A shifting system

A combination of gear shifting and external spline technology, which is applied in the field of shifting systems of automobile transfer cases, and can solve problems such as failure to shift gears, slipping and loosening of internal and external splines, and gear disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

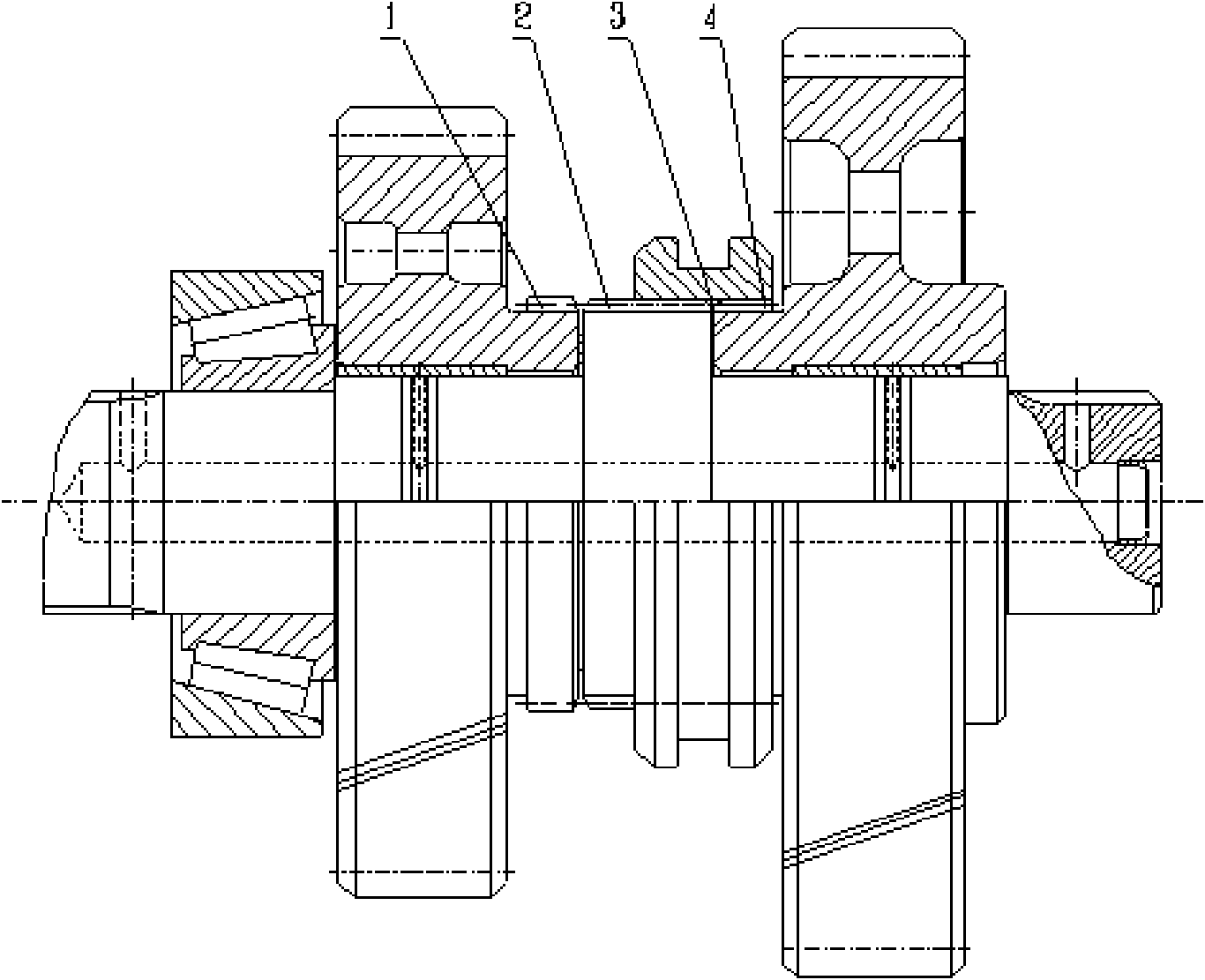

[0040] Drive pinion shifting spline 1, input shaft shifting outer spline 2, shifting combination sleeve inner spline 3, active large gear shifting outer spline 4 adopt splines of the same specification (module, number of teeth are the same).

