Pipe assembly with anti-disengagement sealing structure

A sealing structure and anti-loosening technology, applied in the direction of pipe/pipe joint/pipe fitting, passing element, sleeve/socket connection, etc., can solve the problems of poor sealing effect, high engineering cost, and pipe detachment, etc., to achieve enhanced sealing Effect, long service life, fixed and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

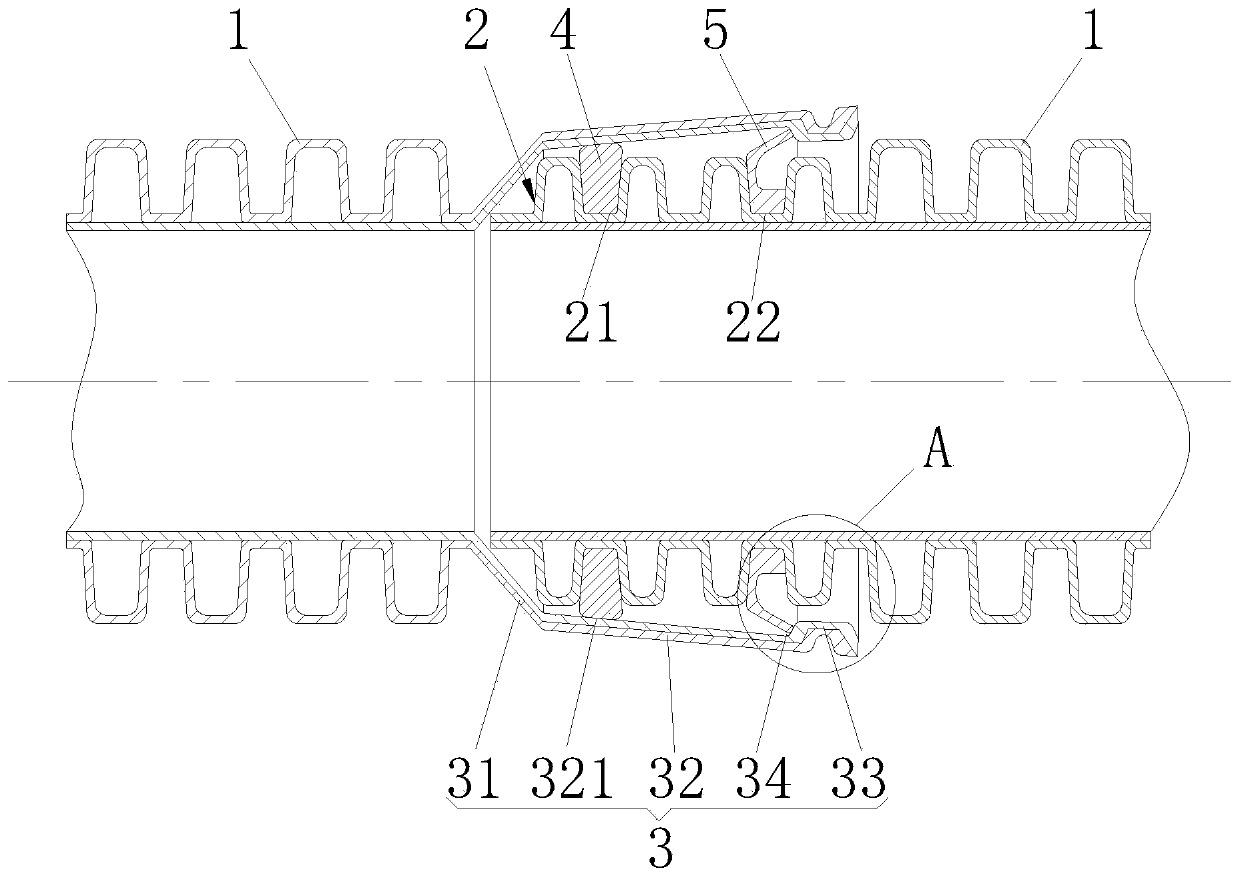

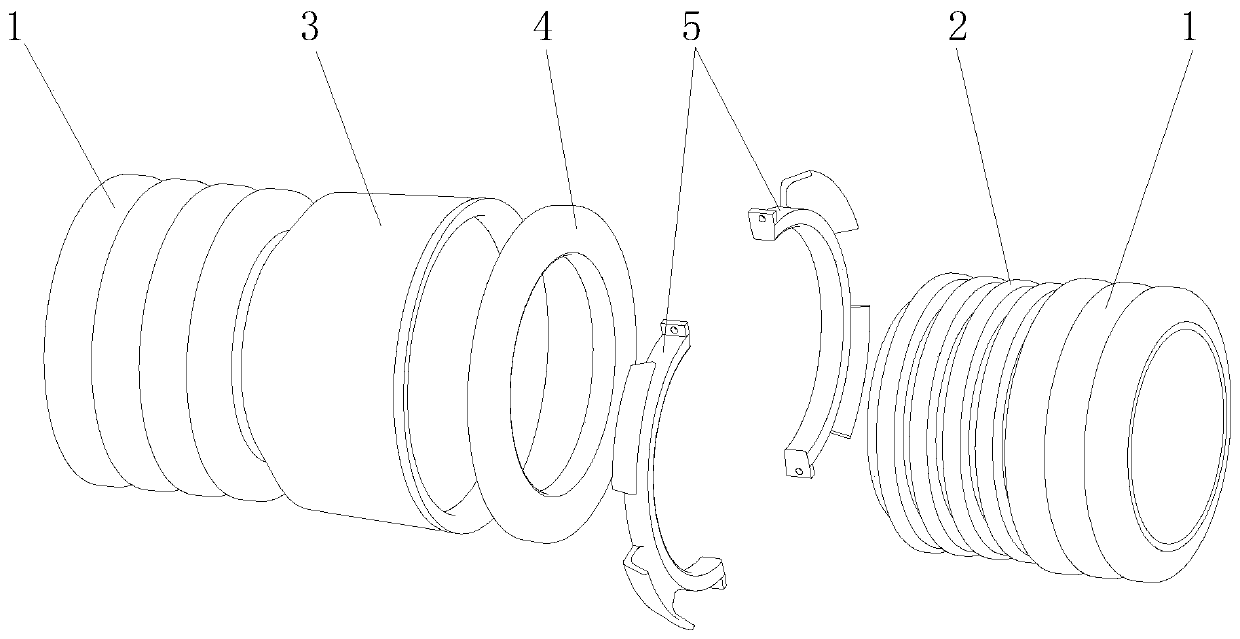

[0038] Such as Figure 1-5 As shown, a pipe assembly with an anti-off sealing structure is characterized in that: it includes at least two pipes 1; one end port of one pipe 1 is fixedly connected with a tubular socket section 2, and the other pipe 1 A tubular socket section 3 for matching with the socket section 2 is fixedly connected to the port at one end, and the pipe assembly with an anti-off sealing structure also includes the outer peripheral wall of the socket section 2 and the inner peripheral wall of the socket section 3 between the sealing ring 4 and the anti-off piece 5;

[0039] The outer peripheral wall of the socket section 2 is provided with a sealing ring installation groove 21 for installing the sealing ring 4 and an anti-off part installation groove 22 for installing the anti-off part 5 arranged around the outer peripheral wall, and the sealing ring installation groove The groove 21 is located close to the outer port of the socket section 2, and the anti-loo...

Embodiment 2

[0050] Such as Figure 5 As shown, the difference between the present embodiment and the first embodiment is that, preferably, the sealing ring 4 is provided with grooves 41 on both end faces in the axial direction and on the outer peripheral wall. After the groove 41 is provided, the deformation of the sealing ring 4 is larger, and the size of the sealing ring 4 can be enlarged in advance, and the fit is tighter after pressing, and the sealing effect is better.

