Anti-dropping sealing structure connected between corrugated pipes

A sealing structure and bellows technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of poor sealing effect, high engineering cost, pipe detachment, etc., and achieve enhanced sealing Effectiveness, long service life and reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

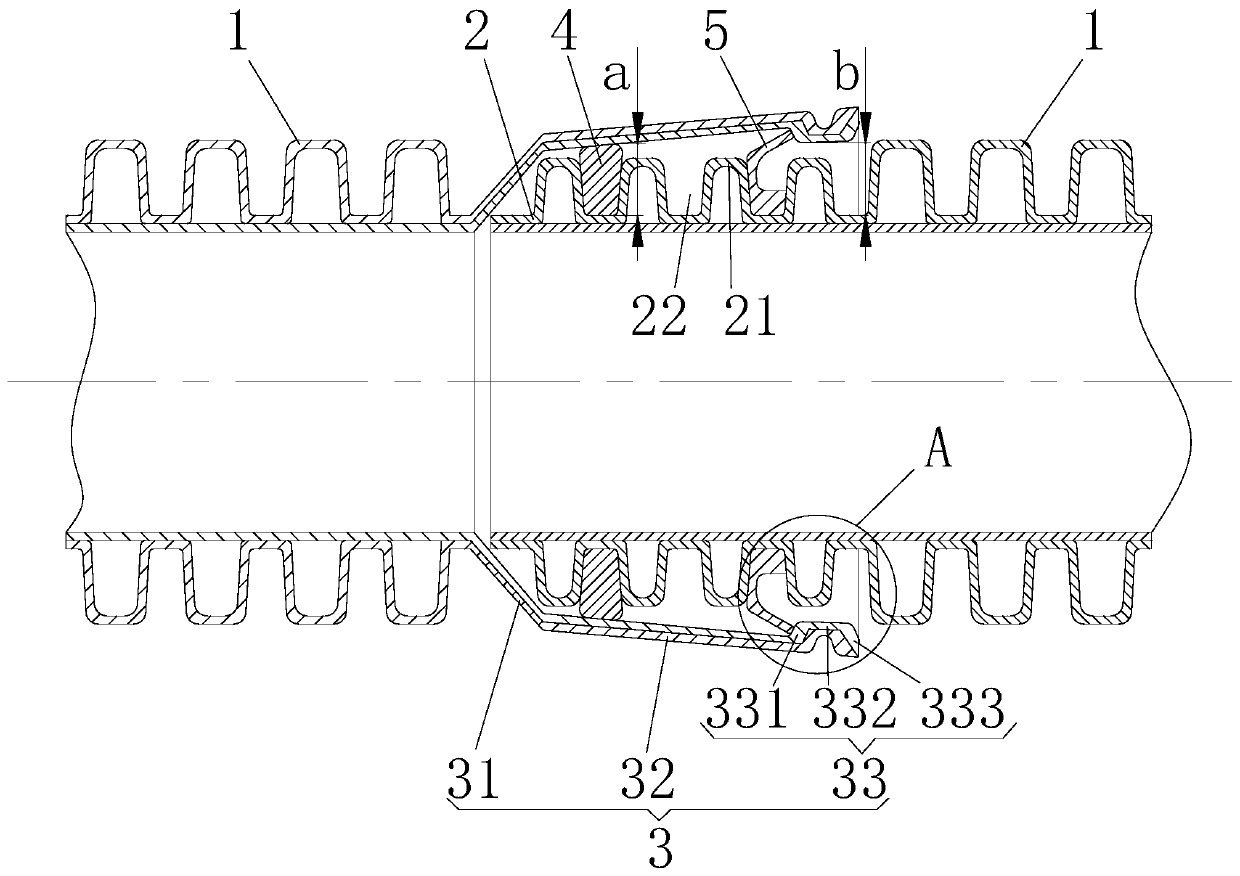

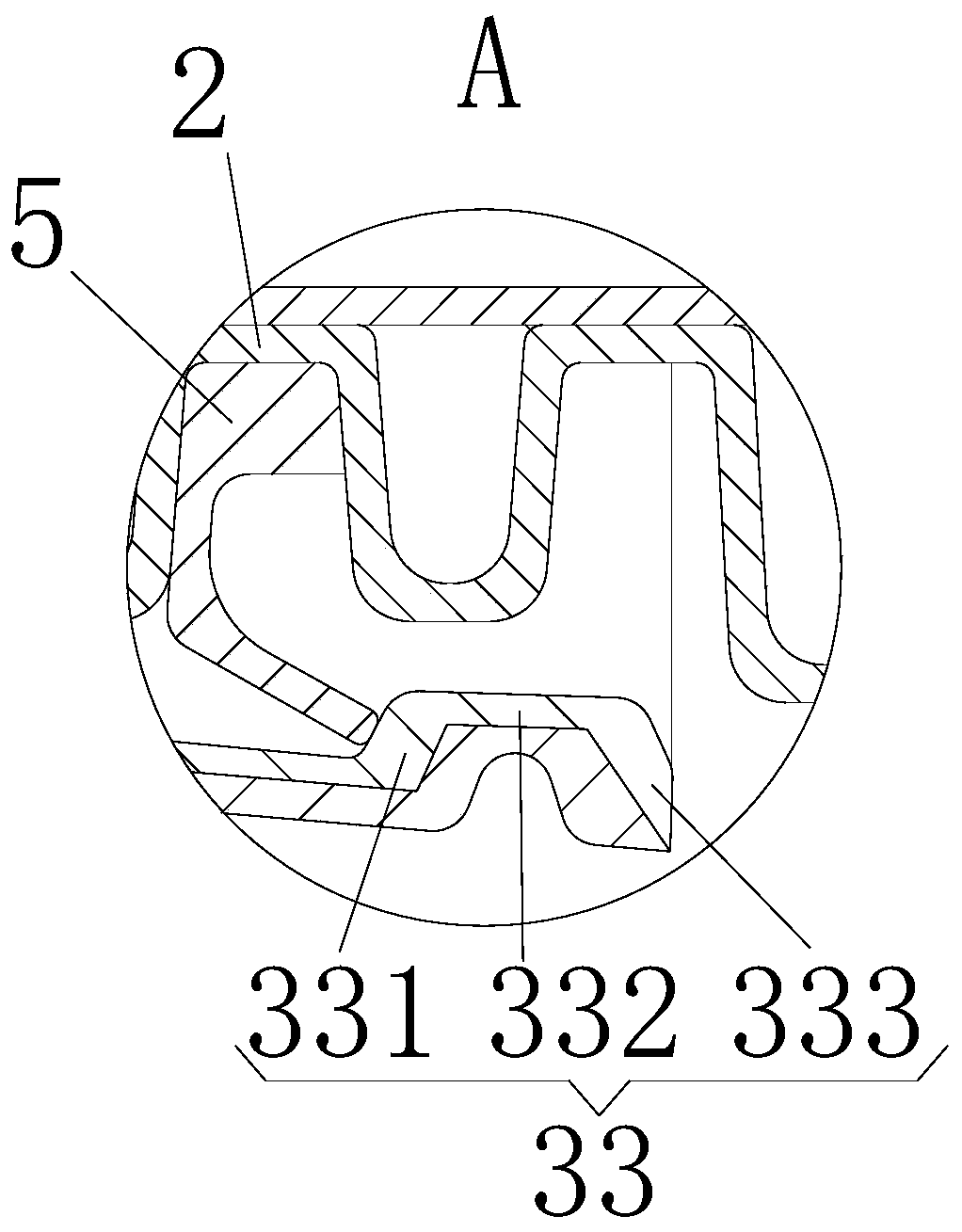

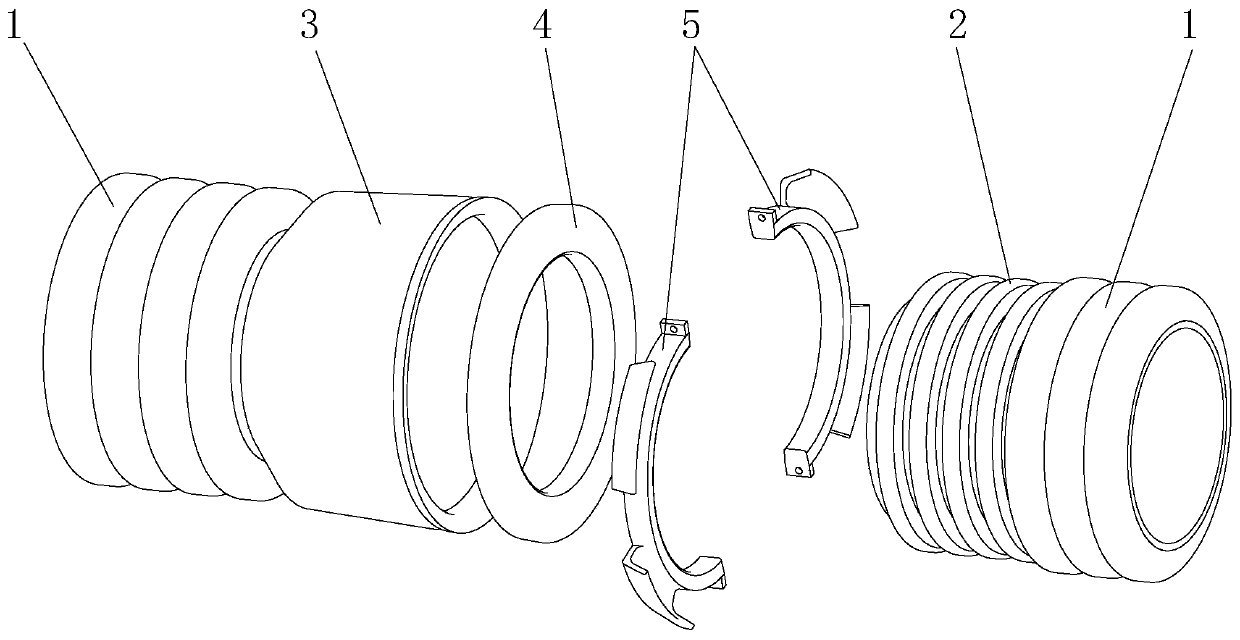

[0028] Such as Figure 1-4 Shown is an anti-off sealing structure for the connection between bellows provided in this embodiment, including a socket section 2 fixedly connected to the port of one section of bellows 1, and a socket section 2 fixedly connected to the port of another section of bellows 1 for The socket section 3 mated with the socket section 2, the sealing ring 4 arranged between the socket section 2 and the socket section 3, and the anti-off piece 5 arranged between the socket section 2 and the socket section 3; The outer peripheral wall of the socket section 2 has a corrugated structure in which crests 21 and troughs 22 are arranged alternately in the axial direction, the sealing ring 4 is arranged in a wave trough 22 at the front end of the socket section 2, and the anti-dropping member 5 is arranged on the socket section 2 in a trough 22 at the rear end, the socket section 3 includes a limiting section 31, a receiving section 32 and a clamping section 33 arra...

Embodiment 2

[0036] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that, in order to further ensure the sealing effect, grooves 41 are provided on the front side, rear side and outer peripheral wall of the sealing ring 4 . After the groove 41 is provided, the deformation of the sealing ring 4 is larger, and the size of the sealing ring 4 can be enlarged in advance, and the fit is tighter after pressing, and the sealing effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com