Constant pressure variable radial piston pump

A constant pressure variable, radial column technology, applied in the direction of variable capacity pump components, pumps, multi-cylinder pumps, etc., can solve the problems of affecting the normal operation of the pump, insufficient locking force, falling off of the connecting rod, etc., to achieve simple structure, The effect of high rated pressure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

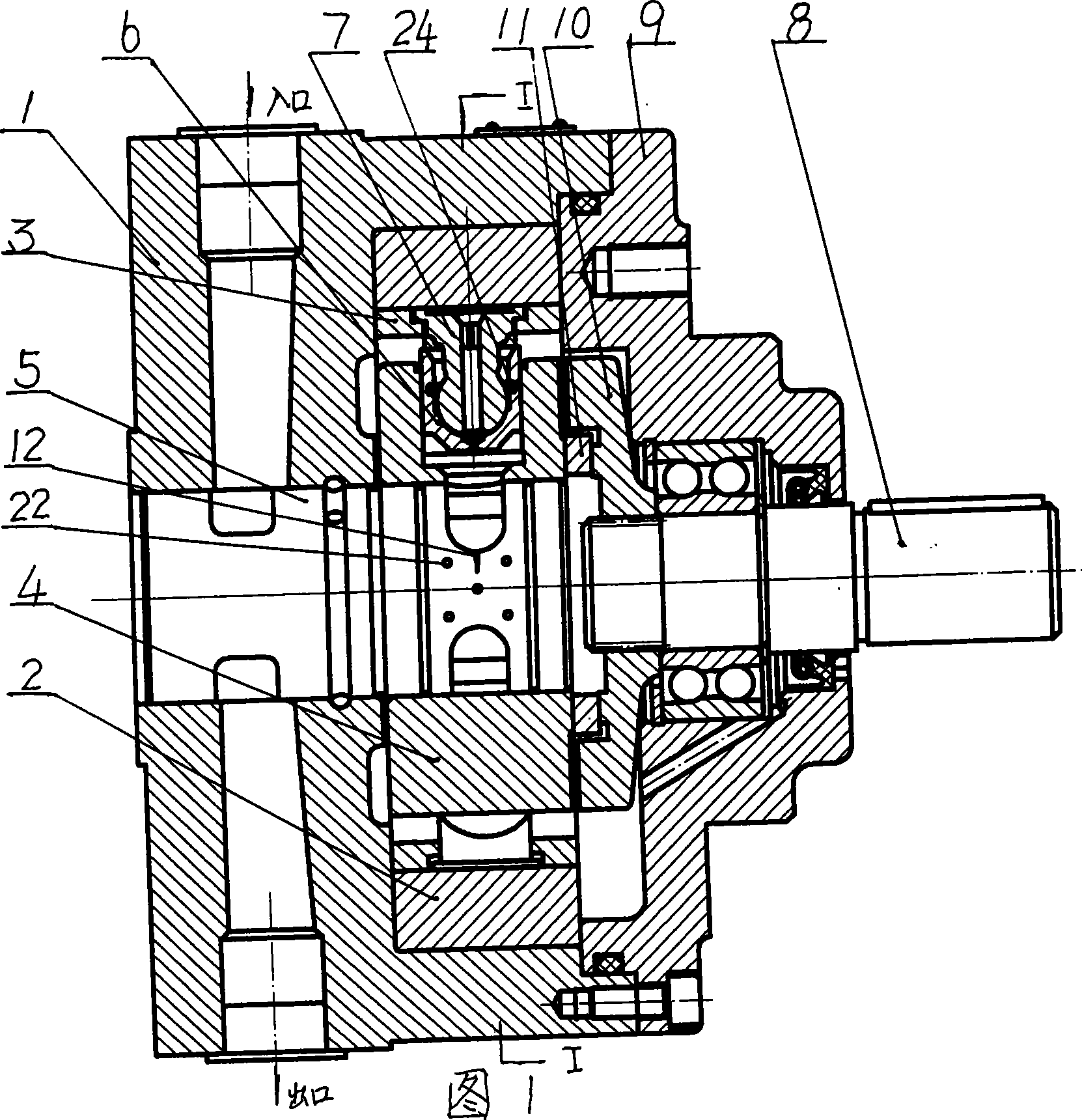

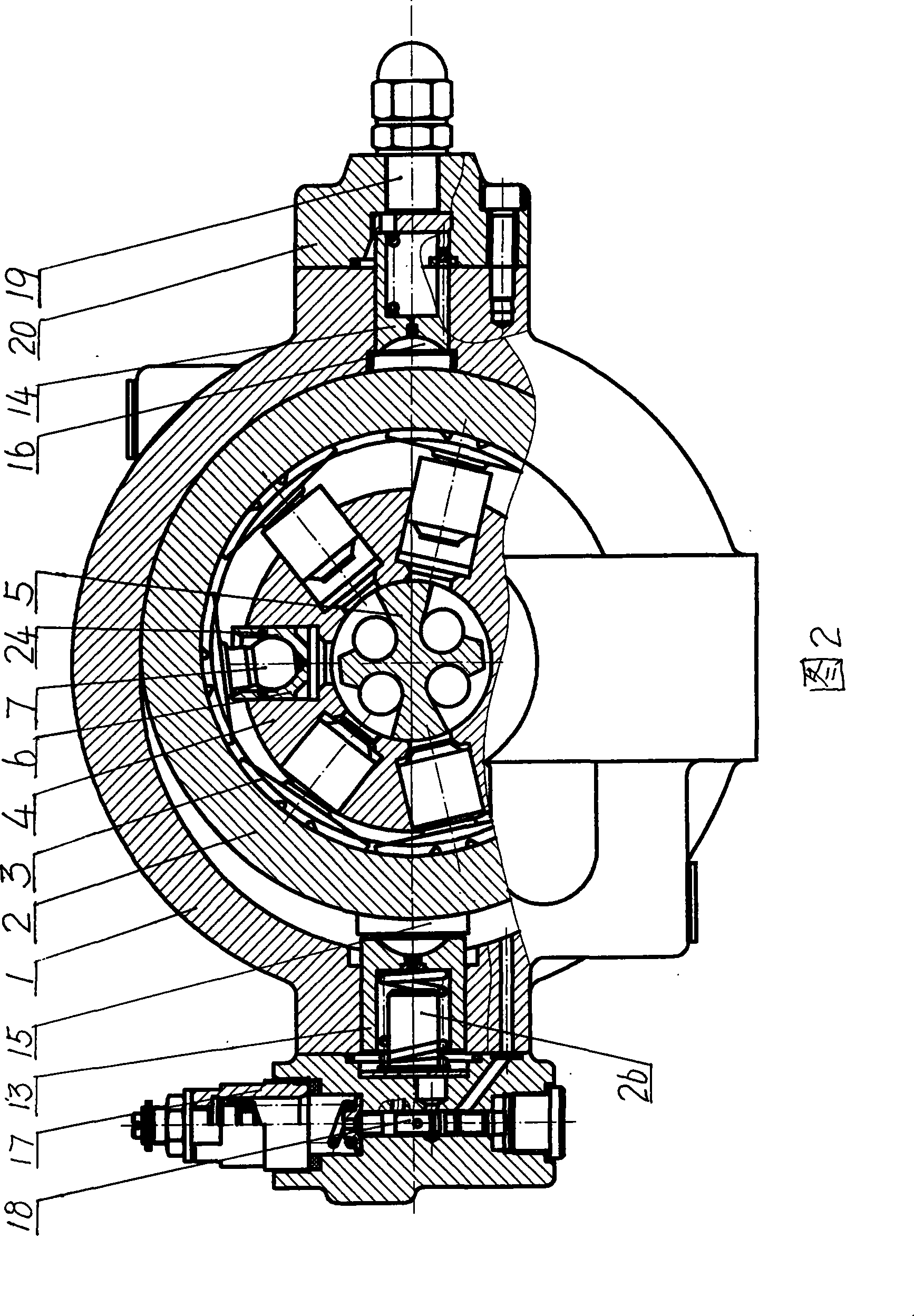

