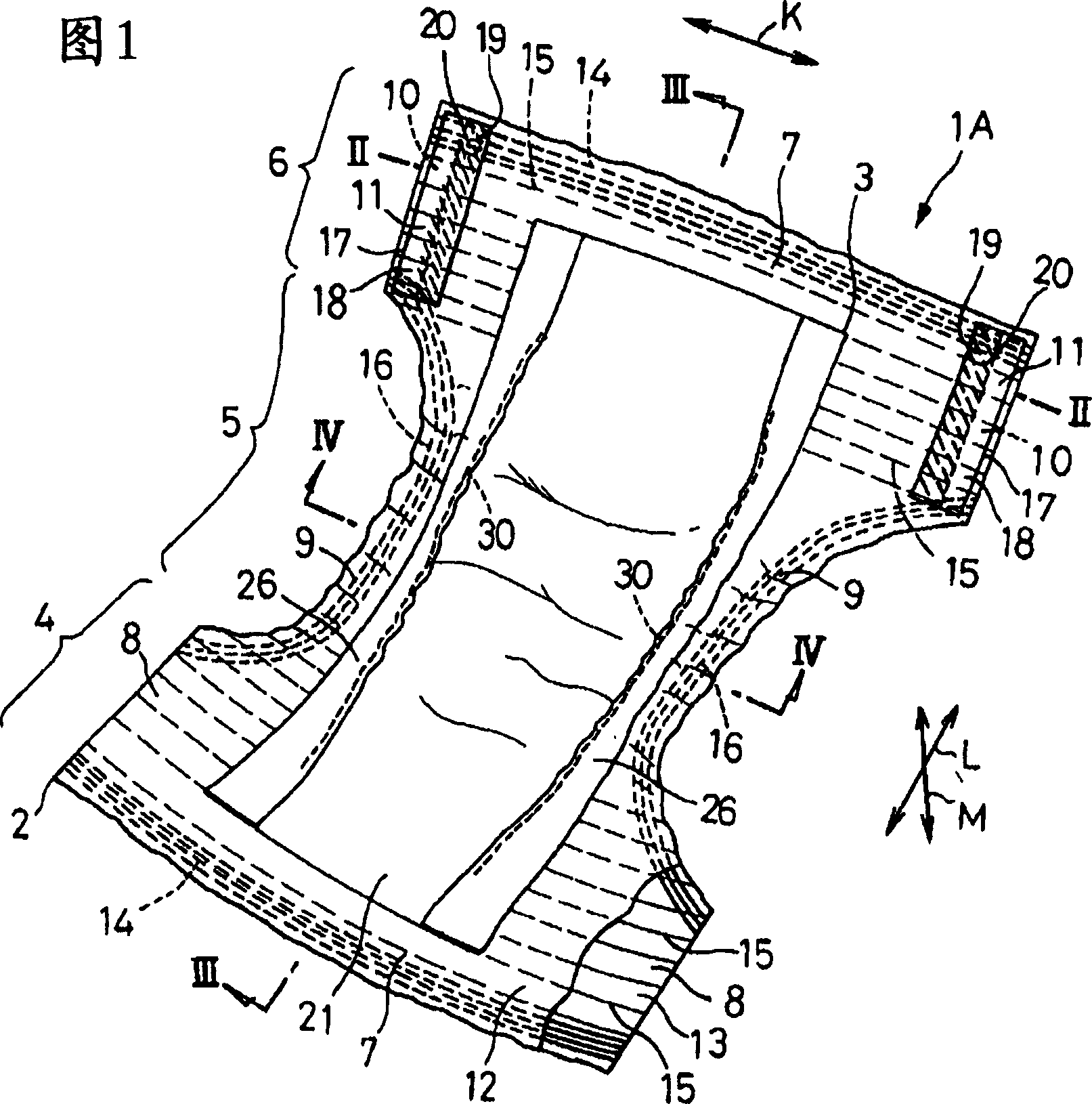

Disposable wearing article

Owner:UNI CHARM CORP

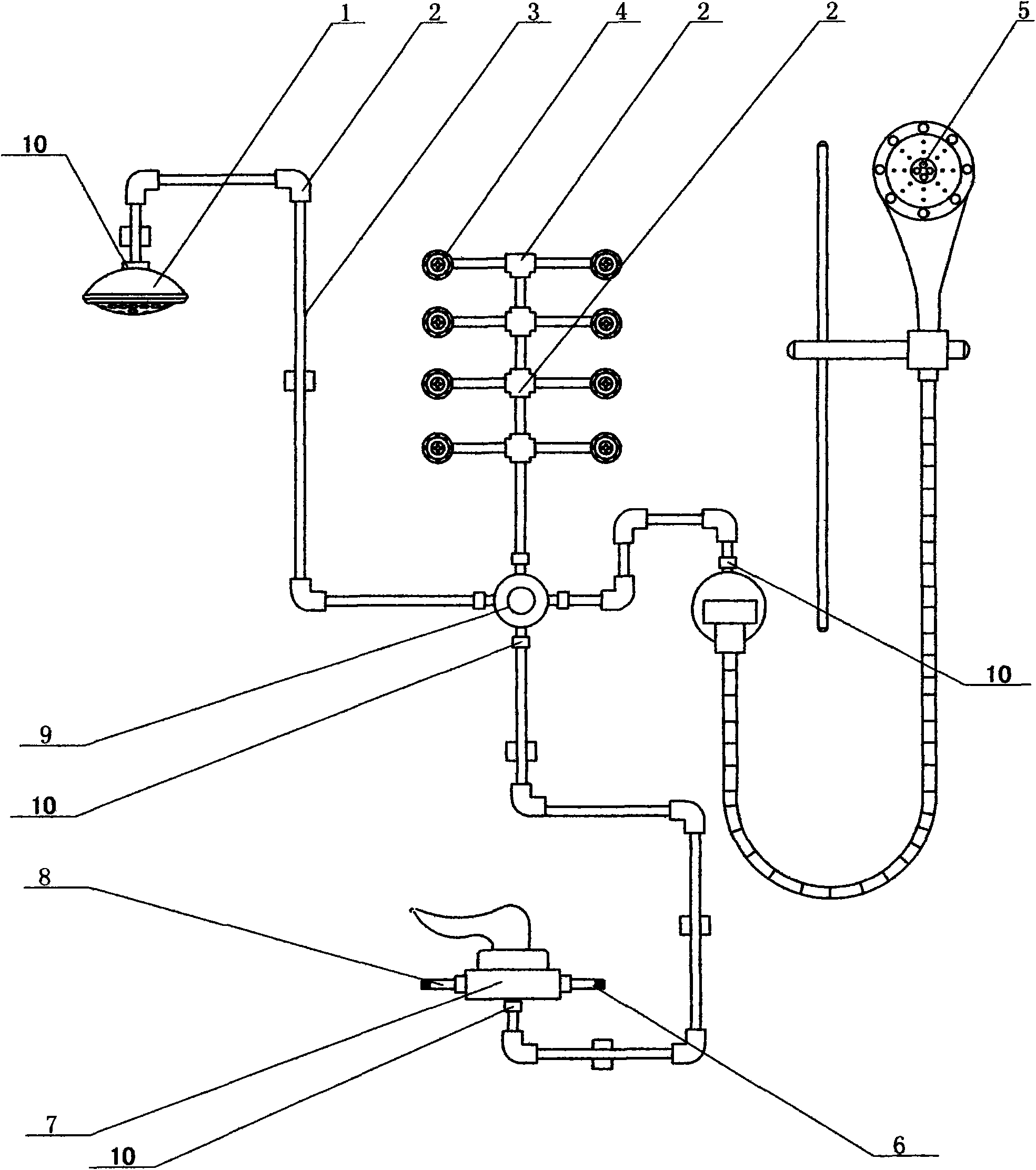

Polypropylene plastic water pipe for shower room backboard

InactiveCN101634390AImprove toughnessNot easy to agePipe connection arrangementsSpray nozzleHot melt

The invention relates to a polypropylene plastic water pipe for a shower room backboard. The water pipe of the shower room backboard is respectively provided with a top-spray shower head pipeline, a movable shower head pipeline, a massage spray nozzle pipeline and a foot massage spray head pipeline. Connecting pipelines and each functional component are connected by various joints, and splicing joints of all assemblies are of thread type. Polypropylene plastic water pipes are connected in a hot melt way. A polypropylene movable joint is conveniently connected with a water faucet, a shower head, spray nozzle threads or other pipes with threads. When connected, the water-spray massage spray nozzle is connected by a movable joint from the water faucet, then the polypropylene plastic water pipe is connected with the spray nozzles of the shower room, and the quantity of spray nozzles is a plurality. A three-way and a four-way of the polypropylene plastic joint are connected by branch pipes in the hot melt way, and each branch pipe is connected with one spray nozzle. A water inlet of the spray nozzle is made into a screw rod and matched with a nut of the polypropylene movable joint, the massage spray nozzles are respectively inserted into spray nozzle holes of the shower room backboard, a tightening washer is fastened, a rubber washer is lined, and the movable nut is sleeved into the screw rod of the spray nozzle and tightened.

