Building material conveying device

A technology for conveying devices and building materials, applied in the processing of building materials, construction, building construction, etc., can solve problems such as low efficiency, high construction costs, complex structures, etc., and achieve the effect of good slip and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

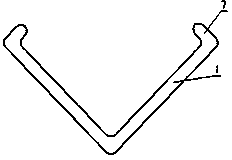

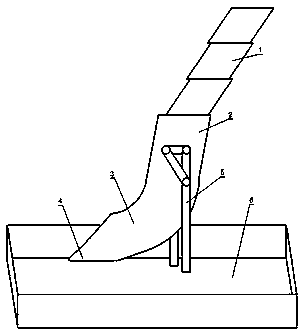

[0042] A construction material conveying device, comprising a conveying unit and a collecting unit 6 connected to the conveying unit; In the direction from top to bottom, the structure is drawn layer by layer from the inner layer to the outer layer, wherein the inner surface of the innermost pull plate 1 is smooth, and the outer surface is provided with sliding and pulling ribs along the vertical direction. Wherein the inner surface of the outermost drawing board 1 is provided with a sliding drawing groove along the vertical direction, and the outer surface is smooth, and the outer surface of the drawing board 1 of the other middle layer is provided with a sliding drawing groove along the vertical direction. Pull convex flute, the inner surface is provided with sliding and pulling grooves along the vertical direction.

Embodiment 2

[0044] A kind of construction material conveying device, with the embodiment 1, the difference is that the sliding and pulling ribs provided on the outer surface of the pulling plate 1 of the innermost layer and the middle layer are set as T-shaped, and the middle layer and the middle layer The size of the sliding and drawing groove provided on the inner surface of the outermost drawing plate 1 matches the upper end transverse dimension of the T-shaped sliding and drawing convex corrugation.

Embodiment 3

[0046] A construction material conveying device, the difference is that the middle layer and the outermost layer of the pull plate 1 are provided with stoppers on both sides of the bottom of the sliding pull groove on the inner surface, The gap distance between the edges of the two side blocks matches with the lower end transverse dimension of the T-shaped sliding and pulling ribs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com