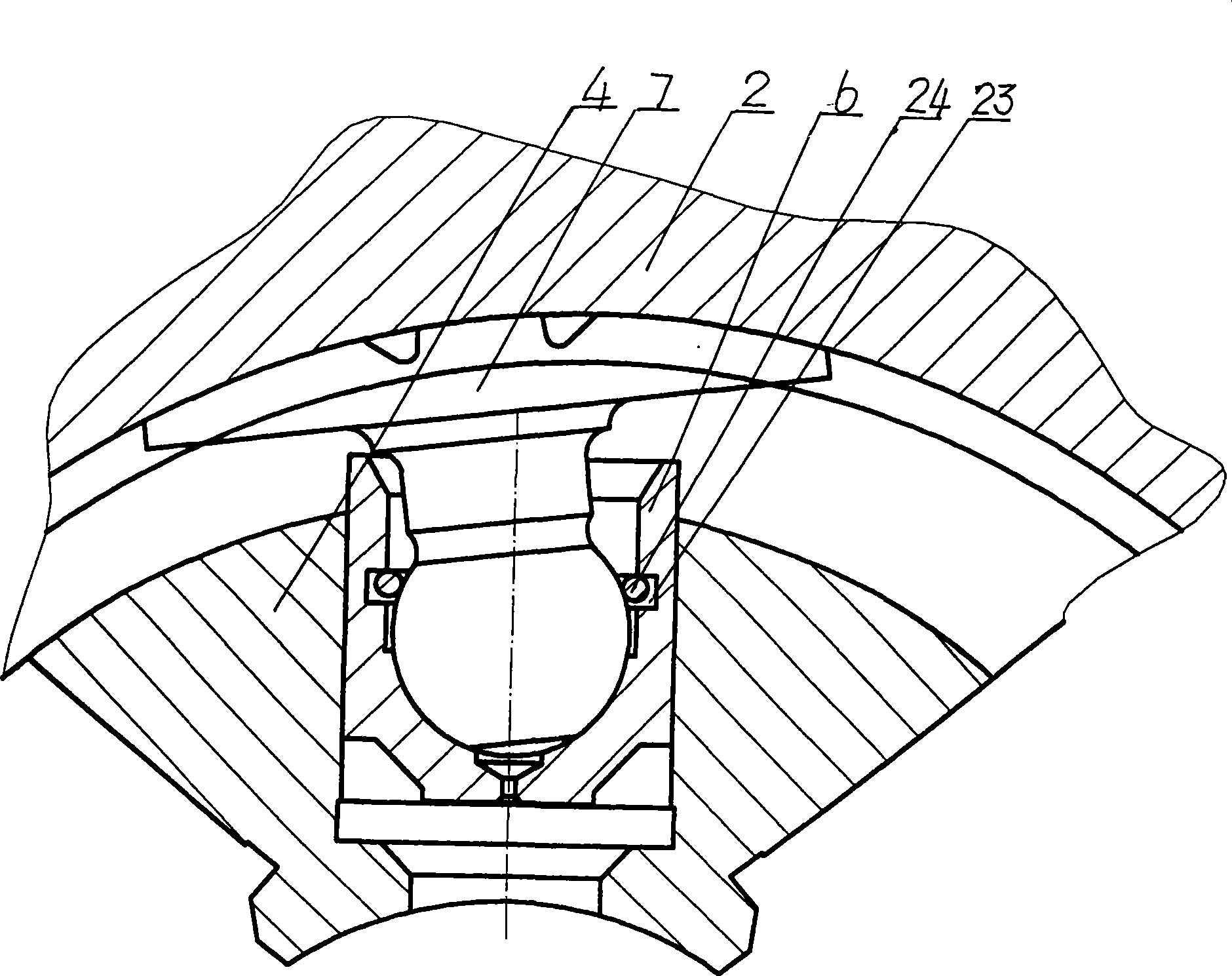

[0025] In order to further understand the characteristics and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows in conjunction with the accompanying drawings, please refer to Fig. 1— Figure 7 .

[0026] Figure 1- image 3 As shown: the present invention is mainly composed of a pump casing 1, a stator 2, a return ring 3, a rotor 4, a flow distribution shaft 5, a plunger 6, a connecting rod 7, a transmission shaft 8, a pump cover 12, a coupling 13, and a cross slider 14 , large control plunger 16, small control plunger 17, A slider 18 and B slider 19, manual constant pressure variable valve 20, the inner hole of the pump casing 1 is oblong; the annular stator 2 is slippery with the pump casing 1 , both sides of the inner circle of the stator 2 are respectively matched with the return ring 3, the return ring 3 is made of ZQA19-4 aluminum bronze, the main chemical composition is: Cu=87.34%, Zn=0.05%, Pb=0.077...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com