Owner:段云平

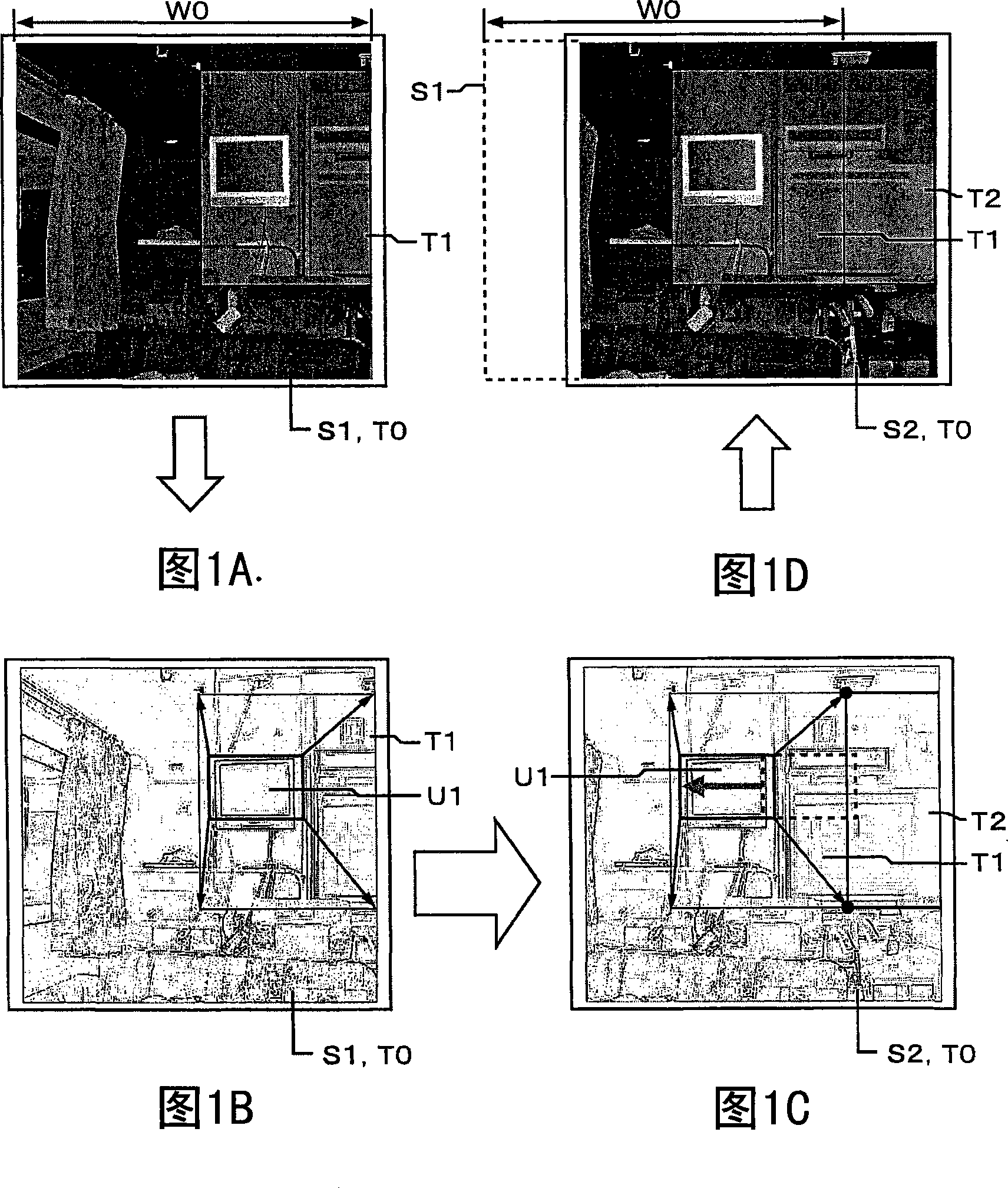

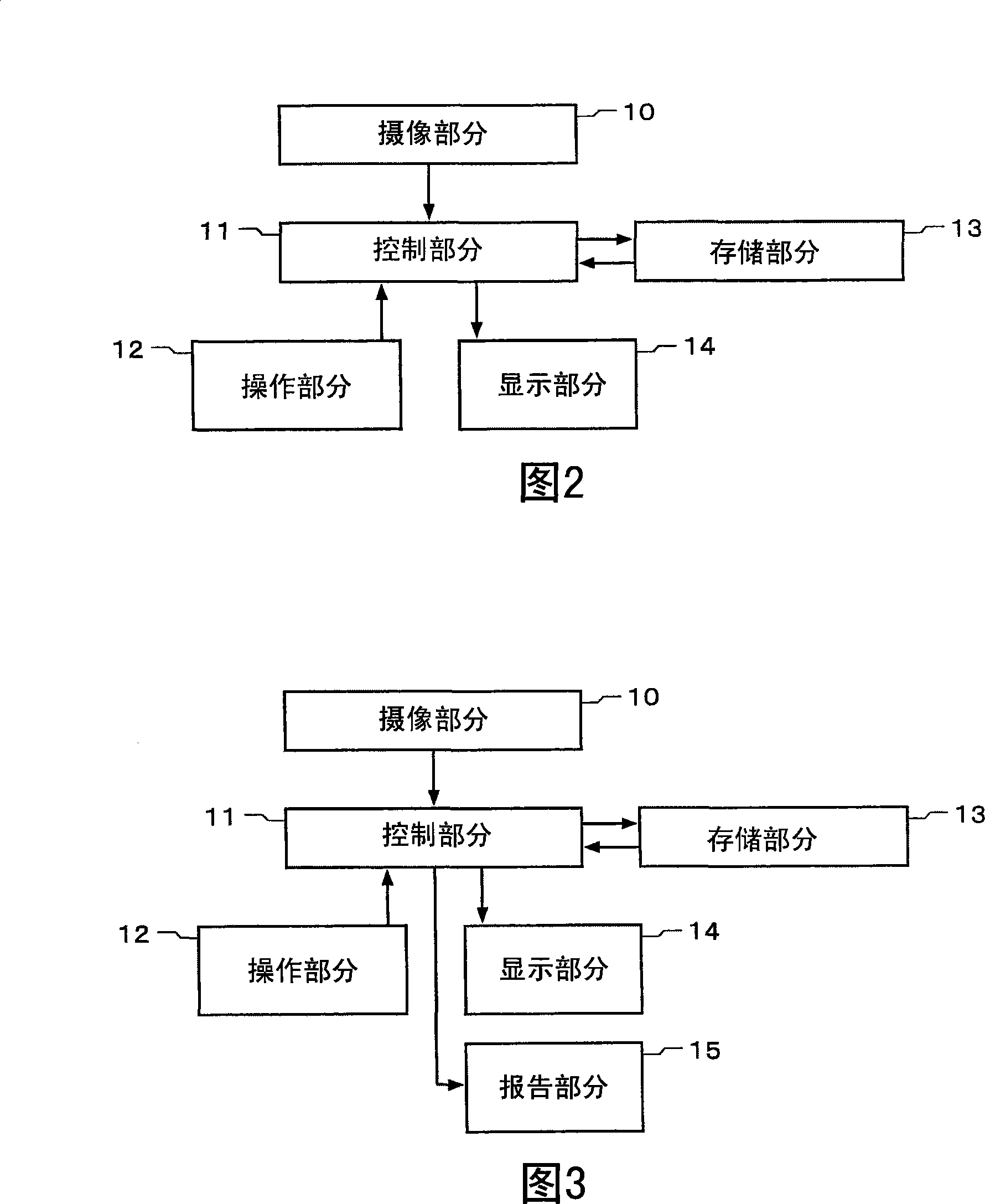

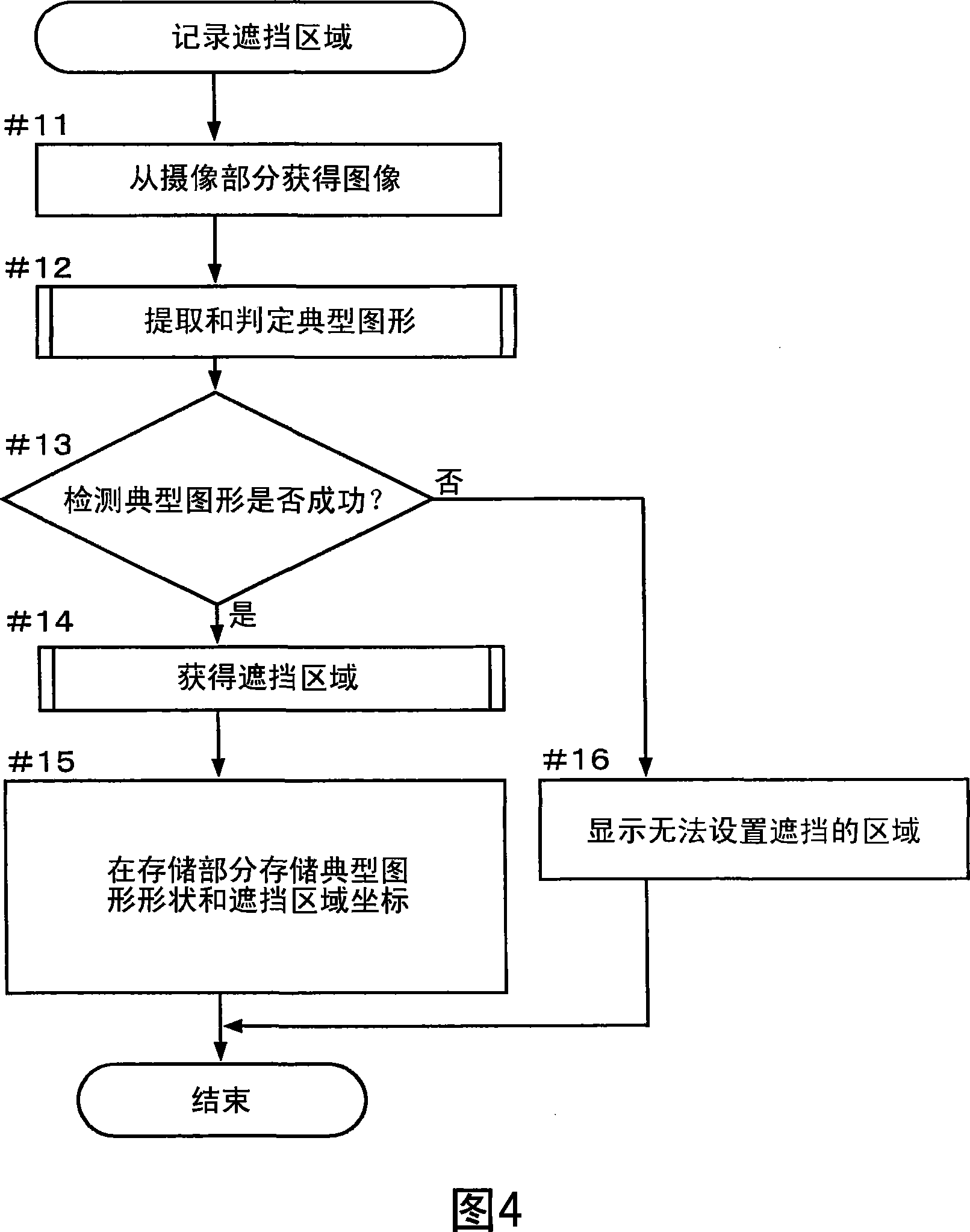

Device with imaging function

InactiveCN101166234AWon't come offTelevision system detailsCharacter and pattern recognitionData displayGraphics

Owner:FUNAI ELECTRIC CO LTD

Safety tyre

InactiveCN1887608AAvoid damageWill not cause displacementTyre partsEngineeringMechanical engineering