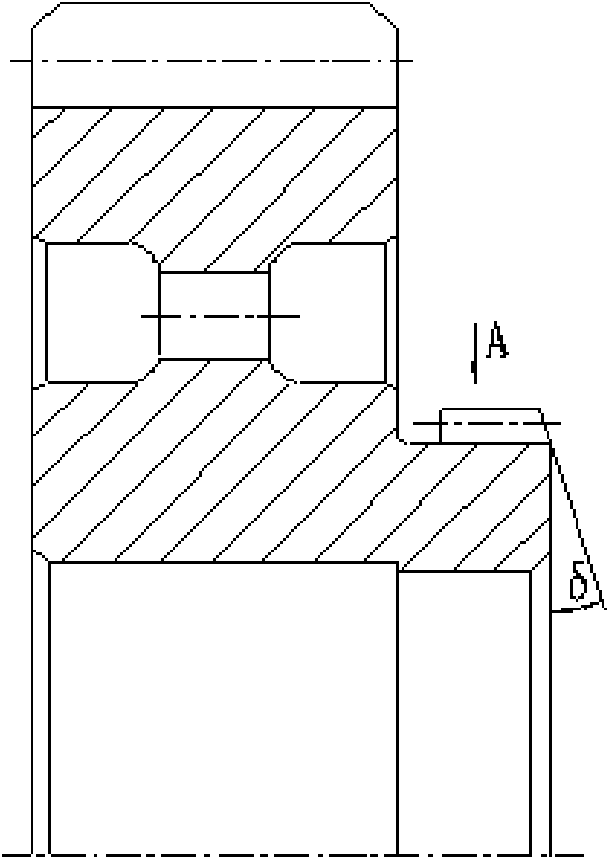

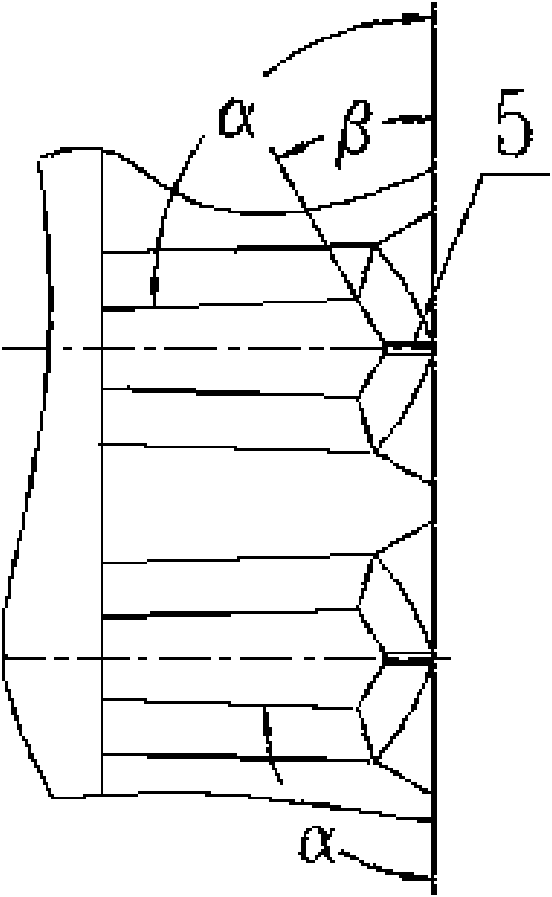

[0041] And the outer heads of the outer splines 1 of the driving pinion and the outer splines 4 of the driving gear shift are retracted, and the side of the outer head of the outer splines 1 of the driving pinion and the side of the outer splines 1 of the driving pinion form an angle of δ The angle between the outer head side of the external spline 4 of the active large gear and the side of the external spline 4 of the active large gear forms an angle of δ. The inner spline is divided into two symmetrical parts. The left and right inner splines are respectively retracted at the two sides near the end face. The two sides of the head form an angle with the two sides of the inner spline 3 of the shift coupling sleeve respectively. is the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com