Embodiment 3

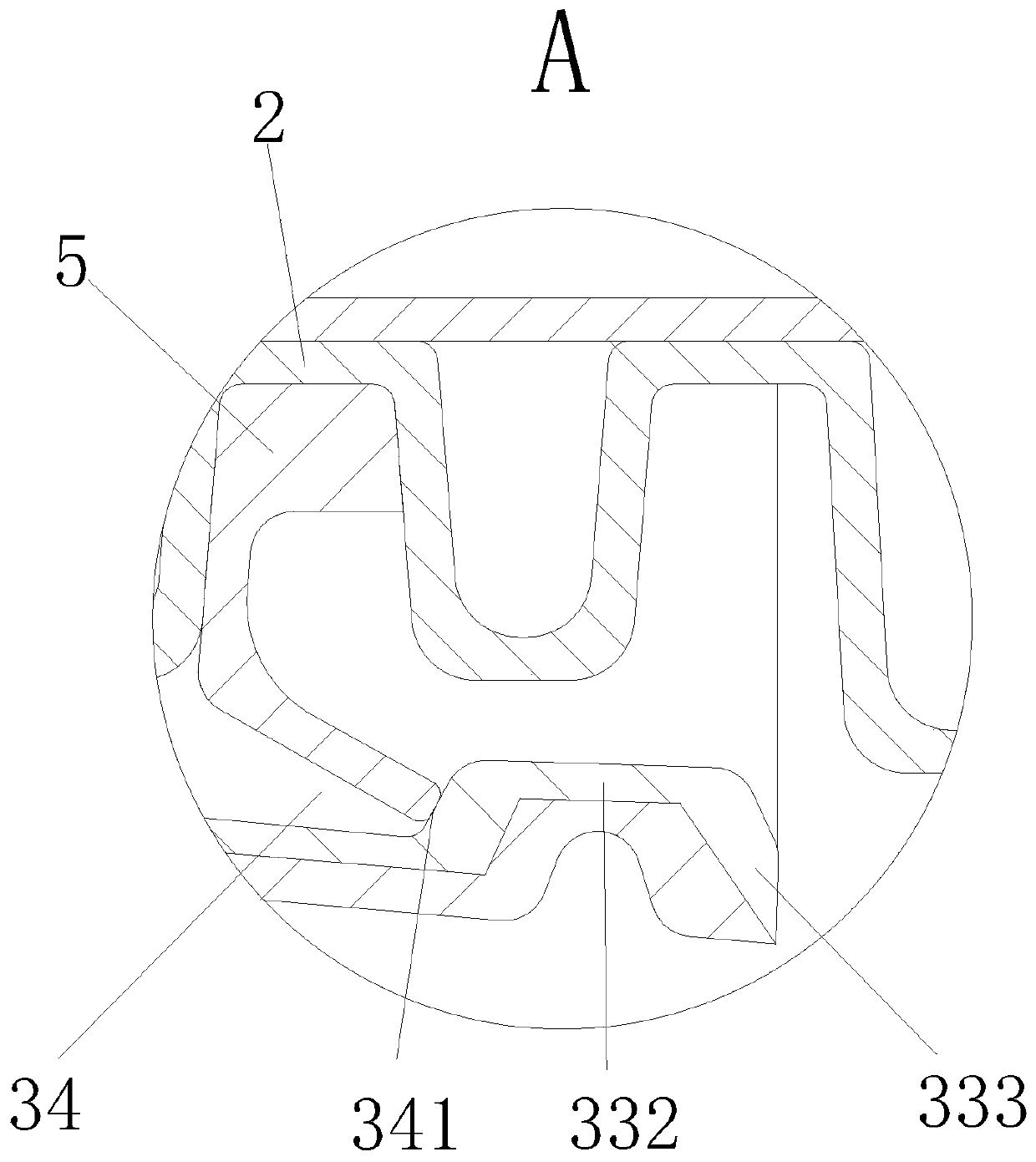

[0052] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is: preferably, the inner peripheral wall of the sealing receiving section 32 is connected to the first conical sealing section 321 and the conical sealing section 321 The second tapered sealing section 322 between the resisting walls 341 is connected, and the taper of the first tapered sealing section 321 is smaller than that of the second tapered sealing section 322 .

[0053] Preferably, the socket section 3 further includes an annular protection tube 35 connected to the axially outer side of the clamping section 33 , and the diameter of the inner wall of the annular protection tube 35 is larger than the outer diameter of the peak of the pipe 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com