Owner:陈旭东

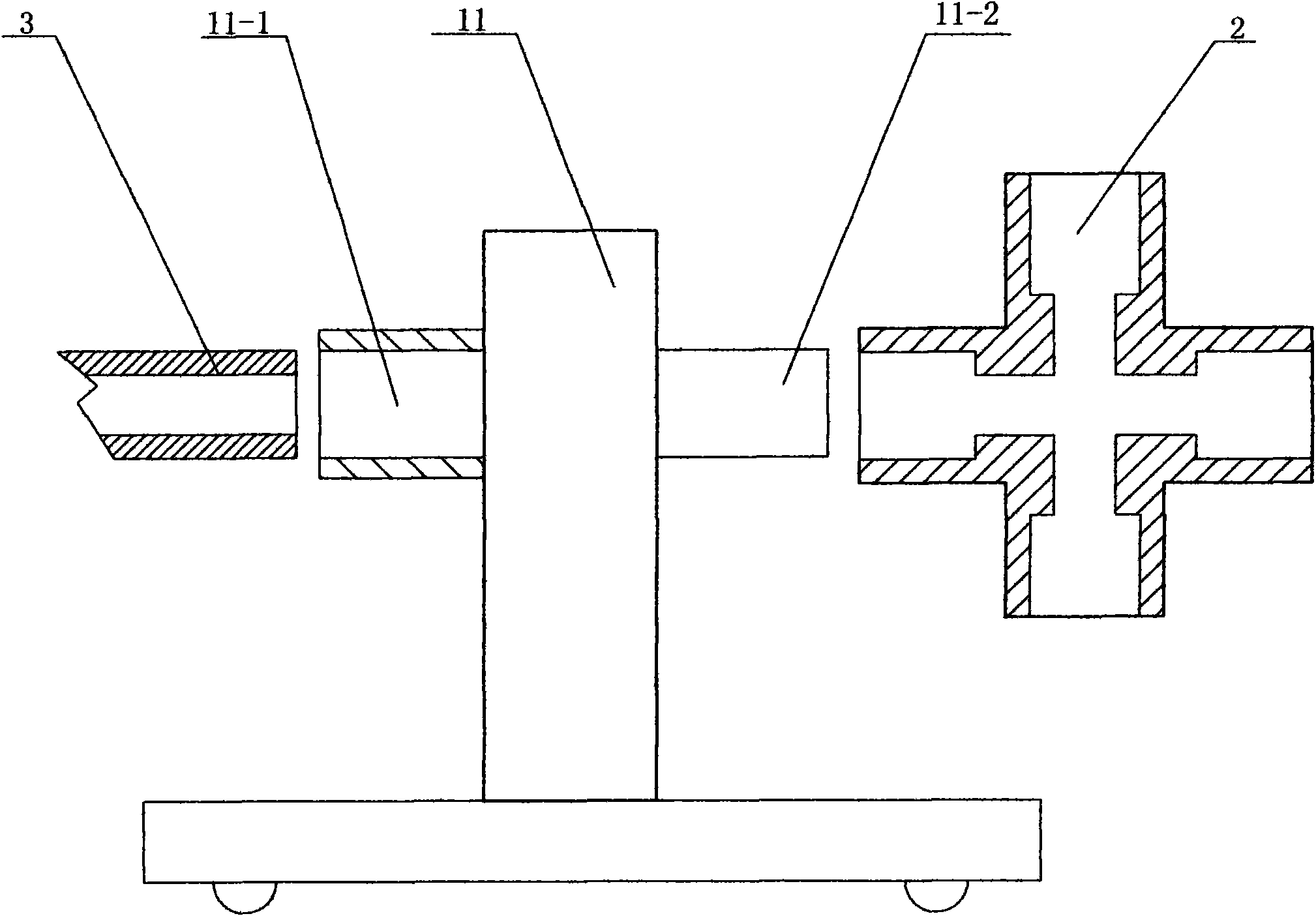

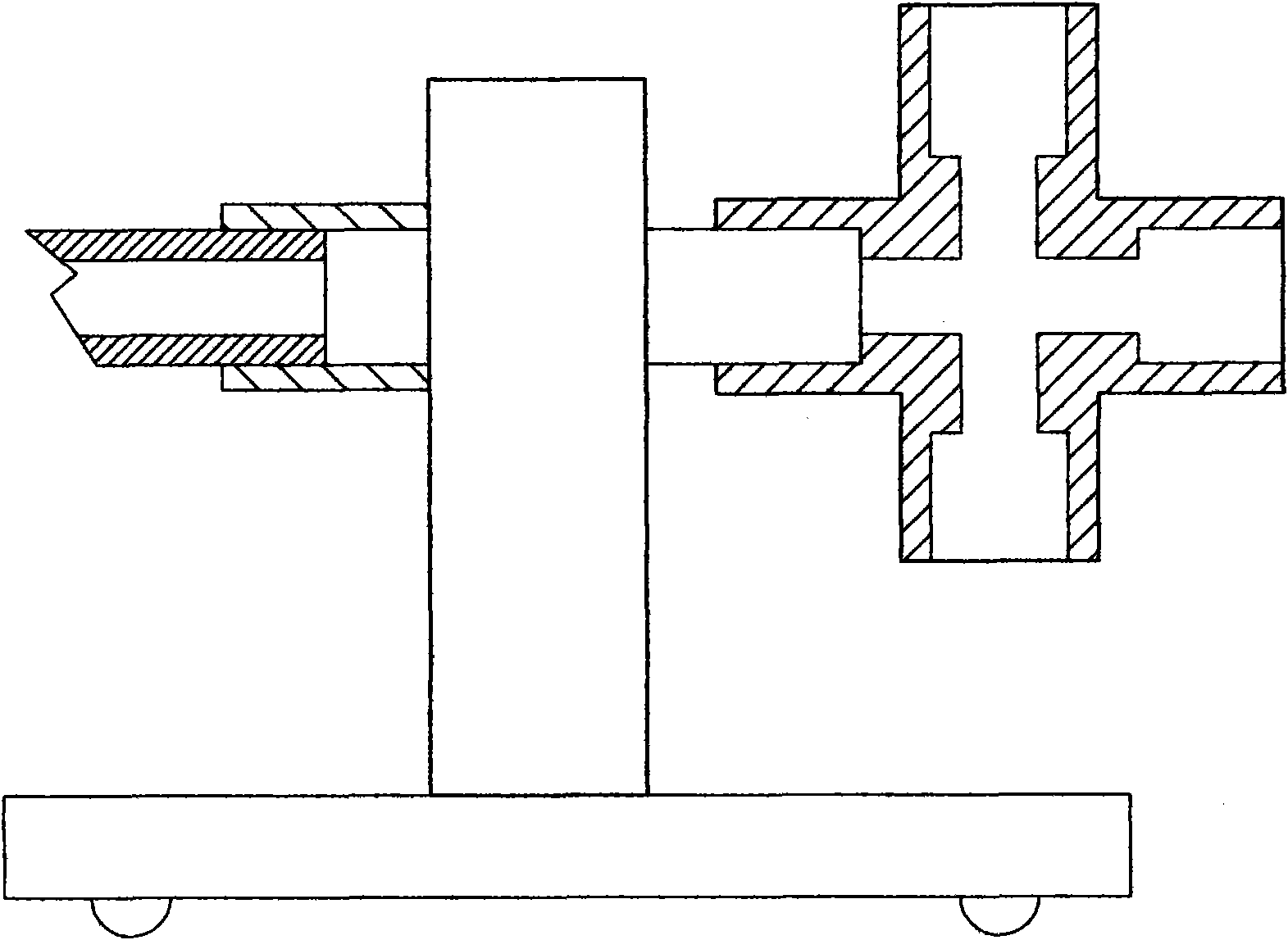

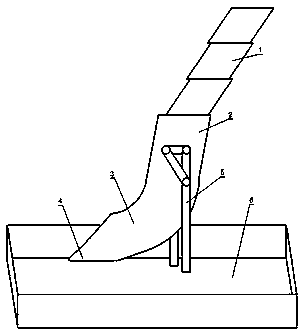

Building material conveying device

ActiveCN103643797ATransportation safetyImprove reliabilityBuilding material handlingPush and pullProblem of time

The invention relates to a building material conveying device which comprises a conveying unit and a collecting unit connected with the conveying unit, wherein the conveying unit comprises multiple layers of stacked push-pull plates which can be pushed and pulled layer by layer from the inner layer to the outer layer in a top to down direction, wherein the inner surface of a push-pull plate on the innermost layer is smooth, and a sliding push-pull raised ridge is formed on the outer surface in the vertical direction; a sliding push-pull groove is formed in the inner surface of a push-pull plate on the outermost layer in the vertical direction, and the outer surface is smooth; and sliding push-pull raised ridges are formed on the outer surfaces of the rest push-pull plates on the middle layer in the vertical direction, and sliding push-pull grooves are formed in the inner surfaces of the push-pull plates in the vertical direction. The problems of time consumption, labor consumption and lower efficiency of a conventional building material conveying method can be solved, the defects of complicated structure, larger energy consumption and high construction cost are overcome, and the building material conveying device has the advantages of simple and ingenious structure, convenience and safety in use and capability of improving construction efficiency and safety, and can meet requirements of actual construction conditions.

Owner:JINLING INST OF TECH

Electronic steering gear

