Aluminum alloy tin electroplating treating method

A treatment method, electro-tinning technology, which is applied in the field of aluminum alloy processing, can solve the problems of serious oxidation and burning of alloys, achieve the effects of changing crystal appearance, enhancing the effect of degreasing, and preventing surface scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

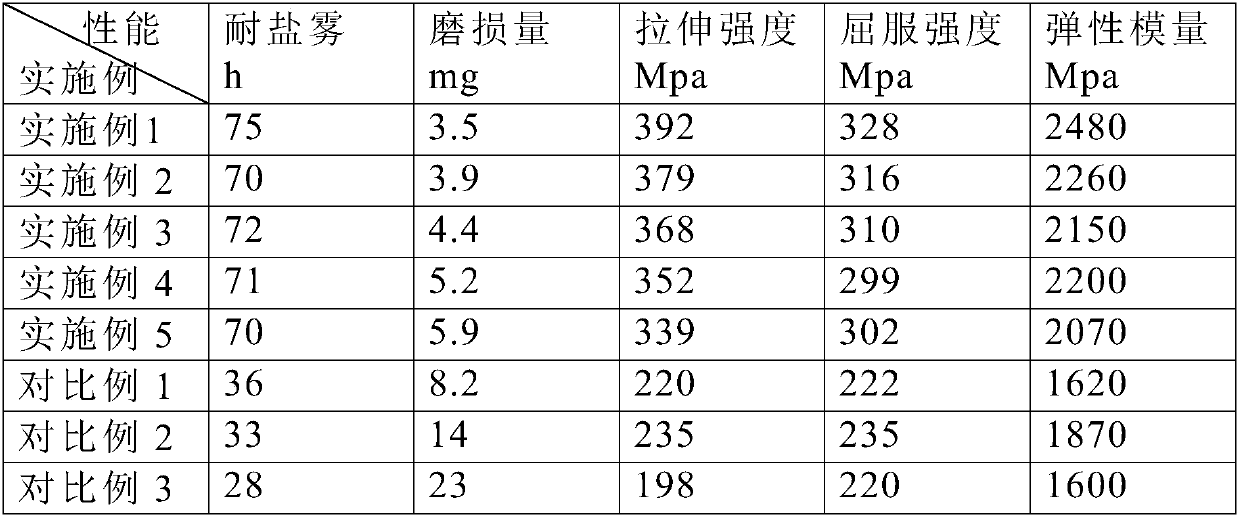

Examples

Embodiment 1

[0024] The aluminum alloy semi-finished product was first degreased by alkaline treatment at 38°C for 12 minutes, then washed with absolute ethanol for 3 minutes, and then washed twice with distilled water for 3 minutes each time, and then put the cleaned aluminum alloy in 38g / Treat in 1 L of NaOH solution for 4min, then wash with distilled water at 35°C, then wash with cold water, and finally wash with a small amount of ordinary sulfuric acid to obtain a pretreated aluminum alloy semi-finished product; the degreasing solution in the degreasing treatment is 18% Na 2 CO 3 and 4% coconut acid diethanolamide dissolved in 78% water;

[0025] Then, the pretreated aluminum alloy semi-finished product is subjected to tinning treatment for 6 minutes. The treatment temperature is 45°C within the first 3 minutes of starting electroplating, and the treatment temperature within the next 3 minutes is 55°C. Among them, the electroplating tin solution: SnSO 4 35%, sodium imidazoline dicarb...

Embodiment 2

[0028] Alkaline degreasing treatment of aluminum alloy semi-finished products at 36°C for 14 minutes, followed by washing with absolute ethanol for 3 minutes, and then washing with distilled water for 3 times, each time for 3 minutes, and then putting the cleaned aluminum alloy into 37g / Treat in 1 L of NaOH solution for 4 minutes, then wash with distilled water at 32°C, then wash with cold water, and finally wash with a small amount of ordinary sulfuric acid to obtain a pretreated aluminum alloy semi-finished product; the composition of the degreasing solution is: Na 2 CO 3 16.5%, Diethanolamide Cocoate 4.5%, Water 79%;

[0029]Then, the pretreated aluminum alloy semi-finished product is electroplated for 9 minutes, and the treatment temperature is 42°C within the first 4 minutes of electroplating, and the treatment temperature within the next 4 minutes is 52°C; among them, the composition of the tin plating solution is: SnSO 4 30%, sodium imidazoline dicarboxylate 18%, 1,...

Embodiment 3

[0032] Alkaline degreasing treatment of aluminum alloy semi-finished products at 38°C for 12 minutes, followed by washing with absolute ethanol for 4 minutes, and then washing with distilled water for 3 times, each time for 4 minutes, and then putting the cleaned aluminum alloy into 36g / Treat in 1 L of NaOH solution for 3.5min, then wash with distilled water at 38°C, then wash with cold water, and finally wash with a small amount of ordinary sulfuric acid to obtain a pretreated aluminum alloy semi-finished product; the composition of the degreasing solution is: Na 2 CO 3 19%, Coco Diethanolamide 3.5%, Water 77.5%;

[0033] Then, the pretreated aluminum alloy semi-finished product is electroplated for 4 minutes. The treatment temperature is 48°C within the first 2 minutes of electroplating, and the treatment temperature within the next 2 minutes is 58°C; among them, the electroplating tin solution: SnSO 4 32%, sodium imidazoline dicarboxylate 16%, 1,10-phenanthroline 18%, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com