The invention discloses an electronic steering gear which comprises a motor. A ball screw is arranged below the motor, a fixing seat is arranged on the ball seat, a first belt wheel is arranged on a rotating shaft of the motor, a second belt wheel is arranged at one end, close to the rotating shaft, of the ball screw, and the first belt wheel and the second belt wheel are connected through a belt. The electronic steering gear is simple in structure, ingenious in design, free of causing disconnection of a motor shaft and the ball screw and convenient to maintain.

Owner:CHONGQING LONGRUN AUTOMOBILE STEERING GEARS

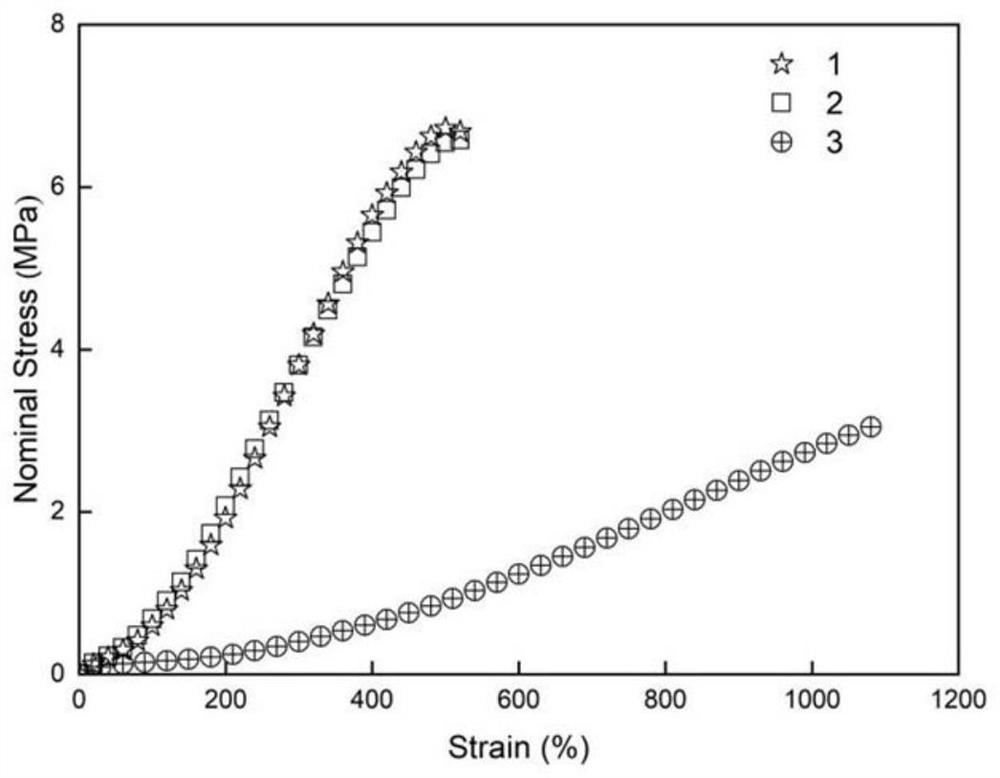

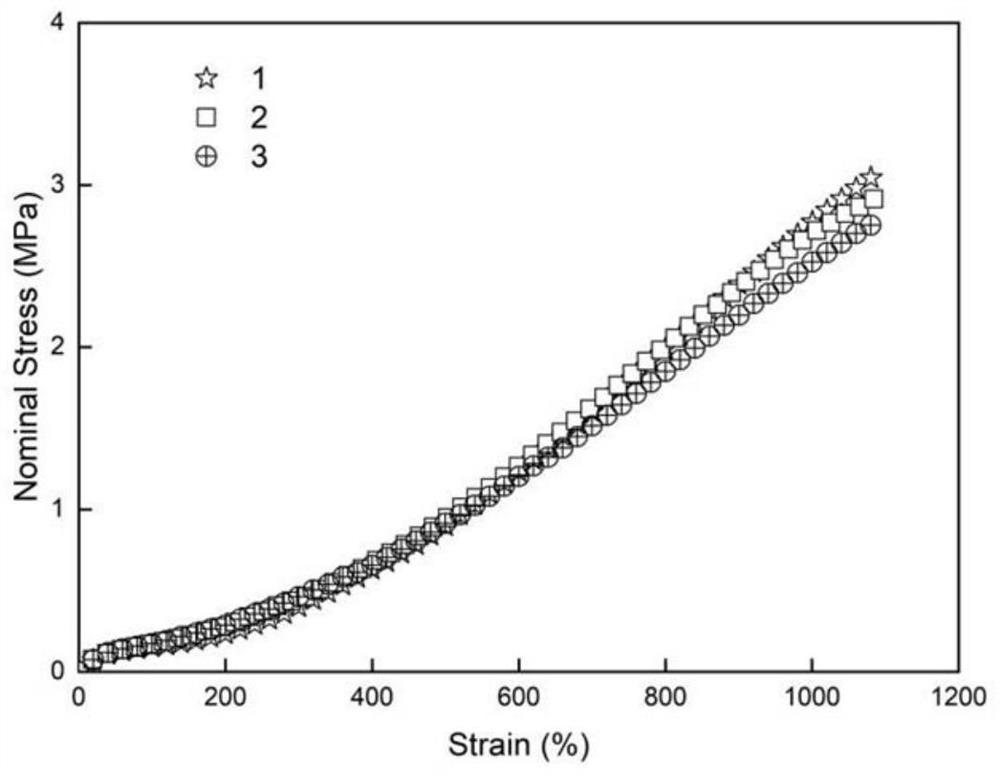

Anisotropic dielectric elastomer fiber driver and preparation method thereof

ActiveCN113199844ARealize low voltage driveReduce thicknessPiezoelectric/electrostriction/magnetostriction machinesSynthetic resin layered productsPolymer scienceFiber bundle

The invention discloses an anisotropic dielectric elastomer fiber driver and a preparation method thereof. The driver is composed of one or more sub-fibrous driver wall surfaces which are attached to each other. Each sub-fibrous driver comprises at least two anisotropic dielectric elastomer layers and at least two flexible electrode layers, and the anisotropic dielectric elastomer layers and the flexible electrode layers are overlapped in a staggered mode and wound into a fibrous structure. According to the method, an anisotropic dielectric elastomer film with reduced thickness and microstructure orientation is prepared through a mechanical strain induction method based on a physically-crosslinked block copolymer thermoplastic elastomer, and a light and fully-flexible dielectric elastomer fiber driver outputting linear displacement in the axial direction is prepared in a laminated winding mode. Driving deformation can be output in a directional mode, the driving performance is greatly improved, meanwhile, low-pressure driving is achieved, fiber bundles are assembled, and multiple motion modes of stretching, bending and rotating are generated.

Owner:ZHEJIANG UNIV

Structure and method for welding target material and backboard

ActiveCN101518851BRealize large area weldingPrevent oxidationVacuum evaporation coatingSputtering coatingBonding strengthMaterials science

The invention relates to a structure and a method for welding a target material and a backboard, wherein the method for welding the target material and the backboard comprises the following steps: proThe invention relates to a structure and a method for welding a target material and a backboard, wherein the method for welding the target material and the backboard comprises the following steps: providing a tantalum target material; forming an intermediate layer on the welding surface of the tantalum target material; and performing welding operations on the intermediate layer through a hot isostviding a tantalum target material; forming an intermediate layer on the welding surface of the tantalum target material; and performing welding operations on the intermediate layer through a hot isostatic pressing method so as to weld a copper or copper alloy backboard to the tantalum target material. The method can perform extensive welding to effectively prevent metals form being oxidized and imatic pressing method so as to weld a copper or copper alloy backboard to the tantalum target material. The method can perform extensive welding to effectively prevent metals form being oxidized and improve the bonding strength between the tantalum target material and the copper or the copper alloy backboard, thus the tantalum target material cannot break away in the sputtering process so as to perprove the bonding strength between the tantalum target material and the copper or the copper alloy backboard, thus the tantalum target material cannot break away in the sputtering process so as to perform sputter coating normally.form sputter coating normally.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

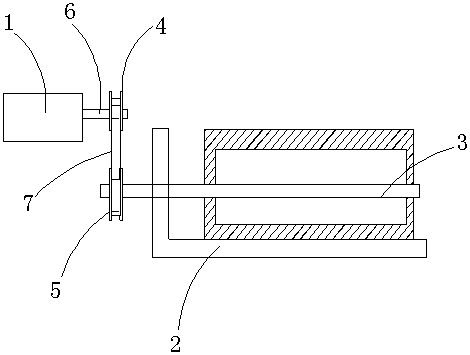

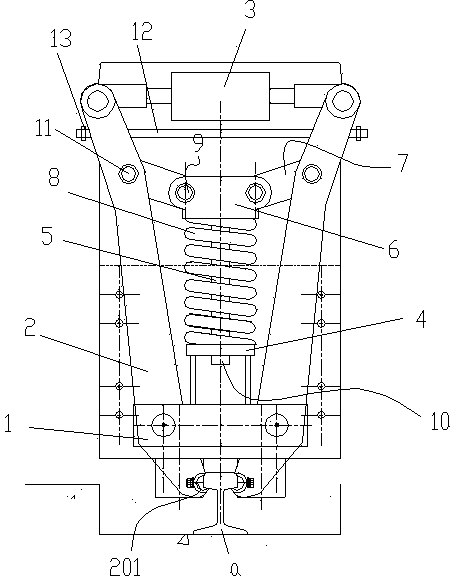

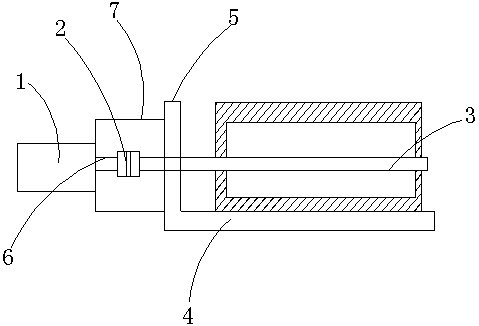

Waveguide welding fixture

ActiveCN108788370AGuaranteed welding deformation requirementsWon't come offWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention discloses a waveguide welding fixture which comprises a supporting platform and a plurality of sets of clamping assemblies arranged in the length direction of the supporting platform. Each clamping assembly comprises two supporting bases and two swing blocks, wherein the two supporting bases are symmetrically fixed to the two ends of the supporting platform, and the two supporting bases are arranged on the two sides of the supporting platform in the width direction; each swing block comprises a swing block body and a rotating base, wherein the swing block body and the rotating base form the whole of the swing block, the lower end of the rotating base is connected with the corresponding supporting base through a rotating shaft, the lower end face of each swing block body is incontact with the upper end face of the supporting platform, and the opposite inner side faces of every two corresponding swing blocks are provided with protrusions with semicircular cross sections; and the length direction of the protrusions is the same as the length direction of the supporting platform, and the center lines of the protrusions are parallel to the upper end face of the supportingplatform. The waveguide welding fixture solves the problems that during second-time vacuum brazing of a waveguide antenna, first-time-welding welding line comes away, and the direct size accuracy is difficult to guarantee.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

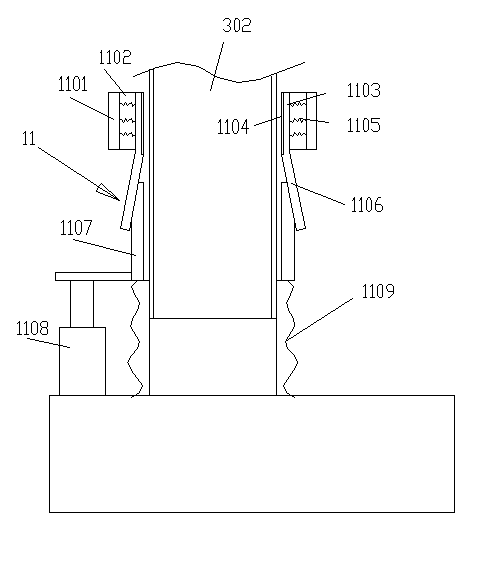

Heating electrode for reinforcement heated and upset end

ActiveCN105903868AAvoid offsetPrevent offset, etc., can effectively prevent the end of the steel bar from bendingMetal-working apparatusPower apparatusElectric spark

The invention discloses a heating electrode for a reinforcement heated and upset end. The heating electrode comprises an electrode bracket; a power device and a heating electrode are arranged on the electrode bracket; the power device pushes the heating electrode to move, or pushes the electrode bracket to drive the heating electrode to move; a slide column is arranged on the electrode bracket, and is provided with a spring; the front end of the spring is arranged at the back end of the heating electrode; the back end of the spring is fixed; and a spring located in a compression state applies the spring acting force to the heating electrode. The heating electrode is a floating form, continuously generates the thrust in the heating process, guarantees no release between the electrode and the end surface of a reinforcement due to heating softness of the reinforcement, is uniform and fast in heating, can prevent generation of electric sparks, is high in heating efficiency, only needs the time of about 2 seconds, and improves the machining efficiency.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

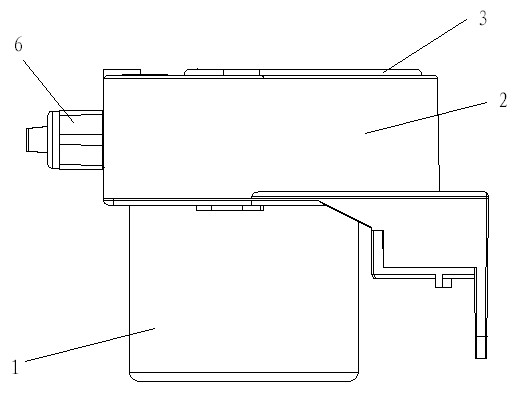

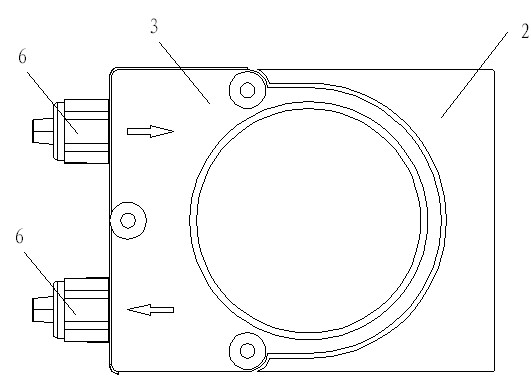

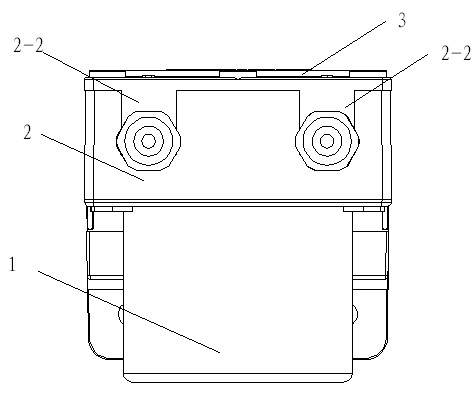

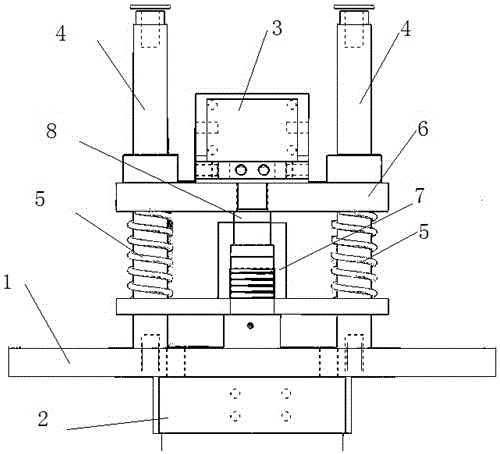

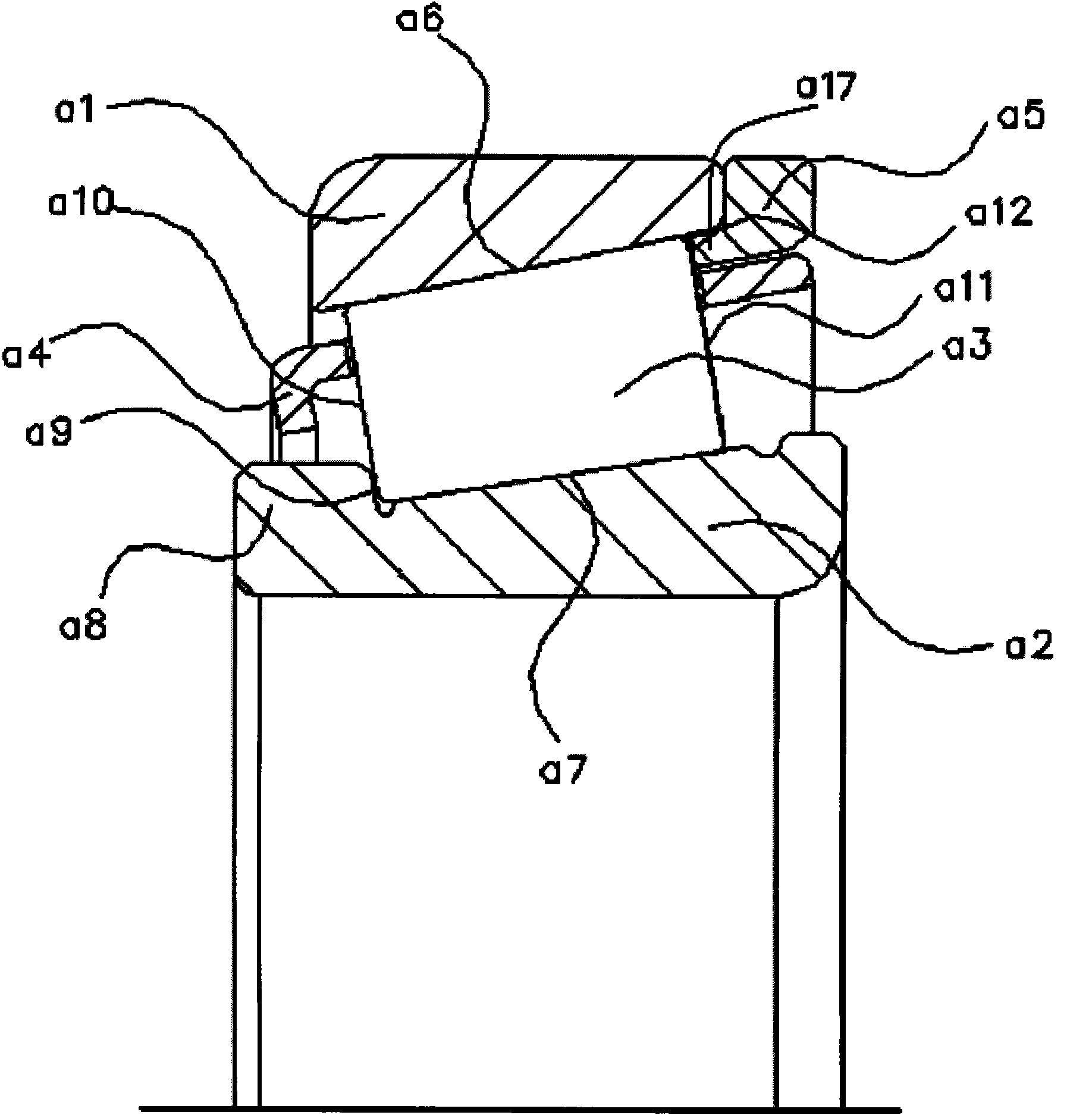

Integral hydraulic rail clamping device

InactiveCN103539008ALong working distanceControl lengthTravelling gearEngineeringMechanical engineering

The invention discloses an integral hydraulic rail clamping device. The rail clamping device comprises a base, a hydraulic station, travelling wheels and a clamping device, wherein the hydraulic station is mounted on the base; the travelling wheels are arranged on the base; the clamping device is arranged on the base; a mounting plane is arranged on the base; the clamping device comprises a base, a pair of clamping pliers with chucks and a telescopic device; the clamping pliers are hinged on the base; the telescopic device drives the pair of clamping pliers to rotate; a guide sleeve is fixed on the base; a guide rod is arranged in the guide sleeve; a blocking ring is fixed at the upper end of the guide rod; a clamp nut is arranged at the lower end of the guide rod; the blocking ring is hinged with the clamping pliers by a pair of link rods; a compression spring arranged between the blocking ring and the guide sleeve is sleeved on the guide rod. The integral hydraulic rail clamping device has a simple structure, is easy to manufacture, can clamp rails firmly under the unforeseen circumstances such as power failure and the like, and can not come away.

Owner:HUZHOU YANGXI ELEVATORING EQUIP

Steering gear with buffer effect

InactiveCN103818463AGood cushioning and shock absorptionImprove carrying capacityElectrical steeringBall screwCoupling

The invention discloses a steering gear with a buffer effect. The steering gear comprises a base, a motor and a ball screw. The base is provided with a base plate with a retainer plate at the end. The motor is fixed to the outer side surface of the retainer plate through a motor holder. The ball screw is arranged at the position, corresponding to a motor revolving shaft, in the retainer plate, and is connected with the motor revolving shaft through a coupler. The steering gear is simple in structure and skillful in design. As the flexible coupler has certain capacity of compensating relative deviation between two axes of the coupled two shafts, and particularly, the flexible coupler with metal elastic elements has good buffering and damping performance and high bearing capacity and is adaptable to occasions with high changes of speed and load and with high temperature or low temperature, separation of the motor shaft and the ball screw is avoided and maintenance is facilitated.

Owner:CHONGQING LONGRUN AUTOMOBILE STEERING GEARS

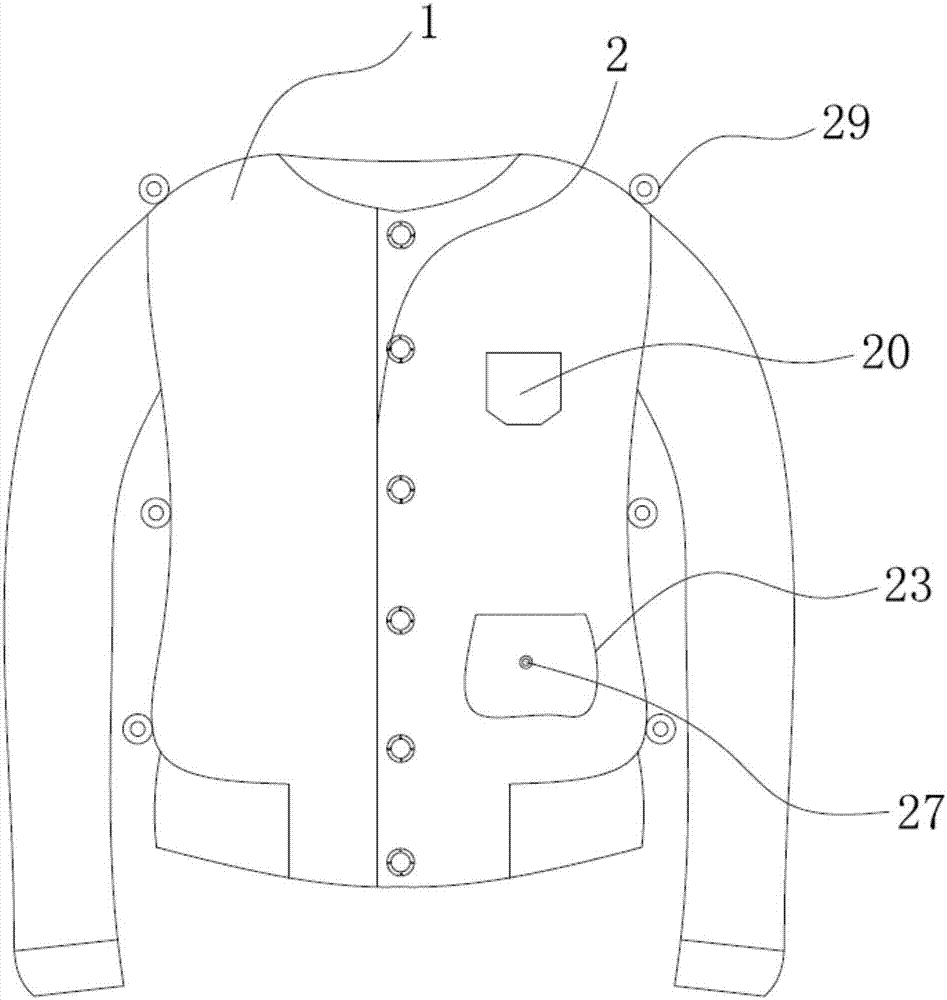

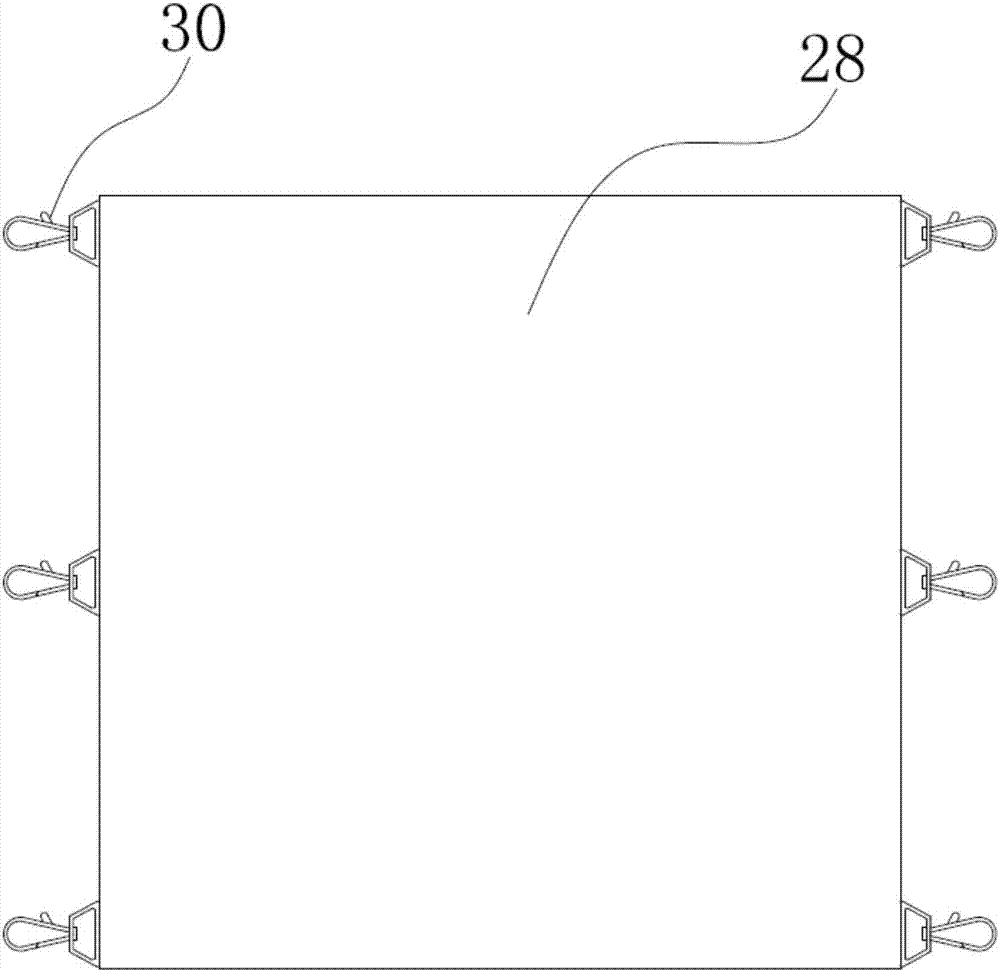

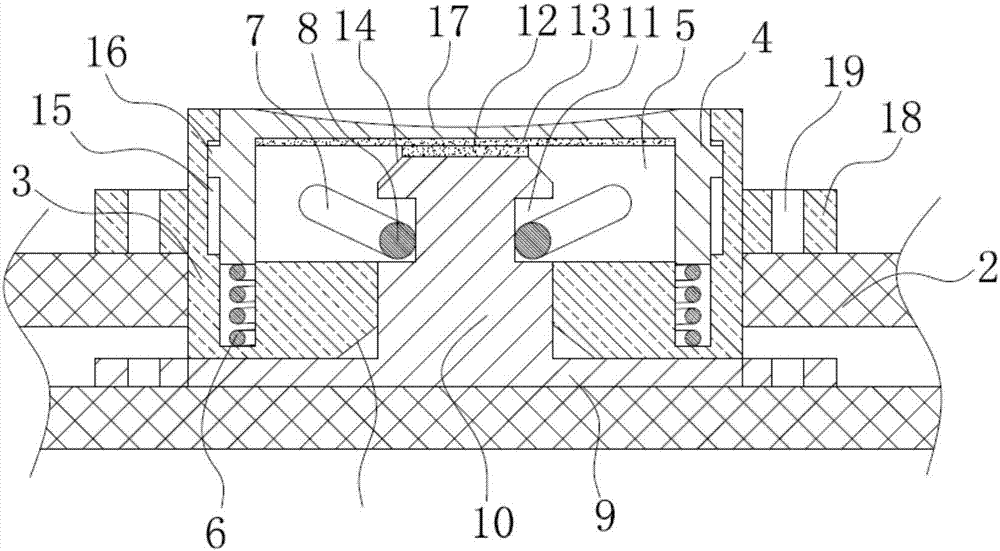

Coat suitable for children with autism

ActiveCN107361419AOptimize connection structureFit to wearProtective garmentNatural stateEngineering

The invention discloses a coat suitable for children with autism. The coat comprises a coat body, a placket, internal buckles and external buckles; each internal buckle includes a buckle body and a push button arranged inside the buckle body, and the buckle body is internally provided with a stepped hole with an upper larger diameter hole end face and a lower smaller diameter hole end face; the buckle body is internally provided with a spring, and the push button is fixed on the top of the spring; the inter wall of the push button is provided with at least a pair of sliding chutes arranged oppositely, and a sliding block pin is arranged between the limiting chutes and slidably matched with the limiting chutes; each external buckle includes a limiting part and a plug fixed on the surface of the limiting part, and the upper part of the plug is provided with an annular neck; the plug passes through the stepped hole, and the annular neck is positioned above the smaller diameter hole of the stepped hole; when the spring is in a natural state, the sliding block pin slides to the lower parts of the sliding chutes and is matched with the annular neck in a clamping mode, and the plug is matched with the annular neck in a clamping mode; when the spring is in a compression state, the sliding block pin slides to the upper parts of the sliding chutes and is separated from the annular neck. The coat suitable for children with autism has the advantages of being novel in structure and convenient to wear, can exercise the coordination of two hands and the flexibility of the coordination of hands and eyes at the same time, and therefore is suitable for children with autism to wear.

Owner:浙江金钥匙儿童用品有限公司

An electronic communication equipment mounting box

ActiveCN109246955APrevent movementAct as a support limitMachine supportsSpringsElectronic communicationNormal conditions

The invention belongs to the technical field of mounting boxes, in particular to an electronic communication equipment mounting box, which includes a support base, a mounting box, a support bar; underthe normal condition, that the support rod and the mounting box can keep the stable state without being impacted by the triggering mechanism, the limiting disk, the universal joint and the limiting mechanism, but the ordinary mounting box may be damaged when being impacted, and the signal transmission line in the mounting box is pulled out; When the mounting box is impacted, the mounting box andthe support rod will move horizontally in the impacted direction; As that support rod is disengage from the inner re of the universal joint under the action of the impact force, the mounting box is prevented from being damaged by the large impact force directly, the mounting box is protected, and the mounting box can be prevented from moving under the driving of the impact object, and the signal transmission line in the mounting box is pulled out; At that same time, the universal joint swing with the support rod so as to facilitate the support rod to smoothly disengage from the base.

Owner:王媛玲

Anti-dropping sealing structure connected between corrugated pipes

InactiveCN110425354APrevent axial springbackEasy to installSleeve/socket jointsEngineeringWave trough

The invention relates to an anti-dropping sealing structure connected between corrugated pipes. The anti-dropping sealing structure comprises a spigot section, a socket section, a sealing ring and ananti-dropping part; a corrugated structure in which the peaks and troughs are alternately arranged in the axial direction is formed in the outer peripheral wall of the spigot section, the sealing ringis arranged in a wave trough at the front end of the spigot section, the anti-dropping part is arranged in a wave trough at the rear end of the spigot section, the socket section comprises a limitingsection, a receiving section and a clamping section, and the inner peripheral wall of the limiting section and the inner peripheral wall of the receiving section are both in a big-end-front conical shape; and the shapes of the front side wall, the rear side wall and the inner peripheral wall of the sealing ring are matched with the shapes of the wave troughs, the outer circumferential wall of thesealing ring is tightly matched with the inner circumferential wall of the receiving section, the lower end of the anti-dropping part is fixedly connected into the wave trough, the spigot section isinserted into the socket section, and the upper end of the anti-dropping part abuts against the clamping section. According to the corrugated pipe assembly, the sealing ring is effectively prevented from driving the pipe to axially rebound, so that not only the installation is convenient, but also the sealing effect is ensured, even the later geological sedimentation is not separated, and the service life is long.

Owner:KANGMINGYUAN GUIZHOU SCI & TECH DEV CO LTD

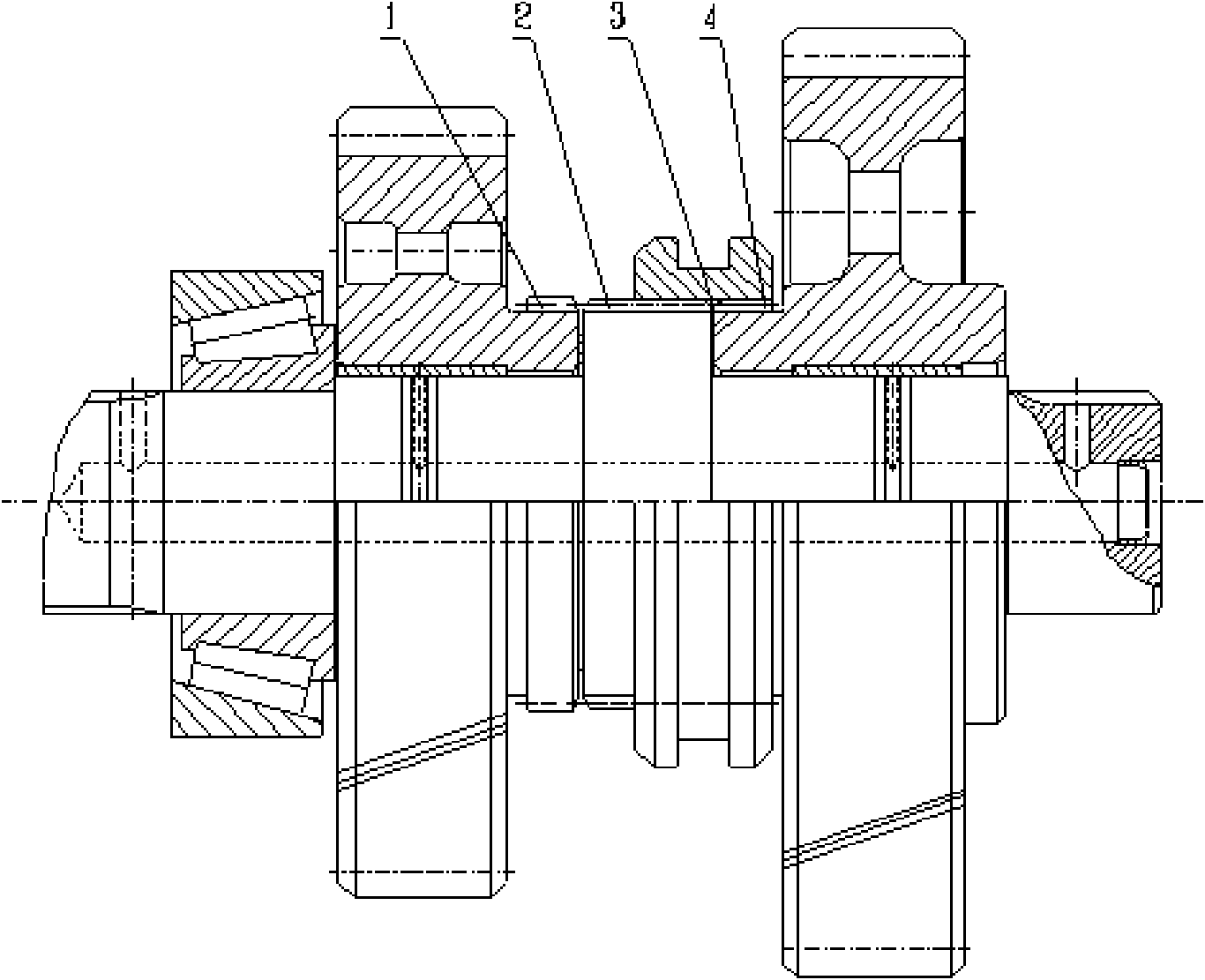

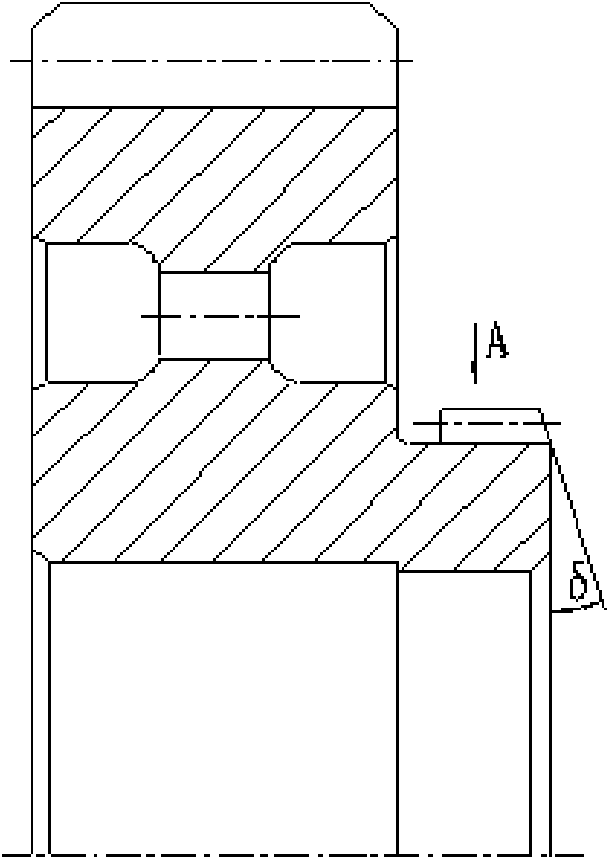

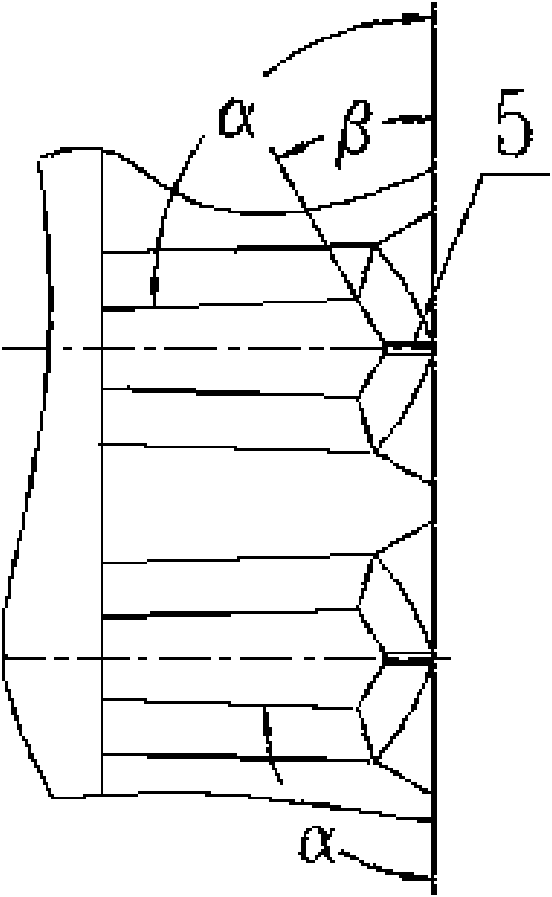

Conical roller bearing

The invention discloses a conical roller bearing. At the large-diameter end of an outer ring rollway of the conical roller bearing, a floating check ring is arranged on an outer ring, a flange protruding out of an inner ring rollway is formed on the small-diameter end of the inner ring rollway, and the large-diameter end of the inner ring rollway does not protrude out of the inner ring rollway; when the bearing is subjected to reversed axial force, the large end face of a conical roller contacts the floating check ring, the small end face of the conical roller contacts the flange on an inner ring, the reversed axial force is transferred by the flange on the inner ring, the conical roller and the floating check ring, the bearing is not released, so that one conical roller bearing can be subjected to two-way axial force; and the same effect can be achieved without using the two conical roller bearings, so the use of the conical roller bearing is prevented from being influenced due to the release of the conical roller bearing, and the space of installing the conical roller bearing is saved.

Owner:CSC BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com